Page 1

Section E Index

PBSS Series

NEMA 4X,12 & 13 (30.5mm) Pushbutton

Wall-Mount..............................................E2

PBXD-SS Series

NEMA 4X,12 & 13 (30.5mm) Pushbutton

Wall-Mount..............................................E4

BN4-SS Series

NEMA 4X JIC Clamp Cover Wall-Mount ..E6

BN4-CHSS Series

NEMA 4X JIC Continuous Hinge

Wall-Mount..............................................E8

BN4-AL Series

NEMA 4X Lift-Off Cover Wall-Mount ......E10

BN4-CHAL Series

NEMA 4X JIC Continuous Hinge

Wall-Mount............................................E12

WC-CSS Series

NEMA 12 Consolet Single Door.............E14

STAINLESS STEEL AND NON-METALLIC ENCLOSURES

N412-SSC ULTIMATE Series

NEMA 4X Single Door Wall-Mount.........E16

N412-WSSC ULTIMATE Series

NEMA 4X Single Door With

Window Wall-Mount...............................E19

N412-SS3PTC ULTIMATE Series

NEMA 4X Single Door Wall-Mount.........E21

N412-CSSST ULTIMATE Series

NEMA 4X Slope Top Single Door...........E24

SSN4-WF3PT Series

NEMA 4X Two Door Wall-Mount ............E26

SSN4 Series

NEMA 4X Single Door Wall-Mount.........E28

ALN4 Series

NEMA 4X Single Door Wall-Mount.........E30

SSN4-3PT Series

NEMA 4X Single Door Wall-Mount.........E32

E1

SSN4-3PTW Series

NEMA 4X Painted White Single Door

Wall-Mount ...........................................E34

SSN4D Series

NEMA 4X Two Door Floor-Mount...........E36

N4S-FSSS/FSSSA/FSDSS Series

NEMA 4X Single Door Freestanding.....E38

SSN4D-3PT Series

NEMA 4X Two Door Floor-Mount...........E40

WA-SSFSN43PT Series

NEMA 4X Single Door Freestanding.....E42

WA-SSFSDN43PT Series

NEMA 4X Two Door Freestanding.........E44

Non-Metallic

Enclosures ...........................................E50

Accessories .........................................E77

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 2

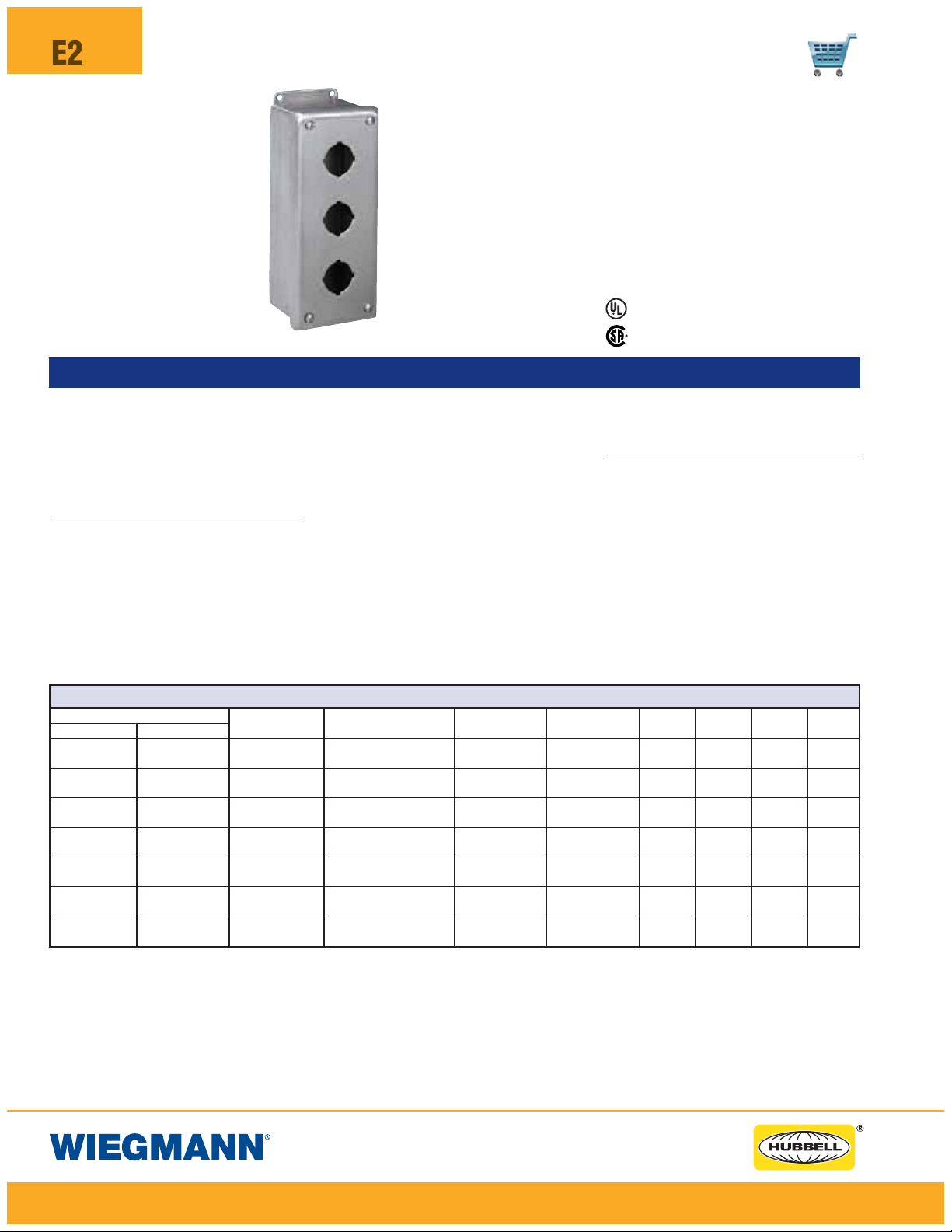

E2

PBSS SERIES ENCLOSURES

NEMA 12, 4 & 4X (30.5MM) PUSHBUTTON WALL-MOUNT

FEATURES-SPECIFICATIONS

PBSS3

Industry Standards

UL 508, Types 4, 4X, 12 & 13

CSACertified,Type4,4X&12

NEMA/EEMAC Type 4, 4X, 12 & 13

UL File E64791

CSA File LL66078

Applications

Designed to hold all standard brands

of pushbuttons, switches and pilot lights.

Provide protection from dust, dirt,

oil and water. PBSS Series designed

for areas where serious corrosion

problems exist.

Construction

• Bodies and doors fabricated from 14

gauge 304 or 316L stainless steel

• Continuously welded seams ground

smooth

• Closed cell oil resistant neoprene

gasket

PBSS SERIES (30.5MM) PUSHBUTTON ENCLOSURES

CATALOG NUMBER

304 SS 316L SS

PBSS1 PBSS1A 14/14

PBSS2 PBSS2A 14/14

PBSS3 PBSS3A 14/14

PBSS4 PBSS4A 14/14

PBSS6 PBSS6A 14/14

PBSS9 PBSS9A 14/14

PBSS12 PBSS12A 14/14

BODY/DOOR ENCLOSURE SIZE MOUNTING OVERALL

STEEL GAUGE H X W X D C X E L X M

• External mounting plates, top and

bottom of enclosure

• Captivated cover screws thread

into sealed wells

• Standard “4-way” pushbutton holes

accept all brands of oil-tight push

buttons, switches and pilot lights

• Enclosures 9.50" x 6.25" x 3.00"

Finish

• Cover and outside of enclosure

have a smooth grained finish

Acces sories

• See pages H16-H27 for Painted

Gray PB Series

• See page J4 for hole seals

and larger have internal detachable

hinges to hold cover open during

wiring, yet permit quick removal

• Grounding provisions provided

FIAB

3.50x3.25x2.81 2.38x4.00 4.50x3.56 3.00 2.41 1.78 1.88

(89x83x71) (60x102) (114x90) (76) (61) (45) (48)

5.75x3.25x2.81 2.38x6.25 6.75x3.56 3.00 2.41 1.78 1.88

(146x83x71) (60x159) (171x90) (76) (61) (45) (48)

8.00x3.25x2.81 2.38x8.50 9.00x3.56 3.00 2.41 1.78 1.88

(203x83x71) (60x216) (229x90) (76) (61) (45) (48)

10.25x3.25x2.81 2.38x10.75 11.25x3.56 3.00 2.41 1.78 1.88

(260x83x71) (60x273) (286x90) (76) (61) (45) (48)

9.50x6.25x3.09 5.38x10.00 10.50x6.56 6.00 2.69 2.16 2.63

(241x159x79) (137x254) (267x167) (152) (68) (55) (67)

9.50x8.50x3.09 7.63x10.00 10.50x8.81 8.25 2.69 2.16 2.63

(241x216x79) (194x254) (267x224) (210) (68) (55) (67)

11.75x8.50x3.09 7.63x12.25 12.75x8.81 8.25 2.69 2.16 2.63

(298x216x79) (194x311) (324x224) (210) (68) (55) (67)

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 3

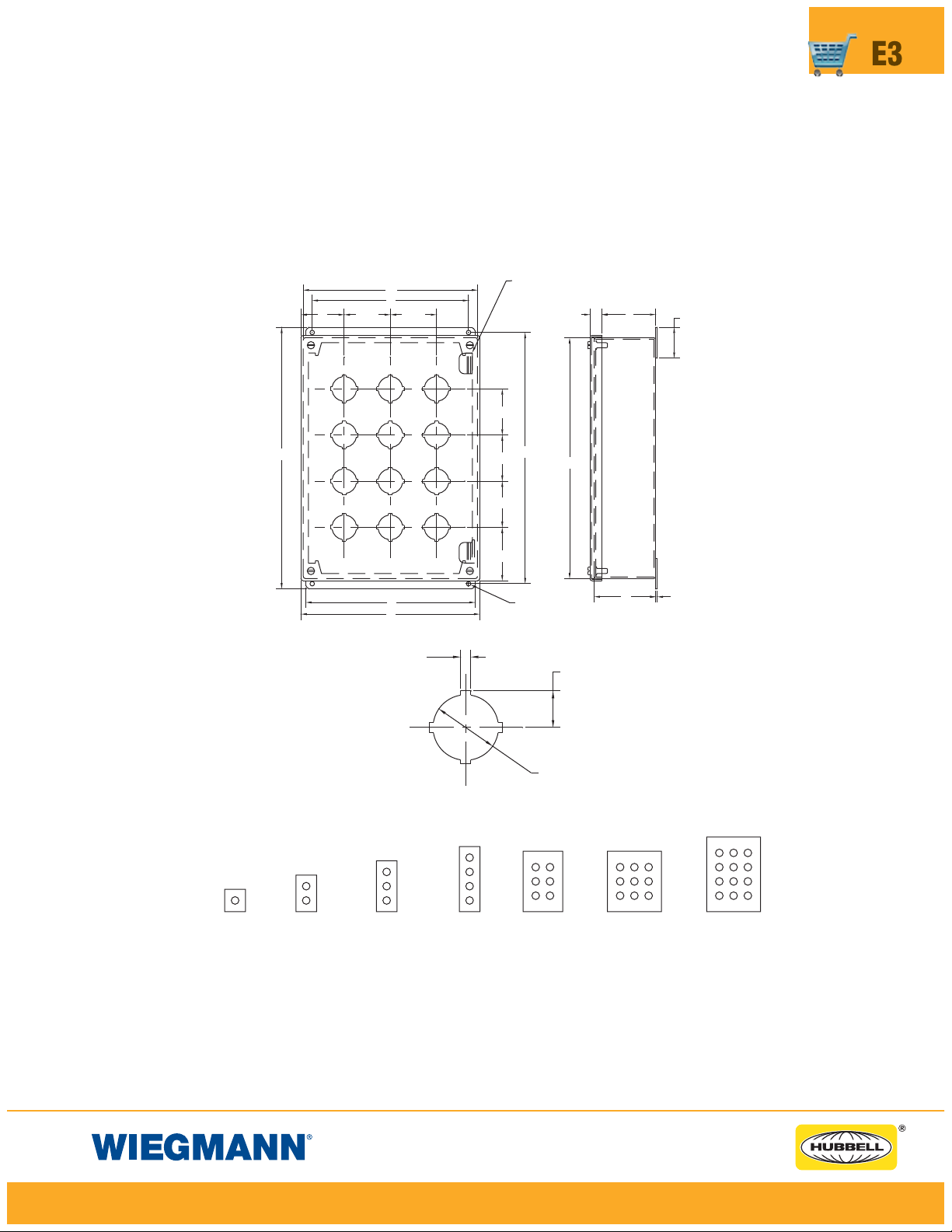

PBSS SERIES ENCLOSURES

NEMA 12, 4 & 4X (30.5MM) PUSHBUTTON WALL-MOUNT

HINGES PROVIDED WHEN

2.25

W >= 6.25"

0.56

I

1.63

W

C

A

2.252.25

E3

L

Hole Arrangements

F

M

0.19 TYP

Standard 4-Way Pushbutton

2.25

2.25

B

E

Ø 0.25 TYP

Ø 1.20 TYP

H

0.67 TYP

D

14 GA.

PBSS1

PBSS1A

PBSS2

PBSS2A

PBSS3

PBSS3A

PBSS4

PBSS4A

PBSS6

PBSS6A

PBSS9

PBSS9A

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

PBSS12

PBSS12A

Page 4

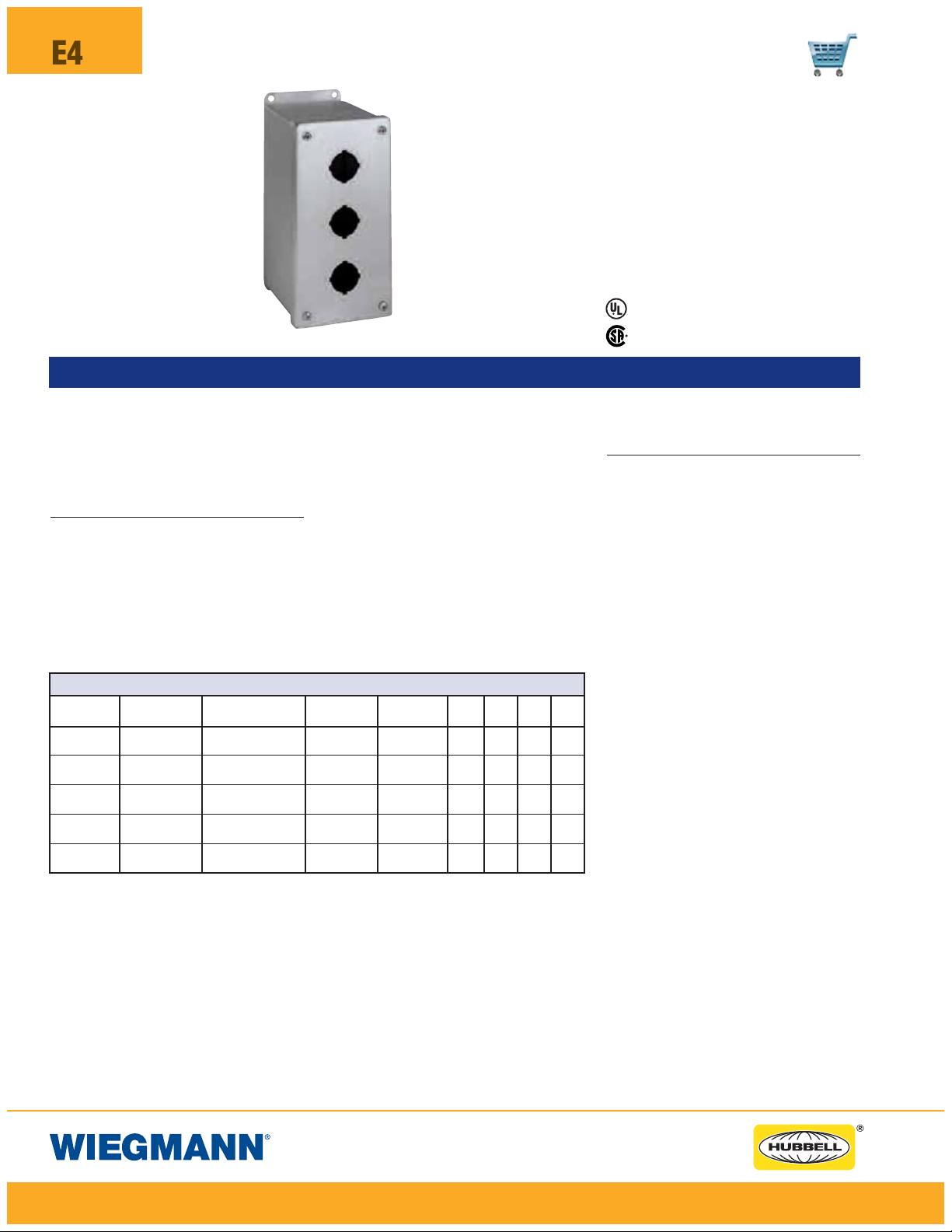

E4

PBXD - SS SERIES ENCLOSURES

NEMA 4, 4X, 12 & 13 (30.5MM) PUSHBUTTON WALL-MOUNT

Industry Standards

UL 508, Types 4, 4X, 12 & 13

CSACertified,Type4,4X&12

NEMA/EEMAC Type 4, 4X, 12 & 13

JIC EL-1-71

UL File E64791

PBXD3SS

FEATURES-SPECIFICATIONS

Applications

Designed to hold 30.5mm oil-tight

pushbuttons, switches, and pilot

lights. Provide protection against dirt,

dust, oil, and water. Extra deep

design accommodates additional

contact blocks for pushbuttons.

Construction

• Bodies and doors fabricated from

14 gauge 304 stainless steel

• Continuously welded seams ground

smooth

• Closed cell oil resistant neoprene

• External mounting plates, top and

bottom of enclosure

• Captivated cover screws thread

into sealed wells

• Standard “4-way” pushbuttons

holes accept all brands of oil-tight

push buttons, switches and pilot

lights

• 6.00" x 4.00" x 4.75" and larger

have internal detachable hinges to

hold cover open during wiring, yet

permit quick removal

• Grounding provisions provided

gasket

PBXD-SS SERIES STAINLESS PUSHBUTTON ENCLOSURES

CATALOG BODY/DOOR ENCLOSURE SIZE MOUNTING OVERALL

NUMBER STEEL GAUGE HXWXD EXC LXM

PBXD1SS 14/14

PBXD2SS 14/14

PBXD3SS 14/14

PBXD4SS 14/14

PBXD16SS 14/14

4.00x4.00x4.81 3.13x4.50 5.00x4.31 3.75 4.41 2.19 2.16

(102x102x122) (79x114) (127x110) (95) (112) (56) (55)

6.00x4.00x4.81 3.13x6.50 7.00x4.31 3.75 4.41 2.19 2.03

(152x102x122) (79x165) (178x110) (95) (112) (56) (52)

8.00x4.00x4.81 3.13x8.50 9.00x4.31 3.75 4.41 2.19 1.97

(203x102x122) (79x216) (229x110) (95) (112) (56) (50)

10.00x4.00x4.81 3.13x10.50 11.00x4.31 3.75 4.41 2.19 1.78

(254x102x122) (79x267) (279x110) (95) (112) (56) (45)

11.75x10.75x4.81 9.88x12.25 12.75x11.06 11.50 4.41 2.19 2.61

(298x273x122) (251x311) (324x281) (292) (112) (56) (66)

CSA File LL66078

Finish

• Cover and outside of enclosure

have a smooth grained finish

Acces sories

• See pages H16-H27 for

Painted Pushbutton enclosures

• See page J4 for hole seals

FIAB

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 5

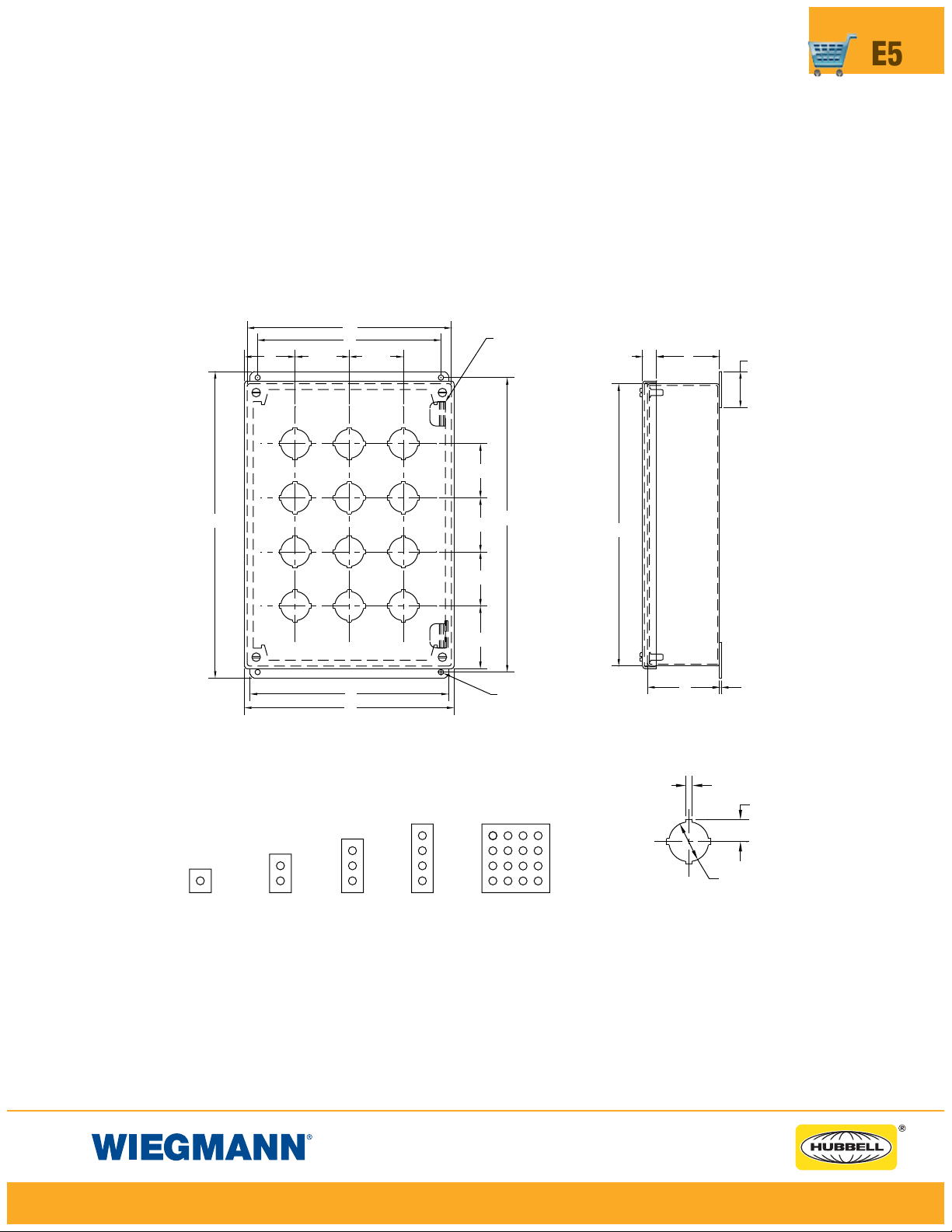

PBXD - SS SERIES ENCLOSURES

NEMA 12 & 13 (30.5MM) PUSHBUTTON WALL-MOUNT

E5

W

E

A

L

2.252.25

F

M

HINGES PROVIDED WHEN

W>=6.25"

2.25

C

2.25

2.25

B

Ø 0.25 TYP

0.56

H

I

D

1. 6 3

14 GA .

PBXD Hole Arrangements

PBXD4SSPBXD3SSPBXD2SSPBXD1SS

0.19 TYP

PBXD16SS

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

0.67 TYP

Ø 1.20 TYP

Standard 4-Way

Pushbutton

Page 6

E6

BN4 - SS SERIES ENCLOSURES

NEMA 4X JIC CLAMP COVER WALL-MOUNT

Industry Standards

UL 50, Types 4, 4X, 12 & 13

(6X6X4&above)

UL508,Types4,4X,12&13(6X4X

3&smaller)

CSACertified,Types4&12

NEMA/EEMAC Type 4, 4X, 12 & 13

JIC EL-1- 71

UL Files E23553, E64791

BN4060604SS

FEATURES-SPECIFICATIONS

Applications

Provides unmatched protection for

housing electrical components in

highly corrosive environments. This

enclosure is used in indoor and outdoor settings that are frequently wet

or have constant exposure to water,

other liquids, or contaminants.

Construction

• Bodies and doors fabricated

from 16 gauge type 304 or 316L

stainless steel

• Continuously welded seams ground

smooth, less knockouts or holes

BN4-SS SERIES JIC CLAMP COVER STAINLESS ENCLOSURES

CATALOG N UM BE R ENCLOSURE SIZE

304 SS 316L SS

BN4040403SS BN4040403SSA

BN4060403SS BN4060403SSA

BN4060604SS BN4060604SSA

BN4080604SS BN4080604SSA

BN4100804SS BN4100804SSA

BN4121005SS BN4121005SSA

BN4141206SS BN4141206SSA

BN4161406SS BN4161406SSA

*Back panels must be ordered separately.

HXWXD

4.00x4.00x3.00

(102x102x76) (121x51) (140x143) (64) (109) (76) (35) (35) (64) (16) (110)

6.00x4.00x3.00

(152x102x76) (124x73) (171x51) (191x143) (64) (109) (76) (14) (35) (60) (64) (16) (160)

6.00x6.00x4.00

(152x152x102) (124x124) (171x102) (191x194) (90) (160) (127) (14) (60) (60) (90) (16) (160)

8.00x6.00x4.00

(203x152x102) (175x124) (222x102) (241x194) (90) (160) (127) (14) (60) (86) (90) (16) (211)

10.00x8.00x4.00

(254x203x102) (226x175) (273x152) (292x244) (90) (211) (178) (14) (86) (38) (90) (16) (262)

12.00x10.00x5.00

(305x254x127) (276x226) (324x203) (343x295) (115) (262) (229) (14) (51) (76) (115) (16) (313)

14.00x12.00x6.00

(356x305x152) (327x276) (375x254) (394x346) (141) (313) (279) (14) (51) (76) (141) (16) (364)

16.00x14.00x6.00

(406x356x152) (378x327) (425x305) (445x397) (141) (363) (330) (14) (89) (38) (141) (16) (414)

• Sealed with poured in place

polyurethane gasket

• External mounting plates, top and

bottom of enclosure

• Weldnuts are provided on models

6.00" x 4.00" and larger to secure

optional panel

• Stainless steel screws and clamps

on four sides of cover assure

watertight seal

• Grounding provisions provided

• Optional panels and terminal kits

must be ordered separately

BACK PANEL

CATALOG NUMBER*

WHITE 304 SS “G”

—— — —

P0604 P0604SS P0604G

P0606 P0606SS P0606G

P0806 P0806SS P0806G

P1008 P1008SS P1008G

P1210 P1210SS P1210G

P1412 P1412SS P1412G

P1614 P1614SS P1614G

CSA File LL66078

Finish

• Cover and outside of enclosure

have a smooth grained finish

• Optional back panels are white

polyester powder or grained finish

stainless steel

• Optional “G” panels have a con-

ductive finish (See page I2)

Acces sories

• Back panels (reference tables)

• See pages J1-J22

BACK PANEL

SIZEAXB CXE LXM

4.88x2.88 6.75x2.00 7.50x5.63 2.53 4.31 3.00 0.56 1.38 2.38 2.53 0.63 6.31|

4.88x4.88 6.75x4.00 7.50x7.63 3.53 6.31 5.00 0.56 2.38 2.38 3.53 0.63 6.31

6.88x4.88 8.75x4.00 9.50x7.63 3.53 6.31 5.00 0.56 2.38 3.38 3.53 0.63 8.31

8.88x6.88 10.75x6.00 11.50x9.63 3.53 8.31 7.00 0.56 3.38 1.50 3.53 0.63 10.31

10.88x8.88 12.75x8.00 13.50x11.63 4.53 10.31 9.00 0.56 2.00 3.00 4.53 0.63 12.31

12.88x10.88 14.75x10.00 15.50x13.63 5.53 12.31 11.00 0.56 2.00 3.00 5.53 0.63 14.31

14.88x12.88 16.75x12.00 17.50x15.63 5.53 14.31 13.00 0.56 3.50 1.50 5.53 0.63 16.31

MOUNTING OVERALL

4.75x2.00 5.50x5.63 2.53 4.31 3.00

FGI JKNO PQ

1.38 1.38 2.53 0.63 4.31

—

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 7

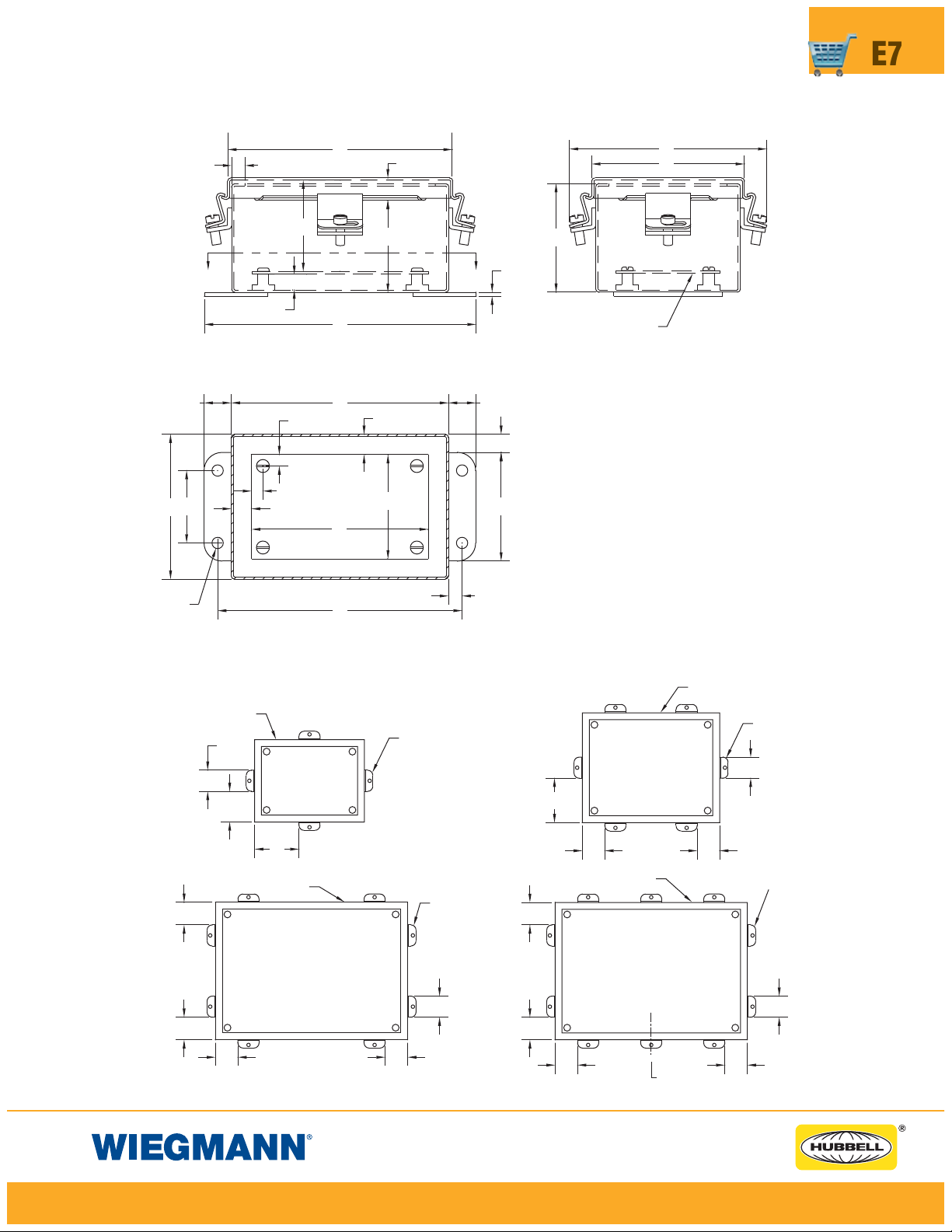

BN4 - SS SERIES ENCLOSURES

NEMA 4X JIC CLAMP COVER WALL-MOUNT

E7

Q

0.38

F

XX

0.75

E

W

Ø0.31

TYP

0.44

0.31 TYP

0.31 TYP

J

L

H

A

C

O

0.56

B

P

D

14 GA.

Panel (Order Separate)

0.75

0.50

Notes:

1. Panels are 14 Ga. steel.

I

2. Panel Screws are #10-32 Pan Head.

0.38

M

G

SECTION X-X

CLAMP BRACKET LOCATIONS

BODY

CLAMP

1. 2 5

BN4040403SS

BN4060403SS

BN4060604SS

BN4080604SS

K

N

BODY

K

BN4121005SS

BN4141206SS

K

BRACKET

NN

CLAMP

BRACKET

1.25

BN4100804SS

K

BODY

K

BN4161406SS

K

BODY

CLAMP

BRACKET

1.25

NN

CLAMP

BRACKET

1. 2 5

C

NN

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 8

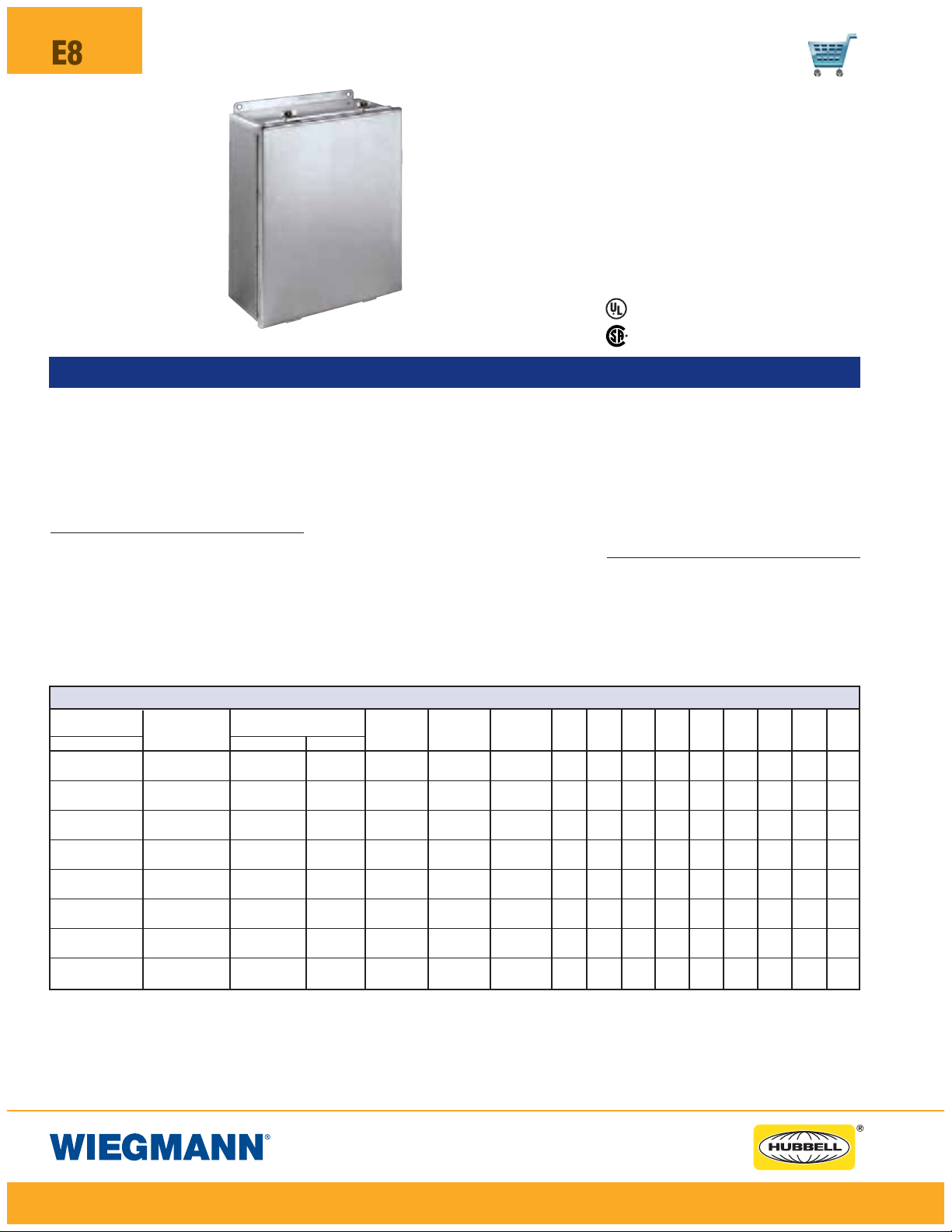

E8

BN4 - CHSS SERIES ENCLOSURES

NE MA 4X JIC CONTINUOUS HINGE WALL-MOUNT

Industry Standards

UL 50, Types 4, 4X, 12 & 13

CSA Certified, Types 4 & 12

NEMA/EEMAC Type 4, 4X, 12 & 13

JIC EL-1-71

UL File E6924, E64791

BN4141206CHSS

CSA File LL66078

FEATURES-SPECIFICATIONS

Applications

Provides unmatched protection for

housing electrical components in

highly corrosive environments. This

enclosure is used in indoor and outdoor settings that are frequently wet

or have constant exposure to water,

other liquids, or contaminants.

Construction

• Bodies and doors fabricated from

16 gauge type 304 stainless steel or

16 gauge type 316L stainless steel

• Suffix “A” = 16 gauge type 316L

stainless steel

• Continuously welded seams ground

smooth, less knockouts or holes

BN4-CHSS SERIES JIC CONTINUOUS HINGE STAINLESS ENCLOSURES

CATALOG BACK PANEL

NUMBER

304 SS / 316L SS

BN4060404CHSS 6.00x4.00x4.00 P0604 P0604G 4.88x2.88 6.75x2.00 7.50x5.00 3.53 4.31 3.00 0.56 1.38 2.38 3.53 6.31 2.78

BN4060404CHSSA (152x102x102) P0604SS ---- (124x73) (171x51) (191x127) (90) (109) (76) (14) (35) (60) (90) (160) (71)

BN4060604CHSS 6.00x6.00x4.00 P0606 P0606G 4.88x4.88 6.75x4.00 7.50x7.00 3.53 6.31 5.00 0.56 2.38 2.38 3.53 6.31 2.78

BN4060604CHSSA (152x152x102) P0606SS ---- (124x124) (171x102) (191x178) (90) (160) (127) (14) (60) (60) (90) (160) (71)

BN4080604CHSS 8.00x6.00x4.00 P0806 P0806G 6.88x4.88 8.75x4.00 9.50x7.00 3.53 6.31 5.00 0.56 2.38 3.38 3.53 8.31 2.78

BN4080604CHSSA (203x152x102) P0806SS ---- (175x124) (222x102) (241x178) (90) (160) (127) (14) (60) (86) (90) (211) (71)

BN4100804CHSS 10.00x8.00x4.00 P1008 P1008G 8.88x6.88 10.75x6.00 11.50x9.00 3.53 8.31 7.00 0.56 3.38 1.50 3.53 10.31 2.78

BN4100804CHSSA (254x203x102) P1008SS ---- (226x175) (273x152) (292x229) (90) (211) (178) (14) (86) (38) (90) (262) (71)

BN4121006CHSS 12.00x10.00x6.00 P1210 P1210G 10.88x8.88 12.75x8.00 13.50x11.00 5.53 10.31 9.00 0.56 2.00 3.00 5.53 12.31 4.78

BN4121006CHSSA (305x254x152) P1210SS ---- (276x226) (324x203) (343x279) (141) (262) (229) (14) (51) (76) (141) (313) (121)

BN4121206CHSS 12.00x12.00x6.00 P1212 P1212G 10.88x10.88 12.75x10.00 13.50x13.00 5.53 12.31 11.00 0.56 2.50 2.50 5.53 12.31 4.78

BN4121206CHSSA (305x305x152) P1212SS ---- (276x276) (324x254) (343x330) (141) (313) (279) (14) (64) (64) (141) (313) (121)

BN4141206CHSS 14.00x12.00x6.00 P1412 P1412G 12.88x10.88 14.75x10.00 15.50x13.00 5.53 12.31 11.00 0.56 2.00 3.00 5.53 14.31 4.78

BN4141206CHSSA (356x305x152) P1412SS ---- (327x276) (375x254) (394x330) (141) (313) (279) (14) (51) (76) (141) (364) (121)

BN4161406CHSS 16.00x14.00x6.00 P1614 P1614G 14.88x12.88 16.75x12.00 17.50x15.00 5.53 14.31 13.00 0.56 3.50 1.50 5.53 16.31 4.78

BN4161406CHSSA (406x356x152) P1614SS ---- (378x327) (425x305) (445x381) (141) (363) (330) (14) (89) (38) (141) (414) (121)

*Back panels must be ordered separately.

In order to purchase conductive panels, please add a “G” suffix to the white panel part numbers.

ENCLOSURE SIZE

HXWXD

CATALOG NUMBER*

WHITE / 304 SS

• Sealed with poured in place

polyurethane gasket

• External mounting feet

• Weldnuts are provided on models

6.00" x 4.00" and larger to secure

optional back panel

• Stainless steel screws and clamps,

equal to enclosure construction, on

three sides of cover assure watertight seal

• Door removed by pulling stainless

steel continuous hinge pin

• Grounding provisions provided

• Optional panels and terminal kits

must be ordered separately

BACK PANEL MOUNTING OVERALL

SIZEAXB CXE LxM

“G”

Finish

• Cover and outside of enclosure

have a smooth grained finish

• Optional back panels are offered in

a white polyester powder, grained

finish stainless steel or with a conductive finish (See page I2)

• Optional “G” panels have a con-

ductive finish (See page I2)

Acces sories

• Back panels (reference tables)

• See pages J1-J22

FGI JKNOPQ

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 9

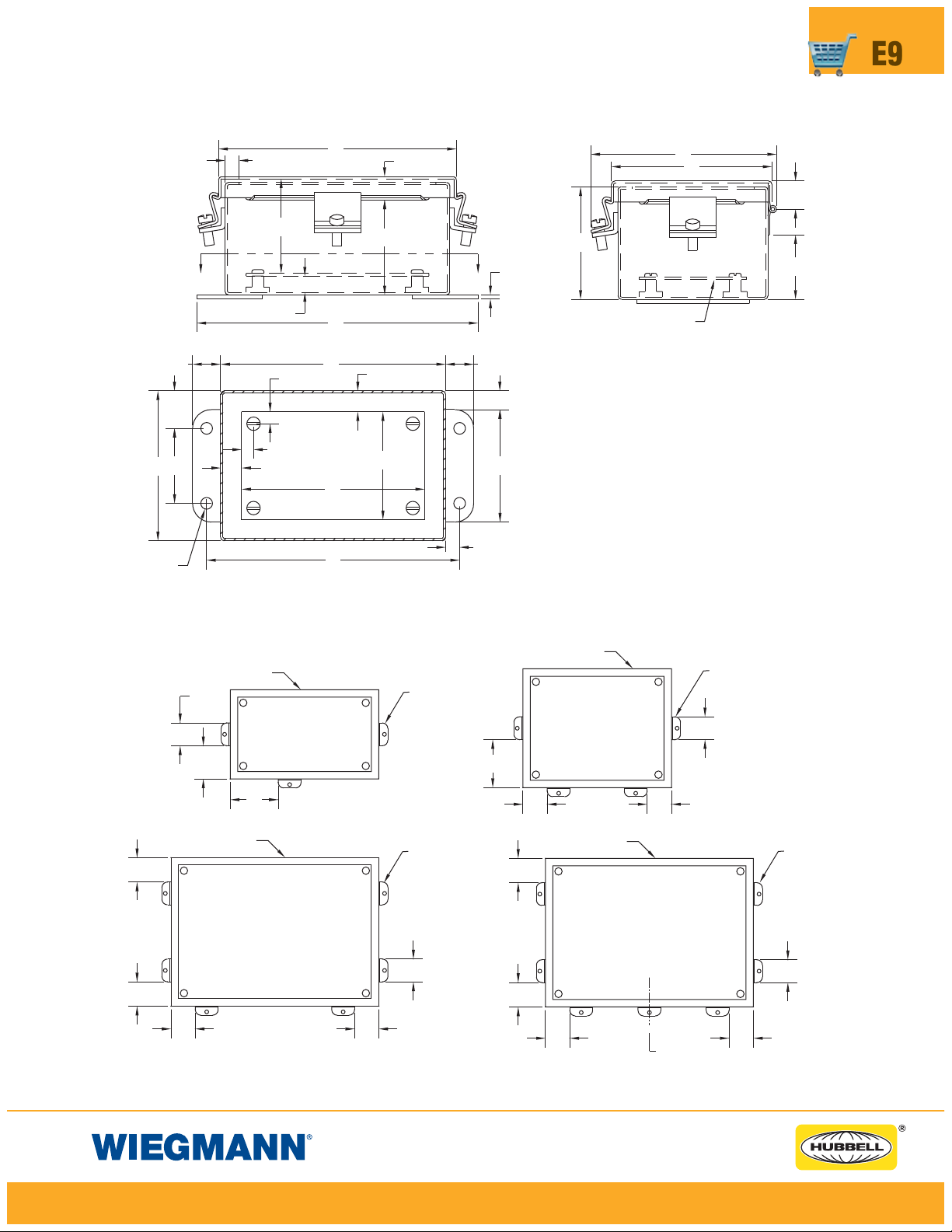

BN4 - CHSS SERIES ENCLOSURES

NE MA 4X JIC CONTINUOUS HINGE WALL-MOUNT

E9

0.75

1.00

W

Ø 0.31

TYP

0.38

F

XX

0.44

0.31 TYP

0.31 TYP

E

J

P

L

H

A

C

SECTION X-X

O

0.56

B

0.63

0.75

0.50

0.38

14 GA.

I

D

Panel (Order Separate)

Notes:

1. Panels are 14 Ga. steel.

2. Panel screws are #10-32 Pan Head.

M

G

0.75

Q

CLAMP BRACKET LOCATIONS

BODY

BODY

1. 2 5

BN4060404CHSS

BN4060604CHSS

BN4080604CHSS

K

N

BODY

K

BN4121006CHSS

BN4121206CHSS

BN4141206CHSS

K

NN

CLAMP

BRACKET

CLAMP

BRACKET

1.25

BN4100804CHSS

K

NN

BODY

K

BN4161406CHSS

K

C

CLAMP

BRACKET

1.25

CLAMP

BRACKET

1. 2 5

NN

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 10

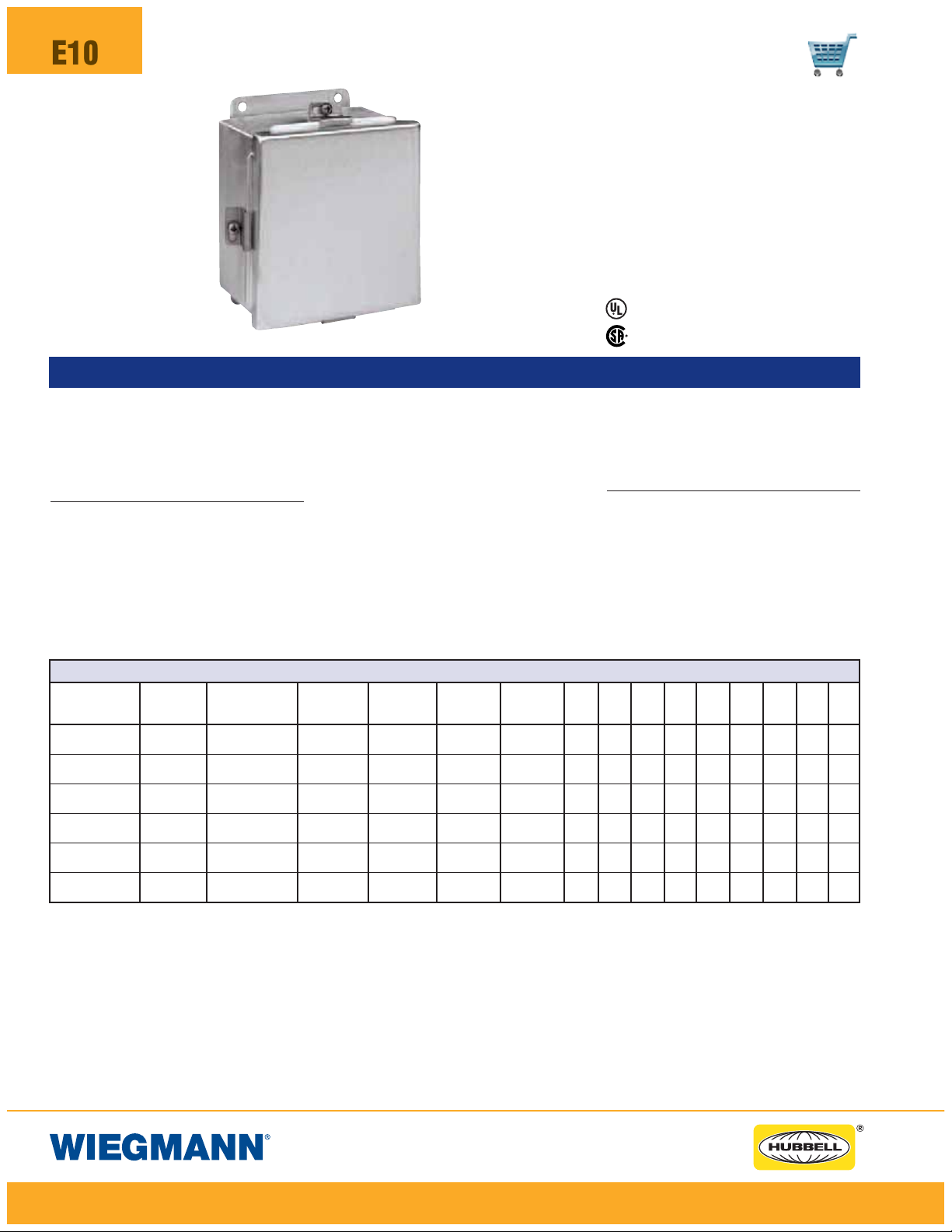

E10

BN4 - AL SERIES ENCLOSURES

NEMA 4 LIFT OFF COVER WALL-MOUNT

FEATURES-SPECIFICATIONS

BN4060604AL

Industry Standards

UL 50, Types 4, 4X, 12 & 13

CSA Certified, Types 4 & 12

NEMA/EEMAC Type 4, 4X, 12 & 13

JIC EL-1- 71

UL File E6924, E23553

CSA File LL66078

Applications

Designed as an instrument housing or

junction box for electrical, electronic,

or pneumatic components. It is ideal

for applications where a lightweight,

corrosion resistant enclosure is required.

Construction

• Bodies and doors fabricated from

.080-inch thick (2 millimeters)

5052-H32 aluminum

• Continuously welded seams ground

smooth, less holes or knockouts

• Closed cell oil resistant neoprene

gasket

• External mounting plate, top and

bottom of enclosure

• Weldnuts are provided on Models

6.00" x 4.00" and larger to secure

optional panel

• Stainless steel screws and clamps

on four sides of cover to assure

water tight seal

• Optional panels and terminal kits

must be ordered separately

• Grounding provisions provided

BN4-CH SERIES CLAMP COVER ALUMINUM ENCLOSURES

CATALOG

NUMBER

BN4060604AL 14/14

BN4080603AL 14/14

BN4100804AL 14/14

BN4121005AL 14/14

BN4141206AL 14/14

BN4161406AL 14/14

*Back panels must be ordered separately

BODY/DOOR BACK PANEL

ALUMINUM

GAUGE

ENCLOSURE SIZE

HXWXD

6.00x6.00x4.00

(152x152x102) (124x124) (171x102) (191x194) (90) (160) (127) (14) (60) (60) (90) (16) (160)

8.00x6.00x3.50

(203x152x89) (175x124) (222x102) (241x194) (77) (160) (127) (14) (60) (86) (77) (16) (211)

10.00x8.00x4.00

(254x203x102) (226x175) (273x152) (292x244) (90) (211) (178) (14) (86) (38) (90) (16) (262)

12.00x10.00x5.00

(305x254x127) (276x226) (324x203) (343x295) (115) (262) (229) (14) (51) (76) (115) (16) (313)

14.00x12.00x6.00

(356x305x152) (327x276) (375x254) (394x346) (141) (313) (279) (14) (51) (76) (141) (16) (364)

16.00x14.00x6.00

(406x356x152) (378x327) (425x305) (445x397) (141) (363) (330) (14) (89) (38) (141) (16) (414)

CATALOG

NUMBER*

P0606

P0806

P1008

P1210

P1412

P1614

Finish

• Exterior and doors of enclosures

have a smooth grained finish

• Optional back panels are white

polyester powder

Acces sories

• Back panels (reference tables)

• See pages J1-J22

BACK PANEL MOUNTING OVERALL

SIZEAXB CXE LXM

4.88x4.88 6.75x4.00 7.50x7.63 3.53 6.31 5.00 0.56 2.38 2.38 3.53 0.63 6.31

6.88x4.88 8.75x4.00 9.50x7.63 3.03 6.31 5.00 0.56 2.38 3.38 3.03 0.63 8.31

8.88x6.88 10.75x6.00 11.50x9.63 3.53 8.31 7.00 0.56 3.38 1.50 3.53 0.63 10.31

10.88x8.88 12.75x8.00 13.50x11.63 4.53 10.31 9.00 0.56 2.00 3.00 4.53 0.63 12.31

12.88x10.88 14.75x10.00 15.50x13.63 5.53 12.31 11.00 0.56 2.00 3.00 5.53 0.63 14.31

14.88x12.88 16.75x12.00 17.50x15.63 5.53 14.31 13.00 0.56 3.50 1.50 5.53 0.63 16.31

FG I JKNOPQ

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 11

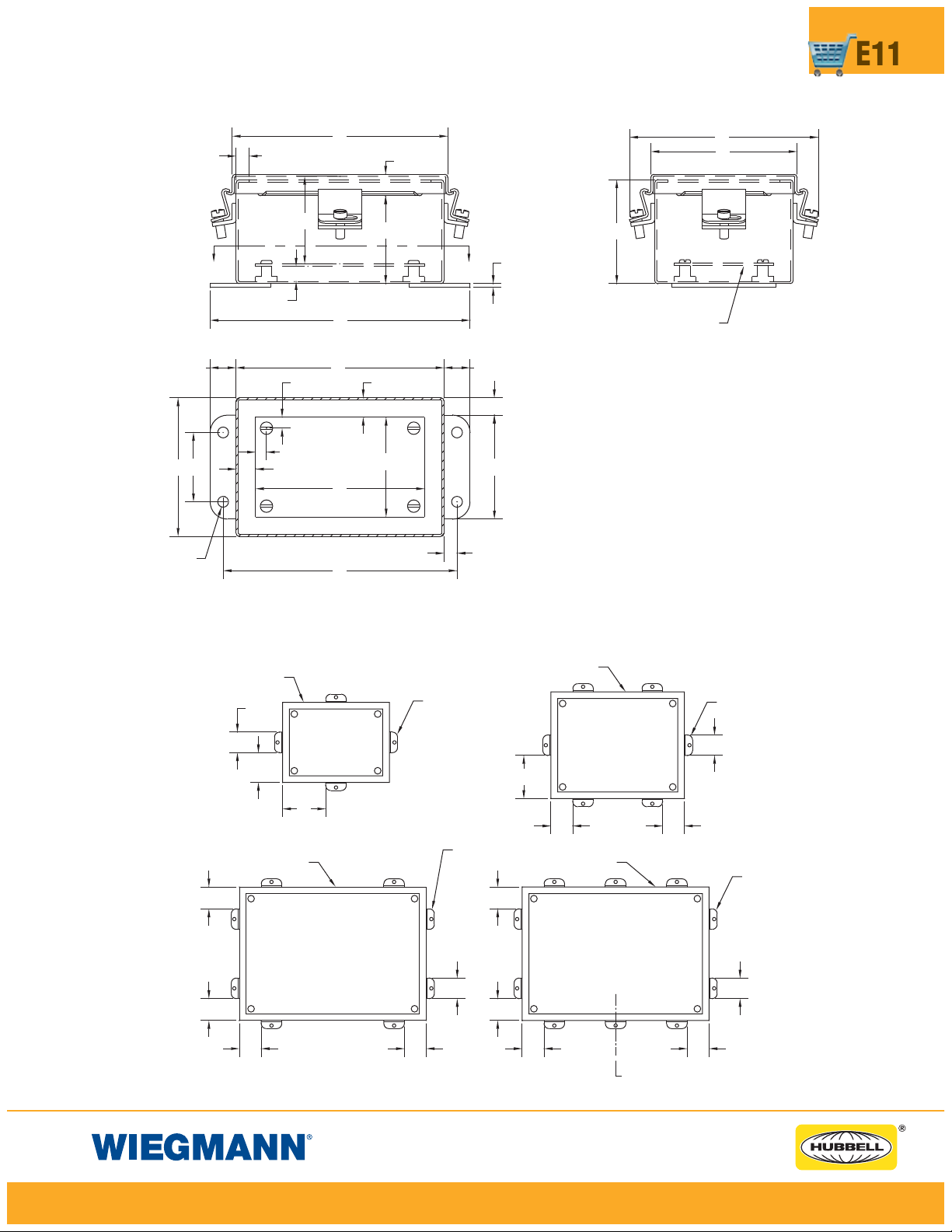

BN4 - AL SERIES ENCLOSURES

NEMA 4 LIFT OFF COVER WALL-MOUNT

E11

0.75

W

Ø 0.31

TYP

Q

0.38

F

X

0.44

L

H

E

0.31 TYP

J

A

C

SECTION X-X

P

O

14 GA.

X

0.560.31 TYP

B

0.75

0.50

I

0.38

D

Panel (Order Separately)

Notes:

1. Panels are 14 Ga. steel.

2. Panel screws are #10-32 Pan Head.

M

G

CLAMP BRACKET LOCATIONS

BODY

CLAMP

1. 2 5

BN4060604AL

BN4080603AL

K

N

BODY

K

BN4121005AL

BN4141206AL

K

BRACKET

CLAMP

BRACKET

K

1. 2 5

K

NN

BODY

CLAMP

BRACKET

BN4100804AL

K

BODY

BN4161406AL

1. 2 5

NN

CLAMP

BRACKET

1. 2 5

NN

C

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 12

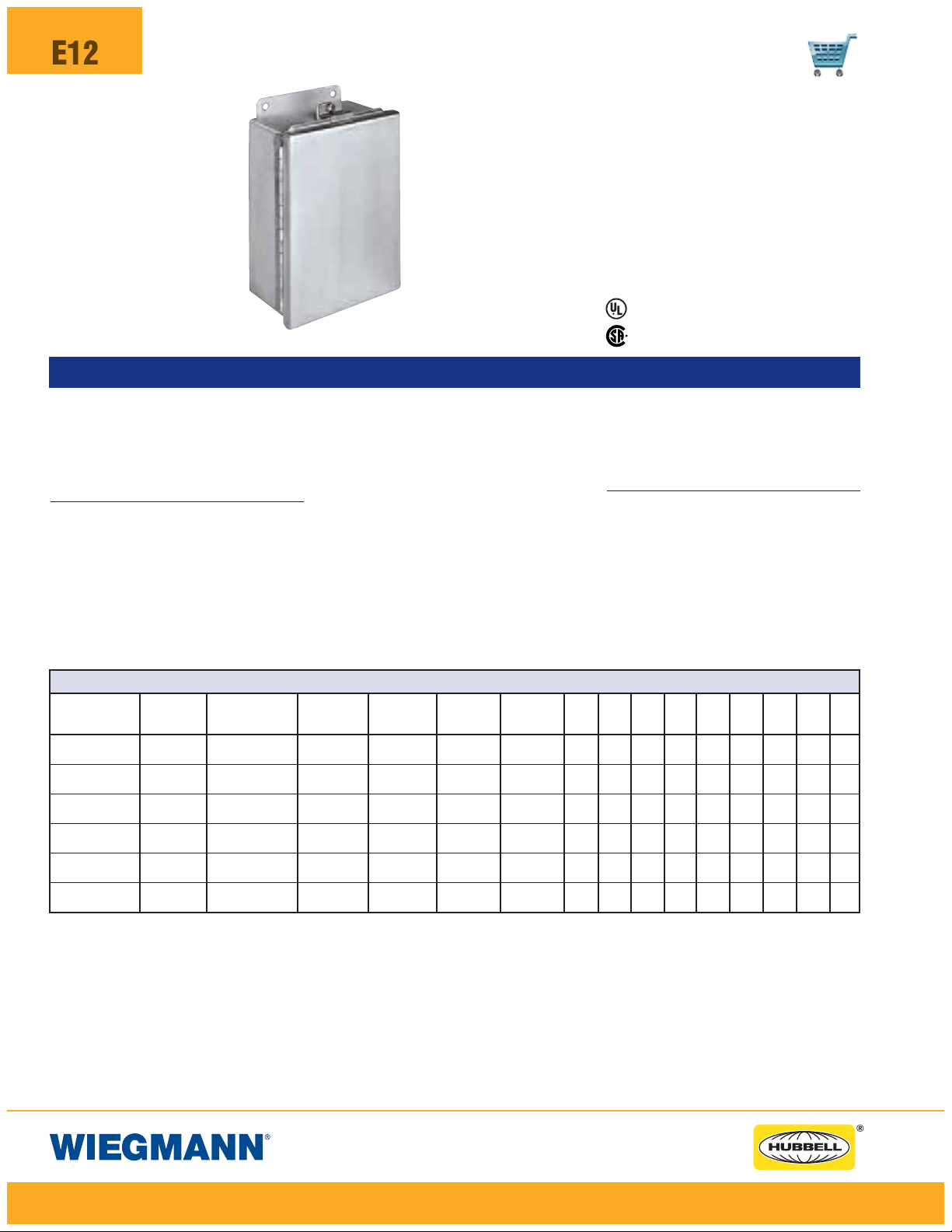

E12

BN4 - CHAL SERIES ENCLOSURES

NEMA 4X JIC CONTINUOUS HINGE WALL-MOUNT

Industry Standards

UL 50, Types 4, 4X, 12 & 13

CSACertified,Types4&12

NEMA/EEMAC Type 4, 4X, 12 & 13

JIC EL-1- 71

UL File E6924, E64791

BN4080603CHAL

FEATURES-SPECIFICATIONS

Applications

Designed as an instrument housing or

junction box for electrical, electronic,

or pneumatic components. It is ideal

for applications where a lightweight,

corrosion resistant enclosure is required.

Construction

• Bodies and doors fabricated from

.080-inch thick (2 millimeters)

5052-H32 aluminum

• Continuously welded seams ground

smooth, less holes or knockouts

• Closed cell oil resistant neoprene

• External mounting plate, top and

bottom of enclosure

• Weldnuts are provided on Models

6.00" x 4.00" and larger to secure

optional panel

• Stainless steel screws and clamps

on three sides of cover to assure

water tight seal

• Optional panels and terminal kits

must be ordered separately

• Grounding provisions provided

• Cover removed by pulling stainless

steel continuous hinge pin

gasket

BN4-CHAL SERIES CONTINUOUS HINGE ALUMINUM ENCLOSURES

CATALOG

NUMBER

BN4060604CHAL 14/14

BN4080603CHAL 14/14

BN4100804CHAL 14/14

BN4121005CHAL 14/14

BN4141206CHAL 14/14

BN4161406CHAL 14/14

*Back panels must be ordered separately.

BODY/DOOR BACK PANEL

ALUMINUM

GAUGE

ENCLOSURE SIZE

HXWXD

6.00x6.00x4.00

(152x152x102) (124x124) (171x102) (191x178) (90) (160) (127) (14) (60) (60) (90) (160) (71)

8.00x6.00x3.50

(203x152x89) (175x124) (222x102) (241x178) (77) (160) (127) (14) (60) (86) (77) (211) (58)

10.00x8.00x4.00

(254x203x102) (226x175) (273x152) (292x229) (90) (211) (178) (14) (86) (38) (90) (262) (71)

12.00x10.00x5.00

(305x254x127) (276x226) (324x203) (343x279) (115) (262) (229) (14) (51) (76) (115) (313) (96)

14.00x12.00x6.00

(356x305x152) (327x276) (375x254) (394x330) (141) (313) (279) (14) (51) (76) (141) (364) (121)

16.00x14.00x6.00

(406x356x152) (378x327) (425x305) (445x381) (141) (363) (330) (14) (89) (38) (141) (414) (121)

CATALOG

NUMBER*

P0606

P0806

P1008

P1210

P1412

P1614

BACK PANEL MOUNTING OVERALL

SIZEAXB CXE LXM

4.88x4.88 6.75x4.00 7.50x7.00 3.53 6.31 5.00 0.56 2.38 2.38 3.53 6.31 2.78

6.88x4.88 8.75x4.00 9.50x7.00 3.03 6.31 5.00 0.56 2.38 3.38 3.03 8.31 2.28

8.88x6.88 10.75x6.00 11.50x9.00 3.53 8.31 7.00 0.56 3.38 1.50 3.53 10.31 2.78

10.88x8.88 12.75x8.00 13.50x11.00 4.53 10.31 9.00 0.56 2.00 3.00 4.53 12.31 3.78

12.88x10.88 14.75x10.00 15.50x13.00 5.53 12.31 11.00 0.56 2.00 3.00 5.53 14.31 4.78

14.88x12.88 16.75x12.00 17.50x15.00 5.53 14.31 13.00 0.56 3.50 1.50 5.53 16.31 4.78

CSA File LL66078

Finish

• Exterior and doors of enclosures

have a smooth grained finish

• Optional back panels are white

polyester powder

Acces sories

• Back panels (reference tables)

• See pages J1-J22

FG I J K NO PQ

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 13

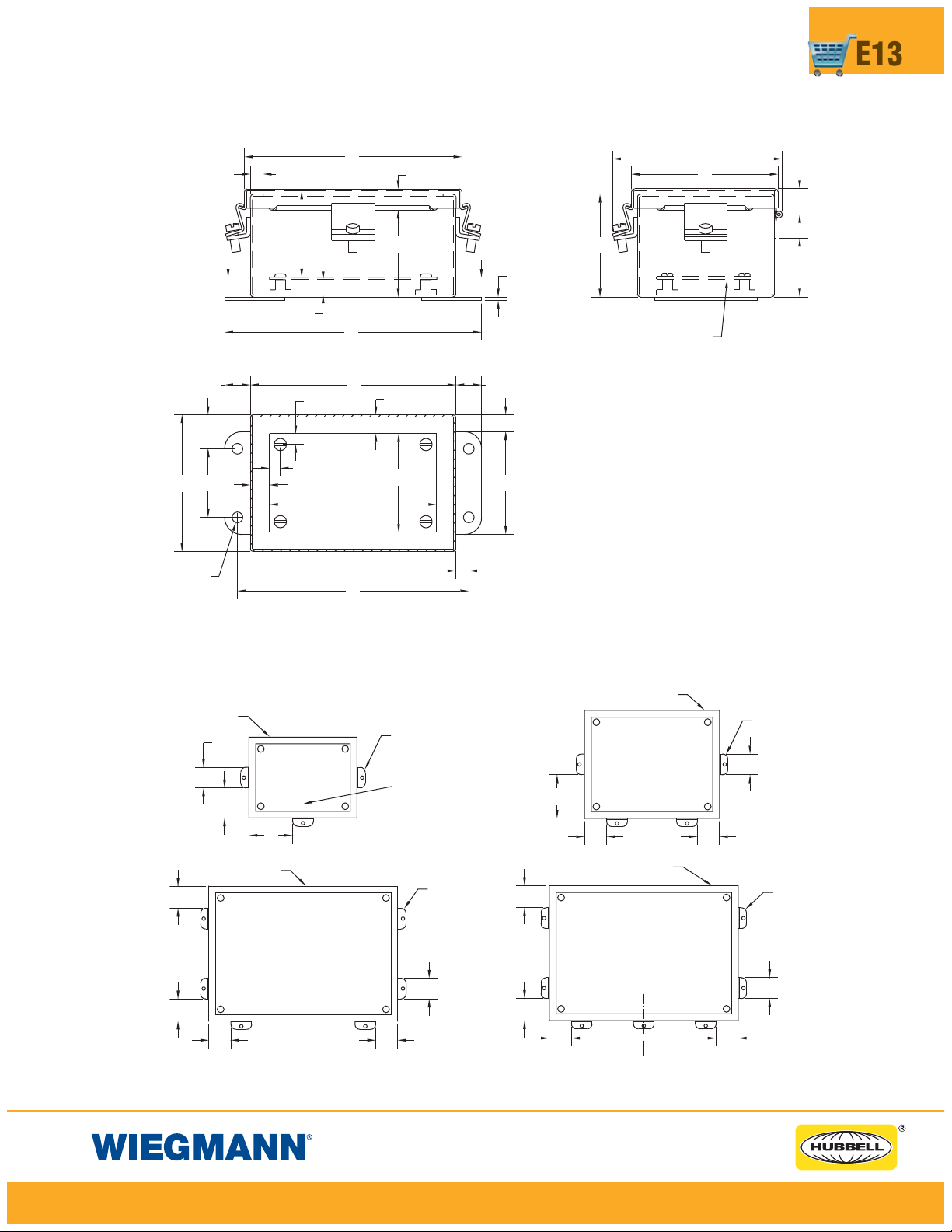

BN4 - CHAL SERIES ENCLOSURES

NEMA 4X JIC CONTINUOUS HINGE WALL-MOUNT

E13

0.75

W

Ø0.31

TYP

1. 0 0

P

0.38

F

X

0.44

L

H

0.31 TYP

E

0.31 TYP

J

A

C

O

0.56

B

0.63

X

0.75

0.38

0

.50

D

14 GA.

Panel (Order Separately)

Notes:

1. Panels are 14 Ga. steel.

2. Panel screws are #10-32 Pan Head.

I

M

G

0.75

Q

SECTION X-X

CLAMP BRACKET LOCATIONS

BODY

1.25

K

N

BODY

K

BN4121005CHAL

BN4141206CHAL

K

CLAMP

BRACKET

BN4060604CHAL

BN4080603CHAL

CLAMP

BRACKET

1.25

NN

K

K

K

BODY

BN4100804CHAL

BODY

BN4161406CHAL

C

CLAMP

BRACKET

1.25

NN

CLAMP

BRACKET

1.25

NN

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

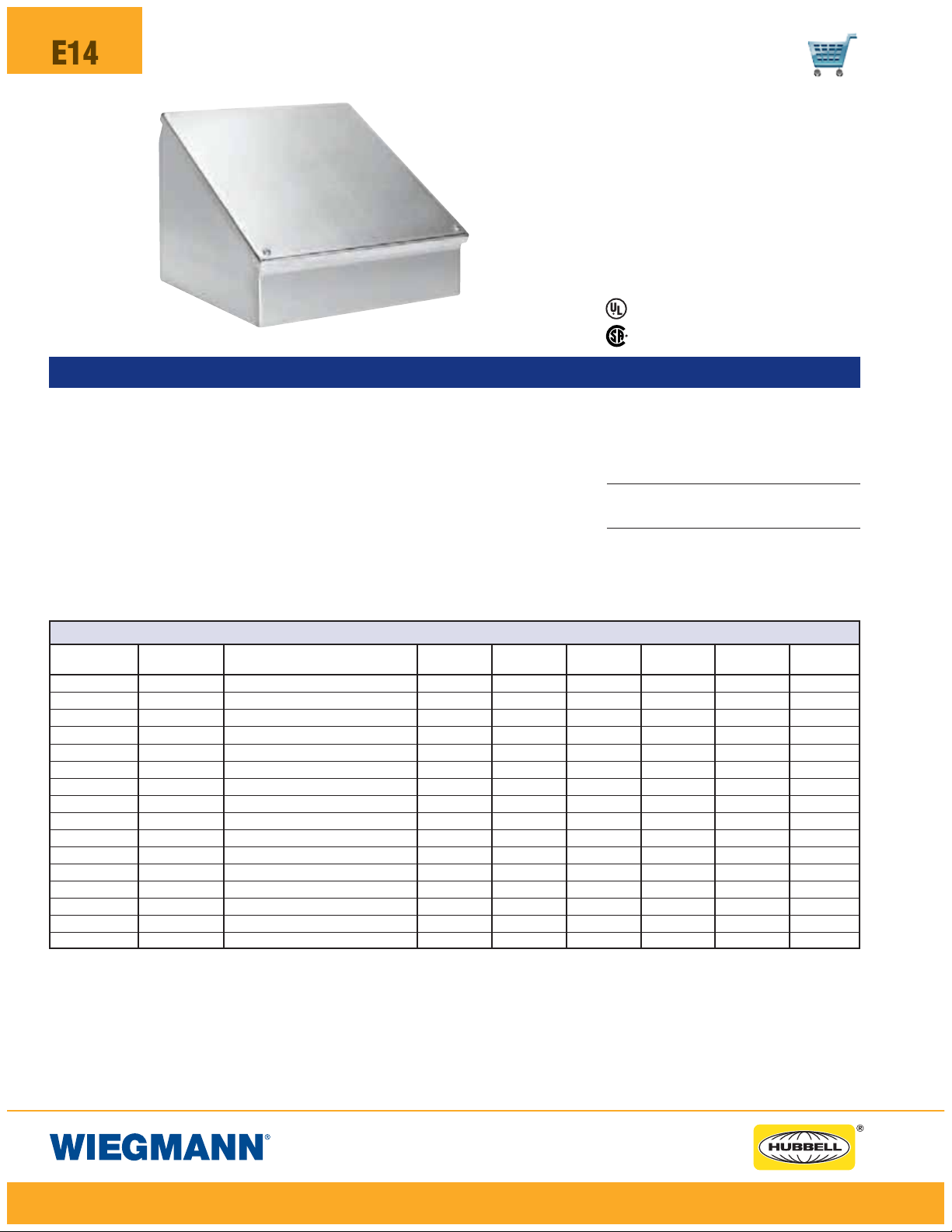

Page 14

E14

WC - CSS SERIES ENCLOSURES

NEMA 12 CONSOLET SINGLE DOOR

Industry Standards

UL 508, Types 12 & 13

CSA Certified, Type 12

NEMA/EEMAC Type 12 & 13

JIC EL-1-71

UL Files E64791

WC12C12SS

CSA File LL66078

FEATURES-SPECIFICATIONS

Applications

Designed to house a variety of

electronic control or instrumentation

devices. Consolets provide protection

from dust, dirt, oil, and water. Flexible

design allows for mounting on either

or two sides, creating control surfaces

of 30 degrees or 60 degrees. Consolets

can be mounted on desktops,

pedestals, or other flat surfaces.

WC-CSS SERIES CONSOLET ENCLOSURES

CATALOG BODY/DOOR ENCLOSURE SIZE

NUMBER STEEL GAUGE HXWXD

WC08C08SS 14/14 8.00x8.00x7.09 (203x203x180) 5.69 (144) 7.44 (189) 6.56 (167) 7.44 (189) 8.31 (211) 8.31 (211)

WC08C12SS 14/14 8.00x12.00x7.09 (203x305x180) 5.69 (144) 7.44 (189) 6.56 (167) 11.44 (291) 8.31 (211) 12.31 (313)

WC08C16SS 14/14 8.00x16.00x7.09 (203x406x180) 5.69 (144) 7.44 (189) 6.56 (167) 15.44 (392) 8.31 (211) 16.31 (414)

WC08C20SS 14/14 8.00x20.00x7.09 (203x508x180) 5.69 (144) 7.44 (189) 6.56 (167) 19.44 (494) 8.31 (211) 20.31 (516)

WC12C12SS 14/14 12.00x12.00x9.09 (305x305x231) 7.69 (195) 10.91 (277) 10.56 (268) 11.44 (291) 12.31 (313) 12.31 (313)

WC12C16SS 14/14 12.00x16.00x9.09 (305x406x231) 7.69 (195) 10.91 (277) 10.56 (268) 15.44 (392) 12.31 (313) 16.31 (414)

WC12C20SS 14/14 12.00x20.00x9.09 (305x508x231) 7.69 (195) 10.91 (277) 10.56 (268) 19.44 (494) 12.31 (313) 20.31 (516)

WC12C24SS 14/14 12.00x24.00x9.09 (305x610x231) 7.69 (195) 10.91 (277) 10.56 (268) 23.44 (595) 12.31 (313) 24.31 (618)

WC16C16SS 14/14 16.00x16.00x11.09 (406x406x282) 9.69 (246) 14.38 (365) 14.56 (370) 15.44 (392) 16.31 (414) 16.31 (414)

WC16C20SS 14/14 16.00x20.00x11.09 (406x508x282) 9.69 (246) 14.38 (365) 14.56 (370) 19.44 (494) 16.31 (414) 20.31 (516)

WC16C24SS 14/14 16.00x24.00x11.09 (406x610x282) 9.69 (246) 14.38 (365) 14.56 (370) 23.44 (595) 16.31 (414) 24.31 (618)

WC16C30SS 14/14 16.00x30.00x11.09 (406x762x282) 9.69 (246) 14.38 (365) 14.56 (370) 29.44 (748) 16.31 (414) 30.31 (770)

WC16C36SS 14/14 16.00x36.00x11.09 (406x914x282) 9.69 (246) 14.38 (365) 14.56 (370) 35.44 (900) 16.31 (414) 36.31 (922)

WC20C20SS 14/14 20.00x20.00x13.09 (508x508x333) 11.69 (297) 17.84 (453) 18.56 (471) 19.44 (494) 20.31 (516) 20.31 (516)

WC20C24SS 14/14 20.00x24.00x13.09 (508x610x333) 11.69 (297) 17.84 (453) 18.56 (471) 23.44 (595) 20.31 (516) 24.31 (618)

WC20C30SS 14/14 20.00x30.00x13.09 (508x762x333) 11.69 (297) 17.84 (453) 18.56 (471) 29.44 (748) 20.31 (516) 30.31 (770)

Construction

• Bodies and doors fabricated from

14 gauge 304 stainless steel

• Continuously welded seams ground

smooth, less knockouts or holes

• Captivated cover screws thread

into sealed wells

• Control panel is continuously

hinged along bottom edge

ENLKI J

• Closed cell oil resistant neoprene

gasket

• Grounding provisions provided

Finish

• Smooth brushed finish

Acces sories

See pages J1-J22

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 15

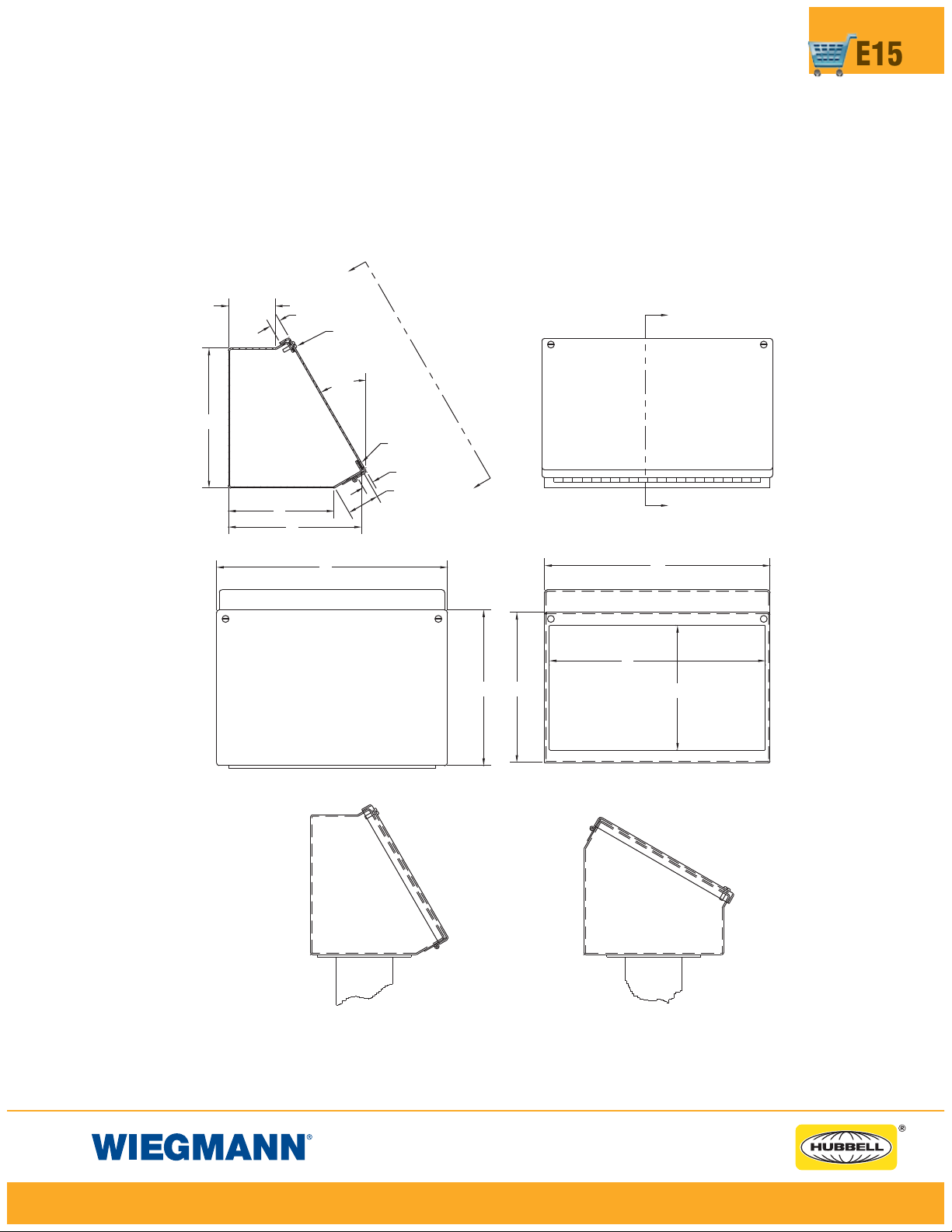

WC - CSS SERIES ENCLOSURES

NEMA 12 CONSOLET SINGLE DOOR

Y

E15

2.44

N

0.56

E

D

SECTION X-X

CAPT IVE

SCREW

30º

J

NEOPRENE

GASKET

0.56

1. 7 5

Y

K

I

H

X

X

W

L

VIEW Y-Y

VIEW Y-Y WITH COVER REMOVED

60º

30º

Consolet can be positioned at 30º or 60º angle.

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 16

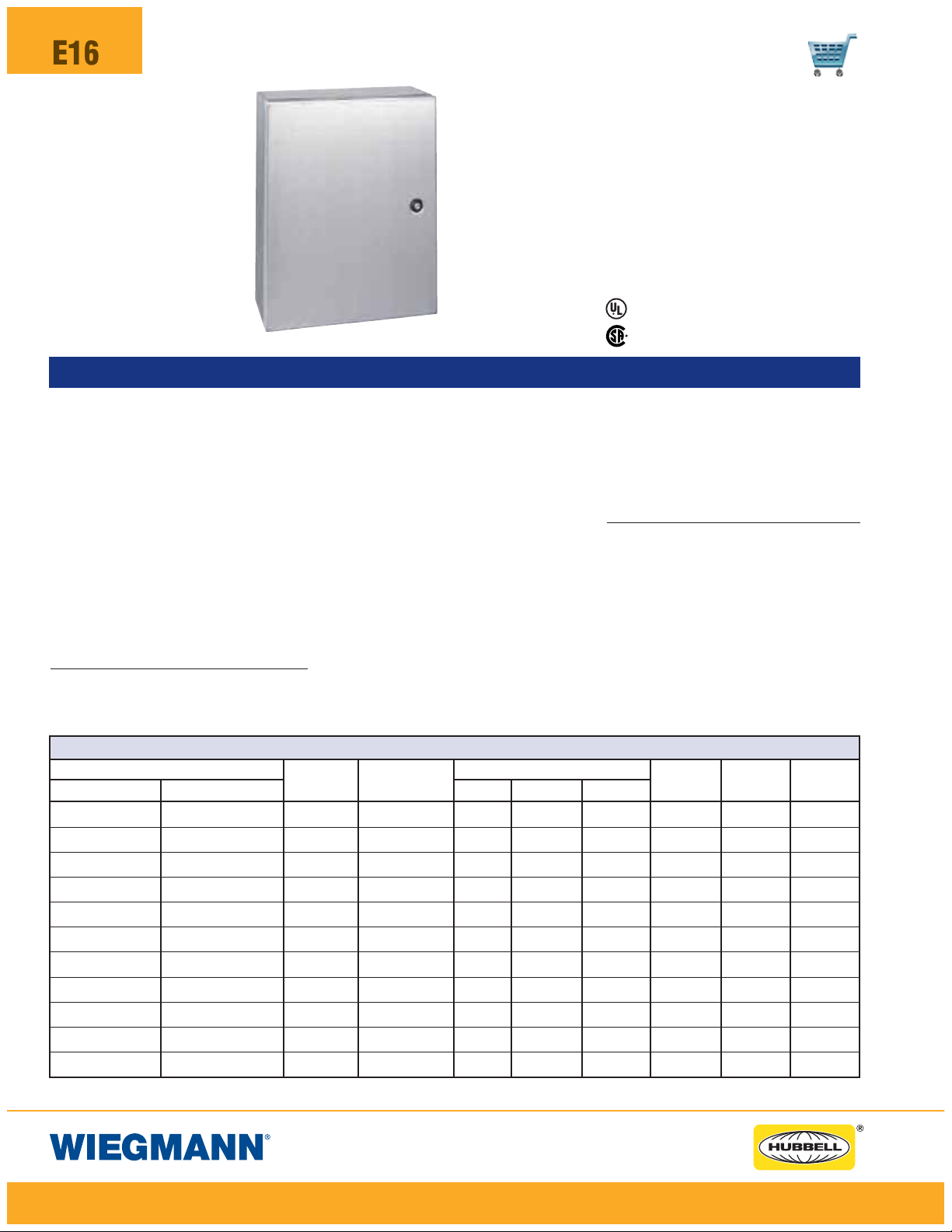

E16

N412 - SSC ULTIMATE SERIES ENCLOSURES

NEMA 4X SINGLE DOOR WALL-MOUNT

Industry Standards

UL 508, Types 4, 4X, 12 & 13

CSA Certified, Types 4, 4X, 12 & 13

NEMA/EEMAC Type 4, 4X, 12 & 13

Wall mounting brackets required to

maintain UL/ CSA external mounting

requirements.

UL Files E64791

N412201606SSC

FEATURES-SPECIFICATIONS

Applications

Hubbell Wiegmann N412SSC ULTIMATE

Stainless Steel Series Enclosures are

designed to house and protect electrical

and electronic components from harsh,

dirty environments. For use in installations where dirt, dust, oil, water, or other

contaminants are present. It is typically

used in the following areas where corrosion-resistant protection is needed: food

processing plants, pharmaceutical manufacturing facilities, petrochemical

plants, pulp and paper processing, and

waste water treatment facilities.

Streamlined styling, flush latching, and

attractive Stainless Steel finish complement any high tech electronic equipment.

Construction

• Bodies and doors fabricated from 14

gauge 304 or 316L Stainless Steel

N412-SSC ULTIMATE SERIES SINGLE DOOR STAINLESS ENCLOSURES

CATALOG NUMBER BACK PANEL CATALOG NUMBER*

304 SS 316L SS

N412121206SSC

N412161206SSC

N412161606SSC

N412201606SSC

N412202006SSC

N412161208SSC

N412161608SSC

N412162008SSC

N412201608SSC

N412202008SSC

N412241608SSC

N412121206SSAC

N412161206SSAC

N412161606SSAC

N412201606SSAC

N412202006SSAC

N412161208SSAC

N412161608SSAC

N412162008SSAC

N412201608SSAC

N412202008SSAC

N412241608SSAC

• Continuously Plasma welded seams

• Increased tub opening for better

access

• Concealed hinges

• Doors are interchangeable and easily

removable

• Ground stud located in door

• 1/4-turn semi-flush oil tight latches

are supplied to hold door securely

closed

• Print pocket is provided

• Doors are sealed with poured-inplace polyurethane gasket**

• Mounting holes in rear of enclosure

• Studs for mounting optional back

panel (the Ultimate back panels

have increased in size to accommodate larger foot-print installations)

BODY/DOOR

STEEL GAUGE

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

ENCLOSURE SIZE

HXWXD

12.00x12.00x6.00

(305x305x152)

16.00x12.00x6.00

(406x305x152)

16.00x16.00x6.00

(406x406x152)

20.00x16.00x6.00

(508x406x152)

20.00x20.00x6.00

(508x508x152)

16.00x12.00x8.00

(406x305x203)

16.00x16.00x8.00

(406x406x203)

16.00x20.00x8.00

(406x508x203)

20.00x16.00x8.00

(508x406x203)

20.00x20.00x8.00

(508x508x203)

24.00x16.00x8.00

(610x406x203)

WHITE 304 SS “G”

NP1212C

X

NP1612C

X

NP1616C

X

NP2016C

X

NP2020C

X

NP1612C

X

NP1616C

X

NP2016C

X

NP2016C

X

NP2020C

X

NP2416C

—

NP1612SSC

NP1616SSC

NP2016SSC

NP2020SSC

NP1612SSC

NP1616SSC

NP2016SSC

NP2016SSC

NP2020SSC

NP2416SSC

CSA File LL66078

Finish

• All exterior surfaces have a smooth

grained finish

•

Optional back panels are white polyester

powder

• Optional “G” panels have a con-

ductive finish (See page I5)

Accessories

• Back panels (see reference tables)

• Window door (see reference tables)

• See pages J1-J22. See pages J20J22 for ULTIMATE Series

Accessories

•

Optional N412MFKSS mounting foot kit

must be ordered separately

NP1212CG

NP1612CG

NP1616CG

NP2016CG

NP2020CG

NP1612CG

NP1616CG

NP2016CG

NP2016CG

NP2020CG

NP2416CG

BACK PANEL

SIZE A & B

10.2x10.2

(259x259)

14.2x10.2

(361x259)

14.2x14.2

(361x361)

18.2x14.2

(462x361)

18.2x18.2

(462x462)

14.2x10.2

(361x259)

14.2x14.2

(361x361)

14.2x18.2

(361x462)

18.2x14.2

(462x361)

18.2x18.2

(462x462)

22.2x14.2

(564x361)

CE

6.00

(152)

8.00

(203)

8.00

(203)

10.00

(254)

10.00

(254)

8.00

(203)

8.00

(203)

8.00

(203)

10.00

(254)

10.00

(254)

10.00

(254)

Continued on page E17

—

—

—

—

—

—

—

—

—

—

—

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 17

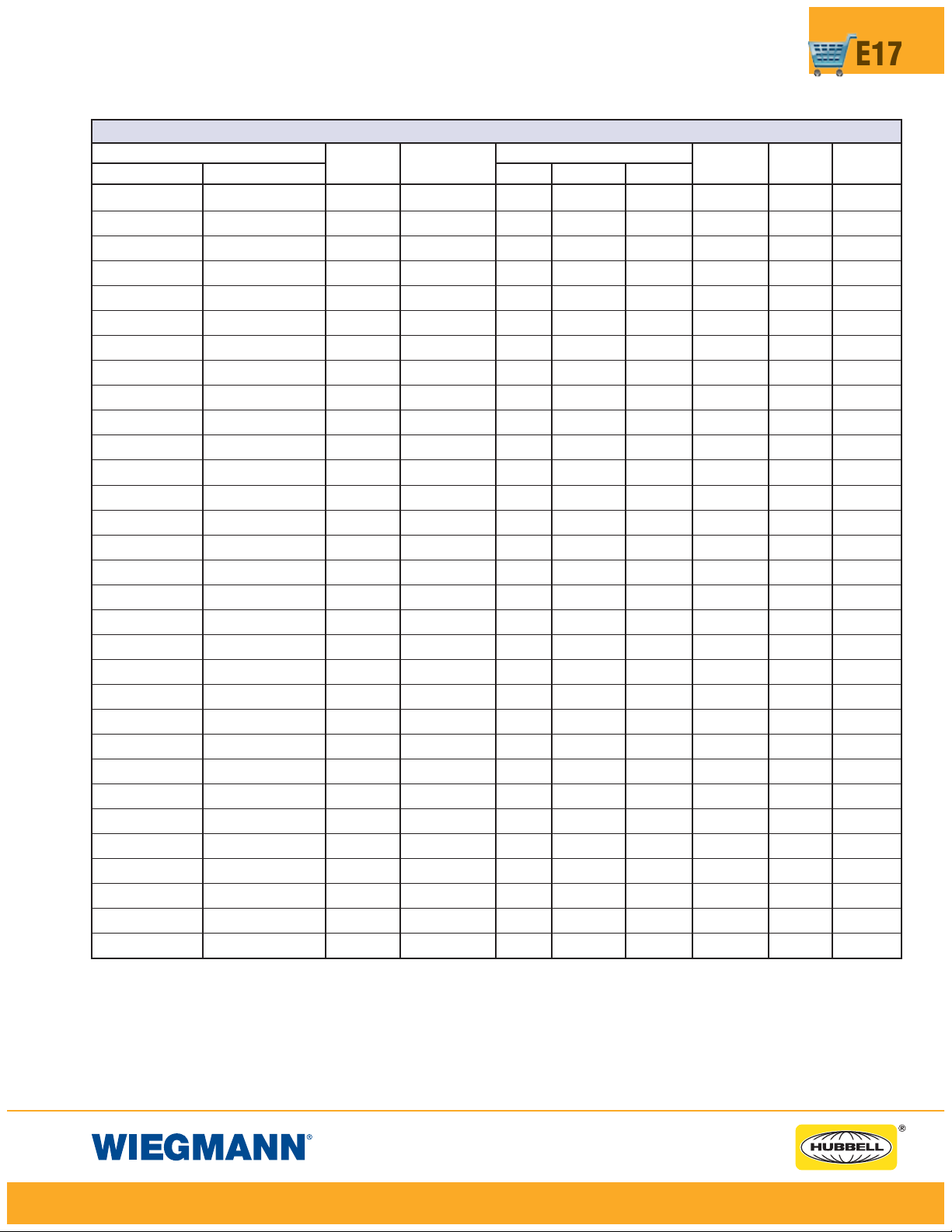

N412 - SSC ULTIMATE SERIES ENCLOSURES

NEMA 4X SINGLE DOOR WALL-MOUNT

N412-SSC ULTIMATE SERIES SINGLE DOOR STAINLESS ENCLOSURES (CONT.)

CATALOG NUMBER

304 SS 316L SS

N412242008SSC

N412242408SSC

N412302408SSC

N412303008SSC

N412362408SSC

N412363008SSC

N412161210SSC

N412161610SSC

N412162010SSC

N412201610SSC

N412202010SSC

N412241610SSC

N412242010SSC

N412242410SSC

N412302410SSC

N412303010SSC

N412362410SSC

N412363010SSC

N412363610SSC

N412423610SSC

N412483610SSC

N412603610SSC

N412202012SSC

N412242412SSC

N412302412SSC

N412362412SSC

N412363012SSC

N412363612SSC

N412423612SSC

N412483612SSC**

N412603612SSC**

N412242008SSAC

N412242408SSAC

N

N

N412362408SSAC

N412363008SSAC

N412161210SSAC

N412161610SSAC

N412162010SSAC

N412201610SSAC

N412202010SSAC

N

N412242010SSAC

N412242410SSAC

N412302410SSAC

N412303010SSAC

N412362410SSAC

N412363010SSAC

N412363610SSAC

N412423610SSAC

N412483610SSAC

N412603610SSAC

N412202012SSAC

N412242412SSAC

N412302412SSAC

N412362412SSAC

N412363012SSAC

N412363612SSAC

N412423612SSAC

N412483612SSAC

N412603612SSAC**

412302408SSAC

412303008SSAC

412241610SSAC

BODY/DOOR

STEEL GAUGE

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

ENCLOSURE SIZE

HXWXD

24.00x20.00x8.00

(610x508x203)

24.00x24.00x8.00

(610x610x203)

30.00x24.00x8.00

(762x610x203)

30.00x30.00x8.00

(762x610x203)

36.00x24.00x8.00

(914x610x203)

36.00x30.00x8.00

(914x762x203)

16.00x12.00x10.00

(406x305x254)

16.00x16.00x10.00

(406x406x254)

16.00x20.00x10.00

(406x508x203)

20.00x16.00x10.00

(508x406x254)

20.00x20.00x10.00

(508x508x254)

24.00x16.00x10.00

(610x406x254)

24.00x20.00x10.00

(610x508x254)

24.00x24.00x10.00

(610x610x254)

30.00x24.00x10.00

(762x610x254)

30.00x30.00x10.00

(762x762x254)

36.00x24.00x10.00

(914x610x254)

36.00x30.00x10.00

(914x762x254)

36.00x36.00x10.00

(914x914x254)

42.00x36.00x10.00

(1067x914x254)

48.00x36.00x10.00

(1219x914x254)

60.00x36.00x10.00

(1524x914x254)

20.00x20.00x12.00

(508x508x305)

24.00x24.00x12.00

(610x610x305)

30.00x24.00x12.00

(762x610x305)

36.00x24.00x12.00

(614x610x305)

36.00x30.00x12.00

(914x762x305)

36.00x36.00x12.00

(914x914x305)

42.00x36.00x12.00

(1067x914x305)

48.00x36.00x12.00

(1219x914x305)

60.00x36.00x12.00

(1524x914x305)

BACK PANEL CATALOG NUMBER*

WHITE 304 SS “G”

NP2420C

X

NP2424C

X

NP3024C

X

NP3030C

X

NP3624C

X

NP3630C

X

NP1612C

X

NP1616C

X

NP1620C

X

NP2016C

X

NP2020C

X

NP2416C

X

NP2020C

X

NP2424C

X

NP3024C

NP3030C

NP3624C

NP3630C

NP3636C

NP4236C

NP4836C

NP6036C

NP2020C

NP2424C

NP3024C

NP3624C

NP3630C

NP3636C

NP4236C

NP4836C

NP6036C

NP2420SSC

NP2424SSC

NP3024SSC

NP3030SSC

NP3624SSC

NP3630SSC

NP1612SSC

NP1616SSC

NP1620SSC

NP2016SSC

NP2020SSC

NP2416SSC

NP2020SSC

NP2424SSC

NP3024SSC

NP3030SSC

NP3624SSC

NP3630SSC

NP3636SSC

NP4236SSC

NP4836SSC

NP6036SSC

NP2020SSC

NP2424SSC

NP3024SSC

NP3624SSC

NP3630SSC

NP3636SSC

NP4236SSC

NP4836SSC

NP6036SSC

NP2420CG

NP2424CG

NP3024CG

NP3030CG

NP3624CG

NP3630CG

NP1612CG

NP1616CG

NP1620CG

NP2016CG

NP2020CG

NP2416CG

NP2020CG

NP2424CG

NP3024CG

NP3030CG

NP3624CG

NP3630CG

NP3636CG

NP4236CG

NP4836CG

NP6036CG

NP2020CG

NP2424CG

NP3024CG

NP3624CG

NP3630CG

NP3636CG

NP4236CG

NP4836CG

NP6036CG

BACK PANEL

SIZE A & B

22.2x18.2

(564x462)

22.2x22.2

(564x564)

28.2x22.2

(716x564)

28.2x28.2

(716x716)

34.2x22.2

(869x564)

34.2x28.2

(869x716)

14.2x10.2

(361x259)

14.2x14.2

(361x361)

14.2x18.2

(361x467)

18.2x14.2

(467x361)

18.2x18.2

(467x467)

22.2x14.2

(564x361)

18.2x18.2

(467x467)

22.2x22.2

(569x569)

28.2x22.2

(716x564)

28.2x28.2

(716x716)

34.2x22.2

(869x564)

34.2x28.2

(869x716)

34.2x34.2

(869x869)

40.2x34.2

(1021x869)

46.2x34.2

(1173x869)

58.2x34.2

(1478x869)

18.2x18.2

(462x462)

22.2x22.2

(564x564)

28.2x22.2

(716x564)

34.2x22.2

(869x564)

34.2x28.2

(869x716)

34.2x34.2

(869x869)

40.2x34.2

(1021x869)

46.2x34.2

(1173x869)

58.2x34.2

(1478x869)

E17

CE

12.00

(305)

4.00

(102)

4.00

(102)

4.00

(102)

4.00

(102)

4.00

(102)

8.00

(203)

8.00

(203)

8.00

(203)

10.00

(254)

10.00

(254)

10.00

(254)

10.00

(254)

4.00

(102)

4.00

(102)

4.00

(102)

4.00

(102)

4.00

(102)

4.00

(102)

21.00

(533)

24.00

(610)

30.00

(762)

10.00

(254)

4.00

(102)

4.00

(102)

4.00

(102)

4.00

(102)

4.00

(102)

21.00

(533)

24.00

(610)

30.00

(762)

—

16.00

(406)

22.00

(559)

22.00

(559)

28.00

(711)

28.00

(711)

—

—

—

—

—

—

—

16.00

(406)

22.00

(559)

22.00

(559)

28.00

(711)

28.00

(711)

28.00

(711)

—

—

—

—

16.00

(406)

22.00

(559)

28.00

(711)

28.00

(711)

28.00

(711)

—

—

—

* Back panels must be ordered separately.

** Enclosures are supplied with closed cell neoprene gasket (not foam-in-place).

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

DATA SUBJECT TO CHANGE WITHOUT NOTICE

Page 18

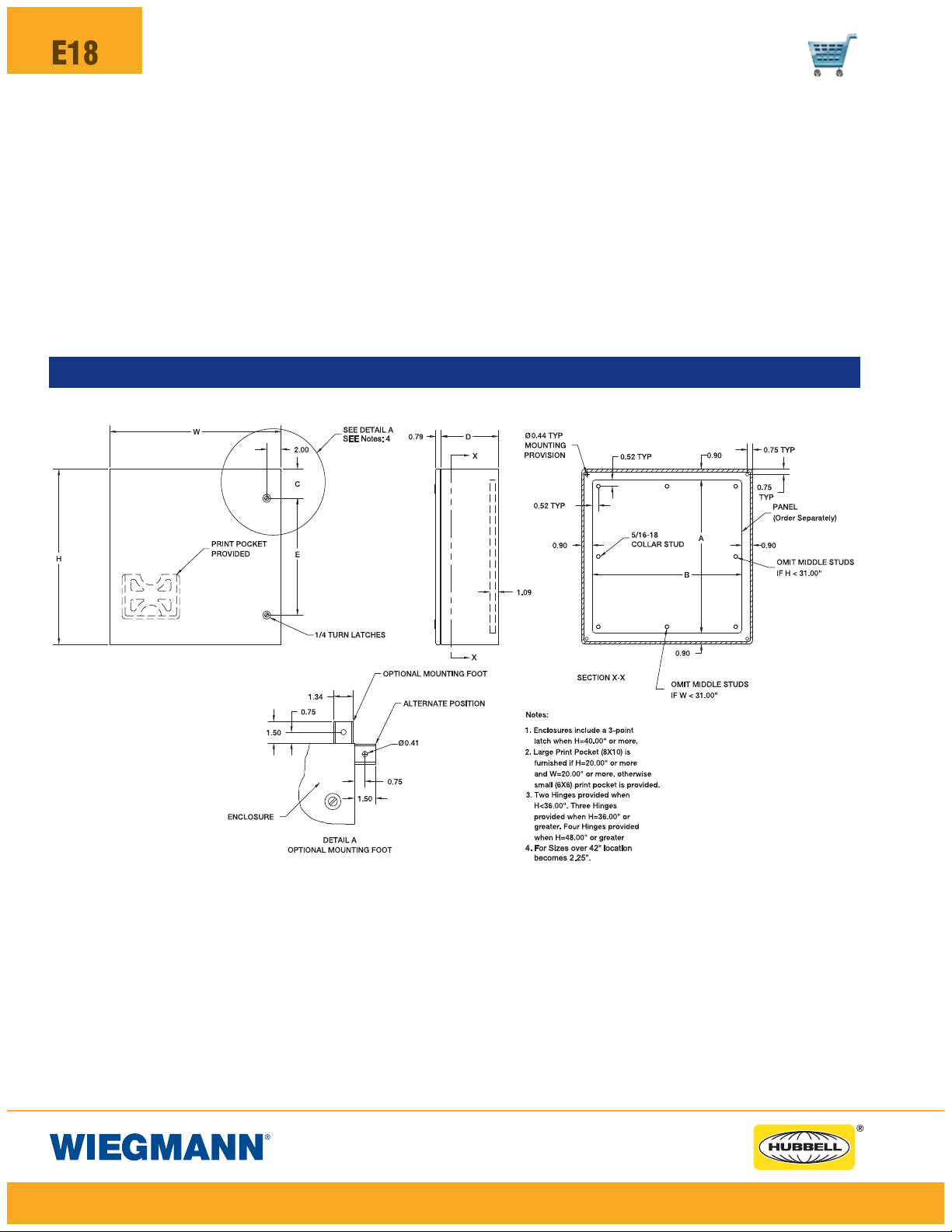

E18

N412 - SSC ULTIMATE SERIES ENCLOSURES

NEMA 4X SINGLE DOOR WALL-MOUNT

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 19

N412 - WSSC ULTIMATE SERIES ENCLOSURES

NEMA 4X SINGLE DOOR WALL-MOUNT WITH WINDOW

Industry Standards

UL 508, Types 4, 4X, 12 & 13

CSA Certified, Types 4, 4X, 12 & 13

NEMA/EEMAC Type 4, 4X, 12 & 13

Wall mounting brackets required to

maintain UL/ CSA external mounting

requirements.

UL Files E64791

E19

N412202006WSSC

CSA File LL66078

FEATURES-SPECIFICATIONS

Applications

Hubbell Wiegmann N412WSSC

ULTIMATE Stainless Steel Series

Enclosures are designed to house

and protect electrical and electronic

components from harsh, dirty environments. For use in installations where

dirt, dust, oil, water, or other contaminants are present. It is typically used

in the following areas where corrosion-resistant protection is needed:

food processing plants, pharmaceutical manufacturing facilities, petrochemical plants, pulp and paper

processing, and waste water treatment facilities. Streamlined styling,

flush latching, and attractive Stainless

Steel finish complement any high tech

electronic equipment.

N412WSSC ULTIMATE SERIES SINGLE DOOR WITH WINDOW STAINLESS ENCLOSURES

CATALOG

NUMBER

N412121206WSSC

N412161206WSSC

N412201606WSSC

N412202006WSSC

N412242006WSSC

N412242406WSSC

N412302406WSSC

N412121208WSSC

N412161208WSSC

N412201608WSSC

N412202008WSSC

N412242008WSSC

*Back panels must be ordered separately. **Enclosures are supplied with closed cell neoprene gasket (not foam-in-place).

BODY/DOOR

STEEL GAUGE

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

ENCLOSURE SIZE

HXWXD

12.00x12.00x6.00

(305x305x152)

16.00x12.00x6.00

(406x305x152)

20.00x16.00x6.00

(508x406x152)

20.00x20.00x6.00

(508x508x152)

24.00x20.00x6.00

(610x508x152)

24.00x24.00x6.00

(610x610x152)

30.00x24.00x6.00

(762x610x152)

12.00x12.00x8.00

(305x305x203)

16.00x12.00x8.00

(406x305x203)

20.00x16.00x8.00

(508x406x203)

20.00x20.00x8.00

(508x508x203)

24.00x20.00x8.00

(610x508x203

Construction

• Bodies and doors fabricated from

14 gauge 304 Stainless Steel

• Continuously Plasma welded seams

• Increased tub opening for better access

• Concealed hinges

• Plexiglass viewing window

• Doors are interchangeable and

easily removable

• Grounding provisions provided

(tub only)

• 1/4-turn semi-flush oil tight latches

are supplied to hold door securely

closed

• Print pocket is provided

• Doors are sealed with poured-inplace polyurethane gasket**

VIEWABLE

WINDOW AREA

7.50 x 6.25

(191 x 159)

11.50 x 6.25

(292 x 159)

15.50 x 10.25

(394 x 260)

15.50 x 14.25

(394 x 362)

19.50 x 14.25

(495 x 362)

19.50 x 18.25

(495 x 464)

25.50 x 18.25

(648 x 464)

7.50 x 6.25

(191 x 159)

11.50 x 6.25

(292 x 159)

15.50 x 10.25

(394 x 260)

15.50 x 14.25

(394 x 362)

19.50 x 14.25

(495 x 362)

BACK PANEL CATALOG NUMBER*

WHITE “G”

NP1212C

X

NP1612C

X

NP2016C

X

NP2020C

X

NP2420C

X

NP2424C

X

NP3024C

X

NP1212C

X

NP1612C

X

NP2016C

X

NP2020C

X

NP2420C

NP1212CG

NP1612CG

NP2016CG

NP2020CG

NP2420CG

NP2424CG

NP3024CG

NP1212CG

NP1612CG

NP2016CG

NP2020CG

NP2420CG

• Mounting holes in rear of enclosure

• Studs for mounting optional back

panel (the Ultimate back panels

have increased in size to accommodate larger foot-print installations)

Finish

• All exterior surfaces have a smooth

grained finish

•

Optional back panels are white polyester

powder

• Optional “G” panels have a con-

ductive finish (See page I5)

Accessories

• Back panels (see reference tables)

• See pages J1-J22. See pages J20J22 for ULTIMATE Series Accessories

•

Optional N412MFKSS mounting foot kit

must be ordered separately

BACK PANEL

SIZEA&B

10.2x10.2

(259x259)

14.2x10.2

(361x259)

18.2x14.2

(462x361)

18.2x18.2

(462x462)

22.2x18.2

(564x462)

22.2x22.2

(564x564)

28.2x22.2

(716x564)

10.2x10.2

(259x259)

14.2x10.2

(361x259)

18.2x14.2

(462x361)

18.2x18.2

(462x462)

22.2x18.2

(564x462

CE

6.00

(152)

8.00

(203)

10.00

(254)

10.00

(254)

12.00

(305)

4.00

(102)

4.00

(102)

6.00

(152)

8.00

(203)

10.00

(254)

10.00

(254)

12.00

(305)

Continued on page E20

—

—

—

—

—

16.00

(406)

22.00

(559)

—

—

—

—

—

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 20

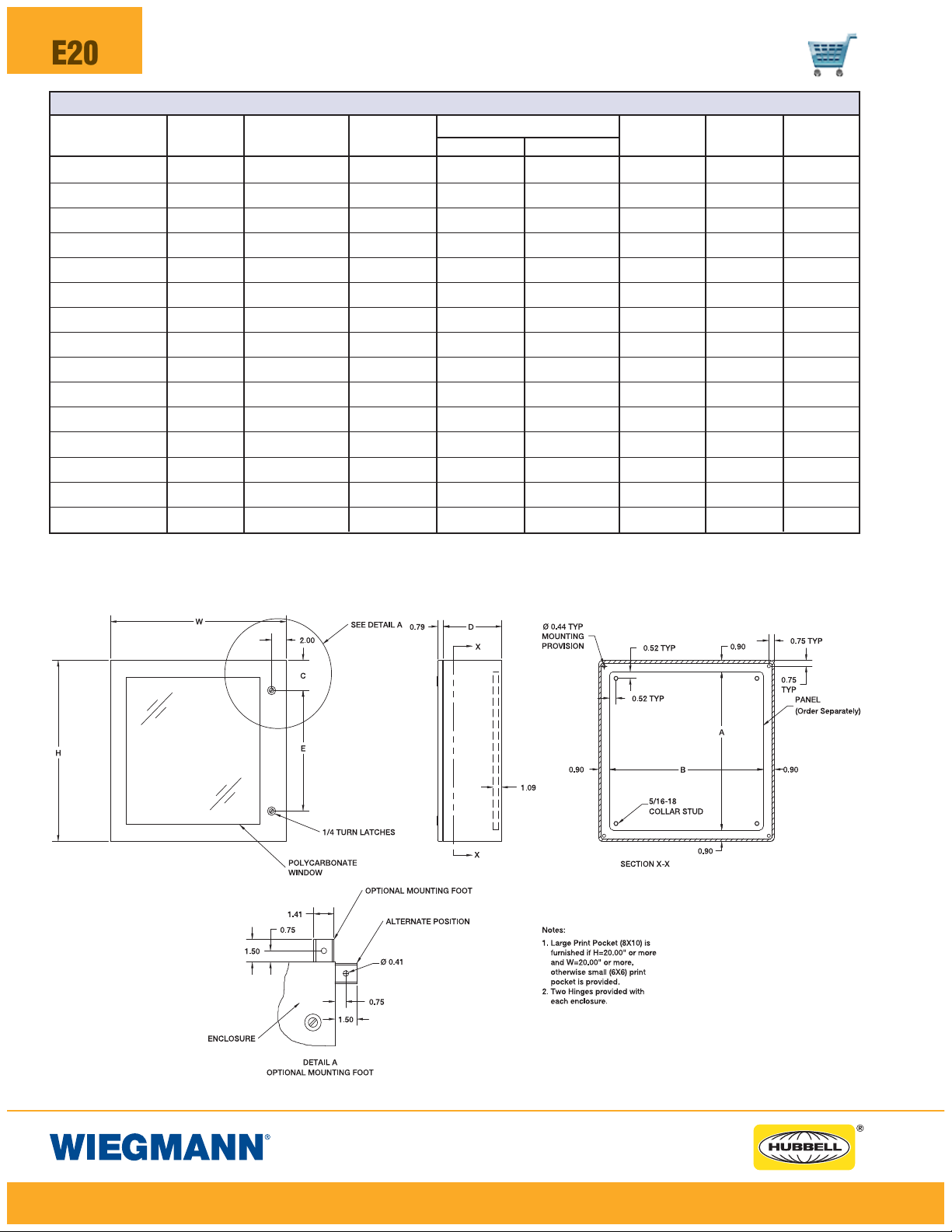

E20

N412 - WSSC ULTIMATE SERIES ENCLOSURES

NEMA 4X SINGLE DOOR WALL-MOUNT WITH WINDOW

N412WSSC ULTIMATE SERIES SINGLE DOOR WITH WINDOW STAINLESS ENCLOSURES (CONT.)

CATALOG

NUMBER

N412242408WSSC

N412302408WSSC

N412161210WSSC

N412201610WSSC

N412202010WSSC

N412242010WSSC

N412242410WSSC

N412302410WSSC

N412202012WSSC

N412242012WSSC

N412242412WSSC

N412302412WSSC

N412242416WSSC**

N412242420WSSC**

N412302420WSSC**

*Back panels must be ordered separately.

**Enclosures are supplied with closed cell neoprene gasket (not foam-in-place).

BODY/DOOR

STEEL GAUGE

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

14/14

ENCLOSURE SIZE

HXWXD

24.00x24.00x8.00

(610x610x203)

30.00x24.00x8.00

(762x610x203)

16.00x12.00x10.00

(406x305x254)

20.00x16.00x10.00

(508x406x254)

20.00x20.00x10.00

(508x508x254)

24.00x20.00x10.00

(610x508x254

24.00x24.00x10.00

(610x610x254)

30.00x24.00x10.00

(762x610x254)

20.00x20.00x12.00

(508x508x305)

24.00x20.00x12.00

(610x508x305)

24.00x24.00x12.00

(610x610x305)

30.00x24.00x12.00

(762x610x305)

24.00x24.00x12.00

(610x610x406)

24.00x24.00x12.00

(610x610x508)

30.00x24.00x20.00

(762x610x508)

VIEWABLE

WINDOW AREA

19.50 x 18.25

(495 x 464)

25.50 x 18.25

(648 x 464)

11.50 x 6.25

(292 x 159)

15.50 x 10.25

(394 x 260)

15.50 x 14.25

(394 x 362)

19.50 x 14.25

(495 x 362)

19.50 x 18.25

(495 x 464)

25.50 x 18.25

(648 x 464)

15.50 x 14.25

(394 x 362)

19.50 x 14.25

(495 x 362)

19.50 x 18.25

(495 x 464)

25.50 x 18.25

(648 x 464)

19.50 x 18.25

(495 x 464)

19.50 x 18.25

(495 x 464)

25.50 x 18.25

(648 x 464)

BACK PANEL CATALOG NUMBER*

WHITE “G”

NP2424C

X

NP3024C

X

NP1612C

X

NP2016C

X

NP2020C

X

NP2420C

X

NP2424C

X

NP3024C

X

NP2020C

NP2420C

NP2424C

NP3024C

NP2424C

NP2424C

NP3024C

NP2424CG

NP3024CG

NP1612CG

NP2016CG

NP2020CG

NP2420CG

NP2424CG

NP3024CG

NP2020CG

NP2420CG

NP2424CG

NP3024CG

NP2424CG

NP2424CG

NP3024CG

BACK PANEL

SIZEA&B

2.2x22.2

2

(564x564)

28.2x22.2

(716x564)

14.2x10.2

361x259)

(

18.2x14.2

(462x361)

18.2x18.2

(462x462)

22.2x18.2

(564x462)

22.2x22.2

(564x564)

28.2x22.2

(716x564)

18.2x18.2

(462x462)

22.2x18.2

(564x462)

22.2x22.2

(564x564)

28.2x22.2

(716x564)

22.2x22.2

(564x564)

22.2x22.2

(564x564)

28.2x22.2

(716x564)

CE

4.00

(102)

4.00

(102)

8.00

(203)

0.00

1

(254)

10.00

(254)

12.00

(305)

.00

4

(102)

4.00

(102)

10.00

(254)

12.00

(305)

4.00

102)

(

4.00

(102)

4.00

102)

(

4.00

(102)

4.00

(102)

16.00

(406)

22.00

(559)

—

—

—

—

16.00

(406)

22.00

(559)

—

—

16.00

(406)

22.00

(559)

16.00

(406)

16.00

(406)

22.00

(559)

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 21

N 4 1 2 - S S 3 P T C & S S A 3 P T C U LT I M AT E S E R I E S E N C L O S U R E S

N E M A 1 2 , 4 & 4 X S I N G L E D O O R W A L L - M O U N T

Industry Standards

UL 508 Listed, Types 4X, 12 & 13

CSA Cer tified, Types 12 & 13

NEMA/EEMAC Type 4X, 12 & 13

UL F i l es E6 4 7 9 1

E21

N4122016 06SS 3 PTC

F E AT U R E S - S P E C I F I C AT I O N S

Applications

Hubbell Wiegmann N412SS3PTC

ULTIMATE Series Enclosures are

designed to house and protect electrical and electronic components from

harsh, dirty environments. For use in

installations where dirt, dust, oil, water,

or other contaminants are present.

Streamlined styling, flush latching, and

attractive durable finish complement

any high tech electronic equipment.

Construction

• Bodies and doors fabricated from

14 gauge 304 or 316 stainless steel.

• Enclosures less than 24" in height

will contain 1 point latching.

• Doors are interchangeable and

easily removable.

• Grounding studs are welded to door

and body assuring a positive ground.

• Print pocket is provided.

• Foam in place door gasket.

• Mounting holes in rear of enclosure.

• Collar studs for mounting optional

back panel.

• With a 3pt 316L SS Padlocking

Handle.

• Continuously welded seams ground

smooth, less holes or knockouts.

N 4 1 2 S S 3 P T S E R I E S S I N G L E D O O R W A L L M O U N T S T A I N L E S S EN C L O S U R E S

CATAL OG NUM BE R

N4 12121 20 6S S1 PT C 12. 00x12.0 0x6.00 (3 05x30 5x 152) NP1 21 2C NP 12 12 SSC NP 1212C G

N4 12161 20 6S S1 PT C 16. 00x12.0 0x6.00 (4 06x30 5x 152) NP1 61 2C NP 16 12 SSC NP 1612C G

N4 12161 60 6S S1 PT C 16. 00x16.0 0x6.00 (4 06x40 6x 152) NP1 61 6C NP 16 16 SSC NP 1616C G

N4 12201 60 6S S1 PT C 20. 00x16.0 0x6.00 (5 08x40 6x152) NP2 01 6C NP 20 16 SSC NP 2016C G

N4 12202 00 6S S1 PT C 20. 00x20.0 0x6.00 (5 08X50 8x 152) NP 2020C NP20 20 SS C N P2 02 0CG

N4 12161 20 8S S1 PT C 16. 00x12.0 0x8.00 (4 06x30 5x203) NP1 61 2C NP 16 12 SSC NP 1612C G

N4 12161 60 8S S1 PT C 16. 00x16.0 0x8.00 (4 06x40 6x203) NP1 61 6C NP 16 16 SSC NP 1616C G

N4 12162 00 8S S1 PT C 16. 00x20.0 0x8.00 (4 06x50 8x203) NP1 62 0C NP 16 20 SSC NP 1620C G

N4 12201 60 8S S1 PT C 20. 00x16.0 0x8.00 (5 08x40 6x203) NP2 01 6C NP 20 16 SSC NP 2016C G

N4 12202 00 8S S1 PT C 20. 00x20.0 0x8.00 (5 08x50 8x203) NP2 02 0C NP 20 20 SSC NP 2020C G

N4 12241 60 8S S3 PT C 24. 00x16.0 0x8.00 (6 10x40 6x203) NP2 41 6C NP 24 16 SSC NP 2416C G

N4 12242 00 8S S3 PT C 24. 00x20.0 0x8.00 (6 10x50 8x203) NP2 42 0C NP 24 20 SSC NP 2420C G

N4 12242 40 8S S3 PT C 24. 00x24.0 0x8.00 (6 10x61 0x203) NP2 42 4C NP 24 24 SSC NP 2424C G

N4 12302 40 8S S3 PT C 30. 00x24.0 0x8.00 (7 62x61 0x203) NP3 02 4C NP 30 24 SSC NP 3024C G

N4 12303 00 8S S3 PT C 30. 00x30.0 0x8.00 (7 62x76 2x203) NP3 03 0C NP 30 30 SSC NP 3030C G

N4 12362 40 8S S3 PT C 36. 00x24.0 0x8.00 (9 14x61 0x203) NP3 62 4C NP 36 24 SSC NP 3624C G

*Back panels must b e ordered separately.

EN CLOSU RE SIZ E BA CK PANEL CATAL OG NUMB ER * BA CK PANEL

H X W X D

WH ITE 30 4 SS “G”

CS A F i le LL 6 6 0 78

Finish

• All exterior surfaces have a smooth

grained finish, interior has a standard commercial finish

•

Optional back panels are white poly-

ester powder

• Optional “G” panels have a con-

ductive finish (See page I5)

Accessories

• Optional N412MFKSS mounting foot

kit must be ordered separately**

• Back panels (see reference tables)

• Window door (reference tables)

• See pages J1-J22.

SI ZE A X B

10 . 2 x 1 0 . 2 (2 5 9 x 259)

14 . 2 x 1 0 . 2 (3 6 1 x 259)

14 . 2 x 1 4 . 2 (3 6 1 x 361)

18 . 2 x 1 4 . 2 (4 6 2 x 361)

18 . 2 x 1 8 . 2 (4 6 2 x 462)

14 . 2 x 1 0 . 2 (3 6 1 x 259)

14 . 2 x 1 4 . 2 (3 6 1 x 361)

14 . 2 x 1 8 . 2 (3 6 1 x 462)

18 . 2 x 1 4 . 2 (4 6 2 x 361)

18 . 2 x 1 8 . 2 (4 6 2 x 462)

22 . 2 x 1 4 . 2 (5 6 4 x 361)

22 . 2 x 1 8 . 2 (5 6 4 x 462)

22 . 2 x 2 2 . 2 (5 6 4 x 564)

28 . 2 x 2 2 . 2 (7 1 6 x 564)

28 . 2 x 2 8 . 2 (7 1 6 x 716)

34 . 2 x 2 2 . 2 (8 6 9 x 564)

Continued on page E 22

www.hubbell-wiegmann.com

Da t a S ubje c t To Cha n g e With o u t Noti c e

Page 22

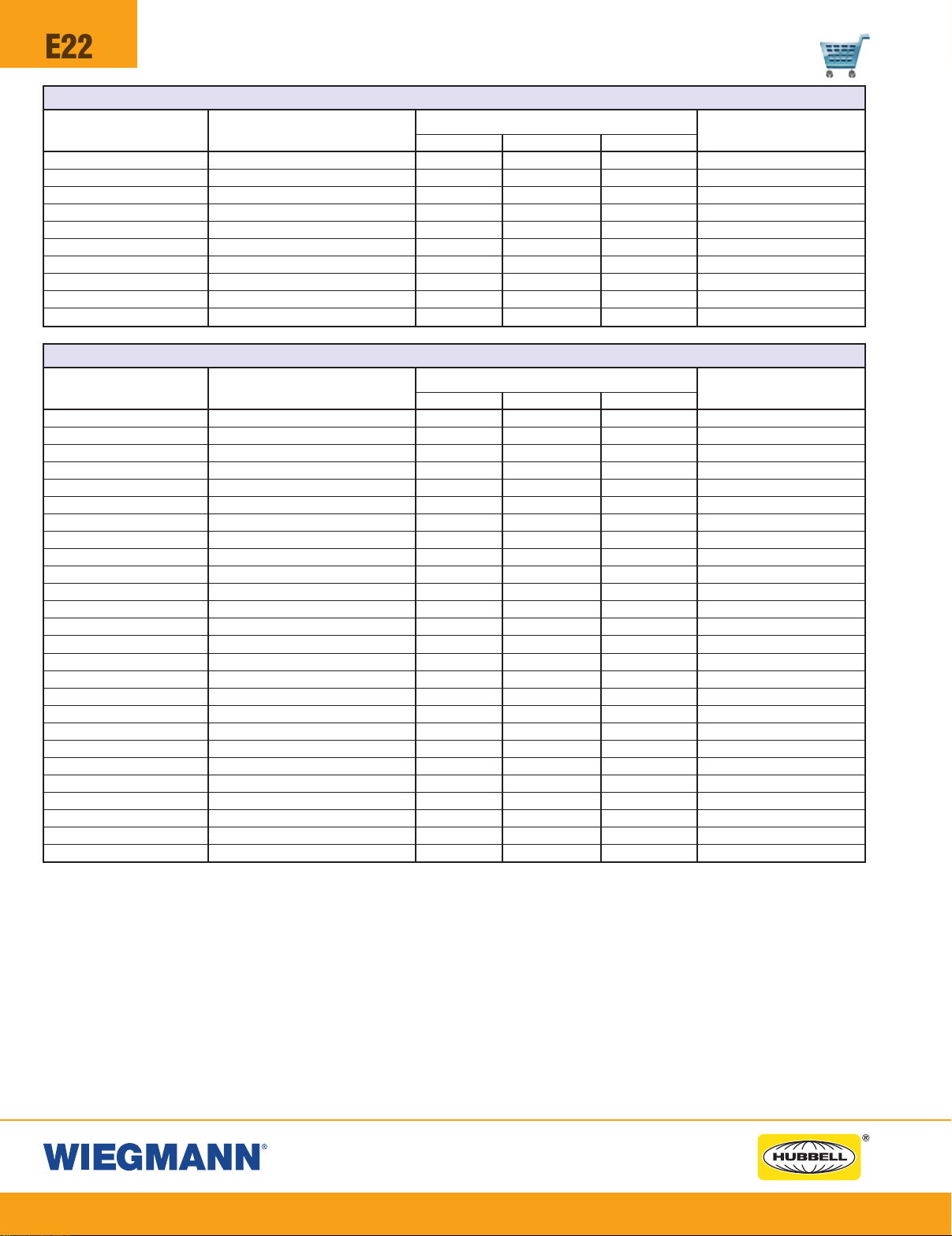

E22

N 4 1 2 - S S 3 P T C & S S A 3 P T C U LT I M AT E S E R I E S E N C L O S U R E S

N E M A 4 X S I N G L E D O O R W A L L - M O U N T

N 4 1 2 S S 3 P T C S E R I E S S I N G L E D O O R W A L L M O U N T S T A I N L E S S E N C L O S U R E S C O N T ’ D .

CATAL OG NUM BE R

N4 12363 00 8S S3 PT C 36.0 0x 30.00 x8 .00 (91 4x762x2 03) N P3 63 0C NP 36 30 SS C NP 36 30 CG

N4 12202 01 2S S3 PT C 20.0 0x 20.00 x1 2.00 (5 08x508x 305) N P2 02 0C NP 20 20 SS C NP 20 20 CG

N4 12242 41 2S S3 PT C 24.0 0x 24.00 x1 2.00 (6 10x610x 305) N P2 42 4C NP 24 24 SS C NP 24 24 CG

N4 12302 41 2S S3 PT C 30.0 0x 24.00 x1 2.00 (7 62x610x 305) N P3 02 4C NP 30 24 SS C NP 30 24 CG

N4 12362 41 2S S3 PT C 36.0 0x 24.00 x1 2.00 (9 14x610x 305) N P3 62 4C NP 36 24 SS C NP 36 24 CG

N4 12363 01 2S S3 PT C 36.0 0x 30.00 x1 2.00 (9 14x762x 305) N P3 63 0C NP 36 30 SS C NP 36 30 CG

N4 12363 61 2S S3 PT C 36.0 0x 36.00 x1 2.00 (9 14x914x 305) N P3 63 6C NP 36 36 SS C NP 36 36 CG

N4 12423 61 2S S3 PT C 42.0 0x 36.00 x1 2.00 (1 067x914 x305 ) NP 42 36 C NP4 23 6S SC N P4 23 6C G

N4 12483 61 2S S3 PT C 48.0 0x 36.00 x1 2.00 (1 219x914 x305 ) NP 48 36 C NP4 83 6S SC N P4 83 6C G

N4 12603 61 2S S3 PT C 60.0 0x 36.00 x1 2.00 (1 524x914 x305 ) NP 60 36 C NP6 03 6S SC N P6 03 6C G

N 4 1 2 S S A 3 P T C S E R I E S S I N G L E D O O R W A L L M O U N T S T A I N L E S S E N C L O S U R E S

CATAL OG NUM BE R

N4 12121 20 6S SA 1P TC 12.00x 12.00 x6 .00 (30 5x305x1 52) NP 1212C NP12 12 SS C N P1 21 2CG

N4 12161 20 6S SA 1P TC 16.00x 12.00 x6 .00 (40 6x305x1 52) NP 1612C NP16 12 SS C N P1 61 2CG

N4 12161 60 6S SA 1P TC 16.00x 16.00 x6 .00 (40 6x406x1 52) NP 1616C NP16 16 SS C N P1 61 6CG

N4 12201 60 6S SA 1P TC 20.00x 16.00 x6 .00 (50 8x406x1 52) NP 2016C NP20 16 SS C N P2 01 6CG

N4 12202 00 6S SA 1P TC 20.00x 20.00 x6 .00 (50 8X508x1 52) NP2 02 0C NP 20 20 SS C N P2020 CG

N4 12161 20 8S SA 1P TC 16.00x 12.00 x8 .00 (40 6x305x2 03) NP 1612C NP16 12 SS C N P1 61 2CG

N4 12161 60 8S SA 1P TC 16.00x 16.00 x8 .00 (40 6x406x2 03) NP 1616C NP16 16 SS C N P1 61 6CG

N4 12162 00 8S SA 1P TC 16.00x 20.00 x8 .00 (40 6x508x2 03) NP 1620C NP16 20 SS C N P1 62 0CG

N4 12201 60 8S SA 1P TC 20.00x 16.00 x8 .00 (50 8x406x2 03) NP 2016C NP20 16 SS C N P2 01 6CG

N4 12202 00 8S SA 1P TC 20.00x 20.00 x8 .00 (50 8x508x2 03) NP 2020C NP20 20 SS C N P2 02 0CG

N4 12241 60 8S SA 3P TC 24.00x 16.00 x8 .00 (61 0x406x2 03) NP 2416C NP24 16 SS C N P2 41 6CG

N4 12242 00 8S SA 3P TC 24.00x 20.00 x8 .00 (61 0x508x2 03) NP 2420C NP24 20 SS C N P2 42 0CG

N4 12242 40 8S SA 3P TC 24.00x 24.00 x8 .00 (61 0x610x2 03) NP 2424C NP24 24 SS C N P2 42 4CG

N4 12302 40 8S SA 3P TC 30.00x 24.00 x8 .00 (76 2x610x2 03) NP 3024C NP30 24 SS C N P3 02 4CG

N4 12303 00 8S SA 3P TC 30.00x 30.00 x8 .00 (76 2x762x2 03) NP 3030C NP30 30 SS C N P3 03 0CG

N4 12362 40 8S SA 3P TC 36.00x 24.00 x8 .00 (91 4x610x2 03) NP 3624C NP36 24 SS C N P3 62 4CG

N4 12363 00 8S SA 3P TC 36.00x 30.00 x8 .00 (91 4x762x2 03) NP 3630C NP36 30 SS C N P3 63 0CG

N4 12202 01 2S SA 3P TC 20.00x 20.00 x1 2.00 (5 08x508x 305) NP 20 20 C NP2 02 0SSC N P2 02 0C G

N4 12242 41 2S SA 3P TC 24.00x 24.00 x1 2.00 (6 10x610x 305) NP 24 24 C NP2 42 4SSC N P2 42 4C G

N4 12302 41 2S SA 3P TC 30.00x 24.00 x1 2.00 (7 62x610x 305) NP 30 24 C NP3 02 4SSC N P3 02 4C G

N4 12362 41 2S SA 3P TC 36.00x 24.00 x1 2.00 (9 14x610x 305) NP 36 24 C NP3 62 4SSC N P3 62 4C G

N4 12363 01 2S SA 3P TC 36.00x 30.00 x1 2.00 (9 14x762x 305) NP 36 30 C NP3 63 0SSC N P3 63 0C G

N4 12363 61 2S SA 3P TC 36.00x 36.00 x1 2.00 (9 14x914x 305) NP 36 36 C NP3 63 6SSC N P3 63 6C G

N4 12423 61 2S SA 3P TC 42.00x 36.00 x1 2.00 (1 067x914 x305) NP4 23 6C NP 42 36S SC NP423 6C G

N4 12483 61 2S SA 3P TC 48.00x 36.00 x1 2.00 (1 219x914 x305) NP4 83 6C NP 48 36S SC NP483 6C G

N4 12603 61 2S SA 3P TC 60.00x 36.00 x1 2.00 (1 524x914 x305) NP6 03 6C NP 60 36S SC NP603 6C G

EN CLOSU RE SIZ E BA CK PANEL CATAL OG NUMB ER * BA CK PANEL

H X W X D

EN CLOSU RE SIZ E BA CK PANEL CATAL OG NUMB ER * BA CK PANEL

H X W X D

WH ITE 30 4 SS “G”

WH ITE 30 4 SS “G”

SI ZE A X B

34 . 2 x 2 8 . 2 (8 6 9 x 716)

18 . 2 x 1 8 . 2 (4 6 2 x 462)

22 . 2 x 2 2 . 2 (5 6 4 x 564)

28 . 2 x 2 2 . 2 (7 1 6 x 564)

34 . 2 x 2 2 . 2 (8 6 9 x 564)

34 . 2 x 2 8 . 2 (8 6 9 x 716)

34 . 2 x 3 4 . 2 (8 6 9 x 869)

40 . 2 x 3 4 . 2 (1 0 2 1 x869)

46 . 2 x 3 4 . 2 (1 1 7 3 x869)

58 . 2 x 3 4 . 2 (1 4 7 8 x869)

SI ZE A X B

10 . 2 x 1 0 . 2 (2 5 9 x 259)

14 . 2 x 1 0 . 2 (3 6 1 x 259)

14 . 2 x 1 4 . 2 (3 6 1 x 361)

18 . 2 x 1 4 . 2 (4 6 2 x 361)

18 . 2 x 1 8 . 2 (4 6 2 x 462)

14 . 2 x 1 0 . 2 (3 6 1 x 259)

14 . 2 x 1 4 . 2 (3 6 1 x 361)

14 . 2 x 1 8 . 2 (3 6 1 x 462)

18 . 2 x 1 4 . 2 (4 6 2 x 361)

18 . 2 x 1 8 . 2 (4 6 2 x 462)

22 . 2 x 1 4 . 2 (5 6 4 x 361)

22 . 2 x 1 8 . 2 (5 6 4 x 462)

22 . 2 x 2 2 . 2 (5 6 4 x 564)

28 . 2 x 2 2 . 2 (7 1 6 x 564)

28 . 2 x 2 8 . 2 (7 1 6 x 716)

34 . 2 x 2 2 . 2 (8 6 9 x 564)

34 . 2 x 2 8 . 2 (8 6 9 x 716)

18 . 2 x 1 8 . 2 (4 6 2 x 462)

22 . 2 x 2 2 . 2 (5 6 4 x 564)

28 . 2 x 2 2 . 2 (7 1 6 x 564)

34 . 2 x 2 2 . 2 (8 6 9 x 564)

34 . 2 x 2 8 . 2 (8 6 9 x 716)

34 . 2 x 3 4 . 2 (8 6 9 x 869)

40 . 2 x 3 4 . 2 (1 0 2 1 x869)

46 . 2 x 3 4 . 2 (1 1 7 3 x869)

58 . 2 x 3 4 . 2 (1 4 7 8 x869)

*Back panels must b e ordered separately.

www.hubbell-wiegmann.com

Da t a S ubje c t To Cha n g e With o u t Noti c e

Page 23

N412 - SS3PTC & SSA3PTC ULTIMATE SERIES ENCLOSURES

NEMA 4X SINGLE DOOR WALL-MOUNT

E23

W

SEE DETAIL A

3-POINT

HANDLE

H

2.25

H/2

FRONT VIEW

1.41

1.50

0.75

ENCLOSURE

0.79

RIGHT VIEW

OPTIONAL MOUNTING

FOOT

Ø0.41

ALTERNATE POSITION

D

A

0.75

TYP.

0.90

TYP.

0.52

TYP.

A

0.75

TYP.

0.52

TYP.

0.90

TYP.

Ø0.44 TYP.

MOUNTING

PROVISION

A

B

PANEL

(Order Separately)

5/16-18

COLLAR STUD

SECTION A-A

Notes:

1. Large Print Pocket (8 X 10) is

furnished if H=20.00" or more

and W=20.00" or more

Otherwise, small (6 X 6) print

pocket is provided.

2. Two Hinges provided when

H<36.00".

Three Hinges provided when

H=36.00" or greater.

Four Hinges provided when

H=48.00" or greater.

DETAIL A

(OPTIONAL MOUNTING FOOT)

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 24

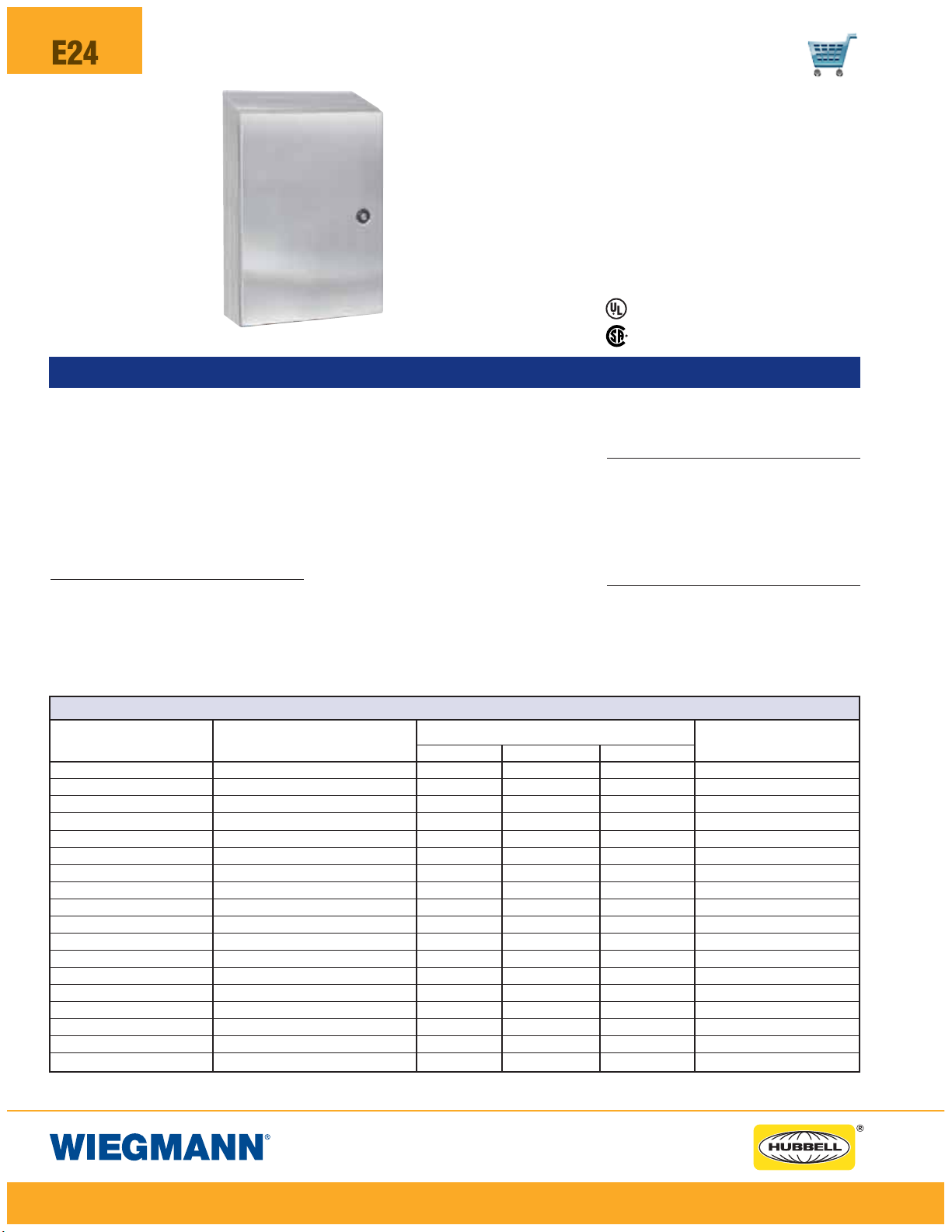

E24

N412 - CSSST ULTIMATE SERIES SLOPE-TOP ENCLOSURES

NEMA 12, 13, 4 & 4X STAINLESS SINGLE DOOR

Industry Standards

UL 508 Listed, Types 4, 4X, 12 & 13

CSA Certified, Types 4, 4X & 12 & 13

NEMA/EEMAC Type 4, 4X, 12 & 13

UL Files E64791

N412201612CSSST

FEATURES-SPECIFICATIONS

Applications

Hubbell Wiegmann N412CSSST ULTIMATE Series Enclosures are designed

to house and protect electrical and

electronic components from harsh, dirty

environments. For use in installations

where dirt, dust, oil, water, or other contaminants are present. Streamlined

styling, flush latching, and attractive

durable finish complement any high

tech electronic equipment.

Construction

• Bodies and doors fabricated from

14 gauge 304 stainless steel.

• Continuously Plasma welded seams

• Increased tub opening for better

• 20˚ sloped top

• Sloped “Top tub flange”

• Concealed hinges

• Doors are interchangeable and

easily removable

• Grounding provisions provided

• 1/4-turn semi-flush oil tight latches

are supplied to hold door securely

closed

• Print pocket is provided

• Doors are sealed with poured-inplace polyurethane gasket**

• Mounting holes in rear of enclosure

• Studs for mounting optional back

panel (the Ultimate back panels

access

N412 CSSST ULTIMATE SERIES ENCLOSURES NEMA 4X STAINLESS SLOPE TOP SINGLE DOOR

CATALOG NUMBER

N412161208CSSST 16.00x12.00x 8.00 (406x305x203) NP1612 NP1612SSC NP1612G

N412161608CSSST 16.00x16.00x 8.00 (406x406x203) NP1616 NP1616SSC NP1616G

N412201608CSSST 20.00x16.00x 8.00 (508x406x203) NP2016 NP2016SSC NP2016G

N412201612CSSST 20.00x16.00x12.00 (508x406x305) NP2016 NP2016SSC NP2016G

N412202008CSSST 20.00x20.00x 8.00 (508x508x203) NP2020 NP2020SSC NP2020G

N412202012CSSST 20.00x20.00x12.00 (508x508x305) NP2020 NP2020SSC NP2020G

N412242008CSSST 24.00x20.00x 8.00 (610x508x203) NP2420 NP2420SSC NP2420G

N412242408CSSST 24.00x24.00x 8.00 (610x610x203) NP2424 NP2424SSC NP2424G

N412242412CSSST 24.00x24.00x12.00 (610x610x305) NP2424 NP2424SSC NP2424G

N412302408CSSST 30.00x24.00x 8.00 (762x610x203) NP3024 NP3024SSC NP3024G

N412302412CSSST 30.00x24.00x12.00 (762x610x305) NP3024 NP3024SSC NP3024G

N412303008CSSST 30.00x30.00x 8.00 (762x762x203) NP3030 NP3030SSC NP3030G

N412363008CSSST 36.00x30.00x 8.00 (914x762x203) NP3630 NP3630SSC NP3630G

N412363012CSSST 36.00x30.00x12.00 (914x762x305) NP3630 NP3630SSC NP3630G

N412363016CSSST 36.00x30.00x16.00 (914x762x406) NP3630 NP3630SSC NP3630G

N412363612CSSST 36.00x36.00x12.00 (914x914x305) NP3636 NP3636SSC NP3636G

N412483616CSSST** 48.00x36.00x16.00 (1219x914x406) NP4836 NP4836SSC NP4836G

N412603616CSSST** 60.00x36.00x16.00 (1524x914x406) NP6036 NP6036SSC NP6036G

*Back panels must be ordered separately.

**Enclosures are supplied with closed cell neoprene gasket (not foam-in-place).

ENCLOSURE SIZE BACK PANEL CATALOG NUMBER* BACK PANEL

HXWXD

WHITE 304 SS “G”

CSA File LL66078

have increased in size to accommodate larger foot-print installations)

• Ultimate Accessory Driven

Finish

• All exterior surfaces have a smooth

grained finish

•

Optional back panels are white polyester powder

• Optional “G” panels have a con-

ductive finish (See page I5)

Acces sories

• Optional N412MFKSS mounting foot

kit must be ordered separately**

• Back panels (see reference tables)

• See pages J1-J22.

SIZE A X B

14.2x10.2 (361x259)

14.2x14.2 (361x361)

18.2x14.2 (462x361)

18.2x14.2 (462x361)

18.2x18.2 (462x462)

18.2x18.2 (462x462)

22.2x18.2 (564x462)

22.2x22.2 (564x564)

22.2x22.2 (564x564)

28.2x22.2 (716x564)

28.2x22.2 (716x564)

28.2x28.2 (716x716)

34.2x28.2 (869x716)

34.2x28.2 (869x716)

34.2x28.2 (869x716)

34.2x34.2 (869x869)

46.2x34.2 (1173x869)

58.2x34.2 (1478x869)

Continued on page E24

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 25

N412 - CSSST ULTIMATE SERIES SLOPE-TOP ENCLOSURES

NEMA 12, 13, 4 & 4X STAINLESS SINGLE DOOR

E25

H

FRONT VIEW

2.00

QUARTER

TURN

LATCH

W

ENCLOSURE

C

F

1.50

SEE DETAIL A

1.41

0.75

A

20°

A

D

RIGHT VIEW

OPTIONAL MOUNTING

FOOT (ONLY BOTTOM CAN BE

MOUNTED THIS WAY)

Ø0.41

ALTERNATE POSITION

(TOPMTF.FT.MUSTBE

MOUNTED THIS WAY)

Ø0.44 TYP.

MOUNTING

HOLES

0.90

TYP.

0.75

TYP.

OMIT TWO MIDDLE

STUDS IF W IS LESS THAN 32.00"

OMIT TWO MIDDLE

STUDS IF H IS LESS THAN 31.00"

E

OPTIONAL SUB-PANEL

(Order Separately)

B

0.90

TYP.

A

0.75

TYP.

SECTION A-A

Notes:

1. Large Print Pocket (8 X 10) is

furnished if H=20.00" or more

and W=20.00" or more

Otherwise, small (6 X 6) print

pocket is provided.

2. Two Hinges provided with

H<36.00". Three Hinges

provided when H=36.00" or

greater. Four Hinges provided

when H=48.00" or greater.

DETAIL A

(OPTIONAL MOUNTING FOOT)

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 26

E26

SSN4 - WF3PT SERIES ENCLOSURES

NEMA 4X STAINLESS STEEL WALL MOUNT

Industry Standards

UL 508 Listed, Types 12, (4, 4X pending)

CSA Certified, Types 12, (4, 4X pending)

NEMA/EEMAC Type 12

UL Files E64791

SSN4244208WF3PT

CSA File LL66078

FEATURES-SPECIFICATIONS

Applications

SSN4WF Series are intended for use in

housing electrical and electronic controls, instruments, components, and

associated wiring, these enclosures

incorporate double-hinged doors which

provide convenient access. Designed

for outdoor use in protecting components from dust, dirt, oil, and water..

Construction

• Bodies and doors fabricated from

14 gauge steel.

• Continuously welded seams ground

smooth, less knockouts or holes.

• Body stiffeners are added in larger

enclosures for extra rigidity.

• Rolled lip around all side of enclo-

SSN4-WF3PT SERIES ENCLOSURES NEMA 4X STAINLESS STEEL WALL MOUNT

CATALOG NUMBER

SSN4244208WF3PT 24.00x42.00x 8.00 (610x1067x203) NP4224 NP4224G 21.00x39.00 (991x533) No No

SSN4244808WF3PT 24.00x48.00x 8.00 (610x1219x203) NP4824 NP4824G 21.00x45.00 (533x1143) No No

SSN4304210WF3PT 30.00x42.00x10.00 (762x1067x254) NP4230 NP4230G 27.00x39.00 (686x991) No No

SSN4304810WF3PT 30.00x48.00x10.00 (762x1219x254) NP4830 NP4830G 27.00x45.00 (1143x686) No No

SSN4306010WF3PT 30.00x60.00x10.00 (762x1524x254) NP6030 NP6030G 27.00x57.00 (686x1448) No No

SSN4364212WF3PT 36.00x42.00x12.00 (914x1067x305) NP4236 NP4236G 33.00x39.00 (838x991) No No

SSN4364812WF3PT 36.00x48.00x12.00 (914x1219x305) NP4836 NP4836G 33.00x45.00 (838x1143) No No

SSN4366012WF3PT 36.00x60.00x12.00 (914x1524x305) NP6036 NP6036G 33.00x57.00 (838x1448) No No

SSN4424212WF3PT 42.00x42.00x12.00 (1067x1067x305) NPDD4242 NPDD4242G 39.00x39.00 (991x991) No Yes

SSN4424812WF3PT 42.00x48.00x12.00 (1067x1219x305) NPDD4842 NPDD4842G 39.00x45.00 (991x1143) No Yes

SSN4426012WF3PT 42.00x60.00x12.00 (1067x1524x305) NPDD4260 NPDD4260G 38.00x56.00 (965x1422) No Yes

SSN4484812WF3PT 48.00x48.00x12.00 (1219x1219x305) NPDD4848 NPDD4848G 44.00x44.00 (1118x1118) No Yes

*Back panels must be ordered separately.

ENCLOSURE SIZE

HXWXD

sure opening is provided to

exclude liquids and contaminants.

• Two independent doors with removable center post.

• 3 PT 316L SS padlocking handles

• Doors are removable by pulling

heavy gauge stainless continuous

hinge pin.

• Doors are sealed with a poured in

place polyurethane gasket.

• Collar studs are provided for

mounting optional sub panels.

• External mounting feet are provided

for mounting.

• Grounding provisions provided.

• Removable print pocket is provided

BACK PANEL

CATALOG NUMBER*

WHITE “G”.

Finish

• Doors, sides, top, bottom have a

grained smooth service.

•

Optional back panels are white polyester powder

• Optional “G” panels have a con-

ductive finish (See pages I5)

Acces sories

• See pages I4 for Sub Panels

• Back panels (see reference tables)

• See pages J1-J22.

BACK PANEL

SIZE A X B

STIFFENER

DOOR BODY

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 27

SSN4 - WF3PT SERIES ENCLOSURES

NEMA 4X STAINLESS STEEL WALL MOUNT

SUB-PANEL

2.00

TYP.

C

A

C

0.88

TYP.

C

L

H/2

W

3.75

TYP.

0.63

TYP.

3-POINT

HANDLE

(2 PL.)

REMOVEABLE

MULLION

3.00

TYP.

YY

0.63

TYP.

CONTINUOUS

HINGE (2 PL.)

1.93

0.63

TYP.

1.38

TYP.

H - 2.13

H

0.75

TYP.

W/2 - 2.38 TYP.

W/2 - 3.25 TYP.

H - 2.75

1.38

TYP.

D

X

D

X

Ø0.44

TYP.

C B

C

L

1.25

TYP.

0.44

MOUNTING

FEET (6 PL.)

(Order Separately)

OMIT TWO MIDDLE STUDS

IF W < 31.00

E27

1.25

TYP.

C

OMIT TWO MIDDLE

STUDS IF H < 31.00

3/8-16 COLLAR

STUDS

0.88

TYP.

3/8-16 COLLAR

STUD

1.09

1.38

LEFT DOOR

14 GA.

12 GA.

SECTION Y-Y

NOT TO SCALE

SECTION X-XSIDE VIEWFRONT VIEW

RIGHT DOOR

NEOPRENE

GASKET

14 GA.

0.75

www.hubbell-wiegmann.com

Data Subject To Change Without Notice

Page 28

E28

SSN4 SERIES ENCLOSURES

NEMA 4X SINGLE DOOR WALL-MOUNT

Industry Standards

UL 508, Types 4, 4X, 12 & 13

CSA Certified, Types 4 & 12

NEMA/EEMAC Type 4, 4X, 12 & 13

UL Files E64791

SSN4161206

CSA File LL66078

FEATURES-SPECIFICATIONS

Applications

Provides unmatched protection for

housing electrical components in

highly corrosive environments. This

enclosure is used in indoor and outdoor settings that are frequently wet

or have constant exposure to water,

other liquids, or contaminants.

A wide variety or type 316L stainless

steel enclosures are available specifically for applications in food processing pants and offshore oil exploration.

Construction

• Bodies and doors fabricated from

14 gauge type 304 or 316L stainless

steel. 316L stainless steel has the

best corrosion resistance of the

• Continuously plasma welded seams

• Door and body stiffeners are

included in larger enclosures for

added rigidity

• A rolled lip around three sides of

door and all sides of enclosure

opening provided to exclude liquids and contaminants

• Quick and easy to operate stainless

steel door clamps are provided

• Hasp and staple is provided for

padlocking

• Doors are sealed with poured-inplace polyurethane gasket

• Collar studs for mounting optional

back panels

• Print pocket is provided

• External mounting feet are provided

for mounting enclosures

• Grounding provisions provided

Finish

• All exterior surfaces of enclosures

have a smooth grained finish

• Optional back panels are white

polyester powder (See page I4)

• Optional “G” panels have a con-

ductive finish (See page I4)

Acces sories

• Back panels (reference tables)