Page 1

WHITE-RODGERS

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

This Hydraulic-Action temperature control is readily applicable for many types of commercial or industrial refrigeration applications.

The speed of response of the temperature sensitive

element makes it particularly applicable to display cases,

unit coolers, walk-in boxes, etc., where there is no excessive humidity.

TYPE 201

REFRIGERATION

TEMPERATURE CONTROL

Adjustable Differential

INSTALLATION INSTRUCTIONS

DESCRIPTION

THESE CONTROLS MUST BE INSTALLED BY A

QUALIFIED INSTALLER.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical

codes and ordinances.

This control is a precision instrument, and should be

handled carefully. Rough handling or distorting components could cause the control to malfunction.

This control has been accurately calibrated at the factory.

Any attempt to calibrate this control will void the White-

Rodgers warranty.

When the temperature in the controlled area rises, the

fluid in the coiled element expands, causing the contacts

in the switch mechanism to snap closed, turning on the

refrigeration system.

Observe the following general rules when selecting a

control location:

1. The switch mechanism of this control may be mounted

in any location, provided that the temperature and

humidity of the air in which it is located do not cause

condensation on the switch parts.

2. It should be located so as to be in an average

PRECAUTIONS

CAUTION

To prevent electrical shock and/or equipment

damage, disconnect electric power to system at

main fuse or circuit breaker box until installation

is complete.

WARNING

Do not use on circuits exceeding specified voltages. Higher voltages will damage control and

could cause shock or fire hazard.

PRINCIPLE OF OPERATION

As the refrigeration system cools the controlled area, the

fluid in the coiled element contracts. When the temperature reaches the control setting, the contacts snap open,

turning off the system.

INSTALLATION

temperature of the controlled area.

3. Never locate control on or near an outside wall.

4. Don’t locate it close to a false source of heat or cold

such as strong light, sunlight, hot or cold water pipes

in wall, etc.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, FAX (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

Printed in U.S.A.

PART NO. 37-1121B

Replaces 37-1121, 37-9088 & 37-9193

9545

Page 2

INSTALLATION CONT.

5. If the electric conduit goes to a warmer room, put rock

wool around the wires in the conduit where it enters

the control to prevent the flow of warm moist air into

the switch.

WIRING

All wiring should be done in accordance with local and national electrical codes and ordinances.

If the manufacturer of the cooling equipment has supplied

a wiring diagram, follow such recommendations. The

following diagrams show general use of these controls.

Temperature

control

To line switch

and power supply

HOT

GND

Circuit showing temperature control to open and

close refrigerant valve. Suction pressure control

starts and stops compressor through motor starter.

High side

pressure control

(if used)

CAUTION

Do not twist or uncoil the coiled element on top of

the case. Do not attach conduit to top of control

through the coiled element. Run conduit to bottom of control instead.

Circuit showing temperature control controlling compressor directly.

To line switch

and power supply

Motor

starter

High side

pressure

control

Suction

pressure

control

Temperature

control

Solenoid

refrigerant

valve

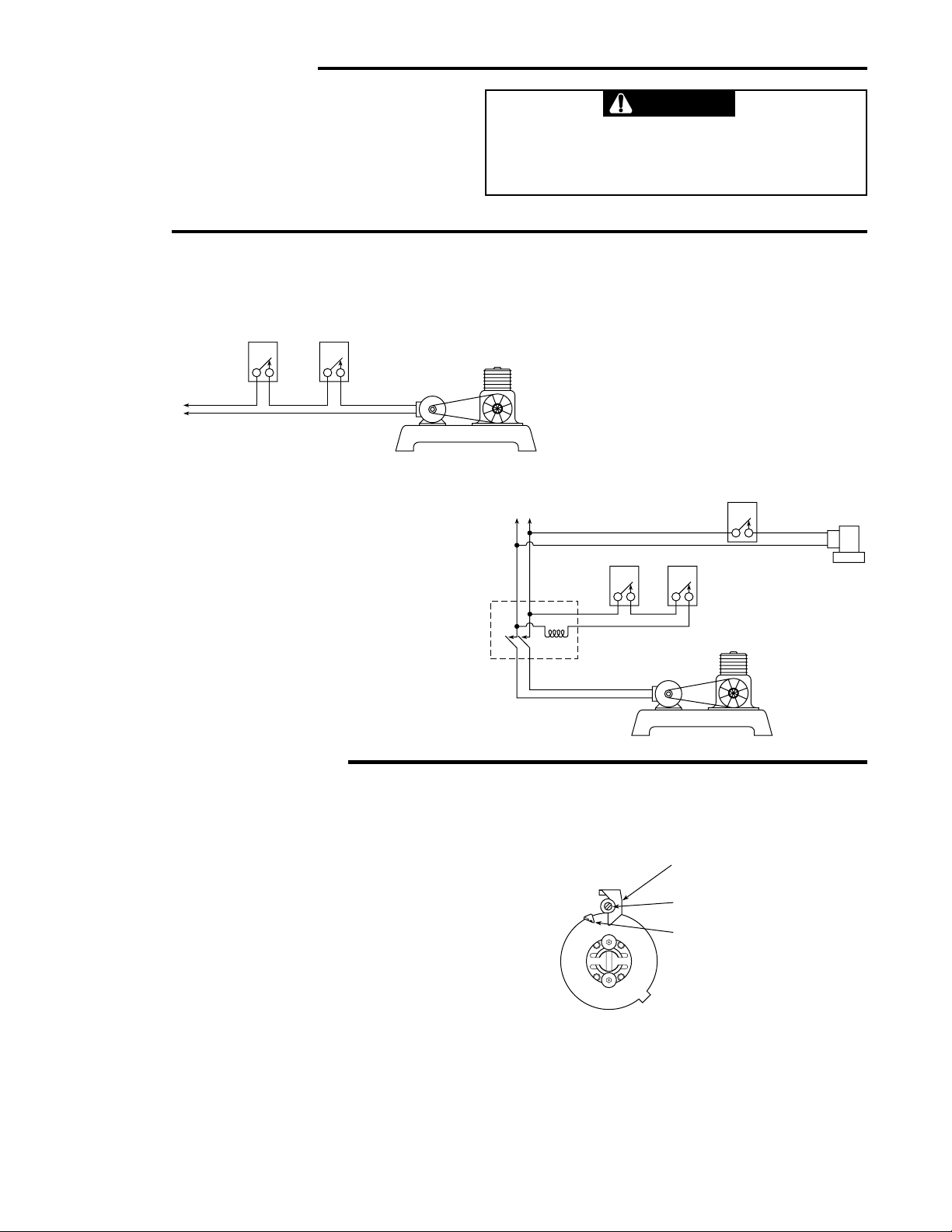

SETTING THE CONTROL

CONTROLS WITH ADJUSTABLE DIFFERENTIAL

The movable indicator points to the temperature at which the

compressor starts. The fixed indicator points to the temperature

at which the compressor will stop. The difference between these

two indicators is the differential.

To set the control, do the following:

1. Use a screwdriver in the slot on the front of the control to turn

the dial so that the fixed indicator (B) points to the temperature at which the compressor is to stop.

2. Turn the differential adjusting screw (C) until the movable

indicator (D) points to the temperature at which the compressor is to start.

“B” Fixed indicator

(cut-out point)

“C” Differential

adjusting screw

“D” Movable indicator

(cut-in point)

2

Page 3

TYPE 201

RÉGULATEUR DE TEMPÉRATURE

WHITE-RODGERS

INSTRUCTIONS D’INSTALLATION

Utilisateur: conservez ces instructions pour vous y référer au besoin!

SI VOUS NE LISEZ PAS ATTENTIVEMENT CES INSTRUCTIONS AVANT

D’INSTALLER ET D’UTILISER LA COMMANDE, VOUS RISQUEZ DE CAUSER

DES BLESSURES ET DES DOMMAGES MATÉRIELS.

DE RÉFRIGÉRATION

Différentiel réglable

Ce régulateur de température à mécanisme hydraulique

s’adapte à plusieurs types de systèmes de réfrigération

commerciale ou industrielle.

La rapidité du temps de réponse de l’élément

thermosensible rend la commande particulièrement

adaptée aux étalages, chambres froides, etc., où il n’y a

pas trop d’humidité.

LA COMMANDE DOIT ÊTRE INSTALLÉE PAR UN

TECHNICIEN QUALIFIÉ.

Ne dépassez pas les charges nominales.

Tout le câblage doit être conforme aux codes et règlements

locaux et nationaux qui régissent les installations

électriques.

Cette commande est un instrument de précision qui doit

être manipulé avec soin. Elle peut se détraquer si elle est

manipulée de façon négligente ou si des composantes

sont déformées.

La commande a été calibrée avec précision lors de la

fabrication. Toute tentative de calibrer l’appareil annulera

la garantie de White-Rodgers.

DESCRIPTION

PRÉCAUTIONS

ATTENTION

Afin de prévenir les chocs électriques et les

dommages matériels pendant l’installation,

coupez l’alimentation électrique au panneau de

distribution principal.

AVERTISSEMENT

N’installez pas cet appareil sur des circuits qui

dépassent la tension nominale. Une tension trop

élevée peut endommager la commande et poser

des risques de chocs électriques et d’incendie.

Lorsque la température de la zone contrôlée augmente,

le fluide dans le serpentin se dilate. Ceci entraîne la

fermeture des contacts de l’interrupteur et la mise en

marche de l’équipement de réfrigération.

Choisir l’emplacement du régulateur en suivant les règles

suivantes :

1. L’interrupteur du régulateur peut être placé à n’importe

quel endroit pourvu que la température et l’humidité de

l’air ambiant n’entraînent pas de condensation sur les

pièces de l’interrupteur.

2. Le régulateur doit être placé là où la température

correspond à la moyenne de la zone contrôlée.

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, Télécopieur (314) 577-1517

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, Télécopieur (905) 475-4625

Imprimé aux États-Unis

PRINCIPE DE FONCTIONNEMENT

Lorsque l’équipement de réfrigération fait augmenter la

température de la zone contrôlée, le fluide dans le serpentin

se contracte. Lorsque la température atteint le point de

consigne, les contacts sont ouverts, ce qui arrête

l’équipement de réfrigération.

INSTALLATION

3. Ne jamais installer le régulateur sur un mur extérieur

ou à proximité d’un tel mur.

4. Ne jamais installer le régulateur près d’une source

ponctuelle de chaleur ou de froid, comme une lampe

puissante, les rayons du soleil, des tuyaux d’eau

chaude ou froide dans un mur, etc.

PIÈCE No 37-1121B

Remplace 37-1121, 37-9088 & 37-9193

9545

Page 4

INSTALLATION (suite)

5. Si le conduit électrique traverse un mur vers une pièce

plus chaude, placer de la laine minérale autour des fils

à l’endroit où ils pénètrent dans le régulateur. Ceci

empêchera l’air chaud et humide de pénétrer dns

l’interrupteur.

CÂBLAGE

Tout le câblage doit être conforme aux codes et règlements locaux et nationaux

qui régissent les installations électriques.

Si le fabricant de l’équipement de réfrigération

recommande un schéma de câblage, alors veuillez vous

y référer. Les schémas suivants correspondent à un

usage typique du régulateur.

Vers l’interrupteur

To line switch

et l’alimentation

and power supply

du secteur

Temperature

Régulateur

control

SOUS

TENSION

HOT

GND

NEUTRE

High side

Manostat du côté

pressure control

élevé (si employé)

(if used)

ATTENTION

Ne pas tordre ou dérouler le serpentin situé sur le

dessus du boîtier. Ne pas fixer de conduit au

régulateur en le passant au centre du serpentin,

mais le raccorder plutôt au dessous du régulateur.

Circuit du régulateur contrôlant

directement un compresseur.

Circuit du régulateur employé pour ouvrir et fermer

la vanne du réfrigérant. Le manostat d’aspiration

met le compresseur en marche et hors marche par

l’intermédiaire du démarreur du moteur.

Démarreur

du moteur

RÉGLAGE DE LA COMMANDE

RÉGULATEUR À DIFFÉRENTIEL REGLABLE

L’indicateur mobile donne la température à laquelle le

compresseur sera mis en marche. L’indicateur fixe donne

la température à laquelle le compresseur sera arrêté. Le

différentiel est l’écart entre ces deux indicateurs.

Pour régler le régulateur, procéder de la façon suivante :

1. Introduire un tournevis dans la fente située sur l’avant

de la commande. Tourner le cadran jusqu’à ce que

l’indicateur fixe (B) indique la température à laquelle le

compresseur doit s’arrêter.

2. Tourner la vis de réglage du différentiel (C) jusqu’à ce

que l’indicateur mobile (D) indique la température à

laquelle le compresseur doit démarrer.

Vers l’interrupteur et

To line switch

l’alimentation du secteur

and power supply

Manostat du

Motor

starter

High side

pressure

côté élevé

control

Suction

Manostat

pressure

control

d’aspiration

B Indicateur fixe

(point d’enclenchement)

C Vis de réglage

du différentiel

D Indicateur mobile

(point de déclenchement)

Temperature

Régulateur

control

Électrovanne

Solenoid

du réfrigérant

refrigerant

valve

2

Loading...

Loading...