Page 1

01/30/2008

White-Westinghouse

Mighty

ww-100

INSTRUCTION

MenderTM

MANUAL

Page 2

01/30/2008

Table

Parts

Getting

Bobbin

Threading

Place

Raise

Contents

of

and

Started

Winding

the

Wound

the

Bobbin

accessoiy

the

MendingAScain

Changing

Needle

TABLE

Top

(Needle)

Bobbin

Thread

-

OF

CONTENTS

Thread

—

3

4

6

-—

—

--

——

—__—

7

9

11

12

13

14

AdjustTension—

—

15

Page 3

01/30/2008

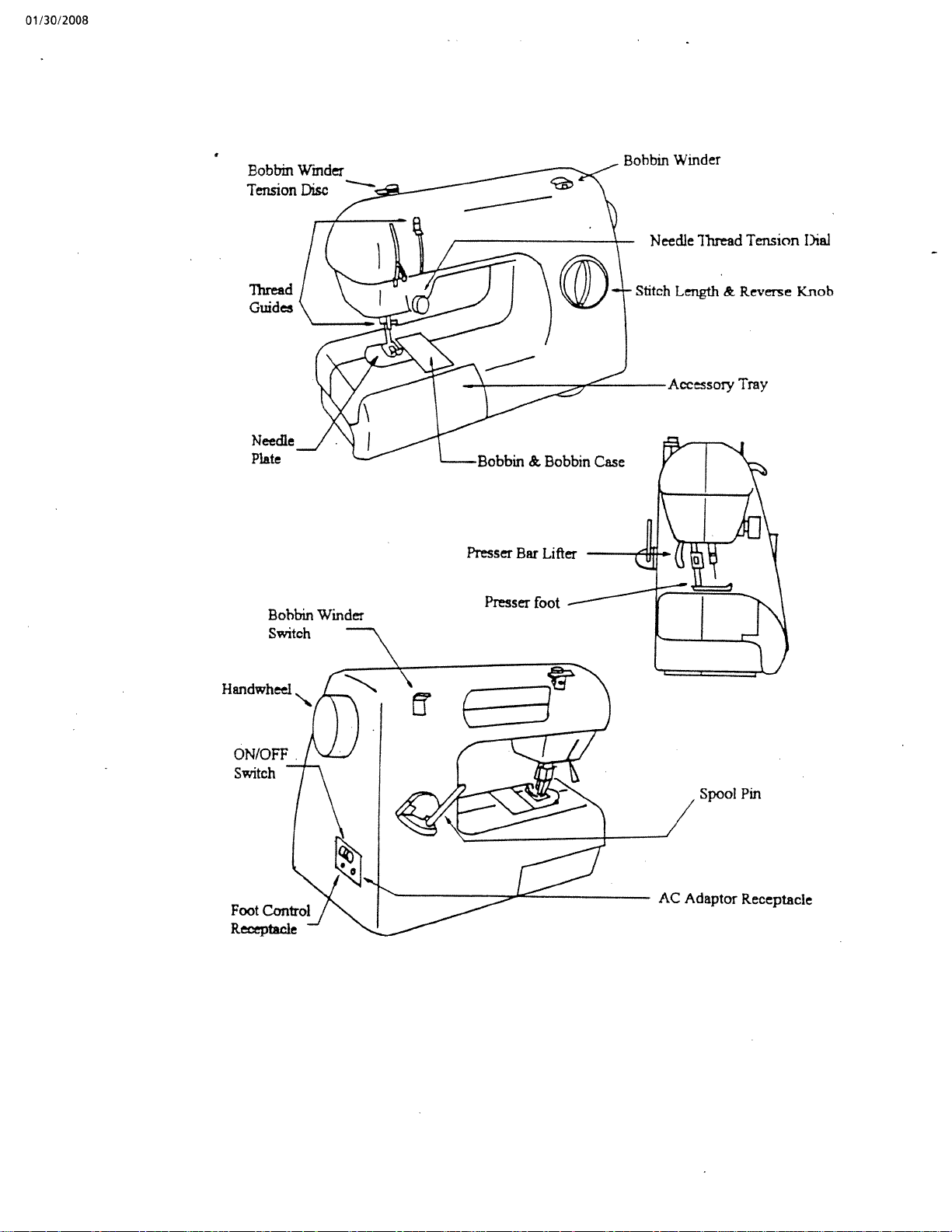

Bobbin

Tension

Thread

Guides

Needle

Plate

Bobbin

Switch

Winder

Disc

Winder

Presser

Presser

Bar

Lifter

foot

Bobbin

Needle

Stitch

Winder

Thread

Length

Reverse

&.

Tension

I)iai

Knob

Switch

Receptacle

AC

Spool

Adaptor

Pin

Receptacle

Page 4

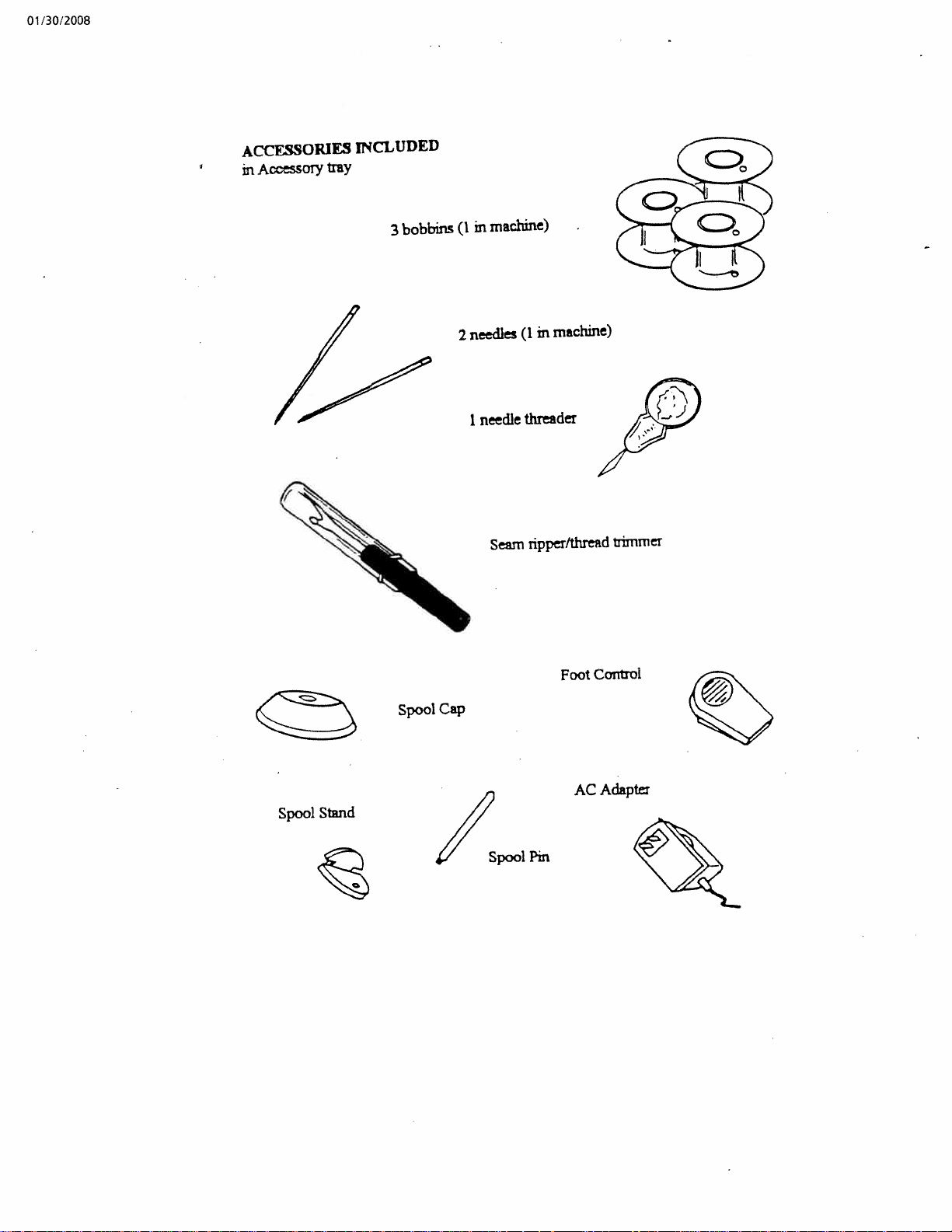

LO

8OOIOEI

4flIOSSDDV

Aui

ui

1ossooV

aafl1DI

E

t)

U!

suzqqoq

t

I

spU

pU

um

i)

(unpLU

U!

(;unowU1

1pB1tT

pxtç/zdd!1

iztutu

podS

pums

POdS

deD

tood/

uij

ooj

DV

IcmUOD

izdvpy

Page 5

01/30/2008

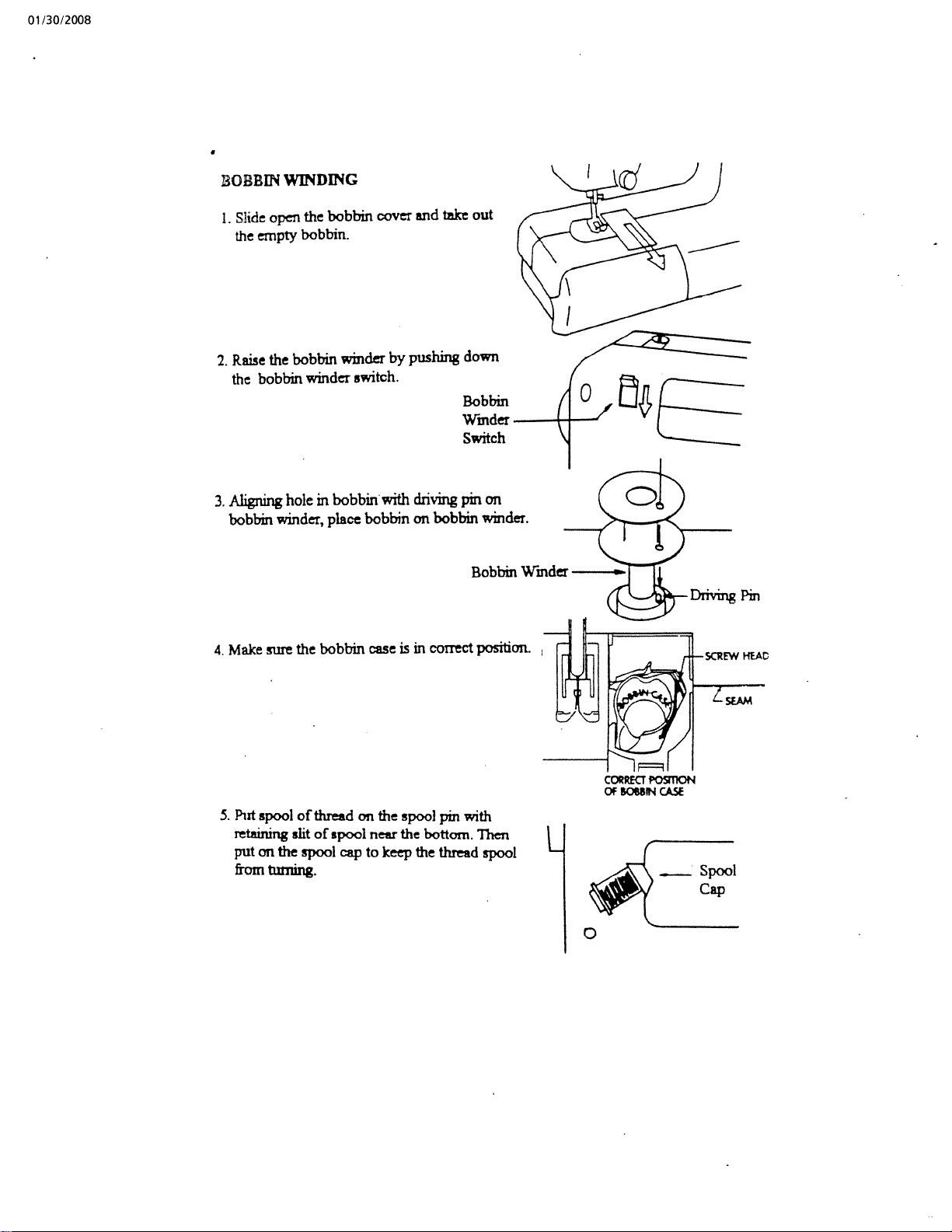

BOBBIN

Slide

1.

the

Raise

2.

the

Aligning

3.

bobbin

WINDING

open

empty

the

bobbin

hole

windet

the

bobbin.

bobbin

winder

in

bobbin

winder

switch.

bobbin

place

covet

by

with

bobbin

take

and

pushing

driving

on

bobbin

out

down

Bobbin

Winder

Switch

on

pin

winder.

Make

4.

Put

5.

retaining

put

from

sure

spool

on

the

tinning.

bobbin

the

of

threadonthe

of

slit

spool

spooi

case

near

captokeep

in

is

spool

the

the

correct

pin

bottom.

thread

position.

with

Then

spool

L

0

Page 6

01/30/2008

•

THREADING

I.

2.

Pull

the

fist

Pull

thread

thread

thread

thread

guide.

THE

from

guide.

through

TOP

spool

the

(NEEDLE)

and

slip

circular

into

slit

THREAD

the

slit

of

the

of

second

3.

4.

Turn

lever

the

Hold

tension

thread

handwheel

at

hole

thread

discs

tension

its

highest

from

tight

of

dial).

your

and

the

third

toward

position.

right

slip

it

thread

you

to

left.

in

and

Pull

between

guide

make

thread

the

two

(Needle

the

take

through

Take

Lever

Thread

Tension

Dial

up

up

Page 7

01/30/2008

6.

7.

Put

from

Pull

thread

the

first

around

thread

inside

from

thread

tension

through

for

spool

guide,

disc.

the

about

and

then

small

Y

pull

wrap

long.

hole

it

through

one

of

time

the

bobbin

Bobbin

Winder

8.

Cut

9.

thread

desired

10.

Slide

thread

a.fter

the

Cut

thread

wound

bobbin

switch

pow

the

end

few

a

thread

Inromer.

amount

bobbin

winder

up.

switch

tightly

and

coils

are

nd

Then

of

threadiswound.

4

from

from

by

to

step

wound.

the

on

continue

the

bobbin.

the

pushing

ON

position,

on

the

of

top

winding

machine.

bobbin

the

foot

bobbin

the

Remove

Lower

hold

the

control.

by

until

the

the

winder

Stop

HERE

Page 8

01/30/2008

PLACE

Hold

1.

left

the

Feed

2.

the

THE

the

hand

bobbin

the

bobbin

WOUND

thread

and

case

thread

case

end

place

as

through

as

BORBII

with

wound

the

shown.

shown.

the

3”

long

two

by

bobbin

notches

yoin

into

of

Bobbin

Case

1st

notch

Leave

3.

the

threading

about

bobbin

4”

long

toward

isconiplete.

the

of

thread

left

of

laying

you.

on

Then

top

of

bobbin

2nd

notch

Page 9

01/30/2008

3’.A!3E

1.

2.

3.

THE

presser

the

Raise

lifter.

bar

top

the

Hold

counterclockwise

up

back

and

up

thread.

up

ripper

thread.

the

by

the

bobbin

Open

bobbin

open

seem

of

BOBBIN

foot

thread

to

and

you

loop

to

you

If

hands,

to

help.

THREAD

pulling

by

turn

and

make

see

will

find

the

find

can

you

the

it

the

a

thread

is

use

the

up

handwheel

needle

go

formed

loop

end

difficult

the

flat

presser

down

by

of

to

side

back

back

of

into

place.

Then

ends

thread

both

4.

Pull

the

start

bobbin

mending

and

you

slide

can

the

to

cover

now.

the

machine

Page 10

01/30/2008

GETrING

1.

Make

OFF

and

AC

2.

Take

the

the

accessory

ñgure

STARTED

sure

the

position.

adaptor

spool

shown.

power

Connect

plug.

stand

tray

then

switch

the

and

spool

assemble

is

foot

the

in

control

pin

from

as

the

Slide

3.

machine.

the

spool

stand

on

the

rear

left

of

the

L

0

Page 11

01/30/2008

MENDING

1.

Set

by

Raise

2.

andliftupthepresserfoot.

Make

3.

behind

4.

Put

the needle

lower

Step

5.

stitches

step

6.

Thrn

backstitch

stitch

the

needle

swe

the

the

on

off

stitch

A

control

stitch

both

the

needle,

fabric

into

presser

foot

control

overlap

the

foot

control

4

-

SEAM

control

turning

by

threads

under

the

the

control.

stitches

5

your

to

knob.

the

existing

foot

to

old

knob

desired

handwhed

the

ends

presser

old

start

mending

stitches

reverse

to

to

secure

stitch

are

pulled

foot

stitches.

about

the

length

counterclockwise

4

back

md

lower

Then

until

new

Then

1.

position

and

seam.

PRE5SE

SARLJFIER

PRESSER

FOOT

I

f

/

/?

7.

Raise

the

of

from

presser

machine.

the

edge

foot

Then

of

and

fabric.

pull

cut

fabric

both

straight

thread

backward

ends

about

4

Page 12

01/30/2008

cJIANGINGNEEDLE

I.

2.

3.

Raise

Ibid

clamp

Insert

side

the

new

to

needle

the

needle

screw.

needle

right

the

and

Then

Place

to

take

mto

its

highest

loosen

the

as

away

clamp

far

position.

needle

the

the

as

up

old

with

it

needle.

the

will

flat

go.

Needle

Screw

Clamp

Tighten

4.

:1

—)‘tA%&

the

needle

clamp

screw.

Flat

side

Page 13

01/30/2008

handwheeL.

threader

and

the

the

of

Insert

pull

thread

theader

Lower

5.

thread

guide.

Raise

6.

the

through

the

forward

As

the

needle

the

nedIe

to

shown

needle.

from

eye

wire

by

the

on

Put

loop

turning

back

figure.

the

righi

bscktorightThenneedlemthreadecL

thread

filth

through

Pull

Page 14

01/30/2008

ADJUSTING

performance

stitch

Test

you

With

threads

lock

If

straight

Correct

If

straight

Correct

are

correct

both

upper

upper

going

tension

threads

tension

along

turn1ng

by

tension

along

turning

by

THREAD

use.

to

tension

equal

is

in

too

is

upper

too

is

lower

tension

on

®

and

cente

tight,

surface

tension

loose,

surface

TENSION

scrap

a

,

upper

strong

upper

of

dial

bottom

fabric

of

dial

of

lower

end

enough

thread

fabric

illusimtecL

as

thread

as

Illustrated.

material

to

lies

).

lies

©.

(N

Loading...

Loading...