Page 1

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

12345678901234567890123456789012123456789012345678901

FF

INDIND

F

IND

INDIND

FF

ONON

THETHE

ON

THE

ONON

THETHE

WILBURWILBUR

WILBUR

WILBURWILBUR

OUTOUT

OUT

OUTOUT

CURCUR

CUR

CURCUR

MOREMORE

MORE

MOREMORE

WEBWEB

WEB

WEBWEB

TIS.COMTIS.COM

TIS.COM

TIS.COMTIS.COM

..

.

..

WW

W

WW

ILBURILBUR

ILBUR

ILBURILBUR

C C

C

C C

URTISURTIS

URTIS

URTISURTIS

C C

C

C C

OMPOMP

OMP

OMPOMP

ANYANY

ANY

ANYANY

, I, I

, I

, I, I

NCNC

NC

NCNC

GEM-120A Satellite Brewer Instructions

GEMINI COMMERCIAL COFFEE

BREWING SYSTEMS

CONTENTS

Unpacking . . . . . . . . . . .

Function of Gemini . . . .

Setup . . . . . . . . . . . . . . . .

Timer Adjustment . . . . . .

Care & Maintenance .

Trouble Shooting . . . . . .

Parts List Gem 3 & 5 . . . .

Parts List Gemini 120A . .

Wiring Diagrams

Gemini 120A -10 . . . .

Gemini 120A -63 . . . .

Warranty . . . .

Back Cover

..

.

..

10

1

1

1

2

2

3

5

6

9

C

ISO 9001 REGISTERED

5/23/00. 8.9 f-1903.p65.p1X

WILBUR CURTIS COMPANY

Montebello, CA 90640

FOR THE LATEST SPECIFICATIONS AND INFORMATION GO TO

WWW.WILBURCURTIS.COM

Page 2

INSIDE FRONT COVER IS A BLANK PAGE

Page 3

GEMINI 120A

UNPACKING

All products manufactured by the Wilbur Curtis Company are thoroughly inspected at the factory

and are warranted to be free of all defects or faulty workmanship. The Gemini unit is packaged for

maximum protection while being shipped.

Make sure the shipping carton is not damaged

or punctured. Unpack the carton carefully,

inspecting the contents for any damage that

may have occurred in transit. Report any

damage immediately to the freight company.

E

D

B

G

F

H

be used at any time without interrupting the brew cycle. A warmer element, H, keeps the coffee in

the Satellite at the proper temperature.

NOTICE

This brewer must be installed by a professional licensed technician and must comply with all local

electrical, mechanical and plumbing codes having jusrisdiction. Wilbur Curtis Company will not

accept any responsibility if these conditions are not met. This machine must be used for it's intended purpose and the function for which it was designed.

A

C

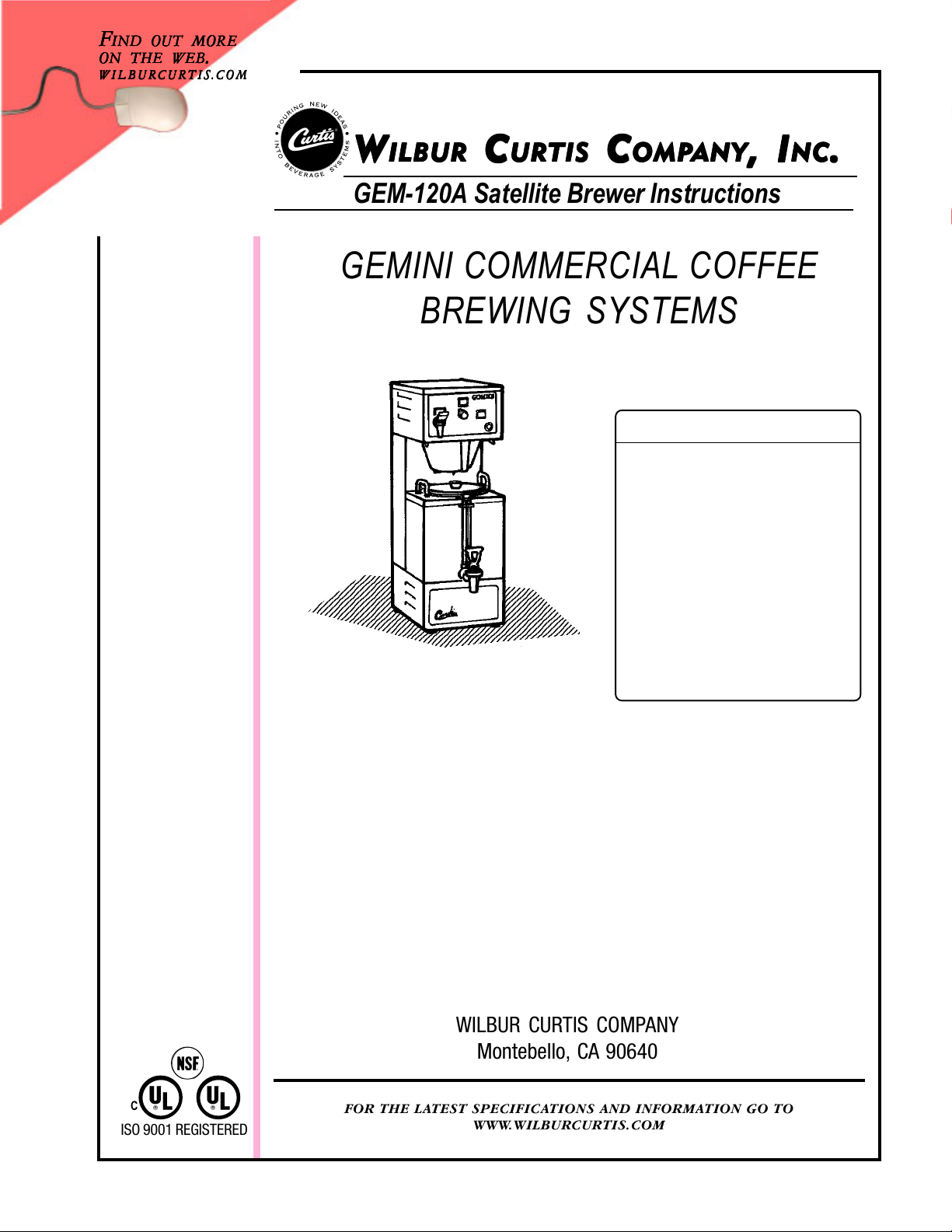

FUNCTION OF THE GEMINI

The water in the heating tank A, is maintained

at the same level at all times by a sensor

called the water level probe B. This controls

the water inlet valve C.

When the brew switch is pushed, a brew cycle

starts: The dump valve D, is opened by the

brew timer E, allowing hot water to be sprayed

over the ground coffee for a specific time

period .

Brewed coffee then pours from the brew cone

F, into the Satellite.

The hot water faucet G, dispenses hot water

for tea, instant beverages, or soups and can

SETUP INSTRUCTIONS

1. Locate a position for the Gemini 120A on a firm and level, counter top.

2. Remove the top cover of the brewer and lid from the heating tank. Hand fill the tank until the

water level is approximately two (2) inches below the probe tip.

3. A 1/4" female flare fitting is required for water supply. Connect the water line to the inlet valve

fitting and turn on the water.

4. With the top cover removed, turn thermostat stem clockwise until it stops.

5. Plug the unit into a power supply outlet and turn toggle switch on. Turn ON/OFF switch to ON

position. Make sure water is flowing into the heating tank. Filling should stop when the water

level reaches the probe tip. When this is verified, replace both tank lid and top cover to the

machine.

6. Allow 15 to 20 minutes for the water in the tank to reach brewing temperature. The

BREW READY light will come on when it reaches the correct temperature.

- 1 -

Page 4

GEMINI 120A

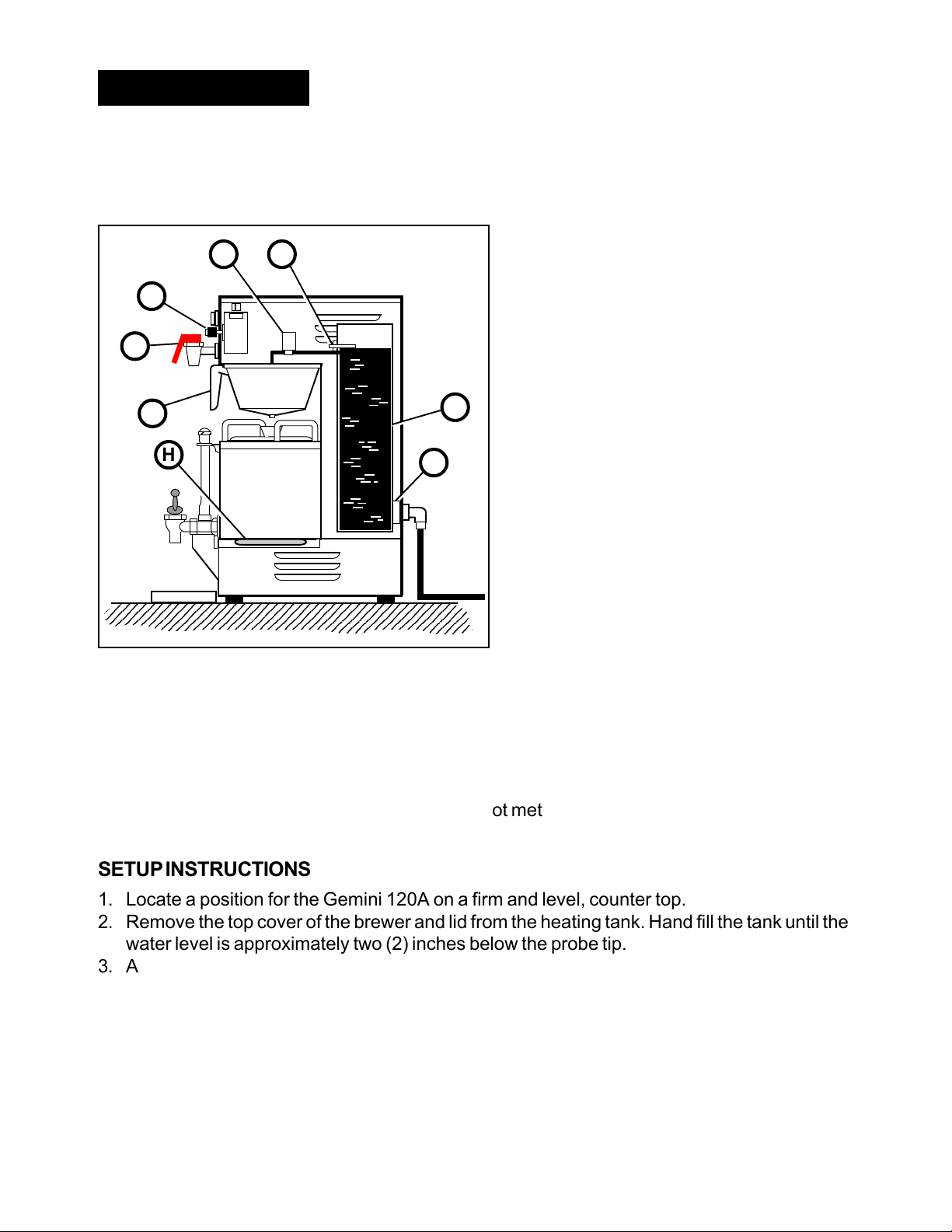

ADJUSTMENT INSTRUCTIONS FOR TIMER WC-603RDS

The Gemini 120A now has a new timer which

was introduced starting from serial number

14866. It is a new, improved version of the

previous WC-603 RD timer. The wiring on

this has remained exactly as on the older

versions to make retrofitting easier.

The timer is mounted inside the upper compartment with the brew selector knob protruding from the center of the front panel (see

illustration, left). The brewer is designed to

brew 24 cups (one gallon maximum). Adjustment of the timer is made on the timer calibration dial. The knob indicator must be set at

the 480 second mark on the dial. On the front

panel, the brew selector switch should be at

2. This setting will deliver one gallon of water

(brew 24 cups) per brew cycle. To brew 12

cups, simply turn the brew selector knob to 1.

If finer adjustments are needed, rotate timer knob to the right to increase the brew time, rotate to

the left to decrease the brewing time.

CARE AND MAINTENANCE OF THE GEMINI 120A

Regular cleaning and preventive maintenance is essential in keeping your Gemini Coffee Brewer

looking and working like new.

WARNING Do not use cleansers, liquids, bleaches, or powder that contain chlorine.

These products cause corrosion and pitting on stainless steel and will void your warranty.

PREVENTIVE MAINTENANCE:

1. Remove the sprayhead from the Gemini 120A and clean once a week or more often in heavy

lime areas.

2. Clean the faucet seat cups twice a week and replace when they are cracked or leaking.

3. Periodic temperature checks or adjustment of thermostat by authorized personnel.

CLEANING

To maintain optimum coffee flavor, the Gem 3 Satellite should be cleaned daily after the last batch

of coffee is used. We recommend the use of urn cleaning powder or Scotch Bright pads for cleaning inside the coffee container.

The outside of the brewer and Satellite should be cleaned with a soft cloth and stainless steel

polish only, to prevent scratching the surface.

Deliming of the heating tank should be done every six (6) months; more often in heavy lime areas.

- 2 -

Page 5

GEMINI 120A

TROUBLE SHOOTING

PROBLEM: WATER DOES NOT FLOW INTO HEATING TANK

POSSIBLE CAUSE

1. Water line turned off or

filter clogged up.

2. Water inlet valve coil

burned out

3. Grounded probe (item

#12)

4. Defective or burned out

water level control board

(item #3)

SOLUTION

Open the water line and make sure water flows to the brewer.

Turn off brewer. Disconnect wires from water inlet coil terminals

and connect a power cord to the terminals. Plug cord into a 110v

outlet and verify that water flow when plugged in and stops when

cord is disconnected. If valve does not respond to this test, replace

the valve.

When water in the heating tank is below the probe tip, yet water is

not refilling, pull the wire off the probe terminal. If water starts flowing

into the tank, find ground, clean or replace the probe.

Pull the wire from the probe terminal. With a volt meter, check the

voltage at the water inlet coil terminals. This should read 110 to 115

volts. If no voltage is present, check the water level control board.

Make sure that the back of the board is grounded securely to the

mounting bracket. Check for loose wire connections. Replace

board.

PROBLEM: WATER IN HEATING TANK OVERFLOWING

POSSIBLE CAUSE SOLUTION

5. Defective water inlet

valve (item #28)

6. Probe limed up (item #12)

7. Loose or ungrounded

water level control board

(item #3)

PROBLEM: WATER IN TANK DOES NOT GET HOT OR WATER TEMPERATURE TOO LOW

POSSIBLE CAUSE

8. Thermostat is off (item #31)

9. Burned out heating

element.

Turn power off and observe the water level in the heating tank. If

water continues to flow in, clean or replace the valve.

Pull wire off from probe terminal. Touch the water tank shell with the

terminal at the end of this wire. If water stops flowing, clean or

replace the probe.

If probe is okay, check the water level control board. The water level

control board must be securely grounded. Check for loose connections. Check for voltage at the inlet valve terminals. Replace board.

SOLUTION

Check the thermostat (item #31) to make sure it is in the ON position. Turn the thermostat stem clockwise until it stops.

Check element for continuity and/or check with clamp ammeter. This

should show a reading of approximately 15 amps. If no power is

going through element, replace it.

- 3 -

Page 6

GEMINI 120A

PROBLEM: WATER IN TANK DOES NOT GET HOT OR WATER TEMPERATURE TOO LOW

POSSIBLE CAUSE

10. Defective thermostat

PROBLEM: WATER NOT FLOWING FROM SPRAYHEAD.

POSSIBLE CAUSE

11. Water level is too low

in heating tank

12. Defective brew switch

(item #41)

13. Defective timer (item #2).

Thermostat may be cutting off before the water temperature reaches

operating temperature. Do not try to reset the thermostat. Replace it.

Check water level in tank. If water is not flowing into the tank, review

steps 1 thru 4, previous page.

Check the continuity between terminals 5B and 4B when the BREW

switch is pressed. If there is no continuity, replace the switch.

Make sure the timer is receiving 110 to 120 volts. You can verify this

by taking a reading with your meter at the end of the YELLOW wire

on terminal 5B of the ON/OFF switch and at terminal A of the timer.

When the timer is activated by the brew switch, you should read

110 to 120 volts across terminals 6 and A of the timer. The RED

wire on terminal 6 supplies power to open the dump valve. If no

voltage is present, replace the timer.

SOLUTION

SOLUTION

14. Burned out dump valve

coil (item #34)

If the timer works when the brew switch is pressed, then check the

dump valve using a voltmeter on the terminals. If it shows 110 to

120 volts but no water flows through the valve, clean out the valve or

replace the coil.

- 4 -

Page 7

ILLUSTRAILLUSTRA

ILLUSTRA

ILLUSTRAILLUSTRA

TED PTED P

TED P

TED PTED P

ARAR

TS BREAKDOWN GEM-3,TS BREAKDOWN GEM-3,

AR

TS BREAKDOWN GEM-3,

ARAR

TS BREAKDOWN GEM-3,TS BREAKDOWN GEM-3,

6

7

-5, -5,

-5,

-5, -5,

-8 -8

-8

-8 -8

5

INDEXINDEX

INDEX

INDEXINDEX

NN

ºº

N

º

NN

ºº

1

2

3

4

5

5A

6

7

8

PARTPART

PART

PARTPART

NN

ºº

N

º

NN

ºº

GEM-5

WC-1201

WC- 114R

GEM 3

WC-3307

WC-5622

WC-2102

WC-2010C

WC-2025

8

11

SATELLITE WARMER STAND,115V . . . . .

POWER CORD 6’ 18/3 BLK . . . . . . . . . .

SWITCH, ROCKER 120V RED . . . . . . . . .

SATELLITE SERVER 1½ GAL . . . . . . . .

LID GEMINI SATELLITE . . . . . . . . . . .

LID, SATELLITE PLASTIC GEM3 (OPTIONAL)

GAUGE GLASS ASSEMBLY, 8” C . . . . . .

SHIELD, 8 INCH GAUGE GLASS . . . . . . .

GAUGE GLASS, 8 INCH . . . . . . . . . . .

12

10

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

17

14

13

9

1

3

NN

N

NN

10

11

11A

12

13

14

15

PARTPART

PART

PARTPART

ºº

º

ºº

9

WC-2007

WC-1901

WC-1800

WC-1841

WC-3705

GEM 4

WC-3503

WC-37102

NN

ºº

N

º

NN

ºº

BRACKET, GAUGE GLASS FORMED . . . . .

SHANK, FAUCET D&T CHROME . . . . . .

FAUCET S’ NONLOCKING . . . . . . . . .

FAUCET, "ESP" BLACK NONLOCKING (OPTIONAL)

KIT FAUCET

SATELLITE STAND . . . . . . . . . . . . .

LEG, SCREW BUMPER 3/8"-16 STD . . . .

KIT, WARMER ELEMENT 100W 120VAC . . . .

INDEXINDEX

INDEX

INDEXINDEX

4

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

S’S’

S’ SERIES . . . . . . . . . . .

S’S’

2

15

Wiring Diagram Gem -5 & -8

WARMER ELEMENT

WHITE

RED

WARMER

SWITCH

120 Volts, 90 Watts

BLACK

5B 4B

3A

WHITE

- 5 -

POWER CORD

GRN

Page 8

GEMINI 120A Parts List

29

26

18

30

5

13

7

6

16

13

15

3

10

18

11

25

8

27

28

23

B

24

17

12

9

B

1

22

15

14

4

21

19

20

31

5/23/00. 8.9 f-1903.p65.p8X

- 6 -

Page 9

GEMINI 120A Parts List

Item

Nº

1

2

3

4

5

6

7

7A

8

9

10

11

12

13

14

14A

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

Part

Nº

WC-3621

WC- 603RDS

WC- 608

WC-2936

WC-5502-01

WC-3920T

WC- 904

WC- 906-04

WC-1200

WC- 826

WC- 517

WC-3763

WC- 817

WC-1809

WC- 202

WC- 203

WC- 114R

WC- 122

WC-2977-01

WC-5310

WC-5451

WC- 947

WC- 102

WC-3503

WC-3338

WC-5452

WC-5450

WC-43058

WC-3765

WC- 829

WC-37008

WC-5466

WC-3920B

Description

BREW CONE, UNIVERSAL 7 1/8" BLK PLASTIC . . . . . . . . . . . . . . . . . . . .

TIMER, BREW SELECTOR 120V GEM-120A . . . . . . . . . . . . . . . . . . . . . . .

LEVEL CONTROL, WATER 120V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPRAYHEAD, RED (.131 DIA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROBE ASSY, WATER LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LABEL, TOP GEM 120A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELEMENT, ENVELOPE HEATING w/SCREWS GEN USE . . . . . . . . . . . . . . .

HEATING ELEMENT, 2000W, 220V W/JAM NUTS . . . . . . . . . . . . . . . . . . . .

POWER CORD, 6' 14/3 BLK SJTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VALVE, INLET 1 GPM 120V 10W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THERMOSTAT, CAPILLARY SPST 277V 22A GEN USE . . . . . . . . . . . . . . .

KIT, VALVE REPAIR FOR WC-866, WC-889, WC-816, WC-817, WC-818 . . . .

VALVE, DELTROL DUMP RIGHT 120V. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FAUCET, HOT WATER W/JAM NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIGHT, BREW 115V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIGHT, BREW 220V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWITCH, ROCKER 120V RED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWITCH, ROCKER BREW 120V GREEN . . . . . . . . . . . . . . . . . . . . . . . . . . .

FITTING ASSY, SPRAYHEAD PLATED TIN NICKEL . . . . . . . . . . . . . . . . . . .

TUBE, 5/16" I.D. SILICONE GEN USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARMER DECK, NO ELEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELEMENT, WARMER 90W, 115V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWITCH, TOGGLE SPST 25A 125/250 VAC RESISTIVE . . . . . . . . . . . . . . . .

LEG, SCREW BUMPER 3/8-16 STD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KIT, BREW CONE W/BASKET SS 7 1/8" DELUXE BLK HANDLE (OPTIONAL)

COVER, FRONT GEM-120A/120P/230A/200R/300IL/600ILD. . . . . . . . . . . . . .

COVER, TOP D500, G230A, G120A, PTB . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLUG, DRAIN PP RED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KIT, VALVE REPAIR (USE ON WC-825 WC-826) . . . . . . . . . . . . . . . . . . . . .

WASHER, .35 GPM .5" USE ON WC-825 . . . . . . . . . . . . . . . . . . . . . . . . . . .

LID ASSEMBLY, TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TANK, COMPLETE GEM-120A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LABEL, BOTTOM GEM-120A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAPER FILTERS

Part Number

GEM- 6

CR- 10

X

Description

FILTER FOR BREW CONE WC-3338 (500/PKG) . . . . . . . . . . . . . . . . . . . . . . . . . .

FILTER FOR BREW CONE WC-3621 (1000/PKG) . . . . . . . . . . . . . . . . . . . . . . . . . .

- 7 -

Page 10

WIRING DIAGRAM – GEM120A-10

- 8 -

VOLTAGE:

WATTAGE:

AMPERAGE:

HERTZ:

WIRES:

PHASE:

120VAC

1775

15

60

2+GND

1

Page 11

WIRING DIAGRAM – GEM120A-63

- 9 -

VOLTAGE:

WATTAGE:

AMPERAGE:

HERTZ:

WIRES:

PHASE:

120/220VAC

1775/2100

15/10

60

3+GND

1

Page 12

WARRANTY

We hereby certify that the products manufactured by the Wilbur Curtis Company, Inc., are, to thebest of our knowledge,

free from all defects and faulty workmanship.

The following warranties and conditions are applicable:

1. 1 Year Parts & Labor from Date of Purchase from Factory: This warranty covers all electrical parts, fittings

and tubing.

2. 40 Months or 40, 000 Pounds of Coffee on a set of Grinding Burrs. (ADS Grinders)

3. 3 Years from Date of Purchase: This warranty covers electronic control boards and leaking or pitting of a

stainless steel body of a Brewer or Urn.

4. 90 Days from Date of Purchase: On replacement parts that have been installed on out of warranty equipment

All in-warranty service calls must have prior authorization from the manufacturer. For an RMA (Return Merchandise

Authorization) number, call the Technical Service Department at 1-800-995-0417. The Wilbur Curtis Company will allow

up to 100 miles, round trip, per in-warranty service call.

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company, Inc., assumes no

responsibility for substitute replacement parts installed on Curtis equipment that have not been purchased from the

Wilbur Curtis Company. Inc The Wilbur Curtis Company will not accept any responsibility if the following conditions are not

met. The warranty does not cover and is void under these circumstances:

1) Improper operation of equipment. The equipment must be used for its designed and intended

purpose and function.

2) Improper installation of equipment. This equipment must be installed by a professional,

certified technician and must comply with all local electrical, mechanical and plumbing codes.

3) Wilbur Curtis Company will not be responsible for the operation of equipment at other than the

stated voltages on the serial plate.

4) Abuse or neglect (including failure to periodically clean or remove lime accumulations).

Manufacturer is not responsible for variation in equipment operation due to excessive lime or

local water conditions.

5) Replacement of items subject to normal use and wear. This shall include, but is not limited to,

light bulbs, shear disks, “0” rings, gaskets, canister assemblies. whipper chambers and plates,

mixing bowls, agitation assemblies and whipper propellers.

6) Any faults resulting from inadequate water supply. This includes, but is not limited to, excessive or low water pressure, and inadequate or fluctuating water flow rate.

7) All repairs and/or replacements are subject to our decision that the workmanship or parts were

faulty and the defects showed up under normal use.

8) All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner.

9) Charges incurred by delays, waiting time, or operating restrictions that hinder the service

technician’s ability to perform service is the responsibility of the owner of the equipment.

This includes institutional and correctional facilities.

10) All claims under this warranty must be submitted to the Wilbur Curtis Company Technical

Service Department before return of the unit to the factory.

11) All equipment returned to us must be repackaged properly in the original carton. No units will

be accepted if they are damaged in transit due to improper packaging.

12) Damaged in transit.

13) The resetting of safety thermostats and circuit breakers, programming and temperature

adjustments are the responsibility of the equipment owner.

NO UNITS OR PARTS WILL BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA).

RMA NUMBER MUST BE MARKED ON THE CARTON OR SHIPPING LABEL.

All in-warranty service calls must be performed by an authorized service center, where service is available. Call the factory

for location near you.

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150

Technical Support Phone: 800/995-0417 (M-F 5:30A - 4:00P PST) E-Mail: techsupport@wilburcurtis.com

Web Site: www.wilburcurtis.com

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

Fax: 323-837-2410

Printed in U.S.A. 8/20/03 F-1903 Rev B

Loading...

Loading...