Page 1

All about the

Use & Care

of your Refrigerator

TABLE OF CONTENTS

Important Safety Instructions ......................2

Features at a Glance ...................................4

Installation ................................................5

Door Removal Instructions ..........................7

Connecting Water Supply ............................9

Controls ...................................................11

Storage Features ......................................13

Automatic Ice & Water Dispenser ..............14

Changing the Filter ...................................18

Normal Operating Sounds and Sights .........19

A06119701 (August 2016)

Care and Cleaning ....................................20

Before you Call .........................................22

Page 2

IMPORTANT SAFETY INSTRUCTIONS

WARNING

Please read all instructions before using this

refrigerator.

For your Safety

• DO NOT store or use gasoline, or other

ammable liquids in the vicinity of this or

any other appliance. Read product labels

for warnings regarding ammability and

other hazards.

• DO NOT operate the refrigerator in the

presence of explosive fumes.

• Avoid contact with any moving parts of

automatic ice maker.

• Remove all staples from the carton. Staples

can cause severe cuts, and also destroy

nishes if they come in contact with other

appliances or furniture.

Denitions

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

WARNING

WARNING indicates a potentially hazardous

situation which, if not avoided, could result

in death or serious injury.

Installation Checklist

Doors

Handles are secure and tight

Door seals completely to cabinet on all

sides

Freezer door is level across the top

Leveling

Refrigerator is level, side-to-side and

tilted 1/4” (6mm) front-to-back

Toe grille is properly attached to

refrigerator

Cabinet is setting solid on all corners

Electrical Power

House power turned on

Refrigerator plugged in

Ice Maker

House water supply connected to

refrigerator

No water leaks present at all connections

- recheck in 24 hours

Ice maker is turned ON

Ice & water dispenser operates correctly

Front lter must be ush with lter

housing (select models)

Final Checks

Shipping material removed

Fresh food and freezer temperatures set

Crisper humidity controls set

Registration card sent in

CAUTION

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

IMPORTANT

IMPORTANT indicates installation, operation

or maintenance information which is important but not hazard-related.

2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

Grounding type wall receptacle

Power cord with

3-prong grounded plug

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Child Safety

Destroy or recycle the carton, plastic bags, and

any exterior wrapping material immediately

after the refrigerator is unpacked. Children

should NEVER use these items to play.

Cartons covered with rugs, bedspreads, plastic

sheets or stretch wrap may become airtight

chambers, and can quickly cause suffocation.

Proper Disposal of your

Refrigerator or Freezer

Risk of child entrapment

Child entrapment and suffocation are not

problems of the past. Junked or abandoned

refrigerators or freezers are still dangerous

– even if they will sit for “just a few days”. If

you are getting rid of your old refrigerator or

freezer, please follow the instructions below to

help prevent accidents.

Proper Disposal of Refrigerators/

Freezers

We strongly encourage responsible appliance

recycling/disposal methods. Check with your utility

company or visit www.recyclemyoldfridge.com for

more information on recycling your old refrigerator.

Before you throw away your old

refrigerator/freezer:

• Remove doors.

• Leave shelves in

place so children

may not easily

climb inside.

• Have refrigerant

removed by a

qualied service

technician.

and ordinances. Consult a qualied electrician.

Avoid connecting refrigerator to a Ground

Fault Interrupter (GFI) circuit. Do not use an

extension cord or adapter plug.

• If the power cord is damaged, it should

be replaced by an authorized service

technician to prevent any risk.

• Never unplug the refrigerator by pulling on

the power cord. Always grip the plug rmly,

and pull straight out from the receptacle to

prevent damaging the power cord.

• Unplug the refrigerator before cleaning

and before replacing a light bulb to avoid

electrical shock.

• Performance may be affected if the voltage

varies by 10% or more. Operating the

refrigerator with insufcient power can

damage the compressor. Such damage is

not covered under your warranty.

• Do not plug the unit into an electrical outlet

controlled by a wall switch or pull cord to

prevent the refrigerator from being turned

off accidentally.

IMPORTANT

Pressing and holding the On/Off button for 3

seconds, located on the left side of the temperature control panel (Electronic controls),

or turning the Freezer and Fresh Food controls to “0” (Mechanical controls) will disable

your refrigerator’s cooling system, but does

not disconnect the power to the light bulb

and other electrical components. To turn off

power to your refrigerator you must unplug

the power cord from the electrical outlet.

WARNING

These guidelines must be followed to ensure

that safety mechanisms in this refrigerator

will operate properly.

Electrical information

• The refrigerator must be plugged into its

own dedicated 115 Volt, 60 Hz., 15 Amp,

AC only electrical outlet. The power cord

of the appliance is equipped with a three-

prong grounding plug for your protection

against electrical shock hazards. It must be

plugged directly into a properly grounded

three prong receptacle. The receptacle must

be installed in accordance with local codes

CAUTION

To avoid personal injury or property damage,

handle tempered glass shelves carefully. Shelves

may break suddenly if nicked, scratched, or

exposed to sudden temperature change.

3

Page 4

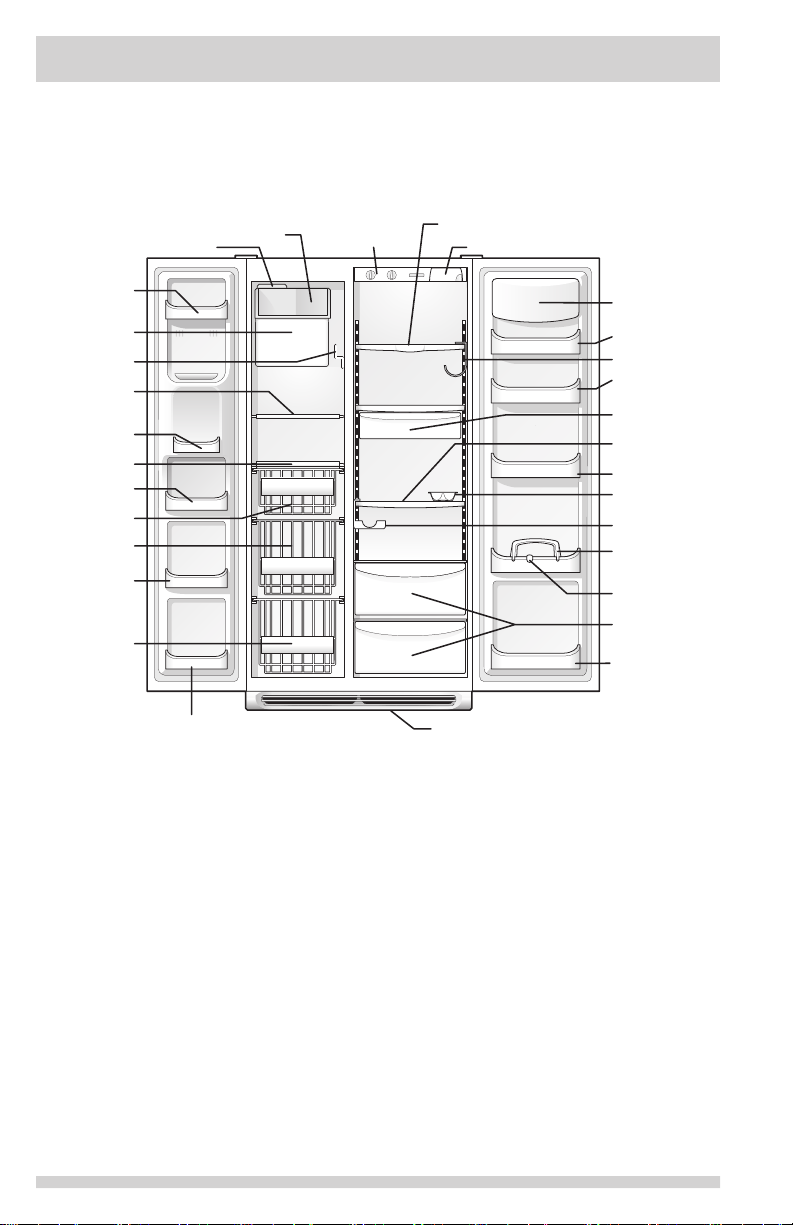

FEATURES AT A GLANCE

SpillSafe

Freezer and

Small Basket

Features may vary according to model

Door Bin

Ice Container

Pizza Shelf

Wire Shelf

Small Items

Door Bin

Wire Shelf

Door Bin

Large Basket

Door Bin

Large Basket

Ice Cream Shelf

Ice Maker

Door Bin

Refrigerator

Controls

Sliding Shelf

Toe Grille

TM

Water Filter

Dairy Door

Door Bin

Wine Rack

Door Bin

Meat Keeper

and Cover

TM

SpillSafe

Fixed Shelf

Door Bin

Egg Tray

Special Item

Rack

Tall Bottle

Retainer

Snugger

Crisper Pan

and Cover

Fixed Door Bin

4

Page 5

INSTALLATION

Installing Toe Grille

Removing Toe Grille

This Use & Care Guide provides general

operating instructions for your model. Use

the refrigerator only as instructed in this

Use & Care Guide. Before starting the

refrigerator, follow these important rst

steps.

Location

• Choose a place that is near a grounded

electrical outlet. Do Not use an extension

cord or an adapter plug.

• If possible, place the refrigerator out of

direct sunlight and away from the range,

dishwasher or other heat sources.

• The refrigerator must be installed on a oor

that is level and strong enough to support

a fully loaded refrigerator.

• Consider water supply availability for

models equipped with an automatic ice

maker. If you do not hook up water to

the refrigerator, remember to turn the ice

maker off.

CAUTION

Do Not install the refrigerator where the

temperature will drop below 55°F (13°C) or

rise above 110°F (43°C). The compressor

will not be able to maintain proper

temperatures inside the refrigerator.

Do Not block the toe grille on the lower front

of your refrigerator. Sufcient air circulation

is essential for the proper operation of your

refrigerator.

Installation

Installation clearances

• Allow the following clearances for ease

of installation, proper air circulation, and

plumbing and electrical connections:

Sides & Top

Back 1 inch

3

/8 inch

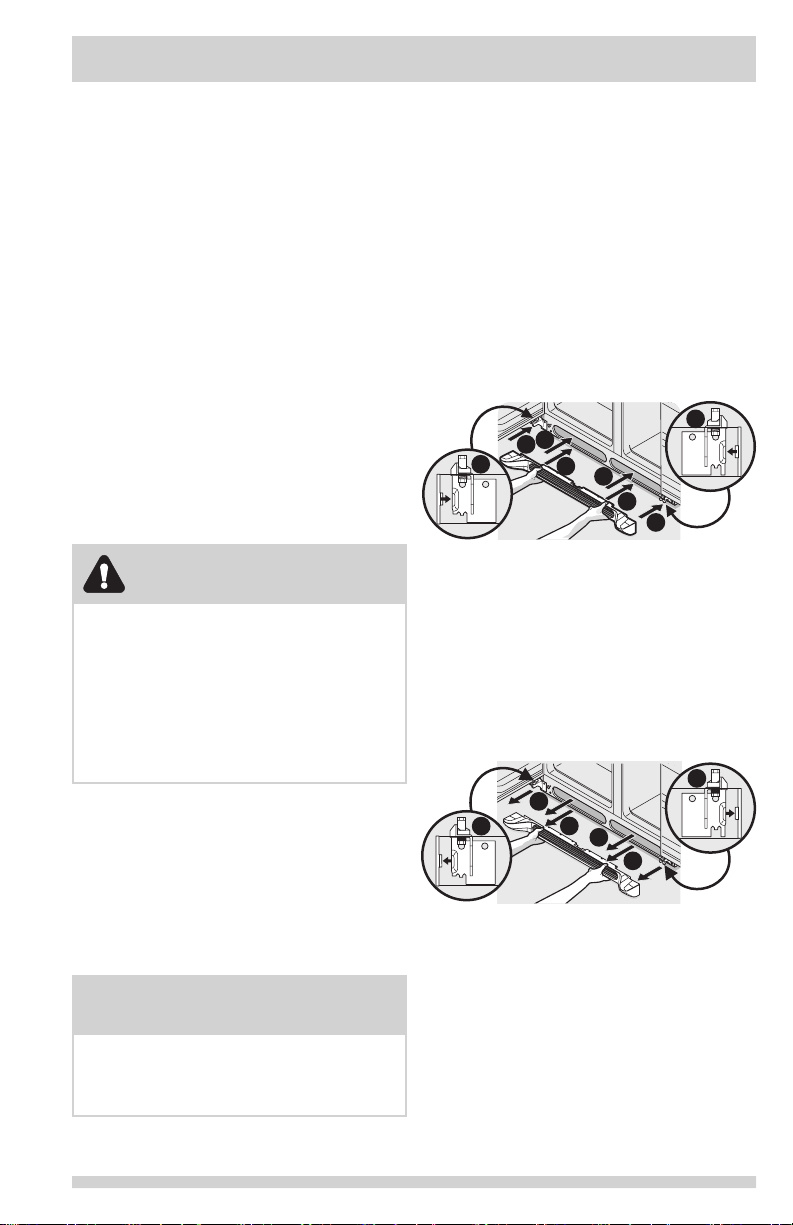

Toe Grille Installation and

Removal

To install toe grille

1 Open both doors. Slide left and right

sides of toe grille over lower hinges of

refrigerator.

2 While pushing toe grille rmly against

cabinet, fasten bottom clips of toe grille to

cabinet.

3 Fasten top clips to cabinet.

4 Close the doors. Fasten right and left side

clips into groove of bottom hinge.

4

3

1

4

To remove toe grille

1 With both doors closed, unfasten right

and left side clips of toe grille from bottom

hinge groove.

2 Open both doors. Press rmly on top of

toe grille until top of toe grille pops off.

3 Pull toe grille outward toward your body

and off of lower hinges.

1

2

3

2

1

1

2

3

2

3

NOTE

If your refrigerator is placed with the door

hinge side against a wall, you may have to

allow additional space so the door can be

opened wider.

5

Page 6

INSTALLATION

9/16"

(14 mm)

Max

Raise

Open Door

Door Opening

NOTE

The refrigerator doors are designed to shut

by themselves within a 20 degree opening.

Your refrigerator should be positioned to

allow easy access to a counter or table when

removing food. For best use of drawers and

freezer baskets, the refrigerator should be

in a position where both the refrigerator and

freezer doors can be fully opened.

Guidelines for nal positioning of

your refrigerator:

• All four corners of the cabinet must rest

rmly on the oor.

• The cabinet should be level at the front

and rear.

• The sides should tilt ¼ inch (6 mm) from

front to back (to ensure that doors close

and seal properly).

• Doors should align with each other and be

level.

All of these conditions can be

met by raising or lowering the

adjustable front rollers.

To level the cabinet using the front rollers:

1 Open both doors and remove the toe grille

(see “Toe Grille Installation and Removal”

in the “Installation” section).

2 Close the doors and use a at-blade

screwdriver or 3/8 inch socket wrench to

raise or lower the front rollers.

3 Ensure both doors are bind-free with their

seals touching the cabinet on all four sides.

To level the doors using the adjustable

lower hinge:

NOTE

Some models will not have a set screw. For

those models follow steps 2 through 4.

1 Before leveling either door, remove set

screw that locks door height into position.

(The door cannot be adjusted without set

screw removed).

2 If the refrigerator door is lower than the

freezer door, raise the refrigerator door by

turning the adjustment screw clockwise

using a 7/16 inch wrench. (See illustration.)

3 If the freezer door is lower than the

refrigerator door, raise the freezer door by

turning the adjustment screw clockwise

using a 7/16 inch wrench. (See illustration.)

Door

Raise

Door

4 After leveling, verify door stop contacts

lower hinge and top of door does

not contact upper hinge through full

movement of door (from fully closed to

fully open).

5 Reinstall set screw, locking the door height.

Door

Raise

Door

Door Stop

Flange

7/16" Wrench and

3/32" Hex Key (some models)

6 Replace the toe grille by tting it into

place (see “Toe Grille Installation and

Removal” in the “Installation” section).

Hinge Flange

Set Screw

(some models)

Hinge

6

Page 7

DOOR REMOVAL INSTRUCTIONS

Getting through narrow spaces

If your refrigerator will not t through an entrance area, you can reduce its size by removing the

doors. Check rst by measuring the entrance.

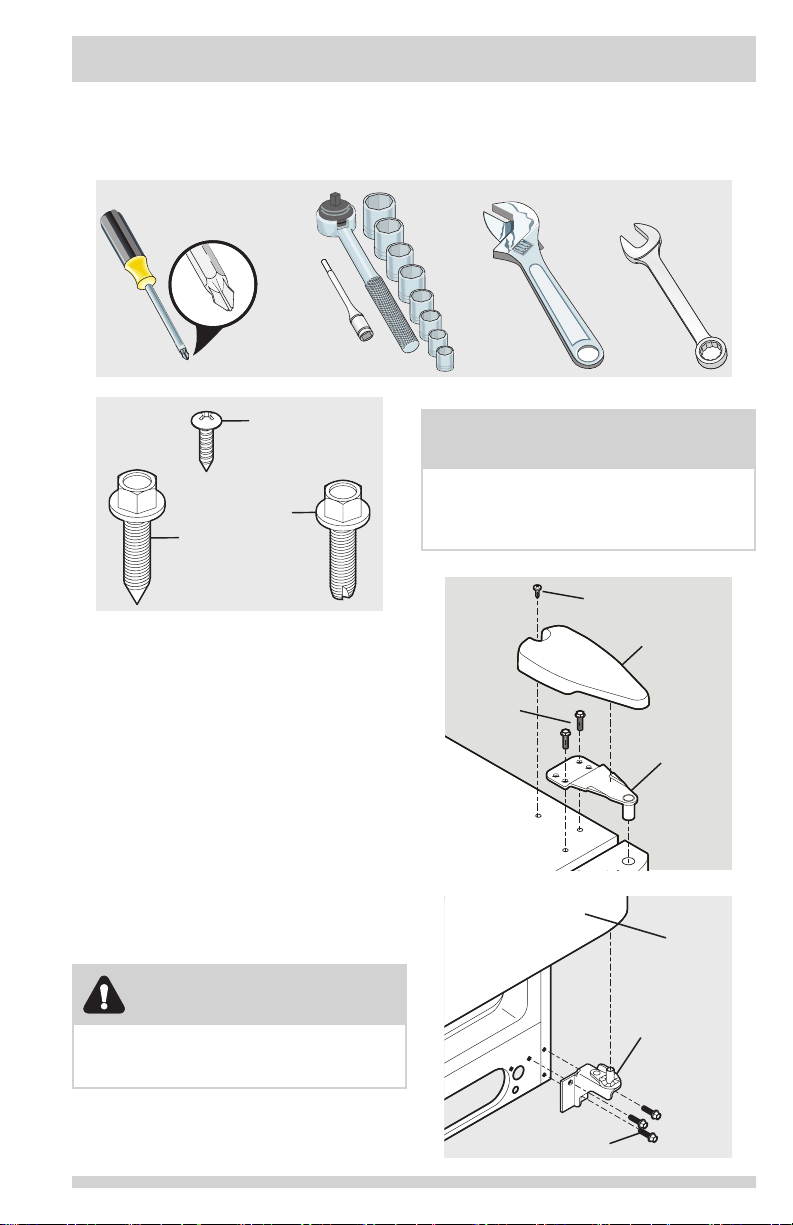

Tools Necessary:

AND

Top Hinge

Cover

Screw

Bottom

Hinge

Screw

Top

Hinge

Screw

1. Disconnect electrical supply.

2. Open both doors, then remove toe grille.

3. Close doors.

To Remove Refrigerator Door:

1. Remove top hinge cover screw on

refrigerator door and remove cover.

2. Trace around hinge with soft lead pencil.

This will make it easier to realign doors

when they are replaced.

3. Remove top hinge and lift refrigerator

door off bottom hinge pin. Set door aside.

4. Remove bottom hinge, if necessary.

5. Reverse this procedure to reinstall

refrigerator door.

OR OR

NOTE

Before you begin, turn Freezer and Fresh

Food controls to “O” and remove electrical

power cord from wall outlet. Remove any

food from door shelves.

Cover Screw

Top

Hinge

Cover

Hinge

Screws

Top

Hinge

Door

CAUTION

Be sure doors are set aside in a secure

position where they cannot fall and cause

personal injury.

Screws

Hinge

Assembly

7

Page 8

DOOR REMOVAL INSTRUCTIONS

To Disconnect

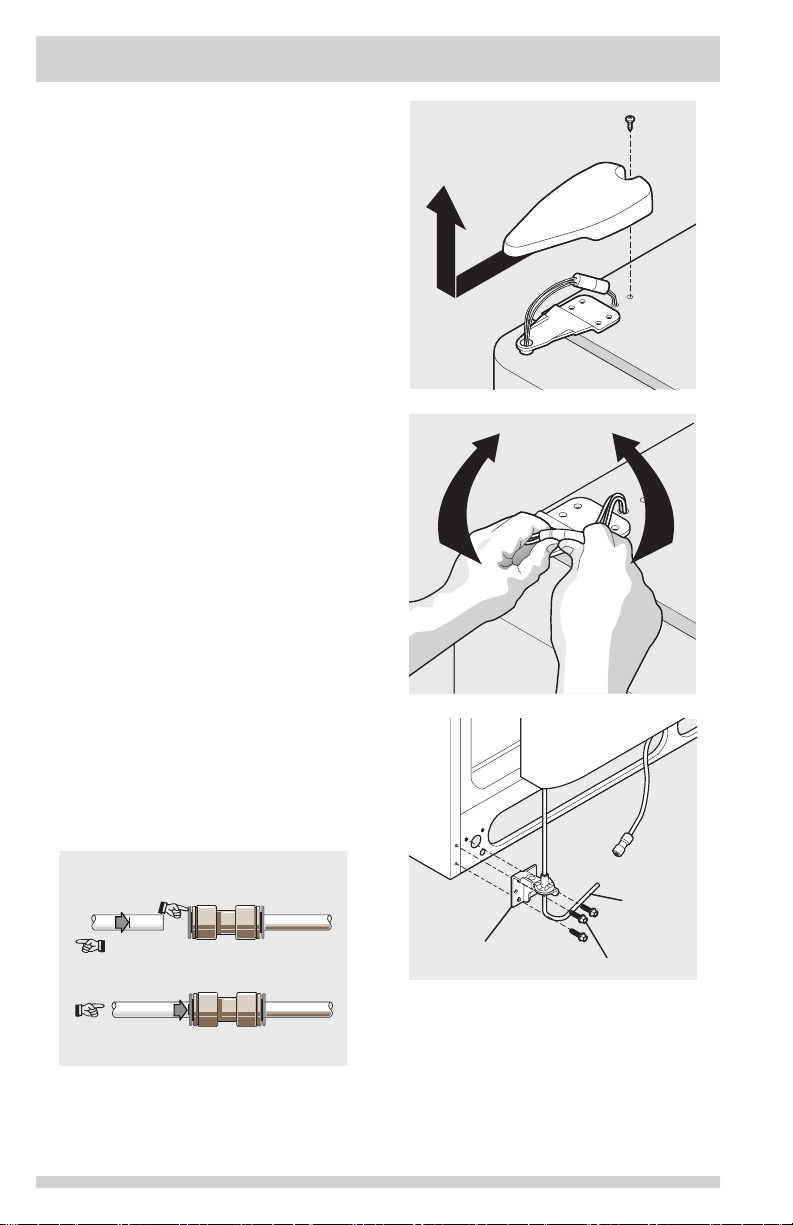

To Remove Freezer Door:

1. Disconnect water line coming from lower

hinge of freezer door at connection

located under front of freezer: Press outer

ring against face of tting, then pull to

remove tube.

2. Remove top hinge cover screw on freezer

door and remove cover.

3. Disconnect wiring harness connector plug

at top hinge: place your thumbs on at

sides of each connector and bend both

parts back and forth, then with rm grasp,

pull both pieces apart.

4. Trace around hinge with soft lead pencil.

This will make it easier to realign doors

when they are replaced.

5. Remove top hinge, allowing wiring harness

to pull through hinge and lift freezer door

off of bottom hinge pin. Lay door down

at to avoid kinking water line.

6. Remove bottom hinge, if necessary.

7. Reverse this procedure to reinstall freezer

door.

When both doors have been reinstalled,

connect water line by inserting tube and push

until mark touches face of tting, replace toe

grille and plug in electrical power cord. Turn

both temperature controls to center position.

Adjust settings as necessary.

1. Press outer ring against face of

fitting

2. Pull to

remove tube

To Connect

Insert tube and push until mark

touches face of fitting

8

Hinge

Assembly

Door

Screws

Water

Line

Tubing

Page 9

CONNECTING THE WATER SUPPLY

WARNING

To avoid electric shock, which can cause

death or severe personal injury, disconnect

the refrigerator from electrical power before

connecting a water supply line to the

refrigerator.

CAUTION

To Avoid Property Damage:

• Copper or Stainless Steel braided tubing

is recommended for the water supply

line. Water supply tubing made of ¼

inch plastic is not recommended to be

used. Plastic tubing greatly increases

the potential for water leaks, and the

manufacturer will not be responsible for

any damage if plastic tubing is used for

the supply line.

• DO NOT install water supply tubing in

areas where temperatures fall below

freezing.

• Chemicals from a malfunctioning softener

can damage the ice maker. If the ice

maker is connected to soft water, ensure

that the softener is maintained and

working properly.

• A shutoff valve to connect the water supply

line to your household water system. DO

NOT use a self-piercing type shutoff valve.

• A compression nut and ferrule (sleeve) for

connecting a copper water supply line to the

ice maker inlet valve.

NOTE

Check with your local building authority for

recommendations on water lines and associated materials prior to installing your new

refrigerator.

IMPORTANT

Ensure that your water supply line connections comply with all local plumbing codes.

Before Installing The Water Supply Line,

You Will Need:

• Basic Tools: adjustable wrench, at-blade

screwdriver, and PhillipsTM screwdriver

• Access to a household cold water line with

water pressure between 30 and 100 psi.

• A water supply line made of ¼ inch

(6.4mm) OD, copper or stainless steel

tubing. To determine the length of tubing

needed, measure the distance from the

ice maker inlet valve at the back of the

refrigerator to your cold water pipe. Then

add approximately 7 feet (2.1 meters), so the

refrigerator can be moved out for cleaning

(as shown).

9

Page 10

Steel

CONNECTING THE WATER SUPPLY

To Connect Water Supply Line To Ice Maker

Inlet Valve

1. Disconnect refrigerator from electric power

source.

2. Place end of water supply line into sink or

bucket. Turn ON water supply and ush

supply line until water is clear. Turn OFF

water supply at shutoff valve.

3. Remove plastic cap from water valve inlet

and discard cap.

4. If you use copper tubing - Slide brass

compression nut, then ferrule (sleeve)

onto water supply line. Push water supply

line into water valve inlet as far as it

will go (¼ inch/6.4 mm). Slide ferrule

(sleeve) into valve inlet and nger tighten

compression nut onto valve. Tighten

another half turn with a wrench; DO NOT

over tighten. See Figure 1.

If you use braided exible stainless

steel tubing - The nut is already

assembled on the tubing. Slide nut onto

valve inlet and nger tighten nut onto valve.

Tighten another half turn with a wrench; DO

NOT over tighten. See Figure 2.

5. With steel clamp and screw, secure water

supply line (copper tubing only) to rear

panel of refrigerator as shown.

6. Coil excess water supply line (copper tubing

only), about 2½ turns, behind refrigerator

as shown and arrange coils so they do not

vibrate or wear against any other surface.

7. Turn ON water supply at shutoff valve and

tighten any connections that leak.

8. Reconnect refrigerator to electrical power

source.

9. To turn ice maker on, lower wire signal

arm (side mounted) or set the ice maker’s

On/Off power switch to the “I” position

(rear mounted).

IMPORTANT

After connecting the water supply, refer to

“How to Prime the Water Supply System”

for important information about priming an

empty water supply system.

Your refrigerator’s water supply system

includes several tubing lines, a water lter,

a water valve, and a water tank. To ensure

that your water dispenser works properly,

this system must be completely lled with

water when your refrigerator is rst con-

nected to the household water supply line.

Plastic Water

Tubing to Ice

Maker Fill

Tube

Clamp

Brass

Compression

Nut

Ferrule

(Sleeve)

Copper

water line

Water Valve

Bracket

Valve Inlet

Water Valve

Copper water line

from household

water supply

(Include enough tubing in loop to allow

moving refrigerator out for cleaning.)

Figure 1

Plastic Water Tubing

to Ice Maker

Fill Tube

Steel

Clamp

Braided

Flexible

Stainless

Steel

Water Line

Water Valve

Bracket

Valve Inlet

Water Valve

6 ft (1.8 Meters) Braided flexible

stainless steel water line from

household water supply.

(Include enough tubing in loop to allow

moving refrigerator out for cleaning.)

Figure 2

10

Page 11

CONTROLS

NOTE

When changing control settings, wait 24 hours for the temperature to stabilize before making

additional changes.

Allowing Cooling Time Before Use

To ensure safe food storage, allow your refrigerator to operate with the doors closed for at least

8 to 12 hours before placing food inside. During this cooling period, you do not need to adjust

the controls, which are preset at the factory.

Setting Cooling Temperatures

Your refrigerator comes with a state-of-the-art electronic digital control system. The system’s

control panel is located at the top of the the fresh food compartment.

The two digital displays on the left half of the control panel indicate the current settings

or temperatures of your freezer and fresh food compartments. The models with a 2-digit

temperature display are for reference only, and do not display the current accurate compartment

temperature. Should you desire to see what the current accurate temperature is, place a

separate thermometer inside the freezer or fresh food compartment in the desired location.

NOTE

The advanced electronic control system in your refrigerator includes additional display modes

that service professionals can use to rapidly diagnose performance issues.

(Single Digit Display - Features may vary according to model.)

11

Page 12

CONTROLS

TEMPERATURE ADJUSTMENT

To adjust the temperature to a higher or lower setting, press the Up (Cold) or Down (Colder)

button closest to the display. The rst time you press the button, the display shows current

setting you entered. Each press of the button after that changes the setting by one.

The display shows your new setting momentarily, then changes back to the current temperature.

Temperature Adjustment

If Fresh Food compartment is too

warm

If Fresh Food compartment is

too cold

If Freezer compartment is too

warm

If Freezer compartment is too

cold

IF TEMPERATURE DISPLAYS FLASH...

If ever you see both temperature displays continuously ashing, it may indicate that the control

system has detected a performance problem. Call your service representative, who can interpret

the ashing message.

To maintain temperatures, a fan circulates air in the refrigerator and freezer compartments. For

good circulation, do not block cold air vents with food items.

Adjust Fresh Food control one

degree colder by pressing Down

(Colder) button.

Adjust Fresh Food control one

degree warmer by pressing the Up

(Cold) button.

Adjust Freezer control one degree

colder by pressing Down (Colder)

button.

Adjust Freezer control one degree

warmer by pressing the Up (Cold)

button.

Numeric Display

Freezer Fresh Food

Warmest 1 1

Factory Setting 6 6

Coldest 9 9

NOTE

Pressing the On/Off button on the control panel disables your refrigerator’s cooling system

but does not disconnect power to lights and other electrical components. To turn off power to

your refrigerator you must unplug the power cord from the wall outlet.

Each time you make settings on the control panel, a single audible tone acknowledges your

input.

Turning the Cooling system on and off

You can disable the cooling system in your refrigerator by pressing the On/Off button located on

the left side of the temperature control panel. To ensure that you do not accidentally turn off the

cooling system, the button does not work unless you press and hold it for three seconds. Once

you disable the cooling system, all refrigeration to the freezer and fresh food compartments

stops. To turn the cooling system back on, you must again press and hold the On/Off button for

three more seconds.

12

Page 13

CAUTION

Higher Humidity Lower Humidity

To avoid personal injury or property

damage, handle tempered glass shelves

carefully. Shelves may break suddenly if

nicked, scratched, or exposed to sudden

temperature change. See “Glass Shelves” in

Care & Cleaning Chart.

Cantilever Shelf Adjustment

Refrigerator shelves are easily adjusted to

suit individual needs. Before adjusting the

shelves, remove all food. Cantilever shelves are

supported at the back of the refrigerator.

To adjust cantilever shelves:

1 Lift front edge up.

2 Pull shelf out.

Replace the shelf by inserting the hooks at

rear of the shelf into the wall bracket. Lower

the shelf into the desired slots and lock into

position.

SpillSafeTM glass shelves (some models) catch

and hold accidental spills. In some models, the

SpillSafeTM shelves slide out for easy access to

food and for fast cleaning. The shelves slide

out independently of their mounting brackets.

Just pull the front of the shelf forward.

Shelves can be extended as far as the stopper

will allow but are not removable from their

mounting brackets.

1

2

Cantilever Glass Shelf

Cantilever Sliding

Glass Shelf

Door storage

Door bins and shelves are provided for

convenient storage of jars, bottles, and cans.

Frequently used items can be quickly selected.

Some models have door bins that can

accommodate gallon-sized plastic drink

containers and economy-sized jars and

containers. Some bins are adjustable for

maximum storage capacity.

The dairy compartment, which is warmer than

the general food storage section, is intended for

short term storage of cheese, spreads, or butter.

STORAGE FEATURES

Fresh Drawers with Humidity

Control (some models)

The fresh drawers, located under the bottom

refrigerator shelf, are designed for storing fruits,

vegetables, and other fresh produce. The fresh

drawers feature humidity control which allows you

to adjust the humidity within the drawer. This can

extend the life of fresh vegetables that keep best

in high humidity. Wash items in clear water and

remove excess water before placing them in the

crispers. Items with strong odors or high moisture

content should be wrapped before storing.

Crisper Humidity Control

NOTE

Leafy vegetables keep best when stored with

the humidity control set on Higher Humidity,

or in a drawer without a Humidity Control.

This keeps incoming air to a minimum and

maintains maximum moisture content.

Crispers

Crispers allow you the

exibility to store any

manner of items including

fruits, vegetables, nuts,

etc. Crispers do not feature

humidity controls.

Cool Drawer (some models)

1

Some models are equipped with a Cool Drawer

2

for storage of luncheon meats, spreads,

cheeses, and other deli items. This drawer

does not have a separate temperature control.

Chill Drawer (some models)

Some models are

equipped with a Chill

Drawer. Chill Drawer

temperatures can be

adjusted by sliding

the Chill Drawer

Temperature Control

in either direction. Use

this pan for short term

storage of bulk meat

items. If meats are to

be kept longer than

one or two days, they

should be frozen. The

Chill Drawer is xed and cannot be moved up or

down. If fruits or vegetables are to be stored in

the Chill Drawer, set the Chill Drawer Temperature

Control to a warmer setting to prevent freezing.

Crisper Drawer

Colder

Warmer

Chill Drawer with

Temperature Control

13

Page 14

AUTOMATIC ICE & WATER DISPENSER

Features may vary according to model.

CUBE Press the CUBE Touch Pad to get cubed ice. A green light will appear above the

CRUSH Press the CRUSH Touch Pad to get crushed ice. A green light will appear above the

LIGHT Press the LIGHT Touch Pad to turn on dispenser light. Press again to turn the

FILTER

STATUS

LOCK The Ice & Water Dispenser can be locked out to prevent unwanted use.

WATER To operate the water dispenser, press a glass against the WATER dispensing

Touch Pad. Press glass against ICE dispensing paddle as far up as possible to catch

all ice.

Touch Pad. Press glass against ICE dispensing paddle as far up as possible to catch

all ice.

light off. The light also turns on automatically when ice and/or water is dispensed.

Replace light bulb with an appliance bulb of the same wattage.

The FILTER STATUS indicator light above the Touch Pad will light up each time the

dispenser is used. The following lter light indications are:

Green The lter is still operating within its specied life cycle.

Amber The lter has reached approximately 80 percent of its useful

life. This is the recommended time to purchase a replacement

lter.

Red The lter is 100 percent used up. Change the lter as soon as

possible.

After the lter cartridge has been changed, press and hold the FILTER RESET

Touch Pad for 10-15 seconds.

NOTE: The Green, Amber and Red lights will ash when reset is completed.

To Lock Out Press the LOCK Touch Pad for 3-5 seconds. A red light will

appear above the Touch Pad.

To Unlock Press the LOCK Touch Pad for 3-5 seconds until the red light

above the Touch Pad goes out.

paddle. To stop dispensing water, pull the glass away from the dispensing paddle.

Dispensed water is not cold. For colder water, add crushed ice or cubes before

dispensing water. A drip tray located at the base of the dispenser catches small

spills and allows them to evaporate. This drip tray is removable and dishwasher

safe. Do not pour water and excess ice in this area because there is no drain.

14

Page 15

AUTOMATIC ICE & WATER DISPENSER

Priming the Water Supply System

Your refrigerator’s water supply system

includes several tubing lines, an advanced

water lter, a distribution valve bank, and a

reserve tank to ensure ample supply to the ice

and water dispenser at all times. This system

needs to be completely lled with water when

rst connected to an external supply line.

CAUTION

For proper dispenser operation, recommended

water supply pressure should fall between 30

psi and 100 psi. Excessive pressure may cause

water lter to malfunction.

To prime the water supply system:

1 Begin lling the tank by pressing and

holding a drinking glass against the water

dispenser paddle.

2 Keep the glass in this position until water

comes out of the dispenser. It may take

about 1½ minutes.

3 Continue dispensing water for about four

minutes to ush the system and plumbing

connections of any impurities (stopping to

empty the glass as necessary).

NOTE

The water dispenser has a built-in device that

shuts off the water ow after three minutes

of continuous use. To reset this shutoff device, simply release the dispenser paddle.

Ice Maker Operation & Care

The ice maker, ice bin, and dispenser feeding

mechanism are located in the top of the freezer

compartment. After the refrigerator is installed

properly and has cooled for several hours, the

ice maker can produce ice within 24 hours. It

can completely ll an ice bin in about two days.

usage conditions. Ice is produced at a rate of 8

cubes every 75 to 90 minutes.

Using the Ice Maker after Installation

Before making ice for the rst time, be sure to prime

the water supply system. Air in new plumbing lines

can result in two or three empty ice maker cycles.

Furthermore, if the system is not ushed, the rst ice

cubes may be discolored or have an odd avor.

IMPORTANT

Small ice cubes or ice chips jamming in the ice

maker may be a sign that your water lter needs

changing. If you have a side mounted ice maker

you may also experience hollow cubes partially

frozen cubes with water inside. When these

cubes are harvested, they break open and spill

water over the other ice cubes in the ice container, forming a solid mass of ice. As the water

lter nears the end of its useful life and becomes

clogged with particles, less water is delivered to

the ice maker during each cycle. The ice maker

can’t ll every cube in the ice maker mold, leading to small cubes or chips that can get caught

between the ice ejector blades and the stripper.

Remember, if your ice maker is jamming with

small ice cubes or it’s been six months or longer

since you last changed your water lter replace

the water lter with a new one. Poor quality

household water may require the lter to be

changed more frequently.

Turning the SIDE MOUNTED Ice

Maker On and Off

To begin ice production, lower the wire signal

arm to the DOWN or ON position. The ice

maker turns off automatically when the ice

container becomes full. To stop the ice maker,

raise the wire signal arm until it clicks and

locks in the UP or OFF position.

ON

Ice Production: What to Expect

How Much Ice Will a Side Mounted Ice

Maker Produce in 24 Hours?

A side mounted ice maker will produce 4 to 4.5

pounds of ice every 24 hours, depending on

usage conditions. Ice is produced at a rate of 8

cubes every 75 to 90 minutes.

How Much Ice Will a Rear Mounted Ice

Maker Produce in 24 Hours?

A rear mounted ice maker will produce 3 to 4

pounds of ice every 24 hours, depending on

OFF

Signal Arm

Wire

15

Page 16

AUTOMATIC ICE & WATER DISPENSER

Wire

Signal Arm

Off On

Turning the REAR MOUNTED Ice

Maker On and Off

Ice production is controlled by the ice maker’s

ON/OFF power switch. To gain access to the

ice maker, pull the ice cream shelf out. Press

the switch to the “O” position to turn it Off and

press it to the “I” position to turn it On. The

ice maker also has a built-in wire signal arm,

which automatically stops ice production when

the ice bin is full. DO NOT use this signal arm

to manually stop the ice maker.

IMPORTANT

Your ice maker is shipped from the factory

with the wire signal arm in the ON position

(side mounted) or with the switch turned ON

(rear mounted). To ensure proper function

of your ice maker, hook up water supply

immediately or turn ice maker OFF by lifting

the wire signal arm until it clicks and locks in

the UP position (side mounted) or turn the

On/Off switch to the Off (0) position (rear

mounted). If the ice maker is not turned off

and the water supply is not connected, the

water valve will make a loud chattering noise.

Ice Maker/Dispenser Tips

• Ice cubes stored too long may develop

an odd avor. Empty the ice container as

explained below.

• Occasionally shake the ice container to

keep ice separated.

• If your refrigerator is not connected to a

water supply or the water supply is turned

off, turn Off the ice maker.

• If you need a large quantity of ice at one

time, it is best to get cubes directly from

the ice container.

16

• The following sounds are normal when the

ice maker is operating:

- Motor running

- Ice dropping into ice container

- Water valve opening or closing

- Ice loosening from tray

- Running water

• When dispensing ice, you will hear a

snapping or clicking sound when the ice

chute opens and closes.

• Turn Off the ice maker when cleaning the

freezer and during vacations.

- If you turn Off the ice maker for a

long period of time, you should also

turn off the water supply valve.

CAUTION

Chemicals from a malfunctioning water softener

can damage the ice maker. If the water supply

to your refrigerator is softened, be sure the

softener is maintained to work properly.

Cleaning the Ice Maker

Clean the ice maker and ice bin at regular

intervals, particularly before you take a

vacation or move.

To clean the ice maker:

1 Turn Off the ice maker.

2 Remove the ice bin by lifting up and out.

3 Empty and carefully clean the ice bin with

mild detergent. Rinse with clear water. Do

not use harsh or abrasive cleaners.

4 Allow the ice bin to dry completely before

replacing in the freezer.

5 Remove ice chips and clean the ice bin

shelf and the freezer door chute.

6 Replace the ice bin. Turn On the ice maker

to resume ice production.

Remove and empty the ice storage bin if:

• An extended power failure (one hour or

longer) causes ice cubes in the ice storage

bin to melt and freeze together, jamming

the dispenser mechanism.

• You do not use the ice dispenser frequently.

Ice cubes will freeze together in the bin,

jamming the dispenser mechanism.

Remove the ice storage bin and shake to

loosen the cubes or clean as explained above.

Page 17

AUTOMATIC ICE & WATER DISPENSER

Auger

CAUTION

NEVER use an ice pick or similar sharp

instrument to break up the ice. This could

damage the ice storage bin and dispenser

mechanism.

IMPORTANT

When removing or replacing the ice bin,

DO NOT rotate the auger in the ice bin. If

the auger is accidentally rotated, you must

realign the auger by turning it in 90 degree

turns (see below) until the ice bin ts into

place with the drive mechanism. If the

auger is not properly aligned when replac-

ing the ice bin, the refrigerator will only

dispense Crushed Ice. The freezer door may

also not close properly causing warm air to

leak into the freezer.

17

Page 18

CHANGING THE FILTER

Locating the Filter

Your refrigerator is equipped with a water

ltering system. The water lter system lters

all dispensed drinking water, as well as the

water used to produce ice.

Water Filter

The water lter is located at the top right side

of the fresh food compartment.

Replacing the Water Filter

In general, you should change the water

lter every six months to ensure the highest

possible water quality. Water Filter Status

on the user interface prompts you to replace

the lter after a standard amount of water

(200 gallons/757 liters for PureSource 3TM)

has owed through the system.

If your refrigerator has not been used for a

period of time (during moving for example),

change the lter before reinstalling the

refrigerator.

Filter Cartridge

Ordering Replacement Filters

To order your replacement lters, please

contact manufacturer.

Here are the product numbers to request when

ordering:

PureSource 3

Water Filter

Part #WF3CB

TM

18

More about your Advanced

Water Filter

The PureSource 3TM ice and water

lter system is tested and certied

to NSF/ANSI Standards 42 and 53

for the reduction of claims specied

on the performance data sheet.

Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system. Systems

certied for cyst reduction may be used on

disinfected waters that may contain lterable cysts.

Test & certication results:

• Rated Capacity - 200 gallons/757 liters for

PureSource 3TM ice and water lter

• Rated service ow - .50 gallons per minute

• Operating Temp.: Min. 33°F, Max. 100°F

• Maximum Rated Pressure - 100 pounds per

square inch

• Recommended Minimum Operating

Pressure: 30 pounds per square inch

To replace your PureSource 3TM water

lter:

It is not necessary to turn the water supply off

to change the lter. Be ready to wipe up any

small amounts of water released during the

lter replacement.

1 Turn Off the ice maker.

2 Remove the lter by pushing on the end/

face of the lter.

3 Slide the old water lter cartridge straight

out of the housing and discard it.

4 Unpackage the new lter cartridge. Using

the alignment guide, slide it gently into the

lter housing until it stops against the snap-

in connector at the back of the housing.

5 Push rmly until the cartridge snaps into

place (you should hear a click as the

cartridge engages the snap-in connector).

6 Press a drinking glass against the water

dispenser while checking for any leaks at

the lter housing. Any spurts and sputters

that occur as the system purges air out of

the dispenser system are normal.

7 After lling one glass of water, continue

ushing the system for about four minutes.

8 Turn On the ice maker.

9 Press and hold the Water Filter button on the

Ice & Water Dispenser control panel for three

seconds. When the display changes from

“Red” to “Green,” the status has been reset.

Page 19

D

OR

NORMAL OPERATING SOUNDS AND SIGHTS

Understanding the Sounds you

may Hear

Your new, high-efciency refrigerator may

introduce unfamiliar sounds. These sounds

normally indicate your refrigerator is operating

correctly. Some surfaces on oors, walls, and

kitchen cabinets may make these sounds more

noticeable.

Following is a list of major components in your

refrigerator and the sounds they can cause:

A Evaporator Refrigerant through the

evaporator may create a boiling or

gurgling sound.

B Evaporator fan You may hear air being

forced through the refrigerator by the

evaporator fan.

C Defrost heater During defrost cycles,

water dripping onto the defrost heater

may cause a hissing or sizzling sound.

After defrosting, a popping sound may

occur.

D Automatic ice maker When ice has

been produced, you will hear ice cubes

falling into the ice bin.

E Electronic control & automatic

defrost control These parts can produce

a snapping or clicking sound when turning

the cooling system on and off.

F Condenser fan You may hear air being

forced through the condenser.

G Compressor Modern, high-efciency

compressors run much faster than in the

past. The compressor may have a highpitched hum or pulsating sound.

H Water valve Makes a buzzing sound each

time it opens to ll the ice maker.

I Drain pan (not removable) You may hear

water dripping into the drain pan during

the defrost cycle.

J Condenser May create minimal sounds

from forced air.

K Motorized damper May produce a light

humming during operation.

L Ice chute When dispensing ice, you will

hear a snapping or clicking sound when

the solenoid opens and closes the ice

chute.

NOTE

Energy efcient foam in your refrigerator is

not a sound insulator.

NOTE

During automatic defrost cycle, a red glow in

the back wall vents of your freezer compartment is normal.

19

Page 20

CARE & CLEANING

Protecting your investment

Keeping your refrigerator clean maintains appearance and prevents odor build-up. Wipe up any

spills immediately and clean the freezer and fresh food compartments at least twice a year.

When cleaning, take the following precautions:

• Never use CHLORIDE or cleaners with bleach to clean stainless steel.

• Do not wash any removable parts in a dishwasher.

• Always unplug the electrical power cord from the wall outlet before cleaning.

• Remove adhesive labels by hand. Do not use razor blades or other sharp instruments which

can scratch the appliance surface.

• Do not remove the serial plate.

Do not use abrasive cleaners such as window sprays, scouring cleansers, brushes, ammable

uids, cleaning waxes, concentrated detergents, bleaches or cleansers containing petroleum

products on plastic parts, interior doors, gaskets or cabinet liners. Do not use paper towels,

metallic scouring pads, or other abrasive cleaning materials or strong alkaline solutions.

NOTE

If you set your temperature controls to turn off cooling, power to lights and other electrical

components will continue until you unplug the power cord from the wall outlet.

CAUTION

• Pull the refrigerator straight out to move it. Shifting it from side to side may damage

ooring. Be careful not to move the refrigerator beyond the plumbing connections.

• Damp objects stick to cold metal surfaces. Do not touch refrigerated surfaces with wet or

damp hands.

IMPORTANT

If you store or move your refrigerator in freezing temperatures, be sure to completely drain

the water supply system. Failure to do so could result in water leaks when the refrigerator is

put back into service. Contact a service representative to perform this operation.

20

Page 21

CARE & CLEANING

Care & Cleaning Tips

Part What To Use Tips and Precautions

Interior & Door

Liners

Door Gaskets • Soap and water Wipe gaskets with a clean soft cloth.

Drawers & Bins • Soap and water Use a soft cloth to clean drawer runners and tracks.

Glass Shelves • Soap and water

Toe Grille • Soap and water

Exterior &

Handles

Exterior &

Handles

(Stainless Steel

Models Only)

• Soap and water

• Baking soda and

water

• Glass cleaner

• Mild liquid

sprays

• Mild liquid

sprays

• Vacuum

attachment

• Soap and water

• Non Abrasive

Glass Cleaner

• Soap and water

• Stainless Steel

Cleaners

Use 2 tablespoons of baking soda in 1 quart of warm

water. Be sure to wring excess water out of sponge

or cloth before cleaning around controls, light bulb or

any electrical part.

Allow glass to warm to room temperature before

immersing in warm water.

Vacuum dust from front of toe grille. Remove

toe grille (see Installation Instructions). Vacuum

backside, wipe with sudsy cloth or sponge. Rinse and

dry.

Do not use commercial household cleaners

containing ammonia, bleach or alcohol to clean

handles. Use a soft cloth to clean smooth handles.

DO NOT use a dry cloth to clean smooth doors.

Never use CHLORIDE or cleaners with bleach to

clean stainless steel.

Clean stainless steel front and handles with nonabrasive soapy water and a dishcloth. Rinse with

clean water and a soft cloth. Use a non-abrasive

stainless steel cleaner. These cleaners can be

purchased at most home improvement or major

department stores. Always follow manufacturer’s

instructions. Do not use household cleaners

containing ammonia or bleach.

Replacing Light

Bulbs

• Unplug

refrigerator

• Wear gloves

• Remove light

cover

• Replace old bulb

• Replace light

cover

• Plug in the

refrigerator

NOTE: Always clean, wipe and dry with the grain to

prevent scratching. Wash the rest of the cabinet with

warm water and mild liquid detergent. Rinse well,

and wipe dry with a clean soft cloth.

CAUTION: Wear gloves when replacing light

bulbs to avoid getting cut.

Use same wattage when replacing bulb

21

Page 22

BEFORE YOU CALL

PROBLEM CAUSE CORRECTION

AUTOMATIC ICE MAKER

Ice maker is not

making any ice.

Ice maker is not

making enough

ice.

Ice maker will not

stop making ice.

Ice cubes are

freezing together.

ICE DISPENSER

Dispenser will not

dispense ice.

Ice dispenser is

jammed.

• Ice maker wire signal

arm is in the “up” or

OFF position.

• Ice maker power

switch is Off.

• Ice maker has small

cube caught in

mechanism.

• Saddle valve on cold

water pipe is clogged

or restricted by foreign

material.

• Ice maker is producing

less ice than you

expect.

• Check to see if water

dispenser is dispensing

slower than normal.

• Ice maker wire signal arm

is being held down by

some item in the freezer.

• Ice cubes are not being

used frequently enough.

• Ice cubes are hollow

(partially frozen cubes

with water inside).

• Freezer control is set

too warm.

• Ice storage container is

empty.

• Freezer temperature is

set too warm.

• Household water line

valve is not open.

• Ice dispensing arm has

been held in for more

than 4-5 minutes.

• Ice has melted and

frozen around auger

due to infrequent

use, temperature

uctuations, and/or

power outages.

• Ice cubes are jammed

between ice maker and

back of ice container.

• Move wire signal arm to the “down” or

ON position. (side mounted)

• Turn power switch to On (“I”) position.

(rear mounted)

• Remove small cube from ice maker. The

ice and water lter cartridge may be

clogged. Replace lter cartridge.

• Turn off household water line valve.

Remove valve. Ensure that valve is not

a self-piercing saddle valve. Clean valve.

Replace valve if necessary.

• Side mounted ice maker should produce

4 to 4.5 pounds (approximately 4 quarts)

of ice every 24 hours. A rear mounted

ice maker should produce 3 to 4 pounds

(approximately 3½ quarts) of ice every 24

hours. Quick Ice option should produce up

to 50% more ice every 24 hours.

• If it is, replace the ice and water lter

cartridge.

• Move item and release wire signal arm.

Remove any ice cubes that are frozen

together over the wire signal arm.

• Remove ice container and discard ice from

container. Ice maker will produce fresh supply.

• The ice and water lter cartridge may be

clogged. Replace lter cartridge.

• Set freezer control to colder setting. Allow

24 hours for temperature to stabilize.

• When the rst supply of ice is dropped into

the container, the dispenser should operate.

• Turn freezer control to a higher setting so that

ice cubes will be made. When rst supply of

ice is made, dispenser should operate.

• Open household water line valve. Allow

sufcient time for the ice to be made. When

ice is made, the dispenser should operate.

• Motor is overloaded. Motor over load

protector will reset in approximately 3

minutes. Ice can then be dispensed.

• Remove ice container, thaw, and empty

the contents. Clean container, wipe dry,

and replace in proper position. When new

ice is made, dispenser should operate.

• Remove ice cubes that are jamming the

dispenser.

22

Page 23

BEFORE YOU CALL

PROBLEM CAUSE CORRECTION

OPENING/CLOSING OF DOORS/DRAWERS

Door(s) will not

close.

Drawers are

difcult to move.

RUNNING OF REFRIGERATOR

Compressor does

not run.

Refrigerator runs

too much or too

long.

Compressor

goes off and on

frequently.

• Door was closed too

hard, causing other

door to open slightly.

• Refrigerator is not level.

It rocks on the oor

when moved slightly.

• Refrigerator is touching

a wall or cabinet.

• Food is touching shelf

on top of drawer.

• Track that drawers

slide on is dirty.

• Freezer control is set

to “OF” or “0”.

• Refrigerator is in

defrost cycle.

• Plug at electrical outlet

is disconnected.

• House fuse blown or

tripped circuit breaker.

• Power outage.

• Room or outside

weather is hot.

• Doors are opened too

frequently or too long.

• Fresh Food/freezer

door may be slightly

open.

• Freezer control is set

too cold.

• Fresh Food/freezer

gasket is dirty, worn,

cracked, or poorly tted.

• Condenser is dirty.

• Thermostat keeps

the refrigerator at a

constant temperature.

• Close both doors gently.

• Ensure oor is level and solid, and can

adequately support the refrigerator. Contact a

carpenter to correct a sagging or sloping oor.

• Ensure oor is level and solid, and can

adequately support the refrigerator. Contact a

carpenter to correct a sagging or sloping oor.

• Remove top layer of items in drawer.

• Ensure drawer is properly installed on track.

• Clean drawer, rollers, and track. See Care

& Cleaning.

• Set freezer control.

• This is normal for a fully automatic defrost

refrigerator. The defrost cycle occurs

periodically, lasting about 30 minutes.

• Ensure plug is tightly pushed into outlet.

• Check/replace fuse with a 15 amp timedelay fuse. Reset circuit breaker.

• Check house lights. Call local electric

company.

• It’s normal for the refrigerator to work

longer under these conditions.

• Warm air entering the refrigerator causes

it to run more. Open doors less often.

• Ensure refrigerator is level. Keep food

and contains from blocking door. See

PROBLEM column OPENING/CLOSING

OF DOORS/DRAWERS.

• Set Fresh Food control to warmer

setting until refrigerator temperature

is satisfactory. Allow 24 hours for

temperature to stabilize.

• Clean or change gasket. Leaks in door

seal will cause refrigerator to run longer in

order to maintain desired temperatures.

• Clean condenser. See Care & Cleaning.

• This is normal. Refrigerator goes on and

off to keep temperature constant.

23

Page 24

BEFORE YOU CALL

PROBLEM CAUSE CORRECTION

DIGITAL TEMPERATURE DISPLAY

Digital temperature

displays are

ashing.

WATER DISPENSER

Dispenser will not

dispense water.

Water has an odd

taste and/or odor.

Water pressure is

extremely low.

WATER/MOISTURE/FROST INSIDE REFRIGERATOR

Moisture collects

on inside of

refrigerator walls.

Water collects on

bottom side of

drawer cover.

Water collects in

bottom of drawer.

WATER/MOISTURE/FROST OUTSIDE REFRIGERATOR

Moisture collects

on outside of

refrigerator or

between doors.

• Electronic control

system has detected a

performance problem.

• Household water line

valve is not open.

• Ice and water lter

cartridge is clogged.

• Filter not fully installed.

• Water has been in the

tank for a period of

time.

• Unit not properly

connected to cold

water line.

• Cut-off and cut-on

pressures are too low

(well systems only).

• Reverse osmosis

system is in

regenerative phase.

• Weather is hot and

humid.

• Door is slightly open.

• Vegetables contain

and give off moisture.

• Washed vegetables

and fruit drain while in

the drawer.

• Weather is humid.

• Door is slightly open,

causing cold air from

inside refrigerator to

meet warm air from

outside.

• Call your Frigidaire service representative,

who can interpret any messages or number

codes ashing on the digital displays.

• Open household water line valve. See

PROBLEM column AUTOMATIC ICE MAKER.

• Replace lter cartridge.

• Push lter in until you hear a “click”.

• Draw and discard 10-12 glasses of water

to freshen the supply and completely

rinse out the tank.

• Connect unit to cold water line that

supplies water to the kitchen faucet.

• Have someone turn up the cut-off and

cut-on pressure on the water pump

system (well systems only).

• It is normal for a reverse osmosis

system to be below 20 psi during the

regenerative phase.

• The rate of frost buildup and internal

sweating increases.

• See PROBLEM column OPENING/

CLOSING OF DOORS/DRAWERS.

• It is not unusual to have moisture on the

bottom side of the cover.

• Move humidity control (some models) to

lower setting.

• Dry items before putting them in the

drawer. Water collecting in bottom of

drawer is normal.

• This is normal in humid weather. When

humidity is lower, the moisture should

disappear.

• See PROBLEM column OPENING/

CLOSING OF DOORS/DRAWERS.

24

Loading...

Loading...