Page 1

Open on Rise – Remote Bulb

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

These controls have open on rise switch action and are designed for low or line voltage heating applications with ranges

to cover such applications as curing rooms, incubators, antifreeze control for stock watering tanks or orchards, developing

tank, aquarium, swimming pool, etc. If the controlled medium is

a liquid, the liquid must not be corrosive to copper.

THESE CONTROLS MUST BE INSTALLED BY A QUALIFIED

INSTALLER.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes and

ordinances.

This control is a precision instrument, and should be handled

carefully. Rough handling or distorting components could cause

the control to malfunction.

This control has been accurately calibrated at the factory. Any

attempt to calibrate this control will void the White-Rodgers

warranty.

If the manufacturer of the heating equipment has recommended

a location for the control, then follow his instructions. If none is

made, the following suggestions should be observed.

The switch mechanism of this control may be mounted in any

convenient location and the capillary should be led over a path

that will protect it from injury.

Excessive capillary should be coiled and secured close to the

switch mechanism.

The temperature sensitive element or “bulb” should be located

in the average temperature of the controlled area.

If intended to operate from air temperature, the bulb should be

located in a place where there is good circulation of air. The bulb

should be held away from the mounting surface with screw eyes

or brackets.

When intended to be immersed into a water circulating sys-

tem, such as the heating system for a swimming pool, observe

the cautions on overrun temperatures shown under SPECIFI-

TEMPERATURE CONTROL

Fixed or Adjustable Differential

INST ALLA TION INSTRUCTIONS

DESCRIPTION

PRECAUTIONS

CAUTION

To prevent electrical shock and/or equipment damage,

disconnect electric power to system at main fuse or

circuit breaker box until installation is complete.

WARNING

Do not use on circuits exceeding specified voltages.

Higher voltages will damage control and could cause

shock or fire hazard.

INSTALLATION

CATIONS. Wells and packing nuts are available for permitting

the bulb to sense the water temperature.

If the control is to be used with a photographic processing

tank, the copper element may cause contamination if immersed

directly into the solution, resulting in a possible fogging of the

film. This may be overcome by inserting bulb into a thin stainless

steel well or plastic tubing having a slide fit over the bulb, or the

bulb may be clamped to the outside surface of the tank and then

covered with insulation to reduce the effects of variations in

room temperature.

Since the copper bulb may be harmful to the fish in an aquarium,

the bulb should be inserted in a thin, snug-fitting, stainless steel

well or plastic tubing for this application.

When the control is to be installed out of doors, such as an anti-

freeze control for stock watering tanks or orchards, the

control must be put in some rain-proof enclosure to keep water

off the switch. There should also be a good ground connection

between the case of the control and earth.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, FAX (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

Printed in U.S.A.

PART NO. 37-1066B

Replaces 37-1066A & 37-9059

9550

Page 2

WIRING

All wiring should be done in accordance with local and national electrical codes and ordinances.

If the manufacturer of the heating equipment has supplied a

wiring diagram, follow such recommendations.

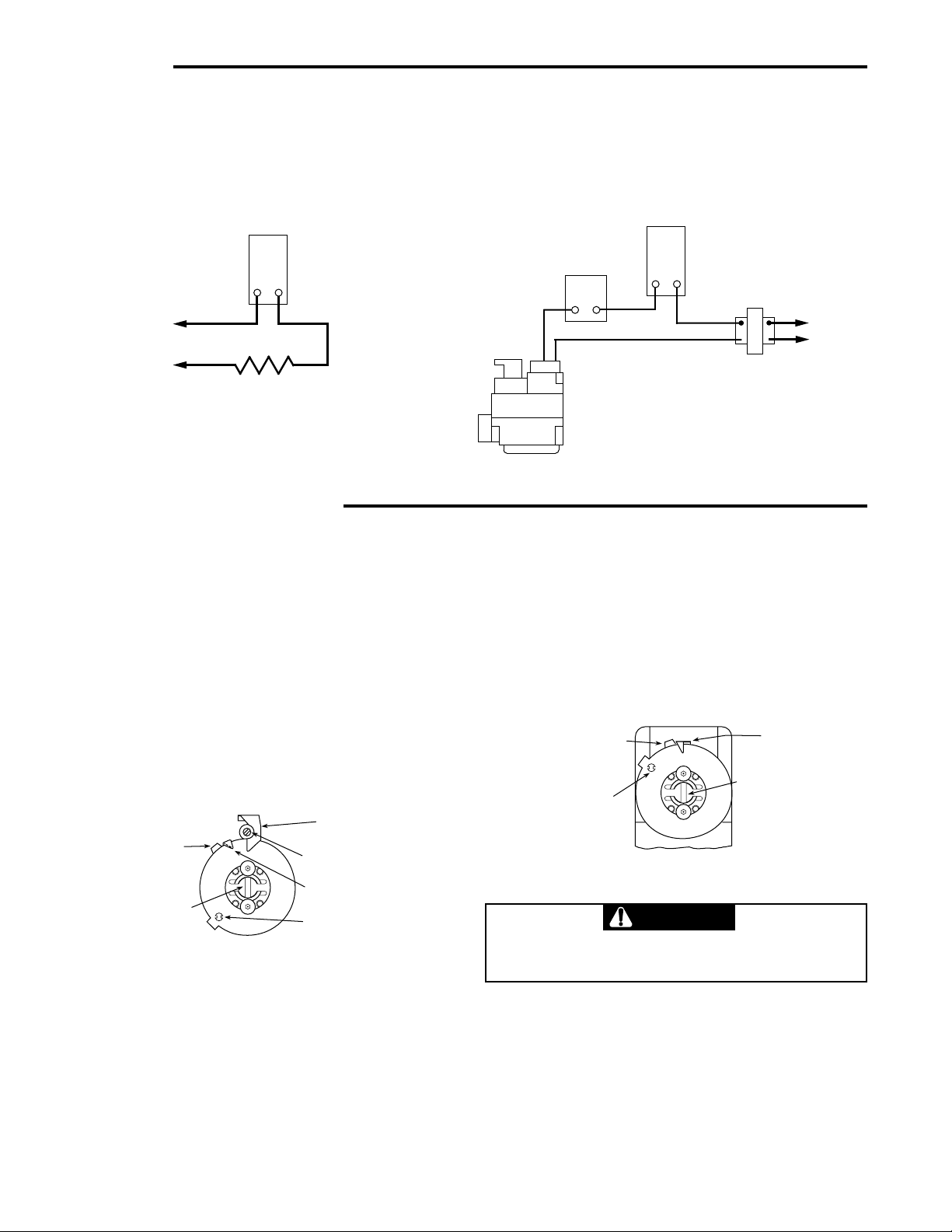

These diagrams show the general use of these controls.

TEMPERATURE

CONTROL

TYPE

230-19

TEMPERATURE

CONTROL

HOT

LINE

N

LOAD

SETTING THE CONTROL

CONTROLS WITH ADJUSTABLE DIFFERENTIAL

The movable indicator points to the temperature at which the

contacts open. The fixed indicator points to the temperature at

which the contacts close. The difference between these two

indicators is the differential.

To set the control:

1. Use a screwdriver in the adjusting slot (A) on the front of the

control to turn the dial so that the fixed indicator (B) points

to the temperature at which the contacts will close.

2. Turn the differential adjusting screw (C) until the movable

indicator (D) points to the temperature at which the contacts

will open.

“B” Fixed indicator

“F” Stop tab

“A” Adjusting

slot

(cut-in point)

“C” Differential adjusting

screw

“D” Movable indicator

(cut-out point)

“E” Stop screw

HIGH

LIMIT

TRANSFORMER

HOT

24VAC

LOW VOLTAGE

GAS VALVE

LINE

N

CONTROLS WITH A FIXED DIFFERENTIAL

The indicator (B) points to the temperature at which the contacts

open.

To set the control:

Use a screwdriver in the adjusting slot (A) on the front of the

control to rotate dial until the desired temperature at which

the contacts will open is positioned directly under the

indicator (B).

“F” Stop tab

“E” Stop screw

“B” Fixed

indicator

“A” Adjusting

slot

CONTROLS WITH ADJUSTABLE STOPS

CAUTION

Setting stop higher than control being replaced could

cause personal injury and/or property damage.

1. Loosen stop screw (E) with enclosed wrench.

2. Set dial to original equipment manufacturer's specification.

3. Without moving the dial, move stop tab (F) against indicator.

4. Retighten stop screw (E).

2

Page 3

WHITE-RODGERS

Utilisateur : conservez ces instructions pour vous y référer au besoin !

SI VOUS NE LISEZ PAS ATTENTIVEMENT CES INSTRUCTIONS AVANT

D’INSTALLER ET D’UTILISER LA COMMANDE, VOUS RISQUEZ DE CAUSER

DES BLESSURES ET DES DOMMAGES MATÉRIELS.

Ces commandes avec commutateur à ouverture sur hausse

sont conçues pour desservir des systèmes de chauffage à

basse tension ou à tension du réseau. Elles ont une plage les

permettant de servir dans les salles de séchage, les incubateurs,

les systèmes antigel de réservoirs d’eau pour le bétail ou les

vergers, les bains de révélateur, les aquariums, les piscines,

etc. Si le milieu contrôlé est un liquide, il ne doit pas corroder le

cuivre.

Ouverture sur hausse, capteur à distance

RÉGULATEUR DE TEMPÉRATURE

À différentiel fixe ou réglable

INSTRUCTIONS D’INSTALLATION

DESCRIPTION

LA PRÉSENTE COMMANDE DOIT ÊTRE INSTALLÉE PAR

UN TECHNICIEN QUALIFIÉ.

Ne dépassez pas les charges nominales.

Tout le câblage doit être conforme aux codes et règlements

locaux et nationaux qui régissent les installations électriques.

Cette commande est un instrument de précision qui doit être

manipulé avec soin. Elle peut se détraquer si elle est manipulée

de façon négligente ou si des composantes sont déformées.

La commande a été calibrée avec précision lors de la fabrication.

Toute tentative de calibrer l’appareil annulera la garantie de

White-Rodgers.

Si un emplacement de la commande est recommandé par le

fabricant de l’équipement de chauffage, alors veuillez vous y

conformer. Si aucun emplacement n’est suggéré, veuillez suivre

les conseils suivants.

L’interrupteur de la commande peut être placé à n’importe quel

endroit pratique. Le tube capillaire doit être acheminé de façon

à être protégé contre les dommages.

Le surplus de tube capillaire doit être enroulé et fixé près de

l’interrupteur.

L’élément sensible ou « capteur » doit être placé là où la

température correspond à la moyenne de la zone contrôlée.

Si la commande doit contrôler la température de l’air, alors situer

le capteur là où l’air circule bien. Tenir le capteur à l’écart de la

surface de montage à l’aide de supports ou de vis à oeillets.

Si la commande doit être immergée dans un système de

circulation d’eau, comme par exemple dans le cas du système

de chauffage de l’eau d’une piscine, alors exercer les précautions

concernant les excès de température qui sont décrites sous

SPÉCIFICATIONS. Il existe des gaines et des écrous de presse-

PRÉCAUTIONS

ATTENTION

Afin de prévenir les chocs électriques et les dommages

matériels pendant l’installation, coupez l’alimentation

électrique au panneau de distribution principal.

AVERTISSEMENT

N’installez pas cet appareil sur des circuits qui dépassent la tension nominale. Une tension trop élevée peut

endommager la commande et poser des risques de

chocs électriques et d’incendie.

INSTALLATION

étoupe qui permettent au capteur de contrôler la températeure

de l’eau.

Si la commande est utilisée dans un bain de traitement

photographique, le capteur de cuivre risque de contaminer la

solution s’il y est plongé directement. Ceci pourrait voiler la

pellicule. Ce problème peut être évité en introduisant le capteur

dans une gaine mince en acier inoxydable ou dans un tube de

plastique qui peut être glissé sur le capteur. Le capteur peut

aussi être fixé à l’extérieur du réservoir et recouvert d’isolant afin de

diminuer l’effet des variations de la température de l’air ambiant.

Puisque le capteur de cuivre peut représenter un danger pour

les poissons d’un aquarium, le capteur utilisé ainsi devra être

introduit dans une mince gaine d’acier inoxydable ou de plastique

bien ajustée.

Lorsque la commande doit être installée à l’extérieur, comme

commande antigel d’un réservoir pour l’eau de bétail ou

d’un verger, par exemple, elle doit être placée dans un boîtier

étanche. Il est aussi important d’assurer une mise à la terre

adéquate du boîtier de la commande.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, Télécopieur (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, Télécopieur (905) 475-4625

Imprimé aux É.-U.A.

PIÈCE No 37-1066B

Remplace 37-1066A & 37-9059

9550

Page 4

CÂBLAGE

Tout le câblage doit être conforme aux codes et règlements locaux et nationaux qui régissent les installations électriques.

Si le fabricant de l’équipement de chauffage recommande un

schéma de câblage, alors veuillez vous y référer.

Les schémas suivants correspondent à un usage typique du

régulateur.

RÉGULATEUR DE

TEMPÉRATURE

RÉGULATEUR DE

TEMPÉRATURE

TYPE

SOUS

TENSION

RÉSEAU

CHARGE

N

230-19

RÉGLAGE DE LA COMMANDE

COMMANDES À DIFFÉRENTIEL RÉGLABLE

L’indicateur mobile donne la température à laquelle les contacts

seront ouverts. L’indicateur fixe donne la température à laquelle

les contacts seront fermés. La différence entre les deux indicateurs représente le différentiel.

Pour régler la commande :

1. Introduire la pointe d’un tournevis dans la fente de réglage

(A) qui se trouve à l’avant de la commande. Tourner le

cadran pour que l’indicateur fixe (B) indique la température

à laquelle les contacts devront être fermés.

2. Tourner la vis de réglage du différentiel (C) jusqu’à ce que

l’indicateur mobile (D) indique la température à laquelle les

contacts devront être ouverts.

LIMITEUR À

MAXIMUM

TRANSFORMATEUR

SOUS TENSION

24 V C.A.

ROBINET À GAZ À

BASSE TENSION

RÉSEAU

N

COMMANDES À DIFFÉRENTIEL FIXE

L’indicateur (B) donne la température à laquelle les contacts

seront ouverts.

Pour régler la commande :

Introduire la pointe d’un tournevis dans la fente de réglage

(A) qui se trouve à l’avant de la commande. Tourner le cadran

pour que la température à laquelle les contacts devront être

ouverts se trouve directement sous l’indicateur (B).

F Butée

E Vis de butée

B Indicateur fixe

A Fente de réglage

F Butée

A Fente de

réglage

B Indicateur fixe

(point d’enclenchement)

C Vis de réglage

du différentiel

D Indicateur mobile

(point de déclenchement)

E Vis de butée

COMMANDES À BUTÉES RÉGLABLES

ATTENTION

Il y a un risque de blessures et de dommages matériels

si la butée est réglée à un point de consigne plus élevé

que celle de la commande qui est remplacée.

1. Desserrer la vis de butée (E) à l’aide de la clé fournie.

2. Régler le cadran selon les recommandations du fabricant de

l’équipement.

3. En prenant soin de ne pas déplacer le cadran, accoter la

butée (F) contre l’indicateur.

4. Serrer à nouveau la vis de butée (E).

2

Loading...

Loading...