widos ESI 4000 Working Instructions Translation

WIDOS Einsteinstr. 5 Telephone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Telefax +49 (0) 71 52 / 99 39 - 40

E-mail: info@widos.de Internet www.widos.de

Kunststoffschweißtechnik

Working Instructions

Translation

WIDOS ESI 4000

Keep for further use!

Headquarters: D-71254 Ditzingen-Heimerdingen Country court Stuttgart HRB 200973 Managing director: Jürgen Dommer

Product Identification

Type: WIDOS ESI 4000

Kunststoffschweißtechnik

Serial no.: / year of construction:

see type label

Customer’s entries

Inventory no.:

Location:

Order of spare parts and sales service:

Manufacturer’s address WIDOS

W. Dommer Söhne GmbH

Einsteinstr. 5

D-71254 Ditzingen-Heimerdingen

T elephone: +49 (0) 71 52 / 99 39 - 0

Telefax: +49 (0) 71 52 / 99 39 - 40

E-mail: info@widos.de

Subsidiaries

WIDOS

WIDOS GmbH W. Dommer AG

An der Wiesenmühle 15 St. Gallerstr. 93

D-09224 Grüna / Sachsen CH-9201 Gossau

Phone: +49 (0) 3 71 / 8 15 73 - 0 Phone: +41 (0) 79 432 5737

Fax: +49 (0) 3 71 / 8 15 73 - 20

18.07.2013 Working Instructions WIDOS ESI 4000 Page 2 of 37

Introduction

Kunststoffschweißtechnik

Purpose of the document

These working instructions give you information about all important questions which refer to

the construction and the safe working of your machine.

Just as we are, you are obliged to engage in these working instructions, as well.

Not only to run your machine economically but also to avoid damages and injuries.

Should questions arise, contact our advisers in the factory or in our subsidiary companies.

We will help you with pleasure.

According to our interest to continuously improve our products and working instructions, we

kindly ask you to inform us about problems and defects which might appear in practical

experience.

Thank you.

Structure of the working instructions

This manual is arranged in chapters which belong to the different using phases of the machine.

Therefore the searched information can be easily found.

18.07.2013 WIDOS

W. Dommer Söhne GmbH

Einsteinstraße 5

D-71254 Ditzingen-Heimerdingen

All rights reserved

Reprinting only allowed with permission of the corporation.

Any changes subject to technical innovations.

18.07.2013 Working Instructions WIDOS ESI 4000 Page 3 of 37

Contens

1. PRODUCT DESCRIPTION .............................................................................................. 6

1.1. Application and intended use.............................................................................................. 6

1.2. Safety measures ...................................................................................................................6

1.3. Conformity.............................................................................................................................6

1.4. Designation of product.........................................................................................................6

1.5. Technical data.......................................................................................................................7

1.6. Equipment..............................................................................................................................7

1.7. Wear parts .............................................................................................................................7

2. SAFETY RULES .............................................................................................................. 8

2.1. Explication of the different symbols ................................................................................... 8

2.2. Obligations of the operator.................................................................................................. 8

2.3. Obligations of the worker ....................................................................................................8

2.4. Structural modifications on the device ..............................................................................9

Kunststoffschweißtechnik

2.5. Dangers by electrical energy ...............................................................................................9

2.6. Danger of stumbling over the connecting line ..................................................................9

2.7. Danger of combustion at the socket...................................................................................9

2.8. Danger by toxic vapors........................................................................................................ 9

2.9. Warranty and liability..........................................................................................................10

3. FUNCTIONAL DESCRIPTION ...................................................................................... 11

4. INDICATING AND OPERATING ELEMENTS .............................................................. 12

4.1. Overview device ..................................................................................................................12

4.2. Welding device....................................................................................................................13

4.3. Control panel .......................................................................................................................14

5. STARTING AND OPERATING...................................................................................... 15

5.1. Security advice....................................................................................................................15

5.1.1. How to work while using a generator ...............................................................................15

5.1.2. How to work with an extension cable...............................................................................16

5.2. Accessories for data read in / out.....................................................................................16

5.2.1. Authorization card.............................................................................................................16

5.2.2. Bar code reading pen.......................................................................................................16

5.2.3. SD – card and reading device.......................................................................................... 16

5.2.4. USB card reader............................................................................................................... 17

5.3. Pipes and sockets...............................................................................................................17

5.4. How to switch on the machine.......................................................................................... 18

5.5. How to weld w ith the ESI 4000 ..........................................................................................19

5.6. How to weld w ithout fitting bar code................................................................................22

5.7. Error messages ...................................................................................................................24

18.07.2013 Working Instructions WIDOS ESI 4000 Page 4 of 37

Contens

5.8. Enter parameters ................................................................................................................24

5.9. How to change the language.............................................................................................25

5.10. How to change date and time............................................................................................27

5.11. How to change authorization.............................................................................................28

5.12. Traceability–how to activate information and pipe length.............................................29

5.13. How to ask for project name prior to each w elding........................................................ 30

5.14. How to delete the memory.................................................................................................31

5.15. Welding data management ................................................................................................32

5.16. Possible defects and their elimination............................................................................. 32

5.17. Short instruction.................................................................................................................32

6. MAINTENANCE / STORING / TRANSPORT ................................................................ 33

6.1. Cleaning and care...............................................................................................................33

6.2. Transport and storing.........................................................................................................33

Kunststoffschweißtechnik

6.3. Waste management............................................................................................................ 33

7. SPARE PARTS LIST..................................................................................................... 34

8. DECLARATION OF CONFORMITY .............................................................................. 37

18.07.2013 Working Instructions WIDOS ESI 4000 Page 5 of 37

WIDOS Einsteinstr. 5 Telephone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Telefax +49 (0) 71 52 / 99 39 - 40

E-mail: info@widos.de Internet www.widos.de

Kunststoffschweißtechnik

1. Product description

This chapter gives important basic information about the product and its prescribed use.

All technical details of the machine are put together as a general arrangement.

1.1. Application and intended use

The WIDOS ESI 4000 was especially designed for the use on building sites in order to weld

PE and PP pipes with all common socket types on the spot.

Any other use exceeding this is to be considered non-intended.

For damages resulting from it, the manufacturer cannot be held liable.

The risk is exclusively on the user’s side.

Also part of the purpose-oriented use is

respecting all the indications of the working instructions and

performing the inspection and maintenance works.

1.2. Safety measures

In case of wrong use, wrong operation or wrong maintenance the machine itself or products

being in the surrounding can be damaged or destroyed.

Persons being in the endangered area may be injured.

Therefore these working instructions have to be thoroughly read and the corresponding safety

advices must be necessary adhered to.

1.3. Conformity

The machine corresponds in its construction to the valid recommendations of the European

Community as well as to the European standard specifications.

The development, manufacturing and mounting of the machine were made very carefully.

1.4. Designation of product

The product is designated by two signs at the frame.

The type-labels are fixed on the control unit and on the basic machine.

They contain the type of the machine, the serial number, and the year of construction.

18.07.2013 Working Instructions WIDOS ESI 4000 Page 6 of 37

Product description Chapter 1

1.5. Technical data

Weight: 12 kg

Voltage: 230 V

Power: 3.2 kW

Current: 16 A

Frequency: 50 Hz

Size: (WxHxD) 370 x 370 x 260 mm

Length connecting cable: 4 m

Length welding cable: 4 m

Material of base frame: Niro

Packing crate (wood, optional):

Size: (WxHxD) 410 x 450 x 330 mm

Weight: 6.4 kg

Packing case (aluminium, optional):

Size: (WxHxD) 400 x 400 x 300 mm

Weight: 4,5 kg

1.6. Equipment

Kunststoffschweißtechnik

Piece Denomination / Function

1 General authorization card

1 User authorization card

1 Initialization card (optional)

1 Bar code reading pen

2 each Adaptor for Ø 4.7

2 each Adaptor flat (optional)

1 SD-card

1 USB card reader

1.7. Wear parts

Piece Denomination Part-no.

2 Adaptor for Ø 4.7 H WAR 001

2 Adaptor flat (optional) HWAF001

Order numbers and individual parts can be inquired from company WIDOS.

18.07.2013 Working Instructions WIDOS ESI 4000 Page 7 of 37

WIDOS Einsteinstr. 5 Telephone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Telefax +49 (0) 71 52 / 99 39 - 40

E-mail: info@widos.de Internet www.widos.de

Kunststoffschweißtechnik

2. Safety rules

A basic premise for working safely and without disturbances is the knowledge of the basic

safety signs and rules.

These working instructions provide you with the most important information to safely run the

device and the safety information has to be respected by all persons working with the device.

2.1. Explication of the different symbols

The working instructions contain the following signs for certain situations:

This symbol indicates a possibly dangerous situation.

The disrespect of it may result in injuries or damages on device parts.

This symbol gives important indications for the proper use of the device.

The disrespect of this indication may lead to malfunctions and damages on

the machine or on parts in the surrounding.

This symbol indicates a possibly dangerous situation due to hot surfaces.

The disrespect of these indications may lead to heavy burns, respectively to

The regulations for the prevention of accidents are valid (UVV).

ignition or even fire.

This symbol indicates a possible danger due to toxic vapors.

The disrespect of it may lead to hygienic damages.

This symbol means a possible danger of injury by spillings.

It is obligatory to wear safety glasses”

2.2. Obligations of the operator

The owner is obliged to only let persons work at the device who

know about basic safety and accident prevention rules and who are instructed in the

handling of the device

the worker also must have read and understood the safety chapter of this manual and

certify this by his signature.

The safety-conscious working of the staff has to be checked in regular intervals.

2.3. Obligations of the worker

Before working at the machine, all persons in charge of it oblige themselves:

to follow the basic safety and accident protection rules.

to have read and understood the safety chapter and the warnings in this manual and to

confirm by their signature that they have understood well.

to inform themselves about the functions of the device before using it.

18.07.2013 Working Instructions WIDOS ESI 4000 Page 8 of 37

Safety rules Chapter 2

Kunststoffschweißtechnik

2.4. Structural modifications on the device

No modifications, extensions or reconstructions may be made on the machine without

permission of the manufacturer. In case of disrespect the warranty or liability will expire.

Machine parts which are not in a perfect condition are to be immediately replaced.

Only use original WIDOS spare and wear parts.

In case of purchase orders please always indicate the machine number!

2.5. Dangers by electrical energy

Only skilled persons are allowed to work at electric appliances.

The electric equipment of the machine has to be regularly checked.

Loose connections and damaged cables have to be immediately replaced.

The device has to be protected against humidity.

Only qualified WIDOS personnel resp. authorized service partners are allowed

to open the device.

2.6. Danger of stumbling over the connecting line

Pay attention that nobody has to step over the connecting lines (230 V).

2.7. Danger of combustion at the socket

You may burn parts of your body , inflammable materials may ignite! The socket

may get hot!

Do not leave the device unattended.

Do not touch the welded socket before the cooling time has elapsed.

Wear protective gloves.

Wear safety glasses.

Keep sufficient safety distance to inflammable materials.

2.8. Danger by toxic vapors

In unfavorable circumstances, toxic vapors may escape during the welding

process.

Care for good ventilation during welding in closed locations.

Keep sufficient space between machine and the welded joint.

18.07.2013 Working Instructions WIDOS ESI 4000 Page 9 of 37

Safety rules Chapter 2

Kunststoffschweißtechnik

2.9. Warranty and liability

Our „General Sales and Delivery Conditions“ are principally valid.

They are at the owner's disposal at the latest when signing the contract.

Warranty and liability demands referring to damages of persons or objects are suspended if

they are caused by one or several of the following reasons:

not using the machine according to the prescriptions

improper transport, building-up, starting and operating the machine and maintenance

operating the machine with defective or improperly installed safety measures

ignoring the information given in this manual

structural changes at the machine without permission

unsatisfactory checking of machine parts which are worn out

repairs performed in an inexpert way

catastrophes by external influence and Acts of God.

18.07.2013 Working Instructions WIDOS ESI 4000 Page 10 of 37

WIDOS Einsteinstr. 5 Telephone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Telefax +49 (0) 71 52 / 99 39 - 40

E-mail: info@widos.de Internet www.widos.de

Kunststoffschweißtechnik

3. Functional description

The socket welding machine ESI 4000 carries out an electric socket welding process in which

pipes are welded to a fitting.

The prepared pipes are fed into the socket and then aligned and clamped in the clamping tool.

The contacts are plugged to the socket.

The sockets are furnished with a bar code, it will be read in with the bar code reading pen or

manually entered at the machine.

The welding process is started, the welding joint is heated (Heating up), and afterwards the

machine automatically shifts.

The welded pipe cools down without tension. (Cooling down)

The welded pipe can be unclamped, the welding process is completed.

18.07.2013 Working Instructions WIDOS ESI 4000 Page 11 of 37

WIDOS Einsteinstr. 5 Telephone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Telefax +49 (0) 71 52 / 99 39 - 40

E-mail: info@widos.de Internet www.widos.de

Kunststoffschweißtechnik

4. Indicating and operating elements

4.1. Overview device

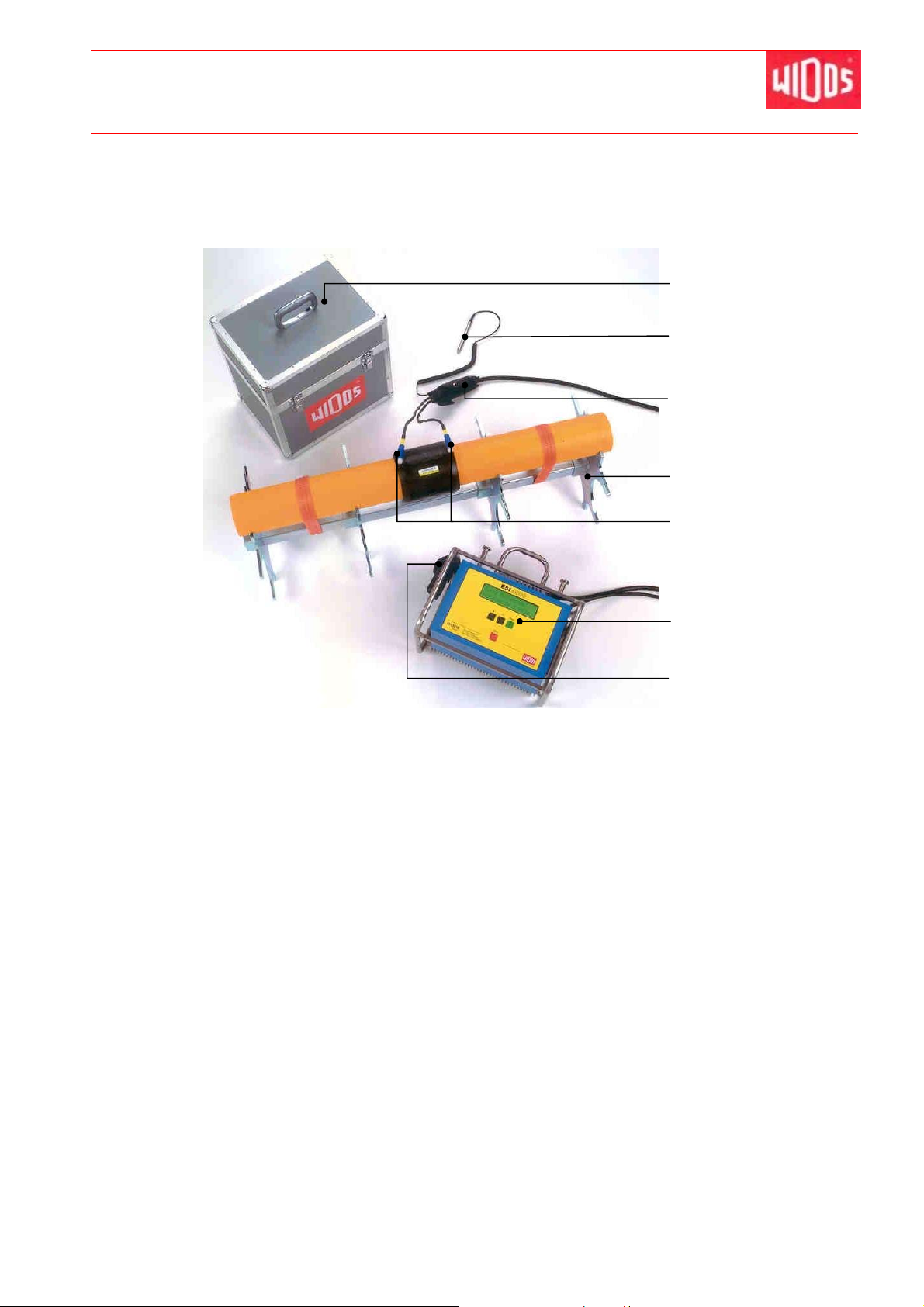

Transport case

Bar code reading pen

Safety bag for bar

code reading pen

Support device with

securing straps

(optional)

Connection plug

Welding device

Bag for adaptors and

authorization cards

18.07.2013 Working Instructions WIDOS ESI 4000 Page 12 of 37

Loading...

Loading...