Widney RSW10KL User Manual

1

GB

RSW10KL

Instantaneous Gas Water Heater

Suitable for use in the following countries:

AT,BE,CH,DE,DK,ES,FI,FR,GB,GR,IE,IT,NL,PT,HU,PL,BG,CY,CZ,LT,RO,SI,SK

INSTALLER MANUAL

GAS SAFETY (INSTALLATION AND USE) REGULATIONS 1998 (AS AMENDED)

It is a Legal requirement that all gas appliances must be installed by a registered

person in accordance with the above regulations.

Failure to install appliances correctly could lead to prosecution. It is in your own

interest, and that of safety, to ensure that the Legal requirements are complied with.

Read these instructions carefully before attempting to operate the appliance. Comply

with all applicable warnings.

Do not interfere with any sealed components, and use the appliance only in

accordance with these instructions.

RECOMMENDATIONS - FOR THE INSTALLER

This appliance must not be installed, adjusted or adapted for use with another type of gas.

GAS SAFETY (INSTALLATION AND USE) REGULATIONS 1998 (as amended)

It is a Legal requirement that all gas appliances must be installed by a registered person in accordance with the above

regulations.

Failure to install appliances correctly may lead to prosecution.

It is in your own interest, and that of safety, to ensure that the legal requirements are complied with.

In addition to the above regulations, this appliance must be installed in accordance with the current IEE Wiring

regulations, Health and Safety Document No 635 'The Electricity at Work Regulations. It should also be in accordance

with the relevant recommendations in the current editions of all relevant National Standards. Your particular attention

is drawn to the following standards relevant to an installation in Leisure Accommodation Vehicles:

BS EN 1647:2004+A1:2008 Leisure accommodation vehicles; Caravan holiday homes; Habitation requirements

relating to health and safety.

BS EN 721:2004 Leisure accommodation vehicles: Safety ventilation requirements.

BS EN 1949:2002 Specification for the installation of LPG systems for habitation purposes in leisure accommodation

vehicles and in other vehicles.

BS 5440-1:2008 Flueing and ventilation for gas appliances of rated input not exceeding 70 kW net (1st, 2nd and 3rd

family gases). Specification for installation of gas appliances to chimneys and for maintenance of chimneys

BS5482-2:1977 Domestic butane- and propane-gas-burning installations: Installations in caravans and non-permanent

dwellings.

Codes of Practice

CoP 501

CoP 502

IMPORTANT: References to the above standards are for guidance only. Installers must always check to ensure that

the references made to EN and BS standards in this document are to the latest requirements.

The installation must be according to national and local regulations and the requirements of the CPD (construction

products directive).

Manufacturer’s instructions must NOT be taken in any way as over-riding statutory regulations

Always refer to technical information provided on the appliance data plate before installing this appliance

Ensure that the appliance is compatible with local regulations

GB

IE

2

INTRODUCTION

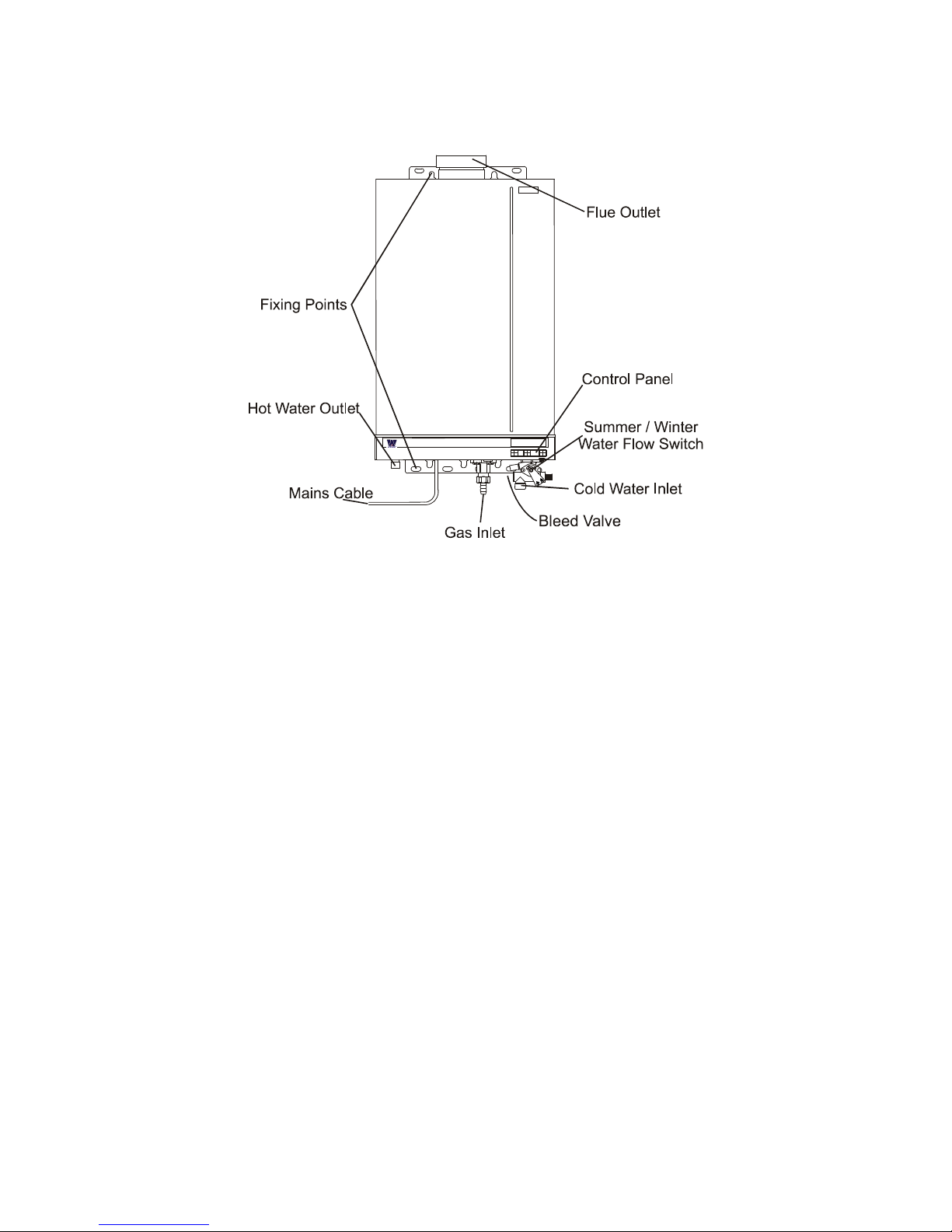

The WIDNEY RSW10KL is a wall hung, room sealed, fan assisted, microprocessor controlled fully modulating gas

Water heater for providing domestic hot water. It is particularly suitable for Caravan Holiday Home and Park Home

use. It is not suitable for road going vehicles.

DO’s and Don’ts

DO read the installation instructions before fitting the product

DO check that the correct gas and Water supply is available

DO use the recommended terminal and Flue Pipe

DO check that the flue system is correctly fitted prior to commissioning

DO NOT attempt to fit this appliance unless you are a qualified fitter

DO NOT operate this appliance before the installation checks are complete

Guidance Notes for POSITIONING AND LOCATION of Water Heater

1. WATER HEATER LOCATION

In positioning the water heater, the following limitations MUST be observed:

The position must allow for a suitable flue termination to be made.

The water heater must be installed on a flat vertical wall capable of supporting its weight. - If the water heater is in a

room containing a bath or shower, the water heater controls and power supply must be situated so that they cannot be

touched by the person using the bath or shower. Your attention is drawn to the current IEE Wiring Regulations, and in

Scotland the electrical provisions of the Building Regulations applicable in Scotland. - A compartment used to enclose

the appliance MUST be designed and constructed specifically for the purpose. An existing cupboard, or compartment,

may be used provided it is modified accordingly.

Please read the warnings located at the end of these instructions before proceeding with INSTALLATION.

2. FLUE TERMINAL POSITION

The heater must be installed so that the terminal is exposed to the external air.

It is important that the position of the terminal allows free passage of air across it at all times.

It is essential to ensure that the products of combustion discharging from the terminal cannot re-enter the building or

vehicle, through ventilators, windows, or other sources of natural air infiltration, such as other flues etc, with the

exception of doors, but not the opening windows thereof.

The minimum acceptable dimensions from the terminal to obstructions and ventilation openings are as follows:

Directly below an opening fixed vent or window etc................. 300mm

Adjacent to an opening fixed vent or window etc..................... 300mm

Below gutters........................................................................ 75mm

From a vertical drain pipe....................................................... 75mm

From an internal or external corner ........................................ 300mm

3

Where the terminal is fitted in a position to which children, the elderly, or disabled people have access (less

than 1.5m above steps, decking or ground), a suitable terminal guard should be fitted. In certain weather

conditions the terminal may emit a plume of steam.

• DO NOT MOUNT within 300mm vertically from a terminal on the same wall or horizontally from a terminal on

the same wall.

3. MINIMUM CLEARANCES

• Minimum clearances of 5mm to the front and sides of the heater must be observed. However full access from

the front in the form of an opening door, must be given to allow access to the controls and for servicing.

• 200mm above the top of the heater case is required for the flue assembly.

• 150mm is required below the heater to allow easy access to the gas isolation cock.

VENTILATION AND SERVICES REQUIREMENT

4. VENTILATION REQUIREMENTS

The following notes are for general guidance:

The Widney RSW10KL is a room sealed appliance and needs no purpose provided combustion air ventilation.

If the water heater is to be built into a small cupboard or compartment (i.e. at minimum clearances) and overheating

can be foreseen (i.e. close proximity to a cooking appliance etc.) permanent air vents are recommended for cooling

purposes in the cupboard or compartment.

5. ELECTRICITY SUPPLY

THIS APPLIANCE IS NOT DESIGNED TO BE USED WITH AN INVERTER, HOWEVER IF THERE IS NO OTHER

ALTERNATIVE THEN A PURE (TRUE) SINE WAVE INVERTER MUST BE USED.

• A 3 amp fused three pin plug and unswitched shuttered socket outlet (both complying with BS 1363 or

equivalent EN standard) or a 3 amp fused double pole isolator with a contact separation of 3mm in all poles

supplying only the heater should be used.

• Installation into a Bathroom – Please refer to the current IEE wiring regulations for installation and refer to the

data plate for product IP rating.

• THIS APPLIANCE MUST BE EARTHED

Where the product is fitted in a bathroom or an area that may be exposed to water spray please ensure that

appropriate electrical protection is provided to the mains connection.

6. GAS SUPPLY

The gas pipes must be copper. Do not connect plastic pipes directly to the heater. It is recommended that the copper

is extended to below the floor of the caravan/vehicle before connecting to plastic.

• Ensure the heater is set for the gas supply intended.

• A gas supply at the rating specified on the data label.

• Ensure the regulator is of sufficient capacity to carry the maximum water heater input plus the demand for any

other installed appliances.

• Ensure the connection between the supply/bottle and the caravan holiday home or park home is designed so

that no more than 2.4mbar of pressure drop occurs.

No more than 3 m of 15mm pipe should be used. Where the supply exceeds 3 m the pipe should be suitably

sized only reducing to 15mm before the water heater

• A full bore isolation valve must be fitted in the supply close to the water heater with either a union or

compression connection between the valve and the appliance to allow safe disconnection of the appliance.

• Connect the gas supply using a 15mm compression fitting.

• The complete installation must be tested for gas soundness.

7. CONNECTIONS TO WATER HEATER

The water pipes must be copper. Do not connect plastic pipes directly to the heater. It is recommended that the

copper is extended to below the floor of the caravan/vehicle before connecting to plastic.

• Ensure the water pipe complies with the requirements

• Remove any swarf or other residues in the pipes.

• Connect the heater using a 15mm compression tap connector fittings

• An isolation valve should be fitted to the inlet connection near to the appliance to allow service disconnection

of the appliance.

8. HOLIDAY HOME SERVICES

• Ensure that the pipe sizing and connections between the supply/bottle regulator and the caravan/vehicle is

designed so that no more than a maximum pressure drop of 2.5mbar occurs.

• This appliance must be fitted with an isolation valve not supplied.

• A cold water supply with a working pressure of a minimum of 0.18 bar measured at the cold water inlet to the

heater is required. Wherever possible the cold supply to the heater should be the first connection off the main

supply in order to minimise hot water flow reduction when cold water services are called for.

4

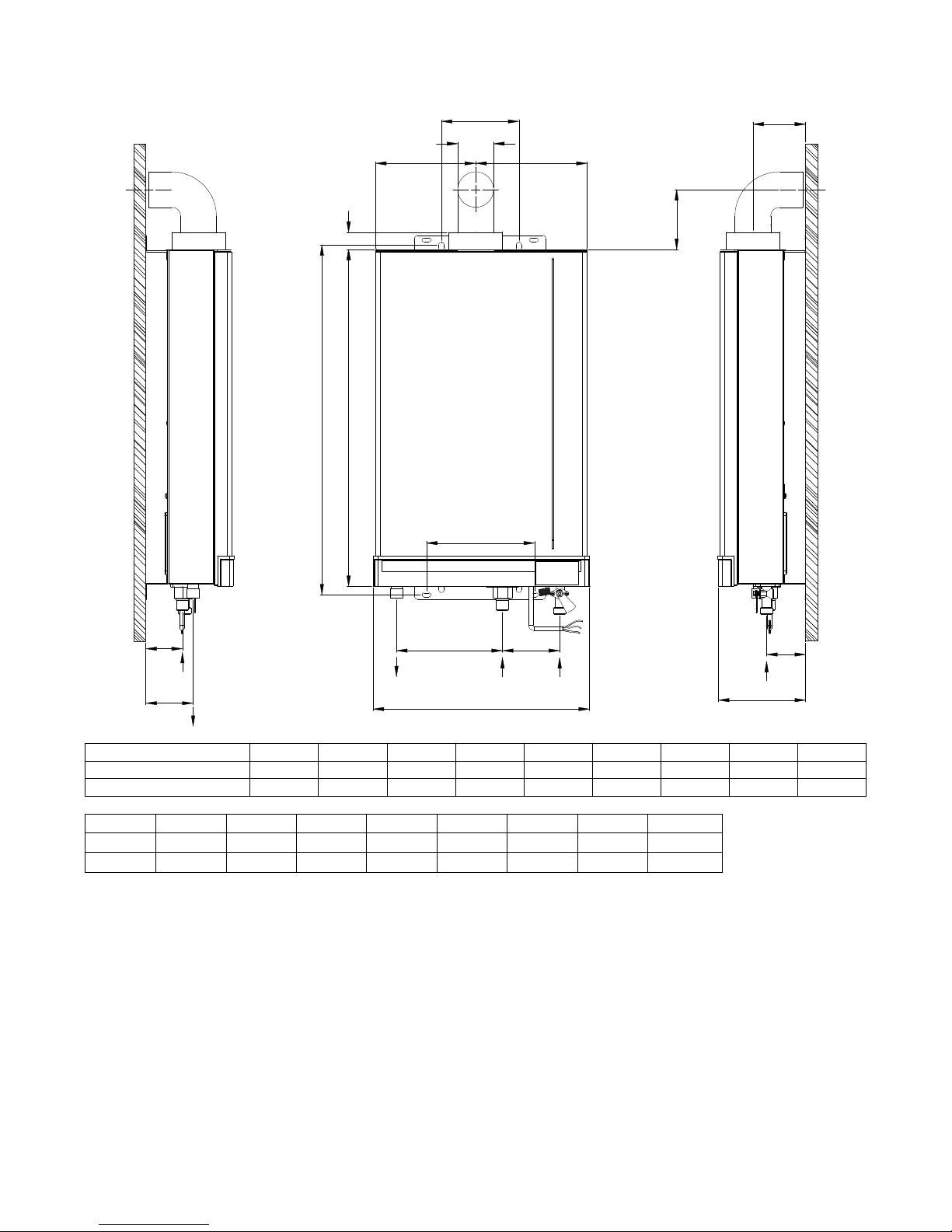

APPLIANCE DIMENSIONS:

A

C

D

B

E

F

G

I

J

M

N

O

P

K

L

GAS

GAS

H

Q

MODEL

A B C D E F G H I

RSW10kl side flue

360 572 135 60-100 25 65

130 180 590

RSW10kl rear flue

360 572 165 60-100 25 95 130 180 590

J K L M N O P Q WEIGHT

40 35 55 175 90 125 187 168 13.6kg

70 65 85 175 90 125 187 168 13.6kg

5

Diagram Bi

INSTALLATION PROCEDURE

9. UNPACKING

The Water heater is supplied in a separate carton. Care should be taken when unpacking to ensure there is no

damage to the product.

Included in the Water heater carton are :- Installation and User instructions, Gas isolation valve & 100mm of 15mm dia

Copper tube.

In a separate pack: Flue kit – comprising of Inlet and outlet rigid tube – Terminal – Elbow - Clamping Rings (2) –

Sealing Collars (2).

THE WATER HEATER MUST BE INSTALLED WITH THE SUPPLIED FLUE KIT

10. SELECTING THE POSITION

Decide where the heater is to be fixed taking into account the installation requirements required under the relevant

standards and sections 1, 2,3,12 of these instructions.

11. WALL MOUNTING

The Water Heater can either be mounted with the flue system exiting to the rear or side of the appliance. For

Wall mounting with flue to the rear refer to paragraph entitled ‘Flue installation to the rear’.

Materials around the flue system – The outer flue will reach a maximum

temperature rise of 35oC. Care should be taken in ensuring that any materials

touching the outer flue are capable of withstanding this temperature for extended

periods. It is recommended that the rubber inner and outer seals are pushed into

the wall aperture before sealing. This will ensure that the outer flue pipe fits

centrally in the wall aperture.

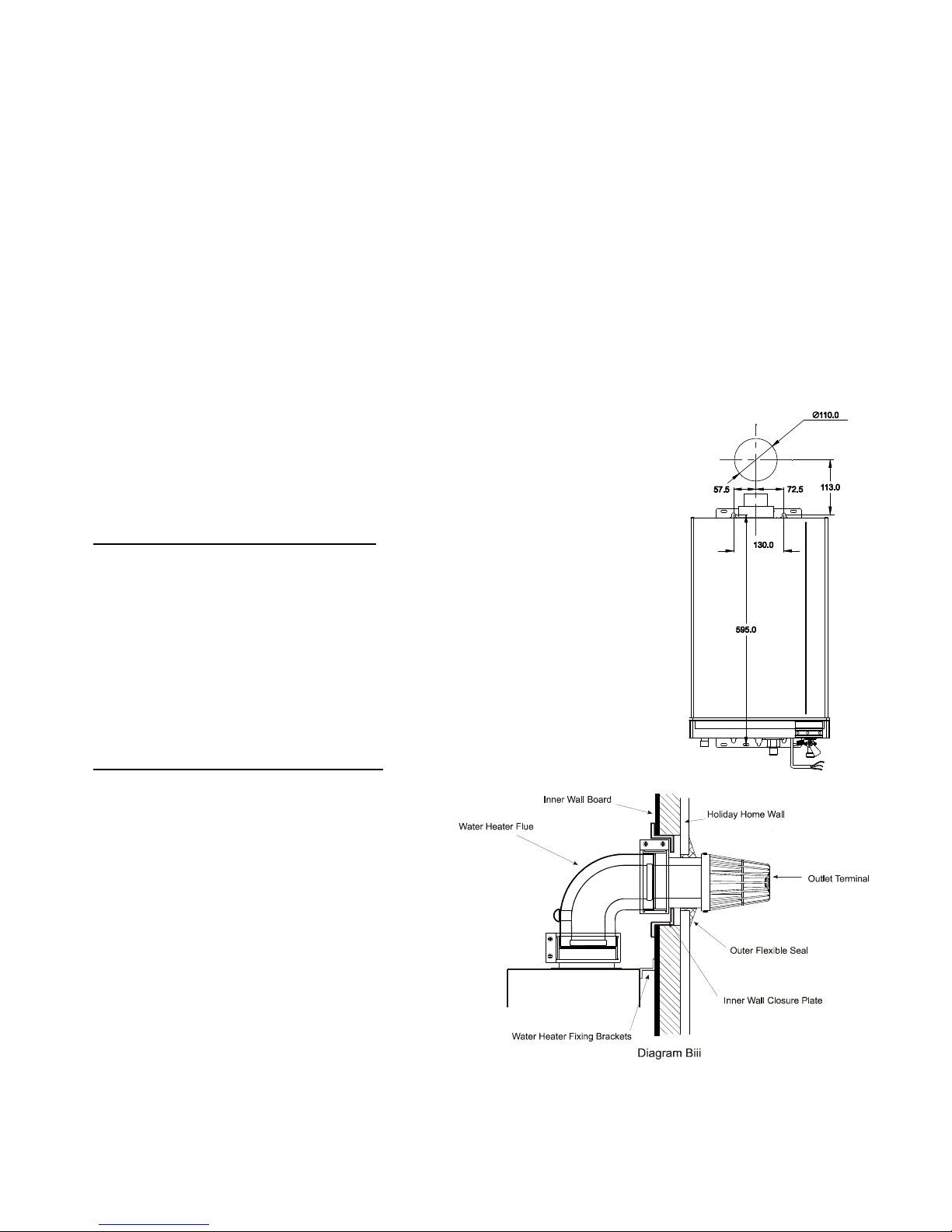

Flue installation to the side: See diagram Bi

The water heater should be mounted on a suitable wall with sufficient structural strength

to ensure adequate support.

1. Mark the position of the fixing holes and the outlet aperture in the wall as

indicated in diagram Bi. Ensure that the position of the flue outlet meets with the

requirements of the relevant standards and is located as detailed in section 2.

2. Cut the hole for the flue liner through the wall of the home.

3. Fix the flue system to the water heater see section 12.

4. Fix the water heater securely through the fixing brackets located at the base

and top of the unit.

5. Go to section 12.

Flue installation to the rear: See diagram Biii

This method of installation requires a fixing kit part

no. RSWFIX01. The fixing kit comprises of two fixing

brackets to replace the fixing brackets fitted to the

water heater and a wall closure plate.

The water heater should be mounted on a suitable

wall with sufficient structural strength to ensure

adequate support.

1. Mark the position of the fixing holes and the

outlet aperture in the wall as indicated in

diagram Bi. Ensure that the position of the

flue outlet meets with the requirements of

the relevant standards and is located as

detailed in section 2.

2. Cut the hole for the flue liner through the

wall of the home.

3. Align the closure plate with the hole in the

inner wall and mark around the closure plate.

4. Cut out the inner section of the wall to fully recess the inner wall closure plate diagram Biii.

5. Insert the closure plate into the wall opening and fix with suitable fixings.

6. Fix the flue system to the water heater see section 12.

7. Go to section 12.

6

12. FLUE INSTALLATION

Positioning:

• The water heater MUST be installed so that the terminal is exposed to the external air.

• It is important that the position of the terminal allows free passage of air across it at all times.

• It is ESSENTIAL TO ENSURE, that products of combustion discharging from the terminal cannot re-enter the

building, or vehicle, through ventilators, windows, or other sources of natural air infiltration, such as other flues

etc, with the exception of doors, but not the opening windows thereof. The minimum acceptable dimensions

from the terminal to obstructions and ventilation openings must be as detailed in section 2.

Installing the flue system:

IMPORTANT

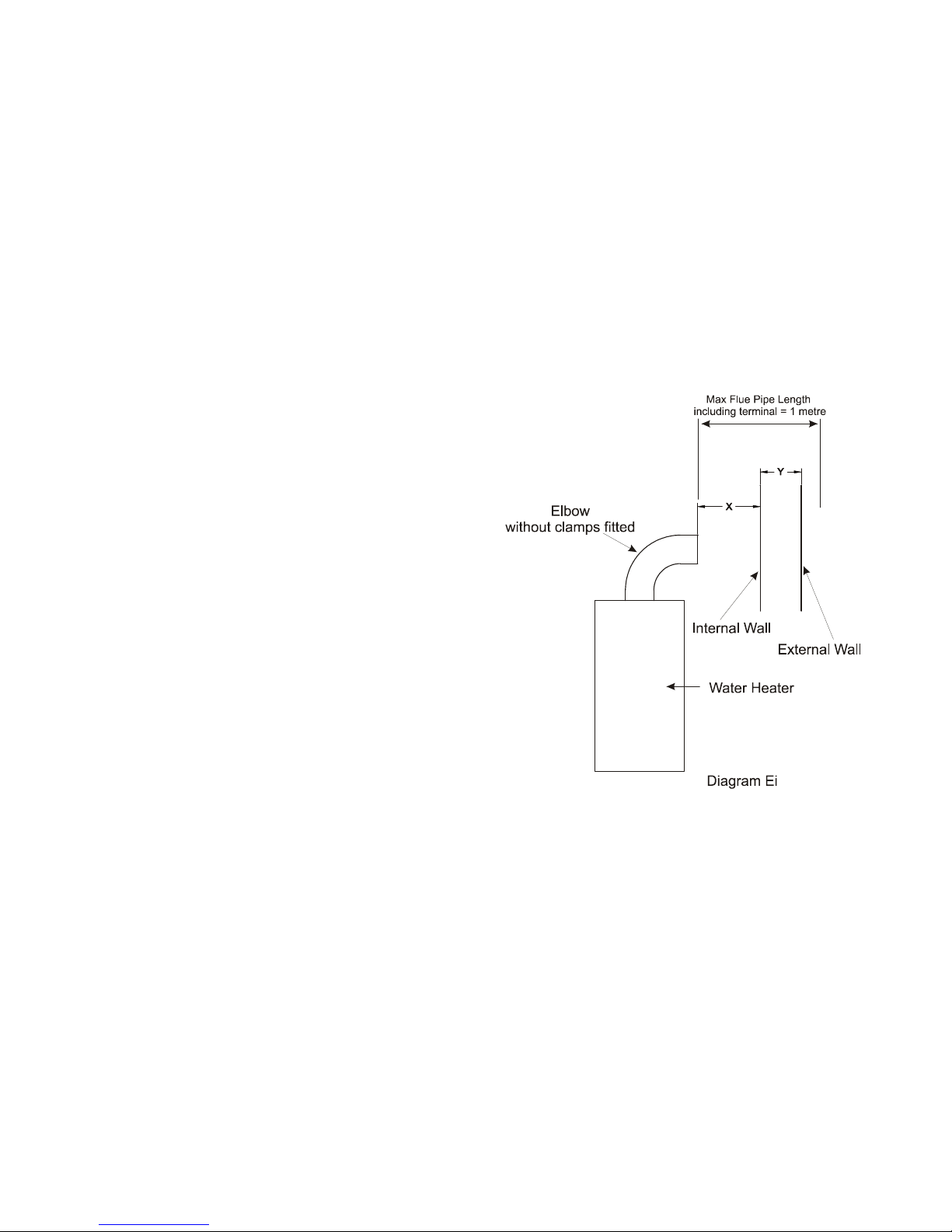

The standard horizontal flue kit supplied with the RSW10KL is part number RSWFK1M. This kit provides for 1

meter of flue length and one 900 elbow. Note: DO NOT INSTALL THIS APPLIANCE WITH MORE THAN ONE 90

0

Elbow (Bend) and more than 1.0 metre of flue length.

Never use a flue kit not specifically approved for use with this appliance.

NOTE: Where the home is pre-installed with the RSW10KL please consult the home manufacture for

replacement part numbers.

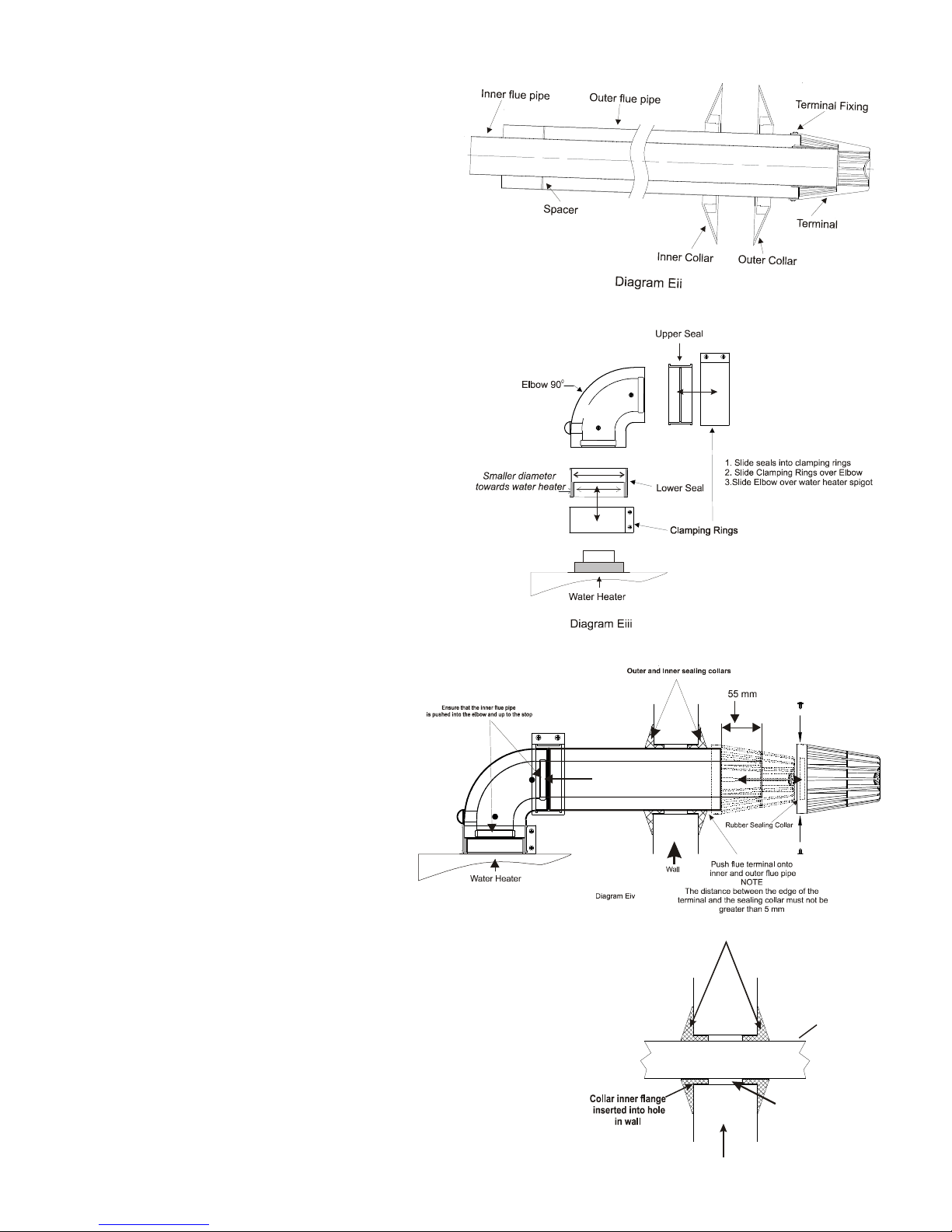

NOTE: The inner flue pipe of the terminal must be cut

accurately and must always be 100 mm longer than the outer

flue in order to ensure correct location in the terminal and

elbow. NOTE: The outer pipe has two holes at one end to

fix the terminal always cut the pipe at the opposite end to

these two holes.

To calculate the correct length of the outer flue use the

following formula and refer to diagram Ei

Formula: dimension X + Y + 20 mm (Note Dimension X is

the distance between the inner wall of the home and the

end of the elbow without the sealing collar attached; in

the case of rear flue installation the appliance should be

fitted with installation Kit RSWFIX01 if this kit is used

then the dimension X = 10mm.)

For calculating the inner flue lengths use the overall length of

the outer flue liner when cut to size and add 100mm.

Two sealing collars are provided to seal the external pipe

against the internal and external wall.RSWSC01.

The flue assembly must be installed with a slight downwards

incline of 20 towards the terminal to prevent the ingress of rain water, which may damage the heater. See diagram Eii.

Terminal Guard: if the position on the outlet terminal is less that 2 meters above ground level it is recommended that

a terminal guard be fitted.

7

Connecting the flue system:

Refer to diagram to assist in assembly.

1. Slide the inner flue pipe into the outer flue

pipe ensuring that the spacer on the inner flue

pipe is evenly positioned - Note for flue

lengths less than 300 mm the spacer is not

required, see diagram Eii.

2. Fit the clamping rings onto the elbow. Note:

ensure that the smaller diameter of the

clamping ring seal is facing the water

heater outlet spigot, see diagram Eiii.

3. Connect one end of the elbow to the water

heater and secure the clamping ring.

4. Slide the inner flue pipe into the elbow then slide

on the inner rubber collar over the flue pipe and

insert the outer flue pipe through the clamping

ring and into the elbow the secure the clamping

ring, see diagram Eiv.

Note: if fitting rear flue the inner rubber collar

should not be fitted.

Note; the inner flue pipe must protrude 55 mm

beyond the outer flue pipe, see diagram Eiv.

8. Fit the water heater to the wall by inserting the

flue pipe through the hole in the wall and

securing the water heater through the fixing

brackets into the pre drilled holes as detailed in section 11.

5. On the outside of the home slide the

outer collar over the outer flue pipe.

6. From the outside of the home locate the

terminal onto the inner flue pipe ensure

that the rubber seal is fitted to the

terminal before fixing to the flue pipe

then push the terminal over the outer

flue pipe.

NOTE The maximum gap on Fig Eiv

ensure that the inner flue pipe is

correctly aligned in the elbow on the

water heater before pushing on fully.

When the terminal is in the correct

position the holes in the terminal will align with the holes in the

outer flue pipe. Secure the terminal to the outer flue pipe with the

fixings provided.

7. If applicable slide the inner collar up to the inner wall and seal

with sealant. See diagram Evi

8. Slide the outer collar up to the outside wall and seal with sealant.

Outer and Inner sealing collars

Wall

Air Gap

Diagram Evi

Outer Flue

Note: 2° down

8

INSTALLATION COMPLETION

13. WIRING

Observe all the usual precautions to ensure that the electricity supply is isolated before beginning any installation

work. The heater should be wired as described in section 5.

Important: this appliance must be earthed.

14. GAS AND WATER CONNECTIONS

Connect the gas and water connections to the appliance using the appropriate fittings. Ensure that the pipe sizing,

material and connections comply with sections 6, 7, and 8 of this manual.

SETTING AND FIRST USE

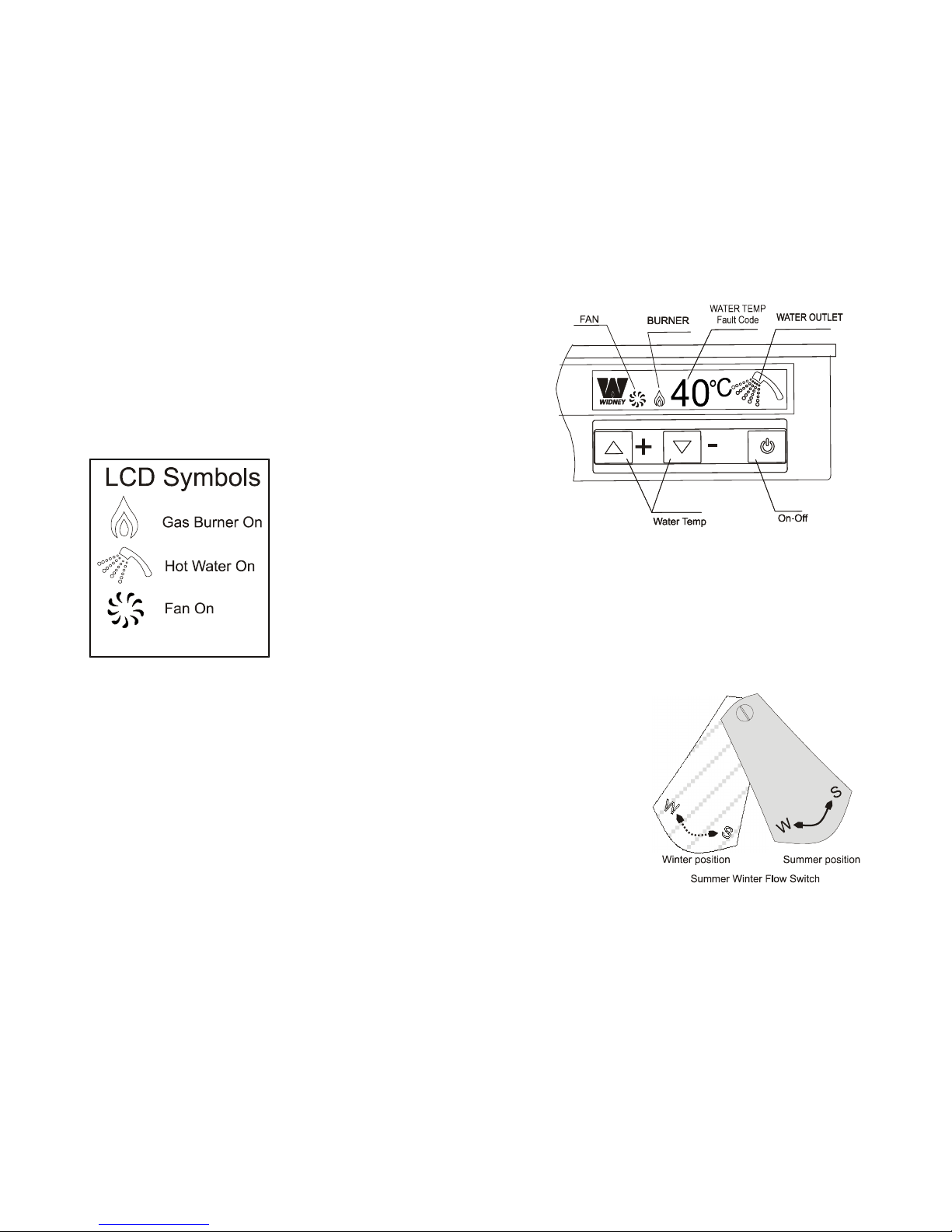

15. THE CONTROL SCREEN

The control screen displays the water temperature, fan operation,

burner operation and water delivery and fault diagnostics information.

In normal operating conditions the screen will display the set water

temperature and operational mode, for example if the water heater is

not being used the temperature will be displayed together with a

shower head. If the water heater is working then the shower head will

display a water effect and the burner and fan will flash on and off.

The temperature of the water that will

be delivered from the appliance is set

by using the up and down buttons on

the left hand side of the panel.

To operate the water heater turn on the power from the mains – (the control panel will

light up and display the number 18 which confirms that PCB mode and settings are

correct for this appliance, the display will then go to a non-illuminated condition), then

switch on the water heater via the on—off switch on the control panel. The water heater

is now in operational mode and will automatically start up when the hot water tap is used.

Water temperature can be set between 350C and 650C it recommended that the optimal

temperature is 400C

16. GENERAL GUIDANCE NOTES ON HOT WATER DELIVERY

The temperature of the hot water is governed by both the ambient temperature of

the cold water supply and its flow rate through the water heater. The flow rate of the

hot water is controlled by the hot outlet tap / shower.

Water Flow settings: The appliance is fitted with a manual water flow adjuster which

should be in the summer position for normal operation; however in very cold

conditions the water inlet temperature may be too low to heat the water effectively. If

this happens then the water flow switch should be set to the winter position.

The water heater can theoretically supply more than one outlet simultaneously;

however in practice the tap which is nearest will receive the most hot water. If the

shower is in use and a kitchen tap is opened virtually all the hot water will be

diverted to the kitchen as it offers the least resistance.

• Due to the restrictive nature of simple mixer showers it is wise to turn the temperature selector down on

the water heater before using the shower.

DO NOT PLACE YOUR HANDS under the tap or use the shower until this initial flow has passed.

Allow time (30 seconds) for the temperature to stabilise after making an adjustment at the tap before making further

adjustments.

17. APPLIANCE SAFETY LOCK-OUT

This water heater has a fault indicator built in to it on the front display, whenever a malfunction is detected in the water

heater the display panel will indicate a fault code and turn the water heater off. Please refer to the fault code section to

diagnose a fault.

9

COMMISSIONING ENGINEER AND END USER FAULT CODES

Fault

Code

Problem Identified Action to take

E0

Input Water Temperature sensor

Fault

Switch off mains power supply – then restart by switching mains supply on and

pressing the on off button on the control panel – If problem persists contact

service

E1 Ignition Failure / No Flame Detected

Switch off mains power supply

Check gas supply and gas pressure at appliance

Restart by switching mains supply on and pressing the on off button on the

control panel

– If problem persists contact service

E3

Blocked Flue—Abnormal wind

Condition

Switch off mains power supply

Check for blockage around outlet terminal

Leave for 30 minutes then restart by switching mains supply on and pressing

the on off button on the control panel – If problem persists contact service

E4 Fan or Power Fault

Switch off mains power supply –

Check mains supply and fuse

Restart by switching mains supply on and pressing the on off button on the

control panel – If problem persists contact service

E5

Outlet water temperature too high /

Over Temperature Protection

Switch off mains power supply –

Check flow of water supply to water heater

Switch on

Check temperature setting on water heater.

Turn to full and re test for temperature.

Turn Winter summer water valve to summer setting.

Switch off mains power supply

Restart by switching mains supply on and pressing the on off button on the

control panel – If problem persists contact service

E6

Water Outlet temperature sensor

failure

Check temperature setting on water heater.

Turn to full and re test for temperature.

Turn Winter summer water valve to winter setting.

Switch off mains power supply

Restart by switching mains supply on and pressing the on off button on the

control panel – If problem persists contact service

E7 DIP Switch incorrect setting

Factory Setting incorrect.

Switch off mains power supply

Switch of gas and water supply

Turn on all services

Restart water heater.

If problem persists contact service

F0 Power on start-up failure

Water is flowing through heater on power up.

Ensure water is NOT flowing through heater when power supplied.

Reset by turning off power and ensure all taps and shower are turned off. Repower water heater to clear fault code.

Loading...

Loading...