Wiedenmann

Operating

Instructions

Deep Aerator

Greens Terra-Spike

G6/135 and G/160

434.001-US

Effective: January 2001

Wiedenmann GmbH - D 89192 Rammingen

Tel. No.: 07345 / 953-02 Fax No.: 07345 / 953 233

2700 Gregory Street, Savannah GA

Phone 912-790-3004 Fax 912-790-3005

WARRANTY

As stated on the warranty certificate you receive when you purchased

the machine, a one year warranty is offered which covers all

malfunctioning parts where the fault is demonstrated as being due to a

structural or material defect. Claims under the warranty should be

made within three days of the

and warranty certificate.

replacement of defective parts. Damage caused by improp

non-observance of the operating instructions, insufficient care or

external influences is not covered by the warranty. Careful observance

of the instructions contained in the operating instructions is,

therefore, a precondition for perfect machine operation.

Improper operation leads to malfunctions which are not covered in the

warranty.

fault's occurrence enclosing the receipt

The warranty provides for the gratuitous

er tre

atment,

Wiedenmann GmbH * Am Bahnhof * D 89192 Rammingen * Fax: 0049 / 7345 / 953233

EC-Declaration of Conformity

We

Am Bahnhof

declare under our sole responsibility, that the product

to which this declaration relates corresponds to the relevant basic safety and

health requirements of the Directive 89/392 (ECC),sowie den Anforderungen der

einschlägigen.

Wiedenmann GmbH

89192 Rammingen

Deep Aerator Greens Terra-Spike

G6/135 and G6/160

Rammingen, the 22. August 2000 Peter Rischar

Technical Service

(Place and date of issue) (Name, function and signature

2

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

of authorised person)

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

3

Introduction

READ THIS MANUAL carefully to learn how to operate and service your

machine correctly. Failure to do so could result in personal injury or

equipment damage. This manual and safety signs on your machine may

also be available in other languages (see your dealer to order).

THIS MANUAL SHOULD BE CONSIDERED

a permanent part of your machine and

should remain with the machine when you sell it.

MEASUREMENTS

in this manual are given in both metric and customary

U.S. unit equivalents. Use only correct replacement parts and

fasteners. Metric and inch fasteners may require a specific metric or

inch wrench.

RIGHT - HAND AND LEFT - HAND

sides are determined by facing the

direction the implement will travel when going forward.

WRITE PRODUCT IDENTIFICATION NUMBERS

(P.I.N.) in the Specification or

Identification Numbers section. Accurately record all the numbers to

help in tracing the machine should it be stolen. Your dealer also

needs these numbers when you order parts. File the identification

numbers in a secure place off the machine.

BEFORE DELIVERING THIS MACHINE,

your dealer performed a predelivery

inspection to ensure best performance.

THIS MACHINE IS DESIGNED SOLELY

for use in customary agricultural and

forestry operations, for lawn and park care, i.e. collecting grass,

leaves and paper (“INTENDED USE“).

Use in any other way is considered as contrary to the intended use.

The manufacturer accepts no liability for damage or injury resulting

from this misuse, and these risks must be borne solely by the user.

Compliance with and strict adherence to the conditions of operation,

service and repair as specified by the manufacturer also constitute

essential elements for the intended use.

THIS MACHINE SHOULD BE OPERATED, serviced and repaired only by persons

familiar with all its particular characteristics and acquainted with

the relevant safety rules (accident prevention).

The accident prevention regulation, all other generally recognized

regulations on safety and occupational medicine and the road traffic

regulations must be observed at all times.

Any arbitrary modifications carried out on this material collection

system will relieve the manufacturer of all liability for any

resulting damage or injury.

THE TRACTORS

4

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

must be conform with the EN836

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

C O N T E N T S Page

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

1.0. Safety..................................................5-11

1.1. Safety Decals....................................9+10

1.2. Safety Equipment................................. 11

2.0. Construction method of Operation....................... 12

2.1. Construction..................................... 12

2.2. Method of Operation.............................. 12

2.3. Product Observation.............................. 12

3.0. Transport.............................................. 13+14

3.1. General.......................................... 13

3.2. Transporting Greens Terra-Spike.................. 14

4.0. Connecting to the Tractor.............................. 15+16

4.1. General.......................................... 15

4.2. Connecting to the Tractor........................ 16

5.0. Detaching from Tractor................................. 17

5.1. General.......................................... 17

5.2. Resting GREENS Terra-Spike....................... 17

6.0. Before Operation........................................ 18-26

6.1. General.......................................... 18

6.2. Indicating and Adjustment Elements............... 19

6.3. Mounting the Tools............................... 20-22

6.4. Setting the Working Depth........................ 23+24

6.5. Setting the Number of Holes...................... 25+26

7.0. Operation.............................................. 27+28

7.1. General.......................................... 27

7.2. Correct Sequence for engaging.....................28

7.3. Malfunctions and Remedies........................ 28

8.0. Maintenance............................................ 29-34

8.1. General.......................................... 29

8.2. Maintenance and Inspection List.................. 29

8.3. Lubrication...................................... 30

8.4. Cleaning GREENS TERRA SPIKE...................... 31

8.5. Changing the oil of the gear unit................ 32

8.6. Replacing the buffer............................. 32

8.7. Setting cleaner.................................. 33

8.8. Hydraulic system................................. 33

8.9. Dismounting/Disposal............................. 34

8.10. Modification.................................... 34

9.0. Additional Equipment................................... 35

10.0. Specification.......................................... 36-40

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

5

1.0. Safety

Recognize safety information

This is the safety-alert symbol.

When you see this symbol on your

machine or in this manual, be

alert to the potential for

personal injury.

Follow recommended precautions

and safe operating practices.

Follow safety instuctions

Carefully read all safety

messages in this manual and on

your machine safety signs. Keep

safety signs in good condition.

Replace missing or damaged safety

signs. Be sure new equipment

components and repair parts

include the correct safety signs.

Replacement safety signs are

available from your dealer.

Learn how to operate the machine

and to use controls properly. Do

not let anyone operate without

instruction.

Keep your machine in proper

working condition. Unauthorized

modifications to the machine may

impair the fuction and/or safety

and affect machine life.

If you do not understand any part

of this manual and need assistance,

contact your dealer.

Observe road traffic regulations

Always observe local road traffic

regulations when using public roads.

6

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

1.0. Safety

Wear protective clothing

Wear close fitting clothing and

safety equipment appropriate to

the job.

Prolonged exposure to loud

noise

can cause impairment or loss of

hearing.

Wear a suitable hearing

protective

device such as earmuffs or

earplugs

to protect against

objectionable or

uncomfortably loud noises.

Operating equipment safety

requires the full attention of

the operator. Do not wear radio

or music headphones while

operating machine.

Stay clear of rotating drivelines

Entanglement in rotating driveline

can cause serious injury or death.

Keep tractor master shield and

driveline shields in place at all

times. Make sure rotating shields

turn freely.

Wear close fitting clothing. Stop

the engine and be sure PTO

driveline

is stopped before making

adjustments,

connections, or cleaning out PTO

driven equipment.

Guard and shields

Keep guards and shields in place

at all times. Ensure that they

are in good condition and installed

correctly.

Always disengage the driveline, shut

off engine and remove key before

removing any guards or shields.

Keep hands, feet and clothing away

from moving parts.

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

7

1.0. Safety

Use safety lights and devices

Prevent collisions between other

road users, slow moving tractors

with attachments or towed

equipment, and self-propelled

machines on public roads.

Frequently check for traffic

from the rear, especially in

turns, and use hand signals or

turn signal lights.

Use headlights, flashing warning

lights, and turn signals day and

night. Follow local regulations

for equipment lighting and

marking. Keep lighting and

marking visible and in good

working order. Replace or repair

lighting and marking that has

been damaged or lost.

An implement safety lighting kit

is available from your dealer.

Avoid welding near pressurized

fluid lines

Flammable spray can be ignited

by welding near pressurized fluid

lines, resulting in severe burns

to yourself and bystanders. Do

not heat by welding, soldering,

using a torch near pressurized

fluid lines or other flammable

materials. Pressurized lines can

be accidentally cut when heat goes

beyond the immediate flame area.

8

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

1.0. Safety

Remove paint before welding or heating

Avoid potentially toxic fumes and

dust.

Hazardous fumes can be generated

when paint is heated by welding,

soldering, or using a torch.

Do all work outside or in a well

ventilated area. Dispose of

paint

and solvent properly.

Remove paint before welding or

heating:

x If you sand or grind paint,

avoid breathing the dust. Wear

an approved respirator.

x If you use solvent or paint

stripper with soap and water

before welding. Remove solvent

or paint stripper containers and

other flammable material from

area. Allow fumes to disperse at

least 15 minutes before welding

or heating.

Avoid high - pressure fluids

Escaping fluid under pressure

can penetrate the skin causing

serious injury.

Avoid the hazard by relieving

pressure before disconnecting

hydraulic or other lines.

Tighten all connections before

applying pressure.

Search for leaks with a piece

of cardboard. Protect hands and

body from high pressure fluids.

If an accident occurs, see a

doctor immediately. Any fluid

injected into the skin must be

surgically removed within a few

hours or gangrene may result.

Doctors unfamiliar with this

type of injury should reference

a knowledgeable medical source.

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

9

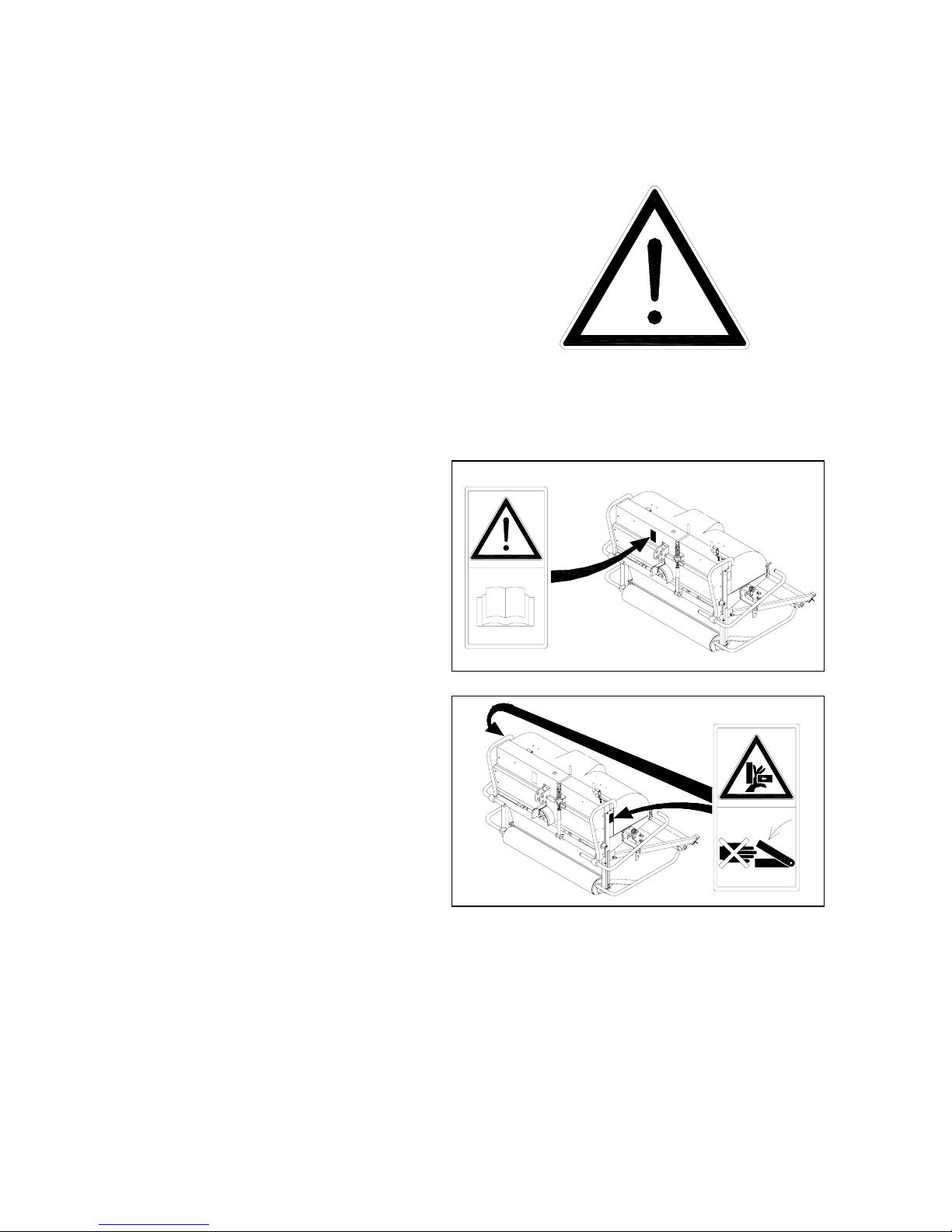

1.1. Safety Decals

Pictorial safety signs

At several important places

of this machine, safety signs

are affixed in order to

signify potenial danger. The

hazard is identified by a

pictorial in a warning

triangle. An adjacent

pictorial provides information

how to avoid personal injury.

These safety signs, their

placement on the machine and

a brief explanatory text are

shown below.

Operator’s manual

This operator’s manual

contains all important

information necessary for

safe machine operation.

Carefully observe all

safety rules to avoid

accidents.

1.0. Safety

Protectors

Never reach into areas of

crushing hazard as long

as any parts may move.

10

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

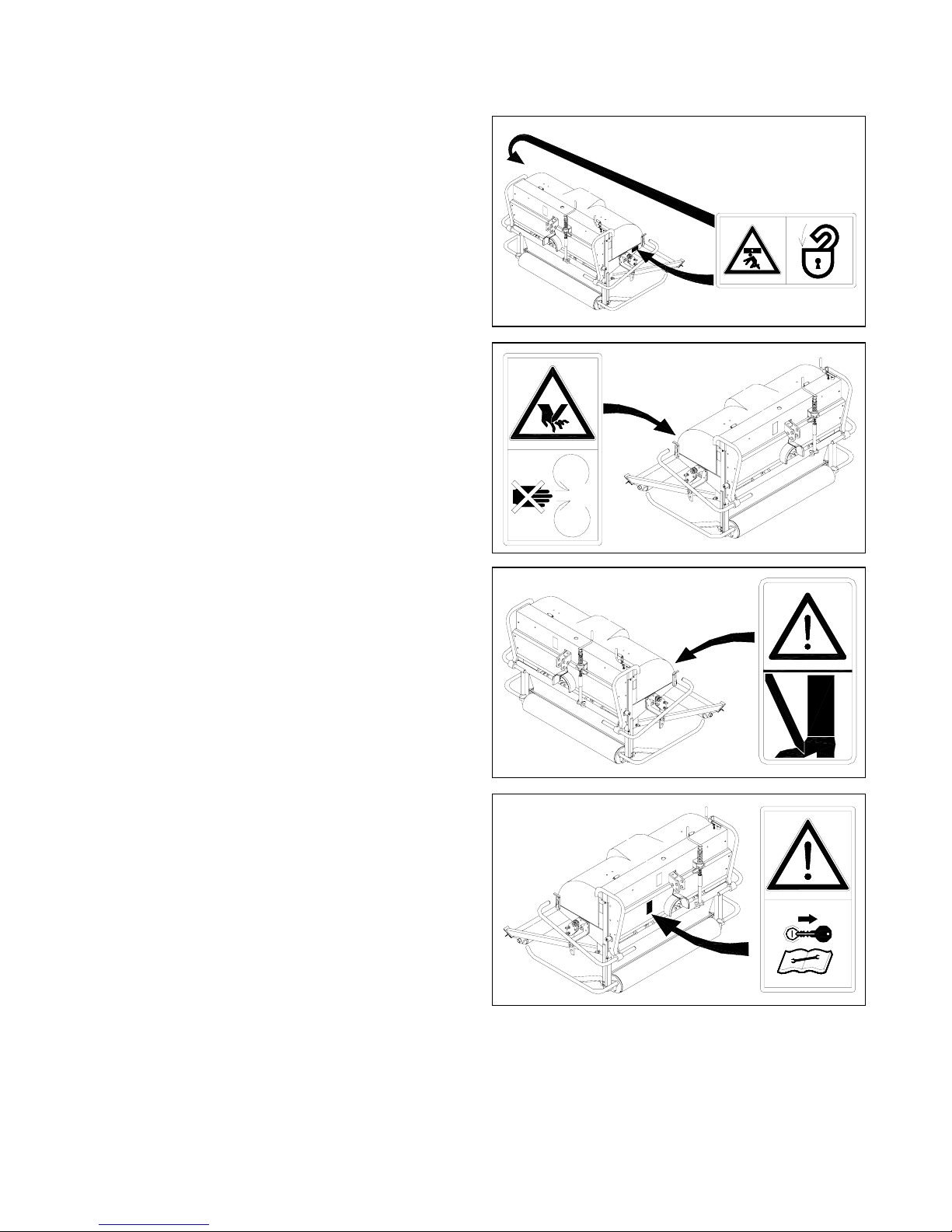

1.1. Safety Decals

Parking position

Before parking fix rear

roller with ring pins and

secure it.

Tools

Never touch moving parts

of the machine. Wait until

they have completely come

to a standstill.

1.0. Safety

Tools

Cutting of foot.

Service

Before performing service or

repair work, shut off engine

and remove key.

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

11

1.0. Safety

1.2. Safety Equipment

GENERAL SAFETY SIGN REQUIREMENTS

A safety sign with the following safety practices or similar set of messages shall be

provided on the machine. The label should be visible to an operator’s position, if possible.

a) Read the operator’s manual.

b) Do not operate the machine without guards, shield, and safety devices in place and

working.

c) Do not operate the machine when children and others are around.

d) Do not allow operation of the machine by untrained personnel.

ATTENTION - DANGER !

Never use GREENS TERRA SPIKE without safety equipment.

Otherwise, you expose yourself and others to extreme

danger.

Moving parts may cause serious injuries.

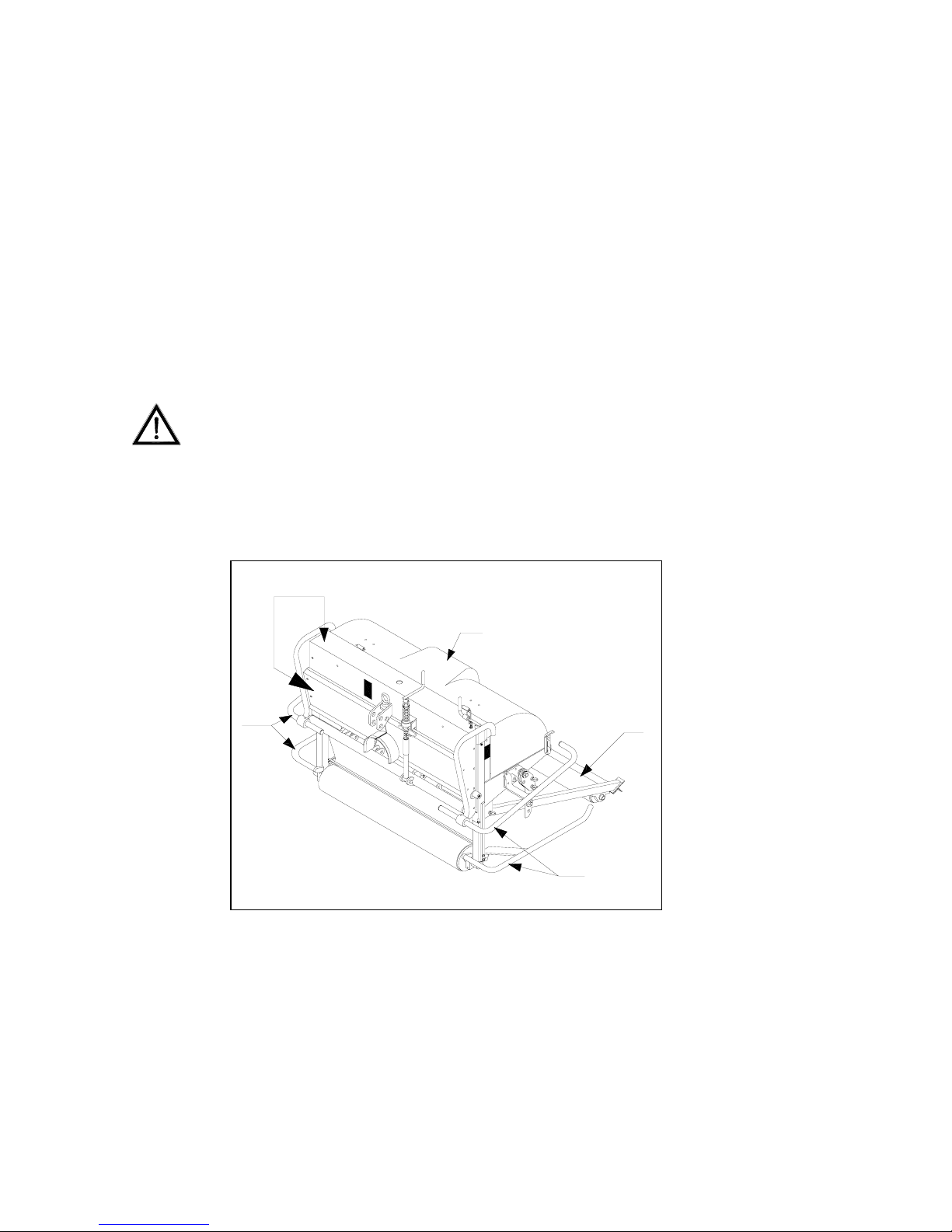

Where to Find Safety Equipment on your Machine

D

C

A

434.46

A

B

A

= Screwed fenders right /

left as spacers.

B

= Back roller with arms

locked with ring pin and

secured.

12

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

C

= Hinged hood, secured by a

lock and holders.

D

= Cover removable by ring

tools only.

2.0. Construction and Method of Operation

2.1. Construction

GREENS TERRA SPIKE consists of

the following parts:

x

Welded machine body

x

Drive

xAdjustable tools

Three gear speeds can be selected

on GREENS TERRA SPIKE.

2.2. Method of Operation

GREENS TERRA SPIKE is hauled by

the tractor and driven by means

of a PTO shaft.

A gear unit inside GREENS TERRA

SPIKE provides for movement of

the tines.

The moving tines are plunged

into the soil.

The angle of entry is adjustable.

With an angle of entry of 90° at

low speed the punched holes are

almost vertical.

With a smaller entry angle

the tines are sluiced in the soil

due to the forward movement.

This breaks up the soil.

The smaller the entry angle,

the more the soil is broken up

(effective down to 70°).

2.3. Product warranty

We are bound by law to warranty

our products starting with

the delivery.

This serves your safety.

Please immediately inform

us about:

x

Defects of the safety devices.

x

Repeated malfunctions.

x Altered setting.

x

Problems in handling the

GREENS TERRA SPIKE.

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

13

14

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

3.1. General

CAUTION - DANGER !

° GREENS TERRA SPIKE is

delivered fastened to a

shipment frame.

° Only use a forklift with

sufficient load-carrying

capacity.

° Keep well clear of lifted

loads. There is danger to

your life if the load

crashes down.

Improper transport and mounting

of GREENS TERRA SPIKE may cause:

3.0. Transport

x

Injury to persons

xDamage to property.

Pay special attention to the

driving direction when

lifting GREENS TERRA SPIKE with

the shipment frame.

We will not accept any

liability for damage resulting

from improper handling.

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

15

3.0. Transport

3.2. Transporting GREENS TERRA SPIKE

CAUTION - DANGER !

Watch out when cutting through

the taut bands.

There is a risk of being

injured by the suddenly

opening bands.

Transport Using a Forklift

If GREENS TERRA SPIKE is still

fastened to the shipment frame:

x

Insert the fork under the

shipment frame

x

Unload GREENS TERRA SPIKE from

the carrier vehicle when

balanced.

x

Cut through the taut bands.

xConnect GREENS TERRA SPIKE to

the tractor and lift it from

the shipment frame.

(See item 4.2.)

Transport Using a Crane

x

Fasten ropes or belts at ring

screw (A) only,

xUnload GREENS TERRA SPIKE when

suspended reliably.

Note:

Immediately inform in writing

the transport company and

Wiedenmann GmbH or the supplier

about shipping damage or missing

parts.

16

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

4.0. Connecting to the Tractor

4.1. General

Always pay attention to:

xThe load of the lower guide

rod connector.

Connect / disconnect GREENS

TERRA SPIKE only with:

x

The engine turned off

xStanding power take-off shaft

x

With fixed and secured

back roller.

Use GREENS TERRA SPIKE

only with:

xthe special PTO shaft

assigned to GREENS TERRA

SPIKE

x

covered PTO shaft and

protected power-take-off

shaft.

Rest GREENS TERRA SPIKE

on the front roller (A)

and back roller (B) only.

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

17

4.0. Connecting to the Tractor

4.2. Connecting to the tractor

Prerequisite for connecting:

x

a three-point hitch.

NOTE:

° if possible use the lower

location hole for mounting

the lower guide rod.

This provides the maximum

lifting distance.

° observe the bending angle

of the PTO shaft.

Mounting steps:

1. Mount the lower guide

rod by:

inserting the bolt(1) and

locking it with the o-ring(2).

2. Mount the upper guide

rod by:

Inserting the bolt(3) and

locking it with the

locking pin.

3. Tighten the tension jack(5)

of the stabilizing chain.

4. Adapt the PTO shaft

(see separate operating

instructions).

5. Mount the PTO shaft by

pushing in the slide pin

of the PTO shaft,

slipping on the PTO

shaft, secure the PTO

shaft protector against

rotating with the shaft.

CAUTION - DANGER !

Check for correct connection

before starting operation.

18

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

19

5.0. Disconnecting from the Tractor

5.1. General

Only rest GREENS TERRA SPIKE:

xon a solid and even base,

xon fully lowered front and

secured back roller.

This provides for a safe stand

of GREENS TERRA SPIKE.

The tines are not damaged.

5.2. Resting GREENS TERRA SPIKE

Proceed as follows:

1. Switch off the tractor,

2. Place the roller in

the lowest position,

(see item 6.5. “Adjusting

the roller“),

3. Lower GREENS TERRA SPIKE

using the back hydraulic

of the tractor,

4. Pull ring pin(A) out of

position (C),

5. Bring back roller in position,

fix with ring pin (A) and

secure it with pin (B) as

shown in picture 434.11,

6. Untighten and remove

the upper guide rods,

7. Untighten and turn buckles

of the lower guide rods,

8. Remove the lower guide rods,

9. Dismount the PTO shaft,

10.Disconnect the hydraulic.

NOTE:

The working depth is changed

due to wear of the tools.

Therefore readjust the working

depth:

1. after each tool replacement,

2. after long working periods

with the same adjustment.

20

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

6.1. General

ATTENTION !

It is important to get familiar with

all devices and operating

elements as well as their

action before starting

service to make sure that

all protective devices have

been properly mounted. It

will be too late for this

during operation!

Ensure that noone is

in the immediate area of

the appliance and the rotating

PTO shaft before turning

on the power take-off shaft.

Observe the operating

instructions while also paying

attention to general safety

specifications and rules for

prevention of accidents!

6.0. Before Operation

Corresponding specifications

must be observed on public

roads!

The weight on the axle in

front must be enough to

maintain steerability

(if needed put on ballast

weights, see operator’s

manual of tractor).

Be careful working on the slope

– DUMPING RISK - !

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

21

6.0. Before Operation

6.2. Indicating and adjustment elements

Shift lever(A) for the

3 gear speeds of the machine

(speed 3 is seen on the

photo 434.12).

NOTE:

The shift lever (A) must snap

into place with an audible

sound. If necessary move the

gear by applying pressure to

a tine holder while standing up

Crank (B) for adjusting the

working depth (by raising or

lowering the roller).

Depth scale (C) and Lineal (D)

(indicates adjusted number).

Crank (E) and spindle (F) for

adjusting the entry angle.

22

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

6.0. Before Operation

6.3. Mounting the Tools

NOTE

When mounting the tines:

1. Lift up GREENS TERRA SPIKE

with tractor hydraulic.

2. Adjust front roller to

lowest position.

3. Put down GREENS TERRA

SPIKE on front roller.

4. Shift the tine holder you

are working with upwards

(by pressing an upper

tine holder).

5. Lubricate the tine holder

in the receiving area.

6. In installation position

the pointed end of the

tine (A) must be backward

(in driving direction).

7. To protect the cone

support of tine holders,

screws and washer are

installed. The cylindric

supports which are not

in use, are protected by

plastic caps.

8. Wrench (B) is for

adjusting and removing

the tines.

Fahrtrichtung

Direction of motion

Direction de la marche

A

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

23

6.0. Before Operation

6.3.1. Mounting the tines into the receiver:

1. Shift up the

tine holder(A).

2. Screw (D) and

washer (E) remove.

3. Adjust nut (B) with

delivered wrench so that

you can see one

thread (C) of the tine.

4. Place tine (F) into the

conical support and

bolt it completely into

nut (B).

5. Check point of tine

to make sure it is backwards

to driving direction.

6. By removing the tines (F)

adjust position edge.

7. Put wrench on nut (B).

8. Hold tine with one

hand firmly.

9. Fix tine by bolting

the nut (B).

B

A

C

E

D

A

F

Fahrtrichtung

Direction of motion

Direction de la marche

NOTE

Check all tines for tight fit:

x

Before using them

x

If they just have been

mounted, after three

minutes of use.

434.35

24

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

6.0. Before Operation

6.3.2. Mounting tines into the cylindrical receiver:

1. Remove plastic cap (D)

at tine holder (A).

2. Loosen nut (C).

3. Place 12 mm[1/2“] tine (E)

or 8 mm [5/16“] tine (F)

with bush (G) as shown in

illustration.

4. Fix screw (B) in

lowering of tines.

5. Fix counter nut (C) to

fix screw (B).

6. Check the tines for

tight fit.

NOTE

Check all tines for tight fit:

x Before using them

A

B

C

D

E

Fahrtrichtung

Direction of motion

Direction de la marche

x If they just have been

mounted, after three

minutes of use.

F

G

Fahrtrichtung

Direction of motion

Direction de la marche

434.38

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

25

6.0. Before Operation

6.4. Adusting the GREENS TERRA SPIKE

NOTE

Always make adjustments

when the device has been

attached and raised.

On delivery of the

GREENS TERRA SPIKE the

rake angle is set to

zero position.

Calculating the Rake Numeral

Tool length “A“ (in in.)

minus the desired working

depth “B“ will yield the

rake numeral “Z“.

Sequence when adjusting the

GREENS TERRA SPIKE :

1)Adjust working depth:

a) Release spring pin (A)

b) shift locking piston (B)

in direction of arrow

c) Turn the crank until the

ruler (D) has reached the

calculated rake numeral

on the graduation (C).

d) Shift locking piston(B)

back and secure

spring pin (A).

26

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

6.0. Before Operation

6.4. Adjusting the GREENS TERRA SPIKE

2)Release the stop-motion device

of the trailing cylinder, for

this end plug the pin (A) into

the hole(C).

3)Lower the GREENS TERRA SPIKE

onto a cylinder feeler.

4)Put the GREENS TERRA SPIKE

into a vertical position,

for this end:

• release the lock nut (D)

• adjust through the crank (E)

ADJUSTMENT:

the front edge (V) must be

placed vertically

• draw up the lock nut (D)

of the above pull rod.

5)The hoeing effect of the

tools in the ground is

achieved by the crank (G)

and the spindle (H).

We recommend using a

position from 0 to 15.

① Position 0

② Position 5

③ Position 10

④ Position 15

6)For working with hollow

tines we recommend putting

the trailing cylinder upright;

for this end:

x Raise the GREENS TERRA SPIKE

Lift off the trailing cylinder

x

by hand

x Release pin (A) and plug it

into the lowest hole of

the adjusting strap (F).

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

27

6.0. Before Operation

6.5. Setting the number of holes

NOTE

The number of holes (per

tine and minute) depends on:

The speed of the tractor‘s

x

power take-off shaft,

The chosen gear speed,

x

(lever (A) in gear

speed III in photo).

For 20mm (3/4“9 or 25 mm (1“)

tines use gear I and II only!

If the hole distance is

too small:

Increase the driving

x

speed, or

x Decrease the speed of the

power take-off shaft.

If the hole distance is too wide:

x Lower driving speed or

x raise up PTO shaft.

Speed of power take-off = number of holes per tine:

Gear speed

Speed of Power Take-off Shaft (rpm)

300 350 400 450 500 540

I 97 113 130 146 162 175

II 129 150 172 193 215 232

III 161 188 215 242 269 290

28

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

6.0. Before Operation

6.5.1. Setting the hole distance

The hole distances depend on:

x the speed of the power take-off shaft and,

x the driving speed.

Driving speed

schwindigkeit 0,5 1,0 1,5 2,0 2,5

mile/hour 0.3 0.6 0.9 1.2 1.6

Speed of

power take-off

shaft

300 rpm

350 rpm

400 rpm

450 rpm

500 rpm

540 rpm

Gear Speed Gear Speed Gear Seed Gear Speed Gear Speed

I II III I II III I II III I II III I II III

84 64 52 168 128 105 259 192 157 336 256 210 431 321 262

73 55 45 146 110 90 221 165 135 292 220 180 336 276 225

65 48 39 130 96 79 193 146 118 260 192 158 322 242 196

57 43 35 114 86 70 171 129 105 228 172 140 285 214 175

51 38 31 102 76 63 154 116 94 204 152 126 257 192 157

47 36 29 94 72 58 143 107 87 188 144 116 238 179 145

Advice for setting an even hole distance.

Typ Hole distance Speed off power

take-off shaft

Gear speed Speed of

forward drive

km/h mile/hour

110 540 U/min I 1.15 0.71

G6 / 135

110 540 U/min II 1.53 0.95

110 540 U/min II 1.91 1.19

130 540 U/min I 1.36 0.85

G6 / 135

130 540 U/min II 1.81 1.12

130 540 U/min III 2.26 1.40

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

29

7.1. General

ATTENTION !

The user of GREENS

TERRA SPIKE is responsible

for persons inside the

working area.

Never operate the GREENS

TERRA SPIKE without its

safety devices. If you

operate the GREENS TERRA

SPIKE without safety

devices, you expose

yourself and others to

extreme danger.

Always check the immediate

surroundings when starting

to drive (CHILDREN!).

Do not drive backwards when

the GREENS TERRA SPIKE is

operating. Avoid big changes

in direction while using

yielding tractors.

7.0. Operation

Operating with closed hood

only.

Check if the hood is secured

on both sides by fastener.

The power take-off shaft:

never switch on when the

x

motor is switched off

always switch off, when

x

it is not required,

always switch off, before

x

you lift up the

GREENS TERRA SPIKE

STOP

30

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

7.0. Operation

7.2. Correct sequence for engaging

NOTE:

Only lower the lifted

GREENS TERRA SPIKE:

xon the area you want to

work and

xonly switch on the drive

of the power take-off

shaft just before

touching the ground.

Sequence:

1. Lower GREENS TERRA

SPIKE close to ground.

2. Switch on PTO.

3. Lower GREENS TERRA

SPIKE completely.

7.3. Malfunctions and remedies

Description Cause Remedy

GREENS TERRA SPIKE

makes knocking

noises

GREENS TERRA SPIKE

ƎjumpsƎ

GREENS TERRA SPIKE

does not operate

although PTO shaft is

running.

Slotted holes form

during work.

Sod is torn out. Not enough roots in

Speed of power

take-off shaft

is too high.

The ground is too

hard or too dry.

Stones in the ground.

Gear speed at gear

unit is not correct.

The ground is too

wet.

The driving speed

might be too high.

the lawn.

Reduce speed of power

take-off shaft or

choose lower gear

speed.

Reduce working depth.

Work ground several

times at several

working cycles.

Check the gear speed

at the gear unit.

Wait until ground is

dry enough to be

worked.

Reduce driving speed.

Mount a pressure

pad (additional

equiment).

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

31

8.1. General

8.0 Maintenance

ATTENTION

Only perform maintenance work

when the GREENS TERRA SPIKE

is mounted. Switch off

the tractor and secure it

against unintentional

ignition.

Immedediately switch off the

GREENS TERRA SPIKE in case of

8.2. Maintenance and inspection list

Operating

hours

x Check tools for tight

fit

3

x Check bolts and screws

for tight fit

All covers See chapter ”Safety”

8

x Check bearing for leaks

x Check oil level in gear

unit

Check Procedure

malfunctions, heavy wear,

unusual noises or danger.

After the maintenance, remove

all parts not belonging to

the GREENS TERRA SPIKE. Then

mount all covers. (See

chapter ”Safety” point 1.2.)

Check the tools

Retighten screws, if

required

Optical control

x See points for manual

Lubricate

Lubrication 8.3

Check gear unit,

clutch, PTO, etc.

Check for noises

see seperate OI

Check PTO for lubrication See separate OI

40 Check tools for cleanness Clean

Check guides for

Optical control

cleanness and lubrication

See points for manual

Lubricate

lubrication 8,3

100

Check for wear and

x

cleanness

Tighten screws or

replace parts, if

required

600 Change oil in gear unit See lubrication

point 8.3

Lubrication

See points for manual lubrication 8.3

in general

32

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

8.3. Lubrication

8.0 Maintenance

x Switch off the machine for

all lubrication work.

x Lubricate more often, if

required, (Until all

lubrication points are

lubricated).

x If you refill oil, always

use the same type of oil.

x Keep all exposed machine

parts, threaded spindles,

and guides slightly

lubricated.

Points for manual lubrication

See figures.

The figures only show one of

several corresponding assembly

groups with lubrication points.

x Clean grease nipple before

lubricating it.

x Clean up leaking grease.

x Before starting the machine

after a longer standstill,

lubricate and maintain the

entire machine.

W

D

A

L

Y

E

E

I

K

L

Y

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

33

8.0 Maintenance

8.4. Cleaning GREENS TERRA SPIKE

Clean the GREENS TERRA SPIKE

regularly. You then prolong

the service life of expensive

components and simultaneously

detect:

x Loose components

x Damaged cables or lines

x Wear and unintended collision

points.

NOTE:

Do not bring plastic and

sealing elements in contact

with aggressive liquids

(e.g. carbon tetrachloride,

tri, benzen, caustic solutions,.

Acids etc.).

Bind drops of oil with a

binding agent and dispose

of it according to the

regulations. Eliminate the

cause.

Only use wire brush and

caustic solutions in case

of emengency.

Auxiliaries and application

Cleaning with water

x All dirty parts, but remember that water

causes rust.

Cleaning with dry cloth

x All sight glasses, signs

and labels.

Cleaning with compressed air

ATTENTION

Attention when you use

compressed air. Put on safety

glasses! Without safety

glasses you risk eye injuries!

Furthermore you blow dirt into

the guides and bearings.

For this reason, try to avoid

this cleaning method..

34

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

8.0 Maintenance

8.5. Changing the oil of the gear unit

x Place the collecting trough

beneath drain screw (A).

x Remove the drainscrew (A)

x When the gear unit is empty,

insert the drain screw and

tighten it.

Remove the exhaust filter

x

and the fuel level plunger(E}.

Insert the funnel into the

x

opening Ļ .

x Add the required amount

of oil.

x Insert the screw (E) and

tighten.

Type Amount of

G6 / 135

G6 / 160

8.6. Replacing the buffers

ATTENTION

Tine holders are under

spring-tension. Risk of

injuries caused by

backwards swinging tines.

1. Swing tine holder (A)

by hand up to stop,

2. remove the screw(B),

3. replace the buffer (C),

4. tighten the screw (B),

5. Swing back tine

holder (A) carefully

to working position.

(0.8 US.gal.)

oil

3.0 liters

Type

of oil

SAE 90

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

35

8.0 Maintenance

8.7. Setting cleaner

Adjust cleaner at front

and rear roller.

Cleaner should be set

with a clearance of

1 mm to the roller.

8.8. Care and maintenance of the

hydraulic system

The hydraulic system is

-

under high pressure!

When looking for leaks use

-

proper devices to avoid

risk of injury!

To work on the hydraulic

-

system it is imperative to

switch off the motor and

secure the tractor against

rolling away!

When connecting hydraulic

-

cylinders and motors,

attention must be paid to

the prescribed hydraulic

tubes’ connection!

- When exchanging the

connections the functions

will be inversed (f.

raising/lowering)

ACCIDENT!-

–RISK OF

Periodically review the

-

hydraulic tubes conditions

for damages or aging and

change them if necessary!

High-pressure fluids,

-

(fuel, hydraulic oil)

emerging under high

pressure can penetrate the

skin causing severe

injuries. Therefore

immediately contact a

physician, otherwise severe

infections can be caused.

Oils, fuels and filter must

-

be duly cleared!

- Be careful rakking hot oil

off

-

–RISK OF BURNING!-

36

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

8.0 Maintenance

8.9. Dismounting / Disposal

ATTENTION !

Take care when you dismount the

GREENS TERRA SPIKE. Read the

chapter "Safety and Precautions"

and observe local safety

regulations.

The following dangers exist:

-

Residual pressure in lines

and adjusting elements,

- Heavy parts might fall

down after dismounting,

-

Sharp edges,

-

The machine might

tilt and crush someone.

Dismouting for disposal

1. Place the GREENS TERRA SPIKE

on stable ground.

2. Remove the oil of the gear

unit and dispose of it.

3. Disassemble GREENS TERRA

SPIKE from the top downwards.

NOTE

Strictly observe the regulations

and laws concerning the disposal

of environmentally hazardous

substances. Get detailed

information about their disposal.

8.10. Unauthorized modification and spare part manufacturing

x Modification of the

GREENS TERRA SPIKE is only

allowed with the permission

of the manufacturer!

x

Original spare parts and

accessories authorized by

the manufacturer guarantee

your safety. The use of other

parts might change the

characteristics of the

GREENS TERRA SPIKE. In this

case we do not accept any

liability. Place contact us.

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

37

9.1. Set of tines

9.0. Additional Equipment

G6/135 G6/160

* Set of tines 8x160mm[5/16“x6“](24 pcs)

*

Set of tines 12x275mm[1/2“x11“](24 pcs)

Set of tines 20x220mm[3/4“x9“](12 pcs) X X

Set of tines 20x275mm[5/8“x7“](12 pcs) X X

* Set of hollow tines 16x190mm

[5/8“x7“](24 pcs)

* Set of hollow tines 20x190mm

[3/4“x7“](24 pcs)

Set of hollow tines 25x200mm

[1“x10“](12 pcs)

NOTE

* recommended to work with

turf retainer.

9.2. Option

X X

X X

X X

X X

X X

G6/135 G6/160

Turf retainer for tines dia 8 and 12 mm

X

[5/16“ and 1/2“]

Turf retainer for tines dia 20 and 25 mm

X

[3/4“ and 1“]

Turf retainer for tines dia 8 and 12 mm

X

[5/16“ and 1/2“]

Turf retainer for tines dia 20 and 25 mm

X

[3/4“ and 1“]

Multi tine holder w/o tines X X

Rotary brush for sand dragging X

Rotary brush for sand dragging X

TERRA TRONIK

X X

Compl. With wiring and installation sheet

Set of lower pull rod connection long X

Set of tools thatching blades X X

38

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

39

10.1. Technical details

H

C

D

10.0. Specifications

E

B

A

K

L

G

F

434.47

40

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

10.1. Technical details

10.0. Specifications

G6 / 135 G6 /160

Height up to connection of lower guide

A

rod (standard version)

Height up to connection of lower guide

B

rod (long version)

Height up to middle of connection of

C

upper guide rod

Height up to connection mm(in.) 700(28) 700(28)

D

Machine length, back roll included mm(in.) 1070(42) 1070(42)

E

Machine width, hoop guard included mm(in.) 1820(72) 2060(72)

F

Frame width mm(in.) 1460(57) 1700(57)

G

Machine height in parking position mm(in.) 1340(53) 1340(53)

H

Diameter of front roller mm(in.) 170(7) 170(7)

K

Diameter of back roller mm(in.) 140(6) 140(6)

L

Distance between mid guide rod connector

and front end power take-off shaft

Working width mm(in.) 1320(52) 1560(61)

Weight kg(lb.) 535(1179) 635(1399)

Max. tine length mm(in.) 275(11) 275(11)

mm(in.) 450(18) 450(18)

mm(in.) 475(19) 475(19)

mm(in.) 970(38) 970(38)

mm(in.) 0(0) 0(0)

Max. working depth, tines included mm(in.) 275(11) 275(11)

Max. working depth, hollow tines included mm(in.) 150(6) 150(6)

Min. power required for tractor KW

(HS)

Min. lifting power at lower guide rod

(standard version)

Step of power take-off shaft tractor rpm 540 540

N 9300 10000

15

(20)

15

(20)

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

41

10.0. Specifications

10.2. Speed of the Power Take-off Shaft

Speed of power take-off = number of holes per tine:

Gear Speed

Speed of Power Take-off Shaft (rpm)

300 350 400 450 500 540

I 97 113 130 146 162 175

II 129 150 172 193 215 232

III 161 188 215 242 269 290

10.3. The hole Distances (Standard Values, in mm)

The hole distances depend on :

The speed of the power take-off shaft and,

-

the driving speed.

-

Driving Speed

km/h

0.5 1.0 1.5 2.2 2.5

mile/hour 0.3 0.6 0.9 1.2 1.

Speed of

Gear Speed Gear Speed Gear Speed

power take-off

shaft

300 rpm

350 rpm

400 rpm

450 rpm

I II III I II III I II III I II III I II III

84 64 52 168 128 105 259 192 157 336 256 210 431 321 262

73 55 45 146 110 90 221 165 135 292 220 180 336 276 225

65 48 39 130 96 79 193 146 118 260 192 158 322 242 196

57 43 35 114 86 70 171 129 105 228 172 140 285 214 175

Gear Speed

Gear Speed

500 rpm

540 rpm

42

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

51 38 31 102 76 63 154 116 94 204 152 126 257 192 157

47 36 29 94 72 58 143 107 87 188 144 116 238 179 145

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

10.0. Specifications

10.4. Metric bolt and cap screw torque values

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

43

10.0. Specifications

10.5. Serial number

Record product identification

number (serial no.) in the space

provided below. Always quote

this number when ordering

spare parts or making

warranty claims.

Product Identification Number:....................

44

Alle Informationen, Abbildungen und technische Angaben in dieser Publikation entsprechen dem neuesten Stand zum Zeitpunkt der

Veröffentlichung. Konstruktionsänderungen jederzeit und ohne Bekanntgabe vorbehalten.

Loading...

Loading...