Wiedenmann Mega Twister Translation Of Original Operating Instructions

Translation of original

operating instructions

Leaf blower

Mega Twister

891.002

From machine ID no. :

Version :

August 2013

891 99 09

2

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

3

|

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

4

Introduction

PLEASE READ THESE OPERATION INSTRUCTIONS CAREFULLY in order to

familiarize yourself the correct method of operation and maintenance

and in order to avoid personal injuries or damage to the machine.

This manual and safety decals on your machine may also be available

in other languages (see your dealer to order).

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your machine and

should remain with the machine when you sell it.

MEASUREMENTS in this manual are given in both metric and customary

U.S. unit equivalents. Only use suitable parts and screws. Metric

and inch fasteners may require a specific metric or inch wrench.

RIGHT - HAND AND LEFT - HAND sides refer to the direction of travel

the implement when going forward.

WRITE PRODUCT IDENTIFICATION NUMBERS (P.I.N.) in the Specification or

Identification Numbers section. Please ensure that all numbers are

correctly recorded. to help in tracing the machine should it be

stolen. Your dealer also requires this number when you order spare

parts. File the identification numbers in a secure place away from

the machine.

BEFORE DELIVERING THIS MACHINE, your dealer performed a pre-delivery

inspection to ensure best performance.

THIS MACHINE IS DESIGNED EXCLUSIVELY for commercial use and generating

wind with air without particles in the air flow in the maintenance

of grassy areas and parks (“INTENDED USE“).

Use in any other way is considered contrary to the intended use. The

manufacturer accepts no liability for damage or injury resulting

from this misuse, and these risks must be borne solely by the user.

Using the equipment in accordance with the specifications also

includes observance of the operating and maintenance conditions as

specified by the manufacturer.

PREDICTABLE MISUSE AND ABUSE. Persons and objects must not be

transported with the machine attached. Do NOT add material to the

blower through the suction screen.

THIS MACHINE SHOULD BE OPERATED, serviced and repaired only by persons

familiar with all its particular characteristics and acquainted with

the relevant safety requirements (accident prevention). The accident

prevention regulations, all other generally recognized regulations

on occupational health and safety, and the road traffic regulations

must be observed at all times. Any unauthorized modifications

carried out on this machine will relieve the manufacturer of all

liability for any resulting damage or injury.

NOTE THE INSTRUCTIONS

for driving on public roads:

"This machine is not suitable for travel on Highways or public

roads. It requires additional equipment for this (lighting kit,

warning signs for slow vehicles/SMV sign, reflectors). Please

contact us if you wish to purchase this optional equipment “

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

5

C O N T E N T S Page

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

1.0. Safety............................................................. 6&15

1.1. Safety Decals.............................................. 11&13

1.2. Safety Equipment........................................... 14

1.3. The safety devices......................................... 15

2.0. Assembly........................................................... 16&22

2.1. General.................................................... 16

2.2. Mounting support wheels.................................... 16

2.3. Mounting roller unit....................................... 17

2.4. Hydraulic adjustment of the blowing nozzle................. 18

2.5. Hydraulic adjustment of the

blowing nozzle with control valve.......................... 19&20

2.6. Mounting electrical blowout nozzle adjustment............. 21

2.7. Mounting blowing nozzle.................................... 22

3.0. Transport.......................................................... 23&26

4.1. General.................................................... 23

4.2. Transporting the Mega Twister.............................. 24&25

4.3. Transportation with three-point attachment................. 26

4.0. Connecting to the tractor.......................................... 27&30

4.1. General.................................................... 27

4.2. Installing on the tractor.................................. 28

4.3. Adapting PTO Shaft......................................... 29

4.4. Supports................................................... 29

4.5. Unscrewing the running gear safety device.................. 29

4.6. Hydraulic connections...................................... 30

5.0. Disconnecting from the tractor..................................... 31&32

5.1. General.................................................... 31

5.2. Removing from tractor...................................... 31

5.3. Disconnecting hydraulic lines.............................. 32

5.4. Disconnecting drive shaft.................................. 32

5.5. Locking support wheels..................................... 32

6.0. Before Using....................................................... 33&35

6.1. General.................................................... 33

6.2. Drive speed and direction of rotation...................... 31

6.3. Top connecting rod position for working.................... 31

6.4. Swiveling the blower housing............................... 35

6.5. Adjusting the blowing nozzle............................... 35

7.0. Operation.......................................................... 36&37

7.1. General.................................................... 36

7.2. Switching on............................................... 36

7.3. Blower wheel............................................... 36

7.4. Danger zone................................................ 37

7.5. Work / Transport........................................... 37

8.0. Maintenance........................................................ 38&49

8.1. General.................................................... 38

8.2. Maintenance intervals...................................... 39

8.3. Lubrication points......................................... 40&41

8.4. Changing the gear oil...................................... 42

8.5. Cleaning................................................... 43

8.6. Hydraulics system.......................................... 43

8.7. Hydraulic connection diagram............................... 44&45

8.8. V – belt................................................... 46

8.9. Tire pressure.............................................. 47

8.10. Dismounting / Disposal..................................... 48

8.11. Unauthorized moddification and spare part manufacturing.... 49

9.0. Scope of delivery / Optional equipment............................. 50651

9.1. Series equipment........................................... 50

9.2. Accessories................................................ 51

10.0. Specification...................................................... 52&57

10.1. Dimensions, weights and other specifications.............. 52&55

10.2. Metric bolt and cap screw torque values................... 56

10.3. Serial Number............................................. 57

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

6

Recognize safety information

This is the safety-alert

symbol. When you see this

symbol on your machine or

in this manual, be alert

to the potential for

personal injury.

Follow recommended

precautions and safe

operating practices.

1.0. Safety

Follow safety instuctions

Carefully read all safety

messages in this manual and on

your machine safety signs. Keep

safety signs in good condition.

Replace missing or damaged

safety signs. Be sure new

equipment components and repair

parts include the current

safety signs. Replacement

safety signs are available from

your dealer.

Learn how to operate the

machine and to use controls

properly. Do not let anyone

operate without instruction.

Keep your machine in proper

working condition. Unauthorized

modifications to the machine

may impair the fuction and/or

safety and affect machine life.

If you do not understand any

part of this manual and need

assistance, contact your

dealer.

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

7

Observe road traffic regulations

Always observe local road

traffic regulations when using

public roads.

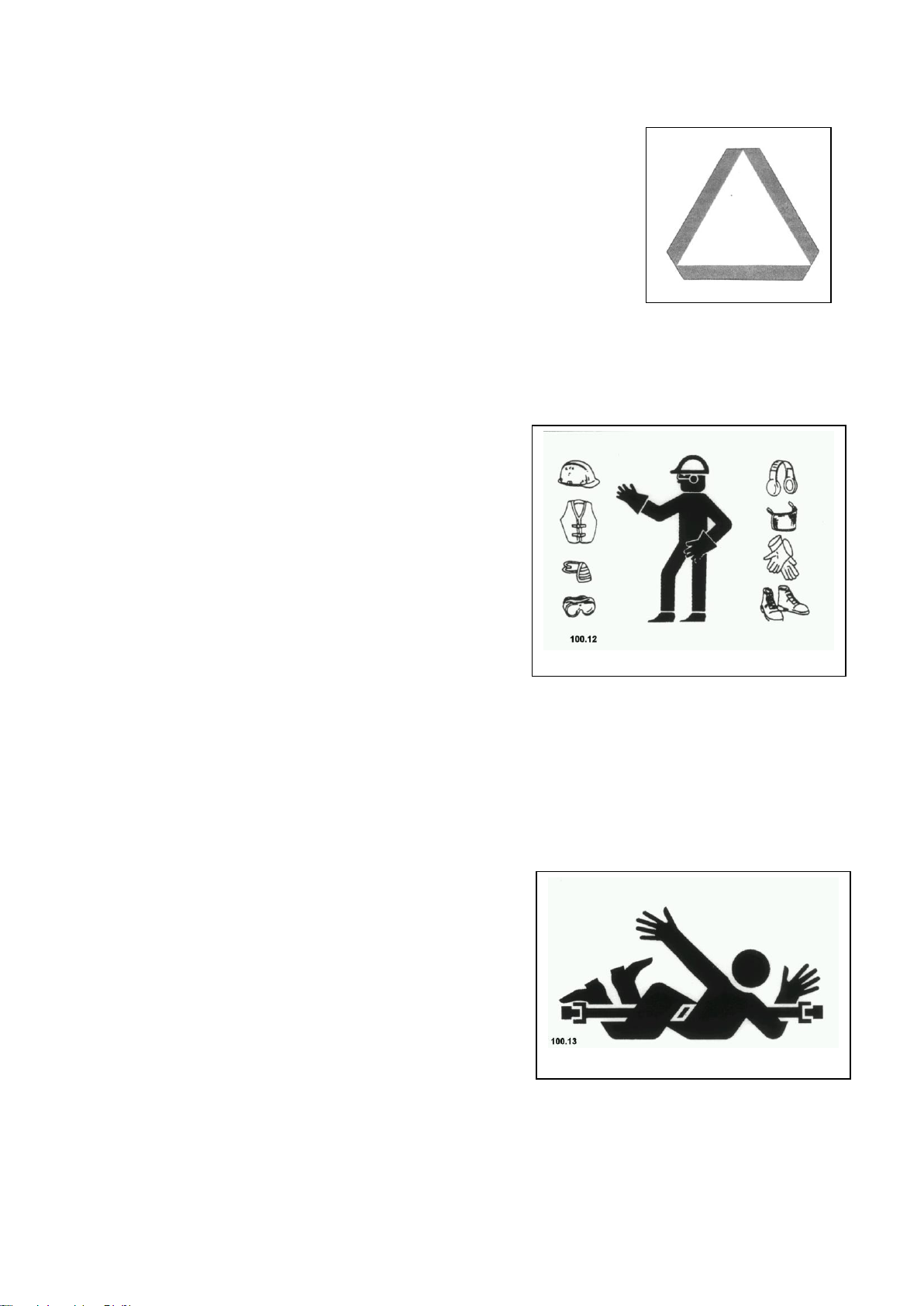

Wear protective clothing

Wear close fitting clothing and

safety equipment appropriate to

the job.

Prolonged exposure to loud

noise can cause impairment or

loss of hearing.

Wear a suitable hearing

protective device such as

earplugs to protect against

objectionable or uncomfortably

loud noises.

Operating equipment safety

requires the full attention of

the operator. Do not wear radio

or music headphones while

operating machine.

1.0. Safety

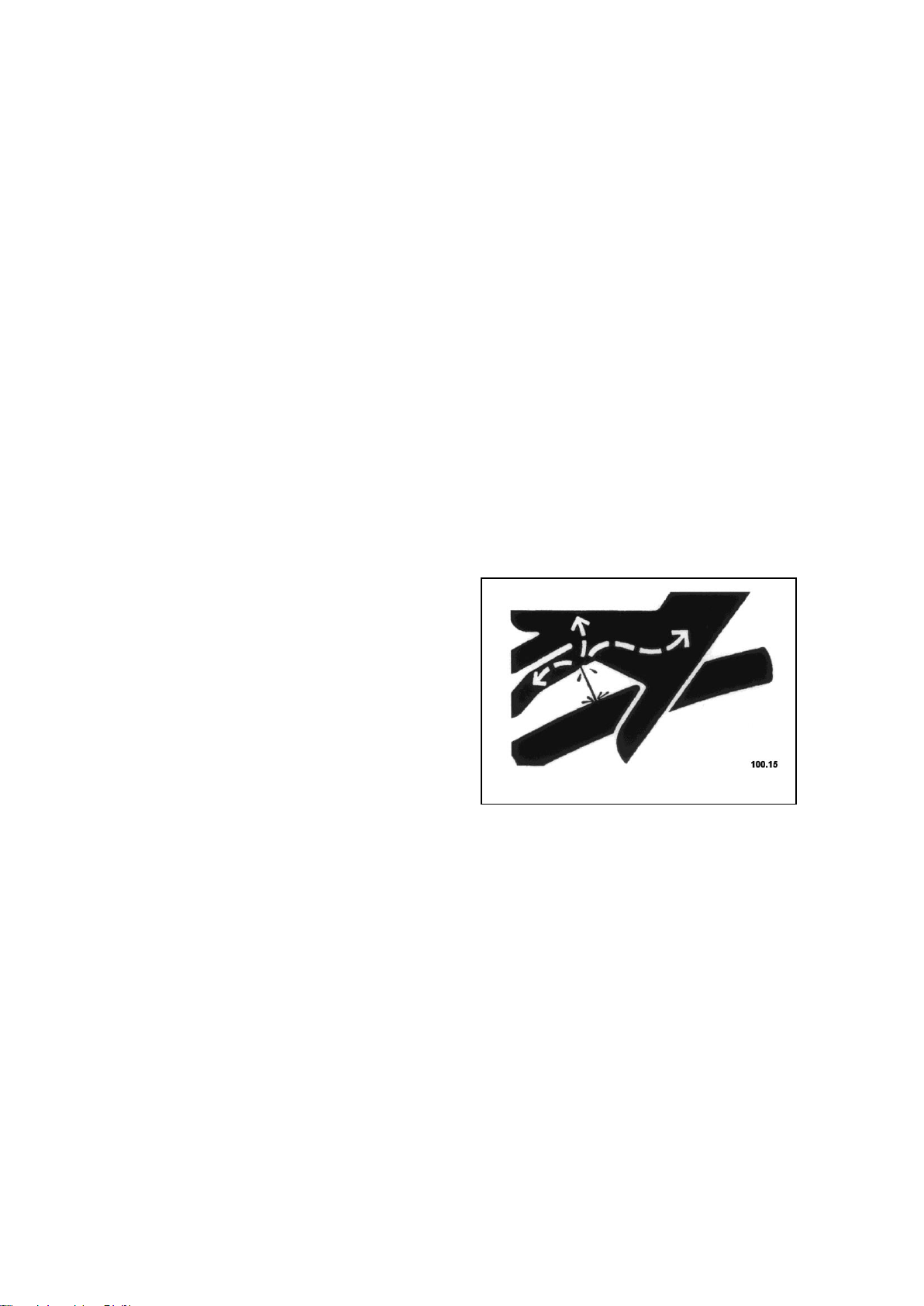

Stay clear of rotating drivelines

Entanglement in rotating

driveline can cause serious

injury or death.

Keep tractor master shield and

driveline shields in place at

all times. Make sure rotating

shields turn freely.

Wear close fitting clothing.

Stop the engine and be sure PTO

driveline is stopped before

making adjustments,

connections, or cleaning out

PTO driven equipment.

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

8

Guard and shields

Keep guards and shields in

place all the times. Ensure

that they are in good condition

and installed correctly.

Always disengage the driveline,

turn off engine and remove key

before removing any guards or

shields.

Keep hands, feet and clothing

away from moving parts.

1.0. Safety

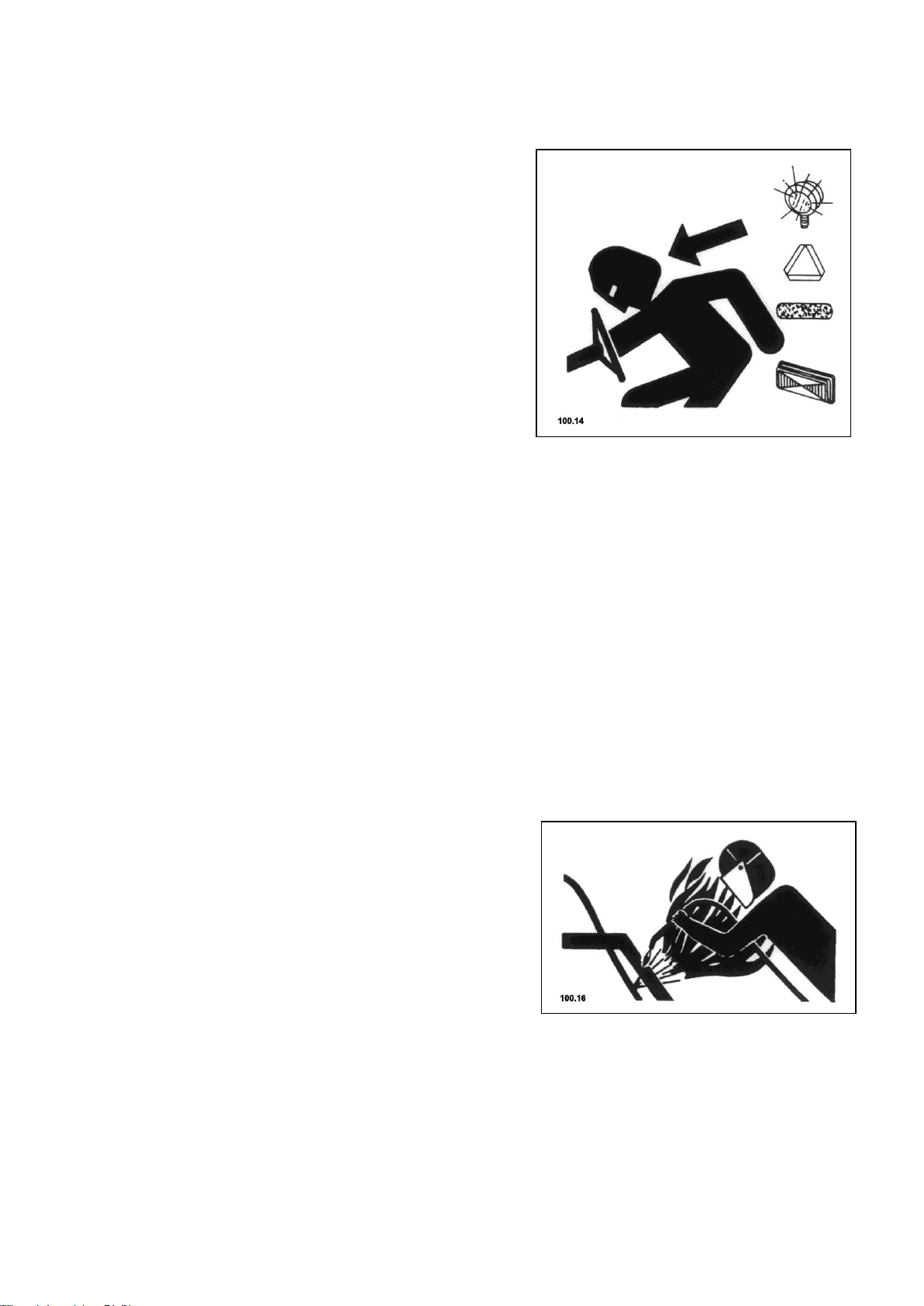

Avoid high - pressure fluids

Escaping fluid under pressure

can penetrate the skin causing

serious injury.

Avoid the hazard by relieving

pressure before disconnecting

hydraulic or other lines.

Tighten all connections before

applying pressure.

Search for leaks with a piece

of cardboard. Protect hands and

body from high pressure fluids.

If an accident occurs, see a

doctor immediately. Any fluid

injected into the skin must be

surgically removed within a few

hours or gangrene may result.

Doctors unfamiliar with this

type of injury should reference

a knowledgeable medical source.

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

9

Use safety lights and devices

Prevent collisions between

other road users, slow moving

tractors with attachments or

towed equipment, and selfpropelled machines on public

roads. Frequently check for

traffic from the rear,

especially in turns, and use

hand signals or turn signal

lights. Use headlights,

flashing warning lights, and

turn signals day and night.

Follow local regulations for

equipment lighting and marking.

Keep lighting and marking

visible and in good working

order. Replace or repair

lighting and marking that has

been damaged or lost. An

implement safety lighting kit

is available from your dealer.

1.0. Safety

Avoid heating near pressurized fluid lines

Flammable spray can be

generated by heating near

pressurized fluid lines,

resulting in severe burns to

yourself and bystanders.

Do not heat by welding,

soldering, using a torch near

pressurized fluid lines or

other flammable materials.

Pressurized lines can be

accidentally cut when heat goes

beyond the immediate flame

area.

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

10

1.0. Safety

Avoid heating near pressurized fluid lines

Welding must be conducted only

by persons with appropriate

qualifications.

Avoid potentially toxic fumes

and dust.

Hazardous fumes can be

generated when paint is heated

by welding, soldering, or using

a torch.

Do all work outside or in a

well ventilated area. Dispose

of paint and solvent properly.

Remove paint before welding or

heating:

If you sand paint, avoid

breathing the dust. Wear an

approved respirator.

If you use solvent or paint

stipper, clean with soap and

water before welding. Remove

solvent or paint stripper

containers and other flammable

material from area. Allow

fumes to disperse at least 15

minutes before welding or

heating.

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

11

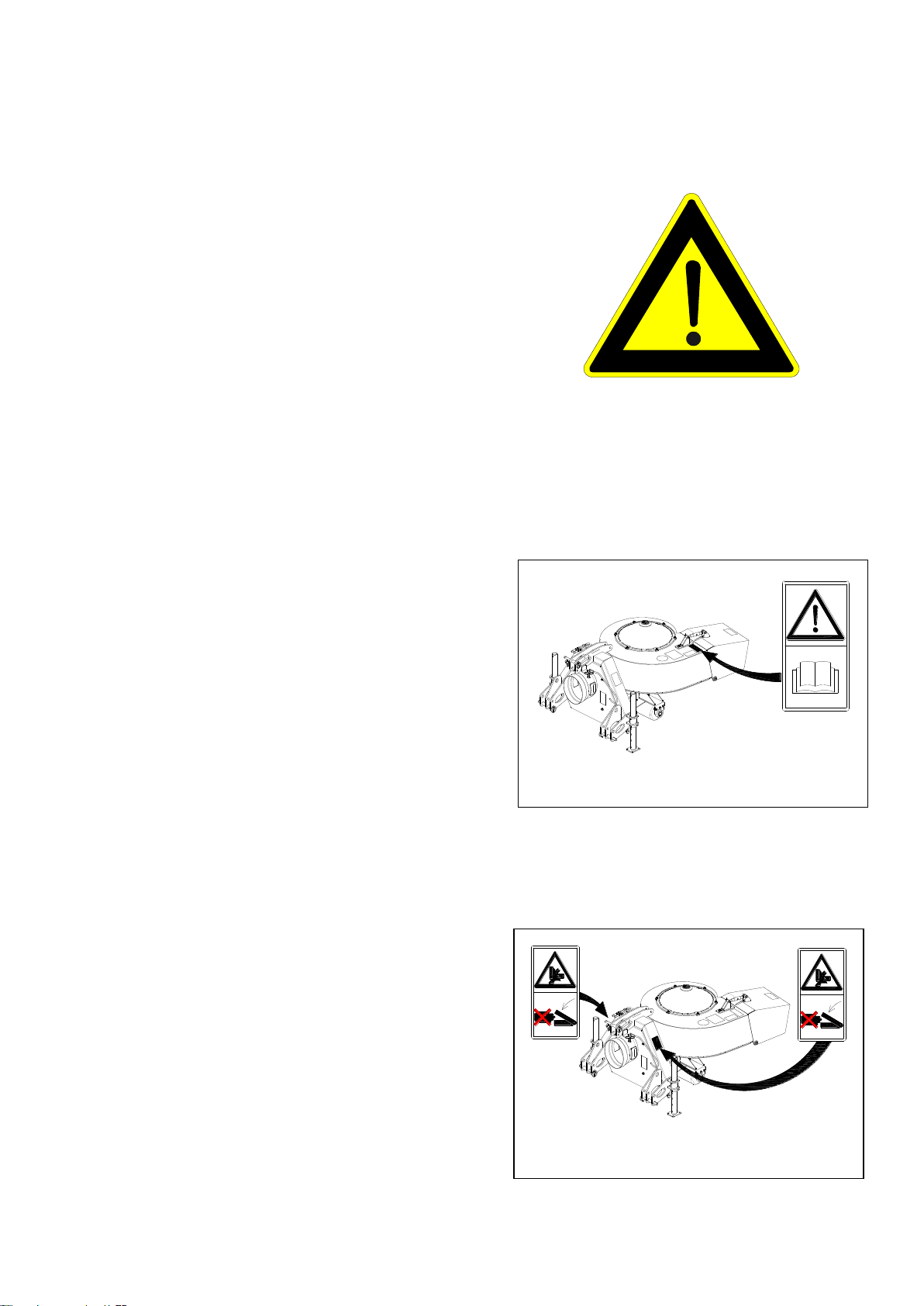

1.1. SAFETY DECALS

891.01

891.02

Pictorial safety signs

At several important places on this

machine safety signs are affixed in

order to signify potential danger.

The hazard is identified by a

exclamation point in a warning

triangle. An adjacent pictorial

provides information on how to

avoid personal injury. These safety

signs, their placement on the

machine and a brief explanatory

text are shown below.

1.0. Safety

Operator’s manual

This operator’s manual contains

all important information

necessary for safe machine

operation.

Carefully observe all safety

rules to avoid accidents.

Swiveling range

Due to danger of crushing,

never put your hands in danger

areas as long as components are

still moving.

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

12

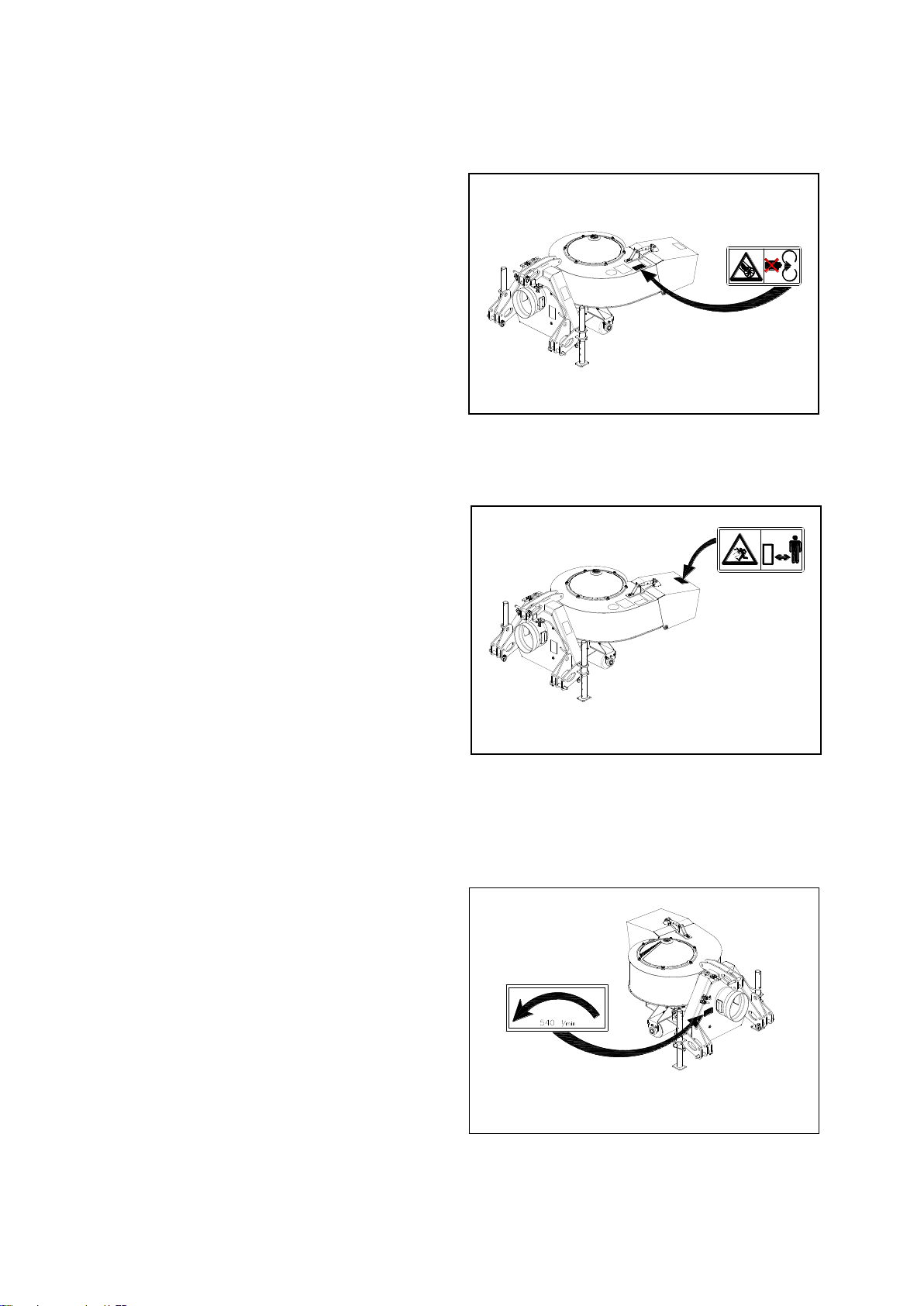

1.1. SAFETY DECALS

891.03

891.04

891.05

Blower

Never put your hands inside the

blower while the engine is

running.

Blowing nozzle

When operating ensure that

sufficient distance is left as

there is a risk of injury from

thrown or flying objects.

1.0. Safety

Power take-off shaft direction of

rotation and speed

It is essential that the

direction of rotation of the

power take-off shaft be

observed. Please check during

commissioning. The specified

speed must not be exceeded

because this would cause

serious damage to the blower.

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

13

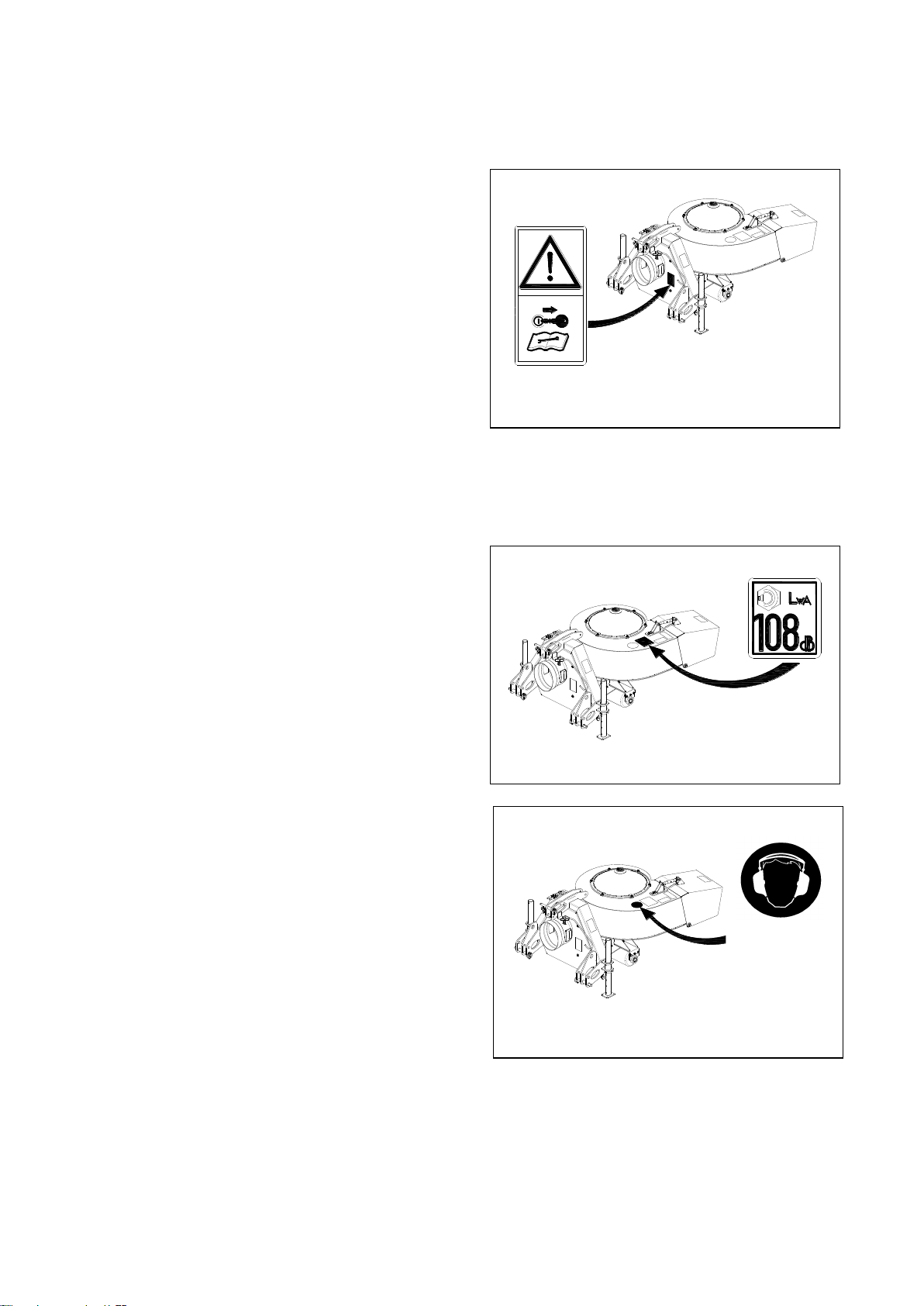

1.1. SAFETY DECALS

891.06

891.07

891.08

Service

Before performing service or

repair work, turn off engine

and remove key.

Noise level

This decal indicates the value

determined in accordance with

Article 13 of Directive

2000/14/EC

When used for several hours, we

recommend the use of ear

protectors.

1.0. Safety

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

14

1.2. Safety instructions

1. Besides the information in

these operating

instructions, please also

observe generally

applicable safety and

accident-prevention

standards!

2. Familiarize yourself with

all equipment and operating

elements and their

functions before starting

work. Ensure that all

protective equipment has

been properly installed.

It is too late to do this

when you have started work!

3. In the working area, the

user is responsible for the

safety of other persons.

4. All persons must be out of

the danger area before

starting.

5. If there are persons in the

danger zone of the machine,

switch off the drives

immediately.

6. During operation on public

highways, the relevant

traffic regulations must be

observed.

7. Before moving off, ensure

that the immediate area of

the machine is clear e.g.

no children nearby. Ensure

that your visibility is not

impaired!

1.0. Safety

9. Mount the appliance only

when the motor and the

power take-off shaft have

been switched-off.

10. Use only cardan shafts

prescribed for the machine

which is being mounted.

11. Always ensure there is

sufficient axle load; the

steering capability of the

vehicle must be

maintained.

12. The driving and

operational

characteristics of the

tractor may be influenced

by the attachment of the

machine. Always adapt your

driving style to match the

terrain and ground

conditions. Special care

should be taken when

working and turning on a

slope.

13. Switch off the machine and

the tractor engine when

performing any maintenance

work. All protective

devices must be mounted

before operating the

blower.

8. Keep all persons clear of

the danger zone of the

machine!

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

15

1.0. Safety

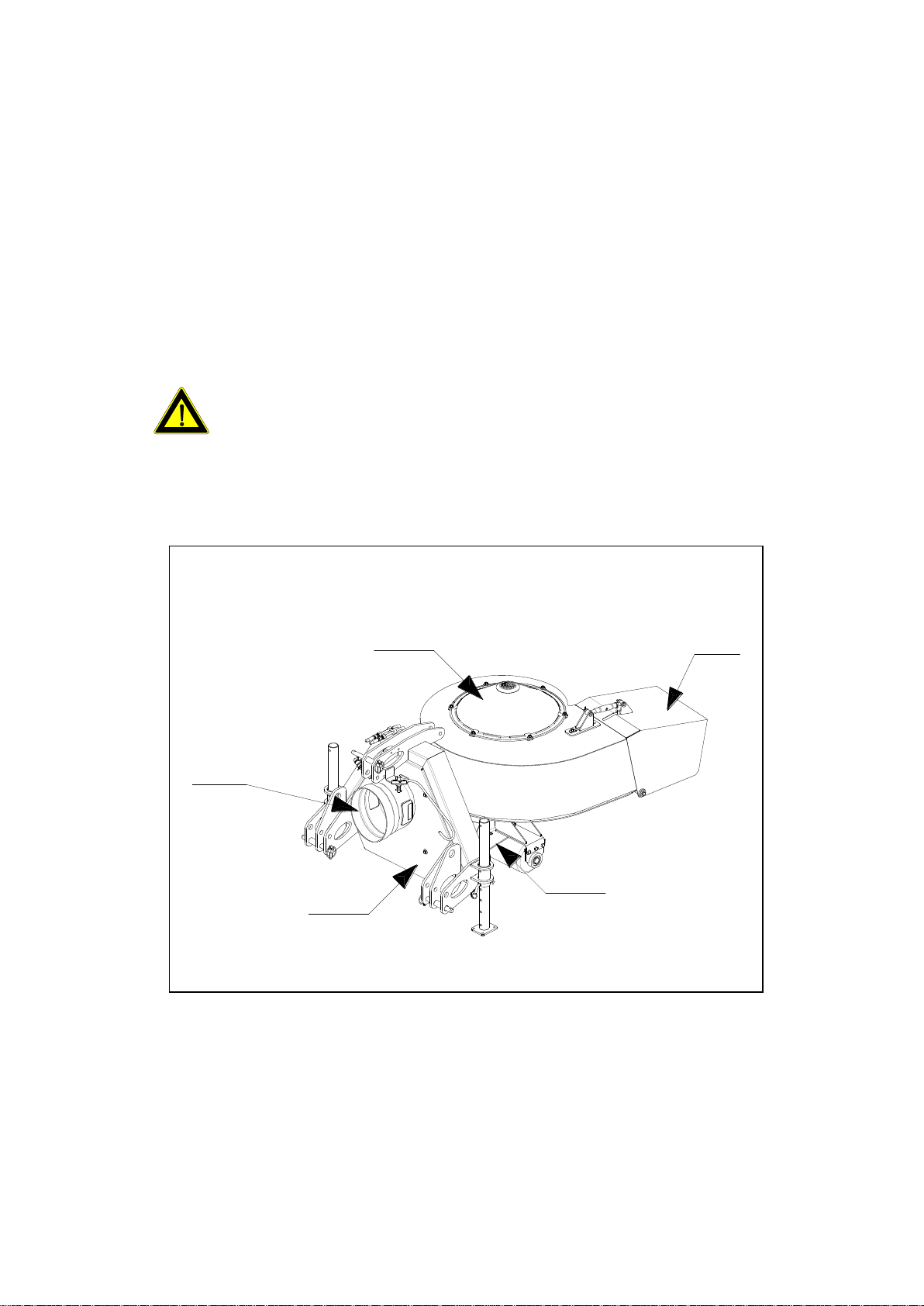

A = Covers, only removable

with tools.

C = Grid plates, only

removable with tools.

B = Protection for p.t.o.

shaft connection can only

be released using a tool.

D = Blower funnel, only

removable with tools.

C

A

B

A

891.09

D

1.3. The safety devices

GENERAL REQUIREMENTS FOR SAFETY IDENTIFICATION

Safety identification with the following safety actions or similar

notification should be attached to the machine. Where possible,

the label should be visible from all work positions.

a) Read the Operating Instructions.

b) Never operate the machine without protection, shields and

functioning safety devices.

c) Never operate the machine if persons, especially children, are

nearby.

d) Never allow the machine to be operated by persons who have not

received instruction.

CAUTION, DANGER! Never operate the Mega Twister without

safety devices. Otherwise you would be exposing yourself

and those around you to extreme danger.

Very serious injuries can be caused by moving parts.

The locations of the safety devices on your machine

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

16

2.1. General

The machine must be attached

to the tractor for all work.

Lift the attached machine

with the rear hydraulics

until the stand can be

inserted into one of the top

holes.

- RISK OF INJURY!

For this work, please use your

personal protective equipment

(PSA) such as: gloves,

goggles, ear protectors.

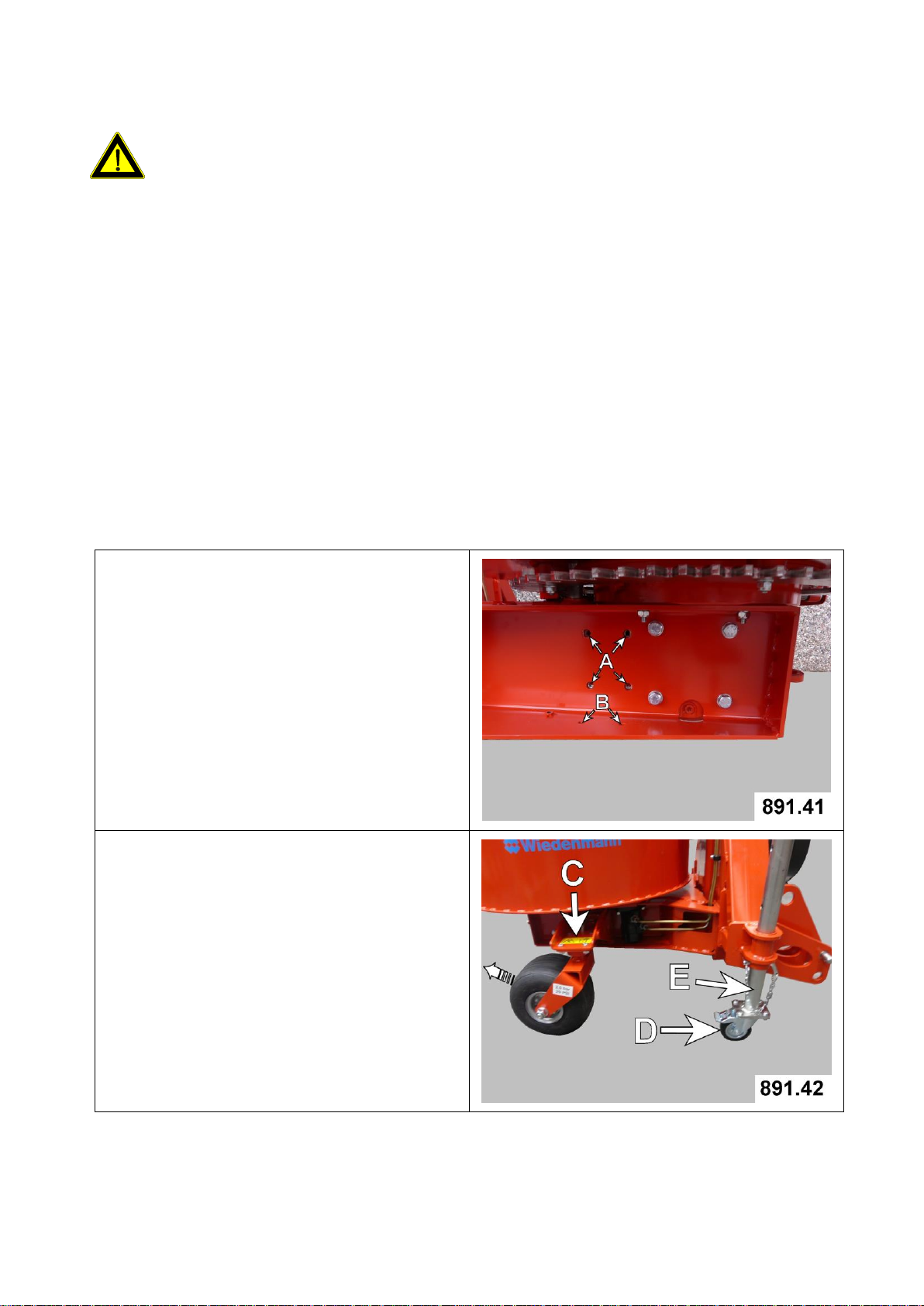

The mounting points for the two

support wheel holders are:

4 threaded holes (A)

2 holes (B)

Figure 891.42 shows the right

support wheel (C) mounted and

the locked wheel is rotated to

the back.

The included support roller with

brake (D) must be fastened to

the bottom of the stand (E).

Attention:

2.2. Mounting support wheels

2.0. Assembly

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

17

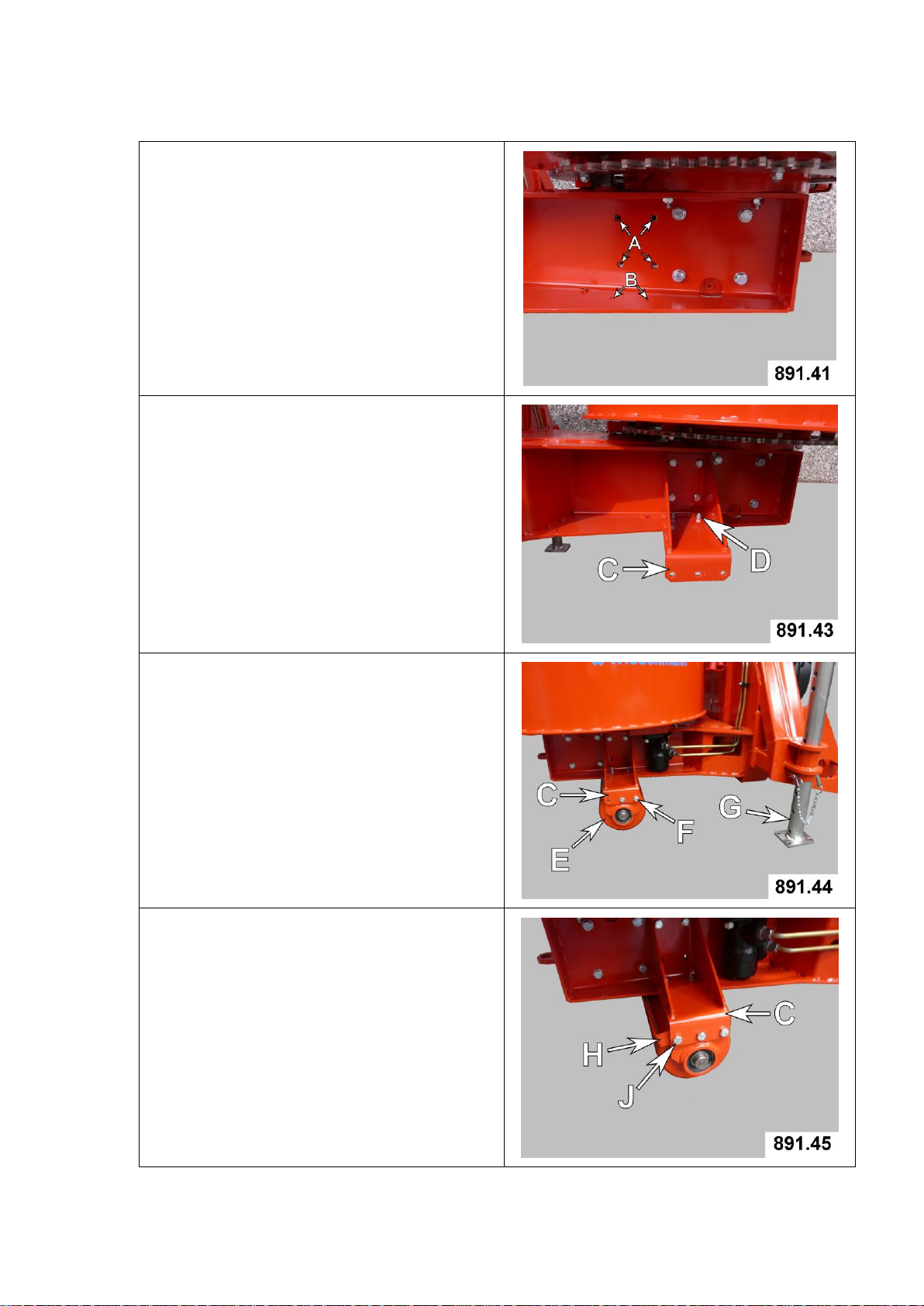

2.3. Mounting roller unit

The mounting points for the

roller unit are:

4 threaded holes (A)

2 holes (B)

Mount support (C) on both

sides..

The hexagonal bolts (D) must be

inserted from below.

The roller (E) with the

bearings must be fastened on

both sides to the support (C)

at the front holes with two

hexagonal bolts each (F).

Support rollers are NOT mounted

on the stand (G) with the

roller unit version.

The wiper bracket (H) is

fastened to the support (C)

with the last hexagon bolts (J)

and fixed to the roller with a

small clearance.

2.0. Assembly

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

18

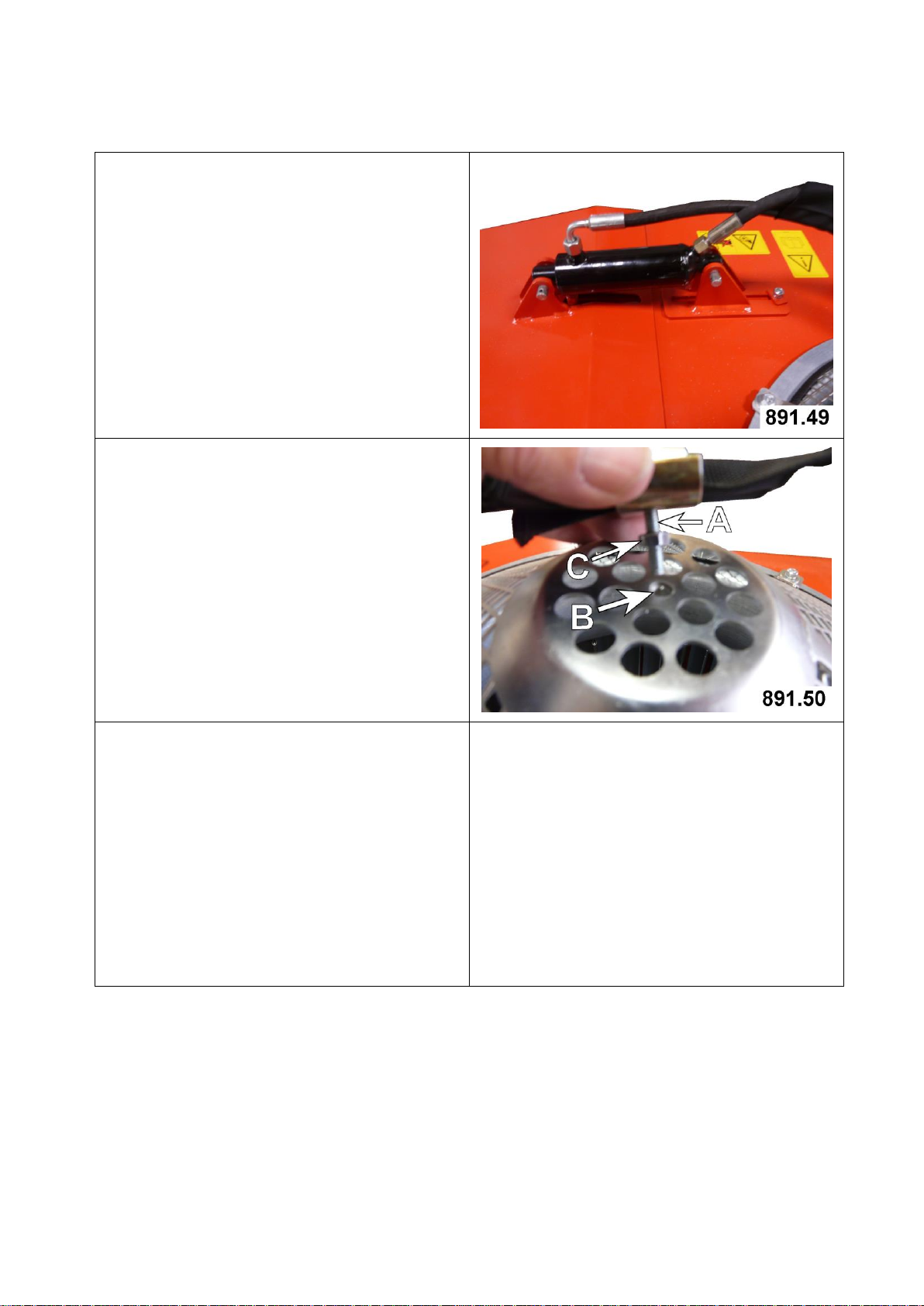

2.0. Assembly

Carried out via an additional

hydraulic cylinder (optional).

Mount the hydraulic cylinder

instead of the mechanical

adjustment.

Secure pin with linch pin.

Screw hexagon bolt (A) into the

thread on the screen (B).

Screw the hexagon nut (C) down

to fix the bolt.

The hydraulic hoses fixed by the

two fastening clips must be able

to move easily.

Take the swiveling of the blower

housing into account when fixing

the hydraulic hoses.

2.4. Hydraulic adjustment of the blowing nozzle

All information, illustrations and specifications in this manual are based on the latest information

available at the time of publication. We reserve the right to make changes at any time without notice.

Loading...

Loading...