Mudguard Assembly Instructions

www.whyte.bike

CAUTION

Whilst fitting these mudguards:

• Confirm they are large enough for the tyres fitted to your bicy-

cle. “38mm” mudguards are suitable for Whyte Cambridge,

Cambridge Varsity, Carnaby, Charing Cross, Cornwall, Devon,

Dorset, Kings Cross, Pimlico, Portobello, Shoreditch, Somerset,

Stirling, Suffolk, Sussex, Victoria & Whitechapel models (Rigid

forks). “46mm” mudguards are suitable for Whyte Caledonian,

Chiltern, Coniston, Malvern & Ridgeway models (Suspension

Forks) and Fairfield (Rigid forks). The Montpellier & Stowe

models have no suitable mounting points for mudguards.

• Check that there will be at least 6mm clearance aroun

d the

tyre when they are fitted correctly.

• It is recommended to apply Loctite 243 Thread-Locker or simi-

lar thread adhesive to the threads of all screws that hold the

stays to either the fork or frame. This will help to ensure they

will not come loose. Carefully follow Loctite’s own assembly

instructions.

• SAFETY CHECK – CONFIRM THE CORRECT OPERATION OF

THE BRAKES AND GEARS AFTER FITTING THE MUDGUARDS. If in doubt either consult the manufacturer’s user

instructions or contact your Whyte Bikes dealer.

Before each and every ride:

• Check that all the fasteners holding the mudguards in place are

still tight.

• If necessary, clean and dirt or road debris from the

inside of

the mudguard, since this will reduce the clearance to the tyre.

WHYTE Mudguard Assembly Instructions

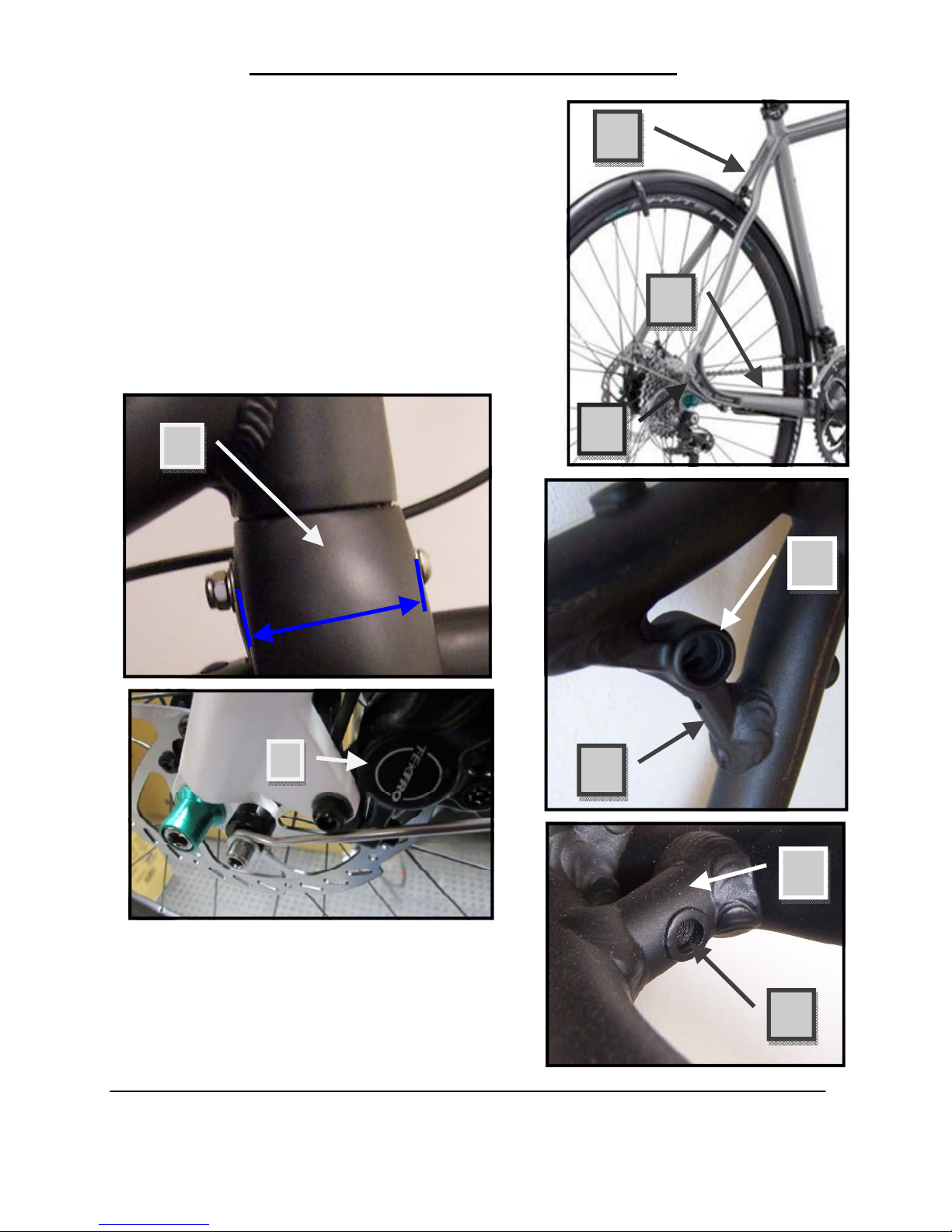

Terminology

1. Front Fork Crown & Thickness.

2. Disc Brake Caliper.

3. Seat-stay.

4. Chain-stay.

5. Rear drop-out.

6. Seat-stay bridge.

7. Stepped seat-stay bridge hole.

8. Chain-stay bridge.

9. Threaded chain-stay bridge hole.

Side Stay Lengths:

300mm long for 46mm wide mudguards.

315mm long for 38mm wide mudguards.

1

1

2

7

6

8

9

3

4

5

WHYTE Mudguard Assembly Instructions

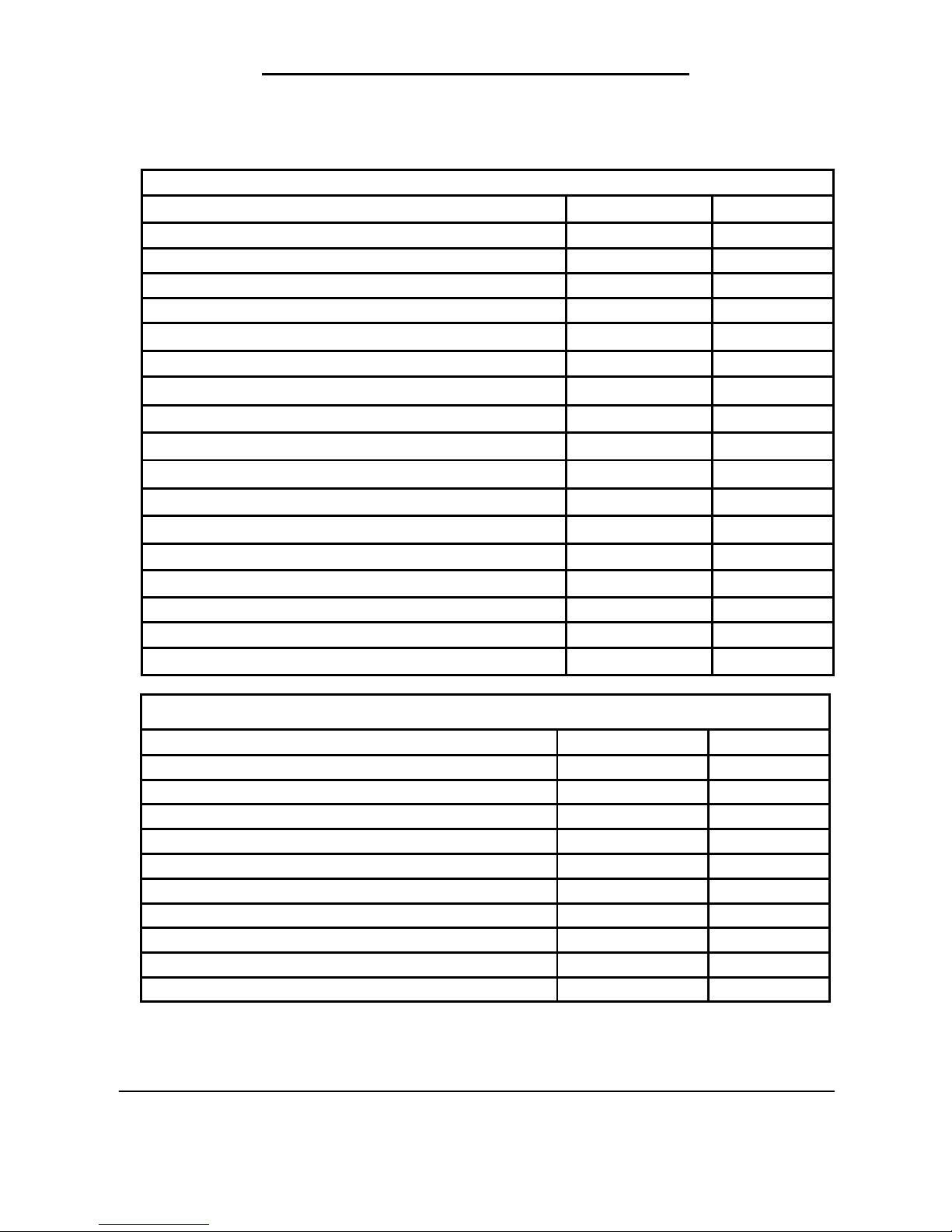

Mounting Hardware:

38mm Wide Mudguards

Description Reference Quantity

Button head cap-screw M5 x 25 long 26 1

Button head cap-screw M6 x 12 long 12 1

Button head cap-screw M6 x 30 long 16 1

Button head cap-screw M6 x 50 long 8 1

Button head cap-screw M6 x 60 long 8 1

Cap-screw M5 x 12 long 6 3

Cap-screw M5 x 16 long 21 4

Cap-screw M5 x 20 long 22 1

Cap-screw M6 x 65 long 8 1

Cycle brake nut M6 thread x 10mm long 18 1

Nut M6 Nylock 10 2

Spacer Ø6.2 hole x Ø15 outside x 5 long 23 2

Spacer Ø5.2 hole x Ø10 outside x 10 long 25 1

Washer Ø5 hole x Ø13 outside x 0.8 thick 7 13

Washer Ø6 hole x Ø12 outside x 1.6 thick 9 3

Washer Ø6 hole x Ø18 outside x 1.6 thick 17 1

Button head cap-screw M5 x 35 long 24 1

46mm Wide Mudguards

Description Reference Quantity

Button head cap-screw M6 x 12 long 12 2

Button head cap-screw M6 x 35 long 19 1

Cap-screw M5 x 12 long 6 2

Cap-screw M5 x 16 long 21 2

Cycle brake nut M6 thread x 10mm long 18 1

Nut M6 Nylock 10 2

Spacer Ø6.2 hole x Ø15 outside x 5 thick 23 1

Washer Ø5 hole x Ø13 outside x 0.8 thick 7 4

Washer Ø6 hole x Ø12 outside x 1.6 thick 9 3

Washer Ø6 hole x Ø18 outside x 1.6 thick 17 1

WHYTE Mudguard Assembly Instructions

Assembling the Front Mudguard:

• Reference figure A. Using a 3mm A/F Allen Key, undo the M4 screw

(1) in one stay bracket (2) by no more than one rotation. Clip the

stay bracket (2) onto the side of the front mudguard (3). Position

the stay bracket (2) approximately 100mm above the mudguard end.

Re-tighten the stay bracket screw according to the torque value

shown in the table on page 15.

15

11

14

4

2

4

4

A

1

0

0

m

m

3

5

0

m

m

Tab

1

0

0

m

m

2

1

5

3

WHYTE Mudguard Assembly Instructions

• Insert a single side-stay (4)

through the threaded sleeve

(5) and also into the end of the

stay bracket (2). Screw the

sleeve (5) into the end of the

stay bracket (2) and lightly

tighten. Repeat this process

for the other items (1, 2, 4 &

5) on the other side of the

mudguard (3). Do not firmly

tighten the sleeves (5) just yet,

as the side-stays (4) may need

to be adjusted later.

• Remove the front wheel from

the bicycle (refer to page 15 of

the Whyte General Instruction Manual on

how to do this).

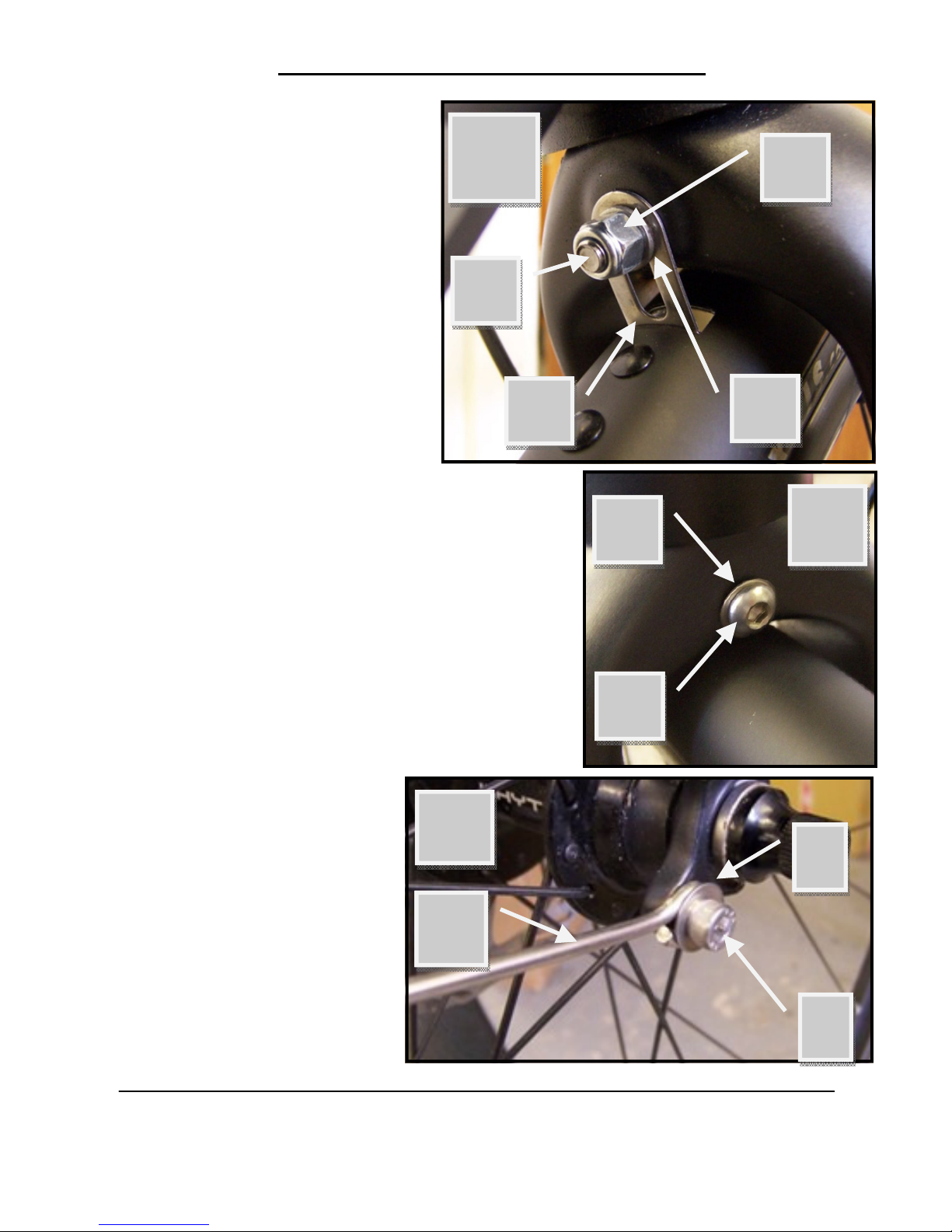

• For Rigid Forks

◊ Reference figures B & C. Depending on

the thickness of the front fork crown

(see Terminology), use either an M6 x

65 capscrew or an M6 x 60 long or 50

long button head cap-screw (8), plus

two small washers with Ø6 holes (9) and

an M6 Nylock hex nut (10) to attach the

bridge bracket (11) to the rear of the

crown of the front

fork.

◊ Reference figure D.

Using an M5 x 12

long cap-screw (6)

and a washer with a

Ø5 hole (7), attach

the looped end of the

side-stay (4) to the

threaded hole in each

of the front fork legs.

B

8

9

11

10

9

8

C

4

6

D

7

WHYTE Mudguard Assembly Instructions

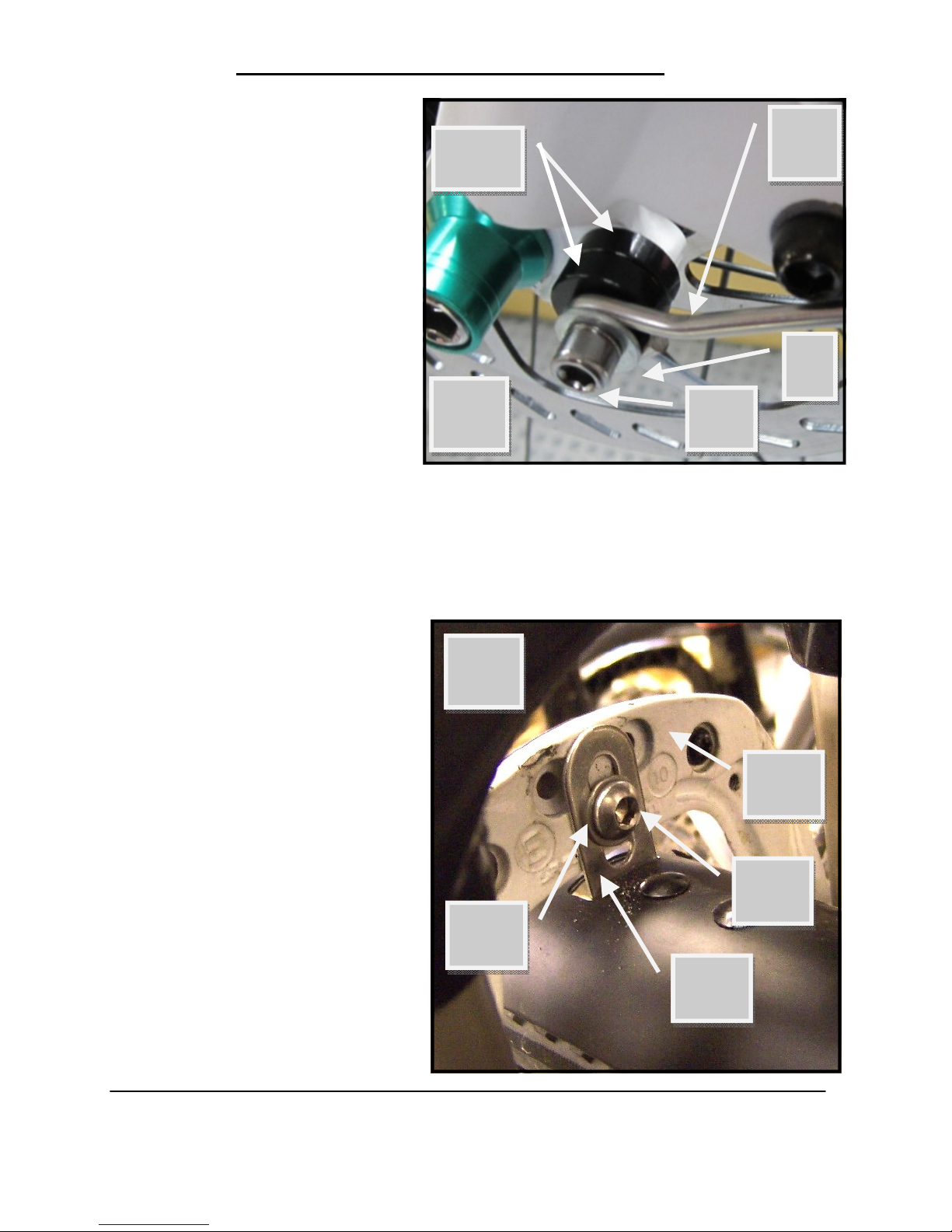

◊ Reference figure E. Us-

ing an M5 x 20 long

cap-screw (22), a

washer with a Ø5 hole

(7) & two 5mm thick

spacers (23), attach

the looped end of the

side-stay (4) to the

threaded hole in the

left front fork leg. For

the threaded hole adjacent to the axle, two

spacers (23) are required to allow the side

-stay (4) to clear the

disc brake caliper (see Terminology). Some other forks have a

t

hreaded hole further up the side of the fork. In this case no

spacers (23) are required.

• For Suspension Forks

◊ Reference figure F. Us-

ing an M6 x 12 long

button head cap-screw

(12) and a small washer with a Ø6 hole (9),

attach the bridge

bracket (11) to the rear

of the lower leg bridge

of the front fork (13).

4

22

E

7

23

F

12

11

13

9

WHYTE Mudguard Assembly Instructions

◊ Reference figure G.

Using an M5 x 12

long cap-screw (6)

and washer with a

Ø5 hole (7), attach

the looped end of

the side-stays (4)

to the threaded

holes in each of the

front fork legs.

• Refit the front wheel

(refer to page 15 of

the Whyte General

Instruction Manual on

how to do this).

• Carefully adjust all the fixing points until the mudguard sits evenly and

c

entrally around the front tyre, with a minimum clearance of 6mm.

Also check there is enough clearance from the mudguard to your foot

when in the pedal rotated fully forwards. Then tighten the fasteners

according to the torque values shown in the table on page 15.

Assembling the Rear Mudguard:

• Slide the bridge bracket (15) onto & around the outside of the rear

mudguard (14) with the tab towards the rear of the frame. Position

the bridge bracket (15) approximately 350mm above the forward

mudguard end (see Figure A on page 6). Check that it is a tight fit

on the mudguard (14).

• Reference figure A on page 6. Using a 3mm A/F Allen Key, undo the

M4 screw (1) in one stay bracket (2) by no more than one rotation.

Clip the stay bracket (2) onto the side of the bare rear mudguard

(14). Position the four stay brackets (2) approximately as shown in

image A, ie: the two lower stays approximately 100mm above the

mudguard end and the two upper stays approximately equal distances

between the mudguard end and the location of the bridge bracket

(15). Insert a side-stay (4) through the threaded sleeve (5) and also

G

4

6

7

WHYTE Mudguard Assembly Instructions

into the end of the stay bracket (2). Screw the sleeve (5) into the end

of the stay bracket (2) and lightly tighten. Repeat this process for the

other items (1, 2, 4 & 5) on

the other locations of the

mudguard (14). Do not firmly

tighten the sleeves (5) just

yet, as the side-stays (4) may

need to be adjusted later.

• Remove the rear wheel from

the bicycle (refer to page 15

of the Whyte General Instruction Manual on how to do

this).

• Reference figures H & J. For a

f

rame without a step in the

seat-stay bridge hole (see

Terminology). Using an M6 x

30 long button head capscrew (16), a

small washer

with a Ø6 hole

(9), a large

washer with a

Ø6 hole (17)

and an M6 Nylock hex nut

(10), attach

the bridge

bracket (15)

to either the

front or rear

of the seatstay bridge

(see Terminolo

gy).

H

15

16

17

J

10

16

9

Tab

WHYTE Mudguard Assembly Instructions

• Reference figures

K & L. For a frame

with a step in the

seat-stay bridge

hole (see Terminol-

ogy). Using an M6

x 12 long button

head cap-screw

(12), a large

washer with a Ø6

hole (17) and an

M6 x 10 long cycle

brake nut (18),

attach the bridge

bracket (15) to

the rear of the

seat-stay bridge

(see Terminology).

K

L

12

17

15

18

WHYTE Mudguard Assembly Instructions

• Reference Figure M. For a

frame with an M5 rivet nut

in the rear of the seat-stay

bridge (eg: Cornwall). Slide

the bridge bracket (15) onto & around the outside of

the rear mudguard (14)

with the tab towards the

front of the frame. Using

an M5 x 16 long button

head cap-screw (21) and

two washers with a Ø5 hole

(7), attach the bridge

bracket (15) to the rear of

the seat-stay bridge (see

T

erminology). One washer

(7) should be placed either

side of the bridge bracket

(15).

• Reference figure N. For a

frame with a threaded

chain-stay bridge boss

(see Terminology). Using

an M5 x 12 long capscrew (6) and a washer

with a Ø5 hole (7), attach

the front end of the mudguard (14) to the threaded hole in rear of the

chain-stay bridge (see

Terminology).

M

7

14

6

N

7

21

15

WHYTE Mudguard Assembly Instructions

• Reference figure P. For a frame with

a non-threaded chain-stay bridge

boss (see Terminology). Using an M6

x 35 long button head cap-screw

(19), two small washers with Ø6

holes (9), a 5mm thick spacer (23)

and an M6 nylock hex nut (10), attach the front end of the mudguard

(14) to the open hole in the chainstay bridge (see Terminology). Use

the spacer between the bridge and

the mudguard to provide clearance

between the mudguard and the

front derailleur (see Terminology).

• Reference figure Q. For a

frame without a chain-stay

bridge, but which has a roller

for the front derailleur cable

(eg: 2013 Kings Cross or 2013

Charing Cross). Using an M5 x

35 long button head capscrew (24), a washer with a

Ø5 hole (7) & two 5mm thick

spacers (23), attach the front

end of the mudguard (14) to

the seat tube through the roller.

9

10

23

19

P

23

24

14

14

Q

WHYTE Mudguard Assembly Instructions

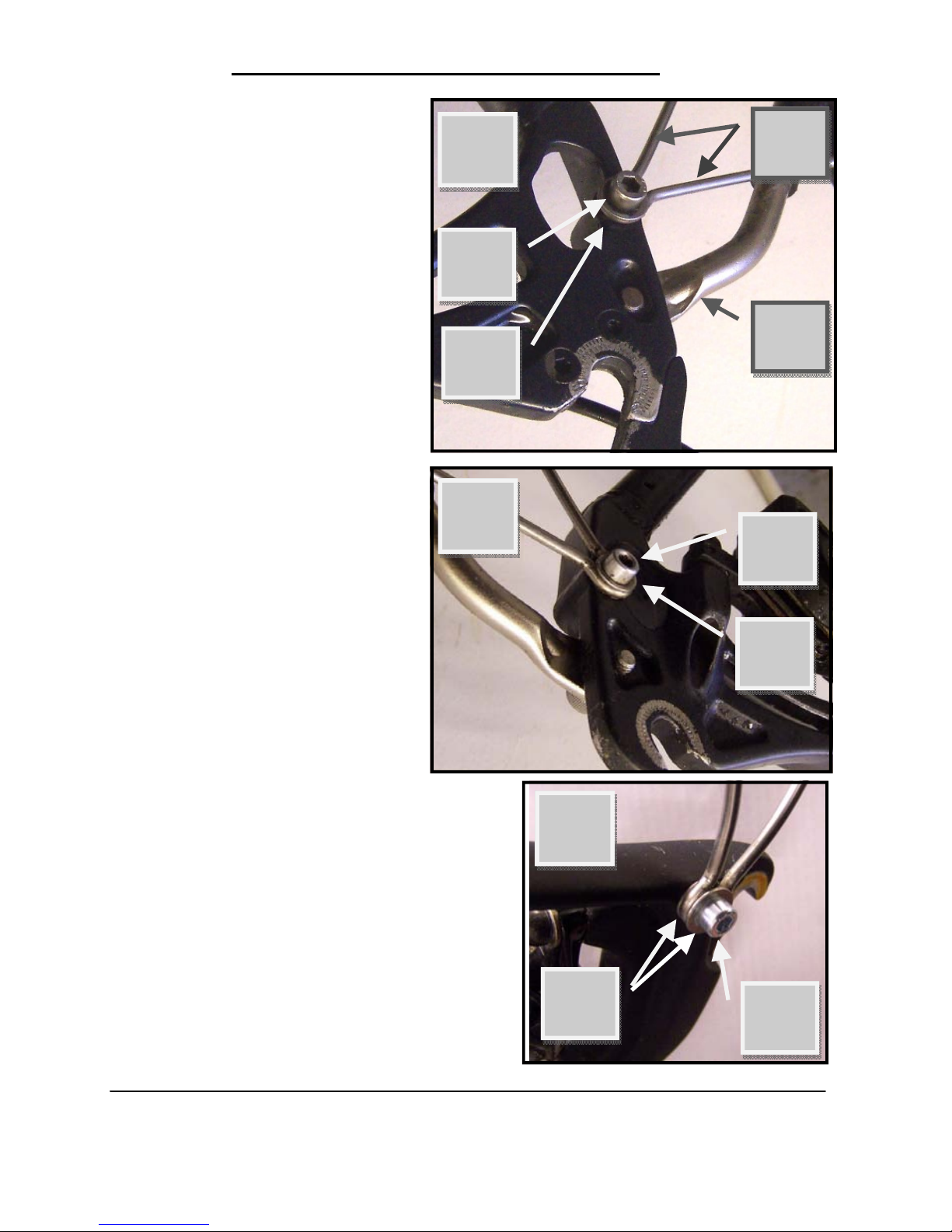

• Reference figures R & S

(showing the inside of each

rear drop-out. Q = right

side & R = left side). For

frames with two M5 threaded holes in each drop-out,

the side-stays (4) should be

mounted on the INSIDE of

rear drop-outs alongside the

M5 threaded holes. This will

allow a rear luggage carrier

(20) to be fitted to the bicycle alongside the M5 threaded holes further down the

drop-out.

Using an M5 x 16 long button head cap-screw (21) and

washer with a Ø5 hole (7),

attach the looped end of the

side-stays (4) to the threaded holes in each of the rear

drop-outs. Ensure that the

side-stays (4) are in the correct location on the mudguard (14) and then tighten

both M5 x 16 long button

head cap-screw (21) into

the drop-outs, BEFORE the rear

wheel is re-fitted.

Reference figure T. For frames with

one M5 threaded hole in each dropout, the side-stays (4) should be

mounted on the OUTSIDE of rear

drop-outs alongside the M5 threaded

holes. Also, for carbon fibre frames,

fit a washer with a Ø5 hole (7) to

both sides of each side-stay (4).

R

20

4

S

7

21

21

7

T

7

21

WHYTE Mudguard Assembly Instructions

• Reference figures U & V. For a frame with

an M5 rivet nut in the rear of the seat tube

(eg: Cornwall). Using an M5 x 25 long button head cap-screw (26), three washers

with a Ø5 hole (7) & a 10mm long spacer

(25), attach the front end of the mudguard

(14) to the seat tube. One washer (7) is

placed onto the head of the cap-screw

(26), then passed through the upper slot

in the mudguard. Then another washer

(7), the spacer (25) and the third washer

is placed onto the cap-screw (26) from the

outside of the mudguard. Then thread the

cap-screw (26) into the seat-tube rivet.

Tighten the cap-screw (26) BEFORE the

rear wheel is re-fitted.

• Refit the rear wheel (refer to page 15 of

t

he Whyte General Instruction Manual on

how to do this).

• Carefully adjust the remaining loose fixing points until the mudguard

(14) sits evenly and centrally around the rear tyre, with a minimum

clearance of 6mm. Then tighten the loose fasteners according to the

torque values shown in the table below.

1 M4 x 10 long cap-screw 2.5 Nm

1.8 lbs.ft

6, 21, 22, 24 or 26 M5 x 12/16/20/25/35

long screws

5.0 Nm

3.7 lbs.ft

8 M6 x 65/60/50 long screws 10 Nm

7.4 lbs.ft

12, 16 or 19 M6 x 12/30/35 long screws 5.0 Nm

3.7 lbs.ft

Item Description Torque

25

U

7

V

26

7

Loading...

Loading...