White-Westinghouse SWX703HS0, SWS1233HS1, SWS1339HQ0, SWS1339HS0, SWS833HQ0 Installation Guide

...Page 1

Installation

Instructions

[::_ii_i,,_!!_[_:ii!i__i_!!i!!iii_i__:iil_211_i!!!i_!!!,_,_,fi!_iiii!__ii_i:,_!_"ii!!!i:,C_iCi!ii_;ii_',,i_i_iiii__ii_!:i'i_i!_,_i_iiiiill_!_i_,i_!iii_ii,_i_!_i!ii!_,:!_i_i:_,_i_ii_:_?,:_!i!!ii!?,_i....

instrucciones

para la instaladOn

Before beginning installation, carefully read these instructions. This will simplify the installation

and ensure the washer is installed correctly and safely. Leave these instructions near the washer

after installation for future reference.

NOTE: The electrical service to the washer must conform with local codes and ordinances and the

latest edition of the National Electrical Code, ANSI/NFPA 70.

Antes de comenzar la instalacion, lea estas instrucciones co atencion. Le facilitaran la

instalacion y asegurar_n que la lavadora sea instalada correctamente y de manera segura. Guarde

estas intstrucciones cerca de Ioa lavadora una yes terminada la instalacion para

referirse a elias en et futuro.

NOTA: el suminstro electro de su lavadora debe estar conforme con los codigos y

ordenanzas locales y la edicion mas reciente del Codigo Etectrico Nacionat ( National Electrical

Code), ANSI/NFPA 70.

Contents

SUBJECT PAGE

Pre-lnstallation Requirements 2

Electrical Requirements 2

Grounding Requirements 2

Water Supply Requirements 2

Drain Requirements 2

Rough-In Dimensions 2

Location 2

Unpacking 2-3

Installation 3

Replacement Parts 3

Requisitos antesde la instalaciOn 4

Requisitoselectricos 4

Requisitos para latoma de tierra 4

Requisitos para elsuministro de agua 4

Requisitos para el drenaje 4

Dimensiones para lainstalaci6n 5

Ubicacion desu hvadora 5

Desempaque 5

Instalacion 5-6

Piezasde repuesto 6

Printed in U.S.A. P/N I34771300 (0608)

Page 2

PRE-INSTALLATION REQUIREMENTS

Tools Required for Installation:

1.

3/8 in. socket wkh ratchet.

2.

Channel-lock adjustable pliers.

3.

Carpenter's level.

ELECTRICAL REQUIREMENTS

CIRCUIT- Individual, properly polarized and grounded 15amp. branch

circuit fused with 15 amp. time delay fuse or circuit breaker.

POWER SUPPLY - 2wire, with ground, 120 volt, single phase, 60 Hz,

Alternating Current.

OUTLETRECEPTACLE - Properly grounded 3-prong receptacle to be

located so the power supply cord isaccessible when the washer is in

an installed position.

GROUNDING REQUIREMENTS

conductor can result in a risk of electrical shock. Check with a licensed

electrician if you are in doubt as to whether the appliance is properly

grounded.

1. The washer MUSTbe grounded. Inthe event of a malfunction or

breakdown, grounding will reduce the risk of electrical shock by

a path of least resistance for electrical current.

2. Since your washer is equipped with a power supply cord having

an equipment-grounding conductor and a grounding plug, the

plug MUST be plugged into an appropriate, copper wired

receptacle that is properly installed and grounded in accordance

with all local codes and ordinances or in the absence of local

codes, with the NationalEbctricalCodes,jq if DOnot, under -_

ANSI/NFPA 70 (latest edition). If in _ _i_tances, ::

doubt, call a licensed electrician. I /17 J or bypassthe

DO NOT cut off or alter the 2r_u2_!2gP!_2g:_J

grounding prong on the power

supply cord. In situations where a --1t1_1_

two-slot receptacle is present, it is _lw

the owner's responsi- Powersupply _

..... cord with 3" tong

blhty to have a hcensed electnclan g_oundingp_u*g_g

replace it with a properly grounded three prong grounding

type receptacle.

3. For added personal safety, connect a separate ground wire (No.

18 minimum) from a top panel hinge screw on the rear of the

washer to a grounded cold water pipe. DO NOTground to a gas

supply pipe or hot water pipe.

4. Grounded cold water pipe MUSThave metal continuity to electrical

ground and MUST register no more than 25 ohms resistance. It

MUST not be interrupted by plastic, rubber, or other electrical

insulating connectors such as hoses, fittings, washers, gaskets

(including water meter or pump). Any electrically insulated

connector should be jumped with a length of No. 4 copper wire

securely clamped to bare metal at both ends with a UL approved

ground clamp.

5.

If a grounded water pipe is not available, a ground rod MUSTbe

used and register no more than 25 ohms resistance when in the

ground. Drive the rod into the ground outside the dwefling and

connect a grounding wire (12 AWG or heavier) between the

grounding screw and the grounding rod. It may take more than

one ground rod to not exceed 25 ohms resistance to ground.

improper connection of the equipment grounding

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within 42 inches (107

cm) of your washer's water inlet. The faucets MUST be 3/4 inch (1.9 2.

cm) garden hose type so inlet hoses can be connected. Water pressure

MUST be between 10 and 120 pounds per square inch (maximum 3.

unbalance pressure, hot vs. cold, 10 psi.) Your water department can 4.

advise you of your water pressure. The hot water temperature should 5.

be about 140 degrees F(60 degrees C). 6.

2

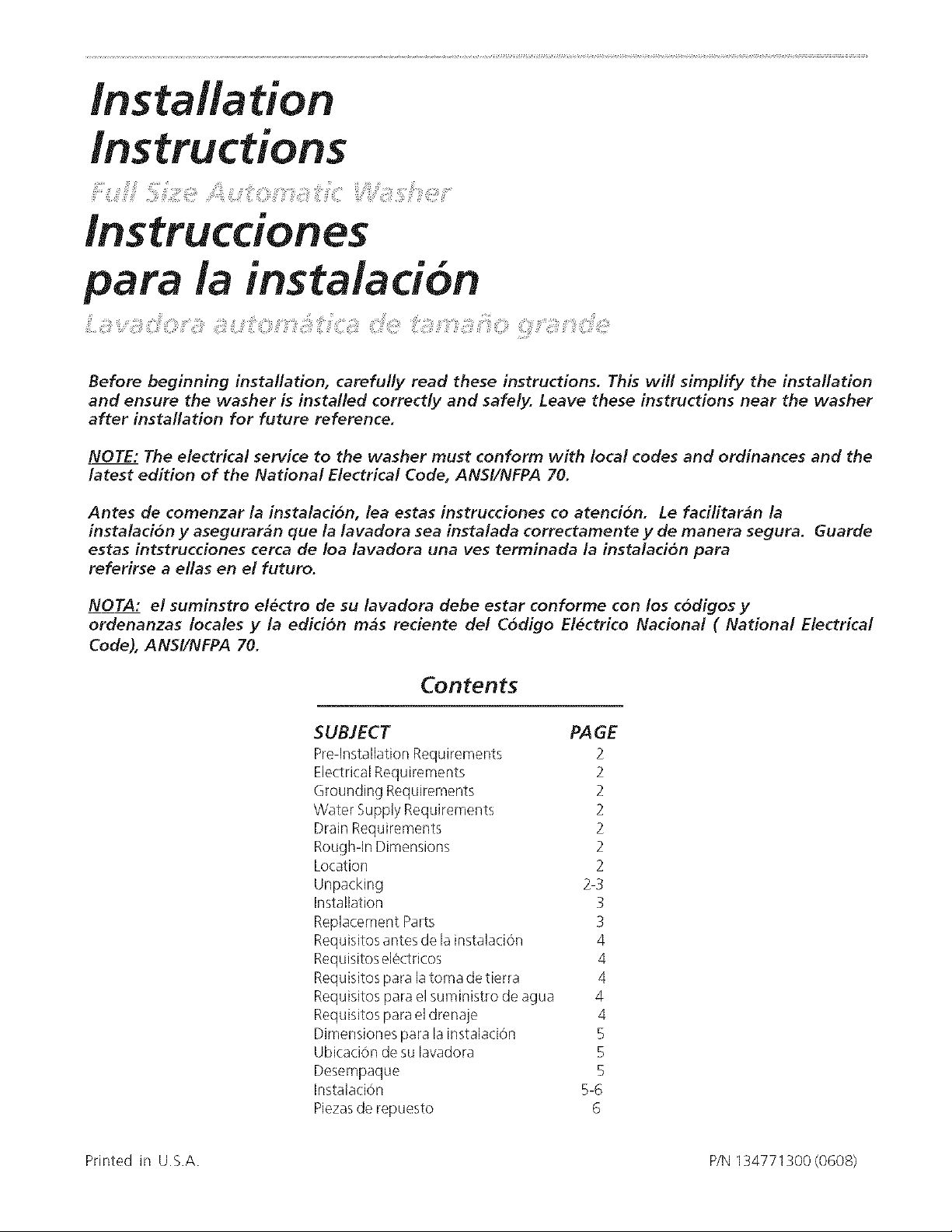

DRAIN REQUIREMENTS

1.

Drain capable of eliminating 17 gallons (64.3 L) per minute.

2.

A standpipe diameter of 1-1/4 in. (3.18 cm) minimum.

3.

The standpipe height above the floor should be:

Minimum height: 33 in. (61 cm)

Maximum height: 96 in. (244 cm)

--T--

_, 96" Max.

33" Min. (244 cm)

(61 crn)

.L __£__

NOTE: For installations requiring a longer drain hose, have a

qualified technician install a longer drain hose according to your

model number. For drain systems in the floor, install a syphon

break kit, P/N 5377678100. Both parts are available from an

authorized parts distributor.

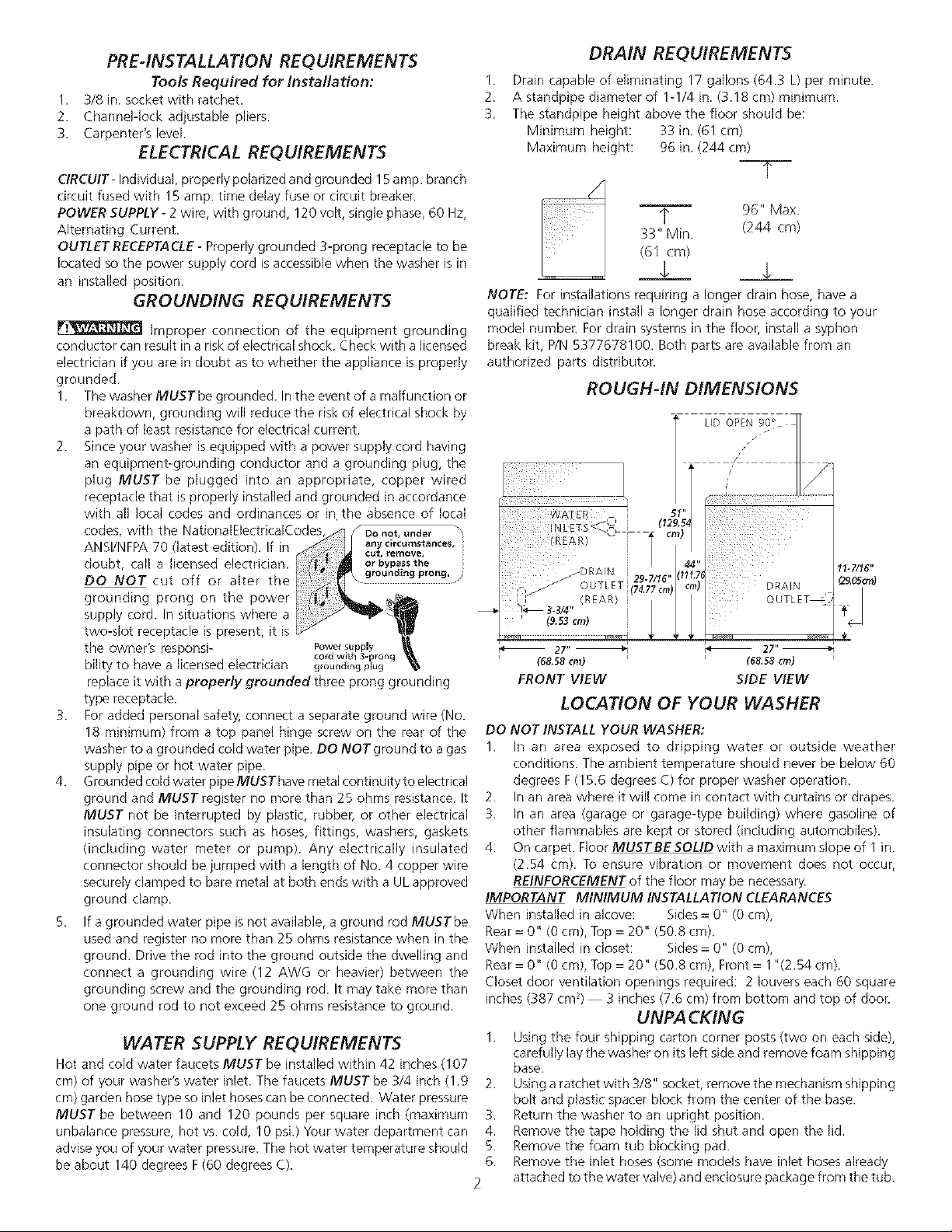

ROUGH-IN DIMENSIONS

VVA_ER _ 51"

NLEfS<J_' 1129.S4

(REAR) •

,,

, OUTLET 29-7/16" (11

I_ 3-3/4"

,J REAR I I

' (9.s3c_)

27"_

(68.58cm)

FRONT VIEW

(74.77cm) c

OUTLETS'/_ "_L

I _ I _

27"_

(6&58cm)

SIDE VIEW

LOCATION OF YOUR WASHER

DO NOT INSTALL YOUR WASHER:

1. In an area exposed to dripping water or outside weather

conditions. The ambient temperature should never be below 60

degrees F(15.6 degrees C) for proper washer operation.

2. In an area where it will come in contact with curtains or drapes.

3. In an area (garage or garage-type building) where gasoline of

other flammables are kept or stored (including automobiles).

4. On carpet. Floor MUSTBE SOLID with a maximum slope of 1in.

(2.54 cm). To ensure vibration or movement does not occur,

REINFORCEMENT of the floor may be necessary.

IMPORTANT MINIMUM INSTALLATION CLEARANCES

When installed in alcove: Sides= 0" (0 cm),

Rear= 0" (0 cm), Top = 20" (50.8 cm).

When installed in closet: Sides= 0" (0 cm),

Rear= 0" (0 cm), Top = 20" (50.8 cm), Front = 1"(2.54 cm).

Closet door ventilation openings required: 2 louvers each 60 square

inches (387 cm 2) 3 inches (7.6 cm) from bottom and top of door.

UNPACKING

1. Using the four shipping carton corner posts (two on each side),

carefully lay the washer on its left side and remove foam shipping

base.

Using aratchet with 3/8" socket, remove the mechanism shipping

bolt and plastic spacer block from the center of the base.

Return the washer to an upright position.

Remove the tape holding the lid shut and open the lid.

Remove the foam tub blocking pad.

Remove the inlet hoses (some models have inlet hoses already

attached to the water valve) and enclosure package from the tub.

11-7/I6"

Page 3

NOTE:

MECHANISM

SHIPPING

BOLT

If the washer isto be transported at alater date, the tub

blocking pad, shipping bolt, and plastic spacer block

should be retained.

PLASTIC SHIPPING BLOCKS

..... SPACER

BLOCK

CABLE TIE

FOAM /

SHIPPING >OWER

PAD CORD

7. From the back of the washer, remove the wire shipping clips

securing the drain hose and power cord. On some models,

PLASTICCLAMPS secure the drain hose to the right side of the

washer backsheet. These clamps form a standpipe to prevent

water siphoning. DO NOT REMOVE THESE CLAMPS.

8. Carefully move the washer to within 4 feet of the final location

for the start of the installation.

SHIPPING CARTON

CORNER POSTS/ DRAIN HOSE

INSTALLATION

1. Run some water from the hot and cold faucets to flush the water

lines and remove particles that might clog up the water valve

screens.

2. Check inlet hoses to ensure that the rubber washers are installed

in each end (If your washer has inlet hoses already attached to

the water valve, proceed to step 4).

3. Carefully connect the inlet hoses to the water

valve (on the left side of the washer cabinet),

tighten by hand, then tighten another 2/3 turn

with pliers.

OVERTIGHTEN THESE CONNECTIONS.

4. Determine which water faucet is the HOT

water faucet and carefully connect the bottom inlet hose he

HOTwater faucet, tighten by hand, then tighten another 2/3

turn with pliers. Carefully connect the top inlet hose to the COLD

water faucet, tighten by hand, then tighten another 2/3 turn

with pliers. _ DO NOT CROSS THREAD OR

OVERTIGHTEN THESE CONNECTIONS.

Turn the water on and check for leaks at both connections.

B. Excessive noise and vibration can be prevented by properly

leveling the washer. For free standinq installation and with the

washer in it's final position, place a level ontop of:he washer.

Adjust the leveling legs so the washer is level front-to-rear and

side-to-side, and stable corner-to-corner.

DO NOT CROSS THREAD OR

CABLE TIE

6. Form a "U" shape on the end of the drain hose with the hose

pointed toward the drain. On some models, a wire retainer needs

to be assembled on the hose in that position. Place the formed

end in a laundry tub or a standpipe and secure with a cable tie

provided in the enclosure package.

NOTE: The standpipe inside diameter must be 1-1/4" (3.18

cm) minimum. There must be an air gap around the

drain hose in the standpipe. A snug hose fit can cause

a siphoning action.

7. Plug the power cord into a grounded outlet.

NOTE: Check to ensure the power is off at a circuit breaker/

fuse box before plugging the power cord into an

outlet.

8. Turn on the power at a circuit breaker/fuse box.

9. Read the Operating Instructions and Owner's Guide provided

with the washer. They contain valuable and helpful information

that will save you time and money.

10. Run the washer through a complete cycle. Check for water leaks

and proper operation.

11. If your washer does not operate, pleasereview the "Avoid Service

Checklist" located in your Owner's Guide before calling for service.

12. Place these instructions in a location near the washer for future

reference.

NOTE: A wiring diagram is located inside the washer console.

REPLACEMENT PARTS

If replacements parts are needed for your washer, contact the source

where you purchased your washer or call 1-800-451-7007 for the

Frigidaire Company Authorized Parts Distributor nearest you.

Destroy the carton and plastic bags after the washer is

unpacked. Children might use them for pla_z Cartons covered with

rugs, bedspreads, or plastic sheets can become airtight chambers

causing suffocation. Placeall materials in a garbage container or make

materials inaccessible to children.

Pressdown on alternate corners and sides and feel for the

slightest movement. Adjust the appropriate leg so the washer

is SOLID on the floor on ALL four legs. Keep the leveling leg

extension at a minimum for best performance of the washer.

The instructions in this manual and all other literature

included with this washer are not meant to cover every possible

condition and situation that may occur. Good safe practice and caution

MUST be applied when installing, operating and maintaining any

appliance.

Maximum benefits and enjoyment are achieved when all the

Safety and Operating instructions are understood and practiced

as a routine with your laundering tasks.

Page 4

REQUISITOS ANTES DE LA INSTALACION

Herramientas necesarias para lainstaladon:

1. Llava de tubo de 3/8 de pulgada.

2. AlicatesajustablesChannel-lock

3. Niveldecarpintero

REQUISITOS ELECTRICOS

CIRCUITO - Circuito derivado individual, correctamente

polarizado y con toma detierra, de 15amperios con fusible

de 15 amperios con retardo o disyuntor.

ALIMENTACiON ELECTRICA - Corriente alterna

monof_isica, 60 Hz, 120 voltios, bifilar, con toma de tierra.

TOMACORRIENTES- EItomacorrientescon 3orificiosytoma

detierra correcta, debe estar ubicadode manera que elcable

electrico sea accesible cuando la lavadora este instalada.

REQUISITOS PARA LA TOMA DE TERRA

Laconexion incorrecta del conductor

de toma detierra deeste equipo puede causar un riesgo de

descargaselect ricas.Consulte aun electricista licenciado si

no estaseguro sielelectrodomestico est.1bienconectado a

tierra.

1. La hvadora DEBEser conectada a una toma de tierra.

Encasode un mal fundonamiento o una falla, la toma

de tierra reduce el riesgo de descargas electricas

proporcionando a la corriente electrica una via con

menos resistenda.

2.

Yaque su lavadora esta equipada con un cableelectrico

que Ilevaun conductor para toma detierra yun enchufe

para toma de tierra, el enchufe DEBE ser insertado en

un tomacomentes adecuado, con hilos de cobre, que

este instalado y conectado a tierra segun todos los

codigos y ordenanzas locales, o si no existen c0digos

locales, con los National Electrical Codes (Codigos

Electricos Nacio alesk ANSI/NFPA70 da edicion mas

reciente). Sino esta BAIONtNUNA

seguro, Ilame a un

electricista licenciado.

NO corte ni modifique la

davija de toma de tierra

del cable electrico. En

casosen que s01ohaya

un tomacomentes de

dos orificios, sera

responsa-bilidad del s_sP_6As

propietario hater que un electricista licenciado Io

cambie por un tomacorrientes de 3 orificios con la

toma de tierra adecuada.

3.

Para mayor seguridad personal, conecte un hilo de

toma de tierra separado (N° 18 como minimo)desde

un tornillo del panel superior en la parte posterior de

la lavadora a una tuberia de agua con conexiOn a

tierra. NO Io conecte a una tubeda de gas ni de

agua caliente.

' CIRCUNSTANCIA

4. La tubena de agua fria con conexi0n a tierra DEBE

tenet continudad metalica hacia la conexi0nelecticia

a tierra y DEBE registrar una resistencia no mayor de

25 ohmios. NO DEBEestarinterru mpida por conectores

de pl_istico,caucho ni otros conectores de aislamiento

el(_cticotales como mangueras, acopladores, arandelas,

juntas (induyendo un contador o una bomba de agua).

Cualquier conector el_cticamente aislado debe ser

conectado en puente con un trozo de alambre de

cobre N° 4 firmemente sujeto en ambos extremos al

metal desnudo con una abrazadera de toma de tierre

aprobada por U.L.

5. Si no se dispone de una tuberia de agua de puesta a

tierra, se DEBE usar una varilla de tierra y registrar

una resistencia no mayor de 25 ohmios cuando este a

tierra, Entierre la varilla fuera de la vivienda y

conecte el abmbre de toma de tierra (AWG 12 o

mayor) entre el tornillo y la varilla de tierra. Puede ue

se requiera mas de una varilla de tierra para no

exceder el valor de resistencia a tierra de 25 ohmios.

REQUISITOS PARA EL

SUMINISTRO DE AGUA

LasIlavesde agua caliente y fria DEBEN estar instaladas a

menos de 42 pulgadas (107 cm) de la toma de agua de la

lavadora. LasIlavesDEBEN serdel tipo manguera dejardin

de 3/4 de pulgada (1,gcm) pala que selespuedan conectar

lostubos de entrada deaguaLa presion del aguaDEBEestar

entre 10y 120 libraspor pulgada cuadrada(presion maxima

de desequilibrio, caliente cont_a fria, 10 libras por pulgada

cuadrada). Sucompaflia desuministro deagua puededecirle

cualeslapresion del agua. Latemperatura delagua caliente

debe ser de unos 140 glados F(60 grados C).

REQUISITOS PARA EL DRENAJE

1. Drenaje que pueda eliminar 17 galones (64,3 L) por

minuto.

2. Diametro de latuberia vertical de I-1/4 pulgadas(3,18

cm) como minimo.

:3. Laaltura de la tuberia vertical por encima del piso debe

ser:

AItura minima: 33 pulgadas(61 cm)

AItura maxima: 96 pulgadas (244 cm)

-7--

q. 96" Max.

33" Min. (244 cm)

(61 cm)

$ $

NOTA:

Paralasinstalaciones que requieran un tubo de drenaje

mas largo, pida a un tecnico capacitado qui instale un

tubo maslargo segun el numero desu modelo.Para los

systemas de drenaje el piso, instale un juego para

detener la accion de sif0n, N° de pieza 5377678100.

Ambos componentes estan disponible en los

distribuidores autorizados de piezasde repuesto.

4

Page 5

DIMENSIONES PARA LA INSTALACION

(1_

(ATRAS) *

SALIDA

AL DREN 29 7,1_¢'

] (ATRAS) (74.77 em

_334"

9.._3 cm)

(68,5_ cm)

VISTAFRONTAL

'_4

I11,"6

_m/ _,UDA

(68.58 cm)

VISTALATERAL

11 7/16"

UBACACION DE SU LAVADORA

NO INSTALESU LAVADORA:

I. En un area expuesta a goteos de qgua o a la

intemperie. La temperature ambiente nunca deber_i

estar por debajo de los 60 grados F(15,6 C) para que

su Bvadora funcione correctamente.

2. En un _ireadonde estara en contacto con persianas o

cortinas.

3. En un area (garaje o construccion similar) donde haya

o se almacene gasolina u otros productos inflamables

(inclusive automoviles).

4. Sobre una alfombra. El piso DEBE SER DURO con

una inclinacion maxima de 1 pulgaga pot pie (1,54

cm). Paraasegurarse de que no existan vibraciones ni

ruidos, puede ser necesario REFORZAR el piso.

IMPORTANTE

DESPEJESMINIMO5 DEINSTALAC!ON

Instalaci0n en una alcoba: Lados, Parte Trasera = 0 cm

(0 pu[g.), Parte Superior = 20 cm (50,8 pulg.)

InstalaciOn en un armario: Lados, ParteTrasera = 0 cm

(0 pu[g.), Parte Superior = 20 cm (50,8 pu[g.), Parte

De[antera = 2.54 corn (1 pulg.)

Aberturas de venti[acion requeridas en [a puerta del

armario: Dosrejillas de ventilacion cada387 cm2(60 pulg))

- 7.6 cm (3 pulg.) desde la parte inferior y superior de la

puerta.

DESEMPAQUE

1. Utilizando las cuatro esquineras de la caja de carton

(dos en cada lado), haga descansar cuidadosamente

la lavadora sobre el lado izquierdo y saque la base de

espuma de embarque.

2. Utilizando la Ilave de tubo de 3/8 de pulgada, saque

ei perno de embarque y el bloque espaciador de

plastico del centra de la base.

NOTA: si lavadora va a set transportada a otto

lugar posteriormente, conserve la espuma de

bloqueo de la tina, el perno de embarque y el

espadador de pl_stico.

BLOQUE DE

29.05 cm)

PERNO DE

EMBARQUE

ESPUMA

PROTECTORA

DE EMBARQUE

BLOQUE EMBARQUE

..ESPACIADOR

DE PLASTICO

ESQUINERAS DE

EMBARQUE DE LA_

CAJA DE CARTON DE DESAGUE

3. Vuelva a colocar la lavadora en la posicion vertical.

4. Quite la cinta que mantiene la tapa cerrada y abra la

tap&

5. Saque la pieza de espuma que bloquea la cavidad.

6. Saque lostubos de entrada de agua (algunos

modelos

tienen los tubos de entrada de agua ya acoplados a

la valvula de agua) y el paquete.

7. Saque las pinzas metalicas del embalaje de la parte

posterior de la lavadora, que sujetan el tubo de

drenaje y el cable electrico. En algunos modelos hay

ABRAZADERA5 DE PLASTICOque sujetan el tubo de

drenaje en el lado derecho del respaldo de la

lavadora. Estasabrazaderas forman una tuberia

vertical para

prevenir el sifonaje de agua. NO SAQUE ESTAS

ABRAZADERAS.

8. Con cuidado, mueva la [avadora a cuatro pies de su

ubicacion definitiva para la instalaci6n final.

INSTALACION

I. Deje correr un poco de agua de las Ilavesde agua

caliente y fria para vaciar las lineas y eliminar las

particulas que pueden obstruir las rejillas de las

valvulas de agua.

2. Examine los tubos de entrada de agua para

asegurarse

de que las arandelas de caucho esten instaladas en

cada extremo. (Si su Bvadora tiene lostubos

acoplados a la valvula de agua, siga con

el paso 4).

3. Comecte con cuidado los

tubos de entrada a la

valvula de agua (en el

lado izquierdo de la

lavadora), apriete a mano

y luego apriete 2/3 de

vuelta con unos alicates.

NO ESTROPEELAS ROSCAS

NI APRIETE ESTASCONEXIONES EXCES!VAMENTE.

:ORDON

ELECTRICO

MANGUERA

Page 6

4. Determine cu_fllde las Ilaves de agua CALIENTEy

conecte con cuidado el tubo inferior de entrada a la

Ilavede agua CALIENTE, apriete a mano y luego apriete

2/3 de vuelta con unos alicates. Conecte con cuidado

el tubo superior de entrada a lallave de agua FRIA,

apriete a mano y luego apriete 2/3 de vuelta con unos

alicates.

NO ESTROPEELAS ROSCAS N!

APRIETEESTASCONEX!ONES EXCESIVAMENTE.

Abra la Ilave del agua y compuebe que no haya fugas

en ninguna de las dos conexiones.

5. La nivelacion del ruido y de la vibracion excesivos de

la lavadora puede ser prevenida correctamente

nivelando la lavadora. Para la instalacion derecha

libre y con la lavadora en ella est_ la posicion final,

pone un nivel encima de la lavadora. Ajuste las

piernas de nivelacion asi que la lavadora es, y

esquina-a-esquina estable de adelante hacia atras y

de lado a lado liana. Presione abajo en esquinas y

lados alternos y sientase para el movimiento mas

leve. Ajuste la pierna apropiada asi que la arandela

es SOLIDA en el piso en las cuatro piernas. Guarde la

extension de nivelacion de la pierna en un minimo

para el mejor funcionamiento de la lavadora.

NOTA: el diametro interno de la tuberia vertical

debe ser de 1-1/4 pulgadas (3,18cm)

como minimo. Debe haber un espacio de

aire alrededor deltubo de drenaje en la

tubeda vertical. Un tubo sin huelgo

puede causar una accion de sifonaje.

7.

Enchufe el cable en un tomacorrientes con toma de

tierra.

NOTA: Asegurese de que la corriente este cortada

enel disyuntor/caja de fusibles antes de

enchufar el cable en el tomacorrientes.

8. Encienda la corriente en eldisyuntor/caja de fusibles.

9. Lea lasInstrucciones para el funcionamiento y la Guia

del propietario incluidas con la lavadora. Contienen

informacion valiosay util que le ahorrara tiempo y

dinero.

I0. Hagafu ncionar la lavadora durante un ciclo

completo. Compruebe que no hayafugas de agua y

que funcione correctamente.

11. Sisu lavadora no funciona, lea la "Lista de

comprobacion para evitar el servicio" que se

encuentra en la Guia del propietario, antesde Ilamar

al servicio tecnico.

12. Guarde estasinstrucciones en un lugar cercano a la

lavadora para poder referirse a eliasen el futuro.

6. Forma una "U" en el extrmo del tubo de drenaje co el

tubo senalando hacia el drenaje. En alginos modelos,

hay que colocar un retenendor metalico en el tubo para

mantenerlo en esa posicion. Coloque el extremo

formado del tubo de drenaje en un oavadero or una

tuberia vertical y fijelo con suj sujetacables incluido en

el paquete.

DE ALAMBRE

NOTA: Dentro de la lavadora, en el panel de servicio, se

encuentra un diagrama de cableado.

PIEZAS DE REPUESTO

Si necesita piezas de repuesto para su lavadora, acuda al

establecimiento donde la compro.

Desechela caja de carton y las bolsas

de plastico una vez que haya desembalado la lavadora.

Los ninos podrian usarlas para jugar. Lascajas de carton

tapadas con alfombras, colchas u hojas de plastico pueden

convertirse en c_irnaras hermOticas, causando asfixia.

Coloque todos los materiales en el basurero o evite que los

ninos tengan acceso a ellos.

_.__ Las instrucciones que aparecen en

este manual y las demas guias incluidas con esta lavadora

no pretenden cubrir todas las condiciones y situaciones

posibles que pueden ocurrir. DEBE tenerse sentido comun

y cuidado al instalar, operar mantener cualquier

electrodomestico.

Seobtiene el maximo de beneficios y resultadoscuando

todas lasinstruccionesde seguridady de funcionamiento

son comprendidas y puestas en pr_ctica de forma

rutinaria cada vez que se lava la ropa.

d

Loading...

Loading...