Widney Revo Installation Instructions Manual

SHORT PARTS LIST

The illustrated short parts list incl udes part numbers.

When ordering quote gas fir e name with part number & descr iption.

Gas Train

PART NUMBER DESCRIPTION

W00018

W00166

Control Valve with rotary igniti on

(LPG)

Control Valve with rotary ignition

(NG)

W00020

W00170

Oxygen depletion device / pilot

assembly (LPG)

Oxygen depletion device / pilot

assembly (NG)

RA002 Radiant (pack of 3)

W00028

W00167

Burner Injector (LPG)

Burner Injector (NG)

W99901

Straight Terminal with Vent

Plain Finish.

For other finishes please contact

customer services

W99801

Angled Terminal with Vent.

Plain Finish.

For other finishes please contact

customer services

W99600

Straight Terminal Non Vented.

Plain Finish.

For other finishes please contact

customer services

W00213

Terminal with Vent

Pantile Roof

For other finishes please contact

customer services

8

Part Number: W00317 Issue E

GB

IE

INSTALLATION & MAINTENANCE INSTRUCTIONS

READ THESE INSTRUCTIONS BEFORE INSTALLING OR SERVICING THE FIRE

IMPORTANT: Before installation ensure that the local distr ibution conditions (ident ified by

the type of gas and pressure) and the adjustment of the appliance are compatibl e.

Revo Natural gas version.

The appliance is suitable f or use with G20 natural gas at a supply pressure of 20mbar f or categories

I2H & I2E and additionally G25 at a su pply pressure of 25mbar (pr essure couple operates) in the c ase

of category I

2E+

& I2L.The following lists all EC m ember states, which have a suit able gas supply for

each category designation:

I2H:- AT, CH, CZ, DK, ES, FI, G B, GR, IE, IT, NO, PT, SE, EE, LT , LV, SI, SK

I2E:- DE, LU - I

2E+

:- BE, FR—I2L:- NL

Revo LPG gas version.

The appliance is suitable f or use with G30 Butane at a supply pr essure of 28-30 mbar and G31

Propane at a supply pressure of 37 mbar for category I

3+.

It is also suitable for G30 But ane and

G31 Propane at a supply pr essure of 30mbar for I

3B/P

The following lists all EC memb er states, which have a suitabl e gas supply for each categor y

designation:

I

3B/P

:- CZ, FI, NL, NO, SE, LT, LV, SI, SK

I 3+:- BE, CH, CZ, ES, FR, GB, IE, IT, PT, EE, CY

It is a legal requirement that all gas appliances are installed by a c ompetent person in accordanc e

with the Gas Safety Installati on and Use Regulations 1994.

Failure to install the applianc e as stated can lead to prosecution, i t is in your interests

that the law is complied with.

Installation and Ventilation requir ements shall be in accordance with these Installation Instructi ons,

BS EN 1949:2002, BS EN 721:1 999, BS5871 and BS EN 16 47:1999.

For the Rep ublic of Irelan d the installation must be carried ou t by a competent p erson and also c onform to the rele vant par ts of :

The current edition of IS 81 3—Domestic Gas Ins tallations

All relevan t national and loca l rules in force

WIDNEY L EISURE LTD.

SAXON BUSINESS PARK, HANBURY ROAD,

STOKE PRIOR, BROMSGROVE,

WORCESTERSHIRE B60 4AD. ENGLAND

TELEPHONE: + 44(0)1527 577800

Email: sales @widney-leisure .co.uk Web: www.wi dney-leisure.co .uk

1

WIDNEY

Revo

Gas Fire

All Model Variants

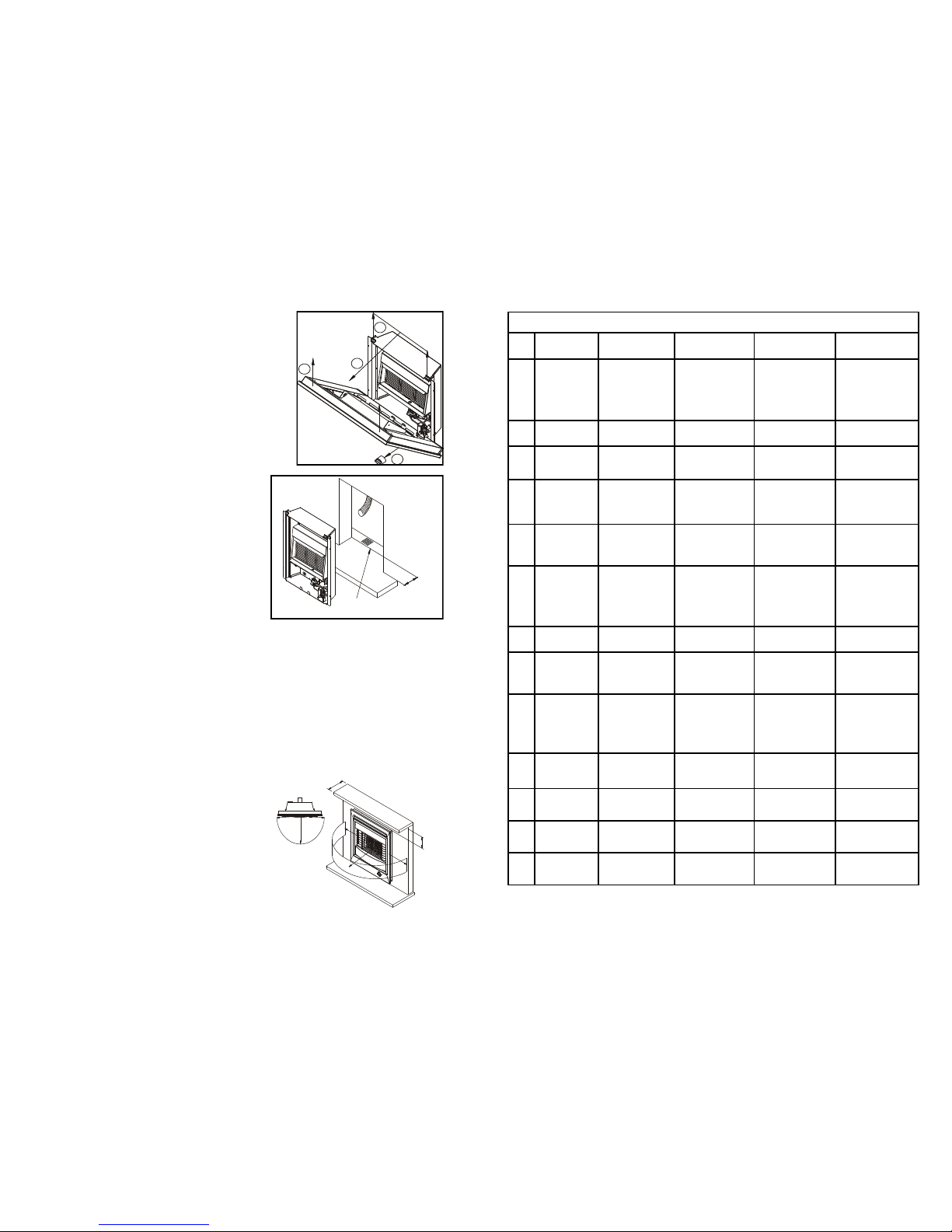

PREPARATION OF THE FIRE:

Note: Before commencing installation it is recommended that

you fill in the appliance details on the rear of the user’s

instruction.

REMOVAL OF THE FIRE FRONT:

Remove the control knob fr om the gas valve by pulling in the

direction of the arrow. Lift the fr ont upwards approximately

10mm to clear the top location brackets taking care not to dist ort

or damage the top louvre vents

Pull the top of the front forw ard approximately 50mm then lif t

clear of the locating tabs in th e base of the fire. (See Fig 1)

REPLACING THE FIRE FRONT:

Reverse the above procedur e taking care to locate the

upturned tabs on the base panel into the slots in the lower

panel return flange on the fire front.

LOCATION:

When locating the fire ensure that the minimum thermal lift of

1690mm as indicated in figure 4 can be achieved.

PREPARING THE APERTURE:

Cut an aperture in the furniture to t he following

dimensions: 560mm High x 440 mm Wide, this ensures a

minimum 5mm air gap between th e fire back and the

furniture is maintained.

It is recommended that the bas e of the fire is supported

and no room air is allowed t o enter the cavity from under

the fire base (See fig 2).

FITT ING THE FIRE :

The fire must only be fitted with recommended flue liner and terminals - please consult the supplier for

further information. The flue liner needs to be prepared prior to fitting. Refer to these instructions and Fig 4

for this stage.

Depending on the construction of the flue cavity, the flue liner can be installed before or after the fire back is

fastened into position. In any installation, the flue liner must be pushed fully over the fire back flue spigot

and secured to the fire and Terminal spigot using steel self-tapping fasteners which will retain the liner into

full position to the terminal/fire spigots. Under no circumstances must the liner be left installed without a

sound connection and the position unfastened.

The fire should be installed as fig 3 with self tapping screws through the 2 fixing brackets on the sides of the

main fire chassis to the fire surround.

Any materials, coatings or finishes used in the construction of the fire surround and hearth must be

specified to tolerate the full radiated and convected and conducted heat from the fire.

POSIT ION OF C OM BUSTI BLE MAT ERI ALS:

It is recommended that no fixed combustible materials are

located within 500mm of the centre line of the fire – measured

from the centre radiant. Any combustible materials used for

the construction of the fireplace that are not subject to direct

line of sight to the ceramic radiants must be able to tolerate

the radiated, conducted and convected heat of the appliance

when operated at full rate. The materials used must comply

with the relevant British or EN standard / Code of Practice for

this installation. Note: It is the responsibility of the installer to

ensure that any material used adjacent to or adjoining the

appliance is fit for purpose. Any loose furnishings should not

be placed within the dimensions as indicated in (Figure 3)

1

2

3

4

Fig 1

Fig 2

Ensure that the Hearth

extends under the Fire

120mm

minimum

Fig 3

100mm

Maximum

100mm

Minimum

500mm

A 500mm line should be

taken from the centre of

the Fire Radiants to a part

500mm in front of the fire

500mm

2

7

WIDNEY LEISURE GAS FIRE TROUBLE SHOOTING TABLE

Fault Action I still hav e a

problem

Action I still ha ve a

problem

1 Fire will Not

Ignite

Check gas pressure

at fire

If pressure is correct

see item2

See trouble shooting

headings for further

assistance: If Fault

not listed contact:

Widney Leisure Ltd

Customer service

2 The pilot does

not spark

Check spark Gap Spark Gap is correct

but has no spark

Replace gas valve

and pilot assembly.

As Above

3 Fire Ignition

Sparks but does

not light

Check pilot jet for

blockage

Pilot is clear but no

gas coming through

Check Main Gas

Valve for blockage

As Above

4 Pilot light

ignites but

main burner

does not ignite

Check main

injector for

blockage

The main injector is

clear but the fire

does not ignite

Check Main Gas

Valve for Blockage

As Above

5 Main burner

ignites but

flame is very

low

Check main

injector for

blockage

The main injector is

clear

Check for blockage

in main gas valve

and pipe work

As Above

6 The main gas

valve is

blocked

Replace gas valve See trouble shooting

headings for further

assistance: If Fault

not listed contact:

Widney Leisure Ltd

Customer service

7 The gas feed

pipe is blocked

Replace gas feed

pipe

As Above

8 Ceramic

Radiant turning

black

(Sooting)

Ensure that no

direct draft is

entering the fire

There are no drafts

around the fire

Check to ensure

radiants are correctly

fitted

As Above

9 The main

burner is

blocked

Replace burner See trouble shooting

headings for further

assistance: If Fault

not listed contact:

Widney Leisure Ltd

Customer service

10 Fire burns with

yellow flame

Ensure that no

direct draft is

entering the fire

There are no drafts

around the fire

Check main injector

for blockage

Contact Widney

Leisure Ltd Customer

service

11 Fire Flame

fluctuates

Ensure that no

direct draft is

entering the fire

There is a draft from

the rear of the fire

Contact:

Widney Leisure Ltd

Customer service

12 Fire appears to

be overheating

Check gas pressure

at fire

The gas pressure is

correct

Contact:

Widney Leisure Ltd

Customer service

13 Fire does not

get hot enough

Check main

injector for

blockage

The injector is clear Check gas pressure

at fire

As Above

Loading...

Loading...