White-Rodgers 20C26S-010, 16C28S-010, 14C26S-010, 10C26S-010 User Manual

by White-Rodgers

Electronic Air Cleaner

SST

Super Slim Twin

Model Number

10C26S-010

14C26S-010

16C28S-010

20C26S-010

OWNERS MANUAL

• Installation

• Operation

• Basic SST Service Guide

• Technical Repair Guide

• Repair Parts

WHITE-RODGERS

SUPER SLIM TWIN

ELECTRONIC AIR CLEANER

OPERATING

LIGHT

ON

OFF

UL Listed

CSA Certified

Please read and familiarize yourself with the contents of this manual

before installing, operating or performing maintenance on the unit.

Part No. 37-6068B

Replaces 37-6068A

Printed In U.S.A.

0021

RULES FOR SAFE

CAUTION

!

INSTALLATION

AND OPERATION

Please read instructions before installing and using the

Electronic Air Cleaner. This will help you obtain the full

benefit from the Electronic Air Cleaner you have selected.

!

WARNING

ELECTROCUTION HAZARD

Shut off power at fuse panel before

servicing.

Failure to do so could result in

serious personal injury or death.

1. Read the Owners Manual and the Rules for Safe

Operation carefully. Failure to follow these rules and

instructions could cause a malfunction of filter or

unsatisfactory service.

2. Follow a regular service and maintenance schedule

for efficient operation.

!

WARNING

Installation of this unit must comply with local

electric codes or other applicable codes.

Review and understand local codes prior to installation.

Failure to do so could result in serious personal

injury or death.

!

WARNING

Do not attempt installation of this unit unless you

are familiar with the necessary tools, equipment,

utility connections and potential hazards.

Installation should be performed only by a qualified service provider.

Failure to do so could result in reduced performance of the unit, serious personal injury or

death.

TABLE OF CONTENTS

Rules for Safe Installation and Operation....... 2

How the Air Cleaner Works ............................ 3

Construction of the Air Cleaner....................... 3

Preinstallation ................................................. 4

Installation....................................................... 6

Wiring Instructions .......................................... 7

Operation ........................................................ 8

Maintenance and Washing ............................. 8

Specifications.................................................. 9

Basic SST Service Guide ............................. 10

Technical Repair Guide ................................ 11

Repair Parts .................................................. 14

CABINET AND CELLS MAY CONTAIN SHARP EDGES.

Use care when servicing unit or handling cells.

Failure to do so could result in minor personal injury.

DID YOU GET THE RIGHT SIZE AIR

CLEANER

Model 10C26S-010 is designed for heating or cooling

blowers delivering 600 to 1200 cubic feet of air per minute

(cfm.)

Model 14C26S-010 is designed for heating or cooling

blowers delivering 1000 to 1600 cfm.

Model 16C28S-010 is designed for heating or cooling

blowers delivering 1000 to 2000 cfm.

Model 20C26S-010 is designed for heating or cooling

blowers delivering 1600 to 2200 cfm.

See specifications on page 9.

BASIC TOOL REQUIRED

Tin Snip

Screwdriver

Rule or Tape Measure

Drill

2

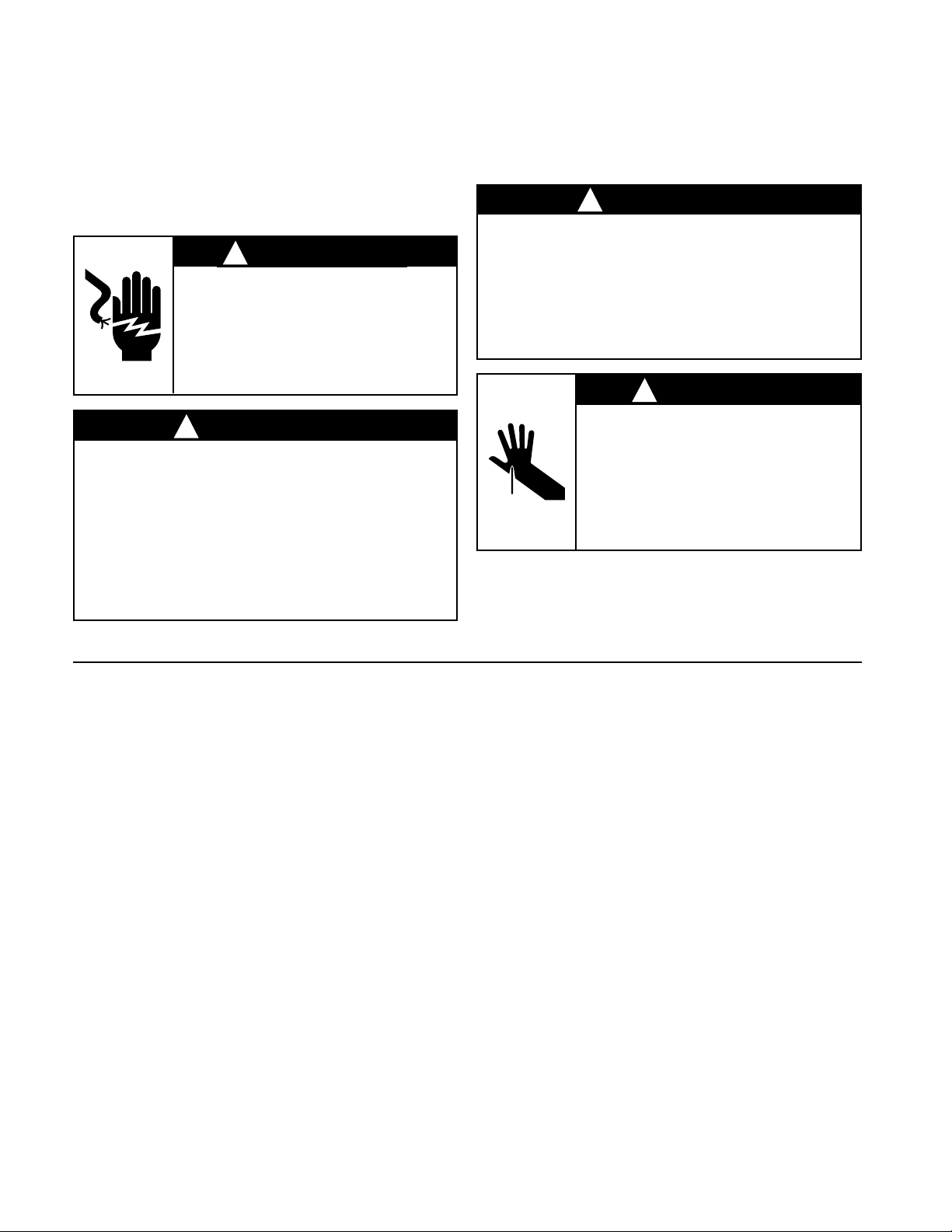

HOW THE AIR CLEANER

Cabinet

Pre-Filters

Handle

Contact

Button

Contact

Button

Collecting Cells

Power Pack

WORKS

Dirt particles flowing through the ducts (Figure 1) first

enters the pre-filters (A) where large particles (hair, lint,

etc.) are trapped. Smaller particles (smoke, dust, pollen,

etc.) pass through these pre-filters and enter the ionizing

section (B). Here each tiny particle receives a positive

electrical charge. These charged particles then enter the

collecting section (C). This section consists of a series of

aluminum plates which are alternately charged negative

and positive.

The positive charge of the particles cause them to be

repelled by the positive plates and attracted to the negative plates where they are collected . . . just as a magnet

attracts iron filings.

Clean-filtered air re-enters the supply duct system.

ABC

Dirty Air In Clean Air Out

Figure 1

CONSTRUCTION OF THE

AIR CLEANER

Not only is your air cleaner easy to install, it is also easy

to operate and maintain. Its basic components, and their

functions, are as follows: (See Figure 2)

Cabinet - mounts to existing duct work and houses the

collecting cells and pre-filters.

Collecting Cells - are made in two sections and perform

the actual collecting of dust, dirt, and other impurities from the air. They contain the ionizing and

collection sections described above.

Each cell must be installed with the ionizing wires

on the air entering side. Each cell must be oriented with the handles and contact button (Figure 2) toward the operator.

Pre-filters - are in two sections which are interchange-

able. They serve as a pre-filter to trap large

particles such as hair and lint before they can

enter the cell sections.

Power Pack- contains operating and power on lights as

well as the solid state components that convert

the 120 volt power supply to the high-voltage,

direct current required for the collecting cell.

Figure 2

3

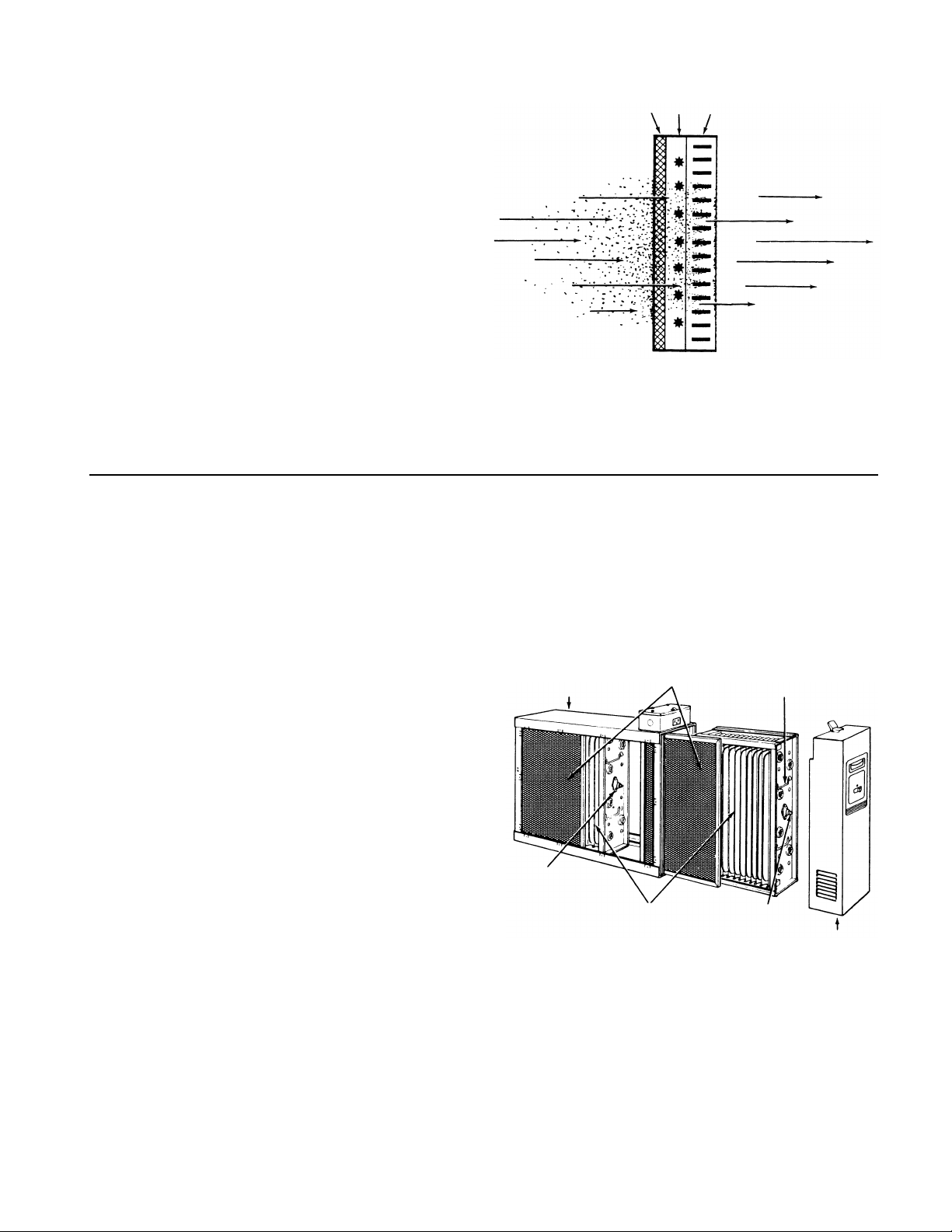

PREINSTALLATION

Not to Exceed 20°

Air Flow

Furnace

Opening

Furnace

Transition Section

(if Needed)

Electronic

Air Cleaner

Air Flow

Electronic

Air Cleaner

Opening

Figure 3

LOCATING THE AIR FILTER

Your air filter must be mounted in the return air duct of a

central forced-air system, on the air entering side of your

furnace. (See Figure 3 for example.)

Select a location that meets the following:

1. The face of the cell will be at a right angle to the air

stream.

2. Allow the following clearances to permit removal of

cells and pre-filters: (See Figures 4 and 5)

Model 10C26S-010 - 14 inches

Model 14C26S-010 - 15 inches

Model 16C28S-010 - 14 inches

Model 20C26S-010 - 15 inches

For complete dimension data refer to Figure 5.

3. The air filter is not to be placed in the discharge of

either the heating or cooling unit.

4. IMPORTANT: If atomizing spray type humidifier is

used, it must be installed downstream from the air

filter.

If your furnace duct system has a pre-installed boot,

discard front cover of boot and slide the air cleaner

component inside the boot. (Applies to 14C26S-010 and

20C26S-010.)

If furnace opening cannot be enlarged to required size, a

transition sheet metal section must be used. Transition

must be planned for each job. Reduction should not be

more than 4 inches per linear foot, approximately 20

angular degrees (Figure 3).

DIRECTION OF AIR FLOW THROUGH THE

AIR CLEANER

Your air cleaner is shipped from the factory with air flow

from left-to-right. If this air flow is suitable for the installation, no further changes need to be made (Figure 4). For

right-to-left air flow, remove both pre-filter and cell sec-

(Interchangeable)

Collecting Cell

Cabinet

Contact

Button

Pre-Filters

(Interchangeable)

Outlet Box

(Interchangeable)

Collecting Cell

Handle

Contact

Button

Removal Clearance

Power Pack

See text for Cell

Figure 4

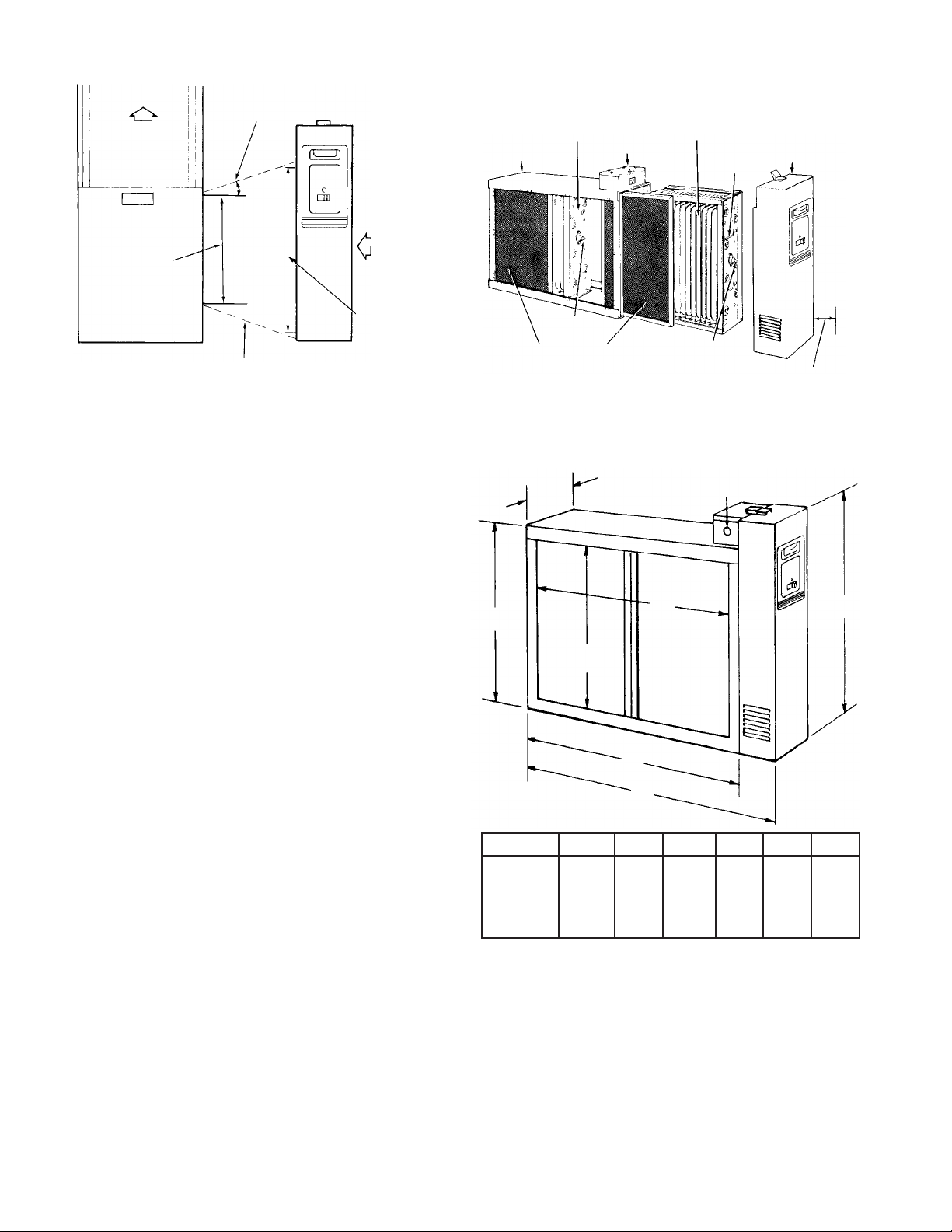

Knockouts for

6 7/8"

E

3/4" Conduit

(three sides)

C

F

D

B

A

MODEL NO. A B C D E F

10C26S-010 24 3/4 21 5/16 18 5/8 13 9/16 16 7/16 19 1/16

14C26S-010 29 11/16 26 1/4 23 5/8 13 9/16 16 7/16 19 1/16

16C28S-010 25 1/2 21 5/16 18 5/8 17 3/4 20 5/8 23 3/8

20C26S-010 29 11/16 26 1/4 23 5/8 17 3/4 20 5/8 23 3/8

Figure 5

tions. Turn cells upside down (with the same end facing

the cabinet opening). This will locate the ionizing wires at

the right, and both contact buttons and cell handles will be

facing the power door. Air flow direction must agree with

arrow embossed on end of collecting cells.

After installing the cell sections, install pre-filters in cabinet tracks on the right. This will again place the pre-filters

on the air entering side (on the same side as ionizing

wires).

4

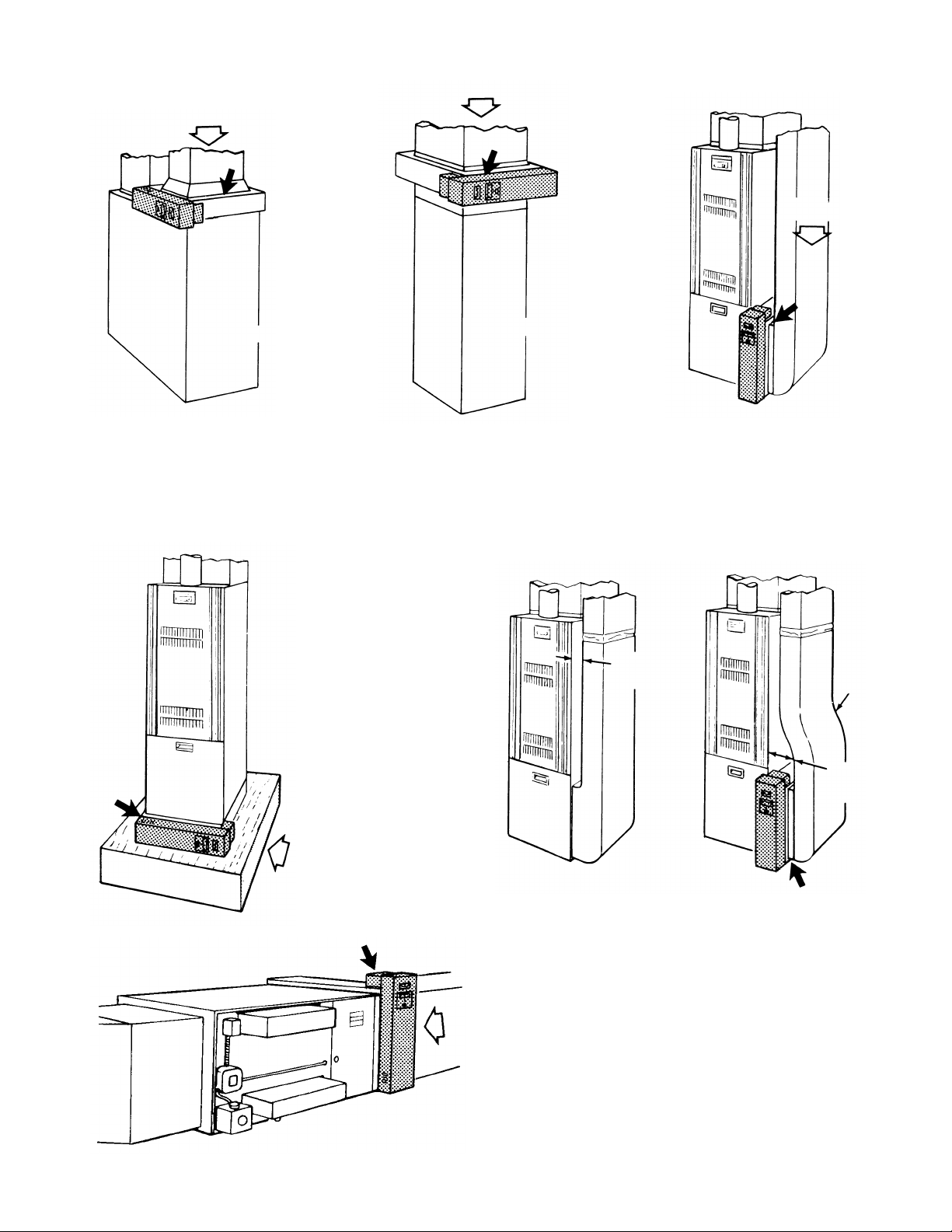

TYPICAL MOUNTING POSITIONS

Air Flow

Figure 8

Air Flow

Air Flow

Rear View

Figure 6

BASEMENT FURNACE

(LOWBOY) (Figure 6)

Cleaner is mounted horizontally in return plenum,

just above furnace.

Figure 7

COUNTERFLOW

FURNACE (Figure 7)

Cleaner is mounted horizontally in return duct or plenum,

just above furnace.

HIGHBOY FURNACE

(Figure 9)

Installation beneath furnace.

Cleaner mounts horizontally,

where return air enters from

below. Raise furnace and install beneath base.

Rear View

HIGHBOY FURNACE

(Figure 8)

Side installation. Cleaner

is mounted vertically,

where return air enters

side inlet of furnace.

Less than

7 Inches

Offset

At Least

9 Inches

Figure 9

Air Flow

Figure 10

OFFSET INSTALLATION

(Figure 10)

Typical use of duct offset to match air filter opening.

If duct connection to furnace allows less than nine

inches for mounting the air cleaner, shorten the

lateral trunk, or attach an offset fitting to the elbow.

Air Flow

HORIZONTAL FURNACE

(Figure 11)

Cleaner is mounted vertically

in the return duct near furnace.

Figure 11

5

Loading...

Loading...