Page 1

DATA SUBJECT TO CHANGE WITHOUT NOTICE

ENVIRONMENTAL CONTROL

TECHNICAL DATA

L14

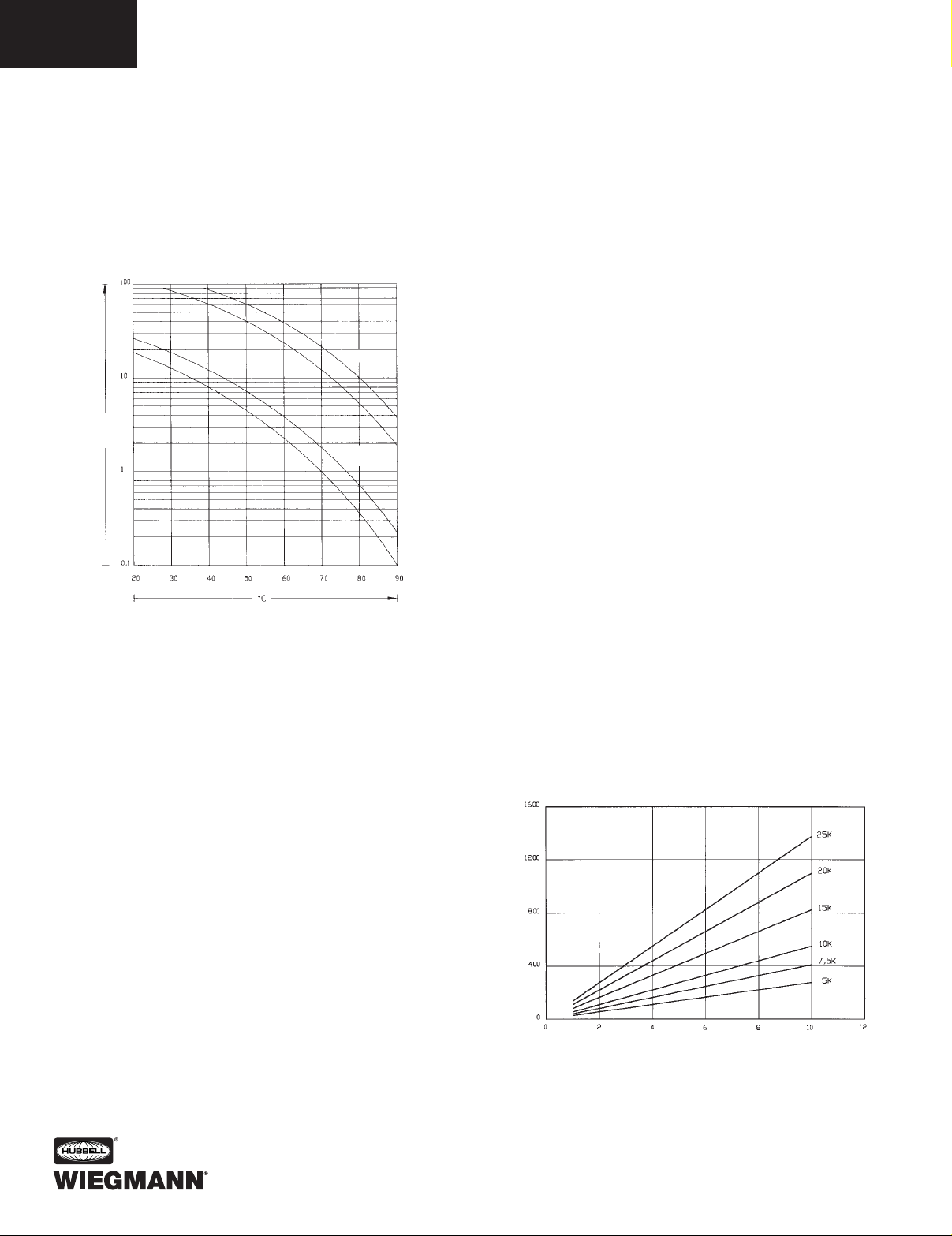

Ever since components have been made to control electrotechnical tasks, heat loss has been a subject to take into

consideration. Sometimes more—sometimes less.

Major problems with heat caused excessive dust accumulation in switchgear equipment because the doors were left

open during the summer to allow the equipment to cool

down. This can result in fluctuations in temperature. These

lead to stress situations that can considerably reduce the

service life of electronic components (see chart).

THREE BASIC COOLING METHODS

When selecting a cooling method there are three types

to consider:

1. Natural Convection — If there is only a minimal heat

gain in your circumstance, use of louvers or grilles with

filters can be effective. This method, however, usually

provides less cooling effect than is necessary with

today’s components (Fig. 1, pg. L15).

2. Forced Convection Air Cooling — If the installation

will be in a clean, non-hazardous environment with an

acceptable ambient (outside the enclosure) temperature

range, a simple forced-air cooling system utilizing outside

air is usually adequate. Combined with an air filter, such

devices generally meet the heat removal needs of typical

electronic equipment and many electrical applications

(Fig. 2a & 2b, pg. L16). Examples of forced convection

air cooling are Filterfans™ and Box Fans.

3. Closed-Loop Cooling — In harsh environments

involving high temperatures, wash-down requirements,

heavy particulate matter or the presence of chemicals

capable of damaging components (NEMA 4 or 12

environments), ambient air must be kept out of the

enclosure. Closed-loop cooling consists of two separate

This chart demonstrates the relationship between temperature and service life.

circulation systems. One system seals out the ambient

air, cooling and recirculating clean, cool air throughout

the enclosure. The second system uses ambient air or

water to remove and discharge the heat (Fig. 3, pg. L18).

Examples of closed-loop cooling equipment employed

with electronics and process controls are air conditioners

and heat exchangers.

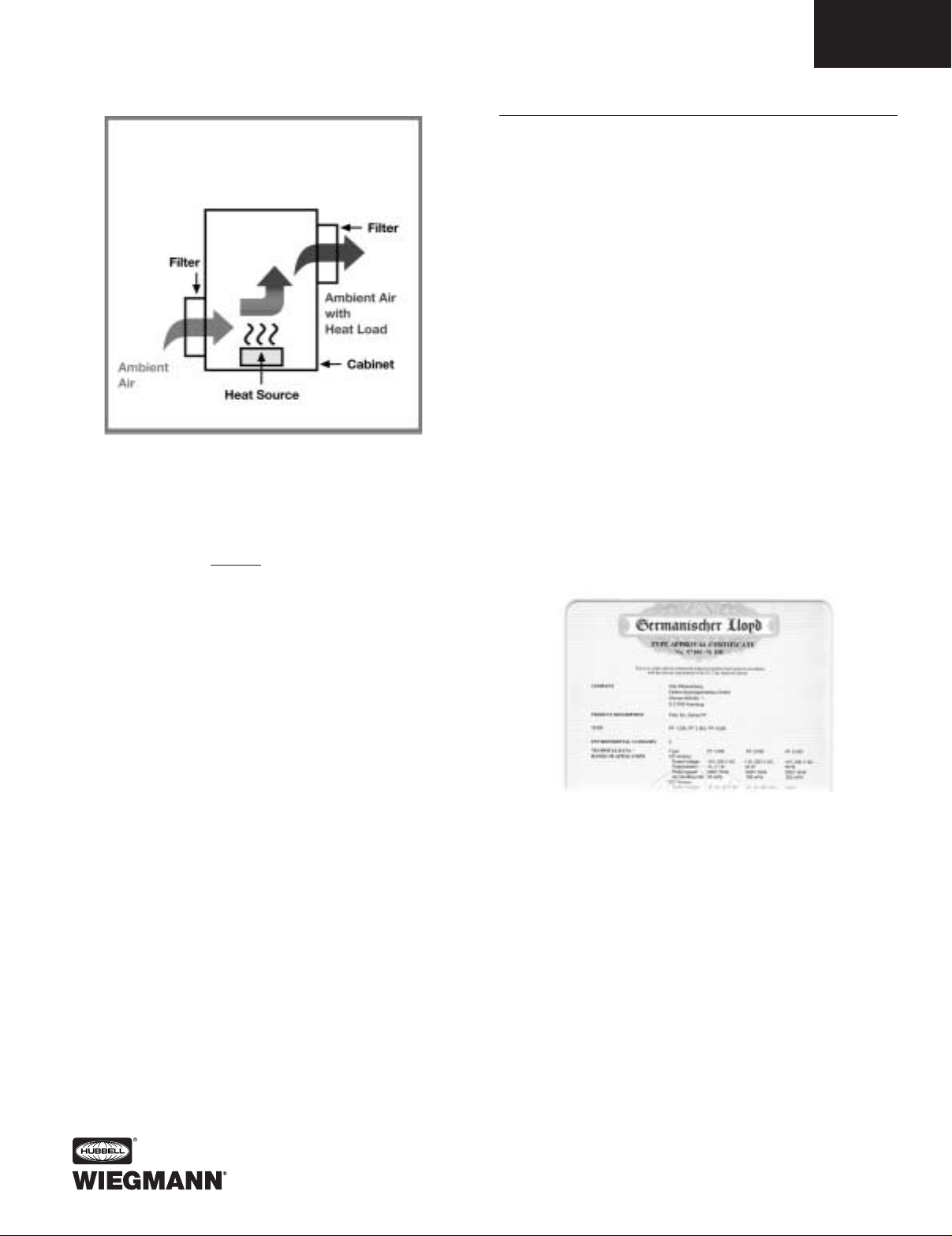

Heat Abduction by Natural Convection

If the ambient temperature is lower than the temperature

inside the switch cabinet, the dissipated heat escapes into

the atmosphere through the surface of the switch cabinet.

The following simple equation is used to calculate the level

of heat radiated from a switch cabinet:

PR[W} = c x A x DT

P

R

[Watt]: Radiation Power

Thermal power radiated from the surface area

of the switch cabinet into the ambience or radiated from the ambience into the switch cabinet.

C[W/m

2

K]: Coefficient of heat transmission

Radiation power per 1m2 surface area and 1K

difference in temperature. This constant is

determined by the material:

Sheet steel -5.5 W/m2K

Stainless steel -3.7 W/m2K

Aluminum -12.0 W/m2K

Plastic -0.2 W/m2K

A[m

2

]: Surface area of switch cabinet

Effective surface area of a switch cabinet

measured according to the specifications of

VDE0660, Part 506.

∆T[K]: Difference in temperature between the

ambience and inside the switch cabinet

Surface area of switch cabinet A[m2]

Heat radiation P[W]

Page 2

DATA SUBJECT TO CHANGE WITHOUT NOTICE

ENVIRONMENTAL CONTROL

TECHNICAL DATA

L15

Heat Abduction with Filterfans

™

Follow the simple equation for calculating the required

air flow volume:

V[m3/h]: Flow volume for a filter fan

Pd[Watt]: Dissipation loss

Thermal power generated inside a switch

cabinet by dissipation loss from components.

A[m2]: Difference in temperature between the

ambience and inside the switch cabinet

In the course of development, absolute priority was given

to the use of high-quality components (plastic material, fan,

filter mat) and comprehensive transparent technical data.

For this purpose we measured every Filterfan

™

and exhaust

filter in a test laboratory.

When considering the use of Filterfans™:

• Always use the Filterfan

™

to propel the cool ambient air

into the switch cabinet. This ensures that slight positive

pressure builds up inside the switch cabinet in comparison

to the ambience and that only air filtered by the Filterfan

™

flows into the switch cabinet. The air propelled into the

cabinet displaces the warm air which exits through the

exhaust filter. If, however, the air is drawn out of the switch

cabinet by suction power, unfiltered air can also enter

through gaps and components

• If you install a combination of Filterfan

™

/exhaust filter, fit

the Filterfan

™

in the lower third of the switch cabinet if

possible. The exhaust filter must be installed as near to

the top as possible to prevent heat pockets in the upper

part of the cabinet

• In switch cabinets consisting of several compartments,

the cool air capacity required should be divided among

two or more Filterfans

™

/exhaust fans. This measure helps

to ensure a more acceptable distribution of temperature

throughout the cabinet

• If you combine a Filterfan

™

with two exhaust filters, the

cool air divides into “Y” shape. In this way, with just one

additional exhaust filter you can considerably improve

the circulation inside the switch cabinet

• Install a thermostat that only trips the Filterfan

™

when

the temperature is too high. This can quite substantially

increase the service life of your filter mat

Natural Convection

Figure 1

(European Patent No. 0439667)

The Filterfan/exhaust filter is centered in the cutout

and held in place across the 4 corners. Installation

time is thus reduced from 12 minutes to virtually

ZERO.

V=

3.1(Pd)

[m3/h]

∆T

Page 3

DATA SUBJECT TO CHANGE WITHOUT NOTICE

ENVIRONMENTAL CONTROL

TECHNICAL DATA

L16

Heat Abduction with a Cooling Unit

Pfannenberg air/refrigerant cooling units operate on the

principle of the Carnot cycle. This means that the cooling

unit functions as a heat pump that “pumps” the thermal

energy abducted from the switch cabinet (heat dissipated

from the components) up to a higher level of temperature

(the ambient temperature can reach levels as high as

+131ºF). The air inside the switch cabinet is cooled down

by the evaporator and is at the same time dehumidified.

Cooling units are used if:

• The outside air cannot be used for cooling

• The required temperature inside the switch cabinet

should be equal to or lower than the required ambient

temperature

• The ambient air is extremely oily or rife with conductive dust

Steps for sizing an air conditioner — Proper selection of

an air conditioner is determined by the following criteria:

• Required cooling capacity in BTUs/hr (steps 1-4)

• Mounting requirements (top or side mounting options)

• Dimensions of air conditioner and enclosure

Figure 2a

Figure 2b

(Preferred Method)

1 Watt = 3.413 BTU/HR.

Determine the internal

heat load in Watts that

must be dissipated.

[Watts ÷ ∆T (Fº)] - [0.22 x Area (ft2)] = Watts/Fº

Capacity Required BTU/HR. Capacity Rating

1 m2= 11.76 ft

2

Calculate the exposed

surface area of the

enclosure: 2[(h x w) +

(h x d) + (w x d)] ÷ 144 =

Area (ft

2

).

1ºC or 1ºK∆T = 1.8ºF T

Determine the temperature

differential by subtracting the

maximum allowable tempera-

ture inside the enclosure (Ti)

from the maximum ambient

temperature outside

the enclosure (To).

To - Ti =

∆T

Page 4

DATA SUBJECT TO CHANGE WITHOUT NOTICE

ENVIRONMENTAL CONTROL

TECHNICAL DATA

L17

Selecting cooling units

• Ascertain the total dissipation loss from the components

installed in the switch cabinet. Take into account the

simultaneity factor, because rarely are all components in

operation at the same time

• Also take the heat radiation from the switch cabinet

into account. If T, <Ta, this must also be added to the

dissipation loss value

• Now select the necessary cooling unit in accordance

with the required refrigeration capacity, ensuring that

the cooling capacity of the cooling unit is at least equal

to the dissipation loss value. Preferable is a figure 10%

in excess of that value

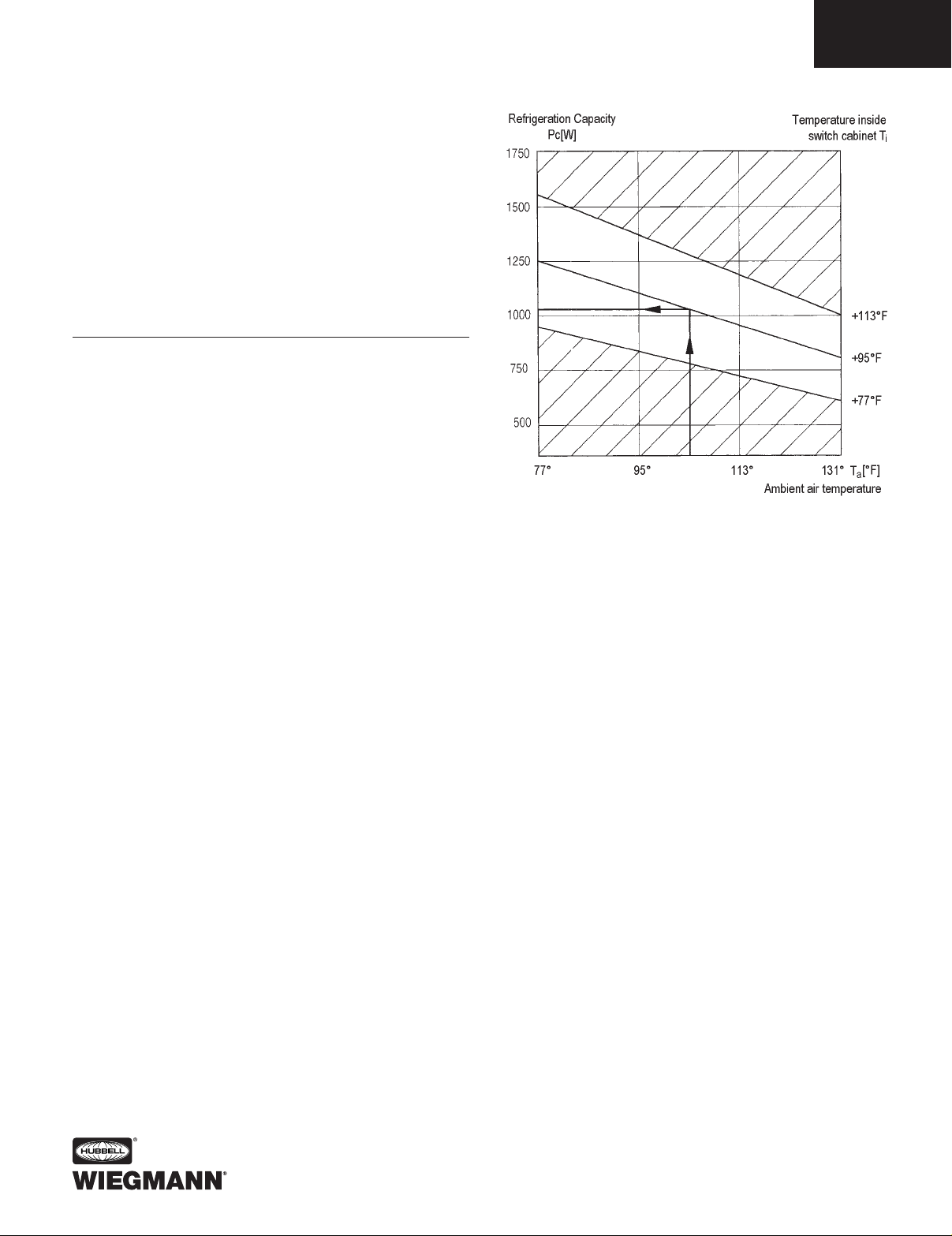

Utilizing characteristic curves for proper selection

of a cooling unit

Characteristic curves for all cooling units are available for

contacting us. These diagrams allow you to determine the

corresponding effective (useful) refrigeration capacity for any

temperature. All relevant data for our cooling units result

from tests in Pfannenberg’s own climatic chamber.

Example:

T

a

= 104ºF and Ti= 95ºF, where

T

i

[ºF]: Maximum admissible temperature inside the

switch cabinet. This value reflects the maximum

operating temperature of components installed in

the switch cabinet. This usually ranges from approx.

95ºF to 113ºF.

T

a

[ºF]: Maximum ambient temperature. Temperature

at which the switch cabinet is installed.

P

c

[Watt]: Refrigeration capacity of a cooling unit.

Only the effective or useful cooling capacity is shown.

Go to the known ambient temperature (T

a

= 104ºF) and

trace a vertical line up to the intersection with 95ºF line.

Then trace a horizontal line left of that intersection until

it meets with the ordinate (vertical axis). This point shows

the refrigeration capacity required. In this example, the

following diagram shows that the value is 1040W.

Important information on the utilization of cooling units

• The refrigeration capacity should exceed the dissipation

loss from the installed components by approximately ten

percent (10%)

• The switch cabinet must be adequately sealed to prevent

the inflow of ambient air

• Use the door contact switch to impede operation with

open doors and consequent excessive accumulation of

condensation

• Use cooling units with a generous clearance between air

inflow and air outflow to prevent poor circulation

• Attach the condensate overflow hose included in the

package of accessories supplied with the unit

• Make sure that the air inflow and air outflow in the external

circuit of the cooling unit circulates satisfactorily to ensure

that the thermal energy is released into the ambience

• When using top-mounted cooling units, make sure that

components with their own fans do not expel the air

directly into the cooling unit’s cool air outflow. This counteraction between the two airflows would otherwise substantially reduce the refrigeration capacity and could cause

heat pockets.

• Make sure that the switch cabinet stands up straight.

Otherwise the condensation cannot drain properly from

the top-mounted unit

• Setting the temperature to the lowest setting is not the

optimal solution due to condensation issues. The value

we have preset on the cooling unit is a sound compromise

between cooling the inside of the switch cabinet and the

accumulation of condensation

Page 5

DATA SUBJECT TO CHANGE WITHOUT NOTICE

ENVIRONMENTAL CONTROL

TECHNICAL DATA

L18

Cooling Control Cabinets

Most electrical & electronic control systems generate substantial amounts of heat during operation. This heat factor intensifies as controls are made more compact, perform more

functions, or are placed in more confined areas. Additional

problems are encountered when the electronic process

control system is located on-site in an industrial setting, as

opposed to a clean computer room. For instance, ambient

temperatures found in a steel mill can be locally very high.

The factory environment can be hostile to the point that

performance and effective life of electronic components are

materially reduced, or the control system fails completely.

Moisture-laden air and airborne particulate matter might be

present to adversely affect electronic components, as is true in

the paper manufacturing industry or in grain storage facilities.

Our air conditioners are designed to perform reliably under

many of these harsh conditions and to provide the cooling

and environmental protection required by sensitive electronic

production control systems.

Factors affecting model selection

Use this section as a basic outline or checklist of the various

conditions to be considered when choosing a cooling unit

for a certain application.

The following three factors must be considered when

selecting a cooling unit:

1. Internal Heat Load

This is the heat dissipated by electronic controls. It is

expressed in watts. One watt equals 3.413 BTU/hr. Thus,

to obtain the approximate cooling capacity required to

remove a specific heat load, the following formula can

be used:

Watts x 3.413 = BTU/hr

For example, a heat load of 800 watts requires an air

conditioner capable of removing at least 2,730 BTU/hr

2. Resistance to air flow in the enclosure

Air-flow is measured in cubic feet per minute (CFM).

Creating appropriate air flow requires that air pressure be

produced by a blower within the air conditioning enclosure.

Resistance to blower-produced air flow is created by

obstructions within the cabinet’s air-flow path. This resistance is called static pressure (SP) and is measured in

inches of water column.

The effect of significant resistance in the cabinet’s air flow

due to static pressure is that it produces a drop in air

pressure, or differential, from the air velocity produced by

the blower. This reduction in cool air flow will decrease the

effective capacity of the cooling unit. So when selecting

the proper cooling unit, allowances must be made for

static pressure.

3. Heat Load From the Surroundings

Ambient conditions can cause a heat gain in the enclosure.

The rated capacity of the cooling unit must be sufficient

to handle this heat gain. When evaluating the additional

heat load gained from the surroundings, consider the

following:

Insulated Cabinet — Normally, well-insulated cabinets

will not gain sufficient ambient heat to affect an air conditioner’s operation. BTU/hr ratings for our air conditioners

have been established at the maximum ambient operating

temperature of 125ºF. A substantial improvement in heat

removal occurs when operating in ambient temperatures

below 125°F.

Uninsulated Cabinets (most common) — Obviously,

this design places more of a burden on the cooling unit.

Heat is conducted to the cool side. Thus, high ambient

heat will be readily transmitted into the cooler enclosure.

To determine the additional capacity required of our air

conditioner installed in an uninsulated cabinet, the surface

square footage of the enclosure must be calculated

to obtain the total effective heat transfer area. For this

calculation, use the surface area of the sides, plus the

area of the top, and omit the bottom area of the cabinet.

Air movement outside the uninsulated cabinet will

increase the heat conducted from the ambient into the

enclosure. When there is little or no air circulation outside

the cabinet, the layer of air immediately adjacent to the

exterior cabinet walls act as an insulating film. Exterior air

movement dissipates this insulating layer of air in proportion to the velocity of the air flow. Substantial ambient air

circulation will increase the transmitted heat load imposed

on the cooling unit. If the cabinet being cooled is not

airtight, then high ambient relative humidity will adversely

affect the cooling effectiveness of the air conditioner.

When humid air infiltrates a poorly sealed enclosure,

the air conditioner is required to use up valuable BTU/hr

capacity just to condense the moisture from the internal

air. Conversely, if the cabinet is well sealed, high ambient

relative humidity has very little effect on the heat capacity

of the air conditioner.

Figure 3

Page 6

DATA SUBJECT TO CHANGE WITHOUT NOTICE

ENVIRONMENTAL CONTROL

TECHNICAL DATA

L19

Why Use a Heater?

Hubbell Wiegmann heater products protect electronic and electrical components

from temperature problems that are below acceptable tolerances. There are

obvious circumstances when extremely low ambient (outside the enclosure)

temperatures would require a heater, but there are also less apparent times that

a heater should be considered. For example, a system may run all day having its

components generate heat, but once the system shuts down for the night, the

quick drop in temperature could cause condensation and possible corrosion —

a heater could be used to maintain a safe and constant temperature.

Heater Sizing

Formula for sizing Hubbell Wiegmann enclosure heating products:

P

H

= (∆T x k x A) – Pv

Variables:

P

H

= Total power required in Watts for application.

∆T = Difference between the minimum required enclosure interior temperature

and the lowest possible exterior temperature, in degrees Kelvin.

“DT” can be calculated using the following formula:

(IT) - (ET)

1.8

= ∆T in ºKelvin

(IT) – Minimum required enclosure interior

temperature [ºF]

(ET) – Lowest possible exterior temperature [ºF]

k = Heat transmission coefficient convection of enclosure material in quiet air.

Painted Steel 0.511 W/(ft

2

ºK)

Stainless Steel 0.344 W/(ft

2

ºK)

Aluminum 1.115 W/(ft

2

ºK)

Plastic (or insulated stainless) 0.325 W/(ft

2

ºK)

A = Enclosure surface area in ft.

2

“A” can be calculated by using the

following formula (assuming a wall-mounted enclosure):

1((H/12) x (W/12)) + 2((W/12) x (D/12)) + 2((H/12 x (D/12)) = A in ft.

2

H = Height of enclosure (in inches)

W = Width of enclosure (in inches)

D = Depth of enclosure (in inches)

Pv = Existing power from installed components (Watts).

Sample with solution:

Required sizing information:

• Wiegmann Painted Steel Enclosure = N12161206 (H =16", W = 12", D = 6")

• Minimum required enclosure interior temperature in Fahrenheit=50ºF (IT)

• Lowest possible exterior temperature in Fahrenheit = -30ºF (ET)

• Existing components generating 50 Watts (Pv)

(50) - (-30)

∆T =

1.8

= 44.44

k = 0.51

A = 2((16/12) x (12/12)) + 2((12/12) x (6/12)) + 2((16/12 x (6/12)) = 4.99

P

H

= (44.44 x 0.51 x 4.99) - 50 = 63 Watts needed to heat the enclosure

H

W

D

Loading...

Loading...