WIDMER TIME RECORDER CO., INC. RS Operation Manual

WIDMER

ROTARY STAMP

OPERATIONS MANUAL

WIDMER TIME RECORDER CO., INC.

228 Park Street 27 Park Place

Hackensack, NJ 07601 New York, NY 10007

Phone: 201 489-3810 (800) 424-4459 Phone: 212 227-0405

Fax: 201 489-3478 Fax: 212 227-0526

2008 Dec09 Revision

2

TABLE OF CONTENTS

Specifications ……………………………………………………………………………...…-4-

Overview …………………………………………………………………………………...…-5-

Installation ……………………………………………………………………………………-8 Installing the Die on the Drum ……………………………………………………...-8 Setting the Paper Guides and Feathering the Documents …………………...…-8 RS Gap Setting Instructions ………………………………………………………..-9-

Setting the Print Position and Paper Length fir Signatures …………………....-10-

Setting the Print Position and Paper Length for Text and Seals ……………...-12 Date and Manual Set Numbers …………………………………………………..-13 Run …………………………………………………………………………………..-13 Catch Tray …………………………………………………………………………..-13 Impression Adjustment …………………………………………………………….-14-

Programming ……………………………………………………………………………….-15 Keypad Operations ………………………………………………………………...-15 Programming Keys ………………………………………………………………...-17 Jog Function ………………………………………………………………………..-17 Batch Counting ……………………………………………………………………..-17 Non-Reset Counter ………...………………………………………………………-19 Print off / Print On ………………………………………………………………….-19 Remove Imprint Die ………..………………………………………………………-20 Preset Programs …………………………………………………………………...-20 Keypad Layout ………………………………………………………………….….-21-

Maintenance ………………………………………………………………………………..-22-

3

OPERATING INSTRUCTIONS FOR RS MODELS

Please check the current voltage and cycles on the specifications plate at the rear of

the machine to be certain that these conform with the power source you intend using.

Please record the serial number, model number, and key numbers for future reference:

Model # ___________________ Serial # ___________________

Executive key # _____________ Operator Key # _____________

Date purchased _____________ From _____________________

SPECIFICATIONS

Dimensions:

Weight …………………….. 55lbs.

Shipping Weight …………..65lbs.

Height ……………………...9”

Length ……………………...12” with tray 20”

Width ……………………….24 1/2

Speed ……………………...Approx. 9,200 per hour / 150 per min Short Form

Approx. 8,400 per hour / 140 per min Long Form

Hopper Capacity:

Height ……………………...3”

Optimum ……...……………200 Sheets, Single ply

Maximum …………………..350 Sheets, Single ply

Document sizes:

Minimum …………………...2 7/8” x 2 7/8”

Maximum …………………..15 1/2 “ x 16”

Color: ……………………………….Two tone light and dark gray

Voltage: …………………………….Standard 115v 60Hz

Optional 240v 50Hz

Program capacity: ………………...9 programs

Spacing accuracy increments in 32nd of an inch

Imprint size maximum …………….2 1/2 “ x 3”

Imprint range ……………………...1/32” to 16”

Feed hopper width:

Overall ……………………..15 1/2” wide

Minimum width ………….…2 7/8”

Ink roller colors:

Standard: Black Ink Roller 4111-1

Optional: 4” long Black Ink Roller 4111-1L4

Blue Ink Roller 4111-2

Fast Dry Blue 4111-2FD

Red Ink Roller 4111-4

Tri Color PRB (purple, red & blue [Regular]) 4111-5

Tri Color BRB (black, red & blue [Narrow]) 4111-6

4

OVERVIEW

The Widmer Model RS Rotary Stamp is designed to perform multiple imprinting jobs.

Including but no limited to, cut sheet and laser check signing, check endorsing (meets

the Federal guide lines for both depositors and banks), document counting, label

printing, dating and fixed wheel numbering. Additionally the model RS-ETV will also

emboss a seal into you document. As the RS is a bottom feed unit there is no change

in the order of the documents as they are processed by the machine. The operator

can also add documents to the hopper as the job progresses which increases the

speed and efficiency of the operation. The RS also has an energy saving feature in

that it turns off its feed motors if no documents are fed in a half a minute.

Security is achieved by the following measures:

1. Executive key for the case lock so only an authorized person can insert and

remove the signature die.

2. Signature die easily removable for storage in a safe.

3. Operator key.

4. Resettable transaction counter

5. Non-resettable cumulative counter

6. Optional tri-color ink roller, to inhibit duplication

7. Optional wavy line background on the signature.

8. Optional text, such as title of the signer (ie. Vice president) or limiting text

(ie. “not valid over $5,000.00”)

The RS can be used as a document counter for total counts or to segregate into

numerical batches such as units of 50 or 100. The operator can turn off the print

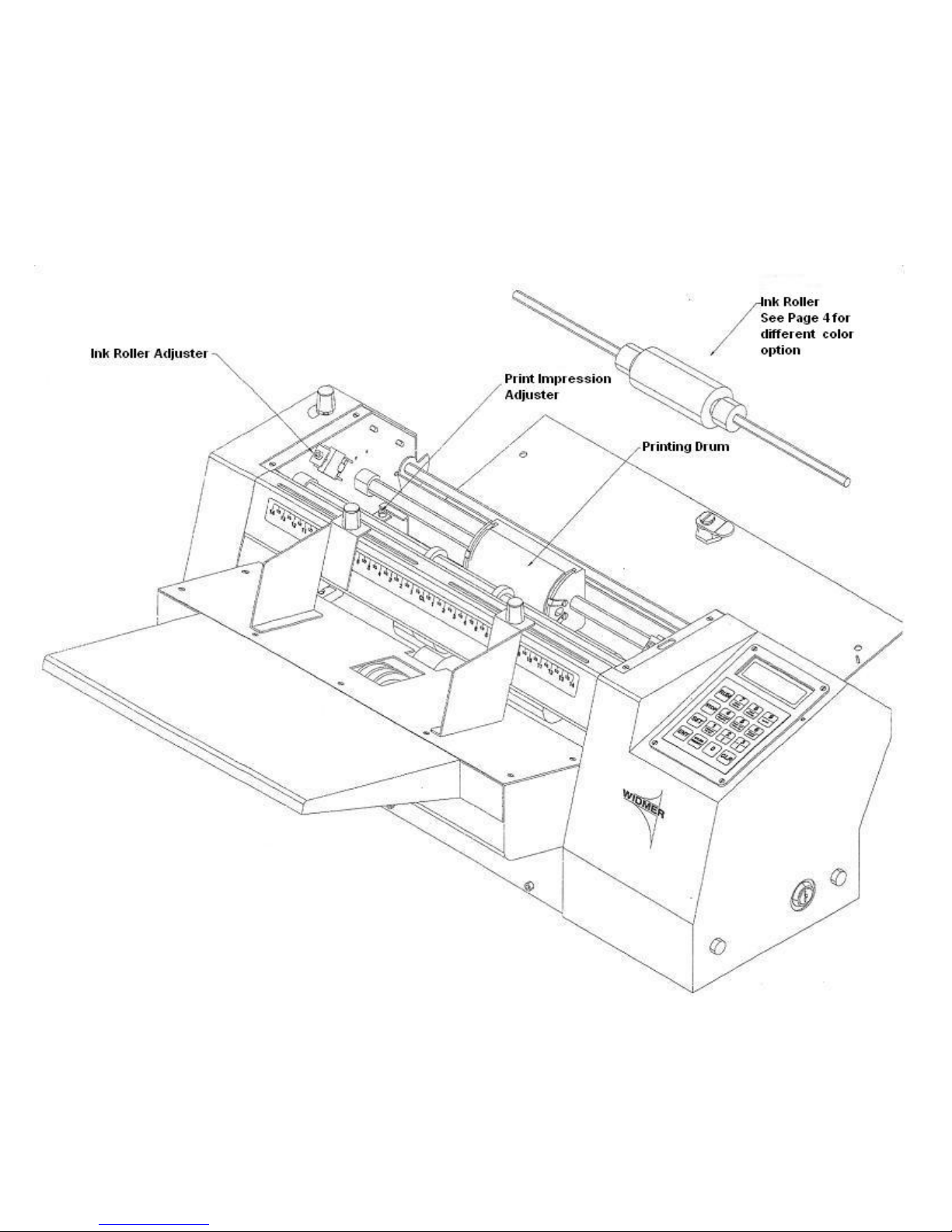

function when counting only is desired. Some models can have a second print drum

and ink roller added.

Some models (RS-D) have a numerical date mechanism and can be used to date

documents and for endorsing checks. Other models (RS-MN) have manual set

number wheels.

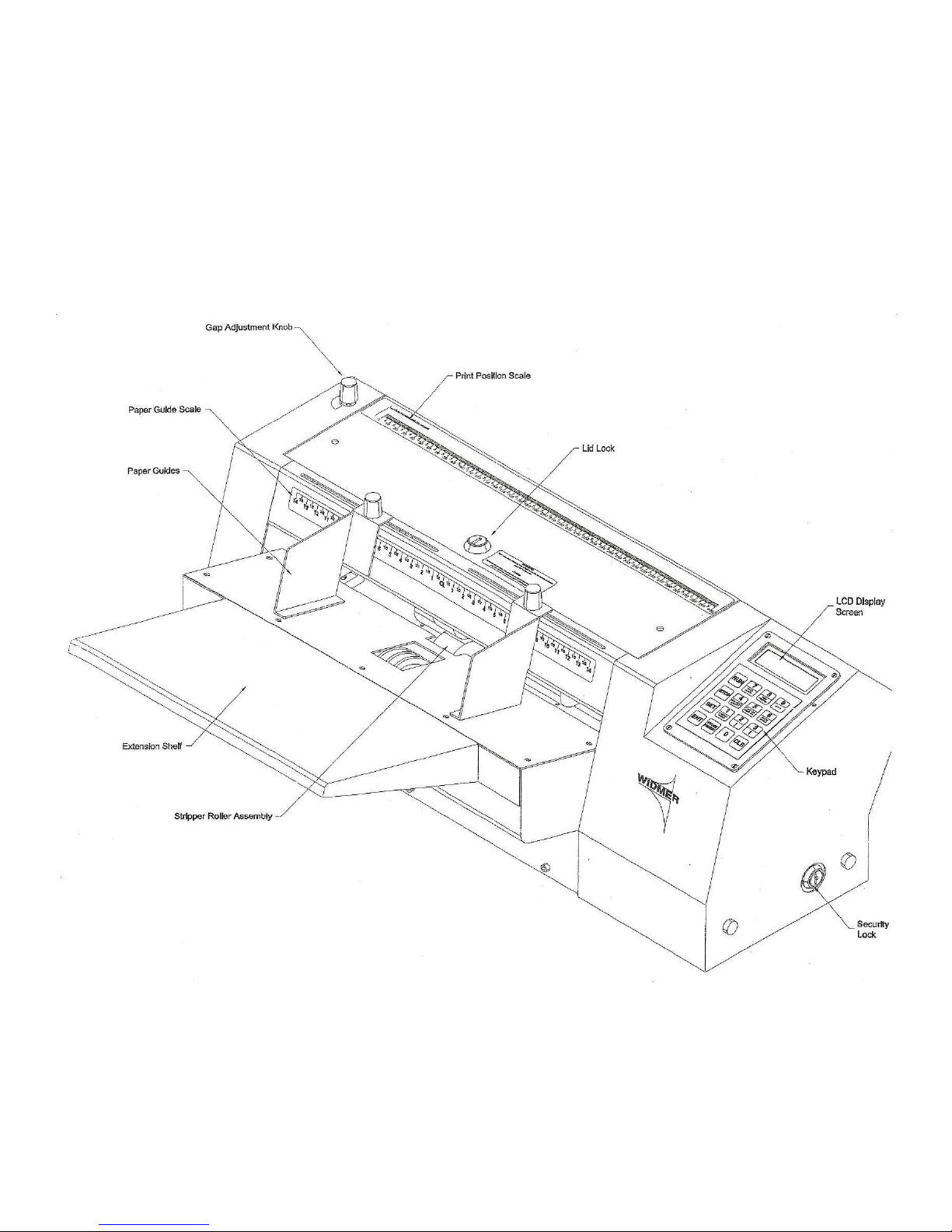

All Models have an adjustable gap setting to select the proper thickness of the items.

Turning the knob opens and closes the gap between the stripper and the feed roller.

The proper setting is so that the thickness of a single sheet will pass but two sheets will

not pass.

The proper location for the document is centered on the feed rollers. Horizontal guides

control side to side movement. The guides can be slid into proper position by

loosening the knobs on each side. The sheets of paper lay across the lip on the

bottom of the guide. Sheet sizes ranging from 2 7/8” by 2 7/8” to 15 1/2” by 16” can be

fed through the RS.

5

6

7

Loading...

Loading...