Page 1

9 502 3018 001

Quick Guide

IIC ImpressIon manual

Page 2

2/10

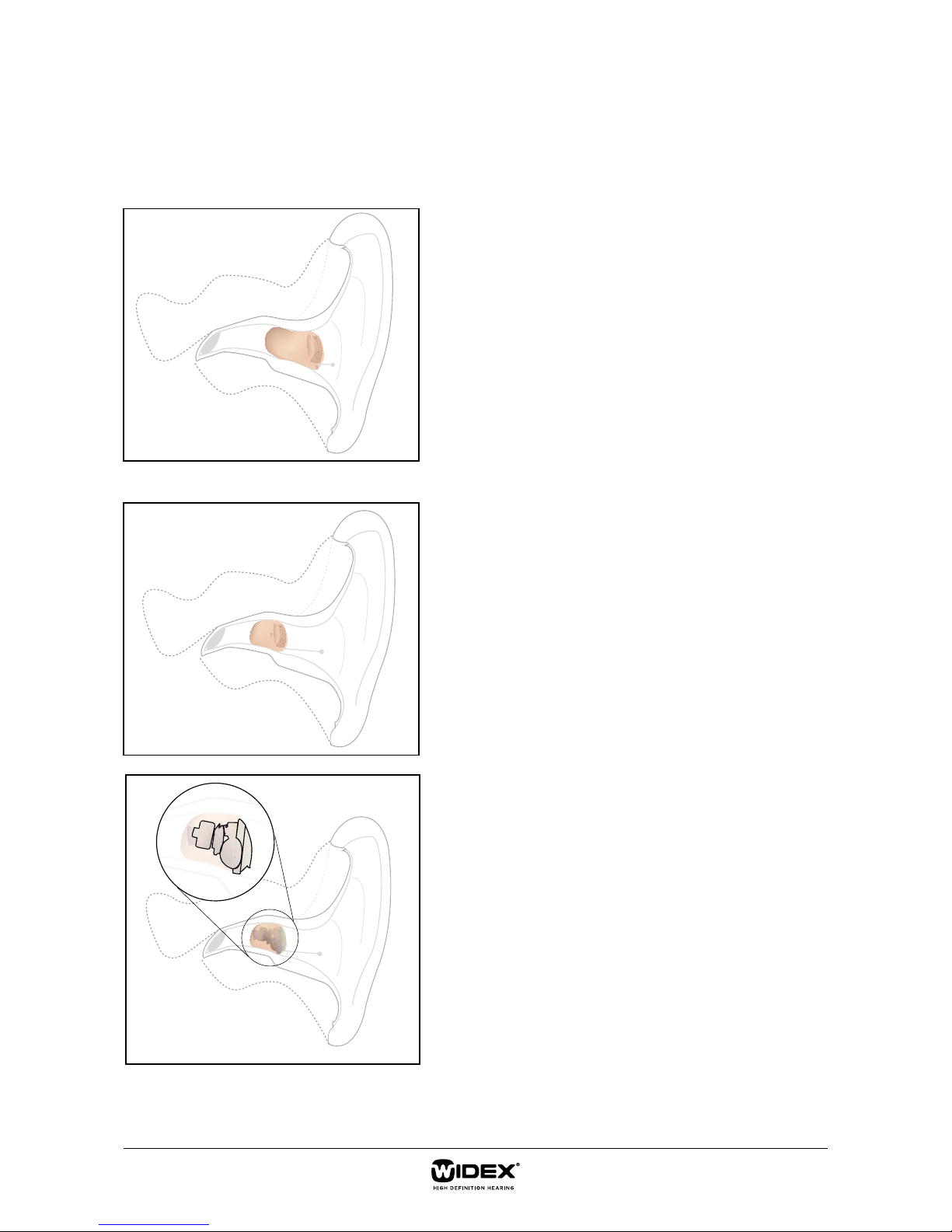

When fitting a client with an IIC (Invisible In Canal), it is important to point out that making a good earmould or shell

is work of high precision.

Each ear canal is individual, and an accurate impression

must be taken in order to collect the data on which the

shell production can be based.

It is especially important to take an impression that is long

enough. Which in most cases mean an impression “Well

past the second bend”. An impression that is not long

enough can make it impossible for CAMISHA to make the

requested IIC solution.

The following pages are intended as a guide to how to take

a deep impression for an IIC hearing aid.

CIC

IIC

CIC vs IIC

The shell of the IIC houses the amplifier circuits, receiver

and battery drawer. These parts are placed in the locations shown, and the ear canal therefore needs to be wide

enough and long enough to accommodate an IIC hearing

aid.

Page 3

3/10

The process of impression-taking can be divided into three

major tasks:

• Inspection of the ear canal and eardrum

• Taking the impression

• Verifying the impression

The following tools are required:

1. Otoscope

2. Otoblock material

3. Impression mass

4. A lightpen

Remember, you should always ensure good hygiene prior

to impression-taking.

1

2

3

4

requIred tools

Page 4

4/10

To make sure that the client is relaxed

during the impression-taking process, it is

important to explain the procedure. You

should:

• Find out whether the client has had

ear impressions taken before.

• Find out whether the client has ever

felt dizziness during impressiontaking.

• Explain the insertion of the otoblock

to protect the eardrum.

• Explain that the ear canal will be

filled with silicone during the hardening process.

• Explain the occlusion eect during

the impression-taking.

• Explain that due to the deep impression, some people may feel the urge

to cough.

takIng the ImpressIon

It is important to make an impression

that is long enough. A common guideline

states that the impression needs to make

it “just past the second bend”, but in cases

where the first and second bends are close

to each other, this is not enough.

You should therefore place the otoblock as

close to the eardrum as possible, to ensure

a suitable impression length.

Page 5

5/10

WidthThickness

Width

TR

Thickness

TR

TR

Length

Thickness

Width

Length

Inner end of HA

Inner end of HA

Transverse receiver

Outer end of HA

www.widex.pro\iicgauge

IIC gauge

The gauge is a guidance tool for hearing

care professionals, to help you determine

whether an IIC hearing aid might be an

option for a given client. Measurement is

a multiple-step process which requires an

impression of the client’s ear canal, the

Widex IIC gauge, and a marker pen. As the

ear canal is oval in shape, measurements

must be undertaken of both the width and

the thickness at dierent points.

Since there are two dierent receiver

designs to choose between, straight and

transverse, the gauge has a brown section

and an orange section, giving the minimum dimensions needed for each of these

solutions.

Please follow the steps below to complete

the verification process.

the verIfICatIon proCess

Page 6

6/10

1. Outer end verification I

First of all, you will need to measure the

minimum width required to place the outer

end of the IIC hearing aid, i.e. the part which

contains the battery drawer.

Hold or place the ear impression with the

canal part pointing upwards. Take the gauge

and place the cutout marked WIDTH in the

green section at the tip, i.e. the inner end of

the canal part, or the narrowest part of the

impression.

Slide it downwards until the impression width

blocks further movement. Mark this point

with a pen.

TR

TR

TR

Page 7

7/10

2. Outer end verification II

Next, turn the impression 90 degrees to

measure the thickness at the marked point.

If the impression does not slide into the cutout marked THICKNESS in the green section,

the marking on the impression will roughly

represent the outer end of the hearing aid.

If the impression slides into the cutout, slide

the gauge further downwards until the impression thickness blocks further movement.

Mark this point with a pen. This lower point

will then roughly represent the outer end of

the hearing aid.

TR

Page 8

8/10

3. Transverse receiver verification I

Next, you will need to check the minimum

width required to place the transverse receiver in the IIC hearing aid.

Hold or place the ear impression with the

canal part pointing upwards.

Place the cutout marked WIDTH TR in the

orange section at the tip of the impression.

Slide it downwards until the impression width

blocks further movement. Mark this point

with a pen.

TR

TR

TR

Page 9

9/10

4. Transverse receiver verification II

Turn the impression 90 degrees to measure

the thickness at the marked point. If the

impression does not slide into the cutout

marked THICKNESS TR in the orange section, the marking on the impression will

roughly represent the inner end of the hearing aid using a transverse receiver.

If the impression slides into the cutout, slide

the gauge further downwards until the impression thickness blocks further movement.

Mark this point with a pen. This lower point

will then roughly represent the inner end of

the hearing aid.

TR

Page 10

10/10

After completing the measurements of

width and thickness needed for a transverse

receiver, you can now measure the length

between the

markings.

Place the cutout marked LENGTH TR (orange section) alongside the canal part of the

impression to check whether the minimum

length has been met for the solution.

5. Length verification (transverse receiver)

6. Normal/Straight receiver verification

If the above verification process has shown that the ear canal is too narrow to fit an IIC with a transverse receiver,

you can alternatively check the minimum width needed to place a NORMAL/STRAIGHT receiver in the IIC hearing

aid. To do this you need to repeat the process described in step 3, step 4 and step 5 using the brown section of

the gauge.

Loading...

Loading...