E-MTB Full Suspension Bike Range

Page 3 Whyte Supplementary Service Manual

Page 37 BOSCH Drive Unit

Page 45 BOSCH PowerTube Battery

Page 57 BOSCH Charger

Page 67 BOSCH Purion Display

Page 75 BOSCH Error codes

1.0 Introduction

2.0 Geometry

3.0 Preparations for riding:

3.1 Making Adjustments

3.2 Whyte Inter Grip Seat Clamp Adjustment

3.3 Set up of Fork

3.4 Set up of Rear Damper

3.5 Suspension Tuning Log

4.0 Safety.

5.0 Lubrication:

5.1 Whyte Inter Grip Seat Clamp

5.2 General Lubrication

6.0 Servicing the Rear Suspension:

6.1 Removing the Rear Shock and Swinging Arm.

6.1.1 Remove the Rear Shock only.

6.1.2 Remove the other rear suspension parts.

6.1.3 Remove the chain-stay & bearings from the Main Frame

6.2 Stripping and Re-assembling Other Rear Suspension Bearings

6.2.1 Extraction of Bearings

6.2.2 Insertion of Bearings

6.2.3 Re-Assembly of Shield Washers / Spacers

6.3 Re-assembling the Rear Suspension

6.3.1 Re-Assembly of the Rear Suspension.

6.3.2 Insert the bearings into the Main Frame, plus

assemble the chain-stays to the Main Frame.

6.3.3 Re-assemble the other rear suspension parts.

6.3.4 Re-assemble the Rear Shock into the Main Frame.

6.2.4: Application of “SKF LGAF 3E” or “Castrol Optimol T”

Anti-Fret Pastes.

7.0 Servicing the Whyte Modular Dropout Systems:

7.1 Disassembly of Modular Rear Dropouts.

7.1.1 Shimano E-Thru

7.1.2 SRAM Maxle 148mm

7.2 Reassembly of Modular Rear Dropouts.

7.2.1 Shimano E-Thru

7.2.2 SRAM Maxle 148mm

8.0 Servicing the Whyte Inter Grip Seat Clamp

Table of Contents

Page 3 2019

WHYTE Service Manual

9.0 Fitting Internal Cables & Hoses.

9.1 To replace cable or hose outers.

9.2 To fit a “Dropper” seat-post with internal cable.

10.0 Removal of Battery

10.1 Location of Bosch Battery On/Off Button.

10.2 Location of Bosch Battery Charge Port.

11.0 Torque Settings.

12.0 Owner’s Notes

Table of Contents (continued)

1.0: INTRODUCTION

Thanks for choosing to purchase this Whyte product. We hope you will enjoy all

the benefits its advanced design and engineering will bring to your riding experience.

This manual will guide you through the set-up, safety and maintenance procedures that are specific to your Whyte bike. For other more general information,

we strongly advise that you also read thoroughly the General Instruction Manual

that is also supplied with your new bike.

Also, please note that the specification of all the components that are fitted to

your bike as standard may be obtained from the Whyte Bikes Brochure or alternatively from the Whyte Bikes website www.whyte.bike

Please remember, if you are in any doubt about your ability to safely service or

repair your Whyte bike, do not ride it and instead arrange for a professional bicycle mechanic at your local Whyte dealer to do the job correctly.

Bundled with this manual, are the respective manufacturers instructions and

manuals for the branded parts and systems that are fitted to your Whyte bike.

Please take time to study all the relevant instruction manuals to ensure you have

a continually safe and well set-up bike before every ride, and to help you build up

a relationship of knowledge between you and your Whyte Dealer.

Happy and safe riding,

Whyte design team

2.0: GEOMETRY

The geometry of the full suspension range of Whyte Bikes is available from the

Whyte Bikes website www.whyte.bike

Page 4

2019

WHYTE Service Manual

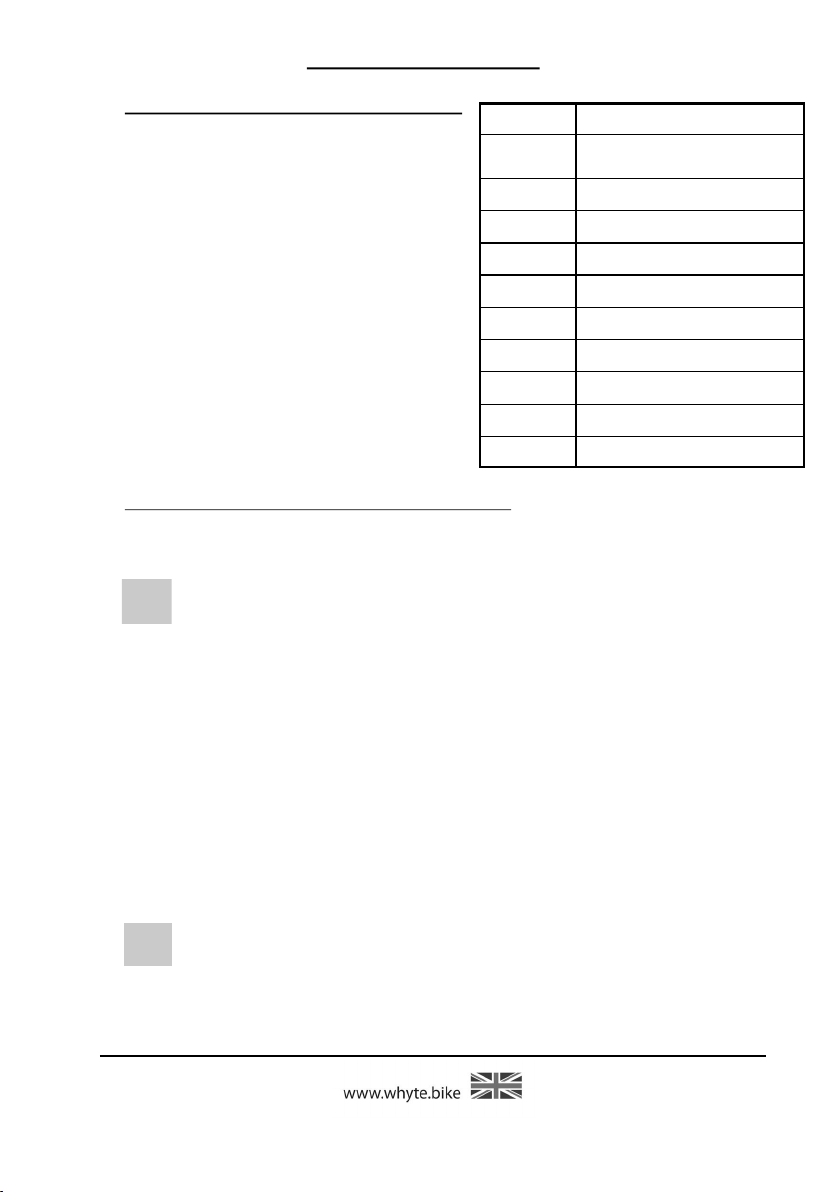

3.0: PREPARATIONS FOR RIDING

3.1: MAKING ADJUSTMENTS

Please refer to the specific component

manufacturers manual or published technical information about adjusting, servicing or replacing the components on your

Whyte bike. Instructions may be downloaded from the relevant manufacturer’s

internet website, as shown in the table to

the right.

In addition, we recommend that you

should also read carefully the advice published by Bosch e-bike systems about

operation of the Bosch e-Bike systems

Bosch www.bosch-ebike.com

Crank

Brothers

DT Swiss www.dtswiss.com

Formula www.formulahubs.com

Fox www.foxracingshox.com

Joytech www.joytech.co.tw

Maxxis www.maxxis.com

Race Face www.raceface.com

SR Suntour www.srsuntour-cycling.com

www.crankbrothers.com

fitted to the Whyte e-MTB. Failure to do

so could result in Serious Injury or Death.

For additional advice on general care of e-

SRAM www.sram.com

WTB www.wtb.com

bikes, Visit:

www.bosch-ebike.com/en/news/care-of-ebikes/

CAUTION! If you are uncertain in any way, about making adjustments to

any components or systems on you Whyte bike, then DO NOT RIDE YOUR

BIKE. Contact your Whyte dealer who will be able to advise you on how to

go about setting up you Whyte bike for riding, and or making adjustments

to the components fitted to your Whyte bike.

3.2: WHYTE INTER GRIP SEAT CLAMP ADJUSTMENT & SERVICE

Tools Required: 5mm Hex Key

Torque Wrench (Ranging from 3Nm to 15Nm)

SKF LGEP2 or Castrol Spheerol AP3 or Finish Line Teflon White

Lithium

Complex grease

The Inter Grip seat clamp design is present on some models of Whyte full suspension mountain bikes. It allows adjustment of the saddle height & direction.

CAUTION! Avoid over-tightening the seat clamp.

In particular, “dropper” Seat Posts may not work correctly if the seat clamp

is over tightened.

Page 5 2019

WHYTE Service Manual

Ite

m

1

2

3

4

5

Description

Cap-screw, M6 x 30mm

Inter-Grip Sleeve,

threaded.

“O” Ring seal, fits in

sleeve groove.

Inter-Grip Sleeve, no

Inter-Grip Pad for

Ø30.9mm Seat Post.

long.

thread.

Fig.1: Inter-Grip Seat Clamp

To adjust the Seat height and/or direction, using the 5mm Hex Key, undo the M6

Capscrew (1) just enough to allow the Seat Post to slide freely up and down. Set the

height and/or direction to the desired level. Re-tighten the M6 Capscrew (1), using

the 5mm Hex Key and Torque Wrench, to the 14Nm limit, as marked on the Plain

Sleeve (4).

If a “dropper” Seat Post is fitted, simultaneously depress the activation trigger and

press down on the Saddle to compress the Seat Post until it is fully compressed. Then

release the activation trigger and the Seat Post should rise up automatically. If this

does not happen, gradually loosen the M6 Capscrew (1) with the %mm Hex Key below the 14Nm limit, until the Seat Post rises automatically. Then firmly twist the Saddle to confirm the Seat Post is still securely gripped by the lowered torque value that

allows the “dropper” Seat Post to function correctly.

CAUTION! When adjusting the saddle height you MUST obey the Minimum

insertion depth requirement marked on the Seat Post. Also consult the manufacturers Seat Post instructions in conjunction with these notes.

3.3: SET UP OF FORK

Tools Required: Good Quality Shock Pump.

Small Ruler

The Front Suspension Fork fitted to your Whyte bike will be pre-set with the standard

settings. Before riding, you may need to adjust these setting. First is the Sag setting

on the fork. This is to ensure the forks are set-up correctly for your own body weight,

allowing the fork to perform as intended.

To set Sag on the Fork, you need to measure the amount the Fork compresses when

you sit on the bike in the normal riding position.

Refer to the specification tables in the relevant Fork manufacturers set up instruc-

Page 6

2019

WHYTE Service Manual

tions to find how to adjust the air spring pressure. Using a Shock pump, either add

or remove air until Sag is correctly set.

Please note that for the detailed instructions for servicing and all matters relating

to the Forks fitted to your Whyte bike, please refer to the relevant manufacturers

instructions.

Rebound Damping adjustment:

This adjustment fine-tunes the speed at which the wheel returns to its normal ride

height after hitting a bump. Refer to the relevant manufacturers instructions to find

out how to adjust the rebound damping. To demonstrate the effect of this function,

turn the adjuster to its slowest setting. Press down on the handlebars to compress

the Forks, then release the load. The suspension recovers very slowly to its original

position.

Repeat the above with the adjuster turned to the fastest setting and the difference

will be seen immediately the load is released. We recommend the optimum setting

is to adjust the re-bound damping to be as slow as possible, but not so slow that

the normal ride height is not recovered. On very rough terrain, if the bike becomes

progressively lower as more bumps are hit then the re-bound damping is set too

slow. On the other hand if the bike feels choppy and not plush then the re-bound

damping is too fast. A bit of trial and error is needed to get the exact setting.

IMPORTANT SAFETY NOTE:

Always stop riding when making adjustments of

any kind to the bicycle!

3.4: SET UP OF REAR DAMPER

Tools Required: Good Quality Shock Pump.

Small Ruler

Your Whyte bike is fitted with either an air spring or a coil spring rear Shock. This

means that for an air Shock, the air pressure in the shock absorber determines the

spring rate and on a coil Shock, the rating of the spring determines the spring rate.

The correct ‘sag’ can be found using the sliding ‘O’ ring fitted to the shaft of the

Shock piston. Slide the ‘O’ ring against the Shock body. Then gently sit on the bike

in your normal riding position and with normal riding gear, including back pack if

applicable, and also raise your feet off the floor. Carefully dismount and measure

the distance the ‘O’ ring has moved away from the Shock body.

The optimum distance for the Quad-Link rear suspension system is shown in the

table to the right. If there is less than that distance fit a Shock pump and release

air pressure. Conversely if there is greater than that distance, fit the Shock pump

and increase air

Repeat the ‘sag’ test until the recommended sag distance is achieved.

For Coil Shock, the spring rate adjustment is made by swapping the spring for a

higher or lower rate spring. If more sag is required, swap the spring for a lower

Model Sag @ 30%

E-150

E-180 19.5mm

16.5mm

Page 7 2019

WHYTE Service Manual

rate spring. If less sag is required, swap the spring for a higher rate spring.

Rear Suspension Set-up - Rebound Damping:

When the damper unit is being compressed, this is known as the compression stroke.

As the suspension unit recovers from compression back towards its full length, this is

called the re-bound stroke. All the shocks fitted as standard to the Whyte full suspension mountain bikes have factory set compression damping, and manually adjustable

rebound damping.

Rebound Damping Adjustment:

The advice in section 3.3 about the fork rebound damping adjustments also applies to

the rear shock.

IMPORTANT SAFETY NOTE:

Always stop riding when making adjustments of any kind to the bicycle!

Platform Damping Adjustment.

The rear Shock fitted to your Whyte bike may have a “platform” facility to adjust the

slow speed compression damping, eg Fox “3pos w/Adj” or SRAM RockShox “Motion

Control”. Please refer to the relevant shock manufactures technical information to

learn how to adjust these features.

Please note, that the Whyte rear suspension systems have been designed not to rely

on excessive low speed compression damping to obtain efficient pedalling performance, and turning on too much low speed damping on the rear shock will compromise the suspensions sensitivity to small bump absorption and traction.

3.5: SUSPENSION TUNING LOG

Record your best suspension settings in the table below, to restore them if necessary,

eg. after dealer servicing of the suspension or if a friend has borrowed your bike.

Rider Weight

Date

(including all

riding kit)

(kg or lbs)

Fork Pres-

sure

(bar or P.S.I)

Fork Rebound

Damping

(# of clicks from

softest setting)

Shock Pressure

(bar or P.S.I)

Page 8

Shock Rebound

Damping

(# of clicks from

softest setting)

2019

WHYTE Service Manual

4.0: SAFETY

IMPORTANT: The following are intended to be advisory notes on the safe

use of your Whyte bike. You should also read thoroughly the General In-

struction Manual also supplied with your new bike. If at any stage you are

uncertain about the safety or safe operation of the bike as a whole, or any specific

component, then DO NOT RIDE YOUR WHYTE and instead please consult the

specific component manufacturers instruction manual or your Whyte Dealer for

advice.

Maximum Weight Limit:

18st. / 114kg (including rider’s pack and all riding equipment )

WARNING: As is the case with all mechanical components, the bicycle is

subjected to wear and high stresses. Different materials and components

may react to wear and stress fatigue in different ways. If the design life of a

component has been exceeded, it may fail suddenly causing possible injury

to the rider. Any form of crack, scratches and decolouring in high stress areas are showing that the component has exhausted its life time and has to be

replaced. If you are in any doubt about one or more components on your

Whyte DO NOT RIDE YOUR BIKE. Consult the specific component manufacturers literature, or take your bike to your local Whyte Dealer.

WARNING: Your Whyte eMTB has been fitted with a Bosch e-MTB e-bike

systems. We strongly recommend that you read, understand and adhere to

the instructions contained in the following Bosch manuals and literature:

• Remote Handlebar control unit

• Battery and Battery Charging

• Drive Unit

• E-Bike Care.

Failure to understand and operate the Bosch components correctly

could result in serious injury or death.

Designed for the following use:

The Whyte eMTB range of bicycles have all been designed, tested and comply with

EN-15194:2017 Safety Standard, for typical mountain biking use.

Page 9 2019

WHYTE Service Manual

5.0: LUBRICATION

Please refer to the Whyte General Instruction Manual for guidance about lubricating

many of the components on your Whyte bicycle.

For the range of bicycles contained in this Supplementary Service Manual, there is

also the following specific guidance:

5.1: WHYTE INTER GRIP SEAT CLAMP

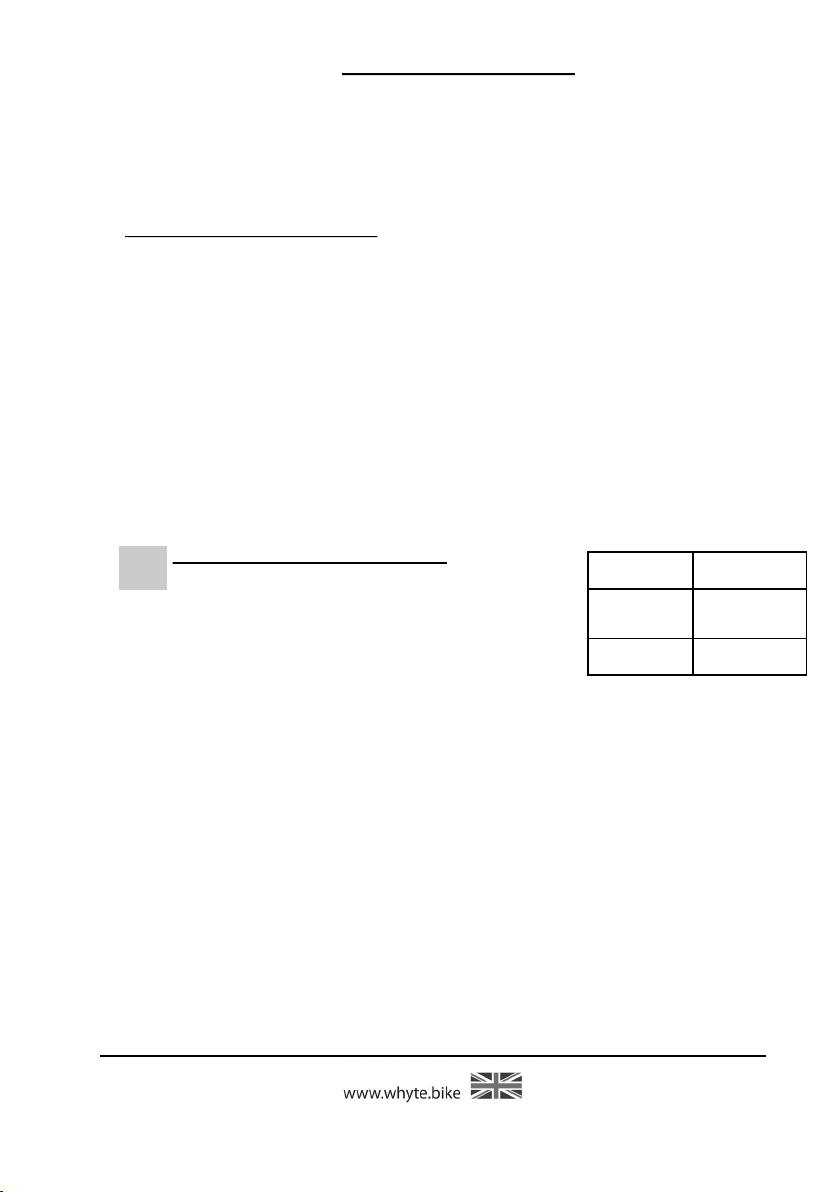

Figure 2: Capscrew Lubrication

Item Lubricant

Description

Lubrication

Interval

1

M6 x 30mm

Capscrew

SKF LGEP2 or Castrol Spherol AP3 or Finish

Line Teflon White Lithium Complex grease

Once a Month

5.2: GENERAL WHYTE LUBRICATION

For the correct lubrication regime and maintenance of all parts on a Whyte bicycle,

please refer to the specific component manufacturers detailed instructions bundled

with this manual or for further information visit the specific manufacturers website.

6.0: SERVICING THE REAR SUSPENSION

6.1: Remove the Rear Shock, Links & Swinging Arm:

Tools Required: 2x 4mm Hex Key

1x 5mm Hex Key - Ball ended

1x 6mm Hex Key

1x 8mm Hex Key

2x T-25 Torx® Keys

Page 10

2019

WHYTE Service Manual

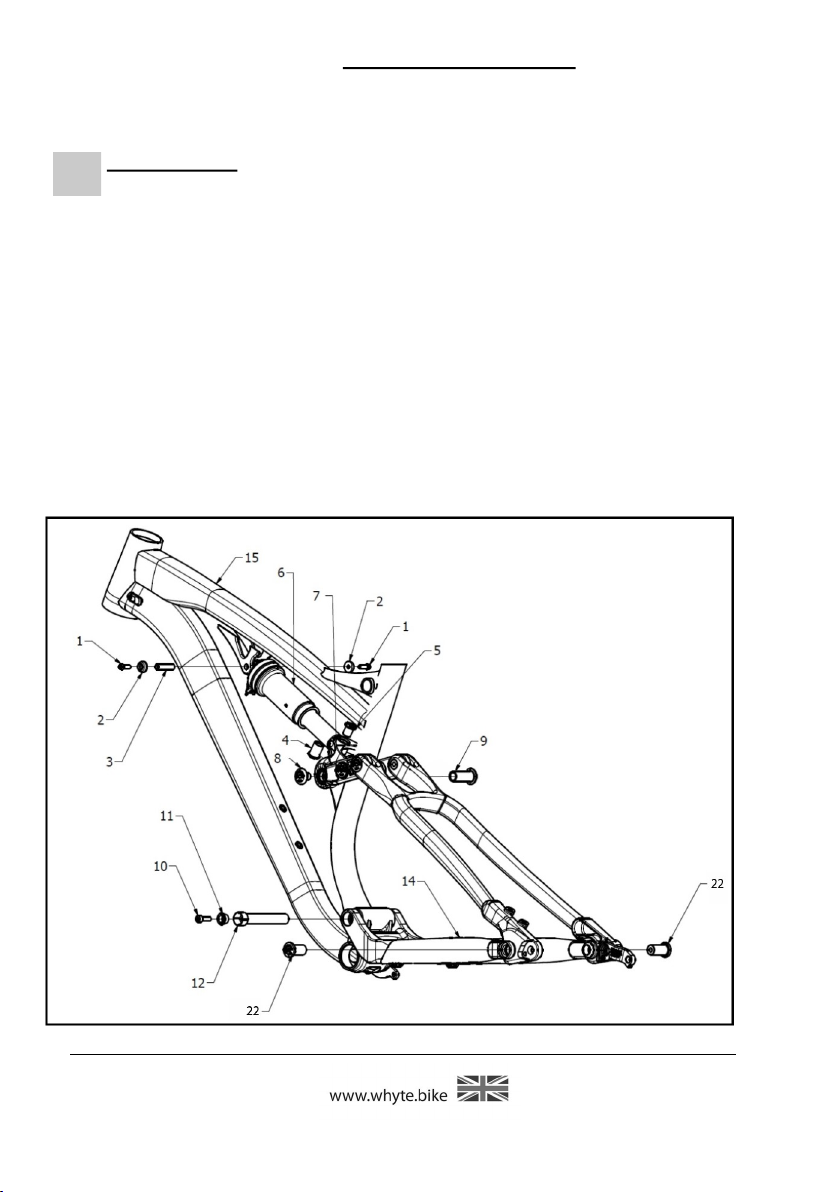

Item Description

1 M5 x 16mm long Socket-head Capscrew (T-25 Torx®)

2 Collar for M5 Capscrew

3 Hollow Pivot Pin Ø8mm x 31mm long

4 Flanged Nut M12 x 19mm long

5 Flanged Screw M12 x 15mm long

6 Rear Shock Absorber

7 Shock Extender

8 M15 x 26mm long Pivot Screw, 15mm Thread (6mm A/F Internal Hex)

9 M15 x 26mm long Pivot Screw, 15mm Thread (6mm A/F Internal Hex)

10 M6 x 20mm long Capscrew (5mm A/F Internal Hex)

11 Tapered Sleeve for Expanding Collet

12 Pivot Pin 80mm long, expanding collet, M15 thread.

13 M15 x 26mm long Pivot Screw, 10mm Thread (6mm A/F Internal Hex)

14 Chain-stays

15 Main Frame

16 Rear Suspension H Link, 99mm centre — to – centre

17 M15 x 25mm long Pivot Screw, 10mm Thread (6mm A/F Internal Hex)

18 Seat-stays

19 Shield Washer (O.D. 23mm)

20 Bearing (Enduro 6802-2RS-MAX)

21 Internal Spacer (49mm long)

22 M15 x 27mm long Pivot Screw, 14mm Thread (6mm A/F Internal Hex)

Page 11 2019

WHYTE Service Manual

6.1.1 To remove only the rear Shock (6) from the frameset

IMPORTANT: When removing Rear Shock and/or Seat & Chain stays al-

ways brace the rear end and Shock to prevent damage to frame when

weight is removed.

Whilst referencing figure 3, using the T-25 Torx® Keys, undo the two M5 x 16mm

long Socket-head Capscrews (1) from the Ø8mm x 31mm long Hollow Pivot Pin (3)

that passes through the Main Frame (15) and front of the Rear Shock (6). Whichever Capscrew (1) becomes undone first, remove it and the adjacent Collar (2),

and pull the Pivot Pin (3) all the way out from the other side.

Using the 6mm Hex Key and the 8mm Hex Key, undo and remove both the

Flanged Nut M12 x 19mm long (4) from the Flanged Screw M12 x 15mm long (5),

that pass through the Shock Extender (7) and the rear of the Rear Shock (6). You

can now remove the Rear Shock (6).

Figure 3: Disassembly of the

Rear Suspension (First Stage)

Page 12

2019

WHYTE Service Manual

Figure 4: Disassembly of the Rear Suspension (Third Stage)

6.1.2 To remove the Link (16) & Swinging Arm (14) from the Main Frame

(15).

Whilst referencing figure 3 & 4, using the 6mm Hex Key, unscrew and remove the

M15 x 26mm Flanged alloy Screws (8 and 9) from the front of the H Link (16).

Next, using the 6mm Hex Key, unscrew and remove the two M15 x 27mm Flanged

alloy Screws (22) at the rear of the Chain-stays (14). Be careful to retain all the

Shield Washers (Items 2 & 3, Figure 7) ready for re-assembly.

To separate the Seat-stays (18) from the H Link (16) and Main Frame (15), whilst

referencing figure 4, using the 6mm Hex Key, unscrew and remove the two M15 x

26mm Flanged alloy Screws (13) at the front of the Seat-stays (18). The Seatstays (18) may now be removed from the H Link (16). Finally to remove the Shock

Extender (7) from the H Link (16), using the 6mm Hex Key, unscrew and remove

the two M15 x 25mm Flanged alloy Screws (17). Be careful to retain all the Shield

Washers (Items 2 & 3, Fig 7) ready for re-assembly.

Page 13 2019

WHYTE Service Manual

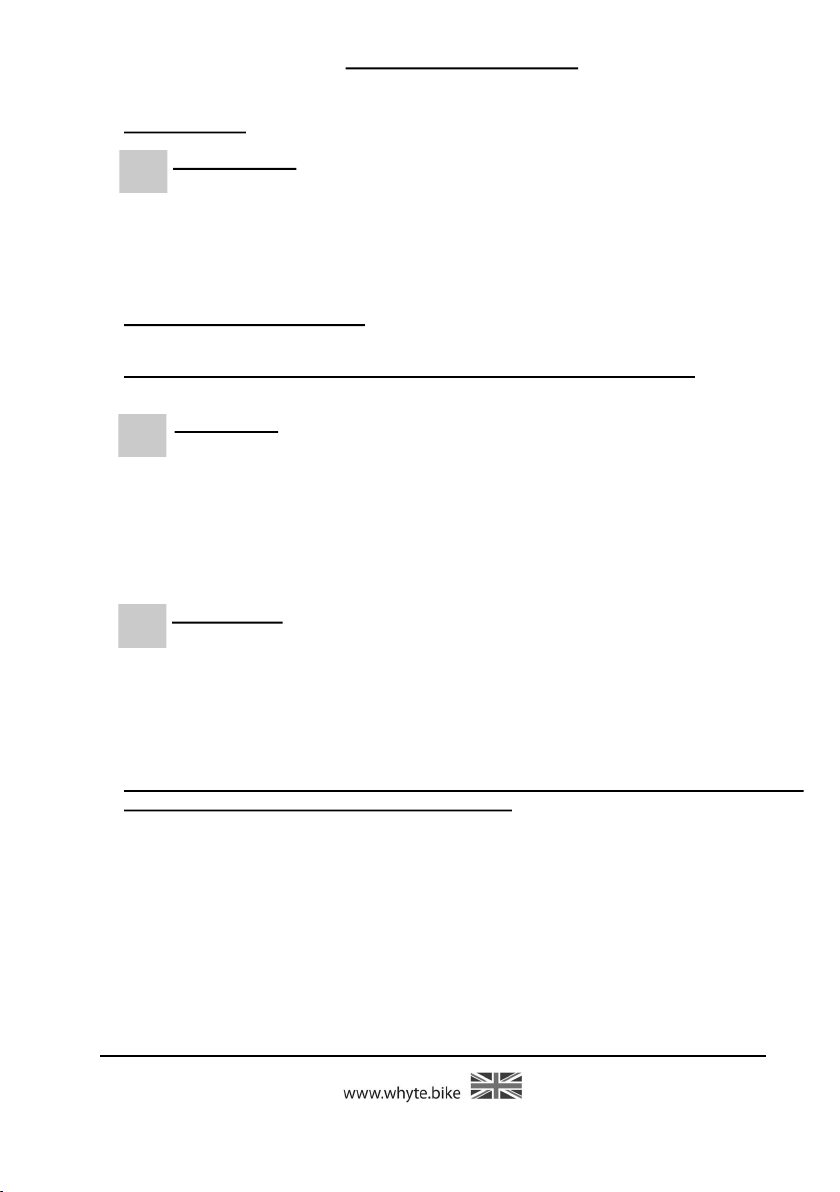

6.1.3 To remove the Chain-stays (14) and Bearings (20) from the Main

Frame (15).

Whilst referencing figure 5, using the 5mm Hex Key, partially unscrew the M6 x

20mm long Capscrew (10) from the Pivot Pin 80mm long, expanding collet, M15

thread (12). Using the 6mm Hex Key, unscrew and remove the Pivot Pin 80mm

long, expanding collet, M15 thread (12). The capscrew (10) may now be completely

removed, to allow the tapered sleeve (11) to be released from the collet (12).

The Chain-stays (14) may now be removed from the Main Frame (15). Be careful to

retain the two Shield Washers (19) ready for re-assembly.

Using the press tools shown in Figure 19, extract the BOLU-WB0025

bearings (20) from both sides of the Main Frame (15). Align the removal tool carefully with the slots in the Spacer (21).

Page 14

Figure 5: Disassembly of the

Rear Suspension (Third Stage)

2019

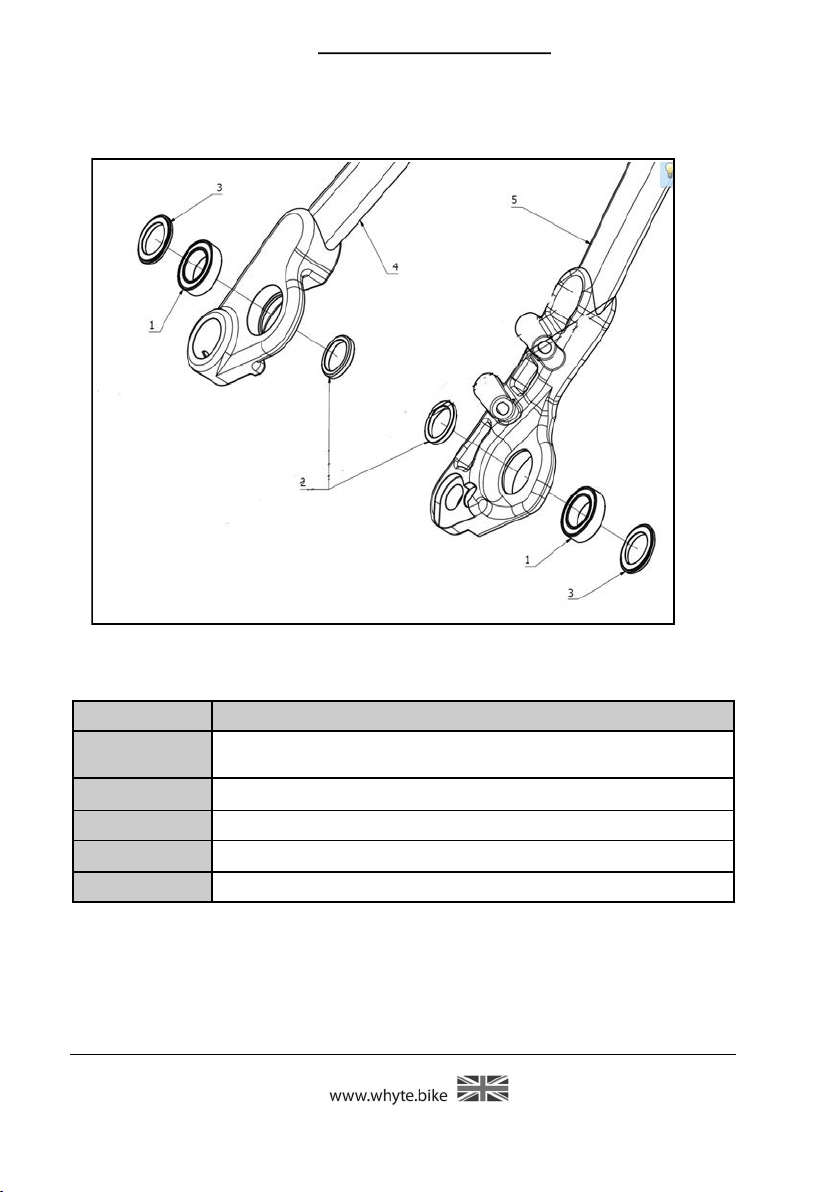

6.2: STRIPPING AND REASSEMBLING OTHER BEARINGS.

(Reference figures 6 & 7)

WHYTE Service Manual

Figure 6: Assembly of Link

Item Description

1

2 Shield washer (O.D. 20mm)

3 Shield washer (O.D. 23mm)

4 Various centre-to-centre dimensions Alloy Link Bodies

ID 15mm, OD 24mm, Width 5mm, bearing

(BOLU-WB0025)

Page 15 2019

Figure 7: Assembly

of the Seat-stays

WHYTE Service Manual

Item Description

1

2 Middle shield washer (O.D. 20mm)

3 Outer shield washer (O.D. 23mm)

4 Right Seat-stay

5 Left Seat-stay

ID 15mm, OD 24mm, Width 5mm, bearing

Page 16

(BOLU-WB0025)

2019

WHYTE Service Manual

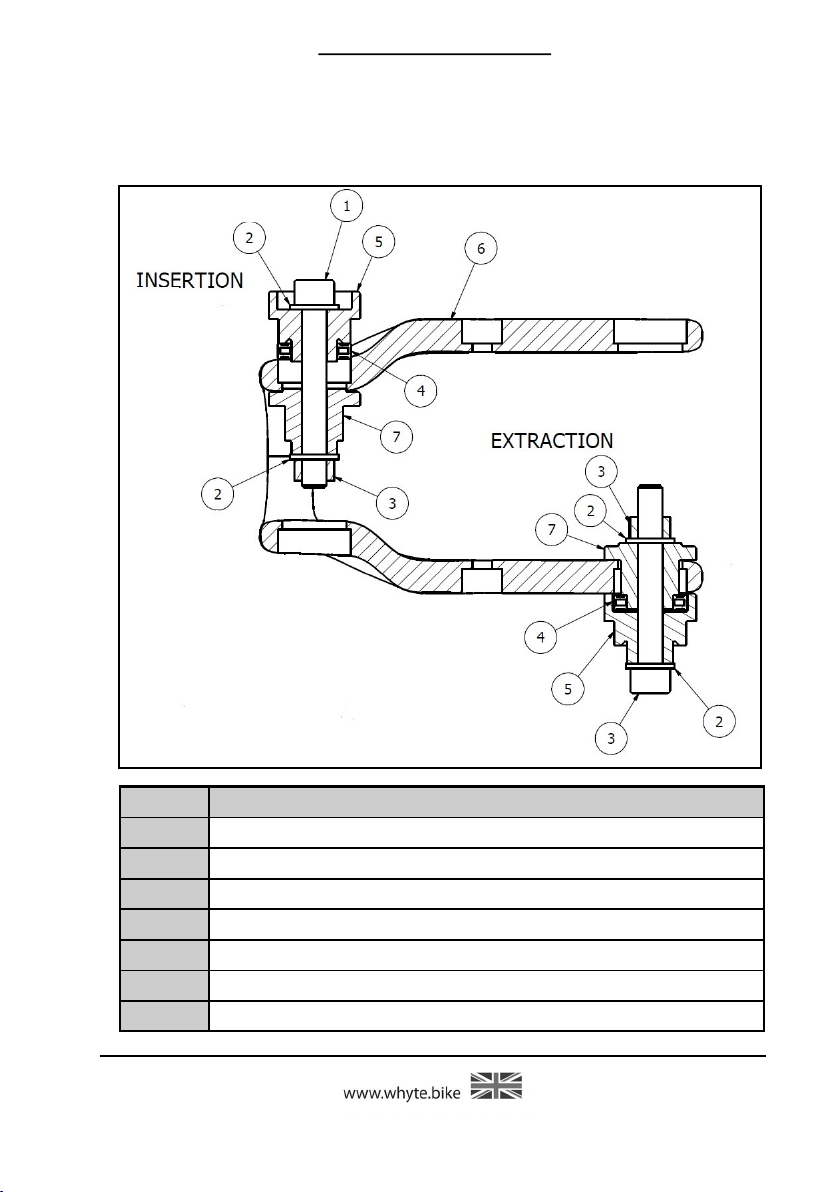

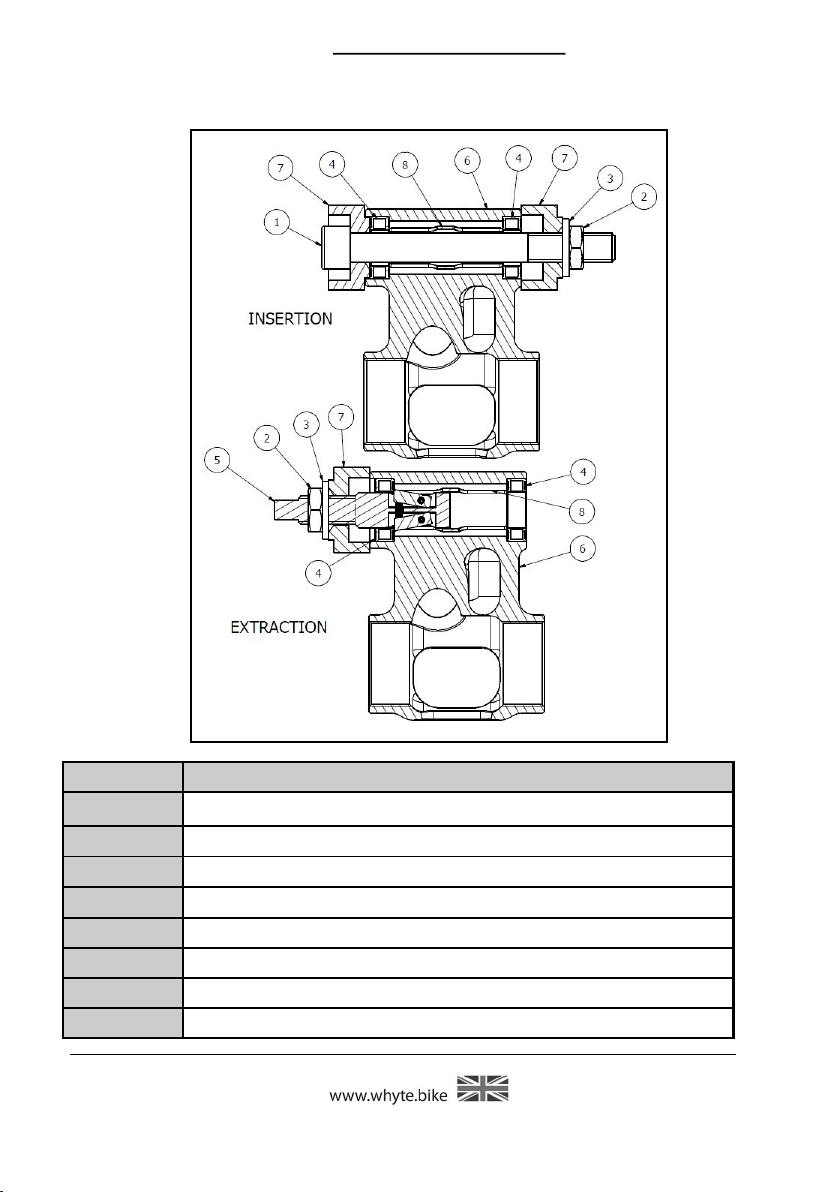

Figure 8: Bearing Insertion & Extraction 6802-2RS-MAX

(Link or Rear of Seat Stay)

Item: Description.

1 M8 Capscrew ISO4162 55 long

2 M8 Washer ISO 7089

3 M8 Nut ISO 4032

4 BOLU-WB0025 Bearing

5 BOLU-WB0025 Bearing Tool 1

6 Mating Component (ie: Link or Seat-Stay)

7 BOLU-WB0025 Bearing Tool 2

Page 17 2019

WHYTE Service Manual

Figure 9: Bearing Insertion & Extraction 6802-2RS-MAX

(Above Main Frame Bottom Bracket)

Item: Description.

1 M8 Capscrew ISO4762 55 long

2 M12 Nut ISO 4035

3 I. D. 12 Washer ISO 7089

4 BOLU-WB0025 Bearing

5 BOLU-WB0025 Bearing Tool 1

6 Mating Component (ie: Bottom Bracket Yoke)

7 BOLU-WB0025 Bearing Tool 2

8 Internal Bearing Spacer

Page 18

2019

WHYTE Service Manual

6.2.1: EXTRACTION OF BEARINGS

Tools required: Either 6802-2RS-MAX or 15268-2RS_MAX Bearing press tool

6mm Hex Key

10mm Hex Key

13mm A/F Spanner

18mm A/F Spanner

To remove the Bearings (4) from the Link or Rear of the Seat-stay (6). Assemble

the parts as shown in figure 8. Using the 6mm Hex Key and 13mm spanner, tighten the assembly together until the Bearing (4) is pressed out of the mating component (6). Repeat on all other Bearings.

To remove the Bearings (4) from the Bottom Bracket Yoke (6). Assemble the

parts shown in figure 9. Using the 10mm Hex Key and 18mm spanner, tighten

the assembly together until the Bearing (4) is pressed out of the mating component (6). Repeat on all other Bearings.

6.2.2: INSERTION OF BEARINGS

Tools required: Either 6802-2RS-MAX or 15268-2RS-MAX Bearing press tool

6mm Hex Key

10mm Hex Key

13mm A/F Spanner

18mm A/F Spanner

Loctite 638

Before inserting the Bearings, make sure all the components are clean from dirt

and have been thoroughly de-greased. To press the Bearings (4) into the mating

component (6) apply a small amount of Loctite 638 to the outside diameter of the

Bearing and to the inside bore of the mating component (6). Next assemble the

components as illustrated in either Figure 8, or 9. It is very important to make

sure the Bearing (4) and Bearing Insertion tool 1 (5) are squarely seated against

the mating component (6). With great care, slowly tighten the M8 Socket head

cap screw (6) with the 6mm Hex Key and the nut (2) with the 13mm Spanner

until you can see the Bearing (4) being pressed squarely into the mating component (6). For the assembly shown in figure 9, use the 10mm Hex Key & the

18mm A/F Spanner. Once the Bearing is fully seated an you can no longer tighten

either the M8 or M12 Socket Head Cap Screws further, undo the nut and bolt and

remove any excess Loctite from around the Bearing, particularly in any internal

threads. Repeat for the remaining Bearings.

IMPORTANT! Allow 24 hours for the Loctite to totally cure.

6.2.3: REASSEMBLY OF SHIELD WASHERS / SPACERS

Tools required: SKF LGEP2 or Castrol Spherol AP3 or Finish Line Teflon

White Lithium

Complex grease

SKF LGAF 3E” or “Castrol Optimol T” Anti-Fret Paste

Apply a good quantity of SKF LGEP2 or Castrol Spherol AP3 or Finish Line Teflon

White Lithium-Complex grease on top of the Bearings. The grease should completely cover each Bearing and be applied on both sides of each Bearing when it is

in the Swinging arm component.

Page 19 2019

WHYTE Service Manual

Assemble the Shield Washer components (Items 19 in figure 5 or items 2 or 3 in figures 6 & 7). If you have applied enough grease, it should spread from under the

Shield Washer or Spacer components as they are positioned. Wipe this excess grease

away from around the Shield Washer or Spacer components.

6.2.4: Application of “SKF LGAF 3E” or “Castrol Optimol T” Anti-Fret Pastes

Once the H Link & Swinging Arm components have been assembled correctly, either

SKF LGAF 3E or Castrol Optimol T paste must be applied to all outside faces of the

Shield Washer components (Items 2 & 3 in Figures 6 & 7) that contact the Main

Frame and Swinging Arm. It is additionally recommended to apply anti-fret paste to

the mating contact surfaces on the Main

Frame and Swinging Arm.

6.3: RE-ASSEMBLING THE REAR SUSPENSION.

Figure 10: Correct

Orientation

6.3.1: Re-assemble the Rear Suspension

Tools Required: 2x 5mm Hex Key

2x 6mm Hex Key

2x T-25 Torx® Key

Torque Wrench

(Ranging from 5Nm to

25Nm)

Reference figures 3,4,5,6 & 10. The re-assembly of the Rear Suspension is essentially the reverse of the dis-assembly procedures 6.1.1, 6.1.2 & 6.1.3.

6.3.2 To re-assemble the Chain-stays (14) and Bearings (20) into the Main

Frame (15) - First Stage.

Before inserting the Bearings, make sure all the components are clean from dirt and

have been thoroughly de-greased. Apply a small amount of Loctite 638 to the outside diameter of the Bearing and to the inside mating bore of the Main Frame (15).

Using the press tools shown in Figure 8 & 9, insert the BOLU-WB0025 Bearings (20)

into both sides of the Main Frame (15). Ensure the spacer (21) is located between

the Bearings (20).

Referencing figure 5, apply either SKF LGAF 3E or Castrol Optimol T paste to all

faces of the Shield Washers (19), Pivot Pin (12) and Screw (10). Place the Shield

Washers (19) alongside the Bearings (20). Insert & align the Chain-Stays (14) between the Washers (19). Insert the Pivot Pin (12) from the left side of the ChainStays (14). Screw the Pivot Pin (12) io the thread in the right side of the ChainStays (14). Insert the Tapered Sleeve (11) and screw in the M6 x 20mm long Capscrew (10).

Page 20

2019

WHYTE Service Manual

6.3.3: To re-assemble the H Link (16), Shock Extender (7) & Seat-stay

(18) onto the Main Frame (15) - Second & Third Stages.

IMPORTANT: Prior to reassembly of the Seat-stay (18) to the H Link (16),

make sure the Seat tube of the Main Frame (15, not shown for clarity) is

inside of the assembly, as in figure 3. Also make sure the H Link is correct

side up, as per figure 10.

Starting with the Seat-stay (18) and the H Link (16), reference figure 4, first check

that the Shield Washers are in place in the H Link (see items 2 & 3 in figure 6) and

apply either SKF LGAF 3E or Castrol Optimol T anti-fret paste to the contacting

faces between the Shield Washers and Seat-stay (18). Then ensure that the Shield

Washers in the H Link (16) are not pushed out, as you place the Seat-stay (18)

inside it. Then pass an M15 x 26mm long Flanged alloy Screw (13) through the

right side of the Seat-stay (18), the adjacent Shield Washers (items 2 & 3, figure

6), and the Bearing in the H Link (16). Using the 6mm Hex Key, Torque tighten

the M15 Flanged alloy Screw (13) to the recommended Torque settings (refer to

the Tightening Torque settings in Section 10.0). Repeat that task to assemble the

left side of the Seat-stay (18) to the H Link (16), also ensuring that the other

Shield Washer in the H Link (16) is not pushed out.

Next, to assemble the Shock Extender (7) and the H Link (16), reference figure 4

(Main Frame 15 not shown for clarity), first check that the Shield Washers are in

place in the Link (see items 2 & 3 in figure 6) and apply either SKF LGAF 3E or

Castrol Optimol T anti-fret paste to the contacting faces between the Shield Washers and Shock Extender (7). Then ensure that the Shield Washers in the Link (16)

are not pushed out, as you place the Shock Extender (7) inside them. Then pass

an M15 x 25mm long Flanged alloy Screw (17) through the H Link (16), the Bearing in Link (See item 1, figure 6), the adjacent Shield Washer & into the thread of

one arm of the Shock Extender (7). Using a 6mm Hex Key, Torque tighten the

M15 Flanged alloy Screw (17) to the recommended Torque settings (refer to the

Tightening Torque settings in Section 10.0). Repeat that task to assemble the other

arm of the Shock Extender (7) to the H Link (16), also ensuring that the other

Shield Washer in the H Link (16) is not pushed out.

Next, to assemble the Link (16) to the Main Frame seat tube (15), reference figures 3 & 4, check that the Shield Washers are in place on the inside of the bearings

that are installed in front of the Link (16), reference figure 6, item (2) and apply

either SKF LGAF 3E or Castrol Optimol T anti-fret paste to the contacting faces between those shield washers and the Link mounting on the Main frame seat tube

(15). Insert the Link (16) between the Main Frame Seat tube (15). Then pass one

M15 x 26mm long Flanged alloy Screw (8 & 9) through the Link (16), the Bearing

in Link (1, figure 6), the adjacent Shield Washer & into the threaded Main Frame

(15). Screw in, from the left side of the H Link (16), the other M15 x 26mm long

Flanged alloy Screw (8) . Using a 6mm Hex Key, Torque tighten the M15 Flanged

alloy Screws (8 & 9) to the recommended Torque settings (refer to the Tightening

Torque settings in Section 10.0). Wipe off any excess grease from around the Main

Frame (15) and the H Link (16).

Finally to assemble the Chainstays (14) to the Seat-Stays (18), reference figure

18, check that the Shield Washers are in place on both sides of each Seat-stay leg

(18) (see items 2 & 3 in figure 6) and apply either SKF LGAF 3E or Castrol Optimol

Page 21 2019

WHYTE Service Manual

Using a 6mm Socket, first Torque tighten the right side of the Pivot Pin (12), to the

recommended Torque settings (refer to the Tightening Torque settings in Section

10.0). Then tighten the M6 x 20mm long Capscrew (10), again to the recommended Torque settings (refer to the Tightening Torque settings in Section 10.0). Wipe

off any excess grease from around the Chain-Stays and Seat-Stays.

6.3.4 To re-assemble the Rear Shock (6) into the Frameset.

Reference figure 17. Take the Rear Shock (6) and apply either SKF LG/AF 3E or

Castrol Optimol T anti-fret paste onto the side faces of the Shock Bushes, that contact the Main Frame (15) and Shock Extender (7). Slide the front of the Rear Shock

(6) into the Main Frame (15) and Shock Extender (7).

IMPORTANT. Ensure the damper is the correct way up, with any dials and

levers facing downwards and towards the front of the frameset, reference figure 10.

First make sure that the 12mm holes in the Shock Extender (7) line up with the rear

end of the Rear Shock (6). Insert the Flanged Nut M12 x 19mm long (4) & screw in

the Flanged Screw M12 x 15mm long (5). Using the 6mm Hex Key and the 8mm

Hex Key, Torque tighten the Flanged Nut M12 x 19mm long (4) into the Flanged

Screw M12 x 15mm long (5), to the recommended Torque settings (refer to the

Tightening Torque settings in Section 10.0). Wipe off any excess grease from

around both ends of the Shock (6).

Make sure that the Ø8mm holes in the Main Frame (15) and the front of the Rear

Shock (6) are all concentric with each other, and push the Ø8mm x 31mm long Hollow Pivot Pin (3) all the way through. Place a Collar (2) over both ends of the Ø8mm

x 31mm long Hollow Pivot Pin (3) and screw in an M5 x 16mm long Socket-head Cap

-screw (1) into both ends of the Pivot Pin (3). Using the T-25 Torx® Keys, Torque

tighten the M5 Cap-screws to the recommended Torque settings (refer to the Tightening Torque settings in Section 10.0).

7.0: SERVICING THE WHYTE MODULAR DROPOUT SYSTEMS.

7.1: Removing the Modular Rear Dropouts

Tools Required: 2mm Hex Key

3mm Hex Key

4mm Hex key

These Rear Drop-outs are a modular design, that can either be replaced if damaged

or converted to one of two different types of through-axle products, ie: Shimano EThru or SRAM Maxle 148mm. Contact your local Whyte dealer to purchase either a

replacement hanger or a conversion kit.

7.1.1: Shimano E-Thru System

Reference figure 11. The Rear Derailleur Hanger (2) is attached to the Right Side of

the Seat-stay (18) by one Countersunk M4 Cap Screw (1). To remove the Rear Derailleur Hanger (2), using the 3mm Hex Key undo that Cap Screw (1) and remove it

Page 22

2019

WHYTE Service Manual

together with the Rear Derailleur Hanger (2). Also, to remove the Adjuster (4),

using the 2mm Hex Key undo the Grub Screw (3) and remove it together with the

Adjuster (4). Take care not to loose any of the components.

7.1.2: SRAM Maxle 148mm “Boost” System

Reference figure 12. The Rear Derailleur Hanger (4) is attached to the Right Side

of the Seat-stay (18) by one M4 Countersunk Cap Screw (3). To remove the Rear

Derailleur Hanger (4), using the 3mm Hex Key undo that Cap Screw (3) and remove it, together with the Rear Derailleur Hanger (4). To remove the Axle Nut (6),

using the 2mm Hex Key undo the Grub Screw (5) and remove it, together with the

Axle Nut (6). Moving across to the Left Side of the Seat-stay (18), again using the

4mm Hex Key undo the M5 Countersunk Cap Screw (2) and remove it, together

with the Drop-out Spacer (1), from the assembly. Take care not to loose any of

the components.

7.2: Re-assembling the Modular Rear Dropouts onto the Swinging Arm

Tools Required: 2mm Hex Key

3mm Hex Key

Torque Wrench (Ranging from 1Nm to 5Nm)

It is important to make sure that all components are clean and free from mud, old

grease and other dirt, which could prevent them from fitting together perfectly.

7.2.1: Shimano E-Thru System

Reference figure 11. Loosely assemble all the parts as shown, making sure the

screws (1) & (3) are correctly positioned, be very careful not to cross-thread

this, on it’s way in. Insert the Rear Wheel and the Shimano E-Thru Rear Axle.

Adjust the Axle as per the Shimano Technical Service Instructions SI-27U0A-001-

00. Whilst adjusting the Rear Axle, make sure the nose of the M5 Grub Screw (3) is

aligned with one of the slots in the Axle Nut (4). Having tightened the Rear Axle,

using the Torque Wrench, tighten the M5 Grub Screw (3) to the correct Torque as

specified in Section 10.0. DO NOT OVERTIGHTEN, since the thread of the Screw

(1) is very small.

Remove the Rear Wheel and using the Torque Wrench, tighten the M4 Countersunk

Head Screw (1) to the correct torque as specified in Section 10.0. DO NOT OVER-

TIGHTEN, since the thread of the Screw (1) is very small.

7.2.2: SRAM Maxle 148mm “Boost” System

Reference figure 12. Loosely assemble all the parts as shown, making sure the

Screws (2), (3) & (5) are correctly positioned, be very careful not to cross-

thread these, on their way in. Insert the Rear Wheel and the SRAM Maxle, as

per the SRAM User Manual 95-4315-004-000. Whilst tightening the SRAM Maxle,

make sure the nose of the M5 Grub Screw (5) is aligned with the single slot in the

Axle Nut (6). Using the Torque Wrench, tighten the M5 Grub Screw (5) to the correct Torque as specified in Section 10.0. . DO NOT OVERTIGHTEN, since the

thread of the Screw (5) is very small.

Page 23 2019

WHYTE Service Manual

Remove the Rear Wheel and using the Torque Wrench, tighten the M4 Countersunk

Head Screw (3) to the correct Torque as specified in Section 10.0. Also tighten the

M5 Countersunk Head Screw (2). DO NOT OVERTIGHTEN, since the thread of the

Screws (2) & (3) are very small. Finally, if necessary, re- adjust the SRAM Maxle

Rear Axle as per the SRAM User Manual 95-4315-004-000.

Item Description

1 M4 x 16mm long Countersunk Head Screw

2 Rear Derailleur Hanger, for Shimano E -Thru Direct Mount (Grey Colour)

3 M4 x 8 long Grub Screw.

4 Axle Nut, for Shimano E-Thru

Figure 11: Whyte Dropout Assembly,

For Shimano E-Thru

18

Page 24

2019

WHYTE Service Manual

Figure 12: Whyte Dropout Assembly,

Item Description

1

2 M5 x 16mm long Countersunk Head Screw

3 M4 x 12mm long Countersunk Head Screw

4 Rear Derailleur Hanger, for SRAM Maxle 148mm (Black Colour)

5 M4 x 8 long Grub Screw.

6 Axle Nut, for SRAM Maxle 142mm (Black Colour)

Dropout Spacer (8mm wide) Left Side, for SRAM Maxle 148mm (Gunmetal Col-

our)

18

For SRAM Maxle 148mm

Page 25 2019

WHYTE Service Manual

Item: Description

1 M6 x 30mm Capscrew

2 Plain Sleeve

3 ‘O’ ring

4 Grip Pad

5 Threaded Sleeve

6 Main Frame

7 Seat Post

8.0: WHYTE INTER GRIP

Figure 22

Inter Grip Seat Clamp

Figure 23

Figure 21:

SEAT CLAMP SERVICE

Tools Required: 2x 5mm

Hex Keys

Small size

flat blade screwdriver

Torque

Wrench (Ranging from 3Nm to

15Nm)

Figure 24

KF LGEP2

or Castrol Spheerol AP3 or Finish

Line Teflon White Lithium

Figure 25

Complex grease

Reference figures 21 to 35. To

service the Inter Grip seat

clamp, carefully follow these

Figure 26

Figure 27

procedures otherwise there is a

risk of damaging some of the

components.

Especially remove and replace the seat-post (7) in the

specified order.

Figures 22 to 23. From the right side of the Main Frame (6) unscrew & remove the

M6 x 30mm long Capscrew (1). Replace that with the longer capscrew and screw

loosely into the Threaded Sleeve (5).

Figures 24 & 25. Push the Threaded Sleeve (5) all the way out of the opposite side of

the Main Frame (6).

Figures 26 to 27. Move to the left side of the Main Frame (6). Place the M6 x 30mm

long Capscrew (1) diagonally through the Grip Pad (4) and onto the Plain Sleeve (2).

Page 26

2019

WHYTE Service Manual

Figure 28

Figure 29

Then push the Plain Sleeve (2) all the way out of the right side of the Main Frame

(6).

Figures 28 & 29. Remove the Seat Post (7) all the way out of the Main Frame (6).

Remove the Grip Pad (4) from either side of the Main Frame (6). The ‘O’ rings (3)

may be removed from the Threaded Sleeve (5) and the

Plain

Figure 30

Figure 33

Figure 31

Figure 34

Figure 32

Figure 35

Sleeve (2), using the small size flat blade screwdriver.

To re-assemble the Inter Grip seat clamp, coat the ‘O’ rings (3) with a small quantity of grease. Carefully fit the ‘O’ rings (3) into the grooves in the Threaded Sleeve

(5) and the Plain Sleeve (2). Also place some grease onto the threaded end of the

M6 Capscrew (1).

Figures 30 & 31. Place the Grip Pad (4) into the hole in the Main Frame (6) such

that the curved face is towards the seat tube in the Main Frame (6). Insert the

Seat Post (7) to help align the Grip Pad (4).

Figures 32 & 33. From the left side of the Main Frame (6), insert the Plain Sleeve

(2) and make sure the 45° angled edge on the Plain Sleeve (2) touches the 45°

angled edge on the Pad (4).

Figures 34 & 35. Move to the right side of the Main Frame (6) and insert the

Threaded Sleeve (5), aligning the 45° angled edge to touch the 45° angled edge on

the Grip Pad (4). Place the M6 Capscrew (1) through the Threaded Sleeve (5), the

Page 27 2019

WHYTE Service Manual

Pad (4) & screw into the Threaded Sleeve (5).

Both of the Sleeves (2 & 5) should be nearly flush with the edge of the hole in the

Main Frame (6) when the assembly goes tight. If this is not the case, one or other of

the four 45° angled edges are not touching each other, so re-align as necessary to

make sure both of the Sleeves (2 & 5) are nearly flush.

Then follow the instructions in section 3.2 to set the height and direction of the Seat

Post (7).

9.0: INTERNAL CABLES & HOSES

Tools Required: Small size flat blade screwdriver

Short length of inner gear cable

A torch or front bicycle light

Figure 37

Figure 36

Figure 40

Figure 38

General Note:

Figure 41

Figure 39

Take care if refitting or replacing the rubber covers, since too much force will damage

them.

9.1 To replace cable or hose outers.

Reference figures 36 to 41. When replacing outer cables and or brake hoses, most of

the holes in the frame are large enough (25mm long x 8mm wide) simply to manipulate the outer cable or brake hose into or out of the hole. However the two holes for

the rear derailleur cable in the chain-stay are necessarily small, therefore the following method is needed to refit a new outer cable:

Figures 36 & 37: Using a piece of inner cable, feed into the entrance hole in the right

-side chain-stay, near the drop-out, then through the exit hole at the opposite end of

the chain-stay. This will probably need several attempts pushing to & fro to find the

hole, please be patient!

Figures 38 & 39: At the drop-out end, push the outer cable onto the inner cable and

Page 28

2019

WHYTE Service Manual

then feed the outer cable into the chain-stay following the same path as the inner

cable.

Figure 40: Make sure the inner cable is held tight where it emerges from the chainstay at the opposite end, otherwise it will be pushed out. Eventually the outer cable will reach the front of the chain-stay. Then manipulate both the inner cable

and the outer cable, whilst also pushing the outer cable forwards with a lot of force

and the outer cable should also find the exit hole.

Figure 41: Push the outer cable all the way through the exit hole and finally remove the inner cable.

9.2 To fit a “Dropper” seat-post with internal hose.

Take care to abide by safety recommendations.

Figure 42

Figure 45

Figure 48 Figure 49

Figure 51

Figure 43 Figure 44

Figure 46

Figure 52

Figure 47

Figure 50

Figure 53

Page 29 2019

WHYTE Service Manual

CAUTION: Before installing the seat-post, carefully consult the product

manufacturer’s own instructions.

Reference figure 42. First prise out the two blank plastic covers near the bottom

bracket with a small screwdriver.

Reference figure 43. Carefully unscrew the hose from the remote actuator.

Reference figure 44. Insert the disconnected hose end into the top of the seat tube

and push down towards the bottom bracket.

Reference figure 45. Manoeuvre the hose end out of the slot at the front of the seat

tube.

Reference figure 46. Push two rubber grommets over the end of the hose. Make

sure the narrower end of the first grommet is facing the seat tube, whilst the narrower end of the second grommet is facing the down tube.

Reference figure 47. Insert the hose end into the down tube and push the hose up

towards the head tube. The grommets will have to be pushed further along the hose

to do this.

Reference figure 48. Prise out the rubber grommet on the side of the down-tube,

near the head tube, with a small screwdriver.

Reference figure 49. Manoeuvre the hose end out of the slot at the top of the down

tube. Use a small hook to assist with capturing the hose end and drawing it towards

the slot. A torch would help to locate the hose end.

Reference figure 50. Push the rubber grommet over the end of the hose. Make sure

the narrower end of the grommet is facing the down tube.

Reference figure 51. Insert the seat-post into the seat tube and simultaneously pull

the hose through the frame.

Reference figure 52. Insert all three rubber grommets into the frame slots. Use a

small screwdriver with care not to split the rubber.

Reference figure 53. Cut the hose to length and follow the product manufacturer’s

instructions to re-assemble and bleed the hydraulic system.

Page 30

2019

WHYTE Service Manual

10.0: Removal Of Battery

Note: Before removing the battery from your Whyte eMTB, please read and understand all relevant documentation from Bosch. To ensure that the battery is not being charged, disconnect

the charger from the remote battery port.

IMPORTANT: For all other Torque settings, refer to the specific manufactur-

ers information bundled with this manual, or alternatively, refer to the specif-

ic manufacturers website for further information.

Tools Required: Torx T-25

Torque Wrench (Ranging from 3Nm to 15Nm)

Tip: Take care to position the bicycle in a suitable work stand clear of the ground to

enable the removal of the battery.

To remove the battery from the bicycle frame, using the T-25 Torx tool, remove the

T-25 Torx bolt (1) from the Bottom Cover (2). It may be necessary to clean out the

head of the T-25 Torx bolt (1) if the bike has been ridden, so that the T-25 Torx

tool can fully function and undo the bolt. It is important to make sure the T-25 Torx

tool fits into the head of the T-25 Torx bolt (1) so as not to ‘round off the head’ of

the T-25 Torx bolt (1) and prevent the removal.

Figure 54: Bosch Battery:

Removal and Reinstallation

Page 31 2019

WHYTE Service Manual

of the bolt. Once the T-25 Torx bolt (1) is removed from the Bottom Cover (2), slide

the Bottom Cover (2) off the Down Tube of the frame (3) in the same direction as

the axis of the Down Tube (3) so as to completely remove the Bottom Cover (2)

from the bicycle. Note: Safely store the Bottom Cover (2) and the T-25 Torx bolt (1).

Next begin to remove the T-25 Torx bolt (4) from the Down Tube (3). IMPORTANT:

Note that if the bike is standing upright or you have the bike in a work stand, then

support the weight of the Bosch Connector Block (5) and the Bosch Battery (6) as

you undo the T-25 Torx bolt (4). Take care to store the T-25 Torx bolt (4) and

Spring Washer (4a) carefully. The Bosch Connector Block (5) will now be able to be

disconnected from the Bosch battery (6). Pull back on the Bosch Connector Block (5)

to disconnect it from the Bosch Battery (6) and remove the Bosch Connector Block

(5) out from the Down Tube (3). The Bosch Battery (6) could slide out of the Down

Tube (3) under it’s own weight at the same time, so take care to look after the wiring loom attached to the Bosch Connector Block (5) as you remove the Bosch Battery (6) from the Down Tube (3).

You should now have the Bosch Battery (6) removed from the frame.

IMPORTANT: At all times follow closely all recommendations from Bosch contained in the Bosch Customer User Manual documentation material bundled

with your bike (or consult the on-line Bosch resources) to fully understand

how to handle and store your Bosch Battery at all times.

To Refit the Bosch Battery (6) is the reverse of the removal process. Slide the Bosch

Battery (6) back into the Down Tube (3).

IMPORTANT: Ensure that the Bosch Battery (6) is in the correct orientation

(see Figure 55). Failure to correctly orientate the battery will result in the

Bosch Connector Block (5) being unable to be re-fitted.

As the Bosch Battery (6) is inserted into the Downtube (3), take care not to foul or

trap the wiring loom associated with the Bosch Connector Block (5) or the control

cables housed in the Down Tube (3). The Bosch Battery (6) should slide smoothly up

into the Down Tube (3). Before the Bosch Battery (6) is fully inserted into the Down

Tube (3), re-fit the Bosch Connector Block (5) into the end of the Bosch Battery (6).

Ensure the Bosch Connector Block (5) is correctly aligned (see Figure 54). With the

Bosch Connector Block (5) now re-connected to the Bosch Battery (6), slide the assembly into the Down Tube (3) until the Bosch Battery (6) ‘bottoms out’ on it’s endstop. Next re-fit the T-25 Torx Bolt (4) and Spring Washer (4a) into the correct

threaded hole (see Figure 54). Tighten the T-25 Torx Bolt (4) to the Bosch Recommended Tightening Torque. (Min 5.0 Nm Max 6.0Nm). Next re-fit the Bottom Cover

(2) onto the Down Tube (3) by sliding the Bottom Cover (2) up the axis of the Down

Tube (3) until the fixing hole lines up with the hole in the Down Tube (3). Re-fit the T

-25 Torx Bolt (1) into the threaded hole. Tighten the T-25 Torx Bolt (1) to the Bosch

Recommended Tightening Torque. (Min 5.0 Nm Max 6.0Nm).

Page 32

2019

WHYTE Service Manual

Figure 55: Bosch Battery:

Correct Orientation for Install

10.1: Location Of Bosch Battery On-Off Button.

Note: Before making adjustments to the Bosch e-bike system, please read and understand all

relevant documentation from Bosch which have been included with your Whyte eMTB.

IMPORTANT: For all other Torque settings, refer to the specific manufac-

turers information bundled with this manual, or alternatively, refer to the

specific manufacturers website for further information.

Tools Required: Torx T-25

Torque Wrench (Ranging from 3Nm to 15Nm)

(See Figure 54 and Figure 56) If you are required to start the eBike system using

the On/Off button located on the Bosch Battery (6), follow the instructions in Section 10.1 to remove the Bottom Cover (2) from the Down Tube (3). You will then

reveal the Access Hole (7) in the Down Tube (3). Press the On/Off button to Start

the e-bike system. Refit the Bottom Cover (2) as described in Section 10.0

Page 33 2019

WHYTE Service Manual

Figure 56: Bosch Battery:

Location of On/Off Button with Battery

Fitted into Down Tube

10.2: Location Of Bosch Battery Charge Port.

Figure 57a Figure 57b

IMPORTANT: At all times follow closely all recommendations from Bosch

contained in the relevant Bosch Customer User Manual documentation material

bundled with your bike (or consult the on-line Bosch resources) to fully under-

stand how to re-charge, handle and store your Bosch Battery.

The position of the remote charge port for the Bosch Battery has been integrated

into the top of the Motor Mount as can be seen in Figure 57a and 57b. To access the

charge port, peel back the sealed cover of the Charge Port marked “Whyte Energy”

to reveal the charge port. Follow the instructions contained in the Bosch Battery Instruction Manual to Charge the Battery. When Charging has finished, re-fit the Remote Charge Port Cover and press firmly to seal the Cover over the Charge port to

prevent ingress of mud and water and other contaminants.

Page 34

2019

WHYTE Service Manual

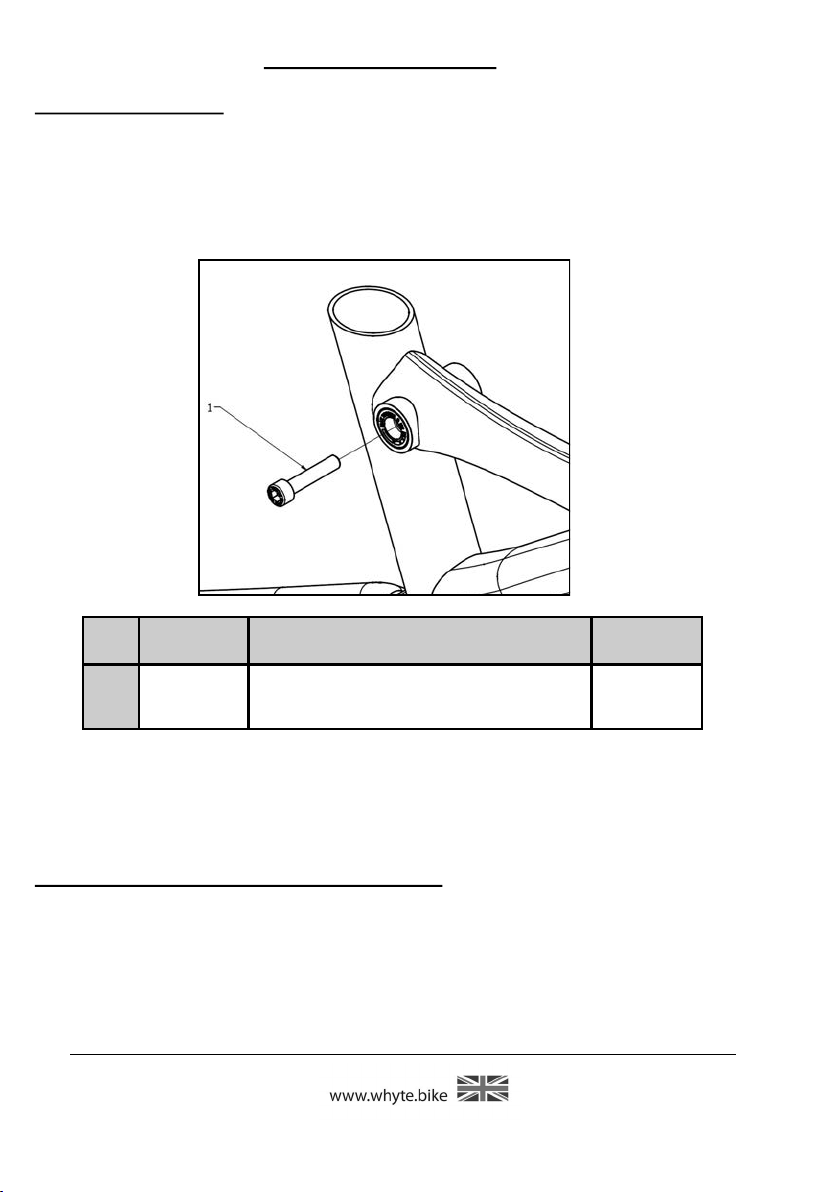

11.0: TORQUE SETTINGS

Torque explained: If no suitable Torque Wrench is available a Torque of 5 lbf.ft can be obtained by applying a force of 5lb, with a Spring Balance, to the end of a spanner, 1 Foot in

length.

IMPORTANT: For all other Torque settings, refer to the specific manufacturers information bundled with this manual, or alternatively, refer to the

specific manufacturers website for further information.

Rear Suspension Nm lbs.ft

M12 Flanged Screw & Flanged Nut

M5 Socket-head Cap Screw (T-25

Torx®)

M12 x 20 long Alloy Flanged Screw

Pivot Pin (link mount, main frame) x 61

long

M15 x 20 long Alloy Flanged Screw

M15 x 26 long Alloy Flanged Screw

M15 x 87 long Pivot Pin

M6 x 20 long Socket Head Capscrew

Rear Dropout Assemblies

M4 Countersunk Screws

M5 Countersunk Screws

M5 Grub Screw

Seat Post Clamp

M6 Cap Screw

16.1 (Min) - 19.9 (Max) 11.9 (Min) - 14.7 (Max)

5.0 (Min) - 6.0 (Max) 3.7 (Min) - 4.4 (Max)

15.0 (Min) - 17.0 (Max) 10.5 (Min) - 12.5 (Max

15.0 (Min) - 17.0 (Max) 10.5 (Min) - 12.5 (Max

15.0 (Min) - 17.0 (Max) 10.5 (Min) - 12.5 (Max

22.0 (Min) - 26.0 (Max) 16.2 (Min) - 19.2 (Max)

9.0 (Min) - 11.0 (Max) 6.1 (Min) - 7.5 (Max)

9.0 (Min) - 11.0 (Max) 6.1 (Min) - 7.5 (Max)

4.2 (Min) - 4.6 (Max) 3.1 (Min) - 3.4 (Max)

4.8 (Min) - 5.2 (Max) 3.6 (Min) - 3.8 (Max)

2.2 (Min) - 2.6 (Max) 1.6 (Min) - 1.9 (Max)

12 (Min) - 14 (Max) 8.9 (Min) - 10.3 (Max)

Page 35 2019

12.0: OWNER’S NOTES

WHYTE Service Manual

Page 36

2019

Performance Line/Cargo Line

BOSCH

37

2 |

A

(1)

(2)

5

–

17 mm

0 275 007 XD4 | (12.02.2019) Bosch eBike Systems

(3)

Safety instructions

Read all the safety information and instructions. Failure to observe the safety in-

formation and follow instructions may result

in electric shock, fire and/or serious injury.

Save all safety warnings and instructions for future reference.

The term battery is used in these instructions to mean all

original Bosch eBike rechargeable battery packs.

u Do not attempt to change – and especially increase –

the power of your drive or the maximum speed that it

supports. Doing this may put yourself and others at risk,

and you may also breach statutory regulations.

u Do not open the drive unit yourself. The drive unit

must only be repaired by qualified personnel using

only original spare parts. This will ensure that the safety

of the drive unit is maintained. Unauthorised opening of

the drive unit will render warranty claims null and void.

u All components fitted to the drive unit and all other

components of the eBike drive (e.g. chainring, chainring receptacle, pedals) must only be replaced with

identical components or components that have been

specifically approved by the manufacturer for your

eBike. This will protect the drive unit from overloading

and becoming damaged.

u Remove the battery from the eBike before beginning

work (e.g. inspection, repair, assembly, maintenance,

work on the chain, etc.) on the eBike, transporting it

with a car or aeroplane, or storing it. Unintentional ac-

tivation of the eBike system poses a risk of injury.

u The push assistance function must only be used when

pushing the eBike. There is a risk of injury if the wheels

of the eBike are not in contact with the ground while using

the push assistance.

u When the push assistance is activated, the pedals may

turn at the same time. When the push assistance function is activated, make sure that there is enough space

between your legs and the turning pedals to avoid the risk

of injury.

u After a ride, do not allow your unprotected hands or

legs to come into contact with the housing of the drive

unit. Under extreme conditions, such as continuously

high torques at low travel speeds, or when riding up hills

or carrying loads, the housing may reach a very high temperature.

The temperature that the drive unit housing may reach is

influenced by the following factors:

– Ambient temperature

– Ride profile (route/gradient)

– Ride duration

– Assistance modes

– User behaviour (personal effort)

– Total weight (rider, eBike, luggage)

– Motor cover on the drive unit

– Heat dissipation properties of the bicycle frame

– Type of drive unit and type of gear-shifting

English – 1

u Use only original Bosch batteries that the manufac-

turer has approved for your eBike. Using other batteries can lead to injuries and pose a fire hazard. Bosch accepts no liability or warranty claims if other batteries are

used.

u Do not make any modifications to your eBike system

or fit any other products that might increase the performance of your eBike system. Doing so will generally

reduce the service life of the system and risks damaging

the drive unit and the bike. You also run the risk of losing

the guarantee and warranty claims on the bicycle you

have purchased. By handling the system improperly you

are also endangering your safety and that of other road

users, thus running the risk of high personal liability costs

and possibly even criminal prosecution in the event of accidents that can be attributed to manipulation of the bicycle.

On sections of the drive, temperatures

>60°C may occur in extreme conditions,

e.g. when carrying consistently high loads at

low speed when riding up hills or transporting loads.

u Observe all national regulations which set out the ap-

proved use of eBikes.

u Read and observe the safety warnings and directions

contained in all the eBike system operating instructions and in the operating instructions of your eBike.

Privacy notice

When you connect the eBike to the Bosch DiagnosticTool,

data about the eBike drive unit (e.g. energy consumption,

temperature, etc.) is transferred to Bosch eBike Systems

(Robert Bosch GmbH) for the purpose of product improvement. You can find more information about this on the Bosch

eBike website at www.bosch-ebike.com

.

Bosch eBike Systems 0 275 007 XD4 | (12.02.2019)

English – 2

Product description and

specifications

Intended use

The drive unit is intended exclusively for driving your eBike

and must not be used for any other purpose.

In addition to the functions shown here, changes to software

relating to troubleshooting and functional enhancements

may be introduced at any time.

Product features

Individual illustrations in these operating instructions may

differ slightly from the actual conditions depending on the

equipment of your eBike.

The numbering of the components shown refers to the illustrations on the graphics pages at the beginning of the

manual.

Drive unit

(1)

Speed sensor

(2)

Speed sensor spoke magnet

(3)

Technical data

Drive unit Drive Unit

Product code BDU450 CX BDU490P

Continuous rated power W 250 250

Torque at drive, max. Nm 75 75

Rated voltage V= 36 36

Operating temperature °C −5 to +40 −5 to +40

Storage temperature °C −10 to +50 −10 to +50

Protection rating IP54 (dust- and splash-proof) IP54 (dust- and splash-proof)

Weight, approx. kg 3 3

The Bosch eBike system uses FreeRTOS (seehttp://www.freertos.org).

Bicycle lights

Voltage approx.

Maximum power

– Front light W 17.4

– Tail light W 0.6

A) Depends on legal regulations, not possible in all country-specific models via the eBike battery

B) When changing the bulbs, ensure that they are compatible with the Bosch eBike system (ask your bicycle dealer) and are suitable for the

Inserting a bulb incorrectly can cause it to blow.

A)

B)

specified voltage. Bulbs must only be replaced with bulbs of the same voltage.

Assembly

Inserting and removing the battery

For inserting and removing the eBike battery in/from the

eBike, please read and observe the battery operating instructions.

Checking the speed sensor (see figure A)

The speed sensor (2) and its spoke magnet (3) must be fitted such that the spoke magnet moves past the speed

sensor at a distance of at least 5 mm and at most 17 mm

with each rotation of the wheel.

Note: If the distance between the speed sensor (2) and the

spoke magnet (3) is too small or too large, or if the speed

sensor (2) is not properly connected, the speedometer display will fail and the eBike drive unit will operate in emer-

Performance Line CX/

Cargo Line

gency mode.

Should this occur, loosen the screw of the spoke magnet (3)

and fasten the spoke magnet to the spoke such that it runs

past the marking on the speed sensor at the correct clearance. If the speed is still not being indicated on the speedometer display after doing this, please contact an authorised

bicycle dealer.

Performance Line Speed/

V= 12

Operation

Start-up

Requirements

The eBike system can only be activated when the following

requirements are met:

– A sufficiently charged battery is inserted (see battery op-

erating instructions).

Drive Unit

Cargo Line Speed

0 275 007 XD4 | (12.02.2019) Bosch eBike Systems

– The on-board computer is properly inserted in the holder

(see on-board computer operating instructions).

– The speed sensor is correctly connected (see "Checking

the speed sensor (see figure A)", pageEnglish–2).

Switching the eBike system on/off

The following options are available for switching on the

eBike system:

– If the on-board computer is already switched on when you

insert it into the holder, the eBike system will be activated

automatically.

– Once the on-board computer and the eBike battery are

fitted, briefly press the on/off button on the on-board

computer.

– With the on-board computer inserted, push the on/off

button on the eBike battery (bicycle manufacturer-specific solutions are possible when there is no access to the

battery on/off button; see the battery operating instructions).

Note: The eBike system always starts in OFF mode for drive

units with a maximum speed of more than 25km/h.

The drive is activated as soon as you start pedalling (except

if you are using the push-assistance function, Switching the

push assistance on/off). The motor output depends on the

settings of the assistance level on the on-board computer.

As soon as you stop pedalling when in normal operation, or

as soon as you have reached a speed of 25/45km/h, the

eBike drive switches off the assistance. The drive is automatically reactivated as soon you start pedalling again and the

speed is below 25/45km/h.

The following options are available for switching off the

eBike system:

– Press the on/off button of the on-board computer.

– Switch off the eBike battery using its on/off button (bi-

cycle manufacturer-specific solutions are possible when

there is no access to the battery on/off button; see the bicycle manufacturer operating instructions).

– Remove the on-board computer from its holder.

If the eBike is not moved for approx. 10 min and no button is

pressed on the on-board computer, the eBike system

switches off automatically in order to save energy.

eShift (optional)

eShift is the integration of electronic gear-shifting systems

into the eBike system. The eShift components are electrically connected to the drive unit by the manufacturer. The

separate operating instructions describe how to operate the

electronic gear-shifting systems.

Setting the assistance level

You can set the level at which the eBike drive assists you

while pedalling on the on-board computer. The assistance

level can be changed at any time, even while cycling.

Note: In some models, the assistance level may be preset

and cannot be changed. There may also be fewer assistance

levels available than stated here.

The requested motor output appears on the display of the

on-board computer. The maximum motor output depends on

the selected assistance level.

The following assistance levels are available as a maximum:

– OFF: Motor assistance is switched off. The eBike can just

be moved by pedalling, as with a normal bicycle. The

push assistance cannot be activated at this assistance

level.

– ECO: Effective assistance with maximum efficiency, for

maximum range

– TOUR: Steady assistance, long range for touring

– SPORT/eMTB:

SPORT: Powerful assistance, for mountain biking and

cycling in urban traffic

eMTB: Optimum assistance whatever the terrain, rapid

acceleration when starting from a standstill, improved dy-

namics and top performance (eMTB only available in

combination with the drive units BDU250P CX, BDU365,

BDU450 CX and BDU480 CX. A software update may be

required.)

– TURBO: Maximum assistance even at high pedalling

speeds, for sport cycling

Assistance level Assistance factor

Performance Line

ECO

TOUR

SPORT/eMTB

TURBO

A)

The assistance factor may vary in some models.

B)

Maximum value

(BDU490P)

60 % 60% 60 %

140 % 140 % 140 %

240 % 240/140...340%

340 % 340 % 400 %

Performance Line CX

(BDU450 CX)

English – 3

A)

Cargo Line

B)

240 %

Bosch eBike Systems 0 275 007 XD4 | (12.02.2019)

English – 4

Switching the push assistance on/off

The push assistance aids you when pushing your eBike. The

speed in this function depends on the selected gear and can

reach a maximum of 6km/h. The lower the selected gear,

the lower the speed of the push assistance function (at full

power).

u The push assistance function must only be used when

pushing the eBike. There is a risk of injury if the wheels

of the eBike are not in contact with the ground while using

the push assistance.

To activate the push assistance, briefly press the WALK

button on your on-board computer. After activation, press

the + button within 3s and keep it pressed. The eBike drive

is switched on.

Note: The push assistance cannot be activated at assistance

level OFF.

The push assistance is switched off as soon as one of the

following occurs:

– You release the + button;

– The wheels of the eBike are locked (e.g. by applying the

brakes or hitting an obstacle);

– The speed exceeds 6 km/h.

The push assistance function is subject to local regulations;

the way it works may therefore differ from the description

above, or the function may even be deactivated completely.

Switching bicycle lights on/off

On the model where the bike lights are powered by the eBike

system, the front light and taillight can be switched on and

off at the same time via the on-board computer.

Notes on cycling with the eBike

system

When does the eBike drive work?

The eBike drive assists your cycling only when you are pedalling. If you do not pedal, the assistance will not work. The

motor output always depends on the pedalling force you apply.

If you apply less force, you will receive less assistance than if

you apply a lot of force. This applies irrespective of the assistance level.

The eBike drive automatically switches off at speeds over

25/45km/h. When the speed falls below 25/45km/h, the

drive automatically becomes available again.

An exception applies to the push assistance function, in

which the eBike can be pushed at low speed without pedalling. The pedals may rotate when the push assistance is in

use.

You can also use the eBike as a normal bicycle without assistance at any time, either by switching off the eBike system

or by setting the assistance level to OFF. The same applies

when the battery is drained.

Interaction between the eBike system and gearshifting

The gear-shifting should be used with an eBike drive in the

same way as with a normal bicycle (observe the operating instructions of your eBike on this point).

Irrespective of the type of gear-shifting, it is advisable to

briefly stop pedalling when changing gear. This will facilitate

the gear change and reduce wear on the powertrain.

By selecting the correct gear, you can increase your speed

and range while applying the same amount of force.

Gaining initial experience

We recommend that you gain initial experience with the

eBike away from busy roads.

Test the various assistance levels, beginning with the lowest

level. As soon as you feel confident, you can ride your eBike

in traffic like any other bicycle.

Test the range of your eBike in different conditions before

planning longer and more demanding trips.

Influences on range

The range is affected by a number of factors, such as:

– Assistance level

– Speed

– Gear shifting behaviour

– Tyre type and tyre pressure

– Age and condition of the battery

– Route profile (gradients) and conditions (road surface)

– Headwind and ambient temperature

– Weight of eBike, rider and luggage

For this reason, it is not possible to predict the range accurately before and during a trip. However, as a general rule:

– With the same assistance level on the eBike drive: The

less energy you need to exert in order to reach a certain

speed (e.g. by changing gears optimally), the less energy

the eBike drive will consume and the higher the range per

battery charge will be.

– The higher the selected assistance level under otherwise

constant conditions, the smaller the range will be.

Taking care of your eBike

Please observe the operating and storage temperatures of

the eBike components. Protect the drive unit, on-board computer and battery against extreme temperatures (e.g. from

intense sunlight without adequate ventilation). Extreme temperatures can cause the components (especially the battery)

to become damaged.

Have your eBike system checked by an expert at least once a

year (including mechanical parts, up-to-dateness of system

software).

Please have your eBike serviced and repaired by an authorised bicycle dealer.

0 275 007 XD4 | (12.02.2019) Bosch eBike Systems

Maintenance and servicing

Maintenance and cleaning

When changing the bulbs, ensure that they are compatible

with the Bosch eBike system (ask your bicycle dealer) and

are suitable for the specified voltage. Bulbs must only be replaced with bulbs of the same voltage.

Do not immerse any components, including the drive unit, in

water or clean them with pressurised water.

Have your eBike system checked by an expert at least once a

year (including mechanical parts, up-to-dateness of system

software).

Please have your eBike serviced and repaired by an authorised bicycle dealer.

After-sales service and advice on using products

If you have any questions about the eBike system and its

components, contact an authorised bicycle dealer.

For contact details of authorised bike dealerships, please

visit www.bosch-ebike.com

Disposal

The drive unit, on-board computer incl. operating unit, battery, speed sensor, accessories

and packaging should be disposed of in an en-

vironmentally correct manner.

Do not dispose of eBikes and their components with household waste.

In accordance with Directive 2012/19/EU

and Directive 2006/66/EC respectively, elec-

tronic devices that are no longer usable and de-

fective/drained batteries must be collected

separately and recycled in an environmentally

friendly manner.

Please return Bosch eBike components that are no longer

usable to an authorised bicycle dealer.

Subject to change without notice.

.

English – 5

Bosch eBike Systems 0 275 007 XD4 | (12.02.2019)

PowerPack 300|400|500/PowerTube 400|500|625

BBS245 | BBR245 | BBS265 | BBR265 | BBS275 | BBR275 |

BBP280 | BBP281 | BBP282 | BBP283 | BBP290 | BBP291

en Original operating instructions

45

2 |

(1)

(13)

(6)

(5)

(12)

(2)

(3) (4)

(7)

(11)

(6)

(5)

(8)

(3)

(4)

(13)

(9)

(12)

0 275 007 XPX | (20.12.2018) Bosch eBike Systems

| 3

(16)

(14)

(6)

(5)

(4)

(12)

(13)

(14)

(15)

(11)

(4)

(3)

Bosch eBike Systems 0 275 007 XPX | (20.12.2018)

4 |

A

B

(6)

(5)

(7)

7°

(8)

(10)

(9)

(10)

(1)

(6)

(5)

(2)

0 275 007 XPX | (20.12.2018) Bosch eBike Systems

C

(5)

| 5

1

(14)

(6)

2

D

(5)

(6)

2

(15)

(15)

1

4

(15)

(14)

3

Bosch eBike Systems 0 275 007 XPX | (20.12.2018)

6 |

0 275 007 XPX | (20.12.2018) Bosch eBike Systems

Safety instructions

Read all the safety and

general instructions. Fail-

ure to observe the safety

and general instructions

may result in electric shock,

fire and/or serious injury.

The contents of lithium-ion battery cells are flammable under

certain conditions. You must therefore ensure that you have

read and understood the rules of conduct set out in these

operating instructions.

Save all safety warnings and instructions for future reference.

The term battery is used in these instructions to mean all

original Bosch eBike rechargeable battery packs.

u Remove the battery from the eBike before beginning

work (e.g. inspection, repair, assembly, maintenance,

work on the chain, etc.) on the eBike, transporting it

with a car or aeroplane, or storing it. Unintentional ac-

tivation of the eBike system poses a risk of injury.

u Do not open the battery. There is a risk of short-circuit-

ing. Opening the battery voids any and all warranty

claims.

u Protect the battery against heat (e.g. prolonged sun

exposure), fire and from being submerged in water.

Do not store or operate the battery near hot or flammable objects. There is a risk of explosion.

u When the battery is not in use, keep it away from pa-

per clips, coins, keys, nails, screws or other small

metal objects that could make a connection from one

terminal to another. A short circuit between the battery

terminals may cause burns or a fire. Short circuit damage

which occurs in this instance voids any and all warranty

claims against Bosch.

u Avoid mechanical loads and exposure to high temper-

atures. These can damage the battery cells and cause the

flammable contents to leak out.

u Do not place the charger or the battery near flam-

mable materials. Ensure the battery is completely dry

and placed on a fireproof surface before charging.

There is a risk of fire due to the heat generated during

charging.

u The eBike battery must not be left unattended while

charging.

u If used incorrectly, liquid may leak from the battery.

Contact with this liquid should be avoided. If contact

accidentally occurs, rinse off with water. If the liquid

comes into contact with your eyes, seek additional

medical attention. Liquid leaking from the battery may

cause irritation or scalding.

u Batteries must not be subjected to mechanical shock.

There is a risk of the battery being damaged.

u The battery may give off fumes if it becomes damaged

or is used incorrectly. Ensure the area is well ventilated and seek medical attention should you experi-

English – 1

ence any adverse effects. The fumes may irritate the

respiratory system.

u Only charge the battery using original Bosch chargers.

When using chargers that are not made by Bosch, the risk

of fire cannot be excluded.

u Use the battery only in conjunction with eBikes that

have original Bosch eBike drive systems. This is the

only way in which you can protect the battery against dangerous overload.

u Use only original Bosch batteries that the manufac-

turer has approved for your eBike. Using other batteries can lead to injuries and pose a fire hazard. Bosch accepts no liability or warranty claims if other batteries are

used.

u Do not use the rack-mounted battery as a handle. Lift-

ing the eBike up by the battery can damage the battery.

u Keep the battery away from children.

u Read and observe the safety warnings and directions

contained in all the eBike system operating instructions and in the operating instructions of your eBike.

The safety of both our customers and our products is important to us. Our eBike batteries are lithium-ion batteries which

have been developed and manufactured in accordance with

the latest technology. We comply with or exceed the requirements of all relevant safety standards. When charged, these

lithium-ion batteries contain a high level of energy. If a fault

occurs (which may not be detectable from the outside), in