Wiedenmann Combi Clean 2350 Original Operating Instructions

Wiedenmann

Translation of original

Operating

Instructions

Sweeper

Combi Clean 2350

2350.002

Stand : August 2005

2350 99 01

Wiedenmann GmbH - D 89192 Rammingen

Tel. No.: +49 7345 / 953-02 Fax No.: +49 7345 / 953 233

EC-Declaration of Conformity

We

Wiedenmann GmbH

Am Bahnhof

89192 Rammingen

declare under our sole responsibility, that the product

Sweeper Combi Clean

Typ 2352 / 2353 / 2354

to which this declaration relates corresponds to the relevant basic safety and

health requirements of the Directive 98/37/EG.

Rammingen, the 27. July 2004 Peter Rischar

Technical Service

(Place and date of issue) (Name, function and signature

of authorised person)

NOTE: The conformity statement is no longer valid if changes are made to the

equipment that have not been agreed with the manufacturer.

2

All information, illustrations and technical specifications in this publication correspond to the latest version as per the time of

publishing. Constructions and designs are subject to modifications without prior notice.

Introduction

READ THIS MANUAL carefully to learn how to operate and service

your machine correctly Failure to do could result in personal

injury or equipment damage. This manual and safety signs on your

machine may also be avaiable in other languages (see yourdealer

to order).

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your machine

and should remain with the machine when you sell it.

MEASUREMENTS in this manual are given in both metric and customary

U.S. unit equivalents. Use only correct repacement parts and

fasteners. Metric and inch fasteners may require a specific

metric or inch wrench.

RIGHT - HAND AND LEFT - HAND sides are determined by facing the

direction the implement will travel when going forward.

WRITE PRODUCT IDENTIFICATION NUMBERS (P.I.N.) in the Specification

or Identification Numbers section. Accurately record all the

numbers to help in tracing the machine should it be stolen. Your

dealer also needs these numbers when you order parts. File the

identification numbers in a secure place off the machine.

BEFORE DELIVERING THIS MACHINE, your dealer performed a predlivery

inspection to ensure best performance.

THIS MACHINE IS DESIGNED EXCLUSIVELY for regular employment in the

maintenance of roads and grassy areas (“SPECIFIED USE“).

Use in any other way is considered as contrary to the intended

use. The manufacturer accepts no liability for damage or injury

resulting from this misuse, and these risks must be borne solely

by the user. Compliance with and strict adherence to the

conditions of operation, service and repair as specified by the

manufacturer also constitute essential elements for the intended

use.

THIS MACHINE SHOULD BE OPERATED, serviced and repaired only by

persons familiar with all ist particular characteristics and

acquainted with the relevant safety rules (accident prevention)

The accident prevention regulation, all other generally

recognized regulations on safety and occupational medicine and

the road traffic regulations must be observed at all times.

Any arbitrary modifications carried out on this material

collection system will relieve the manufacturer of all liability

for any resulting damage or injury.

All information, illustrations and technical specifications in this publication correspond to the latest version as per the time of

publishing. Constructions and designs are subject to modifications without prior notice.

3

C O N T E N T S Page

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

1.0. Safety Measure 5-9

1.1. Safety Label........................................................................................ 10-11

1.2. Safety Directions.................................................................................. 12

2.0. Connecting 13-17

2.1. General............................................................................................... 13

2.2. Installation with standard three-point linkage CAT.1……......................... 13

2.3.

2.4. Extension for standard three-point linkage and triangular coupling........... 15

2.5. Etting cylinder broom............................................................................ 15

2.6. Direction of rotation of cylinder broom.................................................... 16

2.7. Support leg.......................................................................................... 16

2.8. Connecting the hydraulics..................................................................... 16

2.9.

3.0. Disconnecting 18-19

3.1.

3.2. Support leg.......................................................................................... 18

3.3. Dismantling with standard three-point linkage cat.1................................. 19

3.4. Dismantling

Mounting Using the Coupling Triangle

Cardan shaft adjustment....................................................................... 17

General............................................................................................... 18

with Coupling Triangle

................................................ 14

...................................................... 19

4.0. Operating 20-21

4.1. General............................................................................................... 20

4.2. Installation of the side mounting............................................................ 20

4.3. Installation of dirt container................................................................... 21

4.4. Installing lateral broom............................................................................. 21

5.0. Operation 22-24

5.1. General............................................................................................... 22

5.2. Working with the sweeping machine...................................................... 22

5.3. Working speed..................................................................................... 23

5.4. V-belt drive.......................................................................................... 23

5.5. Changing speed of driving motor........................................................... 23

5.6.

5.7.

Switching off lateral broom drive............................................................ 24

Switching on lateral broom drive............................................................ 24

6.0. Maintenance 25-30

6.1.

6.2.

General............................................................................................... 25

Changing the cylinder broom................................................................. 25

6.3. Cleaning.............................................................................................. 26

6.4. Check and tension the drive V-belts....................................................... 26

6.5. Lubrication points................................................................................. 27+28

6.6. Hydraulic installation............................................................................. 29

6.7. Dismounting/Disposal........................................................................... 30

6.8. Modification......................................................................................... 30

7.0. Device combinations

7.1. Versions.............................................................................................. 31

8.0. Additional equipment

7.2. Accessories......................................................................................... 32

9.0. Technical specifications...................................................................................... 33-40

4

All information, illustrations and technical specifications in this publication correspond to the latest version as per the time of

publishing. Constructions and designs are subject to modifications without prior notice.

Recognize safety information

This is the safety-alert symbol.

When you see this symbol on your

machine or in this manual, be

alert to the potential for

personal injury.

Follow recommended precautions

and safe operating practices.

Follow safety instuctions

Carefully read all safety

messages in this manual and on

your machine safety sings. Keep

safety sings in good condition.

Replace missing or damaged safety

sings. Be sure new equipment

components and repair pqarts

include the curret safety sings.

Replacement safety sings are

available from your dealer.

1.0. Safety

Learn how to operate the machine

and to use controls properly. Do

not let anyone operate without

instruction.

Keep your machine in proper

working condition. Unauthorized

modifications to the machine may

impair the fuction and/or safety

and afect machine life.

If you do not understand any part

of this manual and need assistance,

contact your dealer.

All information, illustrations and technical specifications in this publication correspond to the latest version as per the time of

publishing. Constructions and designs are subject to modifications without prior notice.

5

Observe road traffic regulations

Always observe llocal road traffic

regulations when using public roads.

Wear protective clothing

Wear close fitting clothing and

safety equipment appropriate to

the job.

Prolonged exposure to loud noise

can cause impairment or loss of

hearing.

Wear a suitable hearing

protective device such as

earmuffs or earplugs to protect

against objectionable or

uncomfortable loud noises.

1.0. Safety

Operating equipment safety

requires the full attention of

the operator. Deo not wear radio

or music headphones while

operating machine.

Stay clear of rotating drivelines

Entanglement in rotating

driveline can cause serious

injury or death.

Keep tractor master shield and

driveline shields in place at

all times. Make sure rotating

shields turn freely.

Wear close fitting clothing.

Stop the engine and be sure PTO

driveline is stopped before

making adjustments,

connections, or cleaning out

PTO driven equipment.

6

All information, illustrations and technical specifications in this publication correspond to the latest version as per the time of

publishing. Constructions and designs are subject to modifications without prior notice.

Guard and shields

Keep guards and shields in

place all the times. Ensure

that they are in good condition

and installedcorrectly.

Always disengage the driveline,

shut off engine and remove key

before removing any guards or

shields.

Avoid high - pressure fluids

Escaping fluid under pressure

can penetrate the skin causing

serious injury.

Avoid the hazard by relieving

pressure before disconnecting

hydraulic or other lines.

Tighten all connections before

applying pressure.

1.0. Safety

Search for leaks with a piece

of cardboard. Protect hands and

body from high pressure fluids.

If an accident occurs, see a

doctor immediately. Any fluid

injected into the skin must be

surgically removed within a few

hours or gangrene may result.

Doctors unfamiliar with this

type of injury should reference

a knowledgeable medical source.

All information, illustrations and technical specifications in this publication correspond to the latest version as per the time of

publishing. Constructions and designs are subject to modifications without prior notice.

7

1.0. Safety

Keep hands, feet and clothing away

from moving parts.Use safety lights and devices

Prevent collisions between

other road users, slow moving

tractors with attachments or

towed equipment, and selfpropelled machines on public

roads. Frequently check for

traffic from the rear,

especially in turns, and use

hand signals or turn signal

lights.

Use headlights, flashing

warning lights, and turn

signals day and night. Follow

local regulations for equipment

lighting and marking. Keep

lighting and marking visible

and in good working order.

Replace or repair lighting and

marking that has been damaged

or lost. An implement safety

lighting kit is available from

your dealer.

Avoid heating near pressurized

fluid lines

Flammable spray can be

generated by heating near

pressurized fluid lines,

resulting in severe burns to

yourself and bystanders. Do not

heat by welding,

soldering,using a torch near

pressurized fluid lines or

other flammable materials.

Pressurized lines can be

accidentally cut when heat goes

beyond the immediate flamme

area.

8

All information, illustrations and technical specifications in this publication correspond to the latest version as per the time of

publishing. Constructions and designs are subject to modifications without prior notice.

Remove paint before welding or heating

Avoid potentially toxic fumes

and dust.

Hazardous fumes can be

generated when paint is heated

by welding, soldering, or using

a torch.

Do all work outside or in a

well ventilated area. Dispose

of paint and solvent properly.

Remove paint before welding or

heatingh:

• If you sand or grind paint,

avoid breathing the dust.

Wear an approved respirator.

• If you use solvent or paint

stipper with soap and water

before welding. Remove

solvent or paint stripper

containers and other

flammable material from area.

Allow fumes to disperse at

least 15 minutes before

welding or heating.

1.0. Safety

All information, illustrations and technical specifications in this publication correspond to the latest version as per the time of

publishing. Constructions and designs are subject to modifications without prior notice.

9

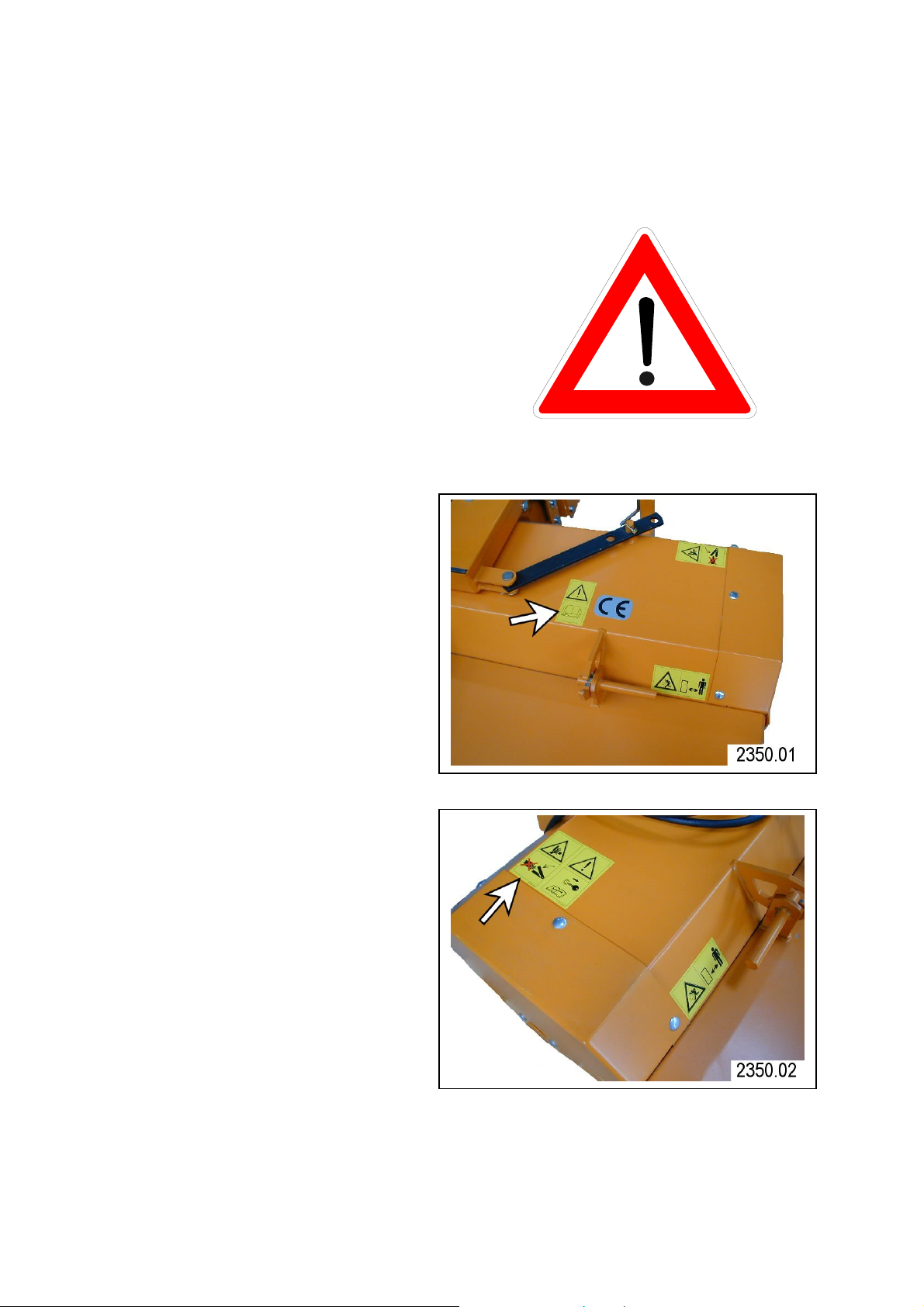

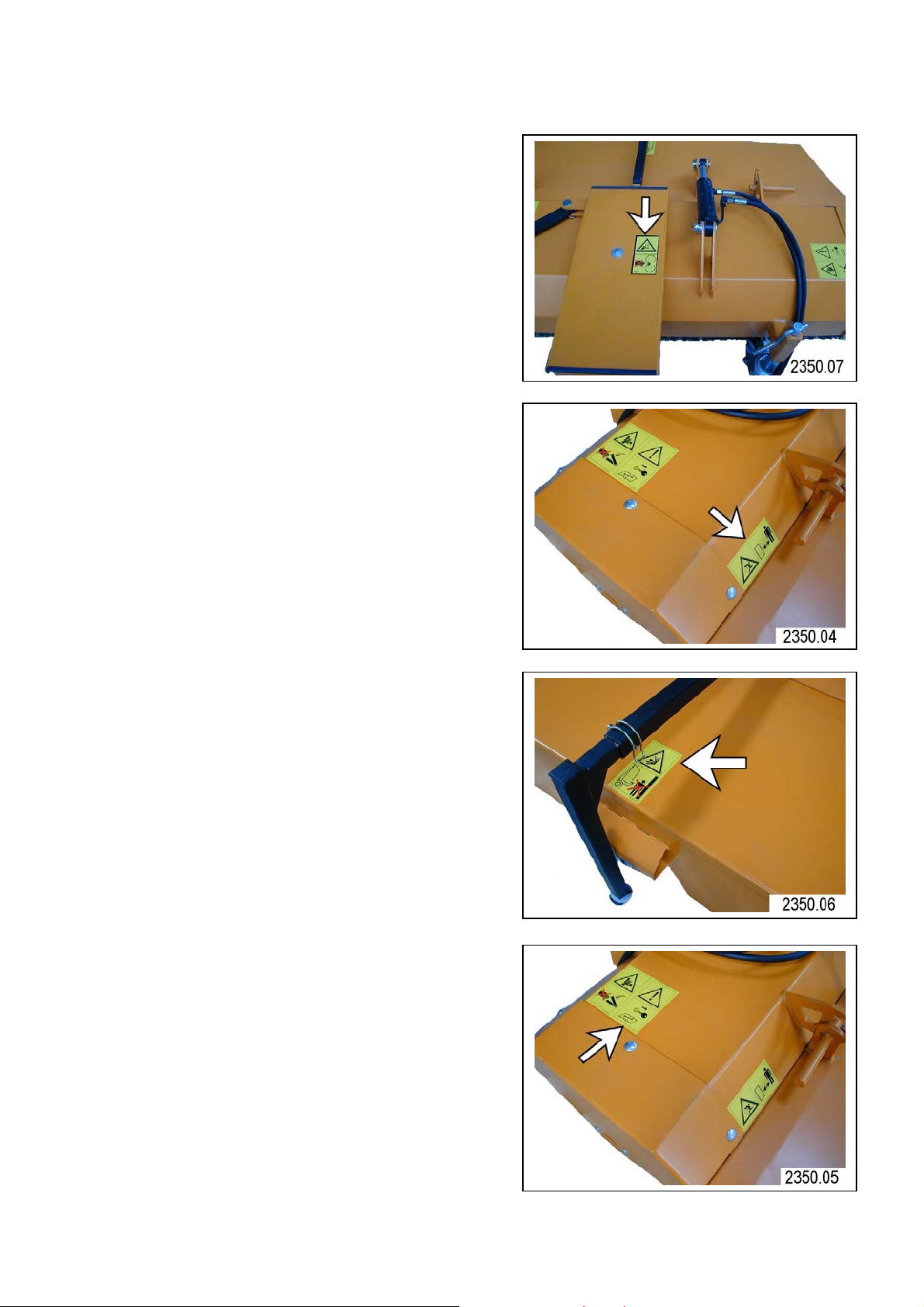

1.1. Safety Decals

Pictorial safety sings

At several important places

of this machine safety sings

are affixed intendent to

signify potenial danger. The

hazard is identified by a

pictorial in a warning

triangle. An adjacent

pictorial provides information

how to avoid personal injury.

These safety sings, their

placement on the nachine and

a brief explanatory text are

shown below.

Operator’ manual

This operator’s manual

containsall important

information necessary for

safe machine operation.

Carefully observe all

safety rules to avoid

accidents.

Protectors

Never reach into areas of

crushing hazard as long

as any parts may move.

1.0. Safety

10

All information, illustrations and technical specifications in this publication correspond to the latest version as per the time of

publishing. Constructions and designs are subject to modifications without prior notice.

1.1. Safety Decals

Avoiding injury from rotating blade

When the engine is running,

keep a safe distance from

the mowing blades.

Tools

When operating ensure that

sufficient distance is left as

there is a risk of injury from

thrown or flying objects.

Container opening

When the tractor engine is

running, stay clear of the

swivel area of the container

Service

Before performing service

or repair work, turn off

engine and remove key.

1.0. Safety

All information, illustrations and technical specifications in this publication correspond to the latest version as per the time of

publishing. Constructions and designs are subject to modifications without prior notice.

11

1.2. Safety instructions

1.0. Safety

- Besides the information in

these operating

instructions, please also

observe generally applicable

safety and accidentprevention standards!

- Familiarise yourself with

all equipment and operating

elements and their functions

before starting work. Ensure

that all protective

equipment has been properly

installed. It is too late to

do this when you have

started work!

- During work operation, the

user is responsible for the

safety of third parties!

- During operation on public

highways, the relevant

traffic regulations must be

observed!

- Before moving off, ensure

that the immediate area of

the machine is clear e.g. no

children nearby. Ensure that

your visibility is not

impaired!

- When driving the machine

outside the work area, the

drive should be switched off

and the attachment placed in

transport position.

- In event of malfunctions

(vibrations) or if the

machine runs over a foreign

object, turn off the drive,

switch off the engine (remove

ignition key or spark-plug

connector) and examine the

machine, particularly the

equipment, for damage.

- Damaged equipment must be

replaced.

- When working on the tool,

precautions should be taken

to prevent injury (e.g.

gloves).

- The driving and operational

characteristics of the

tractor may be influenced by

the attachment of the

sweeper. Always adapt your

driving style to match the

terrain and ground

conditions.

- Keep all persons clear of

the danger zone of the

machine!

- Mount the appliance only

when the motor and the power

take-off shaft have been

switched-off.

- Use only cardan shafts

prescribed for the machine

which is being mounted.

12

All information, illustrations and technical specifications in this publication correspond to the latest version as per the time of

publishing. Constructions and designs are subject to modifications without prior notice.

- Before carrying out any

maintenance work, the machine

and the tractor engine must

be switched off.

All protective devices must

be mounted before initial

operation.

Loading...

Loading...