White-Westinghouse SGR351HS0, SGR351HS1, SGR641HQ0, SGR641HS1, SGR641HS0 Installation Guide

...Page 1

installation instructions

Instrucciones pa

="nstalaci"

_!iii_, _i_'%_ _%_i _i! "_¸ iY% _ _%_i _i _ "_ _

la

\

PiN 134169100F (0804) Printed in U.S.A.

Page 2

CONTENTS

Pro-Installation Requirements .......................................................................................................................................... 2

Electrical Requirements .................................................................................................................................................. 3

Gas Supply Requirements ............................................................................................................................................ 3

Exhaust System Requirements ...................................................................................................................................... 3-4

Location of Your Dryer................................................................................................................................................. 4-5

Mobile Home Installation ............................................................................................................................................... 5

Rough-in Dimensions ..................................................................................................................................................... 6

Unpacking ................................................................................................................................................................... 7

Reversing Door Swing ................................................................................................................................................. 8

Gas Connection ............................................................................................................................................................ 8

General Installation ....................................................................................................................................................... 8

Replacement Parts........................................................................................................................................................ 8

EspaF_ol...................................................................................................................................................................... 9-I4

SAFETY INSTRUCTIONS

Clothes dryer installation and service must be performed by a qualified installer, service agency or the gas supplier.

Install the clothes dryer according to the manufacturer's instructions and local codes•

Before beginning installation, carefully read these instructions. This will simplify the installation and ensure the dryer

is installed correctly and safely. Leave these instructions near the Dryer after installation for future reference•

NOTE: The electrical service to the Dryer must conform with local codes and ordinances and the latest edition of the National

Electrical Code, ANSI/NFPA70, or in Canada, the Canadian electrical code C22.1 part 1.

NOTE: The gas serviceto the Dryer must conform with local codesand ordinances and the latest edition of the National Fuel Gas

Code ANSI Z223.I, or in Canada, CAN/ACG B149.1-2000

NOTE: The Dryer isdesigned under ANSI Z 21.5.1 or ANSI/UL 2158 - CAN/CSA C22.2 No. I 12 (latest editions) for HOME USE

only. This Dryer is not recommended for commercial applications such as restaurants or beauty salons, etc.

Your safety and the safety of others is very important.

We have provided many important safety messagesin the Use & ClareGuide, Operating instructions, Insta%tion Instructions and

on your appliance. Always read and obey all safety messages.

This istt_e safety alert symbol. This symbol alerts you to hazards ttlat can kill or hurt you or others. All safety messages

will be preceded by the safety alert symbol and the word "DANGER" or "WARNING". These words mean:

_ You will be killed or seriously injured if you don't follow instructions.

_ You can be killed or seriously injured if you don't follow instructions.

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell you what can happen if the

instructions are not followed.

_"" RISK OF FIRE. Foryour safety the information in this manual must be followed to minimize the risk of fire or

explosion or to prevent property damage, personal injury or loss of life. SAVE THESEINSTRUCTIONS.

- Do not store or use gasoline or other flammable vapors and liquid in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building or area of all occupants.

• immediately call your gas supplier from a neighbor's phone. Follow the gassupplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for Installation:

1. Phillips head screwdriver.

2. Channel-lock adjustable pliers.

3. Carpenter's level.

4. Flat or straight blade screwdriver.

5. Duct tape.

6. Rigid or flexible metal 4 inch (I0.2 cm) duct.

7. Vent hood.

8. Pipe thread sealer (Gas).

9. Plastic knife.

2

Page 3

ELECTRICAL REQUIREMENTS

[ GASD er I

1. The dryer isequipped with a three-prong (grounding) plug

for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong from

the plug.

CIRCUIT - Individual 15

amp. branch circuit

fused with a I5 amp.

maximum time delay NOTE;Do not

fuse or circuit breaker, underany I '

POWER SUPPLY- 3 wire, remove \

120 volt single phase, 60 grounding \/

Hz,Alternating Current. prong from _ _ PRONG

POWER SUPPLY CORD - plug,

The dryer isequipped with

a 120 volt 3-wire power

cord.

circumstances_

GROUNDING

GAS SUPPLY REQUIREMENTS

Replace copper connecting pipe tha t is not

plastic-coated. Stainless steel or plastic-coated brass MUST

be used.

1. InstalBtion MUSTconform with localcodes, or in ttle absence

of localcodes, with the National FuelGasCode, ANSI Z223.1

(latest edition).

2. The gas supply line stlould be of I/2 inch (1.27 cm) pipe.

3. If codes allow, flexible metal tubing may be usedto connect

your dryer to the gas supply line. The tubing MUST be

constructed of stainless steel or plastic-coated brass.

4. The gas supply line MUST have an individual shutoff valve.

5. A 1/8 inch (0.32 cm) N.RT.plugged tapping, accessible for

test gauge connection, MUST be installed immediately

upstream of the gassupply connection to the dryer.

6. The dryer MUSTbe disconnected from the gassupply piping

system during any pressure testing of the gas supply piping

system at test pressures in excessof I/2 psig (3.45 kPa).

7. The dryer MUSTbe isolated from the gas supply piping

system during any pressure testing of the gassupply piping

system at test pressures equal to or lessthan

1/2 psig (3.45 kPa).

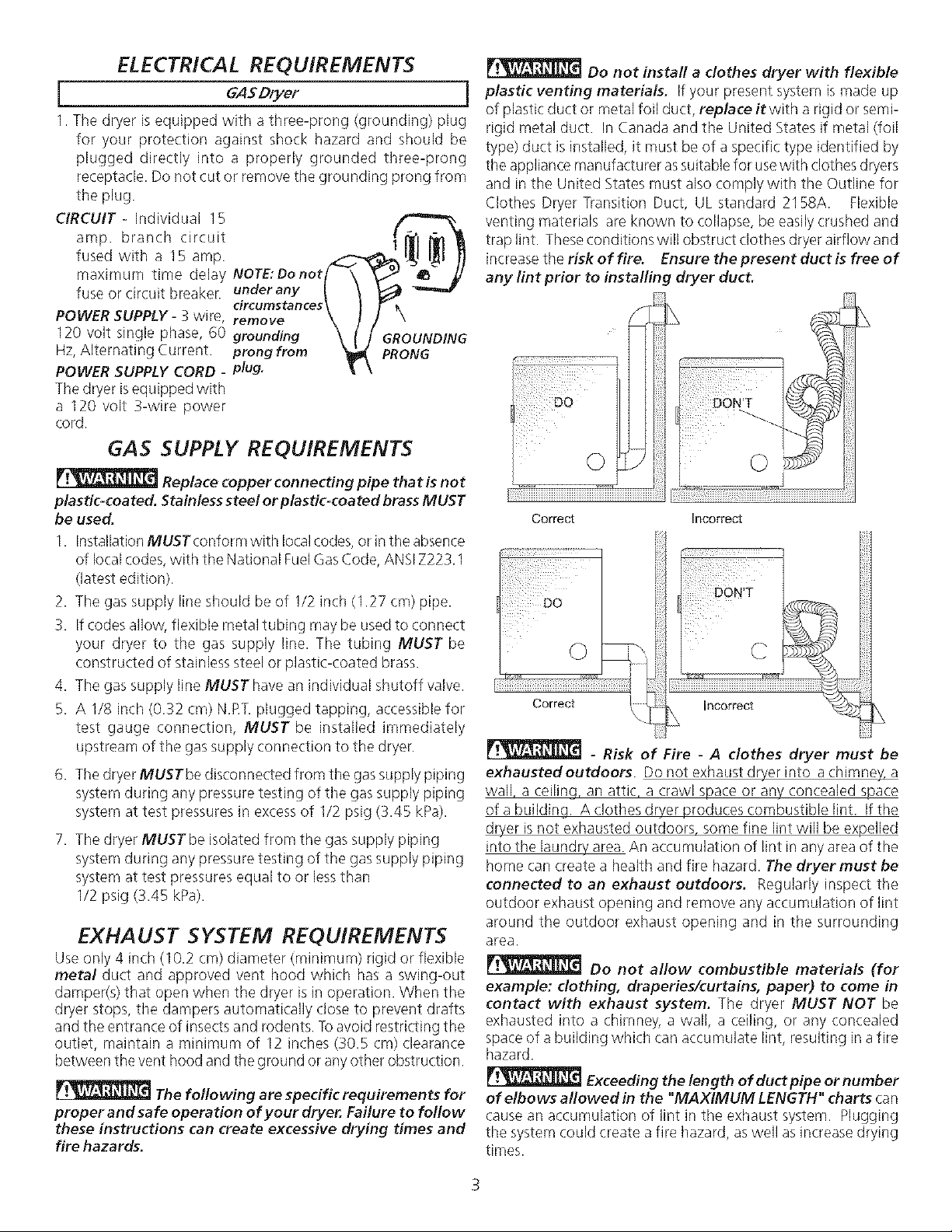

EXHAUST SYSTEM REQUIREMENTS

Use only 4 inch (10.2 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When the

dryer stops, the dampers automatically close to prevent drafts

and the entrance of insects and rodents. Toavoid restricting the

outlet, maintain a minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground or any other obstruction.

The following are specific requirements for

proper and safe operation of your dryer. Failure to follow

these instructions can create excessive drying times and

fire hazards.

Do not install a clothes dryer with flexible

plastic venting materials. If your present system is made up

of plastic duct or metal foil duct, replace it with a rigid or semi-

rigid metal duct. In Canada and the United States if metal (foil

type) duct is installed, it must be of a specific type identified by

the appliance manufacturer assuitablefor usewith clothes dryers

and in the United States must also comply with the Outline for

Clothes Dryer Transition Duct, UL standard 2158A. Flexible

venting materials are known to collapse, be easilycrushed and

trap lint. These conditions will obstruct clothes dryer airflow and

increase the risk of fire. Ensure the present duct is free of

any lint prior to installing dryer duct.

L

Correct Incorrect

d{{{_!_i

Correct

- Risk of Fire - A clothes dryer must be

exhausted outdoors. Do not exhaust dryer into a chimney, a

wall, a ceilinq, an attic, a crawl space or any concealed space

of a building A clothes dryer produces combustible lint. if the

dryer is not exhausted outdoors, some fine lint will be expelled

into the Bundrv area. An accumulation of lint in any area of the

home can create a health and fire hazard. The dryer must be

connected to an exhaust outdoors. Regularly inspect the

outdoor exhaust opening and remove any accumulation of lint

around the outdoor exhaust opening and in the surrounding

area.

Do not allow combustible materials (for

example: clothing, draperies/curtains, paper) to come in

contact with exhaust system. The dryer MUST NOT be

exhausted into a chimney, a wall, a ceiling, or any conceded

space of a building which can accumulate lint, resulting in a fire

hazard.

Exceeding the length of duct pipe or number

of elbows allowed in the "MAXIMUM LENGTH" charts can

cause an accumulation of lint in the exhaust system. Plugging

the system could create a fire hazard, as well as increase drying

times.

mncorrect

L

Page 4

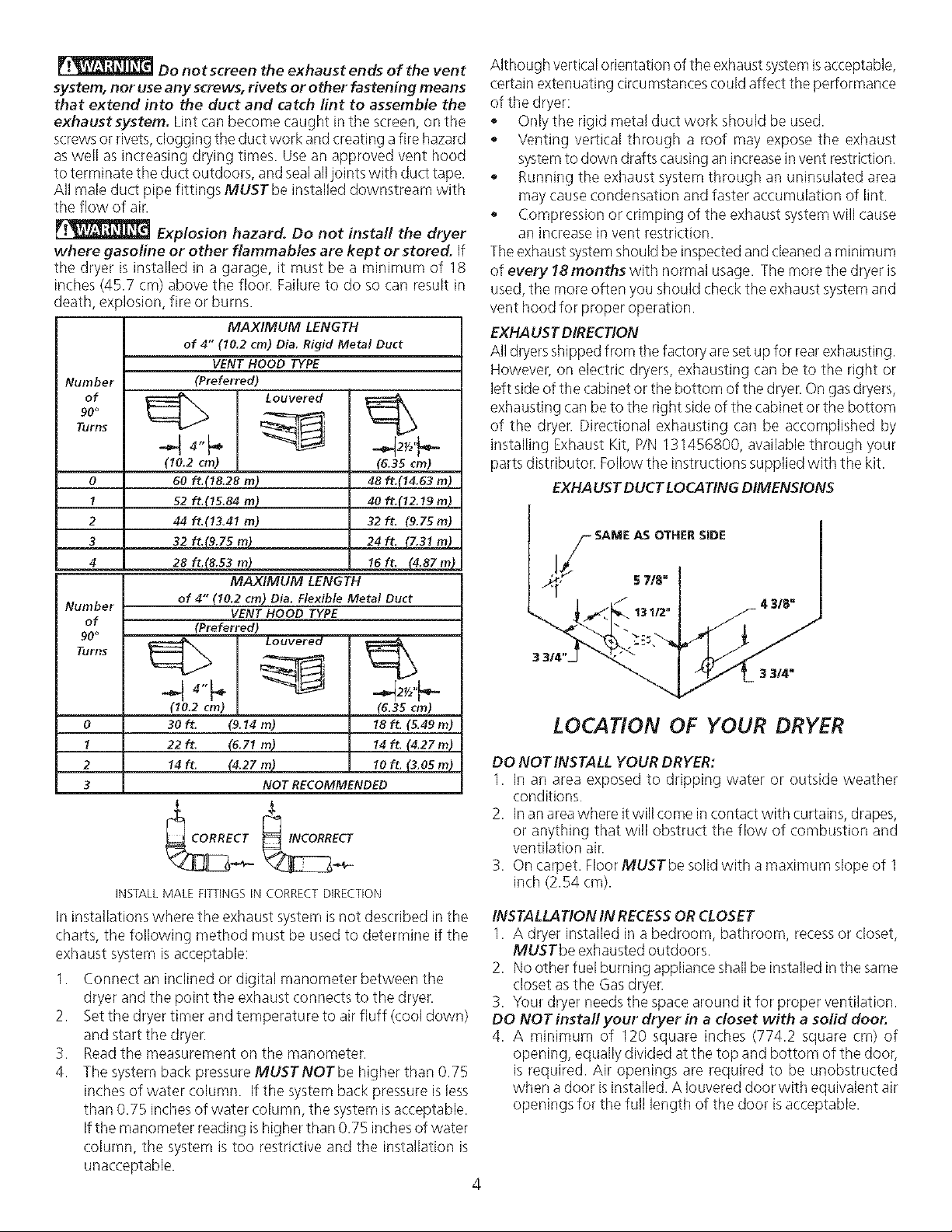

Do not screen the exhaust ends of the vent

system, nor use any screws, rivets or other fastening means

that extend into the duct and catch lint to assemble the

exhaust system. Lint can become caught in the screen, on the

screws or rivets,dogging the duct work and creating afire hazard

as well as increasing drying times. Use an approved vent hood

to terminate the duct outdoors, andsealall joints with duct tape.

All male duct pipe fittings MUST be installed downstream with

the flow of air.

Explosion hazard. Do not install the dryer

where gasoline or other flammables are kept or stored, if

the dryer is installed in a garage, it must be a minimum of 18

inches (45.7 cm) above the floor. Failure to do so can result in

death, explosion, fire or burns.

MAXIMUM LENGTH

of 4" (10.2 cm) Dia. Rigid Metal Duct

VENTHOODTYPE

Number (Preferred)

of _ Louvered

Turl'J_;

90°

(10.2 cm)

0 60 ft.(I8.28 m)

1 52 ft.115.84 m)

2 44 ft.(13.4I m)

3 32 ft._9_Z5 m}

4 28 ft_ m__

(6.35cml

48ft.(14.63m)

40 ft._12_9 m)

32ft. (9.75m)

L 24 ft. L7.31 m)

MAXIMUM LENGTH

Number of 4" (10.2 cm) Dia.FlexibleMetal Duct

of (Preferred)

VENTHOODTYPE

Although vertical orientation of the exhaustsystemisacceptable,

certain extenuating circumstancescould affect the performance

of the dryer:

• Only the rigid metal duct work should be used.

• Venting vertical through a roof may expose the exhaust

systemto down drafts causing an increasein vent restriction.

• Running the exhaust system through an uninsuJated area

may causecondensation and faster accumulation of lint.

° Compression or crimping of the exhaust system will cause

an increase in vent restriction.

Theexhaust systemshould be inspectedand cleaned a minimum

of every 18 months with normal usage. The more the dryer is

used, the more often you should check the exhaust system and

vent hood for proper operation.

EXHAUST DIRECTION

All dryers shipped from the factory areset up for rear exhausting.

However, on electric dryers, exhausting can be to the right or

left side of the cabinet or the bottom of the dryer. On gasdryers,

exhausting can be to the right side of the cabinet orthe bottom

of the dryer. Directional exhausting can be accomplished by

installing Exhaust Kit, P/N 131456800, available through your

parts distributor. Follow the instructions supplied with the kit.

EXHALISTDUCTLOCATING DIMENSIONS

Furies

90° _ Louvered

_ _ . (6.35 cm)

0 30 ft. (9.14 m) 18 ft, (5,49 m)

1 22ft. (6.71 m) 14ft, (4,27rn)

2 14 ft, (4.27 m) 10 ft, (3,05 m)

3 NOT RECOMMENDED

INSTALL MALE FI_INGS IN CORRECT DIRECTION

(10.2 cm)

In installations where the exhaust system is not described in the

charts, the following method must be used to determine if the

exhaust system isacceptable:

1. Connect an inclined or digital manometer between the

dryer and the point the exhaust connects to the dryer.

2. Setthe dryer timer and temperature to air fluff (cool down)

and start the dryer.

3. Readthe measurement on the manometer.

4. The system back pressure MUSTNOTbe higher than 0.75

inches of water column. If the system back pressure is less

than 0.75 inchesof water column, the system isacceptable.

ifthe manometer reading ishigher than 0.75 inchesof water

column, the system is too restrictive and the installation is

unacceptable.

LOCATION OF YOUR DRYER

DO NOTINSTALL YOUR DRYER:

1. In an area exposed to dripping water or outside weather

conditions.

2. Inanarea where it will come in contact with curtains, drapes,

or anything that will obstruct the flow of combustion and

ventilation air.

3. On carpet. Floor MUSTbe solid with a maximum slope of 1

inch (2.54 cm).

INSTALLATION IN RECESSOR CLOSET

1. A dryer installed in a bedroom, bathroom, recessor closet,

MUSTbe exhausted outdoors.

2. No other fuel burning appliance shall be installed inthe same

closet asthe Gasdryer.

3. Your dryer needsthe space around it for proper ventilation.

DO NOT install your dryer in a closet with a solid door.

4. A minimum of 120 square inches (774.2 square cm) of

opening, equally divided at the top and bottom of the door,

is required. Air openings are required to be unobstructed

when a door isinstalled. A Iouvered door with equivalent air

openings for the full length of the door isacceptable.

4

Page 5

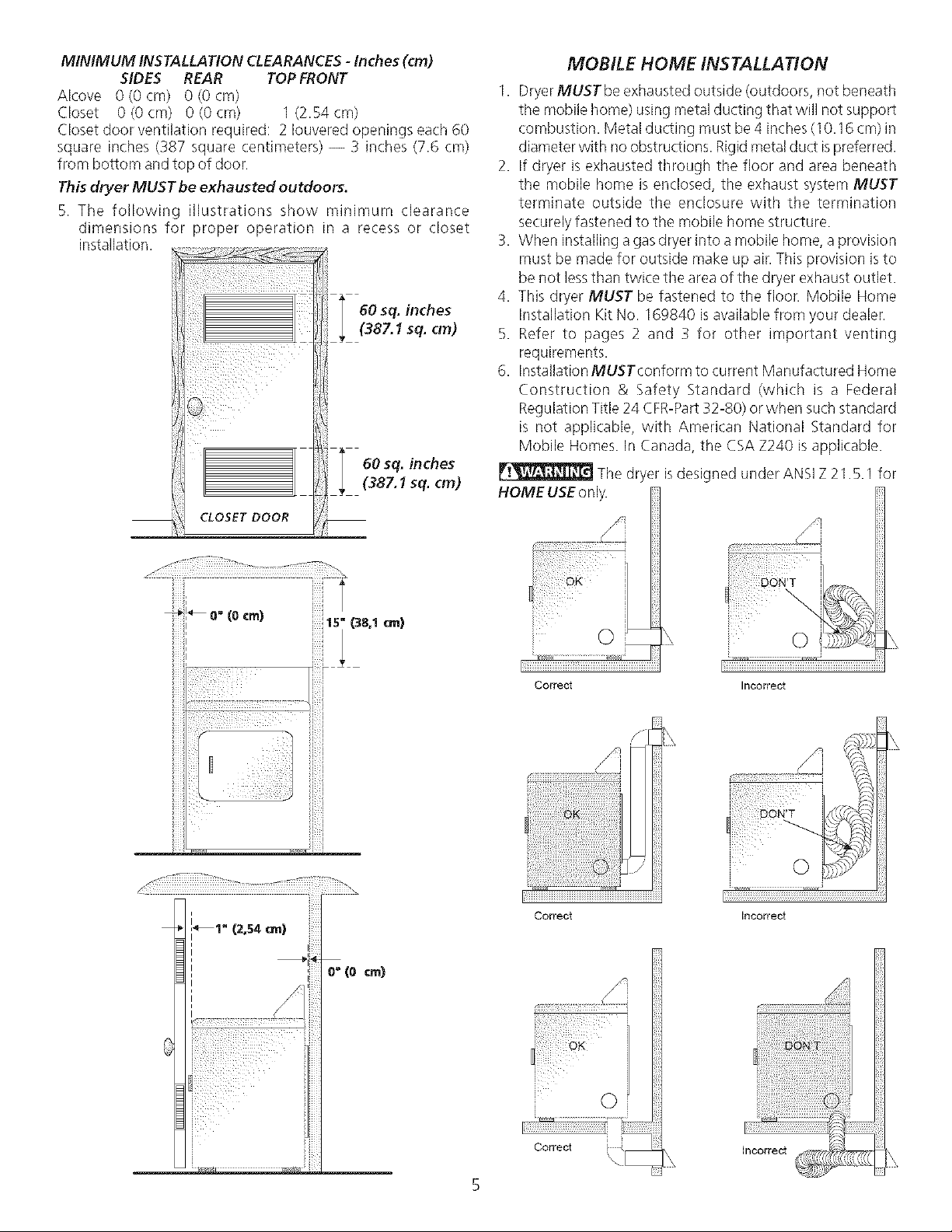

MINIMUM INSTALLATION CLEARANCES -Inches (cm)

SIDES REAR TOP FRONT

Alcove 0(0 crn) 0 (0 cm)

Closet 0 (0 cm) 0 (0 cm) I (2.54 cm)

Closet door ventilation required: 2 Iouvered openings each 60

square inches (387 squale centimeters) -- 3 inches (7.6 cm)

from bottom and top of door.

This dryer MUST be exhausted outdoors.

5. The following illustrations show minimum clearance

dimensions for proper operation in a recess or closet

installation.

60 sq. inches

(387.1 sq. cm)

CLOSET DOOR

i

MOBILE HOME INSTALLATION

1. Dryer MUSTbe exhausted outside (outdoors, not beneath

the mobile home) using metal ducting that will not support

combustion. Metal ducting must be 4 inches (10.16 cm) in

diameter with no obstructions. Rigid metal duct ispreferred.

2. If dryer is exhausted through the floor and area beneath

the mobile home is enclosed, the exhaust system MUST

terminate outside the enclosure with the termination

securely fastened to the mobile home structure.

73.When instaNinga gasdryer into a mobile home, a provision

must be made for outside make up air.This provision isto

be not lessthan twice the area of the dryer exhaust outlet.

4. This dryer MUST be fastened to the floor. Mobile Home

Installation Kit No. 169840 isavailable from your dealer.

5. Refer to pages 2 and 3 for other important venting

requirements.

6. Installation MUSTconform to current Manufactured Home

Construction & Safety Standard (which is a Federal

Regulation Title 24 CFR-Part32-80) or when such standard

is not applicable, with American National Standard for

Mobile Homes. In Canada, the CSA Z240 is applicable.

The dryer

HOME USEonly.

designed under ANSI Z 21.5.1 for

_i_ 0"(Ocrn)

iiiil

Y

if!¸¸¸ o

5i (38,1cm)

Correct Incorrect

i!iii!iiiiiiiiiiiiiii!Ti!iTiii!ili!iii!

_i7_iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

Correct Incorrect

o° (o an}

i

Correct

©

Page 6

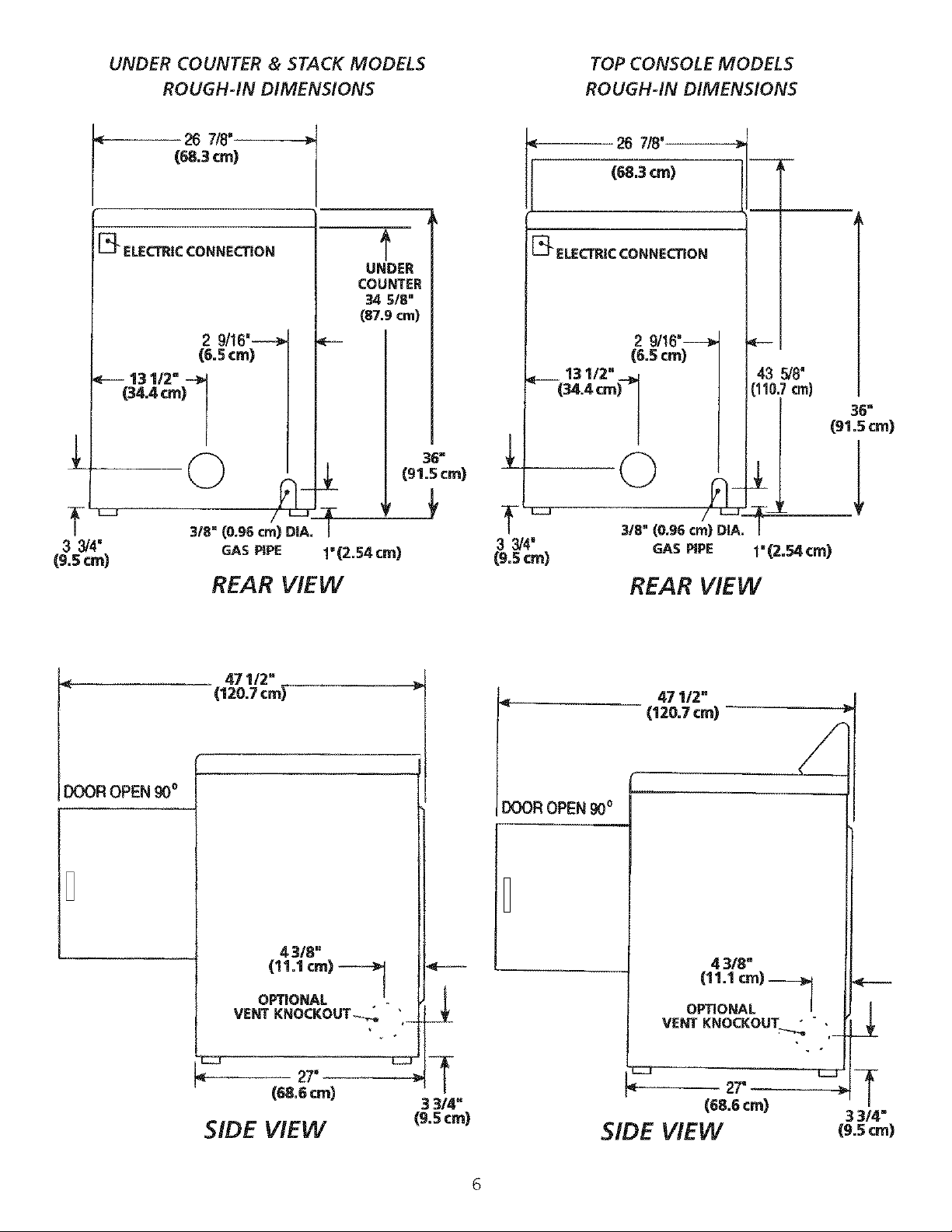

UNDER COUNTER & STACK MODELS TOP CONSOLE MODELS

ROUGH-IN DIMENSIONS ROUGH-IN DIMENSIONS

[_ ELECTRICCONNECTION

(34.4 cm) 1

"EZD

33/4"

(9,5 ¢m)

26 7/8'

(68.3era)

3/8" (0.96 crn) DIA.

GAS PIPE

REAR VIEW

/L_J

T--

UNDER

COUNTER

34 518"

(87.9 cm)

1'(2.54cm)

36"

(91.5 cm)

26 718'.

(68.3cm)

[_ ELECTRICCONNECTION

13 1/2" _...>

(34.4 cm)

0

"EZZi

3 3/4'

(9.5 cm)

3/8" (0.96 crn) DIA, |

2 9/16'-----_

(6.5 cm)

43 _8"

(110.7crn)

36"

(91.5 cm)

F_

GAS PiPE I" (2._ cm)

REAR VIEW

DOOR OPEN 90°

471/2"

(120.7 cm)

mR OPEN _o

4 318"

(11.1 ¢m)

OPTIONAL

VENT KNOCKOUT_,

27_ c:::r

(68.6 ¢m) 27'

3 314" (68.6 cm)

47 1!2"

(I 20.7 ¢rn)

(11.1 cm)

O_ONAL

VE_ KNOCKOUT " "

SIDE VIEW (9.sere) SIDE VIEW

4 3/8"

|

3 3/4"

(9.5 ¢m)

6

Page 7

UNPACKING

REVERSING DOOR SWING

I. Using tile four shipping carton corner posts (two on each

side), carefully laythe dryer on its left side and remove foam

shipping base.

_To prevent damage, do not usethe control panel

as a means to pick up or move the dryer.

NOTE: On under counter model clothes dryers, the top panel

may be removed for installation.

2. Return the dryer to an upright position.

FOAM

SHiPPiNG

PAD

Your dryer is designed so the door swing may be reversed at

any time without additional parts. Conversion isaccomplished

by transferring hinges to the opposite side of the cabinet.

Tochange the direction of the door opening:

1.

Open the dryer door. Remove the four hinge hole plugsfrom

the left side of the door opening. Place nearby for future

installation. NOTE: You may need a plastic knife to help pull

out the plugs. Becareful not to scratch the paint.

2.

Remove the four screws that secure the door hinges to the

dryer front panel (see below). NOTE: Remove one screw

from eachof the two hinges first. Holdthe door firmly before

removing the last two screws.

3. Rotate the door 180° and reinstall the door hinges to the

dryer front panel with the four screws.

4. Install the four hinge hole plugs in the open screw holes on

the right sideof the door opening.

PACKING

\

REMOVE 4 SCREWS

(ONE FROM EACH

HINGE FIRST)

Page 8

INSTALLATION

I. GAS CONNECTlON (Gasdryers on/y)

a. Remove the shipping cap from gas pipe at the rear of the

dryer.

NOTE: DO NOTconnect the dryer to L.Rgas service without

converting the gas valve. An L.R conversion kit must

be installed by a qualified gas technician.

b. Connect a 1/2 inch (1.27 cm) I.D.semi-rigid or approved

pipe from gas supply line to the 3/8 inch (0.96 cm) pipe

located on the back of the dryer. Use a 1/2 inch to 3/8

inch (I .27 cm to 0.96 cm) reducer for a connection. Apply

an approved thread sealer that isresistant to the corrosive

action of liquefied gases on all pipe connections.

c. Open the shutoff valve in the gas supply line.

d. Testallconnections by brushing on asoapywater solution.

NEVER TESTFOR GASLEAKS WITH AN OPEN FLAME.

2. Connect the exhaust duct to outside exhaust system. Use

duct tape to seal alljoints.

13.With the dryer in itsfinal position, adjust one or more of the

legs until the dryer is resting solid on all four legs. Placea

levelon top of the dryer. THEDRYERMUSTBE LEVELAND

RESTING SOLID ONALL FOUR LEGS.

7. If your dryer does not operate, please review the "Avoid

Service Checklist" located in your Owner's Guide before

calling for service.

8. Placethese instructions in a location near the dryer for future

reference.

9. To stack your dryer on a compatible washer call your local

dealer to find your local distributor to purchase a stacking

kit accessory part number 5303937141.

NOTE: A wiring diagram islocated inside the dryer console or

behind the right side panel.

REPLACEMENT PARTS

If replacement parts are needed for your dryer, contact the

source where you purchased your dryer.

Label all wires prior to disconnection when

servicing controls. Wiring errors carl cause improper and

dangerous operation. Verify proper operation after servicing.

Destroy the carton and plastic bags after the

dryer is unpacked. Children might usethem for play. Cartons

covered with rugs, bedspreads, or plastic sheets can become

airtight chambers causing suffocation. Placeall materials in a

garbage container or make materials inaccessible to children.

4. Hug the power cord into a grounded outlet.

NOTE: Check to ensure the power is off at circuit breaker/

fuse box before plugging the power cord into the outlet.

5. Turn on the power at the circuit breaker/fuse box.

Before operating the dryer, make sure the

dryer area is clear and free from combustible materials,

gasoline, and other flammable vapors. Also see that

nothing (such as boxes, clothing, etc.) obstructs the flow

of combustion and ventilation air.

6. Runthe dryer through a cycle check for proper

operation.

NOTE: On gas dryers, before the burner will light, it is

necessaryfor the gas lineto be bled of air.If the burner does

not light within 45 seconds the first time the dryer isturned

on, the safety switch will shut the burner off. If this happens,

turn the timer to "OFF" and wait 5minutes before making

another attempt to light.

The instructions in this manual and all other

literature included with this dryer are not meant to cover every

possible condition and situation that may occur. Good safe

practiceand caution MUSTbe applied when installing, operating

and maintaining any appliance.

8

Page 9

Requerimientos de instalacion preliminares ............................................................................................................................. 10

Requerimientos electricos ..................................................................................................................................................... I0

Requerimientos del suministro de gas...................................................................................................................................... I0

Requerimientos del sistema de escape................................................................................................................................ 10-11

Ubicacion de su secadora .................................................................................................................................................. 11-I 2

Instalacion en casas moviles ................................................................................................................................................. 12

Dimensiones para la instalacion ........................................................................................................................................... 13

Desembalaje ..................................................................................................................................................................... 13

Puerta reversible ................................................................................................................................................................ 13

Instalacion ........................................................................................................................................................................ 14

Piezas de recambio ............................................................................................................................................................ 14

SEGURIDAD de SECADORA

La instalaci6n y el servido de la Secadora de ropa se deben realizar per un instalador calificado, la agencia de servido o el

surtidor de gas.

Instale la Secadora de ropa segun las instrucdones del fabricante y los codigos locales. Antes de comenzar la instalacibn,

lea cuidadosamente estas instrucciones. Esto simplificarb la instalacion y asegurar_ que la secadora se instale correctamente

y de manera segura. Despu_s de completar la instalad6n, coloque estas instrucdones cerca de la secadora para referenda

futura.

NOTA: La alimentad6n el_ctrica para la secadora deber_ cumplir con los c6digos y reglamentos Iocales y con la ultima edition

del Codigo El_ctrico NadonaI, A N$1/NFPA 70o en Canad_ CSA C22.1 Codigo El_ctrico Canadiense, Parte 1.

NOTA: La alimentadbn de gas para la secadora deber,'J cumplir con los c6digos y reglamentos locales y con la ultima edici6n

del Codigo Nadonal para Gases Combustibles, ANSI Z223.1 o en Canad_ CAN/CGA B149.12.

N_ TA: La secad_ra est_ c_asi_cada para US_ D_MES T_C_s_amente_ de acuerd_ c_n _an_rma AN$_ Z21_5.1_ ANSl/UL 2158_

CAN/CSA C22.2No. 112 (las ultimas ediciones). Estasecadora no se recomienda para uso commercial ta l como en restauran tes,

salones de belleza, etc.

Su seguridad y la seguridad de terceros son muy importantes.

Hemos proporcionado muchos mensajes importantes para la seguridad en las Instrucciones de Operacion del Manual de Uso y

Mantenimiento, las Instrucciones de Instalaci6n yen el mismo aparato. Siempre lea y obedezca todos los mensajes para seguridad.

P_Este simbolo significa alerta. Este simbolo Io alerta acerca de peligros que pueden matar o lesionar, tanto a usted como a otras

personas. Todos los mensajes de seguridad seran precedidos por el simbolo de alerta para su seguridad y la palabra "PELIGRO o

ADVERTENCIA " (DANGER" o WARNING.). Estaspalabras significan:

PELIGRO (DANGER) Usted morir_ o resultar_ seriamente lesionado si no sigue las instrucciones siguientes.

ADVER TENCIA(WARNING) Usted puede morir o resultar seriamente lesionado si no sigue las instrucdones

siguientes.

Todos los mensajes de seguridad identificar&n el peligro, le dir&n a usted c6mo reducir la posibilidad de lesi6n y tambi_n

qu_ puede suceder si no se siguen las instrucciones.

_.__ RIESGO DEINCEND!O Parasuseguridad, siga lasinstrucciones contenidas en estemanual a fin de reducir a un

minimo los riesgos de incendio o explosion o para evitar dailos materiales, lesiones personales o la muerte. GUARDE ESTA5

INSTRUCCIONES.

No dma(ene ni utilice gasoli nauotros vapores yliquidos inflamables en la proximidad de esteodecualqu ier otro artefa(to electrico.

QUE DEBE HACERSIPERCIBEOLORA GAS

• Notrate de encender ningOn artefacto electrico.

• Notoque ningOn interruptor electrico; no useningOn telefono ensuedificio.

• Haga salir a todos losocupantes de la habitacion, del edificio ydel Dgar.

• Llame a su proveedor de gas desde el telefono de un vecino. Siga Ds instrucciones del proveedor de gas.

• Sino Iogra comunicarse con su proveedor de gas, Ilamealdepartamento de bomberos.

Lainstalaci6n y elservicio de mantenimiento debe de realizarlos un instalador calificado, la agencia de servicioso el proveedor degas.

REQUERIMIENTOS DE INSTALACION PRELIMINARES

Herramientas y materiales necesarios para la instalacion:

I. Destornillador Phillips

2. Alicates urfiversales

3. Nivel de carpintero

4. Destornillador paratornillo de cabezaplana o recta

5. Cinta paraductos

6. Ducto met:_lico rigido o flexible de 4 "(10,2 cm)

7. Caperuza de salida

8. Se%dor de tubedas (gas)

9. Un cuchillo de pl_%tico

9

Page 10

REQUERIMIENTOS EL£CTRICOS

Secadorasa GAS

Esta secadora esta equipada con un enchufe de tres espigas (de

puesta a tierra) para proteccion encontra de choques electricos y

debe serconectada directamenta en unreceptaculo paratresespigas

el cual debe estar puesto atierra. No torte ni elimine la espiga de

puesta atierra de esteenchufe.

CIRCUITO- Circuito individual derivado de 15amp, con fusibJesde

15 amp. de retardo m_iximo o disyuntor.

ALIMENTAClON ELECTRICA-

Corrientealterna, monof_isica,

60 Hz, 120 voltios, trifilar.

CORDON ELECTRICO-

Lasecadoraesta equipad

conun cord6n electrico

trifilarpara 120voltios.

de! enchufe. TERRA

REQUERIMIENTOS DEL SUMINISTRO DE GAS

F_ Reemplace la tuberia de conexi6n de

cobre que no est_ recubrida con plbstico. El latbn inoxidable

o recubrido con pl_stico DEBESERutilizado.

1. Lainstalaci6n DEBEhacersecumplircon IoscOdigos Iocaleso en

ausenciade losmismos,deacuerdo con losestandaresdelNational

FuelGasCode(C0digo NacionalparaGasesCombustibles), ANSI

Z223.1 (la01timaedition). ParaCanada, el Estandar CAN/CGA

B149 que esteen vigor.

2. La tuberia de alimentaci6n de gas debe ser de 1/2 pulgada

(1,27 cm)de diametro.

3. Siestapermitido por losc6digos locales,se puede usartuberia de

metal para conectar su secadora a la Iineade suministro de gas.

La tuberia DEBE ser fabricada de acero inoxidable o cobre

recubierto de plastico.

4. Latubeda de alimentacidn degasDEBEtener una Ilavedecierre

individual.

5. Una toma de I/8 de pulgada (0,32 cm) N.RT. accesible para

conexion del man0metro de prueba, DEBE ser instalada

inmediatamente aguas ardba de la conexiOn de la tuberia de

alimentacidn de gas a la secadora.

6. Lasecadora DEBE serdesconectada del sistema de tubedas de

alimentaciOn de gas durante cualquier ensayo de presiOn del

sistemade tuberias dealimentaciOn degasrealizado a presiones

de prueba de mas de I/2 Ibs/pulg.2(3,45 kPa).

7. LasecadoraDEBEaislarsedelsistemadetuberiasdealimentacion

degasdurante cualquierensayode presiOndelsistemade tuberias

de alimentacion de gasrealizado en ensayosde presion iguales o

inferiores a I/2 Ibs/pulg.2(3,45 kPa).

REQUERIMIENTOS DEL SISTEMA DE ESCAPE

Utilice solamente ductos metalicos, dgidos o flexibles de 4"

(10,2 cm) de diametro (minimo) y una caperuza de salida de uso

aprobado, con registros que giren haciaafuera que seabren cuando

la secadora se encuentra enfuncionamiento. Cuando la secadora

sedetiene, los registros secierran automaticamente para evitar las

corrientes de aire y la entrada de insectos y roedores. Para evitar

obstruir lasalida,mantenga una altura libre minima de 12"(30,5 cm)

entre lacaperuzade salidayelpiso o entre cualquier otra obstruccidn.

Los siguientes requerimientos son

espedficos para el funcionamiento correcto y seguro de su

secadora, El incumplimiento de estas instrucciones puede

causar prolongacion excesiva del tiempo de secadoy riesgos

de incendio.

[] No instale la Secadora con materiales de ventilaci0n plasticos

fiexibles. EnCanada y los EstadosUnidos sielconducto esde metal

(tipo hoja de aluminio),estedebe serde untipo especificoidentificado

por elfabricante, recomendado para eluso con Secadoras; yen los

EstadosUnidos debe ademas cumplir con la norma UL2158A. Los

materiales de ventilaciOn flexibles se pueden colapsar oapachurrar

f_icilmenteyatrapar pelusa.Estascondiciones obstruiran lacirculaci0n

de aire delaSecadorade ropa yaumentaran elriesgo deincendio.

Sisusistema de escapeactual tiene ductos de plastico o de laminas

metalicas delgadas, _lacelo con un ducto metalico rigido o

flexible. AsegOrese de que los ductos existentes no tengan

pelusas antes de instalar el ducto de la secadora.

i_uii

CORRECTO INCORRECTO

i_iu_i_u_ila_i!_i_i u

!!!i!i!¸¸¸ sl

e

C

INCORRECTO

[] Riesgo de incendio- Lasecadora debe set ventilada al exterior

de lavivienda. Noventile la secadora a una chimenea, pared, techo,

atico, pasaiesentre pisosocualquier espacio oculto de la vivienda.

Lassecadorasde ropa producen pelusacombustible. Sino seventila

lasecadoraal exterior,algunas pelusasfinasseacumularan en elarea

de lavanderia. La acumulaci0n de pelusa en cualquier area de la

vivienda puedeconstituir un peligro sanitarioy un riesgode incendio.

La secadora debe dstar conectada a un sistema de escape que

termine en el exterior de la vivienda. Inspeccione laabertu ra de

escape alexterior con frecuencia y elimine cualquier acumulaci6n

de pelusa en tal abertura yen el area que la rodea.

[] No permita que los materiales combustibles (pot eemplo: la

ropa, cortinas/cortinaies, papel)tenqan contacto con losductos.

[] Excederla Iongitud del conducto rigic[oolosn0meros decodos

permitidos en losdiagramas "LARGOMAXlMO" puede disminuir

lacapacidad deexhaustadon delsistema. Obstruir elconductopuede

provocar peligrodeincendio, asicomoaumentar eltiempo desecado.

[] No obstruva los extremos del tubo de ventihcion, ni utilice

tornillos remaches uotros medios defijadon que puedan obstruir el

conducto yatrapar pelusa. Laspelusaspoddan quedar atrapadas en

losfiltros, en lostornillos oenlosremaches,Iocualobstruida elsistema

de escape ycreanaunriesgodeincendio, asicomotambien

prolongaria el tiempo de secado. Use una caperuza de salida

adecuada paraelextremo delducto que salgaal exterior de lavivienda

y selle todas lasjuntas con cinta adhesiva para ductos. Todos los

accesoriosde tuberia machos, DEBENser instalados aguas abajo del

fiujo de aire.

10

Page 11

r!_ Riesgo de explosion. No instale la secadora

donde se quarda qasolina u otros materiales inflamables. Si la

secadora se instda en un garage, ella debe estar per Io menos 18

pulgadas (45,7 cm)por encima de1suelo. Elincumplimiento puede

resultar enlamuerte, explosion, incendio, o quemaduras.

LARGO MAXIMO

del Cenducto Met_lice Rigido

de 4" (10,2 cm) de Di_metre

TIPO DE CAPERUZA DE SALIDA

(Preferido)

Numero _ Apersianada

de Codo_

ogo°

0 60 pies (18,28 m)

1 52 pies (15,84 m)

2 44 pies (13,41 m)

3 32 pies (9,75 m)

4 28 pies (8,53 m)

LARGO MAXIMO

del Conducto Met&lice Flexible

de 4" (10,2 cm) de Di&metro

TIPO DE CAPERUZA DE SALIDA

(Preferido)

de Codo!

Numero _ Apersianada _

48 pies(14,63m)

40 pies(12,19m)

32 pies (9,75 m)

24 pies (7,31 m)

16 pies (4,87 m)

e Sedebe utilizarsolamente conductos metalicos rigidos.

• Una salida del sistema vertical en el techo, puede exponerle

a uncorriente de aire descendente y disminuir as[sucapaddad

de exhaustacion.

Elaislante que debe atravesar el sistema puede causar

condensacion y disminuir asllacapacidad de exhaustaciOn

del sistema.

Lacapacidad de exhaustacion de un sistema de exhaustadon

comprimido o ondulado puede disminuirse.

E]sistema de exhaustadon debe de set inspeccionado y limpiado

per Iomenos cada 18mesesde usenormal. Cuanto m_islasecadora

esta utilizada, masdebeverificarel buen funcionamiento delsistema

de exhaustacion y de latapa del orifido de ventilacion.

UBICACION DEL ESCAPE

Todaslassecadoras vienen de fabrica equipadas conescape trasero.

Sin embargo, en las secadoras elOctricas,elescapepuede hacerse

al ladederecho o izquierdo del gabinete o en laparte inferior de la

secadora. En lassecadoras a gas, el escape del aire puede estar en

el lade derecho del gabinete o en laparte inferior de la secadora. El

escapedireccional puede efectuarseinstalando un Juegode Escape,

P/N 131456800, disponible a travesdesudistribuidor derepuestos.

Siga lasinstrucciones que sesuministran con eljuego.

DIMENSIONES PARA LA LIB!CACION DELDUCTO DEESCAPE

_- IGUAL QUE ELOTRO LADO

J¢

I J_;.,, s7/8"

] / / (15cra) 4 3/8"

0

1

2 14 pies (4,27m) 10pies (3,05m)

3 NORECOMENDADO

INSTALE LOS ACCESORIO_; MACHOS EN LA DIRECCION CORRECTA

Paralasinstalaci0nescuyassistemadeexhaustacion no seencuentre

en el diagrama, se puede utilizar el metodo acontinuacion para

determinar siel sistema de exhaustacion esapropiado.

1. Conecte un manometro a tube inclinado o digital entre la

secadora yel union de exhaustacion de la secadora.

2. Ponga el contador detiempo de la secadora y la temperatura

a aire frio (enfiriamiento), y la secadora en la posicion de

marcha.

3. Lea la medida indicada enel manometro.

4. La baja presion NO DEBEexceder 0.75 pulgada delacolumna

de agua. Si la baja presion es inferior a 0.75" de la columna

deagua, elsistemaesaceptable. Silalecturaindicauna

presion superior a 0.75" de lacolumna de agua, la capacidad

del circuito esinsuficiente y lainstalacion es inaceptable.

Aungue un sistema vertical seaaceptable, algunas circunstancias

atenuantes pueden afectar elfuncionamiento de lasecadora:

30 pies (9,14m) 18pies (5,49m)

22 pies (6,71m) 14 pies (4,27 m)

UBICACION DE SU SECADORA

NO INSTALESU SECADORA:

1. Enun lugardondepuede habergoteosde aguao quede expuesta

alas inclemencias del tiempo.

2. En un _irea deride pueda entrar en contacto con cortinas,

cortinajes o cualquier otra cosa que obstruya el flujo de

combusti6n yventilaci6n de aire.

3. Sobre alfombras. ElpisoDEBEserfirmecon un desnivel maximo

de I pulgada (2,54 cm).

INSTALA CION DENTRODE UN NICHO OARMARIO

I. Si la secadora es instalada en un dormitorio, cuarto de barlo,

niche o armario, el tube del escapeDEBE serinstalado hacia el

exterior.

2. Nosedebe instalarningun otro artefacto quequeme combustible

en el mismo armario en que est_ instalada la secadora aGas.

3. Lasecadora necesitaespacio asu alrededor paraunaventilaci0n

adecuada.

NO INSTALE LA SECADORA EN UNARMAR/O CON PUERTA

MACIZA.

4. Se requiere come minimo una abertura de 120 pulgadas cua-

dradas (774,2 cm2), dividida equitativamente para la parte

superior e inferior de lapuerta. Cuando seinstalaunapuerta, es

necesarioproveeraberturas para elaire. Unapuerta apersianada

con aberturas para el aire en todo el largo de la puerta es

aceptable.

11

Page 12

DESPEJESM#NIMOS DE INSTALACiON (Puigadas)

PARTE PARTE PARTE

DELANTERA LADOS TRASERA SUPERIOR

Alcoba o

encastradas0(0cm) 0(0cm) 0(0cm) 15(38,1cm)

Armado 1(2,54cm) 0(0cm) 0(0cm) 15(38,1cm)

Ventilaci0n requirida en la )uerta del armario: dos aberturas 2.

rejilladas cada 60 pulg? (387 cm2)--3" (7,6 cm) desde la parte

inferior y superior de lapuetra.

ELTUBO DELESCAPEDELA SECADORA DEBESERINSTALADO 3.

HACIA ELEXTERIOR.

5. Lassiguientes ilustraciOnesmuestran lasdimensiOnesminimas

de espacio libre que debe existir para el buen funcionamiento 4.

de la secadora cuando se instala en un nicho o en un armario.

INSTALAC/ON EN CASAS MOV/LES

I. EltubodeescapedelasecadoraDEBEserinstaladof_adaelexterior

(Elescapedebe colocarse en la parte exteriory nodebajo de lacasa

m6vil.) Debe usarseducto demetal que no seacombustible. Elducto

de metal debe tener cuatro pulgadas (10,16 cm) de diametro y no

tener obstrucciones. Espreferible usarducto de metal que searigido.

Siel tubo de escape de lasecadora corre atrav#_sdel pisoy el area

debajode lacasam6viles cerrada,elducto deescapeDEBEterminar

fuera del recinto, con elextremo final asegurado en contra de la

estructura de la casa movil.

AI instalar unasecadoradegasen una casamovil, hayque instalar

una provision de aire fresco suplementario. Laprovisi6n tiene que

sermasgrande que dosvecesel espacio delescapede lasecadora.

Estasecadora DEBE asegurarse al piso. EIjuego para instalaci0n

en la casa m6vil es el No. 169840 y Io puede adquirir con su

distribuidor.

Vealaspaginas 2y3paraotros requisitosimportantes deventilad0n.

La instalaciOn DEBE cumpNr con las estandares aplicables de la

Manufactured Home Construction & SafetyStandard- Estandares

de SeguridadyConstrucciOn deCasasPrefabricadas(Titulo 24 CFR

- Parte32-80 del Reglamento Federal)o cuando dichosestandares

no sean aplicables, se deben compNr con los estandares de la

American National Standard for Mobile Homes (Estandares

Nacionales Americanas para Viviendas M6viles). EnCanada se

apNcael Estandar CSA Z240.

Estasecadora hasido diser_adaPARA USO

DOMESTICO solamente, de acuerdo con la norma ANSI Z 21._5.1.

PUERTA DEL ARMARIO

O"(0 cm)

_iI i_!i_

iTil¸¸¸¸¸¸¸¸¸sl¸¸ I

n_

iii ii!!!i!i ii!iii!!i!iii i! i !iliiiii!i!!U

Correct Incorrect

L

Correct Incorrect

L

iiiii

i

12

IRcorrect

Page 13

MODEL OS A UTONOMOS

CON CONSOLA SUPERIOR

DIMENSIONES PARA LA INSTALACION

__ 26 7/8"

[_ CONEXION ELECTRICA

2 9/16" (6,5cm)

13 1/2" -_

(34,4 cm)

(68,3 cm)

i

i

i

i

i

I

I

I

43 5/8"

(110,7 era)

DESEMBALAJE

I. Utilizando lascuatro esquinerasdeembarque de lacajadecart0n

(dosa carla lado), coloque cuidadosamente la secadora sobre

el costado izquierdo y saque la basede espuma de embarque.

Paraevitar danos, no useelpanel de control como

un medio para levantar o mover la secadora.

NOTA: Enlosmodelos de secadorasencastradas,elpanel superior

puede ser removido para la instalacion.

2. Vuelva la secadora asu posicion vertical.

PLACA DE

ESPUMA DE

EMBARQUE

L

3 3/4" (9,5 cm)

PUERTA

ABIERTA A 90°

©

CONEXIONDELA I

TUBERIADE GAS 1" (2, 54 cm)

DE3/8" (0,96cm)

VISTA POSTERIOR

47 1/2"

(120,7 cm)

/_-J,

36 _l

_UE

PUERTA REVERSIBLE

Su secadora ha sido diseflada para que la puerta pueda ser

cambiada de lado en cualquier momento sin necesidad de piezas

adicionales. La conversion se hace transfiriendo las bisagras al

lado opuesto del gabinete.

Como cambiar la direction de apertura de lapuerta:

I. Abra la puerta de la secadora. Quite los cuatro receptores del

agujerodela bisagradelladoizquierdodelaaperturadela puerta.

Coloquelosen unlugarcercano para futura instalacion. NOTA:

Puedeque senecesite un cuchillo de pl_isticopara poder sacar

losreceptores. Tenga cuidado de no rayar lapintura.

2. Quite loscuatro tornillos que aseguranlas bisagrasde la puerta

al panelfrontal de lasecadora (verfigura abajo). NOTA: Primero

quite un tornillodecada unade lasbisagras. Mantenga lapuerta

sujetada firmemente antes de quitar losdos ultimos tornillos.

3. Gire la puerta 180° yvuelva acolocar las bisagrasde la puerta

en el panel frontal con los cuatro tornillos.

4. Instale los cuatro receptores de losagujeros de lasbisagras en

los agujeros abiertos en el lado derecho de la apertura de la

puerta.

4 3/8" (11,1 cm)'--_

DISCOOPCI6NAL I

I

REMOVIBLEPARA-_._ "

VENTILACI6N '-

27'

(68,6 cm)

VISTA LATERAL

-'1::::3"

3 3/4" (9,5 cm)

QUITE LOS CUATRO

TORNILLOS (PRIMERO QUITE

UNO DE CADA BISAGRA )

13

Page 14

INS TALA €ION

1. CONEXION DELGAS (._ecadorasa gas solamente)

a. Saque latapa de embarque de la tuberia de gas de la

secadora situada en la parte trasera.

NOTA: NO conecte la secadora al suministro de propano, sin

primeroinstalar eljuego de conversion a propano. EIjuego de

conversion a propano debe serinstalado por untecnico de gas

calificado.

b. Conecte una tuberia semirigida de 1/2" (1,27 cm) D.I.o

una tuberia aprobada, desdelaIineade suministro degas

a la tuberia de 3/8" (0,g6 cm) ubicada en la parte trasera

de lasecadora. Utilice un reductor de 1/2" (1,27 cm) a3/

8" (0,g6 cm) para la conexion. Aplique un sellador de

roscasde uso aprobado, resistente a la corrosion de los

gases licuados, en todas lasuniones de la tuberia.

c. Abra la valvula de cierre en la tuberia de suministro de

gas.

d. Pruebetodas lasconexiones aplicando con unaescobilla

una solucion jabonosa. NUNCA UTILICE UNA LLAMA

ABIERTA PARA DETECTARFUGAS DEGAS.

2. Conecte el ducto de escape al sistema de escape exterior.

Utilice cinta para obturar todas lasuniones.

3. Con lasecadora en suposicion definitiva, regule uno o m_is

tornillos niveladores, hasta que la secadora repose

firmemente sobreIoscuatrotornillos. Coloque un nivelsobre

laparte superior delasecadora.LA SECADORA DEBEESTAR

A NIVEL YREPOSAR$OLIDA YFIRMEMENTESOBRELOS

CUATRO TORNILLOSNIVELADORES.

4. Conecte el cordon electrico a un tomacorriente puesto a

tierra. NOTA:Asegoresedeque lacorrienteestedesconectada

en el disyuntoWcaja de fusibles, antes de conectar el cordon

electrico en el tomacorriente.

5. Conecte lacorriente en el disyuntor/caja de fusibles.

Antes de poner en funcionamiento la

secadora, asegurese de que no haya materiales

combustibles, gasolina y otros vapores inflamables cerca

de la secadora. Adem_s asegurese de que no haya nada

(tal como cajas, ropas, etc.) que obstruya el flujo del aire

de combusti6n y ventilad6n.

7. Si su secadora no funciona, consulte la seccion "Lista de

Control de Averias" que se encuentra en su Manual del

Usuario, antes de Ilamar para obtener servicio.

8. Conserve estas instrucciones cerca de la secadora para

referencia futura.

9. Paraapilar suSecador en unaLavadora compatible Ilame a su

distribuidor local paraencontrar sudistribuidor localycomprar

el numero de parte 5303937141 - accesorio demontaje.

NOTA: Dentro de laconsola de la secadora o debajo del panel

superior seencuentra undiagrama del cableado.

PIEZAS DE RECAMBIO

Sinecesitaobtener piezasde recambioparasusecadora,pongase

en contacto con el distribuidor donde compro susecadora.

Cuando sereparan loscontroles, marque todos

loscablescon etiquetas antes dedesconectados. Cualquier error

de cableado puede causar una operation inadecuada ypeligrosa.

Aseg0resede que lasecadora funcione adecuadamentedespu_s

de repararla.

r_ Destruya la caja de carton, bs bolsas de

pl_isticoy la banda met_lica despues de haber desempacado el

centro de lavanderia. Los nifios pueden ponerse a jugar con

ellos. Lascajas de carton cubiertas con alfombras, colchas o

pedazos de plastico pueden convertirse en camaras sin aire y

causar asfixia. Elimine todos los materiaies poniendolos en la

basura o fuera del alcance de los nihos.

Lasinstrucciones incluidas en este manual y

en el resto de la documentaciOn que seentrega con la secadora

no pueden cubrir todas lassituaciones o condiciones posiblesque

puedan presentarse. Por Io tanto, se DEBEN seguir practicas

seguras y tener cuidado cuando se instah cualquier artefacto

domestico.

6. Haga funcionar lasecadora durante un ciclo completo para

comprobar subuen funcionamiento.

NOTA: En las secadoras a gas, antes de encender el

quemador es necesario purgar el aire de latuberia del gas.

Sielquemador no enciende dentro de 45 segundos, cuando

la secadora se enciende por primera vez, el interruptor de

seguridad apagara el quemador. Si esto sucede, gire el

contador detiempo a la posicion "OFF" (apagado)y espere

5 minutos antes de intentar encender la secadora

nuevamente.

14

Loading...

Loading...