Installation and Operations Manual

WhiteWing Dehumidifiers

SuperDry 90

DEHUMIDIFIERS

P:+888-236-7231

Add: 300 E Valley Drive, Bristol, VA 24201

DEHUMIDIFIERS

※ ※Safety Notes

The WhiteWing Series Dehumidifier must always be connected using a grounded

electrical connection as required for all electrical appliances. The warranty is voided and all

responsibility for the operation transfers to the owner if non-grounded wiring is

utilized.

WhiteWing

Before moving the dehumidifier, turn off dehumidifier and allow pump to empty

reservoir. (Or if unit is already off, press“P”button to confirm drain reservoir is empty).

After the pump has finished operation, unplug the power cord and relocate unit to the

desired position.

If the inside of the unit has gotten wet for any reason, the unit should be opened

and allowed to dry thoroughly before reconnecting to electric and restarting.

For proper operation, neither the inlet nor discharge should be positioned against a

wall. A minimum of 12”clearance between unit and any obstruction is required.

Do not insert any objects or fingers into the inlet or discharge.

All work on unit should be done with the unit“off”and unplugged.

Do not use water to clean unit exterior. Only use a damp cloth to clean exterior and

always unplug the unit first.

Do not use unit as shelf or device to hang clothes. This could cause damage to unit.

Do not stand on machine.

WhiteWing Dehumidifiers must be maintained and serviced by qualified technicians.

Dehumidifiers are intended for use only when the unit is installed in a level

and upright position. Operating the unit in any other position could cause water to come

in contact with the electrical components.

DEHUMIDIFIERS

DEHUMIDIFIERS

※ ※Features/Specifications

The SuperDry Series dehumidifier operates based on the refrigerant principle of

dehumidification.

Automatic (Humidistat) or Manual Control

If power is interrupted during operation, the unit will automatically

restart when power is restored.

Eco-Friendly R410A Refrigerant

Easy access for routine maintenance

Unit can be ducted, if necessary

Pump safety feature – overflow protection

High COP, 2.45L/KWh

Low Sound Levels <56dBA

Self-monitoring system

Drain Pump with both Automatic and Manual Control

Each unit comes standard with a prefilter and Merv 8 filter. High efficiency

and carbon filters are available as options.

SuperDry 90

Identification:

-1-

Contact your installing contractor

Phone

SuperDry Dehumidifiers: +888-236-7231

Customer Service:

For additional questions concerning the operation of your dehumidifier,

For future reference, write down the model, serial number, and date of purchase so

you can identify your unit when seeking assistance. NOTE: data label on back of unit

includes serial number.

Model Number SuperDry 90

Serial Number__________________________

Date of Purchase__________________________

please:

※ ※Table of Contents

Features/Specs.............................................................................................................................. 01

Identification................................................................................................................................. 01

How Your SuperDry Dehumidifier Works..............................................................................02

Unit Overview................................................................................................................................ 03

Operating instructions................................................................................................................ 04

Preparing the Unit for Use.......................................................................................................... 10

Maintenance.................................................................................................................................. 12

Storing Your Dehumidifier.......................................................................................................... 16

Troubleshooting........................................................................................................................... 16

Warranty......................................................................................................................................... 17

Congratulations on purchasing a WhiteWing Dehumidifier! Your new dehumidifier

comes with an extensive warranty plan.

DEHUMIDIFIERS

DEHUMIDIFIERS

SuperDry 90

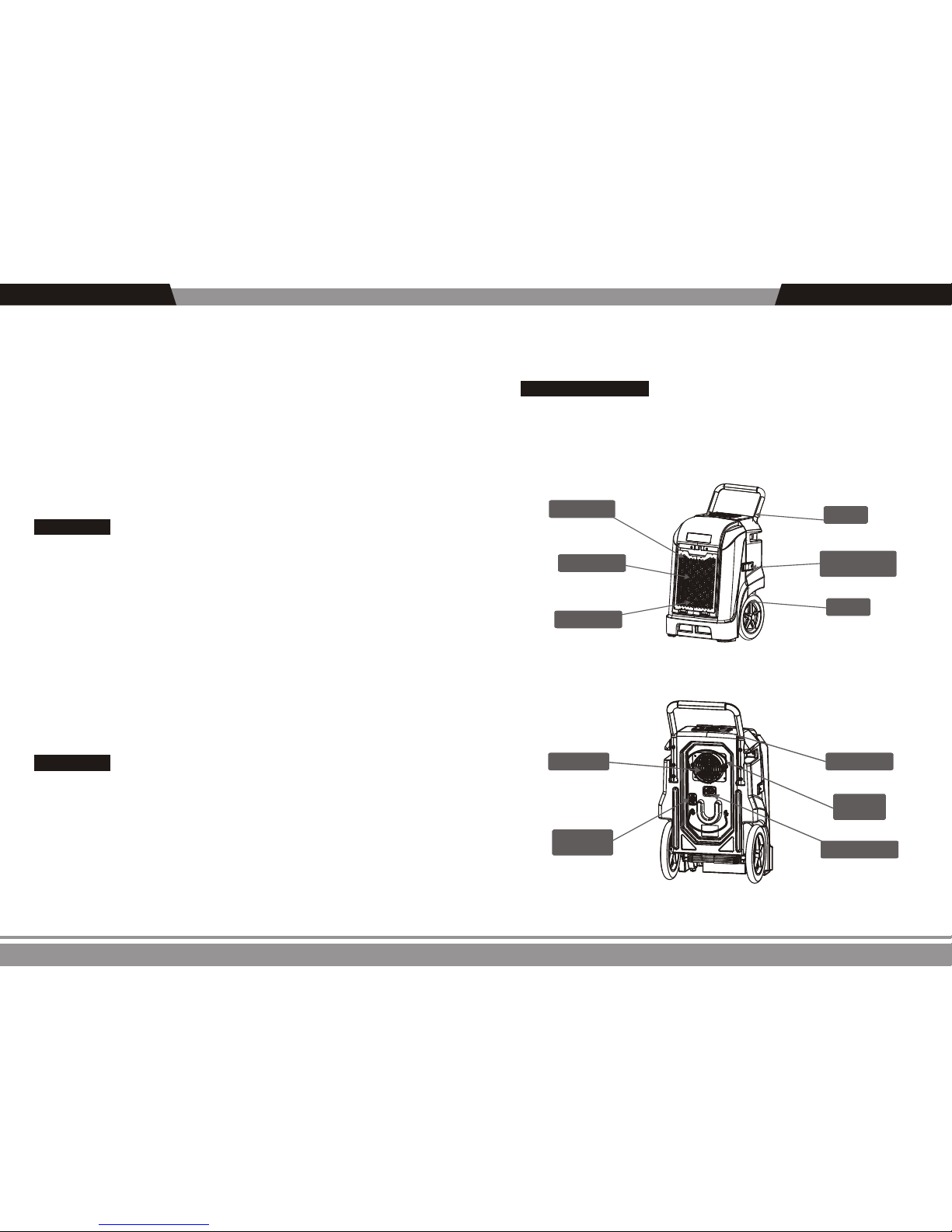

※ Front View

Handle

Wheel

Front cover

Air inlet

Secured Access

Latch

Air Filter

-3-

※Unit Overview※

Control panel

Power Cord Input

Hose and

Cord Rack

Drain Tube

Connection

Air outlet

※ Rear View

-2-

How Your SuperDry Dehumidifier Works

The WhiteWing SuperDry Series Dehumidifier utilizes either its integral humidistat to

monitor the conditioned space or a manual on/off control to energize the compressor

when needed. Air is drawn across an evaporator coil. The evaporator coil is cooler than the

dew point of the air so water vapor will turn into liquid condensation. Air is then reheated

through the condenser coil and distributed back into the room.

Installation:

240 Volts AC may cause serious injury from electric shock.

WARNING!

1. Disconnect electrical power before servicing

2. Only plug unit into grounded electrical outlet

3. Do not use extension cord

4. Do not use plug adapter

Power Supply: 115V, 60 Hz AC Only 1 Phase

Outlet Requirement: 3-Prong, GFI

Circuit Protector: 15 Amp Time Delay Fuse or Circuit Breaker

Alternatively, you can manually control unit to operate independent of space conditions.

Place unit in desired location. The inlet of unit should be at least 8”from any

obstructions. If unit is transported in the horizontal position, allow it to sit in upright

position for at least 30 minutes before operating.

It is recommended that the unit be removed from any location where corrosive or high

VOC content materials are applied.

WARNING!

DEHUMIDIFIERS

DEHUMIDIFIERS

-5-

6. LCD monitor

When the unit is running, the LCD monitor will go dark if no buttons are pushed. Push

any button once to light monitor.

7. LCD display function

(1)Show“Power On”when the machine has already connected but not started.

p

o w e

r

o

n

Use to confirm a selection.

4. Select/OK Button

OK

These buttons are used for adjusting humidity or timer settings.

5. UP Botton Down Botton

Humidity Setting: Adjust the humidity setpoint

Timer Setting: Start Time Setup/Stop Time Setup/Cycle Time Setup

Temperature Scale Switch: Choose between Celsius and Fahrenheit readings

Return: Return to the main menu

NOTE: See Section 8 for more detailed programming instructions.

Four selections are available:

n

U

n

i

t

O

(2) Show“Unit On”when the machine is in working status (This display will change

to next screen in 2 seconds).

(3)The LCD interface shows two lines of data. The first line displays the room

temperature and humidity. On the second line, Job T(working time) and Humidity Setpoint

are displayed on an alternating basis.

I

n

l

e

t

3

2

℃

7 6

%

The contents of the second line alternate every 10 sec.

※Operating instructions※

OK

M

P

Menu

Up Button

Down Button

LCD Monitor

On/Off

Select/OK

Drain Pump

※ Control Panel Operation

1. ON/Off Button

Press this button, and the machine will start running. Press this key again and the

machine will stop running. The display will show room humidity levels except while you’re

pressing another button. NOTE: When unit is turned off, the fan will run for 1 minute prior

to shutting off. “ In addition the condensate pump will pump for approximately 14

seconds to drain the pump reservoir after unit is powered off.”

2. Pump Button

P

For extende d storage or m ovement of the machi ne, press the“Pump”bottom to

remove water from the integral pump’s reservoir.

3. Menu Button

M

Pressing the Menu (M) button, gives you the options to select between two different

control modes as well as adjust the temperature measurement units. Continue pressing

the M button until you get to your desired selection. Press the Select (OK) key to confirm

that selection and move to a submenu.

After you’ve completed your task, select“R”,then press the“select/ok”button to

move back to previous menu, or wait 10 sec to automatically return to the main screen.

-4-

DEHUMIDIFIERS

DEHUMIDIFIERS

T

i

m

e

O

n

0 0 0

5

T

i

m

e

O 0 0 0

5

f f

O

000 000

I

1 1

H

u

m

i

d

T

i

m

e

r

T

e

m

p

U

R

Time remaining to Auto opening

Time remaining to Auto Closing

Time remaining to circulate status

( 1 ) The Humidity Setting (Humid)

a. Press the Menu (M) button. The screen shows:

b. Press the“M”button until “Humid”is flashing. Press “OK”to select this option. The

screen shows:

8. Operation and Display

Note: As long as the machine is plugged into power, the settings can be changed. The unit does

not have to be operating to change setup.

Second screen display options:

J

o

b

.

T

0 0 0

5

0 8 9

L

f

e

i

.

0

H

or

-7-

H

u

m

i

d

R

S

e

t t

i

n

g

3

5

%

c. Press the menu key until the humidity level (bottom left of display) is flashing (it will

either say“Co”f or continuous operation or a number for a specific percentage).

d. Use the“Up”or“Down”buttons to set the machine to your desired level. Press the

“OK”button when finished. The cursor automatically move to“R”which will be flashing.

Press“OK”to confirm move to previous menu or wait 10 seconds and you will

automatically return to the main menu.

-6-

The contents of the second line alternate every 10 sec.

or

J

o

b

.

T 0 0 0

5

H

u

m

i

.

s e

t

5

0

%

(5)

.

Show“Draining”when the pump is draining in both automatic and manual

modes

I

n

l

e

t

3

2

℃

7 6

%

D

r

a

ini

n

g

Once the pump reservoir is drained, the contents of the second line alternately show “job hours”

and “total hours”, alternating every 10 seconds until the one minute final fan cycle is completed.

J

o

b

.

T

0 0 0

5

0 8 9L

f

e

i

.

0H

or

(4)When you press the“Power Off”button, two lines of data will be displayed. The

top line will read“Unit Off”. The bottom line will read“Draining”for approximately 14

seconds while the pump is emptied.

f f

U

n

i

t

O

D

r

a

ini

n

g

Show“Defrosting”when the machine is in defrosting mode. If both“Defrosting”and

“Draining”are occurring simultaneously,“Defrosting”is the display priority.

I

n

l

e

t

3

2

℃

7 6

%

D

i

g

f

t

e

n

r

o s

(6) .Second line of display will rotate through several screens depending on setup

f f

U

n

i

t

O

DEHUMIDIFIERS

DEHUMIDIFIERS

-9-

a. Press the M button until the T.I/O selection is flashing. Press“OK”button to select.

b. Use the“Up”and“Down”arrows to adjust the hours and minute of the first cycle.

c. Use the“M”button to move from 1st line of display to second and adjust second

time period with up and down buttons.

d. Press the“OK”button to confirm the time. (Flashing OFF will turn to ON).

( 3 ) Temperature scale set

This selection allows you to switch the machine from displaying temperature in

degrees Celsius to degrees Fahrenheit.

a. Press the menu key. The screen shows: Humid, Timer, Tempu, R.

H

u

m

i

d

T i

mer

T

e

m

p

U

R

T

e

m

p

U

R

S

e

t t

i

n

n

g

O O

ff

o

F

℃

b. Press the Menu key unit TempU flashes. Press“OK”to select.

c. The screen shows: Celsius degree℃ on/off and Fahrenheit degree the ℉ off/on.

a. Press the M button until the T.off button is flashing. Press“OK”to confirm.

b. Set timer as above.

2) Shut Off Time (T.offSelection). Unit will run for designated time and then turn off.

3) Cycling Timer (T.I/O Selection)

The third selection, T.I/O, lets you set up the machine to cycle on and off during a

specific time frame. For example, you could set the unit to run 8 hours a day and remain

off the other 16 hours. Note: You are selecting on and off periods of time, not set clock

times.

d. Press the menu key to move the cursor to the ℃ on/offor ℉ off/on(flashes).

e. Press to confirm key. The on/off status of C and F will exchange.

-8-

( 2 ) Timer Settings (Timer)

This selection allows you to set a timer for the unit to turn on or turn off. You can also set up cycle

timing, which allows you to set up and repeating cycle of specific on and off durations.

a. Press the menu key several times unit the Timer button is flashing.

Press“OK”button to confirm this option.

f f

n

oo

T

T

T

R

/

.

..

I

0

b. The screen shows: T. on, T. off, T.I / 0,R

H

u

m

i

d

T

i

m

e

r

T

e

m

p

U

R

“

“T.off” – Unit will stop when timer expires

“T.I/O” – Unit will cycle“on”and“off”based on the set time. If unit is off, the

cycling will start with unit“off”. If unit is on, the cycling will start with the unit“on.”

c. Press the menu key to select your desired selection.

T.on” – Unit will start when timer expires

T

i

m

e

r

O

n

O

R

f f

00 00

1) Start Time (T.on Selection)

a. Press to confirm key. The screen runs as follow, the first 00 positions (flashes) at the

same time.

b. Press“Up”and“Down”key to select hour choice between 00-24. Press“Ok”key

to select choice.

c. After the hour selection is confirmed, the minute choice will flash. Select as before

and confirm with“Ok”key.

d. The“OFF”button will now flash. Press“OK”one more time, the“OFF”display will

switch to“ON”and the timer is now set.

DEHUMIDIFIERS

DEHUMIDIFIERS

-11-

The quick connector into

the socket on the connector

Quick connection to draining tube

(

( 4 ) Set unit control as desired and energize.

3 ) Firmly insert power cord into socket on top back of unit.

SuperDry 90

※Maintenance and Repair※

1. Exterior Cleaning

Use a soft, slightly damp cloth to wipe the plastic body.

a. Remove the inlet grille to access the filter

2. Filter cleaning

18’prior to reaching final drain location.

-10-

Ducting of the unit allows conditioning of an adjacent room or focusing discharge in

an area needing focused attention. Diameter for supply ducting is 6”. Flex or layflat

ducting can be used for this purpose.

9.Optional Duct Installation

SuperDry 90

※Preparing the Unit for Use※

( 1 ) Position the machine for a minimum 8”clearance on front and sides. Rear of

machine should be positioned for maximum discharge distance or directly towards a

specific location for spot drying.

If the unit was moved in such a manner that the compressor didn’

t remain in a

vertical

orientation, wait a minimum of 30 minutes before turning the unit“on.”

( 2 ) The included drain line attaches to the unit via a quick connection type fitting

located on the base of the unit.The drain line should be routed to a suitable drain or

outside. Because the unit features an integral drain pump, drain line may go vertically up

DEHUMIDIFIERS

DEHUMIDIFIERS

-13-

b. Pull up the bottom to open

Press this button and pull to open

c. Opening back housing

Hand in this

slot to open

Release this screw at both side,

and open these box locks

-12-

1) Pull up on the handle to

release and gently pull out

on filter assembly.

2) Remove the filter

SuperDry 90

b. Filter may be cleaned by vacuuming or by washing with warm water (no soap or solvents).

Insure filter is dry prior to restarting unit.

※Maintenance

1. Accessing Internal Components

WARNING – ALWAYS UNPLUG UNIT PRIOR TO PERFORMING ANY

MAITENANCE

a. Remove tamperproof screws from side latches

DEHUMIDIFIERS

DEHUMIDIFIERS

-15-

※ At least once per year, clean pump system

Basic-

1. Press the pump button (P) to drain water from reservoir.

2. Disconnect power to dehumidifier.

3. Mix a 16 oz solution of either 1 oz bleach to 15 oz water or 4 oz white vinegar to 12

oz water. Pour into the drain tray at the base of the coils.

Note: If you get any cleaning solution on the coils, flush with water.

4. Allow to soak for 15 minutes.

5. Reconnect power to dehumidifier.

6. Fill reservoir and flush/cycle pump at least two times with clean water.

7. Repeat if needed or refer to Advanced instructions.

Advanced-

1. a. Use manual pump button“P”, to drain water from reservoir.

b. Unplug the dehumidifier and open cover to access pump.

c. Pump head can be removed from reservoir by pressing on tabs.

d. A wet-dry vacuum or towels can be used to remove remaining water from

reservoir.

2. Fill pump reservoir with a diluted cleaning solution (15 oz water to 1 oz bleach or 12

oz water to 4 oz white vinegar).

3. Reassemble pump and use manual pump button to flush mixture through discharge

tubing.

4. Pour same diluted mixture slowly into drain pan under evaporator coil and allow it

to clean hose from pan to pump. This process can be stopped when the pump energizes 1

time.

Note: If you get any bleach/water mixture on coils, flush with water.

5. Pour sufficient clean water through drain pan to force pump to activate twice.

6. Reassemble unit and return it to operational status.

Coil-

If necessary, clean your coils with a vacuum or approved coil cleaner.

-14-

2. Water Pump Maintenance

The pump is designed with q uick connection construction. If service is required,

condensate tube, float switch connections, and the main power cord to pump can easily be

disconnected. The pump can be removed from reservoir by using a flat screwdriver to

gently pry pump assembly from reservoir.

Your WhiteWing SuperDry is equipped with an integral condensate pump designed to

pump condensate from your dehumidifier out to the desired drain. This pump requires

routine maintenance that is not covered by your 1 year p arts warranty. Only a defective

pump will be repaired or replaced during the warranty period.

Preventative Maintenance

As with all pumps, preventative maintenance is necessary to prevent issues from dirt

and slime that may accumulate in the drain system – including the drain pan, hose to the

condensate pump, pump reservoir, pump head and float assembly, and discharge tubing.

Hand in this

slot to open

DEHUMIDIFIERS

DEHUMIDIFIERS

-17-

1. Clear error code by disconnecting power cord and then reconnecting. NOTE: Unit

will not function until error code has been cleared.

2. Manually check t o see if pump is operation al. P ress pump butto n (P) and see if

pump energizes and de-energizes properly and if any water is purged from system. If you

haven’t

cleaned the system recently, check discharge line for obstruction and clean

balance of pump system per instruction above.

3. Replace hoses and or pump if maintenance alone is not sufficient.

Trouble codeHI:

Trouble code:E1,L0,HI

Unit is sensing room temperature

above 100F

Decrease Room Temp

Check Sensor

Check Sensor Cable

Shows E1, L0,HI at the same time

indicated a bad connection, cable

or sensor

Check Cable connection

Replace Cable

Replace Sensor

Pump Alarm-Error Code E4

If a pump alarm is provided on display:

※ ※Warranty

Seller warrants the equipment to be free from defects in workmanship and materials

for a period of 12 months after shipment (60 months/5 years on compressor, evaporator

and condenser). This warranty is limited, however, to the repair or replacement of defective

equipment. If it is necessary to return unit for service, customer is solely responsible for

pro per pack agi ng, transportation co sts . Cu stomer m ust ini tiate wa rra nty proc ess by

contacting factory. Do not send any component or pr oduct back to factory without Return

Material Authorization.

This limited warranty does not apply to any par t or component that is damaged in

transit or when handling, has been subject to misuse, corr osion, chemicals, acts of God has

not been installed, operated or serviced according to the Seller’s instructions, or has been

ope rated beyon d the fac tor y-r ate d capaci ty or has bee n altered in any w ay. Ro utine

maintenance is not covered by this warranty.

-16-

※Storing Your Dehumidifier※

If the unit will be stored for an extended period of time:

1. Turn unit off and allow to dry.

2. Manually drain pump reservoir.

3. Wrap and secure the power cord .

4. Clean the filter mesh.

5. Store in clean,dry environment.

※Troubleshooting※

Trouble code:E1

Trouble code:E3

Solution

Trouble

cause

Filter mesh jammed

Clean the filter

Machine Won’t Work/

Display is Blank

Clean the filter

Display Blank. Power outage

or poor connection

Room temperature outside unit

operating range. HI or LO Error

Check Power Supply

Check both ends of power

cord for good connection

Modify room conditions in

between 33 and 100F.

Cannot start the

dehumidifier

Filter mesh is clogged

Air inlet or outlet jammed

Clear the blockage from

air inlet or air outlet

No Airflow

Loud/Unusual Noise

Unit is not level

Place unit on flat surface

in vertical orientation

Humidity Sensor or

communication error

Check sensor cable is properly

connected. Replace the Senser

Temp Sensor or communication error.

Check sensor cable is properly

connected. Replace the Sensor

Pump dislodged Reassemble pump as necessary

Check for clogged drain lines

Check pump working properly

Service Pump、Replace Pump

Pump detected high water in

reservoir (See Notes Below)

Trouble codeE4:

Trouble codeL0:

Unit is sensing room temperature

below 33F.

Increase room temperature

Check Sensor

Check Sensor Cable

DEHUMIDIFIERS

-18-

Seller’s liability is limited to replacement of defective parts or components and does

not include any cost of labor (including, but not limited to, labor to remove and/or reinstall

any defective part), refrigerant or piping. Customer may elect to have unit fixed locally in

which case required replacement parts will be sent to customer at customer’s expense.

Shall not be responsible for loss of use of any product, loss of time, inconvenience, or

damage to other equipment, or any other indirect or consequential damage with respect

to property whether as a result of breach of warranty, neglect, or otherwise.

TH E WARR ANT IES A ND L IAB ILI TIE S SET FORT H ARE IN L IEU OF AL L O THE R

WARR ANT IES EXP RES SED OR I MPL IED , IN LAW OR I N FACT, I NCLU DIN G IMP LIE D

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE.

WhiteWing’s total liability, regardless of nature of claim shall not exceed original purchase price

of the product. If a product or component is replaced while under warranty, the applicable

warranty period shall not be extended beyond the original warranty time period.

The foregoing s hal l consti tut e the tot al l iabilit y of seller i n th e case of defective

performanceof all or any of the equipment or services provided to Buyer. Buyer agrees to

accept and hereby accepts the foregoing as the sole and exclusive remedy for any breach

or alleged breach of warranty by Seller.

Loading...

Loading...