WIDOS Einsteinstr. 5 Phone +49 / 71 52 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 / 71 52 99 39 - 40

info @ widos.de

www.widos.de

Working instructions

Translation

Heating element-butt welding machine

WIDOS 4001

Kunststoff schweißtechnik

Keep for further use !

Headquarters: D-71254 Ditzingen-Heimerdingen Country court Stuttgart HRB 200973 Managing Director: Jürgen Dommer

Identification of product

Model: Workshop machine

Kunststoff schweißtechnik

Type:

Serial number: / year: see type plate

WIDOS 4001

Customer entries

Inventory- No.:

Location:

Order of spare parts and after sales service

Address of manufacturer WIDOS

W. Dommer Söhne GmbH

Einsteinstr. 5

D - 71254 Ditzingen-Heimerdingen

Phone: +49 / 71 52 - 99 39 - 0

Fax: +49 / 71 52 - 99 39 - 40

E-mail: info@widos.de

Address of subsidiary companies

WIDOS

WIDOS GmbH W. Dommer Söhne AG

An der Wiesenmühle 15 St. Gallerstr. 93

D-09224 Grüna / Sachsen CH – 9201 Gossau

Phone: ++49 371 / 8 15 73 - 0 Phone: ++41 71 / 388 89 79

Fax: ++49 371 / 8 15 73 - 20 Fax: ++41 71 / 388 89 73

25.06.12 Working instructions WIDOS 4001 Page 2 of 59

Introduction

Kunststoff schweißtechnik

Purpose of the document

These working instructions give you information about all important questions which refer to

the construction and the safe working of your machine.

Just as we are, you are obliged to engage in these working instructions, as well.

Not only to run your machine economically but also to avoid damages and injuries.

Should questions arise, contact our advisers in the factory or in our subsidiary companies.

We will help you with pleasure.

According to our interest in making our products and working instructions continuously better,

we kindly ask you to inform us about problems and defects which occur in exercise.

Thank you.

Structure of the working instructions

The working instructions are arranged in chapters, which belong to the different using

phases of the machine.

Therefore the searched information can be found easily.

WIDOS 25.06.2012

W. Dommer Söhne GmbH

Einsteinstraße 5

D-71254 Ditzingen-Heimerdingen

All rights reserved.

Reprinting only allowed with permission of the corporation.

Any changes prior to technical innovations.

25.06.12 Working instructions WIDOS 4001 Page 3 of 59

Contens

Kunststoff schweißtechnik

1. DESCRIPTION OF PRODUCT ...................................................................................... 6

1.1. Mounting and purpose-oriented use ..................................................................................6

1.2. Safety measures....................................................................................................................7

1.3. Conformity .............................................................................................................................7

1.4. Marking of product ...............................................................................................................7

1.4.1.

Technical data ................................................................................................................7

1.4.1.1. WIDOS 4001 general data.......................................................................................7

1.4.1.2. Heating element.........................................................................................................8

1.4.1.3. Planer.........................................................................................................................8

1.4.1.4. Hydraulic aggregate...................................................................................................8

1.4.1.5. Basic unit....................................................................................................................8

1.5. Equipment and accessories: ...............................................................................................9

2. SAFETY RULES .......................................................................................................... 10

2.1. Explanation of the different symbols................................................................................10

2.2. Obligations of the owner....................................................................................................11

2.3. Obligations of the worker...................................................................................................11

2.4. Measure of organization.....................................................................................................11

2.5. Information about safety precautions...............................................................................11

2.6. Instructions for the staff.....................................................................................................11

2.7. Dangers while handling the machine................................................................................12

2.8. Gefahren durch die Hydraulik............................................................................................12

2.9. Special dangers...................................................................................................................12

2.9.1.

Danger of stumbling over hydraulic and electric cables...............................................12

2.9.2.

Danger of being burned at the heating element and at the welding point ....................13

2.9.3.

Danger of clothes being grapped by the planer............................................................13

2.9.4.

Danger of crushing by clamping tools and guide rods .................................................13

2.9.5.

Risk of injury by noise...................................................................................................14

2.10. Structural modifications on the machine .........................................................................14

2.11. Warranty and liability..........................................................................................................14

3. DESCRIPTION OF PROCESS .................................................................................... 15

4. OPERATING AND INDICATING ELEMENTS.............................................................. 16

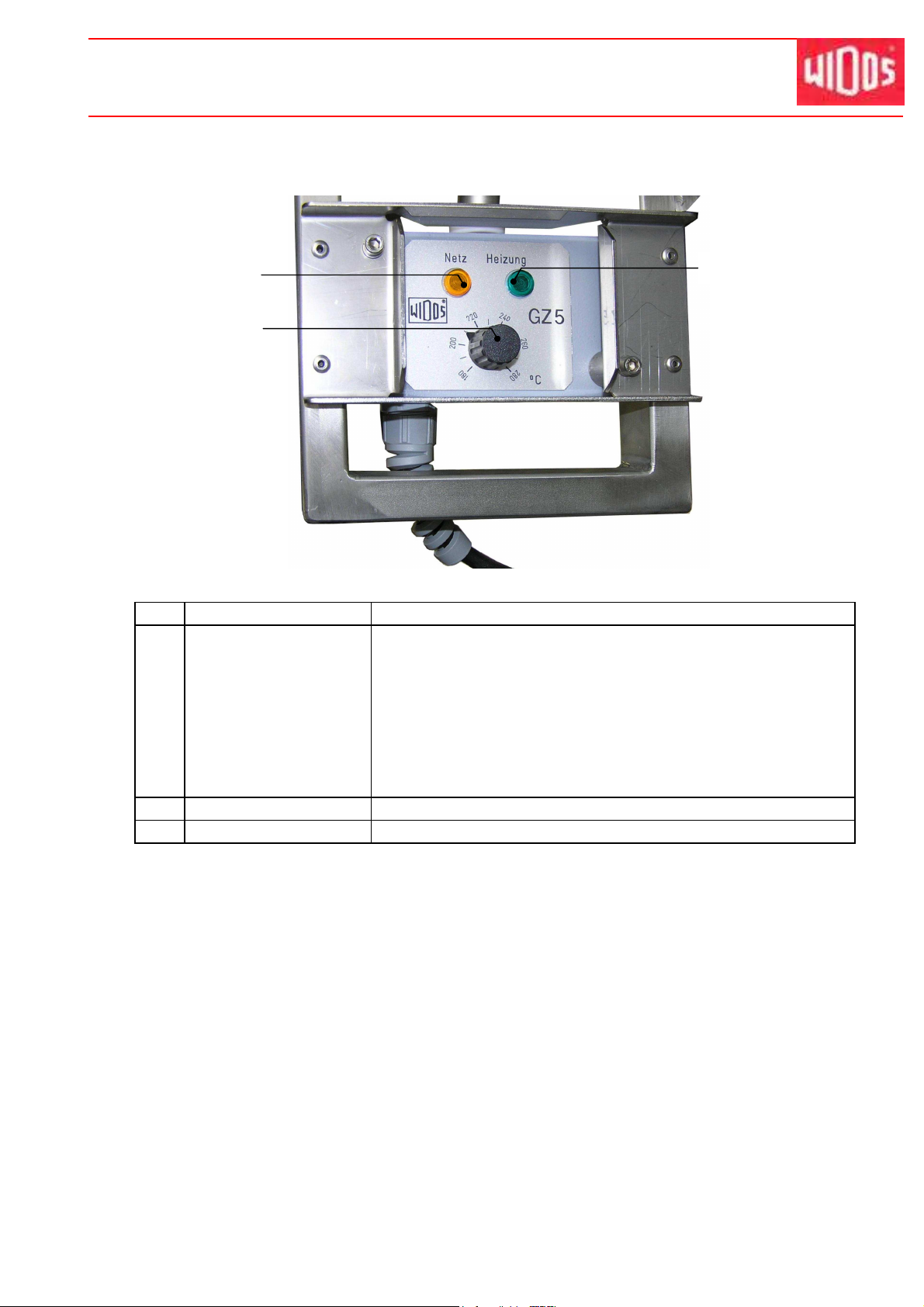

4.1. Elements on the front side.................................................................................................16

4.2. Elements on the right side .................................................................................................17

4.3. Elements on the heating element......................................................................................18

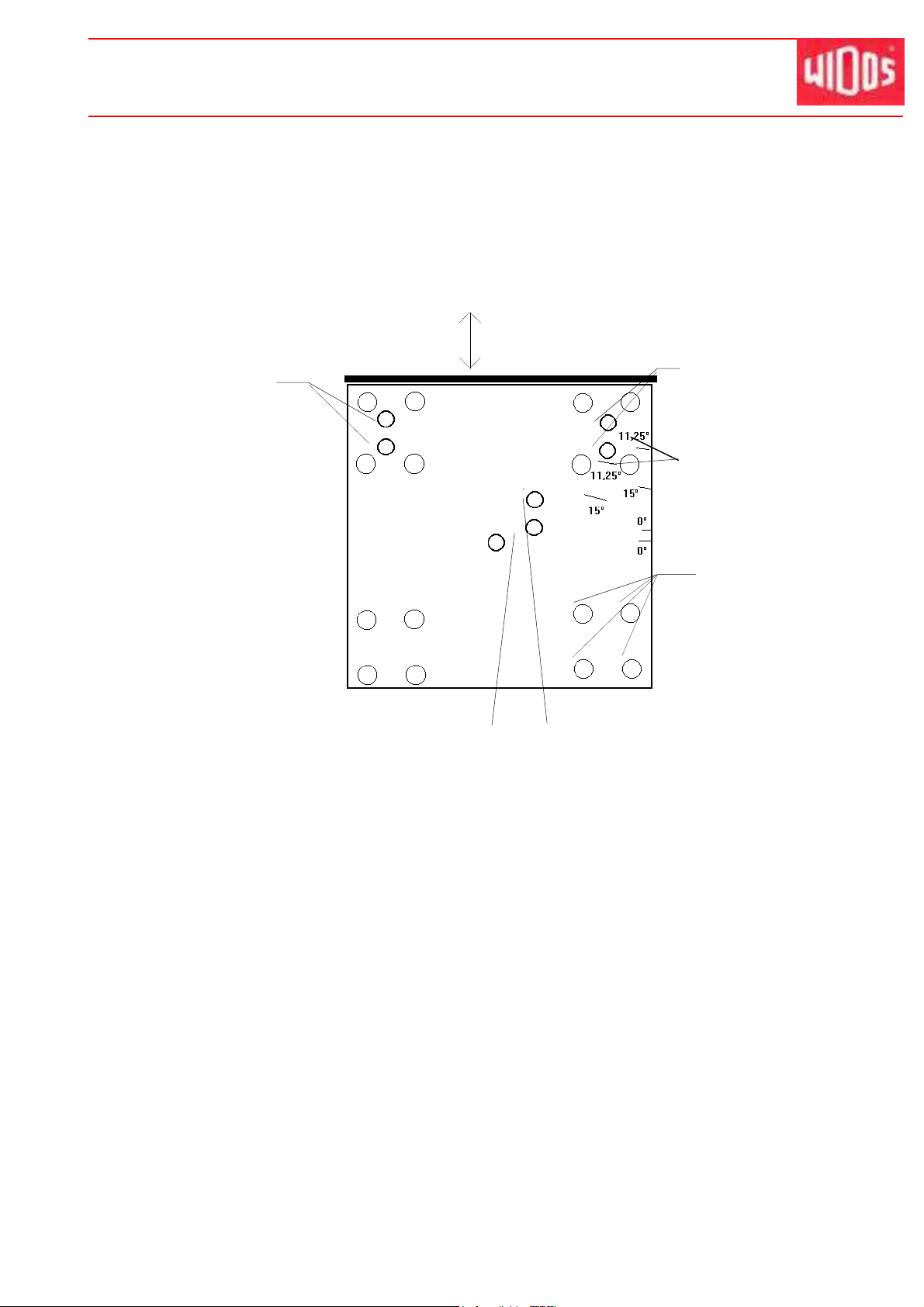

4.4. Wells at the table.................................................................................................................19

5. STARTING AND OPERATING..................................................................................... 20

5.1. Safety indications and Starting .........................................................................................20

5.2. Welding process .................................................................................................................21

5.2.1.

Plane girder for planing only at one side ......................................................................23

25.06.12 Working instructions WIDOS 4001 Page 4 of 59

Contens

Kunststoff schweißtechnik

5.3. Welding logs and tables.....................................................................................................23

5.4. Welding segmented bends ................................................................................................23

5.5. Welding of Cross- and T-pieces ........................................................................................24

6. WELDING LOGS AND TABLES.................................................................................. 26

7. MAINTENANCE AND REPAIR .................................................................................... 31

7.1. Maintenance, Inspection and repair.................................................................................31

7.2. Planer ...................................................................................................................................31

7.3. Checking the level of the hydraulic oil .............................................................................32

7.3.1.

Used hydraulic oil .........................................................................................................32

7.4. Transport .............................................................................................................................32

7.5. Venting the hydraulic cylinders.........................................................................................33

7.6. Clamping elements .............................................................................................................33

7.7. Cleaning of the machine ....................................................................................................33

7.8. Disposal ...............................................................................................................................33

8. WIRING AND HYDRAULIC DIAGRAMS ..................................................................... 34

9. SPARE PARTS LIST ................................................................................................... 37

9.1. Basic machine .....................................................................................................................37

9.2. Clamping tool ......................................................................................................................40

9.3. Planer ...................................................................................................................................42

9.4. Heating element ..................................................................................................................45

9.5. Heating element holder ......................................................................................................47

9.6. Conversion kit for clamping tool.......................................................................................49

9.7. Conversion kit for planer ...................................................................................................51

9.8. Conversion kit for heating element...................................................................................53

9.9. Hydraulic box ......................................................................................................................55

9.10. Plane girder for planing only at one side .........................................................................57

10.

DECLARATION OF CONFORMITY......................................................................... 59

25.06.12 Working instructions WIDOS 4001 Page 5 of 59

WIDOS Einsteinstr. 5 Phone +49 / 71 52 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 / 71 52 99 39 - 40

info @ widos.de

http://www.widos.de

Kunststoff schweißtechnik

1. Description of product

This chapter gives important basic information about the product and its prescribed use.

All technical details of the machine are put together as a general arrangement.

1.1. Mounting and purpose-oriented use

The WIDOS 4001 is a workshop machine and especially designed for the heating element butt

welding of pipes and fittings from Ø = 90 mm - 315 mm (standard diameters are 90 / 110 / 125

/ 140 / 160 / 180 / 200 / 225 / 250 / 280 / 315 mm).

The machine is equipped with an electrohydraulic adjusting device for control and application

of the welding pressure, a planer and a heating element, two transport handles, a basic

clamping device (swivelling on each side up to 15° for the fabrication of segmented bends and

fittings).

For the compensation of diameter tolerances the right-hand clamping tools is axially movable.

Hydraulic unit, planer, heating element and clamping tools can be easily removed for

transporting the machine even into difficulty accessible rooms.

By means of an optional available conversion kit with 2nd cylinder, larger planer and heating

element, even the diameters 355 / 400 and 450 mm can be clamped and welded.

T- and cross pieces up to OD 250 can be welded with an additional special angle clamping

device.

Any other use of this control unit is considered not to be purpose-oriented.

The machine is only to be used in a technically perfect condition, as well as purpose oriented,

safety- and danger-conscious in compliance with the working instructions and the relevant

safety regulations (especially the regulations for the prevention of accidents).

The described plastic welding machine may only be operated, maintained and repaired by

persons who are trained and informed about the dangers.

For personal injuries, material and immaterial damages resulting herefrom, only the user is

responsible!

Also part of the appropriate usage are

•

following all indications of the working instructions and

•

performing the inspection and maintenance works.

25.06.12 Working instructions WIDOS 4001 Page 6 of 59

Description of product Chapter 1

Kunststoff schweißtechnik

1.2. Safety measures

In case of wrong use, wrong operation or wrong maintenance the machine itself or products

being in the surrounding can be damaged or destroyed.

Persons being in the endangered area may be injured.

Therefore these working instructions have to be thouroughly read and the corresponding

safety advices must necessarilly be adhered to.

1.3. Conformity

The machine corresponds in its construction to the valid recommendations of the European

Community as well as to the according European standard specifications.

The development, manufacturing and mounting of the machine were made very carefully.

1.4. Marking of product

The product is marked by a type-plate at the basic machine.

It contains the machine type, the serial number and the year of construction.

1.4.1. Technical data

1.4.1.1. WIDOS 4001 general data

Material: PP; PE 80; PE 100, PVDF

Pipe dimension: Outside-∅ = 90 – 315 mm;

with conversion kit: Outside-∅ = 90 – 450 mm

Total weight (without packing): 285 kg

Fuse protection: 16 A

Power section: 2,5 mm²

Emissions - Noises exceeding 80 dB (A) may occur; during

planing it is obligatory to wear ear protection!

- When using the named plastic materials and

when welding below 260 °C no toxicant damp

arises.

Environmental conditions in the

welding area

- take care for cleanness (no dust at the welding

area)

- if secured by an appropriate measurement that

allowed conditions for welding are indicated, it is

possible to work in any outside temperature

condition as far as the welder is not constrained

in its manual skill.

- avoid humidity, if necessary use a welding tent

- avoid strong sun rays influence

- protect from wind, shut the pipe ends

25.06.12 Working instructions WIDOS 4001 Page 7 of 59

Description of product Chapter 1

1.4.1.2. Heating element

Power: 3,6 kW / 5,4 kW (for conversation kit)

Voltage: 230 V (± 10%) / 400 V (for conversation kit)

Amperage: 16 A (± 10%)

Frequency: 50 Hz

Surface: antisticking coated

Mounted elements: - electronic temperature control

- control lamps

- on/off switch (for conversation kit)

1.4.1.3. Planer

Motor: Monophase universal motor

Power: 1,05 kW / 1,4 kW for conversion kit

Voltage: 230 V (± 10%)

Amperage: 3,8 A / 4,9 A for conversation kit

Frequency: 50 Hz (± 10%)

Gear: Gear ratio: approx. 0,12

Revolutions of planer [1/min] 50 - 70

1.4.1.4. Hydraulic aggregate

Kunststoff schweißtechnik

Power: 300 Watt

Voltage: 230 V (± 10%)

Amperage: 2,7 A

Frequency: 50 Hz

Phase displacement: approx.18°

Hydraulic oil tank: approx. 1 l

Type of protection IP 54

Electric motor and pump:

Engine revolution: 1380 U/min

max. working pump: approx. 250 bar

Working pressure: adjustable up to 250 bar

1.4.1.5. Basic unit

Dimension l x w x h: 1220 x 1000 x 1355 (mm)

Frame material: Constructin steel

Cylinder-∅: 25 mm

Piston rod-∅: 18 mm

max.force (F=P*A) 236 N (at 100 bar)

5,9 kN (at 250 bar)

Moving speed of the piston: approx. 5,6 cm/s

25.06.12 Working instructions WIDOS 4001 Page 8 of 59

Description of product Chapter 1

1.5. Equipment and accessories:

The following tools and accessories are part of the first delivery:

1 Tool bag for 10 parts

1 Socket wrench size 27

1 each Allan key angled size 3 / 6 / 7 / 8

1 each Allan key with T-grip size 4 / 5 / 6

1 Fork wrench size 17 / 19

1 x Plane girder for planing only at one side

1 Screw driver with Torx drive T10

optional different reduction inserts, rollerstands as pipe support, clamping tools

for fabrication of T-pieces

For order numbers and single parts see spare parts list

Kunststoff schweißtechnik

25.06.12 Working instructions WIDOS 4001 Page 9 of 59

WIDOS Einsteinstr. 5 Phone +49 / 71 52 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 / 71 52 99 39 - 40

info @ widos.de

http://www.widos.de

Kunststoff schweißtechnik

2. Safety rules

The basic condition for the safety conscious handling and the fault free operation of this

machine is the knowledge of the basic safety advises and rules.

• These working instructions contain the most important indications for running the machine

according to the safety regulations.

• The safety indications need to be followed by all persons working on the machine.

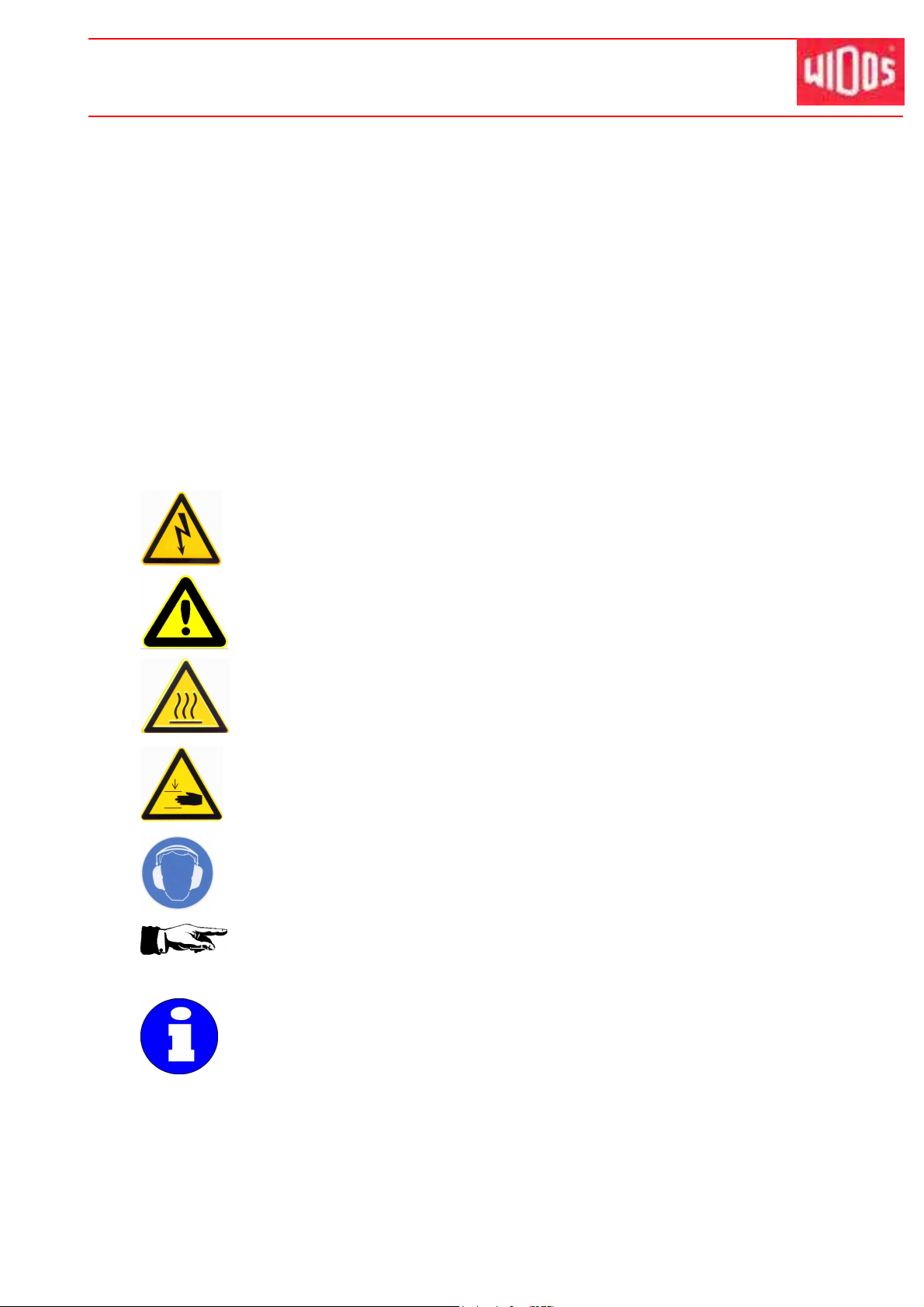

2.1. Explanation of the different symbols

In the working instructions, the following designations and signs are used for potential

dangers:

This symbol means a possibly danger for the life and the health of persons.

• The disrespect of these indications may have heavy consequences for the

health.

This symbol means a possible dangerous situation.

• The disrespect of these indications may cause slight injuries or damages on

goods.

This symbol means a possible dangerous situation due to hot surfaces.

• The disrespect of these indications may conduct to heavy burns,

respectively to self-ignition or even fire.

This symbol means a possible dangerous situation by moving parts of the

machine

• The disrespect of these indications may cause heavy crushing’s of parts of

the body resp. damages of parts of the machine.

This symbol means a possible risk of injury by noise exceeding 80 dB (A).

• Ear protection is obligatory

This symbol gives important indications for the proper use of the machine.

• The disrespect of these indications may conduct to malfunctions and

damages on the machine or on goods in the surrounding.

Under this symbol you get user tips and particularly useful information.

• It is a help in order to use all the functions on your machine in an optimal

way and helps you to make the job easier.

T he ac c id e nt pr e ve n ti o n m e as u re s a r e v al i d ( U VV ) .

25.06.12 Working instructions WIDOS 4001 Page 10 of 59

Safety rules Chapter 2

Kunststoff schweißtechnik

2.2. Obligations of the owner

The owner is obliged only to let persons work at the machine who

• know about basic safety and accident prevention rules and are instructed in the handling of

the machine, as well as who

• have read and understood the safety chapter of this manual and certify this by their

signature.

The safety-conscious working of the staff has to be checked in regular intervals.

2.3.

Obligations of the worker

All persons who are to work at the machine are obliged before working:

• to follow the basic safety and accident protection rules.

• to have read and understood the safety chapter and the warnings in this manual and to

confirm by their signature that they have well understood them.

• to inform themselves about the functions of the machine before using it.

2.4. Measure of organization

• All equipment required for personal safety is to be provided by the owner.

• All available safety equipment is to be inspected regularly.

2.5.

Information about safety precautions

• The working instructions have to be permanently kept at the place of use of the machine.

They are to be at the operator's disposal at any time and without much effort.

• In addition to the manual, the common valid and the local accident protection rules and

regulations for the environmental protection must be available and followed.

• All safety and danger indications on the machine have to be in a clear readable condition.

• Every time the machine changes hands or is being rent to third persons, the working

instructions are to be sent along with and their importance is to be emphasized.

2.6.

Instructions for the staff

• Only skilled and trained persons are allowed to work at the machine.

• It must be clearly defined who is responsible for transport, mounting and dismounting, and

starting the operation.

• A person who is being trained may only work at the machine under supervision of an

experienced person.

25.06.12 Working instructions WIDOS 4001 Page 11 of 59

Safety rules Chapter 2

Kunststoff schweißtechnik

2.7. Dangers while handling the machine

The machine WIDOS 4001 has been constructed according to the latest standards of the

technology and according to the recognized technical rules.

Although, during the operation dangers for the user or for persons standing close as well

as damages for items may occur.

The machine should only be used

• purpose oriented

• in a perfect technical safety condition

Disturbances which may affect the safety of the machine must be cleared immediately.

Only skilled persons are allowed to work at electrical appliances.

• The electrical equipment of the machine has to be checked regularly. Loose connections

and damaged cables have to be replaced immediately.

• Protect the machine from rain and dropping water.

• According to VDE 0100, operation on building sites is only allowed with a current distributor

with FI-security protective switch.

2.8. Gefahren durch die Hydraulik

System sections which have to be opened in case of repair work have to be

depressurized before starting to repair.

There is a danger of hurting your eyes because of a sudden flow compressed

air resp. squirting hydraulic oil. The hydraulic oil can be hot!

• Damaged hydraulic / pneumatic hoses have to be immediately replaced.

• Before starting to work make a visual examination of the hydraulic / pneumatic lines.

• The hydraulic oil is brackish!

The hydraulic oil is to be handled and disposed of in appropriate manner

2.9. Special dangers

2.9.1. Danger of stumbling over hydraulic and electric cables

Pay attention that nobody has to step over the lines.

Favorably pass the lines in order that the danger is minimized.

Do not squeeze and kink the lines or anything likewise.

Avoid the heating-up of hydraulic lines (rise in pressure!).

25.06.12 Working instructions WIDOS 4001 Page 12 of 59

Safety rules Chapter 2

Kunststoff schweißtechnik

2.9.2. Danger of being burned at the heating element and at the welding

point

You can burn yourself, inflammable materials can be ignited.

• The heating element temperature is heated up to more than 200°C!

• Do not leave the machine with heated heating element unsupervised.

• Do not touch the surfaces of the heating element.

• Take enough safety distance to inflammable materials.

• Do wear safety gloves.

• Switch off the heating element after use.

• No third persons should stay inside the range of the moving area of the heating element.

• Swivel and transport the heating element only at the grip.

2.9.3. Danger of clothes being grapped by the planer

System parts and pressure conducts which need to be opened are to be made

pressureless before any kind of repair.

• There is a danger of injuring the eyes by hydraulic oil squirting out.

• Wear tight-fitting clothes.

• Do not wear rings or jewelry during work.

• wear snood-type cap.

• Do not touch the surfaces of the planer.

• Keep away others from the drilling area.

2.9.4. Danger of crushing by clamping tools and guide rods

Heavy injuries can result from crushing:

• upon opening / closing the clamping tools

• upon driving in and out the heating element and planer

• upon opening / closing the slides

• upon mounting the reducer inserts

• Do not touch in-between clamped pipes

• Do not reach between the clamping rings in case the pipes are still to be clamped and in

case you move the clamping tools

• In case of working inside the machine, the mains plug always has to be switched off and

secured against unauthorized activation.

• During the installation of the reducer inserts use a lifting device, do not reach between

reducer insert and clamping tool

• Don’t hinder moving tables.

25.06.12 Working instructions WIDOS 4001 Page 13 of 59

Safety rules Chapter 2

Kunststoff schweißtechnik

2.9.5. Risk of injury by noise

You may sustain hearing damage; the drilling noise exceeds 80 dB A

considerably.

• Ear protection is obligatory during drilling!

2.10. Structural modifications on the machine

• No modifications, extensions or reconstructions may be made on the machine without

permission of the manufacturer.

• Machine parts which are not in perfect condition have to be replaced immediately.

• Only use original WIDOS spare and wear parts.

• In case of order, always state the machine number!

2.11. Warranty and liability

Basically, our "General Terms of sale and delivery“ are valid.

They are at the owner’s disposal latest at conclusion of the contract.

Warranty and liability rights are excluding injuries of persons and property damages if they

are due to one or several of the following reasons:

• Not using the machine purpose oriented.

• Unsuitable transport, mounting, starting, operating and maintenance of the machine.

• Operating the machine without or with not correctly fixed safety devices.

• Not following the indications of the working instructions.

• Unallowed structural modifications on the machine.

• Unsatisfactory inspection of machine parts which are subject to wearing.

• Unsatisfactory performed repairs.

• In case of catastrophes through action of an external body or actions of God.

25.06.12 Working instructions WIDOS 4001 Page 14 of 59

WIDOS Einsteinstr. 5 Phone +49 / 71 52 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 / 71 52 99 39 - 40

info @ widos.de

http://www.widos.de

Kunststoff schweißtechnik

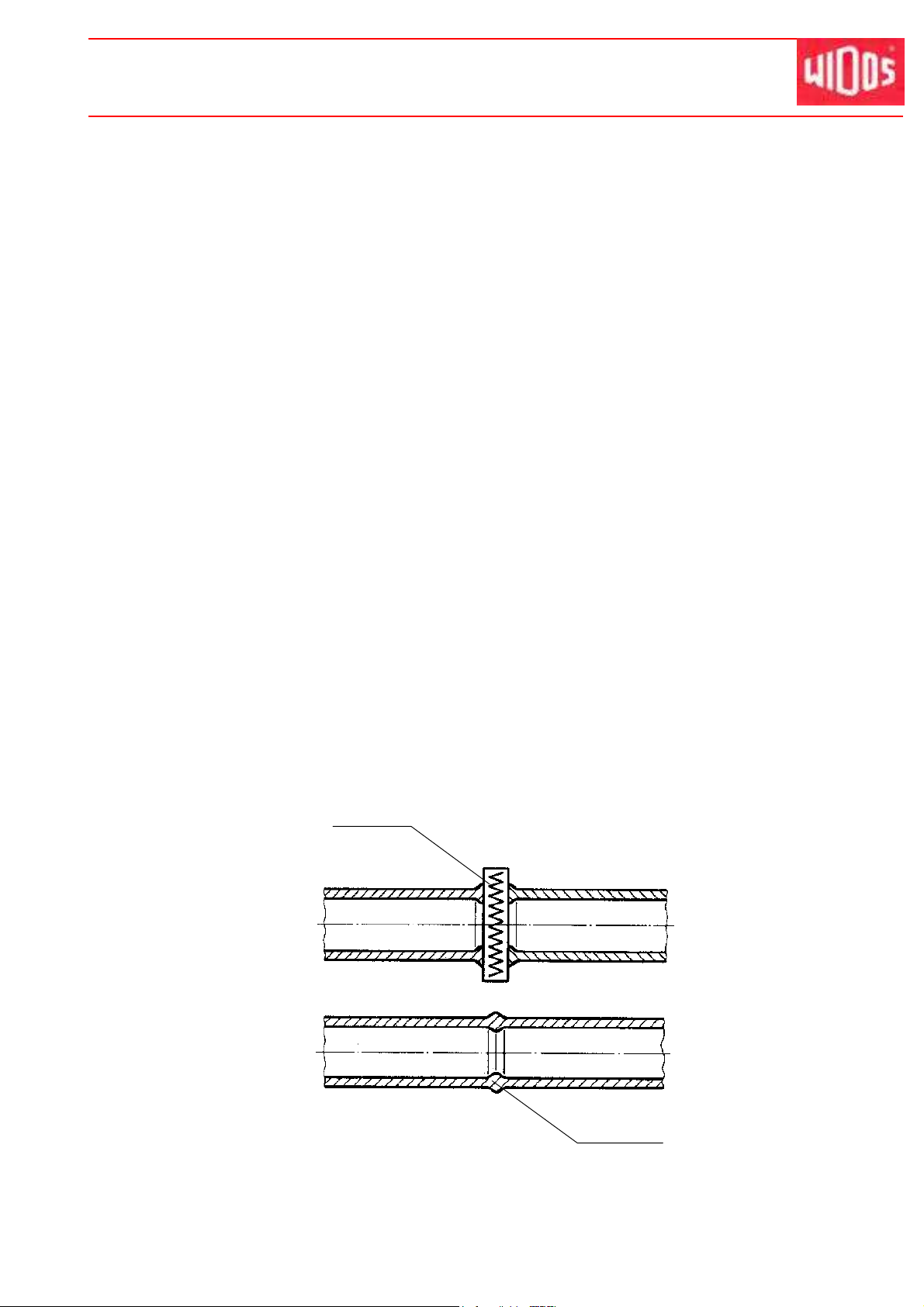

3. Description of process

B as i ca l l y , t h e i n te r na t io n al a nd na t io n al p r o c e s s g u id e li n es ar e to

b e f ol l o w e d !

At first, the clamping tools are fixed on the machine slide.

For the fabrication of angles and bows, the clamping tools can be turned on both sides.

The plastic pipes are clamped by means of the clamping tools.

If necessary, stabilize the pipes by means of roller stands or pipe supports (for bows, a

supporting angle is existing).

Then the front sides of the pipes are planed parallel by means of the planer and the

misalignment of the pipes is checked.

Now the heating element is swivelled in and the pipes are pressed against the heating element

under defined adjusting pressure. This process is called "adjusting".

After the prescribed bead height being reached, pressure is reduced, heat up time begins.

The function of this time is to heat up the pipe ends.

After expiration of the heat up time, the slides are opened, the heating element is swivelled out

quickly and the pipes are closed again hydraulically.

The time gap from the removal of the heating element to joining the pipes is called change

over time.

The pipes are joined under prescribed welding pressure and then cool down under pressure

(cooling time).

The welded joint can be unclamped, the welding process is finished.

Heating element heats

up the pipes up to

welding temperature

Finished welding with

inside and outside bead

25.06.12 Working instructions WIDOS 4001 Page 15 of 59

WIDOS Einsteinstr. 5 Phone +49 / 71 52 99 39 - 0

2

4

5

6

7

3

8

12

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 / 71 52 99 39 - 40

info @ widos.de

http://www.widos.de

Kunststoff schweißtechnik

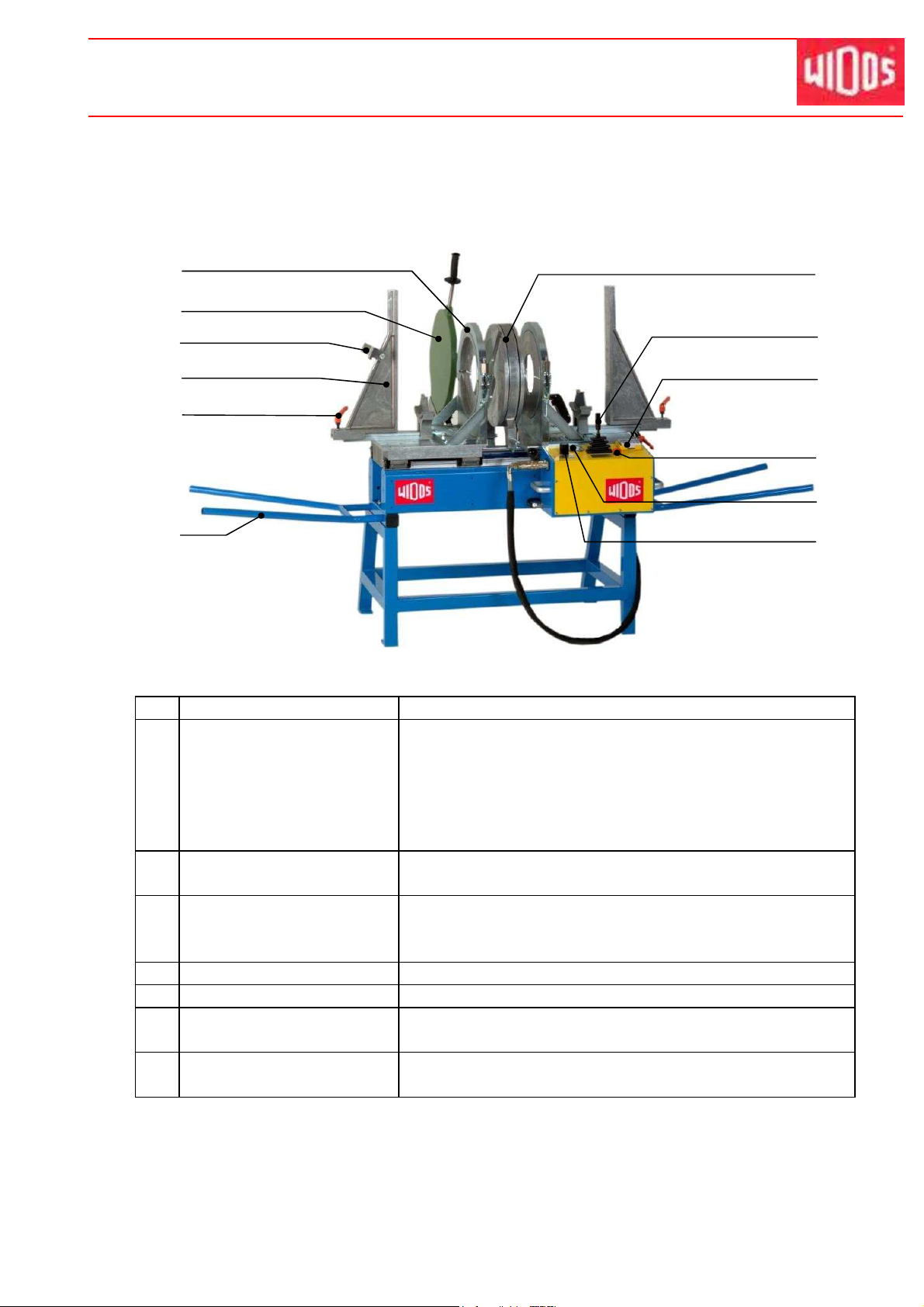

4. Operating and indicating elements

4.1. Elements on the front side

1

No. Denomination Function

1 Clamping tool - swivable up to 15° on both sides.

- Clamping the pipes. By means of the respective

reduction inserts, pipes from OD=90 - 315 mm can be

clamped.

- when using reduction inserts with 22,5° obliquity the

clamping tools need not be turned.

2 Heating element - Bring the pipe up to welding temperature.

- Can be moved sidewards and be swivelled in

3 Pipe support - Clamped pipes can be supported with the corresponding

inserts.

- Bows can be supported on the supporting angles.

4 Supporting angle - Stabilization of bows and angles.

5 Clamping lever - Fixation for supporting angle

6 Carrying handle - Handcarrying the machine

- can be unscrewed if need be.

7 Planer - Planing the pipe ends to be welded.

- Is switched on over the switch at the control desk.

10

11

25.06.12 Working instructions WIDOS 4001 Page 16 of 59

No. Denomination Function

8 Valve lever For opening / closing the slide. There are 4 different

9 Place for stop watch - Place for the delivered stop watch giving a good view

10 Oil dipstick - Oil filler neck / checking the oil level. Oil level must be

11 Manometer - Indication of the hydraulic pressure

12 Setscrew for pressure relief

valve

Operating and indicating elements Chapter 4

positions:

- FORWARDS: slide is closed.

- in the center (without moving): the instantaneous

pressure is held (also by means of the built in pressure

reservoir).

- Pressure release: a possible pressure can be released

without opening the machine. Due to the pressure

reservoir it takes approx. 10 s until the complete

pressure is released.

- BACKWARDS: slide is opened.

on it.

between the two marks.

- Limitation of the hydraulic pressure onto the desired

value. (adjustable from 0 - 250 bar)

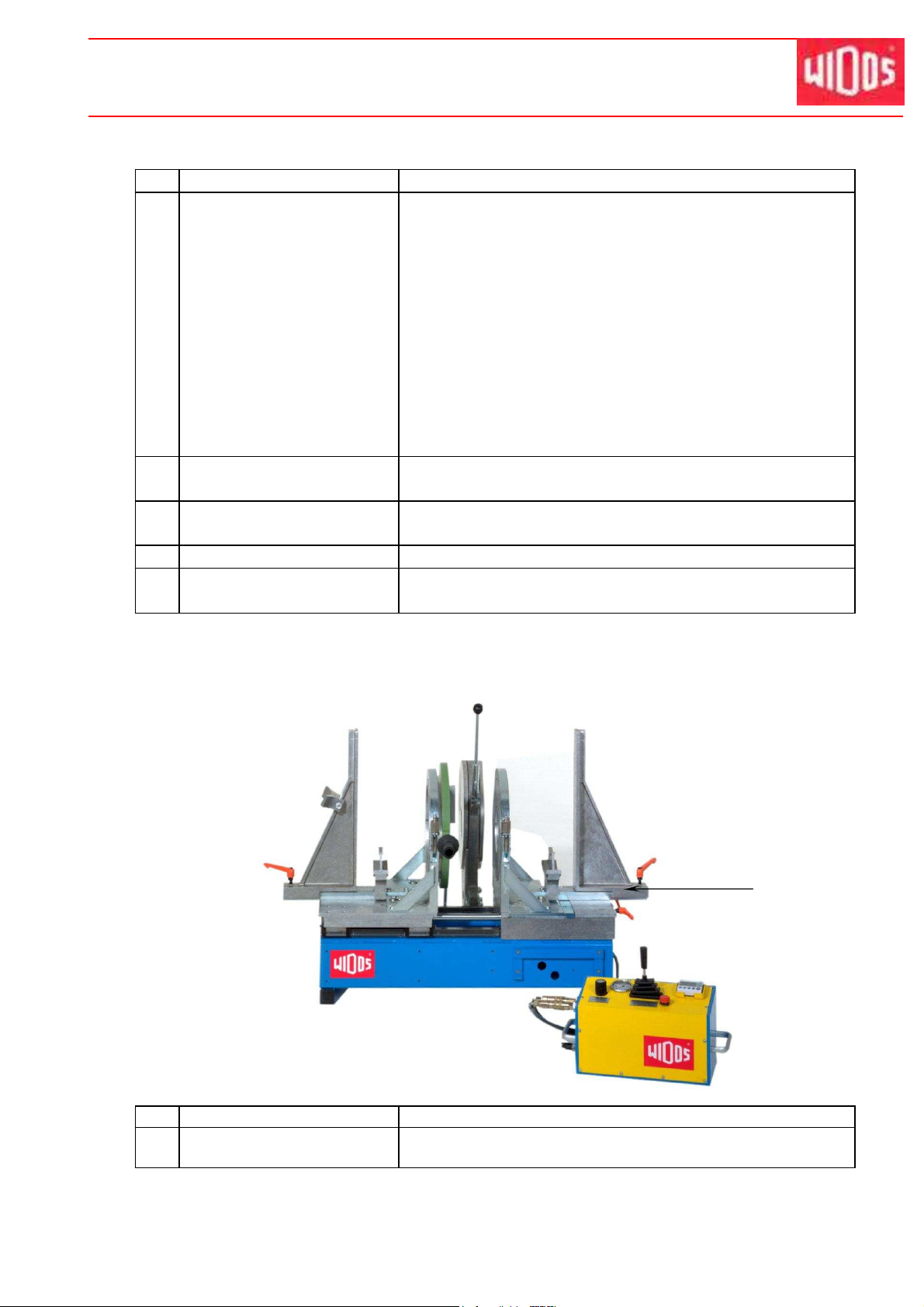

4.2. Elements on the right side

Kunststoff schweißtechnik

No. Denomination Function

1 Clamping lever - Loosen for moving the right table half, for horizontal

mismatch compensation.

1

25.06.12 Working instructions WIDOS 4001 Page 17 of 59

1

2

3

Operating and indicating elements Chapter 4

4.3. Elements on the heating element

No. Denomination Function

1 Control lamp yellow There are three different states:

- off: the heating element is not being heated up at the

moment or is cooling down.

- blinking: the temperature of the heating element is

maintained by a certain pulse-position ratio.

- on: the heating element is being heated up at the moment.

The desired temperature has not yet been reached.

Kunststoff schweißtechnik

2 Control lamp green - Indication for mains operated

3 Control knob - Temperature control

25.06.12 Working instructions WIDOS 4001 Page 18 of 59

Operating and indicating elements Chapter 4

Kunststoff schweißtechnik

4.4. Wells at the table

The clamping tool is fixed on one side by means of a centering bolt which serves as swivelling

axle if angles have to be adjusted.

The clamping tool can be moved forwards/backwards.

At the slooted hole on the clamping tool, any angles from 0-15° can be adjusted. For the exact

setting of 11,25° and 15°, figure stamps are existing.

M o v i n g d i r e c t i o n

Centering bolt for

clamping tool /

swiveling axle

Fixing for clamping tool

back

Fixing for clamping tool

front

Screws for clamping tool

front / back

Angle marks for

clamping tools front /

back

Fixing for table

25.06.12 Working instructions WIDOS 4001 Page 19 of 59

WIDOS Einsteinstr. 5 Phone +49 / 71 52 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 / 71 52 99 39 - 40

info @ widos.de

http://www.widos.de

Kunststoff schweißtechnik

5. Starting and operating

The indications of this chapter are supposed to instruct you in the operation of the machine

and to lead you during the skilled starting of the machine.

This includes:

• the safe operation of the machine

• using all possibilities

• economic operation of the machine

5.1. Safety indications and Starting

The machine may only be operated by skilled and authorized persons.

A plastic welder exam according to DVS and DVGW can be taken for the

qualification.

• In danger situations for mankind and for the machine, the main power connection has to be

immediately removed.

• In case of power fall, there may still be pressure in the hydraulic system. If required release

pressure.

• At the end of the work and during breaks, the machine has to be switched off.

• Also take care that no unauthorized person have access to the machine.

• Protect the machine from wetness and humidity !

• According to VDE 0100, operation on building sites is only allowed with a current distributor

with FI-security protective switch.

Before starting the hydraulic check the level of the oil in order to avoid

damages on the pump.

If necessary add hydraulic oil of the quality HLPD 32 (Chapter: 7.3, 7.3.1).

The heating element surfaces should be clean, especially non greasy, that’s

why they need to be cleaned shortly before each welding or in case of

dirtiness by means of a fibre-free paper and cleaning agent (e.g. technical

pure alcool) or cleaning cloths which are available at the WIDOS company.

The anti-adhesive coating of the heating element should be undamaged in

the working area

Be sure that all hydraulic and electric connections are connected.

• Take care for the ambient conditions:

• Welding must not be performed at direct sunlight.

• If necessary, use a welding umbrella.

• At an ambient temperature under 5° C take the respective measures:

• if necessary use a welding tent or heat up the pipe ends.

• In addition, take measures against dust.

25.06.12 Working instructions WIDOS 4001 Page 20 of 59

Starting and operating Chapter 5

Kunststoff schweißtechnik

5.2. Welding process

B as i ca l l y , t h e c o r r e sp o nd i ng va l id w el d i ng p r e sc r ip t io n s ( I SO / C EN

/ D V S. . . ) h av e t o b e f o l lo w e d.

• Do wear safety gloves as protection against burning.

• A stop watch is needed for registrating the actual times for heating and cooling.

• A table with the prescribed parameters for the pipe dimensions to be welded has to be

available.

• The surfaces of the heating element should be clean, especially free from grease, and for

that purpose, in case of dirtiness, they have to be cleaned with a fibreless paper and

a cleaning agent.

The anti-adhesive coating of the heating element must be undamaged in the working area.

• Switch on heating element and set the required welding temperature on the rotary type

regulator. If the control light flashes, the nominal temperature has been reached and is held

at a constant level (Chapter4.3).

• Set the desired angle at the clamping tools.

• The left clamping tool can be moved forwards and backwards.

• The angle settings 11,25° and 15° can be read at the figure stamps.

• Screw the clambing tools according to the pipe outside diameter to be welded

• Lay the work pieces into the clamping shells, fasten the clamping screws and align the work

pieces to each other.

• Use the WIDOS rollerstand for the alignment of long pipe ends, for bows use the

supporting angle and pipe supports.

• Close the machine meanwhile reading the travel pressure at the manometer.

• The travel pressure is displayed exactly at that moment when the machine with the

clamped pipe starts moving.

• Then open the machine again in such a way that the planer fits in between.

• Swivel in the planer between the ends of the workpieces and let the planer lock.

• Switch on the planer, close the machine and plane with a pressure that lies between 1 and

15 bar over the travel pressure.

• If necessary, use the plane girder for planing only at one side (if planing to size or if using a

welding neck which means that only a little material may be removed).

• Planing should be carried out until a revolving cutting has been formed on both sides.

• Open the machine again, switch off the planer and swivel back the planer out of the

machine.

• Remove the formed chips without touching the surfaces.

• Close the machine.

25.06.12 Working instructions WIDOS 4001 Page 21 of 59

Starting and operating Chapter 5

Kunststoff schweißtechnik

• Check the misalignment and the gap between the two pipes touching one the other.

According to DVS 2207, the misalignment at the pipe outside should not be higher than

0,1 x pipe wall thickness, the acceptable gap not bigger than 0,5 mm.

The right half of the table can be pushed backwards and forwards for the

misalignmentcheck.

Release both clamping levers at the front side of the table.

• In case of a misalignment compensation, a new planing should be performed.

• Take the adjustment pressure for the pipe dimensions to be welded from the table and add

the travel pressure.

• Set the so defined pressure value at the pressure limitation valve and check by actioning

the valve lever.

• Open the machine again somewhat.

• Take heat up time, max. change over time, cooling down time and bead height for the pipe

dimension to be welded from the welding table (Chapter: 6)

• Swivel in the cleaned heating element, brought onto desired temperature, between the

pipes, if necessary wait until the desired temperature has been reached.

• Drive the machine halfs together schock-free under the set adjusting pressure.

• When the prescribed circular bead height is being reached, reduce the pressure.

• For this purpose put the valve lever into position „pressureless“ until the desired heating

pressure is set (heating pressure = approx. 10% of the adjusting pressure).

• Now the heat up time begins. Press the stop watch and compare the actual time with the

desired time taken out of the table.

• Open the machine after completion of the heating time, pull the heating element out as

quickly as possible and drive the machine together without schock-free.

• The maximum time range for this process is given by the value for the change over time

taken out of the table.

• After completion of the welding pressure up-building, press the stop watch and maintain the

control lever for about 10 s in position „pressure“ so that the hydro tank may be filled.

• If required set the pressure again during cooling (the pressure for cooling is the same like

the set adjusting pressure).

• After completion of the cooling time release pressure, remove the welded parts and open

the machine.

The welding process is finished.

25.06.12 Working instructions WIDOS 4001 Page 22 of 59

Starting and operating Chapter 5

A

Kunststoff schweißtechnik

5.2.1. Plane girder for planing only at one side

If planing is necessary only at one side (e.g. at

use of a fitting) the plane girder for planing (A) is

used.

Center the centering bolt of the girder in the

central drill.

Of the planer and hold tightly the girder during

planing.

5.3. Welding logs and tables

If welding angles, the welding surface of the pipe and thus the necessary pressure changes.

Calculate the necessary pressure as follows:

• Take the prescribed value for adjusting or cooling from the table.

• Multiplicate the pressure value with factor /cos (angle).

This will give the following factors:

Welding 15° (chamfered pipe with 7,5°): 1,01

Welding 22,5° (chamfered pipe with 11,25°): 1,02

Welding 30° (chamfered pipe with 15°): 1,04

Welding 45° (chamfered pipe with 22,5°): 1,08

Welding 60° (chamfered pipe with 30°): 1,15

Welding 90° (chamfered pipe with 45°): 1,41

• Add the motional pressure as usual.

All the other welding parameters remain as usual.

angle

5.4. Welding segmented bends

Calculate the sawing angle to be set (corresponding to the required angle at the clamping

tools or clamping inserts) as follows:

angle of the bend

sawing angle = ---------------------------------------------

number of all welding surfaces

Example 1: bend of 90° 4 segments (6 welding surfaces)

90°

sawing angle = ----- = 15°

6

Example 2: bend of 45° in 3 segments (4 welding surfaces)

45°

sawing angle = ----- = 11,25°

4

25.06.12 Working instructions WIDOS 4001 Page 23 of 59

Starting and operating Chapter 5

Kunststoff schweißtechnik

5.5. Welding of Cross- and T-pieces

The optional available clamping device for angles is screwed on together with the adapter

plate and standard tools.

T - pieces (45°, 60° and 90°) and Cross-pieces up to OD=250 mm can be welded.

25.06.12 Working instructions WIDOS 4001 Page 24 of 59

Starting and operating Chapter 5

Kunststoff schweißtechnik

25.06.12 Working instructions WIDOS 4001 Page 25 of 59

WIDOS Einsteinstr. 5 Phone +49 / 71 52 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 / 71 52 99 39 - 40

info @ widos.de

http://www.widos.de

6. Welding logs and tables

Kunststoff schweißtechnik

25.06.12 Working instructions WIDOS 4001 Page 26 of 59

Welding logs and tables Chapter 6

Kunststoff schweißtechnik

25.06.12 Working instructions WIDOS 4001 Page 27 of 59

Foundation: 2207, 2208 DIN 16932 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

PE 80

The value for heating element temperature is between 200° C - 220° C.

The

smaller

the pipe wall the

higher

the temperature.

PE 100

The standard value for heating element temperature is 220° C.

Increase the change-over time and the welding pressure time at PE 100 as fast as possible !

T

pipe

pipe

SDR

bead-up

circular

heat-up

max.

time welding

cool-

diameter

wall

pressure

bead

time

change-

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

over

welding

[bar]

time

[mm]

[mm]

[mm]

time

pressure

[min]

90

90

90

90

90

90

90

90

90

90

110

110

110

110

110

110

110

110

110

110

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

desired

Table for PE

P (N/mm²)

bead-up heat-up

0,15 (PE) time pressure

change- reach full

over welding cool-dow n time

Kunststoff schweißtechnik

time to

pressure in

welding area

temperature

in welding area

time

[s] [s]

2,2 41 4 0,5 22 4 4 4 2

2,8 33 6 0,5 28 4 4 6 3

3,5 26 7 0,5 35 5 5 7 4

4,3 21,0 8 0,5 43 5 5 8 6

5,1 17,6 9 1,0 51 5 5 9 7

5,4 17 10 1,0 54 5 5 10 7

6,7 13,6 12 1,0 67 6 6 12 10

8,2 11 14 1,5 82 6 6 14 11

10,1 9,0 17 1,5 101 7 7 17 14

12,3 7,4 20 2,0 123 8 8 20 16

2,7 41 6 0,5 27 4 4 6 3

3,4 33 8 0,5 34 5 5 8 4

4,2 26 10 0,5 42 5 5 10 6

5,3 21,0 12 1,0 53 5 5 12 7

6,3 17,6 14 1,0 63 6 6 14 9

6,6 17 14 1,0 66 6 6 14 9

8,1 13,6 17 1,5 81 6 6 17 11

10,0 11 21 1,5 100 7 7 21 14

12,3 9,0 25 2,0 123 8 8 25 16

15,1 7,4 30 2,0 151 9 9 30 20

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 28 / 1 of 59

Foundation: 2207, 2208 DIN 16932 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

PE 80

The value for heating element temperature is between 200° C - 220° C.

The

smaller

the pipe wall the

higher

the temperature.

PE 100

The standard value for heating element temperature is 220° C.

Increase the change-over time and the welding pressure time at PE 100 as fast as possible !

T

pipe

pipe

SDR

bead-up

circular

heat-up

max.

time welding

cool-

diameter

wall

pressure

bead

time

change-

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

over

welding

[bar]

time

[mm]

[mm]

[mm]

time

pressure

[min]

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

125

125

125

125

125

125

125

125

125

125

140

140

140

140

140

140

140

140

140

140

desired

Table for PE

P (N/mm²)

bead-up heat-up

0,15 (PE) time pressure

change- reach full

over welding cool-dow n time

Kunststoff schweißtechnik

time to

pressure in

welding area

temperature

in welding area

time

[s] [s]

3,1 41 8 0,5 31 4 4 8 4

3,9 33 10 0,5 39 5 5 10 5

4,8 26 12 1,0 48 5 5 12 6

6,0 21,0 15 1,0 60 6 6 15 8

7,1 17,6 18 1,5 71 6 6 18 10

7,4 17 18 1,5 74 6 6 18 10

9,2 13,6 22 1,5 92 7 7 22 13

11,4 11 27 1,5 114 8 8 27 15

14,0 9,0 32 2,0 140 9 9 32 18

17,1 7,4 38 2,0 171 9 10 38 22

3,5 41 10 0,5 35 5 5 10 4

4,3 33 12 0,5 43 5 5 12 6

5,4 26 15 1,0 54 5 5 15 7

6,7 21,0 19 1,0 67 6 6 19 10

8,0 17,6 22 1,5 80 6 6 22 11

8,3 17 23 1,5 83 7 7 23 12

10,3 13,6 28 1,5 103 7 7 28 14

12,7 11 34 2,0 127 8 8 34 17

15,7 9,0 40 2,0 157 9 10 40 20

19,2 7,4 48 2,5 192 10 11 48 24

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 28 / 2 of 59

Foundation: 2207, 2208 DIN 16932 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

PE 80

The value for heating element temperature is between 200° C - 220° C.

The

smaller

the pipe wall the

higher

the temperature.

PE 100

The standard value for heating element temperature is 220° C.

Increase the change-over time and the welding pressure time at PE 100 as fast as possible !

T

pipe

pipe

SDR

bead-up

circular

heat-up

max.

time welding

cool-

diameter

wall

pressure

bead

time

change-

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

over

welding

[bar]

time

[mm]

[mm]

[mm]

time

pressure

[min]

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

160

160

160

160

160

160

160

160

160

160

180

180

180

180

180

180

180

180

180

180

desired

Table for PE

P (N/mm²)

bead-up heat-up

0,15 (PE) time pressure

change- reach full

over welding cool-dow n time

Kunststoff schweißtechnik

time to

pressure in

welding area

temperature

in welding area

time

[s] [s]

4,0 41 13 0,5 40 5 5 13 5

4,9 33 16 1,0 49 5 5 16 7

6,2 26 20 1,0 62 6 6 20 9

7,7 21,0 25 1,5 77 6 6 25 11

9,1 17,6 29 1,5 91 7 7 29 13

9,5 17 30 1,5 95 7 7 30 13

11,8 13,6 36 2,0 169 9 10 36 22

14,6 11 44 2,0 146 9 9 44 19

17,9 9,0 53 2,0 179 10 11 53 23

21,9 7,4 62 2,5 219 11 12 62 27

4,4 41 16 0,5 44 5 5 16 6

5,5 33 20 1,0 55 5 5 20 8

6,9 26 25 1,0 69 6 6 25 10

8,6 21,0 31 1,5 86 7 7 31 12

10,2 17,6 36 1,5 102 7 7 36 14

10,7 17 38 1,5 107 7 7 38 14

13,3 13,6 46 2,0 136 8 9 46 18

16,4 11 55 2,0 164 9 10 55 21

20,1 9,0 66 2,5 201 10 11 66 25

24,6 7,4 79 2,5 246 12 13 79 30

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 28 / 3 of 59

Foundation: 2207, 2208 DIN 16932 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

PE 80

The value for heating element temperature is between 200° C - 220° C.

The

smaller

the pipe wall the

higher

the temperature.

PE 100

The standard value for heating element temperature is 220° C.

Increase the change-over time and the welding pressure time at PE 100 as fast as possible !

T

pipe

pipe

SDR

bead-up

circular

heat-up

max.

time welding

cool-

diameter

wall

pressure

bead

time

change-

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

over

welding

[bar]

time

[mm]

[mm]

[mm]

time

pressure

[min]

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

200

200

200

200

200

200

200

200

200

200

225

225

225

225

225

225

225

225

225

225

desired

Table for PE

P (N/mm²)

bead-up heat-up

0,15 (PE) time pressure

change- reach full

over welding cool-dow n time

Kunststoff schweißtechnik

time to

pressure in

welding area

temperature

in welding area

time

[s] [s]

4,9 41 20 1,0 49 5 5 20 7

6,2 33 25 1,0 62 6 6 25 9

7,7 26 31 1,5 77 6 6 31 11

9,6 21,0 38 1,5 96 7 7 38 13

11,4 17,6 45 1,5 114 8 8 45 15

11,9 17 46 1,5 119 8 8 46 16

14,7 13,6 56 2,0 147 9 9 56 19

18,2 11 68 2,0 182 10 11 68 23

22,4 9,0 82 2,5 224 11 12 82 28

27,4 7,4 97 3,0 274 13 15 97 34

5,5 41 25 1,0 55 5 5 25 8

6,9 33 31 1,0 69 6 6 31 10

8,6 26 39 1,5 86 7 7 39 12

10,8 21,0 48 1,5 108 8 8 48 15

12,8 17,6 56 2,0 128 8 8 56 17

13,4 17 59 2,0 134 8 9 59 18

16,6 13,6 71 2,0 166 9 10 71 21

20,5 11 86 2,5 205 10 12 86 26

25,2 9,0 104 2,5 252 12 14 104 31

30,8 7,4 123 3,0 308 14 16 123 38

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 28 / 4 of 59

Foundation: 2207, 2208 DIN 16932 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

PE 80

The value for heating element temperature is between 200° C - 220° C.

The

smaller

the pipe wall the

higher

the temperature.

PE 100

The standard value for heating element temperature is 220° C.

Increase the change-over time and the welding pressure time at PE 100 as fast as possible !

T

pipe

pipe

SDR

bead-up

circular

heat-up

max.

time welding

cool-

diameter

wall

pressure

bead

time

change-

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

over

welding

[bar]

time

[mm]

[mm]

[mm]

time

pressure

[min]

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

250

250

250

250

250

250

250

250

250

250

280

280

280

280

280

280

280

280

280

280

desired

Table for PE

P (N/mm²)

bead-up heat-up

0,15 (PE) time pressure

change- reach full

over welding cool-dow n time

Kunststoff schweißtechnik

time to

pressure in

welding area

temperature

in welding area

time

[s] [s]

6,2 41 31 1,0 62 6 6 31 9

7,7 33 39 1,5 77 6 6 39 11

9,6 26 48 1,5 96 7 7 48 13

11,9 21,0 59 1,5 119 8 8 59 16

14,2 17,6 69 2,0 142 9 9 69 19

14,8 17 72 2,0 148 9 9 72 19

18,4 13,6 88 2,0 184 10 11 88 23

22,7 11 106 2,5 227 11 13 106 28

27,9 9,0 127 3,0 279 13 15 127 34

34,2 7,4 152 3,0 342 15 18 152 42

6,9 41 39 1,0 69 6 6 39 10

8,6 33 48 1,5 86 7 7 48 12

10,7 26 60 1,5 107 7 7 60 14

13,4 21,0 74 2,0 134 8 9 74 18

15,9 17,6 87 2,0 159 9 10 87 20

16,6 17 90 2,0 166 9 10 90 21

20,6 13,6 110 2,5 206 10 12 110 26

25,4 11 133 2,5 254 12 14 133 31

31,3 9,0 160 3,0 313 14 16 160 38

38,3 7,4 190 3,5 383 16 20 190 47

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 28 / 5 of 59

Foundation: 2207, 2208 DIN 16932 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

PE 80

The value for heating element temperature is between 200° C - 220° C.

The

smaller

the pipe wall the

higher

the temperature.

PE 100

The standard value for heating element temperature is 220° C.

Increase the change-over time and the welding pressure time at PE 100 as fast as possible !

T

pipe

pipe

SDR

bead-up

circular

heat-up

max.

time welding

cool-

diameter

wall

pressure

bead

time

change-

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

over

welding

[bar]

time

[mm]

[mm]

[mm]

time

pressure

[min]

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

315

315

315

315

315

315

315

315

315

315

355

355

355

355

355

355

355

355

355

355

desired

Table for PE

P (N/mm²)

bead-up heat-up

0,15 (PE) time pressure

change- reach full

over welding cool-dow n time

Kunststoff schweißtechnik

time to

pressure in

welding area

temperature

in welding area

time

[s] [s]

7,7 41 49 1,5 77 6 6 49 11

9,7 33 61 1,5 97 7 7 61 13

12,1 26 76 2,0 121 8 8 76 16

15,0 21,0 93 2,0 150 9 9 93 19

17,9 17,6 109 2,0 179 10 11 109 23

18,7 17 114 2,0 187 10 11 114 24

23,2 13,6 139 2,5 232 11 13 139 29

28,6 11 168 3,0 286 13 15 168 35

35,2 9,0 202 3,0 352 15

43,1 7,4 241 3,5 431 18

18

22

202 43

241 52

8,7 41 62 1,5 87 7 7 62 12

10,9 33 77 1,5 109 8 8 77 15

13,6 26,0 96 2,0 136 8 9 96 18

16,9 21,0 118 2,0 169 9 10 118 22

20,1 17,6 138 2,5 201 10 11 138 25

21,1 17 145 2,5 211 11 12 145 26

26,1 13,6 176 3,0 261 12 14 176 32

32,2 11,0 213 3,0 322 14 17 213 39

39,7 9,0 257 3,5 397 17 20 257 48

48,5 7,4 305 3,5 485 20

24

305 58

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 28 / 6 of 59

Foundation: 2207, 2208 DIN 16932 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

PE 80

The value for heating element temperature is between 200° C - 220° C.

The

smaller

the pipe wall the

higher

the temperature.

PE 100

The standard value for heating element temperature is 220° C.

Increase the change-over time and the welding pressure time at PE 100 as fast as possible !

T

pipe

pipe

SDR

bead-up

circular

heat-up

max.

time welding

cool-

diameter

wall

pressure

bead

time

change-

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

over

welding

[bar]

time

[mm]

[mm]

[mm]

time

pressure

[min]

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

400

400

400

400

400

400

400

400

400

400

450

450

450

450

450

450

450

450

450

450

•

prefabrication under workshop conditions

•

low additional pressure at unclamping

•

no additional pressure during further cooling down

•

load onto the workpieces only after being completely cooled down

•

Join parts with wall thickness

≥15 mm

desired

Table for PE

P (N/mm²)

bead-up heat-up

0,15 (PE) time pressure

change- reach full

over welding cool-dow n time

Kunststoff schweißtechnik

time to

pressure in

welding area

temperature

in welding area

time

[s] [s]

9,8 41 79 1,5 98 7 7 79 13

12,3 33 98 2,0 123 8 8 98 16

15,3 26,0 121 2,0 153 9 9 121 20

19,1 21,0 150 2,5 191 10 11 150 24

22,7 17,6 176 2,5 227 11 13 176 28

23,7 17,0 183 2,5 237 11 13 183 29

29,4 13,6 224 3,0 294 13 16 224 36

36,3 11,0 271 3,0 363 16 19 271 44

44,7 9,0 326 3,5 447 18 23 326 54

54,7 7,4 387 4,0 547 21

27

387 65

11,0 41 99 1,5 110 8 8 99 15

13,8 33 124 2,0 138 9 9 124 18

17,2 26,0 153 2,0 172 9 10 153 22

21,5 21,0 189 2,5 215 11 12 189 27

25,5 17,6 222 2,5 255 12 14 222 31

26,7 17,0 232 3,0 267 12 14 232 33

33,1 13,6 283 3,0 331 15 17 283 40

40,9 11,0 343 3,5 409 17 21 343 49

50,3 9,0 412 4,0 503 20 25 412 60

61,5 7,4 490 4,0 615 23

31

490 71

Remaining under the cool-down time for up to 50% is allowed under the following conditions:

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 28 / 7 of 59

Foundation: 2207, 2208 DIN 16932 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

T

pipe

pipe

SDR

bead-up

circular

heat-up

max.

time welding

cool-

diameter

wall

pressure

bead

time

change-

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

over

welding

[bar]

time

[mm]

[mm]

[mm]

time

pressure

[min]

90

90

90

90

90

90

90

110

110

110

110

110

110

110

125

125

125

125

125

125

125

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

The standard value for heating element temperature is 210° C +/- 10° C.

The

smaller

the pipe wall the

higher

the temperature.

desired

Table for PP

P (N/mm²)

bead-up heat-up

0,10 (PP) time pressure

change- reach full

over welding cool-down time

Kunststoff schweißtechnik

time to

pressure in

welding area

temperature

in welding area

time

[s] [s]

2,2 41 3 0,5 94 4 5 3 2

2,8 33 4 0,5 104 4 5 4 3

3,5 26 5 0,5 117 5 6 5 4

5,1 17,6 6 0,5 145 5 6 6 7

8,2 11 10 1,0 192 6 8 10 14

12,3 7,4 14 1,0 249 7 11 14 20

15,0 6 16 1,0 281 8 14 16 24

2,7 41 4 0,5 103 4 5 4 3

3,4 33 5 0,5 115 5 6 5 4

4,2 26 7 0,5 130 5 6 7 6

6,3 17,6 9 0,5 164 6 7 9 10

10,0 11 14 1,0 217 7 9 14 17

15,1 7,4 20 1,0 283 8 14 20 24

18,3 6 23 1,0 322 9 16 23 29

3,1 41 6 0,5 110 4 5 6 4

3,9 33 7 0,5 124 5 6 7 5

4,8 26 8 0,5 140 5 6 8 7

7,1 17,6 12 1,0 176 6 7 12 12

11,4 11 18 1,0 237 7 11 18 19

17,1 7,4 26 1,0 307 8 15 26 27

20,8 6 30 1,5 348 10 18 30 33

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 29 / 1 of 59

Foundation: 2207, 2208 DIN 16932 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

T

pipe

pipe

SDR

bead-up

circular

heat-up

max.

time welding

cool-

diameter

wall

pressure

bead

time

change-

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

over

welding

[bar]

time

[mm]

[mm]

[mm]

time

pressure

[min]

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

The standard value for heating element temperature is 210° C +/- 10° C.

The

smaller

the pipe wall the

higher

the temperature.

140

140

140

140

140

140

140

160

160

160

160

160

160

160

180

180

180

180

180

180

180

desired

Table for PP

P (N/mm²)

bead-up heat-up

0,10 (PP) time pressure

change- reach full

over welding cool-down time

Kunststoff schweißtechnik

time to

pressure in

welding area

temperature

in welding area

time

[s] [s]

3,5 41 7 0,5 117 5 6 7 4

4,3 33 8 0,5 131 5 6 8 6

5,4 26 10 0,5 149 5 6 10 8

8,0 17,6 15 1,0 189 6 8 15 14

12,7 11 23 1,0 254 7 12 23 21

19,2 7,4 32 1,5 332 9 17 32 30

23,3 6 38 1,5 373 10 20 38 36

4,0 41 9 0,5 126 5 6 9 5

4,9 33 11 0,5 141 5 6 11 7

6,2 26 14 0,5 162 6 7 14 10

9,1 17,6 19 1,0 204 6 9 19 15

14,6 11 29 1,0 277 8 13 29 24

21,9 7,4 42 1,5 359 10 19 42 34

26,6 6 49 2,0 405 11 23 49 41

4,4 41 11 0,5 133 5 6 11 6

5,5 33 14 0,5 151 5 6 14 8

6,9 26 17 0,5 173 6 7 17 12

10,2 17,6 24 1,0 220 7 10 24 17

16,4 11 37 1,0 298 8 15 37 26

24,6 7,4 53 1,5 386 11 21 53 38

29,0 6 60 2,0 423 12 25 60 44

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 29 / 2 of 59

Foundation: 2207, 2208 DIN 16932 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

T

pipe

pipe

SDR

bead-up

circular

heat-up

max.

time welding

cool-

diameter

wall

pressure

bead

time

change-

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

over

welding

[bar]

time

[mm]

[mm]

[mm]

time

pressure

[min]

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

The standard value for heating element temperature is 210° C +/- 10° C.

The

smaller

the pipe wall the

higher

the temperature.

200

200

200

200

200

200

200

225

225

225

225

225

225

225

250

250

250

250

250

250

280

280

280

280

280

280

desired

Table for PP

P (N/mm²)

bead-up heat-up

0,10 (PP) time pressure

change- reach full

over welding cool-down time

Kunststoff schweißtechnik

time to

pressure in

welding area

temperature

in welding area

time

[s] [s]

4,9 41 14 0,5 141 5 6 14 7

6,2 33 17 0,5 162 6 7 17 10

7,7 26 21 1,0 185 6 8 21 13

11,4 17,6 30 1,0 237 7 11 30 19

18,2 11 46 1,0 320 9 16 46 29

27,4 7,4 65 2,0 411 11 23 65 42

33,2 6 76 2,0 456 13 29 76 50

5,5 41 17 0,5 151 5 6 17 8

6,9 33 21 0,5 173 6 7 21 12

8,6 26 26 1,0 197 6 8 26 15

12,8 17,6 38 1,0 255 7 12 38 21

20,5 11 58 1,5 345 9 18 58 32

30,8 7,4 82 2,0 437 12 26 82 47

37,4 6 96 2,5 487 14 32 96 55

6,2 41 21 0,5 162 6 7 21 10

7,7 33 26 1,0 185 6 8 26 13

9,6 26 32 1,0 211 7 9 32 16

14,2 17,6 46 1,0 272 8 13 46 23

22,7 11 71 1,5 367 10 20 71 35

34,2 7,4 101 2,0 463 13 29 101 51

6,9 41 26 0,5 173 6 7 26 12

8,6 33 32 1,0 197 6 8 32 15

10,7 26 40 1,0 227 7 10 40 18

15,9 17,6 58 1,0 292 8 14 58 26

25,4 11 89 1,5 394 11 22 89 39

38,3 7,4 127 2,5 493 14 33 127 57

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 29 / 3 of 59

Foundation: 2207, 2208 DIN 16932 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

T

pipe

pipe

SDR

bead-up

circular

heat-up

max.

time welding

cool-

diameter

wall

pressure

bead

time

change-

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

over

welding

[bar]

time

[mm]

[mm]

[mm]

time

pressure

[min]

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

The standard value for heating element temperature is 210° C +/- 10° C.

The

smaller

the pipe wall the

higher

the temperature.

315

315

315

315

315

355

355

355

355

355

400

400

400

400

400

450

450

450

450

450

•

prefabrication under workshop conditions

•

low additional pressure at unclamping

•

no additional pressure during further cooling down

•

load onto the workpieces only after being completely cooled down

•

Join parts with wall thickness

≥15 mm

desired

Table for PP

P (N/mm²)

bead-up heat-up

0,10 (PP) time pressure

change- reach full

over welding cool-down time

Kunststoff schweißtechnik

time to

pressure in

welding area

temperature

in welding area

time

[s] [s]

7,7 41 33 1,0 185 6 8 33 13

9,7 33 41 1,0 213 7 9 41 16

12,1 26 51 1,0 246 7 11 51 20

17,9 17,6 73 1,0 317 9 16 73 28

28,6 11 112 2,0 420 12 24 112 44

8,7 41 42 1,0 199 6 8 42 15

10,9 33 52 1,0 230 7 10 52 18

13,6 26 64 1,0 264 7 12 64 22

20,1 17,6 92 1,5 341 9 18 92 32

32,2 11 142 2,0 448 13 28 142 48

9,8 41 53 1,0 214 7 9 53 16

12,3 33 66 1,0 249 7 11 66 20

15,3 26 81 1,0 221 7 10 81 17

22,7 17,6 117 1,5 367 10 20 117 35

36,3 11 181 2,0 480 14 31 181 54

11,0 41 66 1,0 231 7 10 66 18

13,8 33 83 1,0 267 8 13 83 23

17,2 26 102 1,0 308 8 15 102 27

25,5 17,6 148 1,5 395 11 22 148 39

40,9 11 229 2,5 508 15 35 229 59

Remaining under the cool-down time for up to 50% is allowed under the following conditions:

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 29 / 4 of 59

Table for PVDF

Foundation: 2208, 2207 Part 15 German association for welding

Use for:

4000 / 4001 / 4002

1 bar on manometer:

23N

T

pipe

pipe

bead-up

circular

heat-up

time welding

cool-

diameter

wall

pressure

bead

time

to reach

pressure

down

OD

(s)

[bar]

min.

[s]

welding

[bar]

time

[mm]

[mm]

[mm]

pressure

[min]

90

90

90

110

110

110

125

125

140

140

160

160

180

180

200

200

225

225

250

250

280

280

315

The standard value for heating element temperature is 240° C +/- 8° C.

The

smaller

the pipe wall the

higher

the temperature.

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

change-

over

max.

time

desired

P (N/mm²) change-

bead-up welding cool-down time

0,10 (PVDF) pressure

heat-up over

time

Kunststoff schweißtechnik

time to

reach full

pressure in

welding area

temperature

in welding area

time

[s]

2,8 4 0,5 68 4 4 5,5

4,3 6 0,5 83 4 6 7,0

5,4 7 0,5 94 5 7 8,5

3,4 5 0,5 74 4 5 6,0

5,3 8 0,5 93 5 8 8,5

6,6 10 0,6 106 5 10 10,0

3,9 7 0,5 79 4 7 6,5

6,0 10 0,6 100 5 10 9,0

4,3 8 0,5 83 4 8 7,0

6,7 13 0,6 107 6 13 10,0

4,9 11 0,5 89 5 11 8,0

7,7 17 0,7 117 6 17 11,0

5,5 14 0,5 95 5 14 8,5

8,6 21 0,8 126 6 21 12,5

6,2 17 0,6 102 5 17 9,5

9,6 25 1,0 136 7 25 13,5

6,9 21 0,7 109 6 21 10,5

10,8 32 1,0 148 7 32 15,0

7,7 26 0,7 117 6 26 11,0

11,9 39 1,1 159 8 39 16,5

8,6 32 0,8 126 6 32 12,5

13,4 49 1,2 174 8 49 18,0

9,7 41 1,0 137 7 41 13,5

3

3

3

3

3

4

3

4

3

4

3

4

4

4

4

4

4

4

4

4

4

4

4

[s]

25.06.2012 Working instructions WIDOS 4000 - 4002 Page 30 of 59

WIDOS Einsteinstr. 5 Phone +49 / 71 52 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 / 71 52 99 39 - 40

info @ widos.de

http://www.widos.de

Kunststoff schweißtechnik

7. Maintenance and repair

Goal of the chapter is to:

• keep the nominal condition and the operation capacity of the machine.

• increase the efficiency by avoiding non-planned outage.

• Efficient planning of the maintenance works and the maintenance tools

7.1. Maintenance, Inspection and repair

All maintenance and repair works have to be basically performed with the

machine in off position.

During this the machine has to be secured against unauthorized switching on.

Prescribed maintenance and inspection works should be performed in time. The

DVS gives the advice of inspection works after 1 year.

Should for machines with a specially high usage percentage the testing cycle be

shortened .

The works should be performed at the WIDOS GmbH company or by an

authorized partner.

The linear guides for heating element and planer must be cleaned every week

e.g. with a brush.

Check the linear guide carriages every 3 months and grease them over the

lubricating nipple if necessary. Chips or other impurities in the guides can be the

cause if the heating element or the planer jam or run heavily.

• Clean the piston rods every month with an oily tissue.

• Check the hydraulic connections every month for tightness, tighten again if necessary.

• The operating staff has to be informed before the starting of the maintenance works.

• Check the tightness of loosened screws.

• Check the function of the safety devices after completion of the maintenance works.

Especially insulation, tension resistence and protective cables resistence.

7.2. Planer

• Check the driving chain in the planer from time to time and lubricate it. For that purpose

screw off the housing of the planer.

• Check the cutting ability of the planer, exchange it if necessary (double sided polished

section, max. chip thickness = 0,2 mm!)

25.06.12 Working instructions WIDOS 4001 Page 31 of 59

Maintenance and repair Chapter 7

7.3. Checking the level of the hydraulic oil

• Before each starting of the machine check the oil level of the hydraulic pump in order

to avoid damages.

• Unscrew the red closing screw (with integrate oil dipstick) on the top of the aggregate.

Clean the oil dipstick with a dry cloth and insert it again into the tank, do not screw.

• Remove the oil dipstick again and check the level by means of the two marks (the oil

level must be between the two marks). In case of oil level being beyond the lower mark

refill oil of the quality HLPD 32 (Chapter:7.3.1) .

• The oil level must not surpass the upper mark because otherwise there is the danger

of overflowing in certain situations.

• Oil level check being finished, tighten again firmly the red closing screw.

7.3.1. Used hydraulic oil

Only use oil of the quality HLPD 32.

Properties: anticorrosive, resistant to ageing, contains wearing resistant

agents, high rating and partly water binding.

The hydraulic oil must be disposed of professionnally.

7.4. Transport

Kunststoff schweißtechnik

• Take care that the machine is not exposed to hurts.

• Handle the machine carefully, take especially care for the electro cables.

• Do not tilt the machine too much, in order to prevent oil slick.

• If need be, dismount the planer and the heating element:

For that purpose remove the heating Remove the four screws (S) from the planer

element from the holder (see arrow) and then the planer itself

S

25.06.12 Working instructions WIDOS 4001 Page 32 of 59

Maintenance and repair Chapter 7

Kunststoff schweißtechnik

7.5. Venting the hydraulic cylinders

Necessary: If a new cylinder has been built in.

Condition: A vent hose must exist preventing oil coming out uncontrolled.

Procedure: Open the slides completely, loosen the vent screw for closing at the

cylinder and connect the vent hose.

Close the slides until there is no air in the vent hose. Repeat the same

process at the vent screw for opening.

There are 2 drilled holes at the right table, one of it is in the middle under the horizontal

movable plate.

The cylinder has to be dismounted completely from the movable table on the left side.

Then open completely the cylinder:

Open the rear vent screw (seen from the cylinder) and screw the vent hose to it.

Move backwards and forwards until there is only oil left in the hose and no more air bubbles.

Unscrew the vent hose and tighten again the screw.

Repeat the same process at the frontal screw.

To be sure that the air has left the cylinder completely, you can perform the following the test:

Drive out the cylinder for the half way as soon as both vent screws are tightened again.

Move slowly forwards and backwards the piston rod.

A continuous resistance signifies that there is no more air in the cylinder.