WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

Kunststoffschweißtechnik

Working instructions

Translation

Heating element socket welding machine

WIDOS 3511

Keep for further use!

20.08.14 Working instructions WIDOS 3511 Page 1 of 39

Introduction

Kunststoffschweißtechnik

Model: Heating element socket welding machine

Type:

Serial number / year of construction:

WIDOS 3511

see type label

Customer entries

Inventory No.:

Location:

Order of spare parts and sales service:

Address of manufacturer WIDOS

W. Dom mer Söhne GmbH

Einsteinstr. 5

D-71254 Ditzingen-Heimerdingen

Phone: +49 (0) 71 52 / 99 39 - 0

Fax: +49 (0) 71 52 / 99 39 - 40

Address of subsidiary companies:

WIDOS

WIDOS GmbH W. Dommer Söhne AG

An der Wiesenmühle 15 St. Gallerstr. 93

D-09224 Grüna / Sachsen CH-9201 Gossau

Phone: +49 (0) 3 71 / 8 15 73 - 0 Phone: +41 (0) 79 432 5737

Fax: +49 (0) 3 71 / 8 15 73 - 20

20.08.14 Working instructions WIDOS 3511 Page 2 of 39

Introduction

Kunststoffschweißtechnik

Purpose of the document

These working instructions give you information about all important questions which refer to

the construction and the safe working of your machine.

Just as we are, you are obliged to engage in these working instruction s, as well.

Not only to run your machine economically but also to avoid damages and injuries.

Should questions arise , contact our advisers in the factory or in our subsidiary compa nies.

We will help you with pleasure.

According to our interest in making our products and working instructions continuously better,

we kindly ask you to inform us about problems and defects which occur in exercise.

Thank you.

Structure of the working instructions

The working instructions are arranged in chapters, which belong to the different using phases

of the machine.

Therefore the searched information can be found easily.

8/20/2014 WIDOS

W. Dom mer Söhne GmbH

Einsteinstraße 5

D-71254 Ditzingen-Heimerdingen

All rights reserved.

Reprinting only allowed with permission of the corporation.

Any changes prior to technical innovations.

20.08.14 Working instructions WIDOS 3511 Page 3 of 39

Contents

Kunststoffschweißtechnik

1.

DESCRIPTION OF PRODUCT ............................................................................6

1.1. Usage and purpose-oriented use .........................................................................................6

1.2. Safety measures .....................................................................................................................6

1.3. Conformity ..............................................................................................................................6

1.4. Designation of the product.................................................................................................... 7

1.4.1. Technical data..................................................................................................................7

1.4.1.1. WIDOS 3511 General data ............................................................................. 7

1.4.1.2. Heating element.............................................................................................. 7

1.5. Equipment and accessories .................................................................................................. 8

2. SAFETY RULES ..................................................................................................9

2.1. Explanation of the different symbols...................................................................................9

2.2. Obligations of the owner ..................................................................................................... 10

2.3. Obligations of the worker....................................................................................................10

2.4. Measure of organization......................................................................................................10

2.5. Information about safety precautions ................................................................................ 10

2.6. Instructions for the staff......................................................................................................10

2.7. Dangers while handling the machine................................................................................. 11

2.8. Dangers caused by electric energy....................................................................................11

2.9. Special dangers....................................................................................................................11

2.9.1. Danger of stumbling over electric cables .......................................................................11

2.9.2. Danger of burning at heating element and welding area ...............................................11

2.9.3. Danger of squeezing by clamping tool and guideways.................................................. 12

2.10. Structural modifications on the machine .......................................................................... 12

2.11. Warranty and liability...........................................................................................................12

3. FUNCTIONAL DESCRIPTION ...........................................................................13

4. OPERATING AND INDICATING ELEMENTS................................................... 14

4.1. Elements at the front............................................................................................................14

4.2. Elements on the heating element.......................................................................................15

4.3. Accessories ..........................................................................................................................15

4.4. Clamping tool left for pipe...................................................................................................16

4.5. Clamping tool for fitting.......................................................................................................16

4.6. Support..................................................................................................................................17

5. STARTING AND OPERATING ..........................................................................18

5.1. Starting..................................................................................................................................18

5.1.1. Assembly of the machine...............................................................................................18

5.2. Welding process...................................................................................................................19

6. WELDING LOG AND TABLES ..........................................................................22

6.1. Table for PP...........................................................................................................................22

20.08.14 Working instructions WIDOS 3511 Page 4 of 39

Contents

Kunststoffschweißtechnik

6.2. Table for PVDF ......................................................................................................................22

6.3. Table for PEHD .....................................................................................................................23

6.4. Table for PB (Polybutene) ...................................................................................................23

6.5. Weld log.................................................................................................................................24

7. MAINTENANCE / STORAGE / TRANSPORT ...................................................25

7.1. Maintenance..........................................................................................................................25

7.2. Storage..................................................................................................................................25

7.3. Transport...............................................................................................................................25

7.4. Cleaning of the machine ......................................................................................................25

7.5. Adjusting of the mismatch compensation......................................................................... 26

7.6. Disposal.................................................................................................................................26

8. ELECTRIC DIAGRAMS .....................................................................................27

9. SPARE PARTS LIST .........................................................................................29

9.1. Basic machine ......................................................................................................................29

9.2. Prism clamping tool for pipes .............................................................................................31

9.3. Prism clamping tool for fitting with support .....................................................................33

9.4. Heating element....................................................................................................................35

9.5. Spigot and socket.................................................................................................................37

10. DECLARATION OF CONFORMITY ..................................................................39

20.08.14 Working instructions WIDOS 3511 Page 5 von 39

WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

Kunststoffschweißtechnik

1. Description of product

This chapter gives important basic information about the product and its prescribed use.

All technical details of th e machine are put together as a general arrangement.

1.1. Usage and purpose-oriented use

The WIDOS 351 1 is exclusively designed for the heating element socket welding of pipes and

fittings out of PE, PP an d PVDF with an outside diameter range from 20 mm to 125 mm.

At heating element socket welding, pipe and fitting are welded overlapping.

The heated tool is adjusted to the siz e of the fitting in a way that a joining pressure is built up at

joining.

Heating element socket joints up to 50 mm pipe diameter can be performed manually.

For diameters as from 63 mm, the use of a weldi ng device is necessary due to the high joining

pressure.

The motion for socket welding is con trolled by means of a transport wheel and a toothed rack.

All use of this machine going beyond is not purpose oriented.

The machine is only to be used in a technically perfect condition, as well as purpose oriented,

safety- and danger-conscious in compliance with the working instructions and the relevant

safety regulations (especially the regulations for the prevention of accide nts).

The described plastic welding machine may only be operated, maintained and repaired by

persons trained and informed about the dangers.

The manufacturer is not responsible for any damages cause d by inexpert handling or

operation.

For personal injuries, material and immaterial damages resulting herefrom, only the user is

responsible!

Prescribed use also means:

following all indications in these working instructions and

performing the inspection and maintenance works.

1.2. Safety measures

In case of wrong use, wrong operation or wrong maintenance, the machine itself or products

standing nearby can be damaged or destroyed.

Persons being in the endangered area may be injured.

Therefore these working instructions have to be thoroughly read and the corresponding safety

advices must be necessarily adhered to.

1.3. Conformity

The machine corresponds in its construction to the valid recommendations of the European

Community as well as to the European standard specifications.

The development, manufacturing and mounting of the machine were made very carefully.

20.08.14 Working instructions WIDOS 3511 Page 6 of 39

Description of product Chapter 1

Kunststoffschweißtechnik

1.4. Designation of the product

The product is designated by a type label at basic machine and heating element.

The labels contain the type of the machine, the serial number and the year of construction.

1.4.1. Technical data

1.4.1.1.

Mat erial : PP, PE, PV DF, PB

Pipe diamete r ran ge: OD = 20 - 125 mm (optional up to OD 150mm)

Transport box (l x w x h): 850 x 670 x 680 mm

Total weight: 80 kg

Protection: 16 A

Emissions:

Ambient conditions: - Keep the workshop clean (especially the welding area

WIDOS 3511 General data

- When using the named pipe materials and when

welding below 260° C or 500° F no toxic damp arises.

must be clean)

- If secured by an appropriate measurement that allowed

conditions for welding are indicated, it is po ssible to

work in any outside temperature condition as far as the

welder is not constrained in its man ual skill- Avoid

humidity, if necessary put up a tent

- Avoid strong sun beams

- If it is windy shut the pipe endings

1.4.1.2. Heating element

Power: 1000 Watt 1000 Watt

Vo ltag e: 230 V ( 10%) 110 V ( 10%)

Current: 4,6 A ( 10%) 9,2 A ( 10%)

Wire cross section: 1,5 mm² 1,5 mm²

Frequency: 50 Hz 60 Hz

Attached elements: - electronic temperature

control

- control lamp

- connecting cable with

plug

Weight : approx. 2 kg approx. 2 kg

- electronic temperature

control

- control lamp

- connecting cable with

plug

20.08.14 Working instructions WIDOS 3511 Page 7 of 39

Description of product Chapter 1

1.5. Equipment and accessories

Pieces Denomination

1 Allan key size 5 (screw in / out the clamping elements)

1 Allan key size 4 (for changing the dial)

1 Allan key with T grip, size 6 (for changing spigots and socke ts)

1 set Gripping tools for pipes Ø 20 – 50 mm

1 set Gripping tools for pipes Ø 50 – 125 mm

1 set Gripping tools for fitting Ø 29 – 68 m m

1 set Gripping tools for fitting Ø 75 – 167 mm

1 set Gripping tools for fitting Ø 29 – 68 mm NIBCO (optional)

1 Dial DVS type B (optional)

1 Dial ASTM mm (optional)

1 Dial ASTM inch (optional)

Kunststoffschweißtechnik

20.08.14 Working instructions WIDOS 3511 Page 8 of 39

WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

Kunststoffschweißtechnik

2. Safety rules

A basic premise for working safe ly and without disturbances is the knowledge of the basic

safety signs and safety rules.

These working instructions provide you with the most important information to run the

machine safely.

The safety information must be followed by all persons who work at the machine.

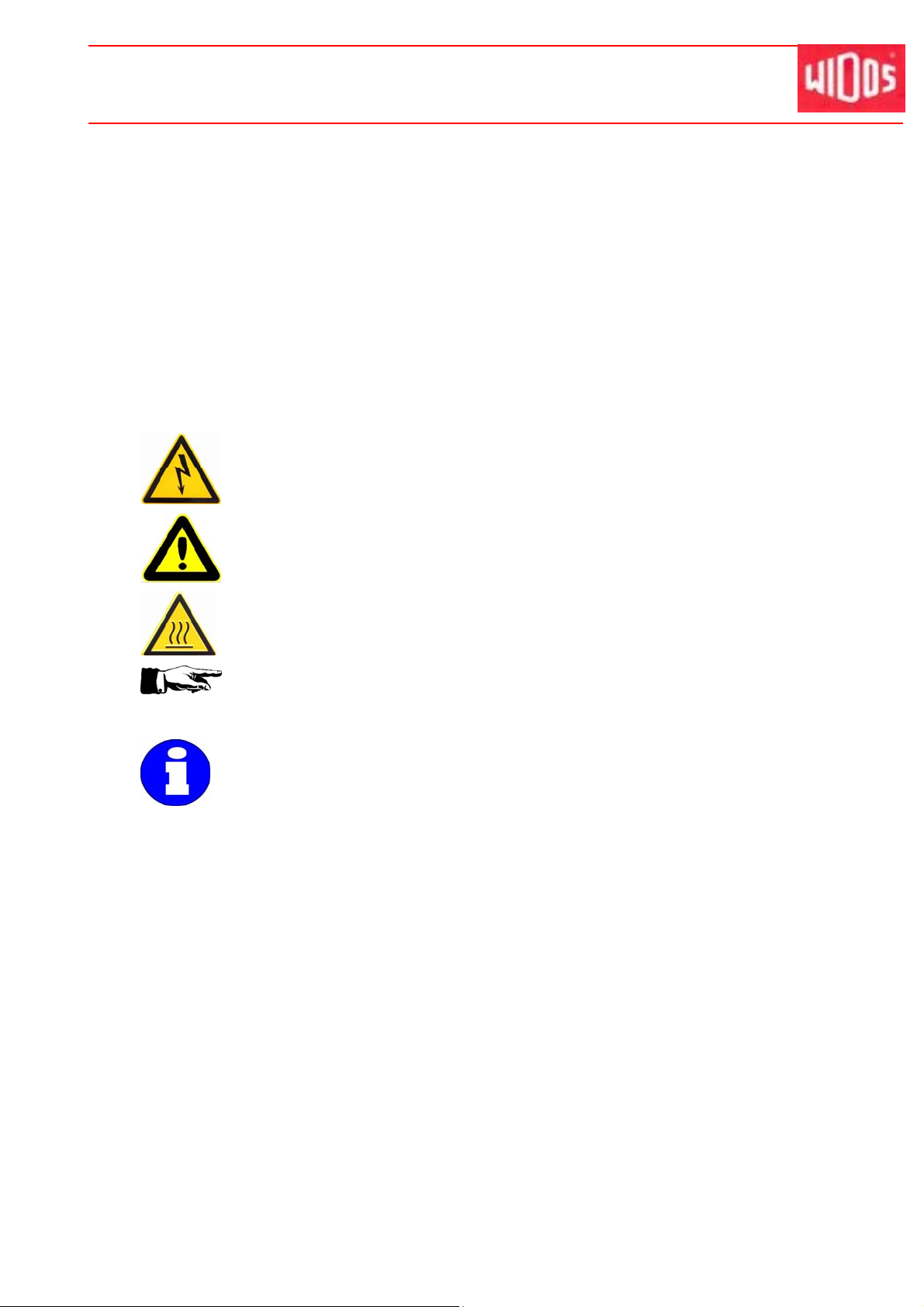

2.1. Explanation of the different sym bols

The working instructions contain the following signs for certain situations:

This symbol means a possibly danger for the life and the health of persons.

The disrespect of these indications may have h eavy consequences for the

health.

This symbol means a possible dangerous situation.

The disrespect of these indications may cause slight injuries or damages on

goods.

This symbol means a possible dangerous situation due to hot surfaces.

The disrespect of these indications may conduct to heavy burns,

respectively to self-ignition or even fire.

This symbol gives important indications for the p roper use of the machine.

The disrespect of these indications may conduct to malfunctions and

damages on the machine or on goods in the sur rounding.

Under this symbol you get user tips and particularly useful information.

It is a help for using all the functions on your machine in an optimal way and

The regulations for the prevention of accidents are valid (UVV).

helps you to make the job easier.

20.08.14 Working instructions WIDOS 3511 Page 9 of 39

Safety rules Chapter 2

Kunststoffschweißtechnik

2.2. Obligations of the owner

The owner is obliged on ly to let persons work at the machine who

know about basic safety and accident prevention rules and are instructed in the handling of

the machine, as well as who

have read and understood the safety chapter of this manual and certify this by their

signature.

The safety-conscious working of the staff has to be checked in regular intervals.

2.3. Obligations of the worker

All persons who are to work at the machine are obliged before working:

to follow the basic safety and accident protection rules.

to have read and understood the safety chapter and the warnings in this manual and to

confirm by their signature that they have well understood them.

to inform themselves about the functions of the machine before using it.

2.4. Measure of organization

All equipment required for personal safety is to be provided by the owner.

All available safety equipment is to be inspected regularly.

2.5. Information about safety precautions

The working instructions have to be permanently kept at the place of use of the machine.

They are to be at the operator's disp osal at any time and without much effort.

In addition to the manual, the common valid and the local a ccident protection rules and

regulations for the environmental protection must be available and followed.

All safety and danger indications on t he machine have to be in a clear readable condition.

Every time the machine changes hands or is being rent to third persons, the working

instructions are to be sent along with and their importance is to be emphasized.

2.6. Instructions for the staff

Only skilled and trained persons are allowed to work at the machine.

It must be clearly defined who is responsible for transport, mounting and dismounting, and

starting the operation.

A person who is being trained may only work at the machine under supervision of an

experienced person.

20.08.14 Working instructions WIDOS 3511 Page 10 of 39

Safety rules Chapter 2

Kunststoffschweißtechnik

2.7. Dangers while handling the machine

The machine WIDOS 351 1 is constructed according to the latest technical standard and the

acknowledged technical safety rules.

However, dangers for the operator or other persons standing nearby m ay occur. Also material

damages are possible.

The machine may only be used

according to the purpose -oriented use

in safety technical impeccable status

Disturbances which may affect the safety of the machine must be cleared immediately

Only skilled persons are allowed to w ork at electrical appliances.

The electrical equipment of the machine has to be checked regularly.

Loose connections and damaged cables have to be replaced immediately.

Protect the heating element and planer from rain and dropp ing water.

According to VDE 0100, the use on c onstruction sites is only allowed with a power

distributor with a FI-safety switch.

2.8. Dangers caused by electric energy

Only skilled persons are allowed to work at electrical appliances!

The electrical equipment of the machine has to be checked regularly. Loose

connections and damaged cables have to be replaced immediately .

If works at alive parts are necessary, a second p erson has to assist who can disconnect the

machine from the mains if necessary.

The heating element has to be protected from rain and dropping water (if need be use a

welding tent).

According to VDE 0100, the use on c onstruction sites is only allowed with a power

distributor with a FI-safety switch.

2.9. Special dangers

2.9.1. Danger of stumbling over electric cables

Make sure that no person must step over the wires.

Make sure that the cables lie in such a way that the danger is maintained at a minimum.

2.9.2. Danger of burning at heating element and welding area

You can burn yourself, inflammable materials can be ignited!

The heating element reaches temperatures of more than 260° C / 500° F!

Do not touch the surface of the heating element.

Do not leave the surfac es of the heating element unattended.

Take enough safety distance to materials which may be ignited.

Do wear safety gloves.

Only swivel the heating element at the handle.

20.08.14 Working instructions WIDOS 3511 Page 11 of 39

Safety rules Chapter 2

When cleaning the hot h eating element with detergents (e.g. with PE – cleaning agent)

there is the danger of inflammation. For this reas on, please take care that the inflammation

point is above the actual temperature of the heating element. Do not bring any fire sources

(e.g. cigarettes) close thereto.

2.9.3. Danger of squeezing by clamping tool and guideways

There is the danger of serious injurie s. On the one hand between the clamping tools

and on the other hand between the ends of the guideways and the machine slide.

Do not grip between the workpieces.

Do not touch the guide ways.

Kunststoffschweißtechnik

2.10. Structural modifications on the machine

Without permission of the manufacturer, no modifications, extensions or reconstructions

may be performed on the machine. Any non-compliance makes expiring the guarantee and

liability demands (chapter 2.5.).

Machine parts that are not in perfect condition are to be replaced immediately .

Only use original WIDOS spare and wear parts.

In case of purchase orders, please always note the machine and version number!

2.11. Warranty and liability

Fundamentally, our "General sales and delivery conditions" are in force.

They are at the buyer's disposal latest when signing the contract.

Guarantee and liability demands referring to damages of persons or things are excluded if they

are caused by one or several of the following reasons:

Not using the machine according to the prescriptions.

Unprofessional transport, building-up, starting, operating and maintenance of the machine.

Running the machine with defective or not properly mounted safety equipment.

Ignoring the information given in these working instruction s.

Structural modifications on the machine without permission.

Unsatisfactory maintenance of parts of the machine which are worn out.

Unprofessionally performed repairs.

In case of c atastrophes and acts of god.

20.08.14 Working instructions WIDOS 3511 Page 12 of 39

WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

Kunststoffschweißtechnik

3. Functional description

Basically, the international and national standard specifications are

to be fulfilled.

First of all, the two workpieces to be welded are put into the clamping device, the fitting is

clamped at the stop of the clamping device.

Then the zero offset is ef fected and the pipe can be clamped in such a way that both

workpieces can be heated up to welding temperature at the same time (heat-up time) with the

help of a socket or sp igot-shaped heating element.

After swinging out the heating element (change-over time), the workpieces are joined (cooling

time).

The pipe end, heating element and fitting socket are to match each other in size in such a way

that a joining pressure will build up during joinin g.

After expiration of the cooling time, the welded joint can be unclamped, the welding process is

finished.

Principle of heating element socket welding

20.08.14 Working instructions WIDOS 3511 Page 13 of 39

WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

Kunststoffschweißtechnik

4. Operating and indicating elements

4.1. Elements at the front

1

2

3

No. Denomination / function

1 Clamping tool left for pipe

2 Handle for pipe clamping tool left s ide, clamping tool open / close

3 Cross handle for slides; both slides open / close

4 Heating element with spigot and socket

5 Clamping tool for fitting right side

6 Universal support for fittings

7 Handle for fitting clamping tool tight side, clamping tool open / close

8 Clamping lever for locking slides

9 Dial (DVS type B / ASTM mm / AST M inch) for insertion depth and zero offset

4

5

6

7

8

9

20.08.14 Working instructions WIDOS 3511 Page 14 of 39

Operating and indicating elements Chapter 4

4.2. Elements on the heating element

No. Denomination Function

10 Switch on/off Red light as soon as the heating ele ment is switched on

11 Knob with slot Setting the heating element temperature

12 Control lamp green Three different states:

13 Grip Swiveling the heating element in / out manually

10

11

12

off: signal showing that the heating element is n ot heated

up at the moment or that it is cooling.

blinking: the temperature of the heating element is

maintained by a defined pulse-position ratio.

on: signal showing that the heating element is heated up at

the moment. The nominal temperature has not

been reached yet.

13

4.3. Accessories

Kunststoffschweißtechnik

No. Denomination / Function

14 Pipe chamferer for 15°-chamfering the pipe end (optional)

15 Spigot

16 Socket

20.08.14 Working instructions WIDOS 3511 Page 15 of 39

14

15

16

Operating and indicating elements Chapter 4

Kunststoffschweißtechnik

4.4. Clamping tool left for pipe

There are two sizes of pipe clamping tool OD 20 - OD 50 mm and OD 50 - OD 125 mm. The

clamping claws of the pipe clamping tool sitting on straight pins internally and externally. The

internal claws are mounted by flat-head screws and the external with star handle.

Clamping jaw inside: Clamping jaw outside:

How to change internal clamping claws:

Remove the flat-head screws and detach the clamping jaws. Set the clamping jaw with

other size on the straight pins and mount it with flat-head scre w.

How to change external clamping claws:

Loosen the star screws detach the clamping claw from straight pins and remove it to the

top. Set the clamping jaw with other size on the straight pins and mount it with star handle.

Marking of size

Straight pin

Flat-head screw

Star handle

4.5. Clamping tool for fitting

There are different sizes of fitting clamping tools:

OD 29 – OD 68 mm, OD 75 – OD 167 mm and

OD 29 – OD 68 NIBCO. The clamping jaws of the

fitting clamping tool sitting on straight pins and are

mounted with flat-head screws.

For changing a jaw rem ove the flat-head screw

and detach the jaw.

Set the clamping jaw with other size on the

straight pins and mount it with flat-he ad screw.

20.08.14 Working instructions WIDOS 3511 Page 16 of 39

Marking of the size

Straight pin

Flat-head screw

Operating and indicating elements Chapter 4

Kunststoffschweißtechnik

4.6. Support

With the support you can support fittings. For long part you can use rotated the support 180°

(right picture).

With clamping lever you fix the support on axis.

Support

Clamping lever

You can with an additional guide bar (optional)

use the support either front or rear .

You can with an additional guide bar (optional)

use the support either front or rear (arrow).

20.08.14 Working instructions WIDOS 3511 Page 17 of 39

WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

Kunststoffschweißtechnik

5. Starting and operating

The indications of this chapter are supposed to instruct you in the operation of the machine

and to lead you during the skilled starting of the machine. This inc ludes:

the safe operation of the machine

using all possibilities

economic operation of the machine

5.1. Starting

The machine may only be operated by initiated and authorized persons.

For the qualification, a p lastic welding exam can be taken according to DVS

and DVGW.

In danger situations for person and the machine, the mains plug has to be

unplugged immediately.

At the end of the work and during breaks, the machine has to be switche d off.

Also take care that no unauthorized person has access to the machine.

Protect the machine from wetness and humidity!

According to VDE 0100, operation on building sites is only allowed with a current

distributor with FI-security protective switch.

The socket and spigot surfaces are t o be clean and, above all, free from

grease. Therefore they are to be cleaned with non-fraying paper and

detergent (e.g. PE – cleaning agent or WIDOS pipe cleansing cloths) before

every welding or if they are dirty.

The nonstick coating of the socket a nd spigot must remain undamaged in the

working area.

Take into account the surrounding conditions:

- The welding may not be performed under direct sun rays influence.

- Use a welding umbrella if necessary.

If the surrounding temperature is under 5°C / 41°F , measures have to be taken:

- Use a welding tent or preheat the pipe ends if n ecessary.

In addition, take measures against rain, wind and dust.

Take measures against rain, wind and dust.

5.1.1. Assembly of the machine

Detach the clamping handles of the transport ca se and lift off the case in an upward

direction.

T urn the case upside down with the open space on top and p ut it on the floor.

Put the case floor togeth er with the machine onto the open case.

Refit the screwed-off heating element handle.

Connect the heating element to the local power supply (230 V / 16 A / 50 Hz) / (1 10V / 15 A

/ 60 Hz).

Assemble the machine in a way that no unauthorized person may touch the swiveled out

heating element, otherwise install a barrier on site.

The machine can be operated now .

20.08.14 Working instructions WIDOS 3511 Page 18 of 39

Starting and operating Chapter 5

Kunststoffschweißtechnik

5.2. Welding process

The respectively valid welding prescriptions (ISO / CEN / DVS...) are to

be basically followed.

Do wear safety gloves as protection against burning!

A stop-watch is to be available in order to be able to register the actual times for heating up

and cooling.

Screw the cleaned and fitting socket and spigot which are free from grease onto the heating

element (spigot right-hand / socket left-hand).

Mount the prism clamping tools for the pipe with a correspon ding diameter range on the left

side (chapter: 4.4).

Mount the prism clamping tool for the fitting with a corresponding diameter range on the

right side (chapter: 4.5). For clamping the fitting, fitting stops are provided.

A welding table is to be available from which you can read the parameters that are

prescribed by the welding regulations for the pip e dimension to be welded.

The heating element socket / spigot are to be clean and, above all, free from grease.

Therefore they are to be cleaned with non-fraying paper and detergent (e.g. spirit) before

every welding or if they are dirty.

The anti-stick coating of the heating element mu st remain undamaged in the working area.

In addition, the workpieces (fitting an d pipe) to be welded must be clean. If need be, clean

them with detergent and non-fraying paper.

The pipe end is to be chamfered to appr. 15°.

approx. 15°

2-3 mm

Switch on the heating element and adjust the necessary welding temperature at the set

screw at the handle. If the control lamp blinks, the nominal temperature has been reached

and is maintained by means of a defined pulse-pause ratio.

Insert the fitting in the right-hand clamping tool onto the limit stop.

Clamp the fitting by handle.

Support the fitting with support if necessary (chapter: 4.6).

Limit stop for fitting

20.08.14 Working instructions WIDOS 3511 Page 19 of 39

Starting and operating Chapter 5

T urn the dial until the position “0” loc ks over the red spot.

Shut the ma chine until the dial rest against the stop bolt (upper left image) and fix this

position with the clamping lever (8).

Dial for metric pipes

Upon resetting and joining drive the

machine with the dial at stop bolt.

Dial for inch pipes

Kunststoffschweißtechnik

Insert the chamfered pipe so that the end face is adjacent to the fitting.

Close the pipe clamping tool and cla mp the pipe by handle.

Positioning of different pipes towards the fitting:

Shut the left clamping to ol by handle and clamp the pipe tightly.

Release the clamping le ver (8) and open the tables.

Swivel the heating element into the machine. The heating element must be immerse d into

the recess on the frame in front.

Drive the slides together and the workpieces with minor force onto the heating socket resp.

against the limit stop of the heating spigot (pipe and fitting must touch the socket / spigot at

the same time.)

Limit stop at the spigot

20.08.14 Working instructions WIDOS 3511 Page 20 of 39

Starting and operating Chapter 5

Secure this position with the clamping lever.

Press the stop watch for the heating time.

After expiration of the he ating time release the clamping lever, open the machine quickly,

swivel out the heating element and drive the slides together immediately shock-free and

with minor force until the dial rests against the stop bolt (change-over time). The maximu m

time frame for this process is predetermined by the value for the change-over time taken

from the table.

Secure the position by clamping lever (8) and press the stop-watch.

Now, the cooling time starts. After expiration of the cooling time open the clamping tools

and remove the welded part.

Release the clamping lever and open the machine.

The welding process is completed

Complete the weld log (chapter 6).

Kunststoffschweißtechnik

20.08.14 Working instructions WIDOS 3511 Page 21 of 39

WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

Kunststoffschweißtechnik

6. W elding log and t ables

Standard values for heating element socket welding of pipeline components at an ambient

temperature of 20° C (68° F) and at a moderate air flow.

Welding temperature for all procedures: 250° C - 270° C / 482° F – 518° F.

6.1. Table for PP

Pipe outside

diameter

[mm] SDR 11,

SDR7,4

SDR6

16 5 *) 4 6 2

20 5 *) 4 6 2

25 7 *) 4 10 2

32 8 *) 6 10 4

40 12 *) 6 20 4

50 18 *) 6 20 4

63 24 10 8 30 6

75 30 15 8 30 6

90 40 22 8 40 6

110 50 30 10 50 8

125 60 35 10 60 8

Heat-up Change-over

(max. time)

SDR 17,6

SDR17

[s]

[s]

[s] clamped

Cool down

[s]

total

[min]

6.2. Table for PVDF

Pipe outside

diameter

[mm] [mm] [s] [s] clamped

16 1,5 4 4 6 2

20 1,9 6 4 6 2

25 1,9 8 4 6 2

32 2,4 10 4 12 4

40 2,4 12 4 12 4

50 3 18 4 12 4

63 3 20 6 18 6

75 3 22 6 18 6

90 3 25 6 18 6

110 3 30 6 24 8

125**) 4 35 6 24 8

20.08.14 Working instructions WIDOS 3511 Page 22 of 39

Min. pipe wall

thickness -

Heat-up

Change-over

(max. time)

Cool down

[s]

total

[min]

Welding tables and welding log Chapter 6

6.3. Table for PE HD

Kunststoffschweißtechnik

Pipe outside

diameter

[mm] SDR 11,

SDR7,4

SDR6

16 5 *) 4 6 2

20 5 *) 4 6 2

25 7 *) 4 10 2

32 8 *) 6 10 4

40 12 *) 6 20 4

50 18 *) 6 20 4

63 24 *) 8 30 6

75 30 18 8 30 6

90 40 26 8 40 6

110 50 36 10 50 8

125 60 46 10 60 8

Heat-up Change-over

(max. time)

SDR 17,6

SDR17

[s]

[s]

[s] [mm] SDR 11,

Cool down

SDR7,4

SDR6

[s]

6.4. Table for PB (P olybutene)

Pipe outside

diameter

[mm]

20**) 2,0 15 6 15 2

25**) 2,3 18 6 15 2

32**) 3,0 20 10 20 4

40**) 3,7 22 14 20 4

50**) 4,6 25 18 30 4

63**) 5,8 28 22 30 6

75**) 6,8 31 26 60 6

90**) 8,2 36 30 75 6

110**) 10,0 42 35 90 6

125**) 11,4 46 40 104 7

*) Due to wall thickness which is too small, this welding method is not recommended.

**) These fields contain merely inter polated values which are not verified by a valid standard

and for which th e WIDOS GmbH does not assume any warranty.

Min. pipe wall

thickness

[mm]

Insertion

depth

[mm]

Heat-up

[s]

Holding (under

pressure)

[s]

Cool down

[min]

Apart from that, the standard values for welding of the plastic pipe or fitting manufacturer are

valid.

20.08.14 Working instructions WIDOS 3511 Page 23 of 39

Welding tables and welding log Chapter 6

6.5. Weld log

Kunststoffschweißtechnik

20.08.14 Working instructions WIDOS 3511 Page 24 of 39

WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

Kunststoffschweißtechnik

7. Maintena nce / Storage / Transport

Goal of the chapter is:

Keeping the nominal sta te and the operation capacity of the machine.

Efficient planning of the maintenance works and the maintenance tools.

Increasing the efficiency by avoiding non planned outage.

7.1. Maintenance

Replace defective parts immediately, be especia lly careful with electric parts - dirt and

wetness are good curre nt conductors.

Use original WIDOS spare parts only.

Prescribed maintenance and inspe ction works have to be carried out in time.

According to DVS, inspection works are recommended after 1 year.

At machines which are used more than average, the inspection cycle should be

shortened.

The works have to be performed at the WIDOS company or at an authorized

partner.

7.2. Storage

Keep the guide rods, toothed rods, toothed wheel and trapezoid spindle free from dirt and

covered with a thin oil film.

Cover the machine during non-use.

Store dry.

7.3. Transport

The machine is transported in a transport box.

T ake care that the cable of the heating element is not squeezed.

Protect the machine from heavy vibrations and shocks.

Make sure that the box cover is correctly locked.

Handle the machine carefully.

7.4. Cleaning of the machine

The used materials and tissues have to be handled and disposed of properly, particularly

when cleaning with solvents

when lubricating with oil and grease

20.08.14 Working instructions WIDOS 3511 Page 25 of 39

Maintenance / storage / transport Chapter 7

Kunststoffschweißtechnik

7.5. Adjusting of the mismatch compensation

Adjusting of the mismatch compensation is only required after repair works or

exchange of spare parts.

It may only be performed by WIDO S staff or respective authorized persons.

You can make an horizontal mismatch compensation (max. 10 mm).

Detach the counter nut and adjust the adjustment bushing until the mismatch is cleared.

Check the line with a gauge for example.

Tighten the counter nut afterwards again.

Adjustment bushing

Counter nut

7.6. Disposal

At the end of the life time, the machine has to be disposed of properly,

non-polluting and in acc ordance with the national laws of waste disposal.

20.08.14 Working instructions WIDOS 3511 Page 26 of 39

WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

Kunststoffschweißtechnik

8. Electric diagrams

20.08.14 Working instructions WIDOS 3511 Page 27 of 39

Electric diagrams Chapter 8

Kunststoffschweißtechnik

20.08.14 Working instructions WIDOS 3511 Page 28 of 39

WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

Kunststoffschweißtechnik

9. Spare parts list

9.1. Basic machine

1 - 3

4 - 5

6

7

8 - 13

14

15- 18

19

20 - 21

22 - 24

25- 26

27

28 - 29

30 - 31

20.08.14 Working instructions WIDOS 3511 Page 29 of 39

Spare parts list Chapter 9

Kunststoffschweißtechnik

Basic machine WIDOS 3511

Pos. Name Piece Order no.

1 Rack down 1 3551029

2 Washer M5 DIN 125 2 0125 E

3 Pan-head screw M 5x20 DIN 7984 2 7984E020

4 Stop bolt 1 3751046

5 Shim ring 8 x 14 x 0,5 DIN 988 1 on request

6 Idler 2 3751005

7 Base frame 1 375001

8 Gear shaft 1 3751006

9 Flange bushing PAF18170P10 1 on request

10 Spacer ring 1 3751009

11 Spur gear 1 372107

12 Retaining ring 12 x 1 DIN 471 1 0471L

13 Feather key A 4x4x22 DIN 6885 1 6885D022

14 Cruciform hub, complete 1 3751008KP

15 Bearing pin 1 3751011

16 Shim ring 20 x 28 x 1 DIN 988 1 0988T010

17 Straight pin 3h11 x 12 DIN 7 1 0007C012

18 Spring-loaded thrust pad 615,3-M10-K-PFR 1 on request

19 Streight pin M 10x16 DIN 913 2 0913J016

20 Clamping lever GN212.3-21-M8-25-D 1 on request

21 Pressure piece 1 370120

22 Linit stop washer DVS type A in mm (optional) 1 3751280

(22 ) Linit stop washer DVS type B in mm (optional) 1 3751250

(22 ) Linit stop washer ASTM in mm (optional) 1 3751270

(22) Linit stop washer ASTM in inch (optional) 1 3751260

23 Disc 1 3751012

24 Flat-head screw M 6x12 DIN 7991 1 7991F012

25 Washer M8 DIN 125 2 0125H

26 Pan-head screw M 8x65 DIN 912 2 0912H065

27 Idler for heating element 1 3751034

28 Pendulum strip 2 3751036

29 Pan-head screw M 6x25 DIN 912 2 0912F025

30 Breaking wave 1 3751035

31 Pan-head screw M 6x30 DIN 7984 2 7984F030

20.08.2014 Working instruction WIDOS 3511 Page 30 of 39

Spare parts list Chapter 9

9.2. Prism clamping tool for pipes

1 - 2

3

4 - 5

6 - 7

8

9

10 - 11

20

21

22

23 - 24

25

26

Kunststoffschweißtechnik

12

13

14

15

16

17 - 19

20.08.14 Working instructions WIDOS 3511 Page 31 of 39

Spare parts list Chapter 9

Prism gripping tool for pipes WIDOS 3511

Pos. Name Piece Order no.

1 Idler for slide 2 3751028

2 Slide bush PSM202520A51 8 on request

3 Acme thread spindle 1 3751023

4 Counter nut 1 3751025

5 Shim D10xD16x0,5 DIN 988 1 0988J005

6 Adjustment bushing 1 3751024

7 Adjusting ring 1 3751045

8 Handwheel 1 3751027

9 Slide left 1 3751002

10 Rack upside 1 3751018

11 Pan-head screw M 5x16 DIN 912 2 0912E016

12 Grub screw M 6x10 DIN 914 3 0914F010

13 bearing bush 1 3751026

14 Straght pin 8 m6x24 DIN 6325 8 6325H024

15 Flat-head screw M 8x30 DIN 7991 4 7991H030

16 bush PAP2525 P10 4 on request

17 Support plate 1 3751019

18 W asher M5 DIN 125 2 0125E

19 Pan-head screw M 5x50 DIN 912 2 0912E050

20 Clamping tool pipe side OD 20 to 50 mm 2 3757012

(20 ) Clamping tool pipe side OD 50 to 125 mm 2 3757011

(20 ) Clamping tool pipe side OD 64 to 150 mm R 1 3757024

(20 ) Clamping tool pipe side OD 64 to 150 mm L 1 3757023

21 Guide block pipe side, rear 1 3751041

22 Guide block pipe side, in front 1 3751040

23 Star handle GN6335.2-50-M8-E 2 on request

24 Grub screw M 8x60 DIN 914 2 0913H060

25 Clamping tool pipe side OD 20 - 50 mm 1 3757015

(25 ) Clamping tool pipe side OD 50 - 125 mm 1 3757014

(25 ) Clamping tool pipe side OD 64 - 150 mm 1 3757022

26 Clamping tool pipe side OD 20 - 50 mm 1 3757016

(26 ) Clamping tool pipe side OD 50 - 125 mm 1 3757013

(26 ) Clamping tool pipe side OD 64 - 150 mm 1 3757021

Kunststoffschweißtechnik

20.08.2014 Working instruction WIDOS 3511 Page 32 of 36

Spare parts list Chapter 9

9.3. Prism clamping tool for fitting with support

Kunststoffschweißtechnik

1

2 - 3

4

5

11 - 13

8 - 10

6

7

14

15

16

21

17

22

23

18

19 - 20

20.08.14 Working instructions WIDOS 3511 Page 33 of 39

Spare parts list Chapter 9

Prism clamping tool for fitting WIDOS 3511

Pos. Name Piece Order no.

1 Clamping tool fitting L/R OD 75 - 167 mm 1 375 7117

(1) Clamping tool fitting L/R OD 29 - 68 mm 1 3757 119

(1) Clamping tool fitting L/R OD 29 - 68 NIBCO 1 3757125

2 Idler for slide 2 3751028

3 Slide bush PSM202520A51 8 on request

4 bearing bush 1 3751026

5 Grub screw M 6x10 DIN 914 3 0914F010

6 Acme thread spindle 1 3751023

7 Slide right 1 3751003

8 Support plate 1 3751019

9 W asher M5 DIN 125 2 012 5E

10 Pan-head screw M 5x50 DIN 912 2 0912E050

11 Counter nut 1 3751025

12 Shim 1 0988J005

13 Adjustment bushing 1 3751024

14 Straght pin 8 m6x24 DIN 6325 4 6325H024

15 Flat-head screw M 8x30 DIN 7991 4 7991H030

16 Bush PAP2525 P10 4 on request

17 Guide block pipe side, rear 1 3751043

18 Guide block pipe side, in front 1 3751042

19 Adjusting ring 1 3751045

20 Handwheel 1 3751027

21 Arrester 1 3751004

22 Guide rod arrester 1 (2) 3751032

23 Eccentric clamp GN927-82-M8-A 1 on request

Kunststoffschweißtechnik

20.08.2014 Working instruction WIDOS 3511 Page 34 of 39

Spare parts list Chapter 9

9.4. Heating element

Kunststoffschweißtechnik

1 (1)

2

3

4

5

11

6

7

8

12

13

14

9

10

15

16

17 - 19

20

21

22

23

24

25

27

26

20.08.14 Working instructions WIDOS 3511 Page 35 of 39

Spare parts list Chapter 9

Kunststoffschweißtechnik

Heating element WIDOS 351 1

Pos. Name Piece Order no.

1 Heating element complete 230V 1 H351 1E

(1) Heating element complete110V 1 H3511E110

2 Cylindrical knob 1 0519-26-M12

3 Fixing element 1 3755005

4 Pan-head screw M 6 x 20 DIN 912 2 0912F020

5 Distance bolt 2 3755004

6 Pan-head screw M 6 x 30 DIN 912 2 0912F030

7 Handlebar 335 long 1 3755003

8 Heating plate bracket 1 3755001

9 Guide bearing 2 LKH1630

10 Pan-head screw M 8 x 30 DIN 912 1 0912H030

11 Heating plate 230 V 1 HP35 11E

(11 ) Heating plate 110 V 1 HP351 1E1 10

12 T emperature probe PT 1000 1 H09082

13 T apped bushing 12x18, M6 2 HGEW-M6

14 Insulating piece 2 371518

15 Pan-head screw M 6 x 90 DIN 912 2 091 2HF0 90

16 Signal lamp green (with low voltage glow lamp) 1 H2 105

17 Thermo regulator GZ 4 1 H0918220

18 Control cnob with groove 1 H09075

19 Scale 180-280 °C, d=33 (design 230 V) 1 H0 9074

(19) Scale 356-536 °F, d=33 (design 110 V) 1 on request

20 Rocker switch red 1 H09 03

(20) Rocker switch red (110 V) 1 H0 9031 10

21 Pan head screw M 4x70 DIN 912 3 0912D070

22 Heat sink with Triac BT 139 1 H0 908 1

23 Teflon insulating disk 1 H09091

24 Short handle case 1 H38 07

25 Cable bushing PG 11 Skintop BS 1 EVK11BS

26 Mains cable with plug (design 230 V) 1 E K32220

(26) Mains cable with plug (design 110 V) 1 on request

27 Raised coutersunk head screw M 4,2x13 DIN 7981 3 7981D013

20.08.2014 Working instruction WIDOS 3511 Page 36 of 39

Spare parts list Chapter 9

9.5. Spigot and socket

1

Kunststoffschweißtechnik

20.08.14 Working instructions WIDOS 3511 Page 37 of 39

Spare parts list Chapter 9

Spigot, socket WIDOS 3511

Pos. Name Piece Order no.

1 Spigot, socket, OD 20-125* compl. DVS type B 1 set H D…SC*

(1) Spigot, socket, OD 20-125* compl. DVS type A 1 set HD …PS*

(1) Spigot, socket, OD 20-125* compl. ASTM (mm) 1 set HD… A*

(1) Spigot, socket, OD ½"-4" * compl. ASTM (inch) 1 set H D…NS *

*) When ordering, please state the dimension of the diameter

Kunststoffschweißtechnik

20.08.2014 Working instruction WIDOS 3511 Page 38 of 39

WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

Kunststoffschweißtechnik

10. Declaration of conformity

In the sense of the guideline, EC Machinery Directive2006/42/EC

Corporation

WIDOS GmbH

Einsteinstr. 5

D-71254 Ditzingen-Heimerdingen

declares that the product

Plastic welding machine

WIDOS 3511

has been designed in compliance with:

1. DIN EN IS O 12100 – 1 and 2 (substitute for DIN EN 292 part 1 and 2)

Safety of machines, basic terminology, general guidelines for design

2. DIN EN 60204.1

Electric equipment of industrial machines

3. DIN EN 605 55, DIN EN 50082, DIN EN 55014,

Electro-magnetic resistance

The working instructions in the mother language of the user are available.

The technical documentation is completely available.

Ditzingen-Heimerdingen, the 8/20/2014

Martin Dommer (Technical director)

20.08.14 Working instructions WIDOS 3511 Page 39 of 39

Loading...

Loading...