Page 1

installation instructions

G_s

Instrucciones de Instalaci6n

Printed in U.S.A.

P/N 137153400A (0903)

Page 2

Table of Contents

Important Safety Instructions ................................................ 2

Pre-installation Requirements ................................................ 2

Installation Requirements .................................................. 3-7

Installed Dimensions ............................................................. 8

Installation Instructions ................................................... 9-11

Reversing door .................................................................... 12

Accessories/Replacement parts ............................................ 12

Espa_ol............................................................................... 13

Important Safety Instructions

Foryour safety the information in this manual must be followed to minimize the risk of fire or explosion or to

prevent property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

Recognize safety symbols, words and labels

Safety items throughout this manual are labeled with a

WARNING or CAUTION based on the risk type as described:

- RISK OF FIRE - Read all of the following instructions before installing and using this appliance:

• Destroy the carton and plastic bags after the dryer is unpacked. Children might use them for play. Cartons covered with

rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Placeall materials in a garbage

container or make materials inaccessible to children.

Clothes dryer installation and service must be performed by a qualified installer, service agency or the gas supplier.

Install the clothes dryer according to the manufacturer's instructions and local codes.

The electrical service to the dryer must conform with local codes and ordinances and the latest edition of the National

Electrical Code, ANSI/NFPA70, or in Canada, the Canadian electrical code C22.1 part 1.

The gas serviceto the dryer must conform with local codes and ordinances and the latest edition of the National Fuel Gas

Code ANSI Z223.1, or in Canada, CAN/ACG B149.1-2000.

The dryer is designed under ANSI Z 21.5.1 or ANSI/UL 2158 - CAN/CSA C22.2 No. 112 (latest editions) for HOME USE

only. This dryer is not recommended for commercial applications such as restaurants, beauty salons, etc.

Do not install a clothes dryer with flexible plastic venting material. Flexible venting materials are known to collapse, be eas-

ily crushed and trap lint. These conditions will obstruct clothes dryer airflow and increase the risk of fire.

The instructions in this manual and all other literature included with this dryer are not meant to cover every possible

condition and situation that may occur. Good safe practice and caution MUST be applied when installing, operating and

maintaining any appliance.

_This symbol alerts you to situations that

may cause serious body harm, death or

property damage.

This symbol alerts you to situations that may

-- cause bodily injury or property damage.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Save these instructions for future reference.

Pre-lnstallation Requirements

Tools and materials needed for installation:

Adjustable pliers

Phillips, straight, & square bit screw-

drivers

Adjustable wrench

Pipe wrench for gas supply (gas dryer)

LP-resistant thread tape (for natural

gas or LPsupply, gas dryer)

Carpenter's level

External vent hood

4-inch (10.2 cm), rigid metal or semi-

rigid metal exhaust duct work

3-wire or 4-wire 240 volt cord kit

(electric dryer)

4 in. (10.2 cm) clamp

Gas line shutoff valve (gas dryer)

1/2NPT union flare adapters (x2) and

flexible gas supply line (gas dryer)

Metal foil tape (not duct tape)

Page 3

Electrical System Requirements

Because of potentially inconsistent voltage capabilities, the use of this dryer with power created by gas powered gen-

erators, solar powered generators, wind powered generators or any other generator other than the local utility company is not

recommended.

Electrical requirements for electric dryer

CIRCUIT- Individual 30 amp. branch circuit fused with 30 amp. time delay fuses or circuit breakers. Use separately fused

circuits for washer and dryer. DO NOT operate a washer and a dryer on the same circuit.

POWERSUPPLY- 3-wire or 4-wire, 240 volt, single phase, 60 Hz, Alternating Current.

This dryer is internally grounded to neutral unless it was manufactured for sale in Canada. Grounding through

the neutral link is prohibited for: (1) new branch circuit installations, (2) mobile homes, (3) recreational vehicles, and (4) areas

where local codes do not permit grounding through the neutral.

OUTLETRECEPTACLE- NEMA 10-30R or NEMA 14-30R receptacle to be located so the power supply cord isaccessiblewhen the

dryer is in the installed position.

GROUNDING CONNECTION - See "Grounding requirements" in Electrical Installation section.

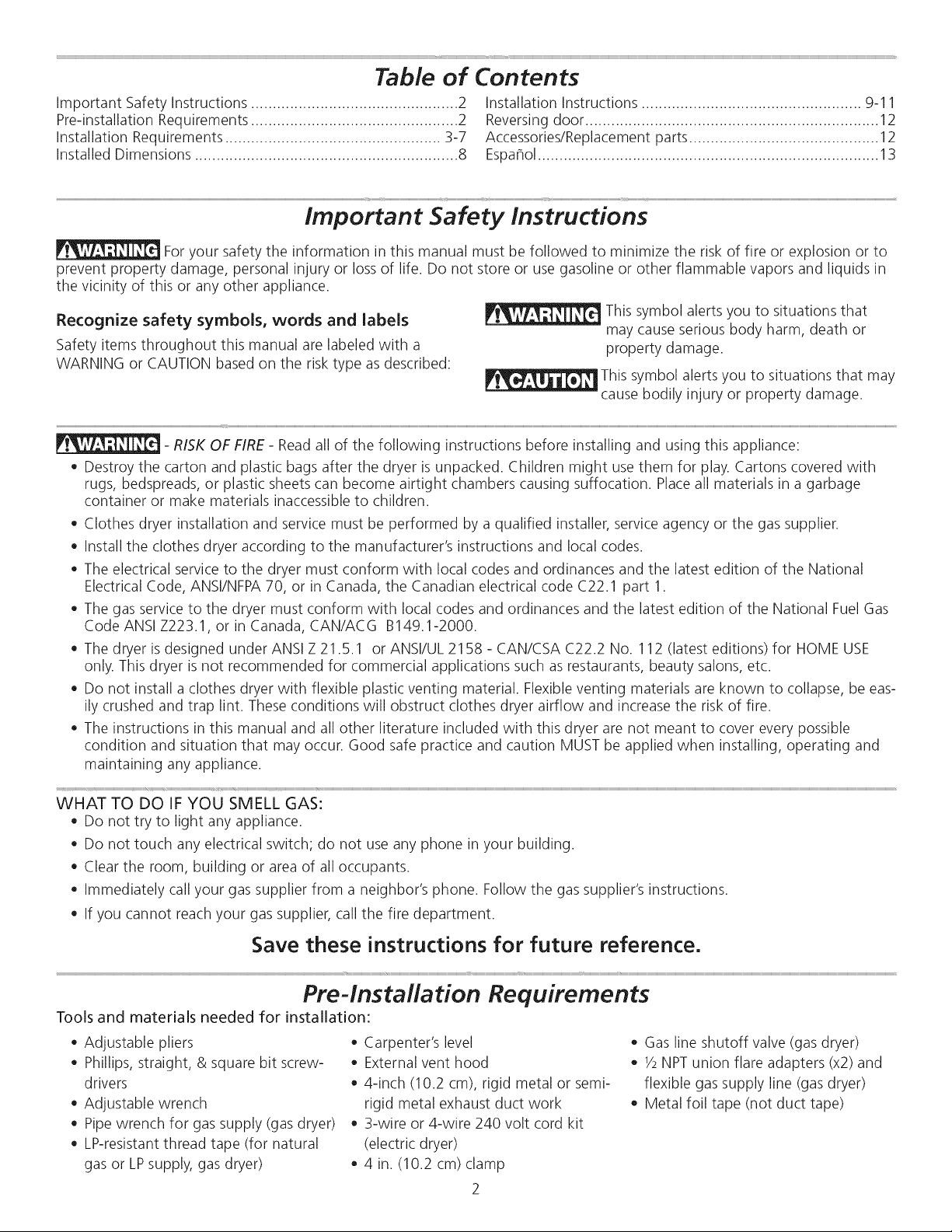

3-WIRE POWER SUPPLY CORD KIT (not supplied)

4-WIRE POWER SUPPLY CORD KIT (not supplied)

3-wire receptacle

(NEMA type 10-30R)

The dryer MUST employ a 3-conductor power supply cord

NEMA 10-30 type SRDTrated at 240 volt AC minimum,

30 amp, with 3 open end spade lug connectors with

upturned ends or closed loop connectors and marked

for use with clothes dryers. For3-wire cord connection

instructions see ELECTRICALCONNECTIONSFORA

3-WIRE SYSTEM.

The dryer MUST employ a 4-conductor power supply cord

NEMA 14-30 type SRDTor ST(as required) rated at 240

volt AC minimum, 30 amp, with 4 open end spade lug

connectors with upturned ends or closed loop connectors

and marked for use with clothes dryers. For4-wire cord

connection instructions see ELECTRICALCONNECTIONS

FORA 4-WIRE SYSTEM.

Dryers manufactured for sale in Canada have factory-

installed, 4-wire power supply cord (NEMA 14-30R).

Electrical requirements for gas dryer

CIRCUIT- Individual, properly polarized and grounded 15 amp. branch

circuit fused with 15 amp. time delay fuse or circuit breaker.

POWERSUPPLY- 2-wire, with ground, 120 volt, single phase, 60 Hz,

Alternating Current.

POWERSUPPLYCORD - The dryer is equipped with a 120 volt 3-wire power

cord.

4-wire receptacle

(NEMA type 14-30R)

Groundingtype

wallreceptacle

f

Do not, under

any circumstances,

cut, remove,

or bypassthe

grounding prong.

GROUNDING CONNECTION - See "Grounding requirements" in Electrical

Installation section.

Powercord with

3-prong grounded plug

Page 4

Gas supply requirements

- EXPLOSION HAZARD - Uncoated copper

tubing will corrode when subjected to natural gas, causing

gas leaks. Use ONLY black iron, stainless steel, or plastic-coat-

ed brass piping for gas supply.

1. Installation MUST conform with local codes, or in the

absence of local codes, with the National FuelGas Code,

ANSI Z223.1 (latest edition).

2. The gas supply line should be 1/2 inch (1.27 cm) pipe.

3. If codes allow, flexible metal tubing may be used to

connect your dryer to the gas supply line. The tubing

MUST be constructed of stainlesssteel or plastic-coated

brass.

4. The gas supply line MUST have an individual shutoff valve.

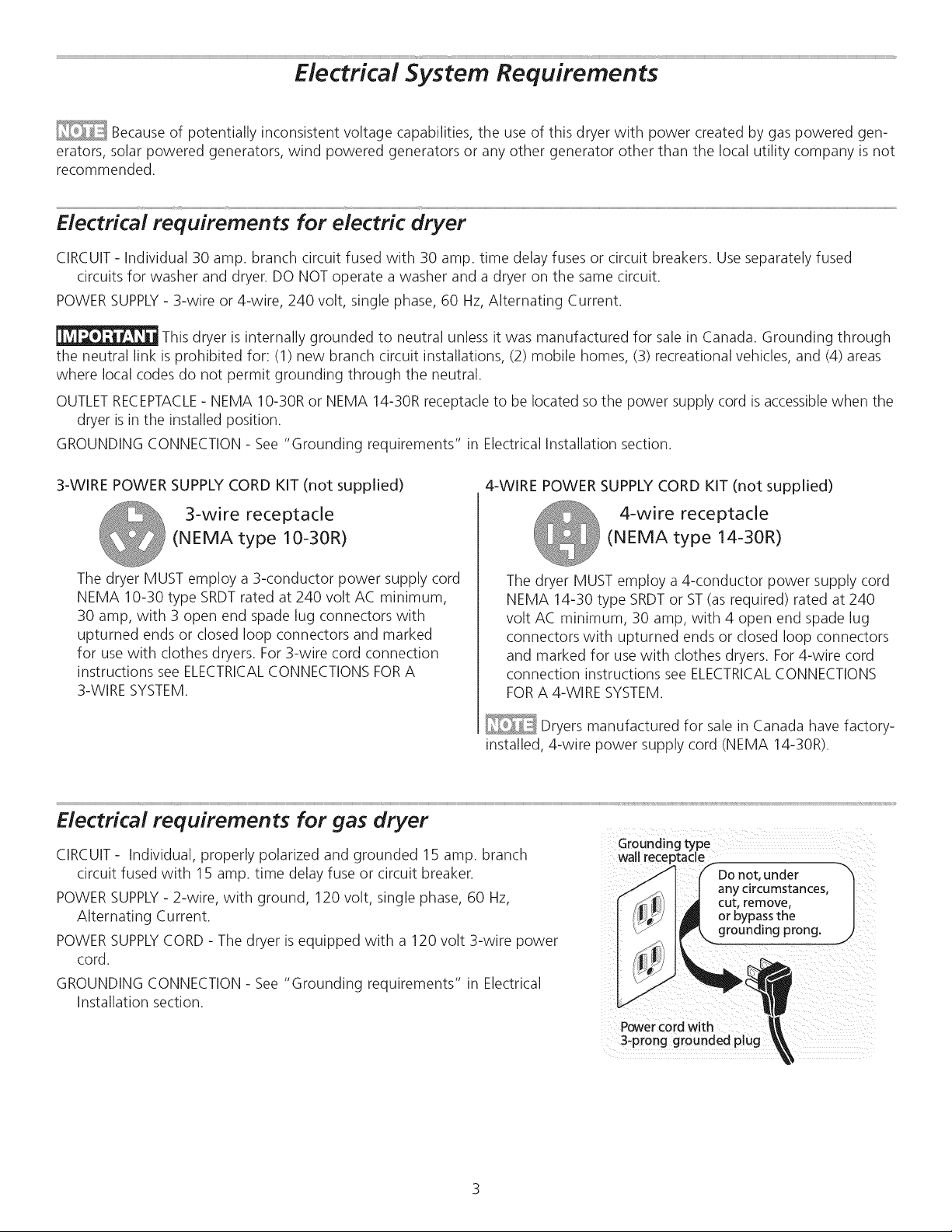

Exhaust system requirements

Use only 4 inch (10.2 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When

the dryer stops, the dampers automatically close to prevent

drafts and the entrance of insects and rodents. Toavoid

restricting the outlet, maintain a minimum of 12 inches (30.5

cm) clearance between the vent hood and the ground or any

other obstruction.

5. A 1/8 inch (0.32 cm) N.RT.plugged tapping, accessible

for test gauge connection, MUST be installed immediately

upstream of the gas supply connection to the dryer.

6. The dryer MUST be disconnected from the gas supply

piping system during any pressure testing of the gas

supply piping system at test pressures in excess of 1/2 psig

(3.45 kPa).

7. The dryer MUST be isolated from the gas supply piping

system during any pressure testing of the gas supply

piping system at test pressures equal to or lessthan 1/2

psig (3.45 kPa).

8. Connections for the gas supply must comply with the

Standard for Connectors for Gas Appliances, ANSI Z21.24.

- FIRE HAZARD - Failure to follow these in-

structions can create excessive drying times and fire hazards.

The following are specific requirements for

proper and safe operation of your dryer.

- FIRE HAZARD - Do not install a clothes

dryer with flexible plastic or metal foil venting materials.

Flexible venting materials are known to collapse, be easily

crushed and trap lint. These conditions will obstruct clothes

dryer airflow and increase the risk of fire.

If your present system is made up of plastic duct or metal foil

duct, replace it with a rigid or semi-rigid metal duct. Also,

ensure the present duct isfree of any lint prior to installing

dryer duct.

Correct Incorrect

Page 5

Exhaust system requirements, continued

- FIRE HAZARD - A clothes dryer must be

exhausted outdoors. Do not exhaust dryer into a chimney, a

wall, a ceiling, an attic, a crawl space or any concealed space

of a building. A clothes dryer produces combustible lint. If

the dryer is not exhausted outdoors, some fine lint will be

expelled into the laundry area. An accumulation of lint in any

area of the home can create a health and fire hazard.

The dryer must be connected to an exhaust outdoors.

Regularly inspect the outdoor exhaust opening and remove

any accumulation of lint around the outdoor exhaust opening

and in the surrounding area.

- FIRE HAZARD -

• Do not allow combustible materials (for example: clothing,

draperies/curtains, paper) to come in contact with exhaust

system. The dryer MUST NOT be exhausted into a chim-

ney, a wall, a ceiling, or any concealed space of a building

which can accumulate lint, resulting in a fire hazard.

Do not screen the exhaust ends of the vent system, or use

any screws, rivets or other fasteners that extend into the

duct to assemble the exhaust system. Lint can become

caught in the screen, on the screws or rivets, clogging the

duct work and creating a fire hazard aswell as increasing

drying times. Use an approved vent hood to terminate the

duct outdoors, and seal all joints with duct tape. All male

duct pipe fittings MUST be installed downstream with the

flow of air.

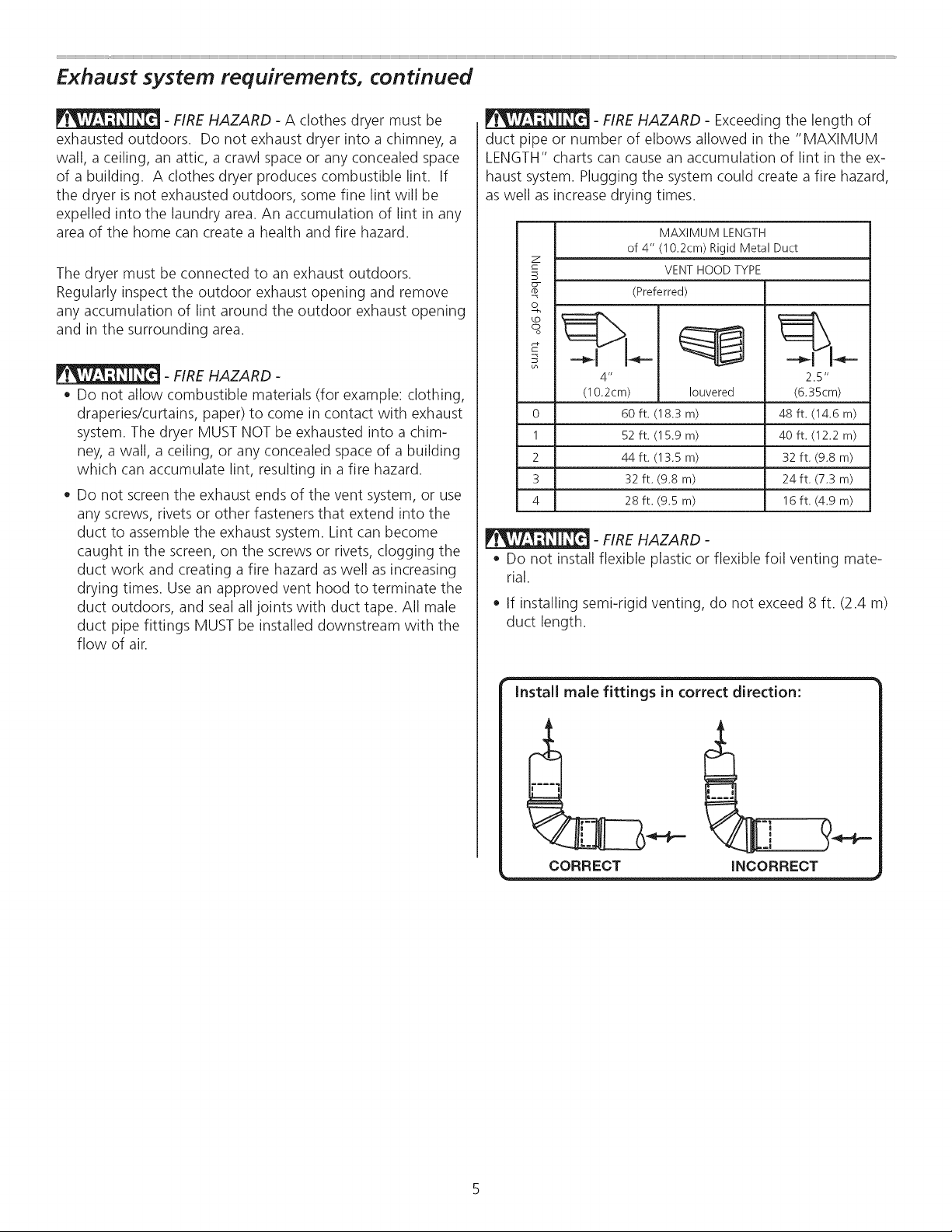

- FIRE HAZARD - Exceeding the length of

duct pipe or number of elbows allowed in the "MAXIMUM

LENGTH" charts can cause an accumulation of lint in the ex-

haust system. Plugging the system could create a fire hazard,

as well as increase drying times.

MAXIMUM LENGTH

of 4" (10.2cm) Rigid Metal Duct

VENT HOOD TYPE

o

o_

0

1

2

3

4

o

(lO.2cm)

(Preferred)

4"

60 ft. (18.3m)

52 ft. (15.9 m)

44 ft. (13.5 m)

32 ft. (9.8 m)

28 ft. (9.5 m)

Iouvered

2.5"

(6.35cm)

48 ft. (14.6 m)

40 ft. (12.2 m)

32 ft. (9.8 m)

24 ft. (7.3 m)

16 ft. (4.9 m)

- FIRE HAZARD -

Do not install flexible plastic or flexible foil venting mate-

rial.

If installing semi-rigid venting, do not exceed 8 ft. (2.4 m)

duct length.

Install male fittings in correct direction:

CORRECT INCORRECT

Page 6

Exhaust system requirements, continued

In installations where the exhaust system is not described in

the charts, the following method must be used to determine

if the exhaust system is acceptable:

1. Connect an inclined or digital manometer between the

dryer and the point the exhaust connects to the dryer.

2. Set the dryer timer and temperature to air fluff (cool

down) and start the dryer.

3. Read the measurement on the manometer.

4. The system back pressure MUST NOT be higher than

0.75 inches of water column. If the system back pressure

is lessthan 0.75 inches of water column, the system is

acceptable. If the manometer reading is higher than .075

inches of water column, the system istoo restrictive and

the installation is unacceptable.

Although vertical orientation of the exhaust system is

acceptable, certain extenuating circumstances could affect

the performance of the dryer:

• Only the rigid metal duct work should be used.

Venting vertically through a roof may expose the exhaust

system to down drafts causing an increase in vent

restriction.

Running the exhaust system through an uninsulated area

may cause condensation and faster accumulation of lint.

Compression or crimping of the exhaust system will cause

an increase in vent restriction.

The exhaust system should be inspected and cleaned a

minimum of every 18 months with normal usage. The

more the dryer is used, the more often you should check

the exhaust system and vent hood for proper operation.

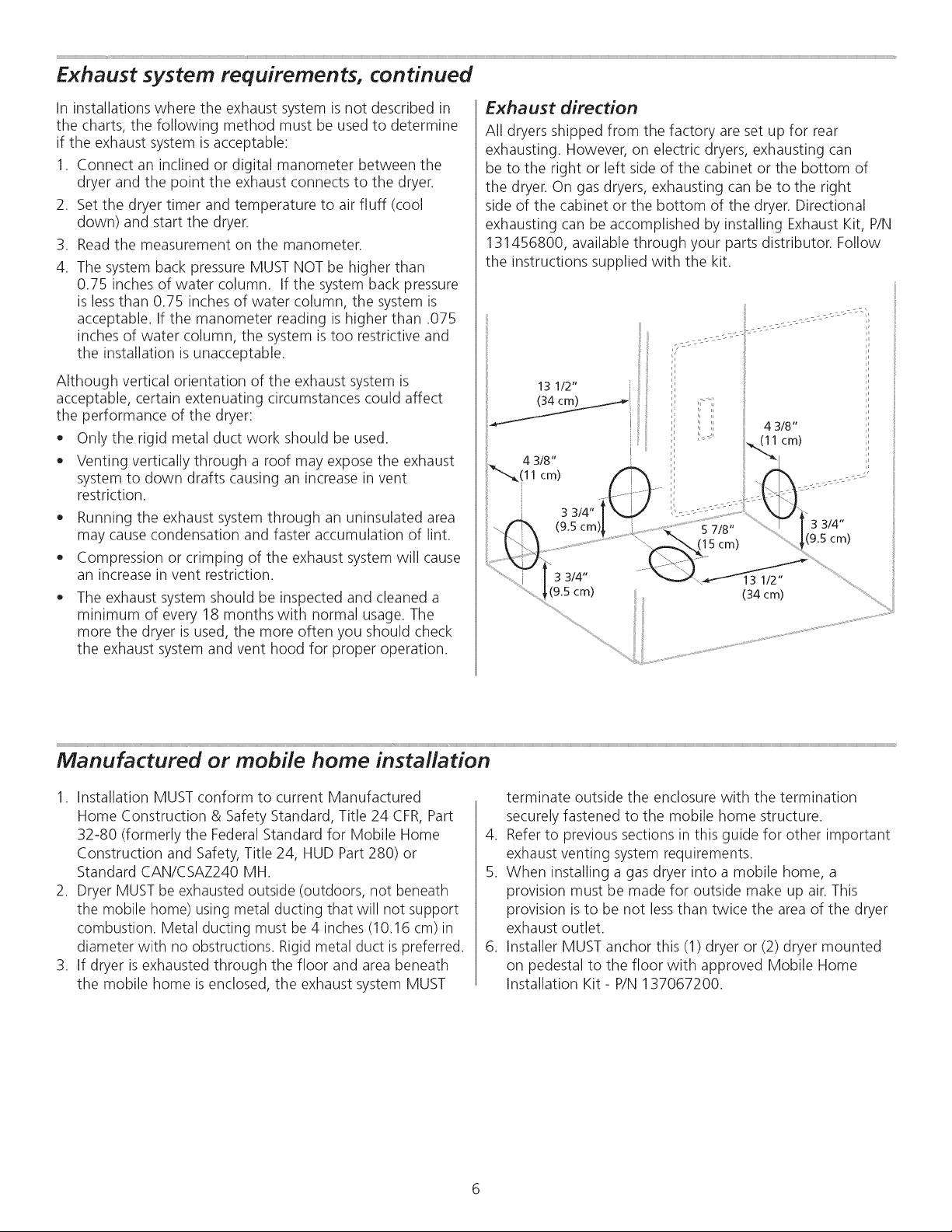

Exhaust direction

All dryers shipped from the factory are set up for rear

exhausting. However, on electric dryers, exhausting can

be to the right or left side of the cabinet or the bottom of

the dryer. On gas dryers, exhausting can be to the right

side of the cabinet or the bottom of the dryer. Directional

exhausting can be accomplished by installing Exhaust Kit, P/N

131456800, available through your parts distributor. Follow

the instructions supplied with the kit.

i," !!

13 1/2"

iii

.... ii

4 3/8"

(11 cm)

4 3/8"

11 crn)

3 3/4"

(9.5 cm

\

3 3/4" 13 1/2"

(9.5 cm) : (34 cm)

',L.... 5 7/8" '_3 3/4"

(15 cm) ,(9.5 cm)

Manufactured or mobile home installation

1. Installation MUST conform to current Manufactured

Home Construction & Safety Standard, Title 24 CFR, Part

32-80 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD Part 280) or

Standard CAN/CSAZ240 MH.

2. Dryer MUST be exhausted outside (outdoors, not beneath

the mobile home) using metal ducting that will not support

combustion. Metal ducting must be 4 inches (10.16 cm)in

diameter with no obstructions. Rigid metal duct is preferred.

3. If dryer isexhausted through the floor and area beneath

the mobile home is enclosed, the exhaust system MUST

terminate outside the enclosure with the termination

securely fastened to the mobile home structure.

4. Refer to previous sections in this guide for other important

exhaust venting system requirements.

5. When installing a gas dryer into a mobile home, a

provision must be made for outside make up air. This

provision isto be not lessthan twice the area of the dryer

exhaust outlet.

6. Installer MUST anchor this (1) dryer or (2) dryer mounted

on pedestal to the floor with approved Mobile Home

Installation Kit- P/N 137067200.

Page 7

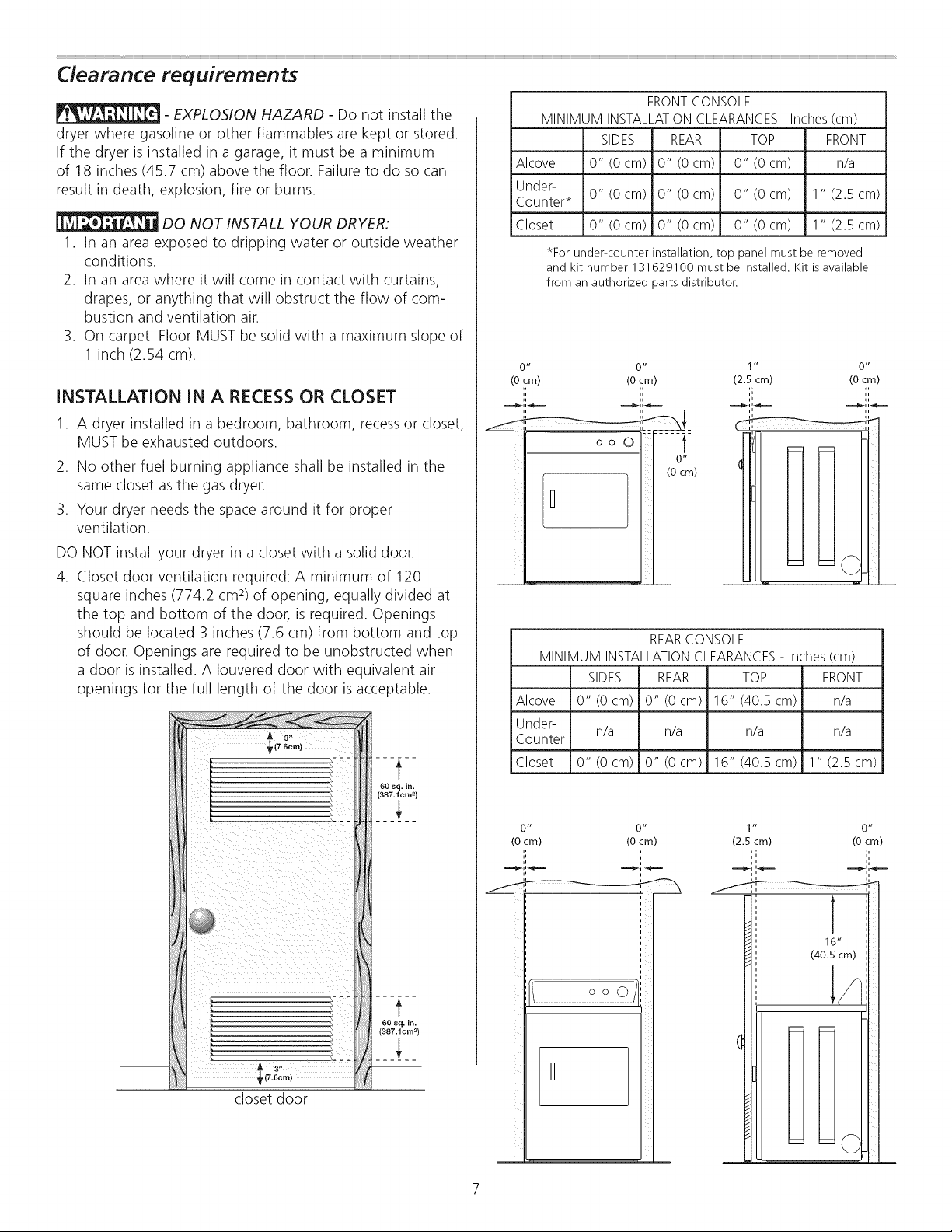

Clearance requirements

- EXPLOSION HAZARD - Do not install the

dryer where gasoline or other flammables are kept or stored.

If the dryer is installed in a garage, it must be a minimum

of 18 inches (45.7 cm) above the floor. Failure to do so can

result in death, explosion, fire or burns.

DO NOT INSTALL YOUR DRYER:

1. In an area exposed to dripping water or outside weather

conditions.

2. In an area where it will come in contact with curtains,

drapes, or anything that will obstruct the flow of com-

bustion and ventilation air.

3. On carpet. Floor MUST be solid with a maximum slope of

1 inch (2.54 cm).

INSTALLATION IN A RECESS OR CLOSET

1. A dryer installed in a bedroom, bathroom, recessor closet,

MUST be exhausted outdoors.

2. No other fuel burning appliance shall be installed in the

same closet as the gas dryer.

3. Your dryer needs the space around it for proper

ventilation.

FRONTCONSOLE

MINIMUMINSTALLATIONCLEARANCES- Inches(cm)

SIDES REAR TOP FRONT

Alcove 0" (0 cm) 0" (0 cm) 0" (0 cm) n/a

Under-

Counter*

Closet 0" (0 cm) 0" (0 cm) 0" (0 cm) 1" (2.5 cm)

0 ,I 0 ,I

(0 cm) (0 cm)

0" (0 cm) 0" (0 cm) 0" (0 cm) 1" (2.5 cm)

*For under-counter installation, top panel must be removed

and kit number 131629100 must be installed. Kit isavailable

from an authorized parts distributor.

1 ii O_l

(2.5 cm) (0 cm)

ooo -ii:

m)

DO NOT install your dryer in a closet with a solid door.

4. Closet door ventilation required: A minimum of 120

square inches (774.2 cm2)of opening, equally divided at

the top and bottom of the door, is required. Openings

should be located 3 inches (7.6 cm) from bottom and top

of door. Openings are required to be unobstructed when

a door is installed. A Iouvered door with equivalent air

openings for the full length of the door is acceptable.

REARCONSOLE

MINIMUM INSTALLATIONCLEARANCES- Inches (cm)

SIDES REAR TOP FRONT

Alcove 0" (0 cm) 0" (0 cm) 16" (40.5 cm) n/a

Under-

Counter

Closet 0" (0 cm) 0" (0 cm) 16" (40.5 cm) 1" (2.5 cm)

0 H

(0 cm)

,,,

n/a n/a n/a n/a

0 ,I

(0 cm)

._.._',',_..,._

1

16"

(40.5 cm)

o o O

closet door

= =©

Page 8

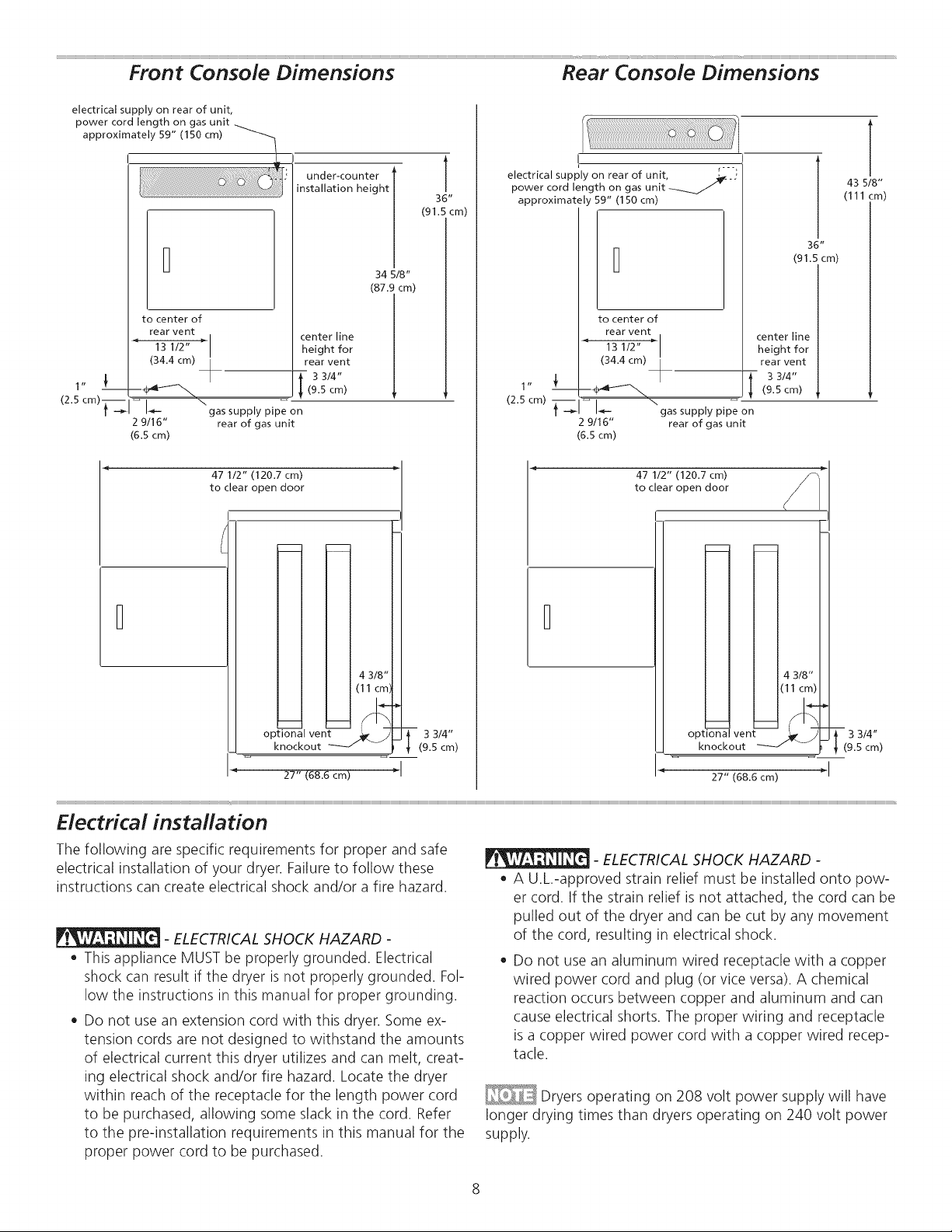

Front Console Dimensions Rear Console Dimensions

electrical supply on rear of unit,

power cord length on gas unit

approximately 59" (150 cm)

1" L

(2.5 cm)_

under-counter l

installation height [

to center of

rear vent center line

13 1/2" _" height for

(34.4 cm) rear vent

--4_t_-"-_ (9.5 cm)

I I

I b- gas supply pipe on

9/16" rear of gas unit

(6.5 cm)

47 112" (120.7 cm)

to clear open door

i 3 3/4"

m m

34 5/8"

(87.9 cm)

T

36"

(91.5 cm)

electrical supply on rear of unit, ,__-_-j

power cord length on gas unit -_

approximately 59" (150 cm)

to center of

rear vent

_" 13 1/2"

(34.4 cm)

1"

(2.5 cm)

_T_ \gas supply pipe on

2 9/16"

(6.5 cm)

rear of gas unit

47 1/2" (120.7 cm)

to clear open door

m

m

center line

height for

rear vent

l 3 3/4"

(9.5 cm)

m

43 5/8"

(111 cm)

4 3/8"

(11 cm)

opt io_-a I yen

knockout _ ----

27" (68.6 cm)

3 3/4"

(9.5 cm)

Electrical installation

The following are specific requirements for proper and safe

electrical installation of your dryer. Failure to follow these

instructions can create electrical shock and/or a fire hazard.

- ELECTRICAL SHOCK HAZARD -

, This appliance MUST be properly grounded. Electrical

shock can result if the dryer is not properly grounded. Fol-

low the instructions in this manual for proper grounding.

• Do not use an extension cord with this dryer. Some ex-

tension cords are not designed to withstand the amounts

of electrical current this dryer utilizes and can melt, creat-

ing electrical shock and/or fire hazard. Locate the dryer

within reach of the receptacle for the length power cord

to be purchased, allowing some slack in the cord. Refer

to the pre-installation requirements in this manual for the

proper power cord to be purchased.

4 3/8"

(11 cm)

opti_l vent

knockout _ --

27" (68.6 cm) _ I

3 3/4"

(9.5 cm)

- ELECTRICAL SHOCK HAZARD -

• A U.L.-approved strain relief must be installed onto pow-

er cord. If the strain relief is not attached, the cord can be

pulled out of the dryer and can be cut by any movement

of the cord, resulting in electrical shock.

• Do not use an aluminum wired receptacle with a copper

wired power cord and plug (or vice versa). A chemical

reaction occurs between copper and aluminum and can

cause electrical shorts. The proper wiring and receptacle

is a copper wired power cord with a copper wired recep-

tacle.

Dryers operating on 208 volt power supply will have

longer drying times than dryers operating on 240 volt power

supply.

Page 9

Grounding requirements - Electric dryer (USA)

- ELECTRICAL SHOCK HAZARD - Improper

connection of the equipment grounding conductor can result

in a risk of electrical shock. Check with a licensed electrician

if you are in doubt as to whether the appliance is properly

grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance for

electrical current.

2. After you purchase and install a 3 wire or 4 wire power

the plug MUST be plugged into an appropriate, copper

wired receptacle that is properly installed and grounded

in accordance with all local codes and ordinances. If in

doubt, call a licensed electrician.

DO NOT modify the plug you've installed on this appliance.

For a permanently connected dryer:

1. The dryer MUST be connected to a grounded metal,

permanent wiring system; or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead

on the appliance.

supply cord having an equipment-grounding conductor

and a grounding plug that matches you wiring system,

Grounding requirements - Electric dryer (Canada)

- ELECTRICAL SHOCK HAZARD - Improper

connection of the equipment grounding conductor can result

in a risk of electrical shock. Check with a licensed electrician

if you are in doubt as to whether the appliance is properly

grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce the

risk of electrical shock by a path of least resistance for

electrical current.

2. Since your dryer is equipped with a power supply

cord having an equipment-grounding conductor and

a grounding plug, the plug must be plugged into an

appropriate outlet that isproperly installed and grounded

in accordance with all local codes and ordinances. If in

doubt, call a licensed electrician.

DO NOT modify the plug provided with the appliance.

1. The dryer is equipped with a three-prong (grounding) plug for your

protection against shock hazard and should be plugged directly into a

properly grounded three-prong receptacle.

2. The plug must be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

If in doubt, call a licensed electrician.

DO NOT cut or remove ground prong from the plug.

Grounding type

wall receptacle

/

Do not, under

any circumstances,

cut, remove,

or bypassthe

grounding prong.

Powercord with

3-prong grounded plug

Page 10

Gas connection

1. Remove the shipping cap from gas pipe at the rear of the

dryer.

DO NOT connect the dryer to L.R gas service

without converting the gas valve. An L.R conversion kit must

be installed by a qualified gas technician.

,

Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or approved

pipe from gas supply line to the 3/8 inch (0.96 cm) pipe

located on the back of the dryer. Use a 1/2 inch to 3/8

inch (1.27 cm to 0.96 cm) reducer for the connection.

Apply an approved thread sealer that is resistant to the

corrosive action of liquefied gases on all pipe connections.

Manual GASFLOW

Shutoff Flare _ Flare

Valve Union Union

; 1 1

:losed t t

k._ Nipple Flexible Inlet Pipeon

Open Connector Back of Dryer

All connections must be wrench-tightened

The supply line must be equipped with an ap-

proved manual shutoff valve. This valve should be located in

the same room asthe dryer and should be in a location that

allows easeof opening and closing. Do not block accessto

the gas shutoff valve.

3. Open the shutoff valve in the gas supply line to allow gas

to flow through the pipe. Wait a few minutes for gas to

move through the gas line.

Shutoff Valve-

Open position

4. Check for gas system leaks with a manometer. If a

manometer is not available, test all connections by

brushing on a soapy water solution.

- EXPLOSION HAZARD - NEVERtest for gas

leaks with an open flame.

Electrical connection (non-Canada) 3-wire cord

- ELECTRICAL SHOCK HAZARD - Failure

to disconnect power source before servicing could result in

personal injury or even death.

1. Turn off power supply to outlet.

2. Remove the screw securing the terminal block access cover in the

upper corner on the back of the dryer.

3. Install a UL-approved strain relief according to the power cord/

strain relief manufacturer's instructions in the power cord entry

hole below the access panel. At this time, the strain relief should

be loosely in place.

4. Thread an UNPLUGGED,UL-approved, 30 amp. power cord,

NEMA 10-30 type SRDT,through the strain relief.

5. Attach the power cord neutral (center wire) conductor to the

SILVERcolored center terminal on the terminal block. Tighten the

screw securely.

6. Attach the remaining two power cord outer conductors to the

outer, BRASScolored terminals on the terminal block. Tighten

both screws securely.

- ELECTRICAL SHOCK HAZARD - Do not

make a sharp bend or crimp wiring/conductor at connections.

3-wire

receptacle

(NEMA type

10-30R)

Neutral

J terminal

DO NOT remove

internal ground in a

3-wire system}

7. Follow manufacturer's guidelines for firmly securing the strain

relief and power cord.

8. Reinstall the terminal block cover.

10

If moving dryer from a 4-wire system

and installing it in a 3-wire system, move the internal

ground from the center terminal back to the GREEN

screw next to the terminal block.

Page 11

Electrical connection (non-Canada) 4-wire cord

- ELECTRICAL SHOCK HAZARD - Failure

to disconnect power source before servicing could result in

personal injury or even death.

1. Turn off power supply to outlet.

2. Remove the screw securing the terminal block access cover in

the upper corner on the back of the dryer.

3. Install a UL-approved strain relief according to the power cord/

strain relief manufacturer's instructionsin the power cord entry

hole below the access panel. At this time, the strain relief should

be loosely in place.

4. Thread an UNPLUGGED,UL-approved, 30 amp. power cord,

NEMA 14-30 type STor SRDT,through the strain relief.

5. Disconnect the internal (WHITE)dryer harness ground wire from

the (GREEN)ground screw next to the terminal block.

6. Attach the ground (GREEN)power cord wire to the cabinet with

the ground (GREEN)screw.Tighten the screw securely.

7. Move the internal dryer harness ground (WHITE)wire to the

terminal block and attach it along with the neutral (WHITE)power

cord wire conductor to the center, SILVERcolored terminal on the

terminal block. Tighten the screw securely.

8. Attach the REDand BLACK power cord conductors to the outer,

BRASScolored terminals on the terminal block. Tighten both

screws securely.

- ELECTRICAL SHOCK HAZARD - Do not

make a sharp bend or crimp wiring/conductor at connections.

9. Follow manufacturer's guidelines for firmly securing the strain

relief and power cord.

10.Reinstall the terminal block cover.

4-wire

receptacle

(NEMA type

14-30R)

GREEN

ground screw

Move internal

ground (WHITE)

wire to neutral

(silver) terminal

for 4-wire system

GREEN

--Neutral

{WHITE wire)

Neutral

WHITE

neutral wire

\

BLACK

or RED

power wire

BLACK

or RED

power wire

General installation

1. Connect the exhaust duct to the outside exhaust system (see

pages 4 through 6). Use of a 4" (10.2 cm) clamp (item A) is

recommended to connect the dryer to the exhaust vent system.

Use metal foil tape to seal all other joints.

2. Carefully slide the dryer to its final position. Adjust one or more of

the legs until the dryer is resting solidly on all four legs. Placea level

on top of the dryer. The dryer MUST be level and resting solidly on

all four legs. Rock alternating corners to check for stability. Remove

and discard door tape.

Be sure the power is off at a circuit breaker/

fuse box before plugging the power cord into an outlet.

3. Plug the power cord into a grounded outlet.

4. Turn on the power at the circuit breaker/fuse box.

5. Read the Use & Care Guide provided with the dryer. It contains ...........

valuable and helpful information that will saveyou time and

money.

6. If you have any questions during initial operation, please review

the "Avoid Service Checklist" in your Use & Care Guide before

calling for service.

7. Place these instructions in a location near the dryer for future

reference.

0

_ _ A

wiring diagram and technical data sheet are

located inside the dryer console.

11

Page 12

Door Reversal Accessories

Your dryer is designed so the door swing may be reversed at

any time without additional parts. Conversion isaccomplished

by transferring hinges to the opposite side of the cabinet.

To change the direction of the door opening:

1. Open the dryer door. Removethe four hinge hole plugs from

the left side of the door opening. Place nearby for future

installation.

You may need a plastic knife to help pull out the

plugs. Be careful not to scratch the paint.

2. Remove the four screws that secure the door hinges to the

dryer front panel (see below).

Failureto use accessories manufactured by (or

approved by) the manufacturer could result in personal injury,

property damage or damage to the dryer.

LP CONVERSION KIT

P/NPCK2003

Gas dryers intended for use in a location supplied with LP

must use a conversion kit prior to installation.

MOBILE HOME INSTALLATION KIT

P/N137067200

Installations in mobile homes require use of MOBILE HOME

INSTALLATIONKIT.

DRYING RACK

Depending on the model you purchased, a drying rack may

have been included in the initial purchase of your dryer.

If your model did not include a drying rack or you desire

another drying rack, you may order one from your local parts

distributor.

DIRECTIONAL VENTING KIT

P/N131456800

Order this kit to utilize the side venting option of the dryer.

Additional hardware available from your local hardware store

will be necessary.

3. Rotate the door 180° and reinstall the door hinges to the

dryer front panel with the four screws.

4. Install the four hinge hole plugs in the open screw holes on

the opposite side of the door opening.

Replacement parts:

If replacements parts are needed for your dryer, contact the

source where you purchased your dryer.

- ELECTRICAL SHOCK HAZARD - Label all

wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous operation. Verify

proper operation after servicing.

TOUCH UP PAINT PENS

White TouchUpPen- P/N5303321319

BisqueTouchUp Bottle - P/N5304414035

BlackTouchUp Pen- P/N5304458932

UNDER-COUNTER INSTALLATION KIT

(front console model only)

For under-counter installation, top panel must be removed

and kit number 131629100 must be installed.

DRYER STACKING KIT

(front console model only)

P/N5303937141

Depending on the model you purchased, a kit for stacking

this dryer on top of matching washer may have been

included in the initial purchase of your dryer. If your model

did not include a stacking kit or you desire another stacking

kit, you may order one.

15 INCH (38 cm) PEDESTAL

(front console model only)

A pedestal accessory,specifically designed for this dryer may

be used to elevate the dryer for ease of use. This pedestal will

add about 15" (38 cm) to the height of your unit for a total

height of 51.25" (130 cm). Contact the location where you

purchased your dryer.

12

Page 13

lndice

instrucciones importantes de seguridad ............................... 13

Requisitos de preinstalacion ................................................ 13

Requisitos de instalaci0n ............................................... 14-18

Dimensiones de la lavadora instalada .................................. 19

instrucciones de instalaci0n ........................................... 19-22

inversion de la puerta .......................................................... 23

Accesorios/Piezas de repuesto ............................................. 23

lnstrucciones importantes de seguridad

Parasu seguridad, debe seguir la informacion de esta guia para minimizar el riesgo de incendio o

explosion o para evitar dahos a la propiedad, lesiones personales o incluso la muerte. No almacene ni utilice gasolina ni otros

liquidos o vapores inflamables cerca de este o de cualquier otro electrodomestico.

Identificaci6n de los simbolos, palabras y avisos de seguridad

Lasindicaciones de seguridad incluidas en este manual aparecen precedidas de un aviso titulado "ADVERTENCIA" o "PRE-

CAUCION", de acuerdo con el nivel de riesgo.

_Este simbolo le advierte sobre situaciones que pueden causar lesiones personales graves, la muerte o

dahos materiales.

_Este simbolo le advierte sobre situaciones que pueden causar lesiones personales o dahos materiales.

Lea las siguientes instrucdones antes de instalar y utilizar este electrodom6stico:

o Despuesde desembalar la secadora, destruya los cartones y lasbolsas de pl_istico. Los nihos podr[an utilizarlos para jugar. Los

cartones cubiertos con alfombras, cubrecamas, o I_iminasde pl_istico pueden convertirse en c_imarasde aire hermeticamente

cerradas y provocar asfixia. Coloque todos los materiales en un basurero o mantengalos fuera del alcance de los nihos.

La instalaci0n y el servicio de la secadora de ropa deben ser Ilevados a cabo por un instalador calificado, agencia de servi-

cios o proveedor de gas.

Instale la secadora de ropa de acuerdo con las instrucciones del fabricante y los codigos locales.

La reparacion eDctrica de la secadora debe cumplir con los codigos y lasordenanzas locales y la 01tima edici0n del Codigo

Electrico Nacional (National Electrical Code), el ANSI/NFPA70, o bien en Canada, el CSA C22.1 del Codigo Electrico de

Canada (Canadian Electrical Code) Parte 1.

El servicio de gas de la secadora debe cumplir con los codigos y las ordenanzas locales, y la ultima edicion del Codigo de

Gas Nacional (National Fuel GasCode), el ANSi Z223.1, o bien en Canada1,el CAN/CGA B149,1-2000.

La secadora se diseh6 conforme a los codigos ANSi Z 21.5.1 o ANSI/UL 2158 - CAN/CSA C22.2 N.° 112 (ultimas edicio-

nes) solo para USO DOMESTICO. No se recomienda esta secadora para uso comercial, como por ejemplo, en restaurantes,

salones de belleza, etc.

Lasinstrucciones de esta guia y todo el material que se incluye con esta secadora no tienen como prop6sito cubrir todas

las condiciones y situaciones que puedan presentarse. Cuando instale, opere o repare cualquier artefacto DEBEtener cui-

dado y hacer uso de buenas pr_icticas de seguridad.

QUI _ HACER SI SIENTE OLOR A GAS:

No intente encender ning0n electrodomestico.

No toque ningun interruptor electrico; no utilice ningun telefono en la vivienda.

Despeje la habitacion, el edificio o el _ireade todos los ocupantes.

Llame inmediatamente a su proveedor de gas desde el telefono de un vecino. Siga las instrucciones del proveedor de gas.

Si no puede ponerse en contacto con el proveedor de gas, Ilame a los bomberos.

Conserve estas instrucciones para referencia futura.

Requisitos de preinstalaci6n

Herramientas y materiales necesarios para la instalaci6n:

Pinzas ajustables

Destornilladores Philips con punta

derecha y cuadrada

Llave ajustable

Llave para tubos de suministro de gas

Cinta aislante resistente al gas LP

(para suministro de gas natural o LP)

Nivel de carpintero

Capucha de ventilacion externa

Conducto de escape de metal rigido

o semirigido de 4 pulgadas (10 cm)

Kit de cablesde alimentaci6ntrifilar o te-

trafilar de 240 voltios (secadoraelectrica)

Abrazadera de 4" (10,2 cm)

V_ilvulade cierre de linea de gas (se-

cadora a gas)

Adaptadores NPIde union acampana-

da (x2) y linea flexible de suministro de

gas (secadora a gas) de 1/2'(15,2 cm)

Cinta de papel aluminio (no cinta

adhesiva aislante)

13

Page 14

Requisitos de! sistema electrico

_: Debido a posibles variaciones en el voltaje, no se recomienda utilizar esta secadora con electricidad generada a

partir de generadores a gas, solares, eolicos ni de ninguna otra clase que no sean los empleados pot su empresa de electri-

cidad local.

Requisitos electricos de la secadora electrica:

CIRCUITO: circuito independiente individual de 30 amp. con fusibles de acci0n retardada o disyuntores. Use circuitos con

fusibles separados para la lavadora y la secadora. NO haga funcionar una lavadora y una secadora en el mismo circuito.

SUMINISTROELECTRICO:trifilar o tetrafilar, 240 V, 1 fase, 60 Hz, corriente alterna.

A menos que hayasido fabricada para la venta en Canada1,estasecadoraest,1conectadaa tierra internamente a

travesde un enlace a un conductor neutro. Laconexi0n a tierra a travesde{ neutro est,1prohibida para: (1) instalacionesde circuitos de

bifurcaci0n nuevos;(2) casasrodantes; (3)vehiculosrecreativos;y (4)_ireascuyas leyeslocalesno permiten la puesta a tierra a travesdel

neutro.

RECEPTACULODELTOMACORRIENTE- recept_iculo NEMA 10-30 R o NEMA 14-30 Rque debe estar ubicado en un lugar al

que pueda acceder el cable de alimentaci0n electrica cuando la secadora este instalada.

CONEXION A TIERRA:consulte "Requisitos de conexi0n atierra" en la secci0n {nstalaci0n electrica.

CABLE DE ALIMENTACION ELECTRICATRIFILAR (no

incluido)

Receptaculo trifilar

(tipo NEMA 10-30R)

La secadora DEBEemplear un cable de alimentaci0n

electrica de 3 conductores tipo NEMA 10-30, SRDT

calificado para CA minima de 240 voltios, 30 amp., con 3

conectores de terminal horquilla con extremos doblados

hacia arriba o de bucle cerrado y calificados para uso en

secadoras de ropa. Paraobtener instrucciones sobre {a

conexi0n trifilar, consulte CONEXIONESELECTRICASPARA

UN SISTEMATRIFILAR.

Requisitos electricos de la secadora a gas:

CIRCUITO- Circuito individual de bifurcaci0n de 15 amp.,

correctamente polarizado y con conexi0n a tierra con fusible

de retardo de 15 amp. o con interruptor autom_itico.

SUMINISTROELECTRICO:corriente alterna de 2 cables, con

conexi0n a tierra, 120 voltios, monof_isica, 60 Hz.

CABLEDE ALIMENTACION ELECTRICA:la secadora est,1

equipada con un cable de alimentaci0n trifilar de 120 voltios.

CONEXION A TIERRA:consulte "Requisitos de conexi0n atierra"

en la secci0n Instalaci0n electrica.

CABLE DE ALIMENTAClON ELECTRICATETRAFILAR (no

incluido)

Receptaculo tetrafilar

(tipo NEMA 14-30R)

La secadora DEBEemplear un cable de alimentacion

electrica de 4 conductores tipo NEMA 14-30, SRDTo

ST(segun se especifique) calificado para CA minima

de 240 voltios, 30 amp., con 4 conectores de terminal

horquilla con extremos doblados hacia arriba o de bucle

cerrado y calificados para uso en secadoras de ropa.

Para obtener instrucciones sobre {aconexi0n tetrafilar,

consulte CONEXIONESELECTRICASPARA UN SISTEMA

TETRAFILAR.

_ Lassecadoras fabricadas para la venta en Canada1vie-

nen con un cable de alimentaci0n electrica tetrafilar (NEMA

14-30R) de flibrica.

Tomacorriente con

retire ni "q

deshabilite la clavija de

conexi6n a tierra bajo

Cord6n el_t-trico de 3 clavijas

con puesta atiema

14

Page 15

Requerimientos del suministro de gas

- PELIGRO DE EXPLOSION - Las tube- 4.

rias de cobre sin recubrimiento se corroen al exponerse al gas

natural, Io que provoca perdiclas de gas. Utilice SOLAMENTE 5.

tuberias de hierro negro, acero inoxiclable o lat6n plastificaclo

para el suministro de gas.

1. Lainstalaci6n DEBErealizarsede acuerdo con los c6digos

localeso, en ausencia de ellos, con el C6cligo de Gas

Nacional (National FuelGas Code), ANSIZ223.1 (Oltima 6.

edici6n).

2. La linea de suministro de gas clebe ser un tubo de 1,27 cm

(1/2 pulgada). 7.

3. Si los c6digos Io permiten, se puecle utilizar un tubo de

metal flexible para conectar la secaclora a la linea de

suministro de gas. Latuberia DEBEser de acero inoxiclable 8.

o de lat6n plastificaclo.

Requisitos del sistema de escape

Utilice solo un conducto de metal flexible o rigido de 10,2

cm (4 pulgadas) de diametro (minimo) y una capucha de

ventilaci0n aprobada que tenga uno o mas reguladores de

tiro que se abran cuando la secadora este en funcionamiento.

Cuando la secadora se detiene, el regulador de tiro se

cierra automaticamente para evitar la corriente de aire y el

ingreso de insectos y roeclores. Para evitar restringir la salida

clel conducto, mantenga un espacio minimo de 30,5 cm

(12 pulgadas) entre la capucha de ventilaci0n y el suelo, o

cualquier otra obstrucci0n.

La linea de suministro de gas DEBEtener una valvula de

cierre individual.

Se DEBEinstalar una clerivaci0n N.RT de 0,32 cm (1/8

pulgadas) con tap0n roscaclo, que permita conectar

un meclidor de prueba, inmecliatamente clespuesde

la conexi0n de suministro de gas a la secadora, en

contracorriente al flujo de gas.

La secadora DEBEestar clesconectada de la tuberia de gas

durante cualquier prueba en la que la presi0n excecla los

3,45 kPa (1/2 psig).

La secadora DEBEestar aislaclade la tuberia de gas

clurante cualquier prueba en la que la presi0n sea igual o

inferior a 3,45 kPa (1/2 psig).

Lasconexiones clelsuministro de gas cleben cumplir con

la norma de conexiones de electrodomesticos a gas, ANSi

Z21.24.

- PELIGRO DE INCENDIO - El no

seguir estas instrucciones puecle producir tiempos de secado

excesivos y peligro de incendio.

Los siguientes son requisitos necesarios para el

funcionamiento seguro y correcto de su secadora.

- PELIGRO DE INCENDIO - No utilice

materiales de ventilaci0n de plastico ni de papel de aluminio

flexibles para instalar la secaclora de ropa. Por Io general,

dichos materiales se clesarman, se deterioran con facilidad y

acumulan pelusa. Estasconcliciones obstruyen el flujo de aire

de la secadora y aumentan el riesgo de incendio.

Si su sistema actual est,1compuesto de un conclucto de

pl_istico o papel de aluminio, reempl_icelo por un conclucto

de metal rigiclo o semirigiclo. Aseg0rese de que el conclucto

existente no tenga pelusas antes de instalar el conclucto de la

secaclora.

Correcto Incorrecto

15

Page 16

Requisitos del sistema de escape (continuaci6n)

- PELIGRO DE INCENDIO - Una seca-

dora de ropa debe tenet ventilaci0n a{ exterior. No ventile {a

secadora a una chimenea, pared, techo, _itico, pasajes entre

pisos ni ning0n espacio oculto de {avivienda. Lassecadoras

de ropa producen pelusa combustible. Si {asecadora no tiene

ventilaci0n a{ exterior, algunas pelusas finas se expulsar_in en

el _ireade lavanderia. La acumulaci0n de pelusa en cualquier

_ireade la vivienda puede constituir un peligro sanitario y un

riesgo de incendio.

La secadora debe estar conectada a un sistema de escape que

termine en el exterior de {avivienda. Inspeccione la abertura

de escape a{ exterior con frecuencia y elimine cualquier

acumulaci0n de pelusa en la abertura y en el _ireaque la

rodea.

- PELIGRO DE INCENDIO -

• No permita que materiales combustibles (pot ejemp{o:

ropa, tapiceria/cortinas, pape{) entrenen contacto con

el sistema de escape. La secadora NO DEBEtenet escape

a una chimenea, una pared, un techo ni ningun espacio

cerrado de un edificio que pueda acumular pelusa y cons-

tituir un peligro de incendio.

No bloquee los extremos de escape de{ sistema de ven-

tilaci0n, ni utilice tornillos, remaches ni otros sujetadores

que se extiendan hacia {a parte interna de{ conducto para

ensamblar{o. Es posible que {a pelusa quede atrapada en

el filtro, los tornillos o los remaches, Io que puede obstruir

la red de conductos y constituir un peligro de incendio,

asi como tambien aumentar los tiempos de secado. En {a

salida de{ conducto a{exterior, utilice una capucha de ven-

tilaci0n aprobada y selle todas {asuniones con cinta para

conductos. Todos los accesorios macho para tubos DEBEN

instalarse teniendo en cuenta el flujo de aire.

- PELIGRO DE INCENDIO - Si se exce-

de la Iongitud del tubo del conducto o el n0mero de codos

permitidos en las tabias de "LONGITUD MAXIMA", se pue-

den acumular pelusas en el sistema de escape. La obstrucci0n

del sistema podria constituir un peligro de incendio, asi como

aumentar los tiempos de secado.

¢h

Conducto de metal r[gido de 10,2 cm (4 pulgadas)

e_

t_

D_

°o 4" aberturas de

0 18.3 m (60 pies) 14.6 m (48 pies)

1 15.9 m (52 pies) 12.2 m (40 pies)

2 13.5 m (44 pies) 9.8 m (32 pies)

3 9.8 m (32 pies) 7.3 m (24 pies)

4 9.5 m (28 pies) 4.9 m (16 pies)

(recomendada)

(10,2 cm) ventilacibn

LONGITUD MAXIMA

TIPO DECAPUCHA DEVENTILACION

2.5"

(6,35 cm)

- PELIGRO DE INCENDIO -

No utilice material de ventilacion flexible de pbistico o

aluminio.

Siva a instalar conductos de ventilaci0n semirrigidos, no

exceda una Iongitud de 8 pies (2,4 m).

Instale los accesorios macho en la direction

correcta:

16

CORRECTO INCORRECTO

Page 17

Requisitos de/sistema de venti/acion (continuacion)

En instalaciones en lasque el sistema de ventilacion no se

describa en las tablas, sedebe utilizar el siguiente metodo

para determinar si dicho sistema esaceptable:

1. Conecte un manOmetro inclinado o digital entre la secadora

y el punto donde el tubo de ventilacion se conecta con la

secadora.

,

Coloque el temporizador y la temperatura de la secadora

en la opcion Air fluff - cool down (Esponjado con aire,

enfriamiento) y ponga en marcha la secadora.

,

Lea la meclicion del manometro.

4.

La contrapresion del sistema NO DEBEset mayor que 2,5

cm (1 pulgada) de columna de agua. Si la contrapresion

del sistema esmenor que 2,5 cm (1 pulgada) de

columna de agua, el sistema es aceptable. Si la lectura

del manometro es mayor que 2,5 cm (1 pulgada) de

columna de agua, el sistema es demasiado restrictivo y la

instalacion es inaceptable.

Si bien la orientacion vertical del sistema de ventilacion es

aceptable, ciertas circunstancias atenuantes podrian afectar el

funcionamiento de la secadora:

o

Solo sedebe utilizar una red de conductos de metal rigido.

o

Si la ventilacion se efectua en forma vertical a traves del

techo, es posible que el sistema de ventilacion se vea

expuesto a r_ifagasdescendentes que restringir_in la

ventilacion.

• Si el sistema de escape se extiende a traves de un _irea

que no est,1aislada, puecle producirse condensacion y una

acumulacion m_isr_ipida de pelusa.

• La compresion o los pliegues del sistema de ventilacion

aumentar_in la restriccion de la ventilacion.

Se debe inspeccionar y limpiar el sistema de ventilacion

cada 18 meses como minimo cuando se le da un uso

normal. Cuanto m_isutilice la secadora, m_isa menudo

deber_i comprobar que el sistema de escape y la capucha

de ventilacion funcionan correctamente.

DirecciOn del Venti/aciOn

Toclaslas secadoras vienen de flibrica equipadas con

ventilacion trasero. Sin embargo, en las secadoras electricas,

el ventilacion puede hacerse al lado derecho o izquierdo

del gabinete o en la parte inferior de la secadora. En las

secadoras a gas, el ventilacion del aire puecle estar en el lado

derecho del gabinete o en la parte inferior de la secadora. El

ventilacion direccional puede efectuarse instalando un Kit de

Ventilacion Direccional, P/N 131456800, disponible a traves

de su distribuidor de repuestos. Siga las instrucciones que se

suministran con el kit.

__ii!___-_ _ _

[/

13 1/2"

4 3/8"

11 cm)

3 3/4"

(9.5 cm

\

3 3/4"

(34 cm)

(9.5 cm)

Instalacion en una casa rodante

1. La instalacion DEBEcumplir con la actual Norma de

Seguridad y Construccion de Casas Rodantes, titulo 24

CFR, Parte 32-80 (que anteriormente se conocia como

la Norma Federal de Seguridad y Construccion de Casas

Rodantes [Federal Standard for Mobile Home Construction

and Safety], titulo 24, HUD parte 280) o la Norma CAN/

CSAZ240 MH.

2. La secadora DEBEtenet evacuacion al exterior (no a la

parte de abajo de la casa rodante) mediante conductos

met_ilicos que no admitan combustion. Los conductos

met_ilicos deben tenet un di_imetro de 10,16 cm (4

pulgadas) y no deben presentar obstrucciones. Se

recomiendan los conductos de metal rigido.

3. Si la secadora tiene evacuacion a traves del piso, y el

_ireadebajo de la casa rodante es cerrada, el sistema de

evacuacion DEBEterminar fuera del espacio cerrado y el

extremo debe quedar sujetado firmemente a la estructura

de la casa rodante.

4. Para obtener informacion sobre otros requisitos

importantes del sistema de escape, consulte lassecciones

anteriores de esta guia.

5. Cuando se instale una secadora a gas en una casa

rodante, se debe dejar espacio en el exterior para la salida

de aire. Este espacio debe set pot Io menos el doble del

_ireade la salida de escape de la secadora.

6. Eltecnico de instalacion DEBEanclar esta secadora (1)

o secadora sobre pedestal (2) al piso usando un kit de

instalacion para casas rodantes, pieza numero 137067200.

17

Page 18

Requisitos de despeje

- PELIGRO DE EXPLOSION - No insta-

le la secadora en el mismo lugar en el que haya o sealma-

cene gasolina u otros productos inflamables. Si la secaclora

se instala en un garaje, debe estar a una altura minima de

45,7 cm (18 pulgadas) por encima del suelo. De Io contrario,

podria producirse una explosion, un incenclio, quemacluras o

incluso la muerte.

NO INSTALE LA SECADORA:

1. En una zona expuesta a la humedacl o a las concliciones

climaticas externas.

2. En un _ireaen la que este en contacto con cortinas, telas

colgantes o cualquier otra cosa que pueda obstruir el

flujo de aire de ventilacion y combustion.

3. Sobre una alfombra. El piso DEBEser firme con una pen-

diente maxima de 2,54 cm (1 pulgada).

INSTALAClON EN UN NICHO O ARMARIO

1. Una secadora instalada en un dormitorio, baflo, nicho o

armario, DEBEtenet ventilacion al exterior.

2. No sedebe instalar ningun otto artefacto de combustion

en el mismo armario que la secadora a gas.

3. La secadora necesita espacio a su alrededor para que la

ventilacion sea adecuada.

CONSOLAFRONTAL

ESPAClOSM{NIMOSPARALAINSTALACION:cm(pulgadas)

LATERALES

Hueco 0 cm (0") 0 cm (0") 0 cm (0") n/d

Empotrada* 0 cm (0") 0 cm (0") 0 cm (0") 2,54 cm (1 ")

Armario 0 cm (0") 0 cm (0") 0 cm (0") 2,54 cm (1")

*Para instalaci6n empotrada, el panel superior debe ser removido y

el kit 131629100 debe ser instalado. El kit puede ser ordenado de su

distribuidor autorizado.

O" O"

(0 cm) (0 cm)

PARTE PARTE PARTE

TRASERA SUPERIOR DELANTERA

1" O"

(2.5 cm) (0 cm)

ooo --ii:

m)

NO instale la secadora en un armario con puerta maciza.

4. Ventilacion requerida en la puerta del armario: Se necesita

un minimo de 774,2 cm2 (120 pulgadas 2)de abertura,

dividido en partes iguales en la parte superior e inferior

de la puerta. Lasaberturas de ventilacion deben estar

ubicadas a 7,6 cm (3 pulgadas) de la parte superior e

inferior de la puerta. Esnecesario que las aberturas de

aire no esten obstruidas al instalar una puerta. Se acepta

una puerta que tenga aberturas de ventilacion distribuidas

uniformemente en toda la superficie.

i 3'(7.6cm}

i ____

CONSOLATRASERA

ESPAClOSM{NIMOSPARALA INSTALACl0N:cm (pulgadas)

LATERALES PARTESUPERIOR

Hueco 0 cm (0") 0 cm (0") 40.5 cm (16") n/d

Empotrada n/d n/d n/d n/d

Armario Ocm(O") Ocm(O") 40.5 cm (16") 2,54 cm (1")

0"

(0 cm)

,,,

ii

ii

PARTE PARTE

TRASERA DELANTERA

0"

(0 cm)

_._',',_..,._

1

16"

(40.5 cm)

o o O

puerta del armario

= =©

18

Page 19

Dimensiones Consola Frontal Dimensiones Consola Trasera

suministro electrico en la parte trase-

ra de la unidad, cable elOctrico en la

parte trasera de la secadora a

de aproximadamente 59" (150 cm)

under-counter l

T

36"

(91.5 cm)

suministro el_ctrico en la parte trase-

ra

de la unidad, cable el_ctrico en la ,_-_-_

parte trasera de la secadora a gas es _"

de aproximadamente 59" (150 cm)

43 5/8"

(111 cm)

hacia el centro de

la ventilacion t_asera

-_ 13 1/2" _'/

(34.4 cm)

9/16"

(6.5 cm)

/

tuberia de suministro de gas en la

parte trasera de la unidad de gas

47 1/2" (120.7 cm)

para destapar abra la puerta

installation height /

altura de la

linea central

para

ventilaci6n

trasera

i 3 3/4"

(9.5 cm)

m m

34 5/8"

(87.9 cm)

:l 3/8"

11 cm)

hacia el centro de

la ventilaciO_ trasera

_" 13 1/2" _|

(34.4 cm) ]

(2.5 cm) _ \

2 9/16"

(6.5 cm)

47 1/2" (120.7 cm)

para destapar abra la puerta

36 II

(91.5 cm)

altura de la

linea central

para

ventilaci6n

trasera

l 3 3/4"

(9.5 cm)

tuberia de suministro de gas en la

parte trasera de la unidad de gas

m m

m

4 3/8"

(11 cm)

dlscoo c_or ren_vl _'_t_

ble para ventilacidn _/ --

27" (68.6 cm) _'I

3 3/4"

(9.5 cm)

Instalacion electrica

Lossiguientes son requisitos necesariospara la instalacion

electrica segura ycorrecta de su secadora. Elno seguir estas

instrucciones puede producir una descargaelectrica y/o incendio.

- PELIGRODEDESCARGA ELE-CTRICA-

• Esteelectrodomestico DEBEestar debidamente conec-

tado a tierra. Si la secadora no est,1conectada a tierra

correctamente, se pueden producir descargas electricas.

Siga las instrucciones de esta guia para vet como se reali-

za una correcta conexion a tierra.

No utilice un cable de extension con esta secadora.Algu-

nos cablesde extension no estan dise_ados para soportar

la cantidad de corriente electrica que utiliza esta secadoray

pueden derretirse, Io que constituye un peligro de descarga

electricay/o incendio. Ubique la secadoraen un lugar donde

el cable de alimentacion que compre esteal alcancedel re-

ceptaculo, permitiendo que el cable quede holgado. Consul-

te los requisitos de preinstalacion de esta guia para ver cual

esel cable de alimentacion correcto que sedebe comprar.

disco opc_-o-nonalrem-_Tvl-

ble para ventilation _/-"

27" (68.6 cm) _ [

3 3/4"

(9.5 cm)

I

- PELIGRODEDESCARGA ELECTRICA-

• Debe instalarse, en el cable de alimentacion, un disposi-

tivo de liberacion de tension aprobado por U.L. Si no se

coloca un dispositivo de liberacion de tension, el cable

podria desenchufarse de la secadora y cortarse por cual-

quier movimiento, y provocar asi una descarga electrica.

No utilice un recept_iculo con cableado de aluminio para

un enchufe y cable de alimentacion con cables de cobre

(o viceversa). La reaccion quimica que tiene lugar entre el

cobre y el aluminio puede causar cortocircuitos electricos.

El recept_iculo y el cableado correcto consiste en un cable

de alimentacion con alambres de cobre con un recept_i-

culo de cables de cobre.

Lassecadoras que funcionan con 208 voltios de co-

rriente electrica tendr_in tiempos de secado m_isprolongados

que las que funcionan con 240 voltios de corriente electrica.

19

Page 20

Requisitos de conexion a tierra: secadora electrica (Estados Unidos)

- PELIGRODEDESCARGA ELE-CTRICA-

Una conexion incorrecta del conductor de conexion a tierra del

equipo puede provocar un peligro de descargaelectrica. Si no

est,1seguro de haber realizadocorrectamente la conexion a

tierra del artefacto, consulte a un electricista autorizado.

Para una secadora conectada a tierra:

1. La secadora DEBEtenet conexi0n a tierra. En el caso

de que {a secadora no funcione correctamente o se

descomponga, la conexi0n a tierra reduce el riesgo de

descarga electrica porque ofrece una trayectoria de menor

resistencia para {a corriente electrica.

2. Despues de comprar e instalar un cable de alimentaci0n

trifilar o tetrafilar con un conductor de conexi6n a tierra,

adecuado con cable de cobre correctamente instalado y

con conexi0n a tierra, de acuerdo con todos los codigos y

lasordenanzas locales. Ante cualquier duda, comuniquese

con un electricista autorizado.

NO realice modificaciones al enchufe que haya instalado en

este artefacto.

Para una secadora conectada de forma permanente:

1. La secadora DEBEestar conectada a un sistema de

cabieado permanente de metal conectado a tierra, o bien

se debe co{ocar un conductor de conexi0n a tierra con

los conductores del circuito y debe estar conectado al

terminal de conexi0n a tierra de{ equipo o a{ cable a tierra

de{ artefacto.

el enchufe DEBEestar conectado a un recept_icu{o

Requisitos de conexion a tierra: secadora electrica (Canada)

- PELIGRODEDESCARGA ELE-CTRICA-

Una conexion incorrecta del conductor de conexion a tierra del

equipo puede provocar un peligro de descargaelectrica. Si no

est,1seguro de haber realizadocorrectamente la conexion a

tierra del artefacto, consulte a un electricista autorizado.

Para una secadora conectada a tierra:

, La secadora DEBEtenet conexi0n a tierra. En el caso

de que {a secadora no funcione correctamente o se

descomponga, la conexi0n a tierra reduce el riesgo de

descarga electrica porque ofrece una trayectoria de menor

resistencia para la corriente electrica.

2. Debido a que la secadora est,1equipada con un cable de

alimentaci0n electrica que cuenta con un conductor de

conexi6n a tierra, el enchufe debe estar conectado a un

tomacorriente correctamente instalado y con conexi0n a

tierra, de acuerdo con todos los c6digos y {asordenanzas

locales. Ante cualquier duda, comuniquese con un

electricista autorizado.

NO realice modificaciones al enchufe que se proporciona con

este artefacto.

Requisitos de conexion a tierra: secadora a gas (Estados Unidos y Canada)

,

La secadora est,1equipada con un enchufe de tres patas

(conexi0n a tierra) para evitar el peligro de electrocuci0n

y debe estar conectada directamente a un recept_iculo

de enchufe de tres patas que cuente con una conexi0n a

tierra adecuada.

, El enchufe debe estar conectado a un tomacorriente

correctamente instalado y con conexi0n a tierra, de

acuerdo con todos los c6digos y las ordenanzas locales.

Ante cualquier duda, comuniquese con un electricista

autorizado.

NO corte ni retire la espiga de conexi0n a tierra del enchufe.

Tomacorriente con

puesta a tierra

retire ni

deshabilite la davija de

conexi6n a tierra bajo

n{nguna circunstancia.

Cord6n el_ctrico de 3 davijas

con puesta atierra

20

Page 21

Conexion de gas

1. Quite el tapon del tubo de gas en la parte trasera de la

secadora.

NO conecte la secadora al servicio de gas

LPsin convertir la wilvula de gas. El kit de conversion a gas LP

debe set instalado pot un tecnico calificado.

,

Conecte un tubo aprobado o uno semi-rigido de 1,27

cm (1/2 pulgada) de di_imetro interior desde la linea

de suministro de gas al tubo de 0,96 cm (3/8 pulgada)

ubicado en la parte trasera de la secadora. Utilice un

reductor de 1,27 cm a 0,96 cm (1/2 pulgada a 3/8

pulgada) para realizar la conexi0n. Aplique un sellador

para roscasque sea resistente a la acci0n corrosiva de los

gases licuados en todas lasconexiones de los tubos.

3. Abra la wilvula de cierre de la linea de suministro de

gas para que el gas fluya a traves de la tuberia. Espere

unos minutos a que el gas fluya a traves de la linea de

suministro de gas.

V_ilvula

de cierre Conector Conector

manual doble doble

FLUJO DE GAS

V_ilvula de cierre:

posiciOn abierta

4. Utilice un manometro para verificar que no haya fugas

Conector Tubo de ladmisiOn

flexible en la parte posterior

Todas las conexiones deben estar ajustadas con Ilave

de la secadora

La linea de suministro de gas debe estar

en el suministro de gas. Si no cuenta con un manometro,

pruebe todas lasconexiones aplicando agua jabonosa en

estas.

compruebe si hay fugas de gas con una llama abierta.

equipada con una wilvula de cierre manual aprobada. Esta

wilvula debe estar ubicada en la misma habitaci0n que la se-

cadora, en una ubicaci0n que permita la facilidad de apertura

y cierre. No bloquee el acceso a la wilvula de cierre de gas.

Conexion electrica (fuera de Canada): trifilar

- PELIGRODEDESCARGA ELE-CTRICA-

El no desconectar el suministro electrico antes de realizar cualquier

reparaciOn puede ocasionar lesiones personales o incluso la muerte.

1. Desconecte el suministro electrico del tomacorriente, trifilar

2. Extraigael tornillo que sujeta la cubierta de accesodel bloque terminal (tipo NEMA

que seencuentra en laesquina superiorde la parte traserade la secadora. 10-30R)

3. Instale un dispositivo de liberaci0n de tension aprobado pot U.L.,

de acuerdo con las instrucciones relativas al cable de alimentacion/

dispositivo de liberaci0n de tension del fabricante, en el orificio de

entrada del cable de alimentacion debajo del panel de acceso. En

este momento, el dispositivo de liberaci0n de tension debe estar

holgadamente en su lugar.

4. Paseun cable de alimentacion aprobado pot U.L. DESENCHUFADO,

de 30 amp. tipo NEMA 10-30, SRDTa traves del dispositivo de

liberaci0n de tension.

5. Conecte el conductor neutro (cable del centro) del cable de

alimentacion al terminal PLATEADOdel centro del bloque terminal.

Ajuste el tornillo con firmeza.

6. Conecte los dos conductores externos restantes del cable de

alimentacion a los terminales externos de color LATONdel bloque

terminal. Ajuste los dos tornillos con firmeza.

- PELIGRODE DESCARGA ELE-CTRICA-

No forme un _ingulo agudo con el cableado/conductor, ni los

doble en el punto de conexion.

7. Siga las pautas del fabricante para sujetar firmemente el dispositivo

de liberacion de tension y el cable de alimentacion.

8. Vuelva a instalar la cubierta del bloque terminal.

21

Recept_iculo

iNO retire la conexibn

interna a tierra

en los sistemas trifilares!

sistema tetrafilar e instalarla en un sistema trifilar,

mueva la conexion a tierra interna del terminal

central nuevamente hacia el tornillo VERDEque se

encuentra junto al bloque terminal.

- PELIGRO DE EXPLOSION - NUNCA

Terminal

J neutro

Paramover la secadora desde un

Page 22

Conexion electrica (fuera de Canada): tetrafilar

- PELIGRODE DESCARGAELECTRICA-

El no desconectar el suministro electrico antes de realizar cualquier

reparacion puede ocasionar lesiones personales o incluso la muerte.

1. Desconecte el suministro electrico del tomacorriente.

2. Extraigael tornillo que sujeta lacubierta de accesodel bloque terminal

que seencuentra en la esquinasuperior de la parte traserade la secadora.

3. Instaleun dispositivo de liberacion de tension aprobado por U.L., de

acuerdo con lasinstrucciones relativasal cable de alimentacion/dispositivo

de liberacion de tension del fabricante, en el orificio de entrada del

cable de alimentacion debajo del panel de acceso.Eneste momento, el

dispositivo de liberacion de tension debeestar holgadamente en su lugar.

4. Paseun cable de alimentacion aprobado por U.L. DESENCHUFADO,

de 30 amp. tipo NEMA 14-30, SRDTo STa traves del dispositivo de

liberacion de tension.

5. Desconecte el cable interno (BLANCO)de conexion a tierra que

integra el enchufe preformado de la secadora del tornillo de

conexion a tierra (VERDE)que est,1junto al bloque terminal.

6. Conecte el cable de conexion a tierra (VERDE)del cable de

alimentacion al gabinete utilizando el tomillo (VERDE)de conexion a

tierra. Ajuste el tornillo con firmeza.

7. Muevael cableinterno (BLANCO)de conexionatierra que integra el

enchufe preformado de la secadoraal bloque terminal y conectelojunto

con el conductor neutro(BLANCO)del cablede alimentacional terminal

PLATEADOdel centro del bloque terminal.Ajuste el tornillo confirmeza.

8. Conecte los conductores ROJOy NEGROdel cable de alimentaciOn a

losterminales externos de color LATONdel bloque terminal. Ajuste los (PLATEADO)paralos

dos tornillos con firmeza.

Receptaculo

tetrafilar

(tipo NEMA

14-30R)

Tornillo VERDE

de conexi6n

a tierra

de conexi6n

a tierra

I able VERDI"

Mueva el cable de

conexi6n interna a

tierra (BLANCO) al

terminal del neutro

sistemas tetrafilares.

Terminal

neutro

Cable BLANCO

neutro

"-1

Cable de

alimentaci6n

NEGRO o ROJO

- PELIGRODEDESCARGA ELE-CTRICA-

No forme un _ingulo agudo con el cableado/conductor, ni los

doble en el punto de conexion.

Cable de

alimentaci6n

NEGRO o ROJO

9. Siga las pautas del fabricante para sujetar firmemente el dispositivo

de liberacion de tension y el cable de alimentacion.

10.Vuelva a instalar la cubierta del bloque terminal.

Instalad6n general

1. Conecte el tubo de escape al sistema de escape exterior (consulte las

paginas 34 a 36). Se recomienda usar una abrazadera (pieza A) de

4" (10,2 cm) para conectar las secadora al sistema de ventilacion de

escape. Utilice cinta de papel de aluminio para sellar lasdemas uniones.

2. Deslice la secadora a su posicion final cuidadosamente. Ajuste una o

varias de las patas de la secadora hasta que se encuentre firme sobre

lascuatro patas. Coloque un nivel en la parte superior de la secadora..........

La secadora DEBEestar nivelada y firme sobre lascuatro patas.

Presione las distintas esquinas para asegurarse de que la secadora esta

estabilizada. Retire y deseche la cinta de la puerta.

Revisela caja del interruptor autom_itico/fu-

sibles para asegurarse de que la electricidad este desconectada

antes de conectar el cable de alimentacion al tomacorriente. {

,

Conecte el cable de alimentacion a un tomacorriente con conexion a tierra.

4. Conecte laelectricidad desde la caja del interruptor autom_itico/fusibles.

5. Consulte la Guia de usoy cuidado que se proporciona con la secadora.Dicha

gu[a contiene informacion util y valiosa que le ahorrar_itiempo y dinero.

6. Si tiene alguna pregunta durante el funcionamiento inicial, repase la

"Lista de control para evitar el servicio tecnico" de su Guia de uso y

cuidado antes de Ilamar al servicio tecnico.

7. Guarde estas instrucciones cerca de la secadora para referencia futura.

_ _r__m_Dentro de la consola de la secadora, encontrar_i una

hoja de informacion tecnica y un diagrama de cableado.

22

I

Page 23

Puerta Reversible

Accesorios

Su secadora ha sido diseflada para que la puerta pueda set

cambiada de lado en cualquier momento sin necesidad de pie-

zas adicionales. La conversion se hace transfiriendo las bisagras

al lado opuesto del gabinete.

C6mo cambiar la direcci6n de apertura de la puerta:

1. Abra la puerta de la secadora. Quite los cuatro receptores

del agujero de la bisagra del lado izquierdo de la apertura

de la puerta. Coloquelos en un lugar cercano para futura

instalacion.

_ Puede que se necesite un cuchillo de pl_istico para po-

der sacar los receptores. Tenga cuidado de no rayar la pintura.

2. Quite los cuatro tornillos que aseguranlas bisagras de la

puerta al panel frontal de la secadora (ver figura abajo).

El no utilizar accesorios fabricados (o

aprobados) por el fabricante puede ocasionar lesiones perso-

nales, dahos a la propiedad o dahos a la secadora.

KiT DE CONVERSION A GAS LP

PiezaNo..PCK2003

Lassecadoras a gas disehadas para el uso en lugares con

suministro de LPrequieren utilizar un kit de conversion antes

de la instalacion.

KIT DE INSTALACION EN UNA CASA RODANTE

PiezaNo.. 137067200

La instalacion en una casa rodante requiere utilizar el KIT DE

INSTALACION ENUNA CASA RQDANTE.

REJILLA DE SECADO

Dependiendo del modelo que haya comprado, es posible que

esta secadora incluya una rejilla de secado. Si el modelo que

adquiri6 no incluye una rejilla de secado o desea una rejilla

adicional, p6ngase en contacto con el distribuidor donde

compro su secadora.

KIT DE VENTILACION DIRECCIONAL

PiezaNo.. 131456800

Ordene este kit para utilizar la opcion de ventilacion lateral.

La tornilleria adicional la puede encontrar en su ferreteria

local.

3. Gire la puerta 180° y vuelva a colocar lasbisagrasde la puerta

en el panel frontal con los cuatro tornillos.

4. Instale los cuatro receptores de los agujeros de las bisagras

en los agujeros abiertos en el lado derecho de la apertura

de la puerta.

Piezas de repuesto:

Si necesita obtener piezas de recambio para su secadora,

pongase en contacto con el distribuidor donde compro su

secadora.

- PELIGRODEDESCARGA ELECTRICA-

Cuando se reparen los controles, rotule todos los cables antes

de desconectarlos. Loserrores de cableado pueden producir un

funcionamiento incorrecto y peligroso. Verifique que el funcio-

namiento es correcto despues de realizar las reparaciones.

MARCADORES DE PINTURA DE RETOQUE

Marcadorde retoque de pintura blanca- PiezaN° 5303321319

Botellade retoque color bisque- PiezaNo..5304414035

Marcadorde retoquede pintura negra- PiezaNo..5304458932

KiT DE INSTALACION EMPOTRADA

(modelos de consola frontal solamente)

Para instalaci0n empotrada, el panel superior debe ser

removido y el kit 131629100 debe ser instalado.

KIT DE SECADORA PARA CENTRO DE LAVADO

(modelos de consola frontal solamente)

PiezaNo.. 5303937141

Dependiendo del modelo que haya comprado, es posible que

esta secadora incluya un kit para instalarla sobre la lavadora

correspondiente. Si el modelo que adquirio no incluye un

kit de instalacion sobre la lavadora o desea un kit diferente,

puede pedir uno.

PEDESTAL DE 15" (38 cm)

(modelos de consola frontal solamente)

Un accesorio de pedestal, especialmente disehado para esta

secadora, se puede utilizar para elevar la unidad y facilitar

su uso. Dicho pedestal agregar_i aproximadamente 38 cm

(15 pulgadas) a la altura de su unidad para una altura total

de 130 cm (51.25 pulgadas). P6ngase en contacto con el

distribuidor donde compro su secadora.

23

Page 24

Loading...

Loading...