Page 1

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

APPLICATIONS

1F98EZ-1421, -1441 Easy Install

For up to 4 Stages Heat and 2 Stages Cool

INSTALLATION INSTRUCTIONS

Configuration

Options

Single Stage Gas, Oil, Electric, Heat Only, Cool

Multi Stage Gas, Oil, Electric, Heat Only, Cool

Heat Pump Single or Two Compressor Systems

Heat Pump

with Dual Fuel

Applications Maximum

Only or Heat Cool Systems

Only or Heat Cool Systems

with up to 2 Stages of Aux / Em Heat

Single or Two Compressor Systems

with up to 2 Stages of Fossil fuel

Heat

Stages

1/1

2/2

4/2

4/2

1F98EZ-1421, -1441 System

12” Touchscreen User Interface

1F98-1491

SPECIFICATIONS

Electrical Rating:

Input-Hardwire ................................................... 20 to 30 VAC

Terminal Load ........................................................... 1.0A per terminal, 2.5A maximum all terminals combined

Setpoint Range ......................................................... 45° to 99°F (7° to 37°C)

Differential (Single Stage) ......................................... Heat 0.6°F; Cool 1.2°F

Differential (Multi-Stage) ........................................... Heat 0.6°F; Cool 1.2°F

Differential (Heat Pump) ........................................... Heat 1.2°F; Cool 1.5°F

Operating Ambient .................................................... 32°F to +105°F (0° to +41°C)

Operating Humidity ................................................... 90% non-condensing max.

Shipping Temperature Range ................................... -40° to +150°F (-40° to +65°C)

Dimensions Interface ................................................ 4-1/2”H x 6”W x 1-1/4”D

Dimensions Control .................................................. 5-1/2”H x 5-3/4”W x 1-1/2”D

Equipment Control

40C01-1400

CAUTION

!

To prevent electrical shock and/or equipment damage,

disconnect electric power to system at main fuse or

circuit breaker box until installation is complete.

Index Page

Installation 2

Wiring Connections 2

Wiring Diagrams 3

Installer Configuration Menu 5

Troubleshooting 8

www.white-rodgers.com

www.emersonclimate.com

ATTENTION: MERCURY NOTICE

This product does not contain mercury. However, this

product may replace a product that contains mercury.

Mercury and products containing mercury must not be

discarded in household trash. Do not touch any spilled

mercury. Wearing non-absorbent gloves, clean up any

spilled mercury and place in a sealed container. For proper

disposal of a product containing mercury or a sealed

container of spilled mercury, place it in a suitable shipping

container. Refer to www.white-rodgers.com for location to

send product containing mercury.

PART NO. 37-7215C

Replaces 37-7215B

1110

1

Page 2

INSTALLATION

WARNING

!

Thermostat installation and all components of the

control system shall conform to Class II circuits per

the NEC code.

Control 40C01-1400

Control can be mounted on wall or equipment. Control has

four mounting holes. Wall anchors and screws are provided

for mounting on drywall. Drill 3/16 hole for drywall mounting.

If mounting on equipment Do Not Mount inside HVAC

equipment. Only mount on outside of HVAC equipment.

WIRING CONNECTIONS

Refer to equipment manufacturers’ instructions for specific

system wiring information. After wiring, see CONFIGURATION

section for proper thermostat configuration.

Connect wires as appropriate for HVAC systems (see wiring

diagrams). To power control, connect the 24 V system hot to

R terminal and common to C on left side of control labelled

“Power”. On initial power up the 7 segment LED on the

Thermostat / Interface 1F98-1491

1) Pull the thermostat/interface off the base. Forcing or

prying on the thermostat will cause damage to the unit.

2) Place base over hole in wall and mark mounting hole

locations on wall using base as a template.

3) Move base out of the way. Drill mounting holes. If you are

using existing mounting holes and the holes drilled are

too large and do not allow you to tighten base snugly, use

plastic screw anchors to secure the base.

4) Fasten base snugly to wall using mounting holes and two

mounting screws. Leveling is for appearance only and will

not affect thermostat operation.

5) Connect wires to terminal block on base (see Figure 1).

6) Push excess wire into wall and plug hole with a fire

resistant material (such as fiberglass insulation) to prevent

drafts from affecting thermostat operation.

7) Carefully line the thermostat up with the base and snap

into place.

control will display E (for communication error) until interface

is connected. With power supplied to control, it is normal for

the green system LED to flash periodically.

With interface connected, the 7 segment LED will display

C to indicate the two devices have initiated communication.

C will disappear after approximately 30 seconds when

communication is established.

BLUE EASY INSTALL INPUTS/OUTPUTS

Easy Install 40C01 Operational / Functional

Control Terminals

R ......................................... 24 VAC Transformer

RC ....................................... 24 VAC Cooling Transformer

RH ....................................... 24 VAC Heating Transformer

C ......................................... 24 V Transformer Common

W/E ..................................... Heating Stage 1

HP Aux/Em Heat Stage 1

W2 ....................................... Heating Stage 2

HP Aux/Em Heat Stage 2

Y .......................................... Compressor Stage 1

Y2 ........................................ Compressor Stage 2

G .......................................... Fan Relay

L Terminal ............................ System Monitor Compatible

with Comfort Aler t Diagnostics

O/B Terminal ........................ Changeover Relay Heat Pump

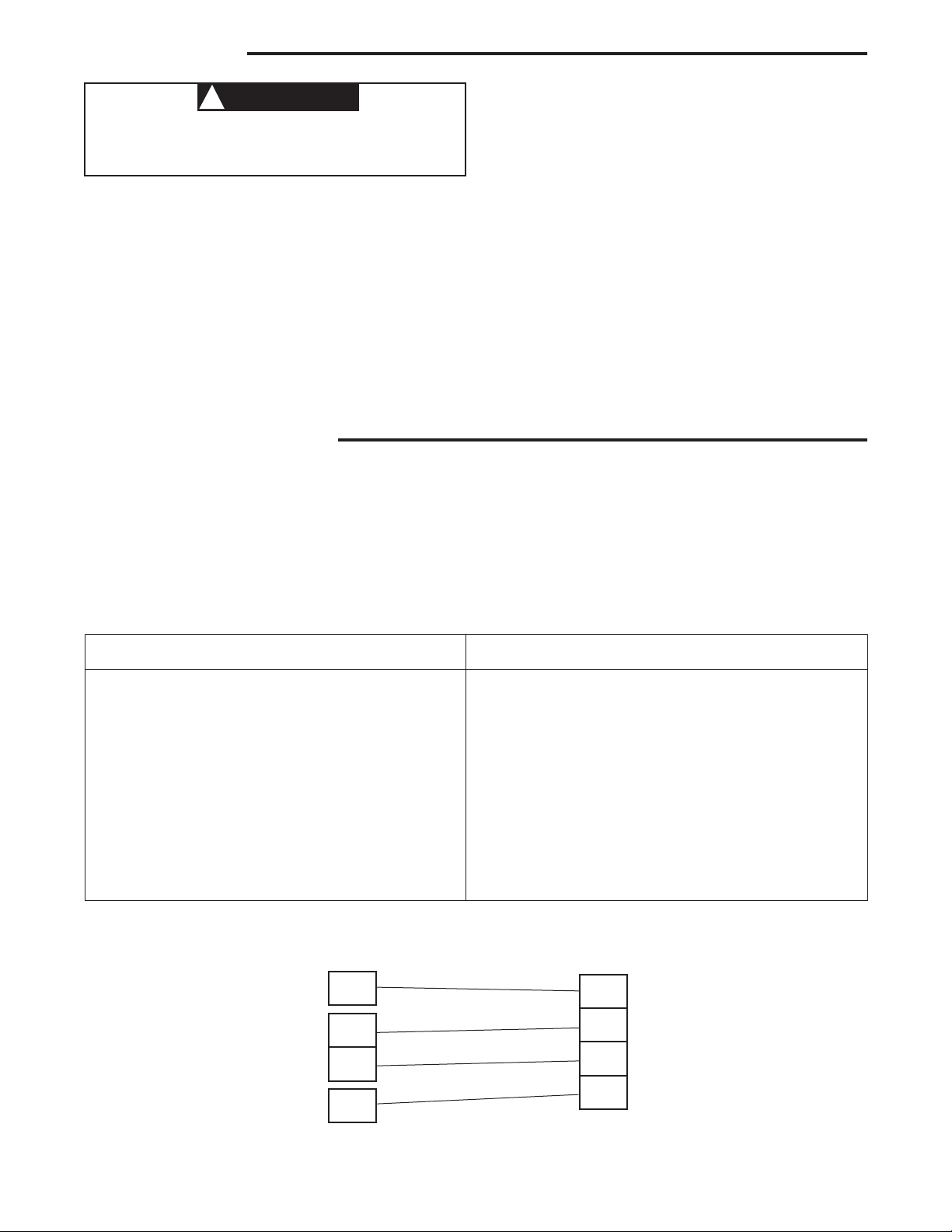

Fig. 1 - Thermostat / Interface to control wiring

R

1

2

Easy Install 40C01 Operational / Functional

Control Terminals

DHM .................................... Dehumidification Relay / Connection

DHM2 .................................. Dehumidification Relay / Connection

HM ....................................... Humidification Relay / Connection

HM2 ..................................... Humidification Relay / Connection

R .......................................... 24 VAC to Interface

1........................................... Data to/from Interface

2........................................... Data to/from Interface

C .......................................... 24 VAC Common to Interface

RJ11 .................................... Field configuration hook-up with RJ11

equipped configuration tool

+ .......................................... Voltage to Outdoor Sensor

S .......................................... Outdoor Sensor Temperature Signal

- ........................................... Voltage to Outdoor Sensor

R

1

2

C

C

40C01Control1F98 Thermostat

2

Page 3

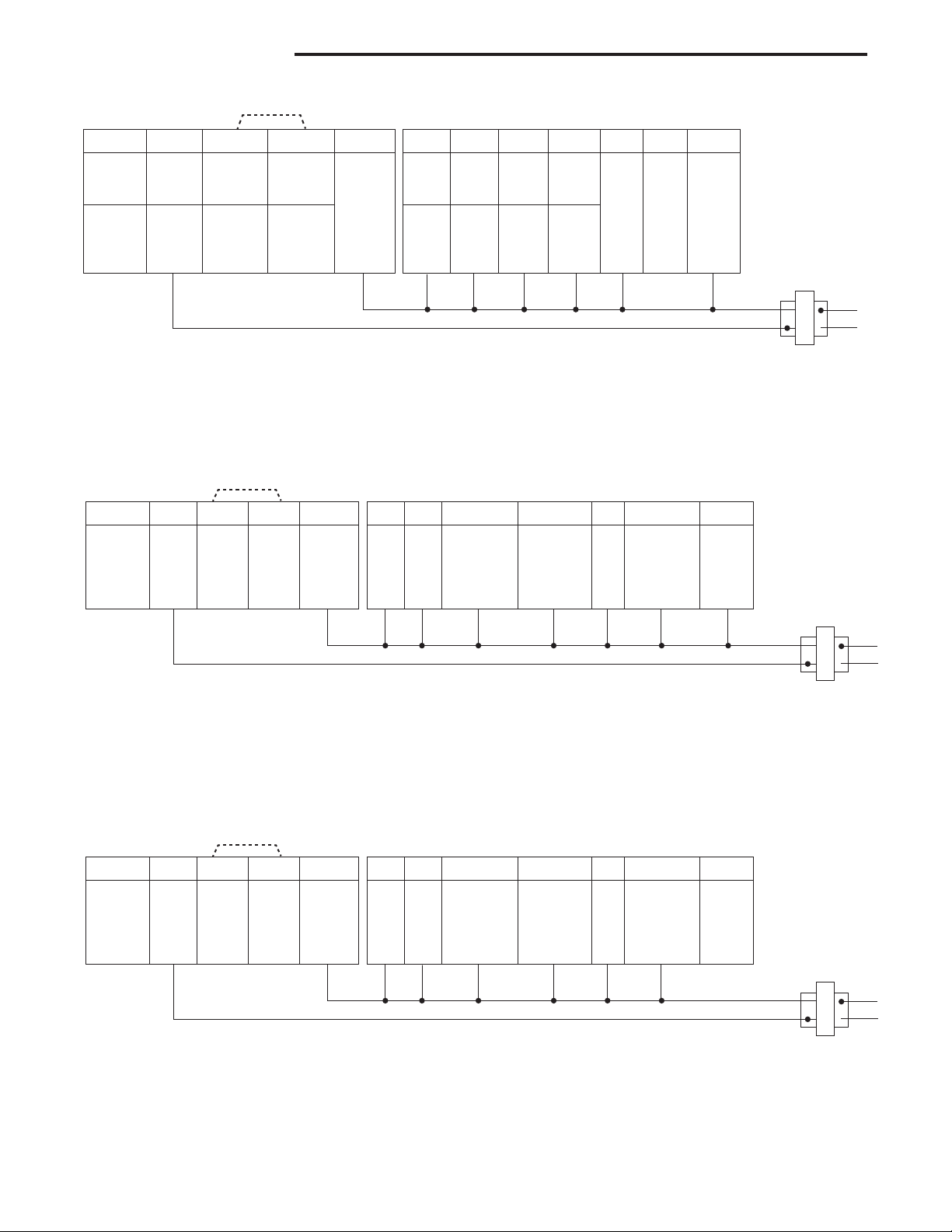

WIRING DIAGRAMS

Fig. 2 - Typical Connection of a Single Stage or Multi-Stage System

*

SYSTEM R RH RC C W/E W2 Y Y2 G O/B L

Single

Stage

Multi

Stage

*Factory installed jumper between RH and RC

Fig. 3 - Typical Connection of Heat Pump System up to 4 Stages Heat / 2 Stages Cool

SYSTEM R RH RC C W/E W2 Y Y2 G O/B L

Heat

Pump

24 VAC

Powe r

24 VAC

Powe r

24 VAC

Powe r

24 VAC

Powe r

for Heating

24 VAC

Powe r

*

24 VAC

Powe r

for

Heating

24 VAC

for Cooling

24 VAC

24 VAC

Powe r

for

Cooling

Powe r

Powe r

Common

Required

24 VAC

24 VAC

Common

Required

Aux /

Em

stage

Heat N/A Cool N/A Fan N/A System

Heat

mode

stage

Aux /

Em

st

1

st

1

nd

2

Heat

mode

nd

2

stage

1st stage

Compressor

Cool

mode

st

1

stage

2nd stage

Compressor

Cool

mode

nd

2

stage

Fan Changeover

Valve

stage

Monitor

System

Monitor

NEUTRAL

24 VAC

HOT

120 VAC

CLASS II

Transformer

*Factory installed jumper between RH and RC

Fig. 4 - Typical Connection of Heat Pump / Dual Fuel System up to 4 Stages Heat / 2 Stages Cool

*

SYSTEM R RH RC C W/E W2 Y Y2 G O/B L

Heat

Pump

*Factory installed jumper between RH and RC

24 VAC

Powe r

24 VAC

Powe r

for

Heating

24 VAC

Powe r

for

Cooling

24 VAC

Common

Required

Fossil

Fuel

st

1

stage

Fossil

Fuel

nd

2

stage

1st stage

Compressor

2nd stage

Compressor

Fan Changeover

Valve

System

Monitor

NEUTRAL

24 VAC

HOT

NEUTRAL

24 VAC

HOT

120 VAC

CLASS II

Transformer

120 VAC

CLASS II

Transformer

3

Page 4

WIRING DIAGRAMS

Wiring Guide for Equipment Accessories

Fig. 5 - Non-Powered Humidifier. HM terminal provides system 24 V on call for humidification

Transformer

R

C

HM DRY

RH HM2

HM

HM2

Fig. 6 - Powered Humidifier. With HM DRY switch in HM2 position, HM and HM2 provide normally

open dry contact for low voltage (24 V) powered humidifier connection.

HM DRY

RH HM2

HM

HM2

Powered

Humidifier

Fig. 7 - Powered Dehumidifier. With DHM DRY switch in DHM2 position, DHM and DHM2 provide

normally open dry contact for low voltage (24 V) whole house powered dehumidifier connection.

RH DHM2

DHM DRY

DHM

DHM2

Powered

Dehumidifier

Non-Powered

Humidifier

Fig. 8 - System Dehumidification with variable speed blower. For systems where low speed requires connect to normally

open 24 V powered DHM terminal for low speed connection on air handler / furnace (24 V removed on dehumidification call).

RH DHM2

DHM DRY

DHM

DHM2

Low Speed

Fan

Fig. 9 - System Dehumidification with variable speed blower. For systems where low speed requires system 24 V on

dehumidification connect 24 V to DHM2 with DHM DRY switch in DHM2 position and connect DHM to low speed

connection on air handler/ furnace.

Transformer

R

C

RH DHM2

DHM DRY

DHM

DHM2

Low Speed

Fan

4

Page 5

INSTALLER/CONFIGURATION MENU

Entering and Navigating the Advanced Installer Configuration Menu

On the Home Screen Display, touch the Menu key to display additional key choices. Touch and hold the Installer Config key

for approximately 3 seconds to enter the Thermostat Options Configuration Menu. Touch and hold the Installer Config key

again for approximately 3 seconds to enter the Advanced Installer Configuration Menu.

Press or Key

Description of

Features in order when

Ref.

using to choose;

#

(Use to step back)

Outdoor / Condenser

1

2

3

4 Heat Cycle Rate FA SL, FA HEAT CYCLE RATE

5 Cool Cycle Rate FA SL, FA COOL CYCLE RATE

6

7

8

9

Configuration AC1 AC0, AC1, AC2, HP1, HP2

Indoor Heat

Configuration GA2 FAN, GA1, GA2, EL1, EL2

B or O terminal

(HP1, HP2 only) O O, b REVERSING VALVE

Auxiliary Cycle Rate

(HP1, HP2 only) FA SL, FA

Energy Management

Recovery On OFF, On

Outdoor Remote

Sensor OFF OFF, On OUTDOOR REMOTE SENSOR

Auxiliary Off

(HP1, HP2 only) OFF

Displayed in

Clock Digits

(Default) Options

to Select Options

OFF, 35-80 (in steps of 1 degree)

From OFF, value changes to 80 AUXILIARY OFF

Displayed in

Message Area

CONDENSER

CONFIG

INDOOR HEAT

CONFIG

AUXILIARY CYCLE

RATE

ENERGY MANAGEMENT

RECOVERY

Dual Fuel Config

10

11 Dehumidification OFF

12

13 Humidification OFF

14

15 Compressor Lockout OFF OFF, On COMPRESSOR LOCKOUT

(HP1, HP2 only) 40

Independent

Dehumidification OFF OFF, On INDEPENDENT DEHUMID

Independent

Humidification OFF OFF, On

OFF, 0 to 50 (in steps of 1 degree)

From OFF, value changes to 40 DUAL FUEL CONFIG

OFF, 40-80 (in 1% steps) - displayed

in the last digits of the Message Area.

From OFF, value changes to 60

OFF, 20-60 (in 1% steps) - displayed

in the last digits of the Message Area.

From OFF, value changes to 40

DEHUM XX% (where XX

is the DEHUM set point)

HUMID XX% (where XX

is the HUM set point)

INDEPENDENT

HUMID

5

Page 6

INSTALLER/CONFIGURATION MENU

W/E

W2

Y

Y2

G

O/B

HM

DHM

Break tab

to have LEDs

on with cover

installed

Configuration

Control can be configured at the equipment by utilizing the configuration plug in tool (F4-1400). The tool mounts to the back

of the interface and plugs into the bottom of the control via the RJ-11 connection. (Note: You cannot have two interfaces

connected to the control at the same time). With control powered, interface is used to configure the application and for

operational checks. Once configured, the interface can be installed in living area.

1) Outdoor / Condenser Configuration. Select the number type A/C (air conditioner) HP Heat Pump and number

of stages. The appropriate Color (A/C= Amber, Heat

Pump=Green) LED will illuminate for the configured Y/Y2

terminals.

2) Indoor / Heat Configuration. Select the number type

GA (Gas) EL (electric) and Fan and number of stages.

The appropriate Color (Amber if gas, Green if electric)

LED will illuminate for the configured W/W2 terminals.

3) B or O Terminal Configuration. If condenser is heat

pump configured then Select either O (default) or B

terminal output configuration. The B/O LED will illuminate

the appropriate color (Amber if B, Green if O)

4) Heat Cycle Rate. Select either FA fast (default) or SL

slow cycle rate. If longer cycles are desired then set to

SL.

5) Cool Cycle Rate. Select either FA fast (default) or SL

slow cycle rate. If longer cycles are desired then set to

SL.

6) Auxiliary Cycle Rate. If condenser is heat pump select

either FA fast (default) or SL slow cycle rate. If longer

cycles are desired then set to SL.

7) Energy Management Recovery. Select either On or Off.

With a selection of On the system will start temperature

setback recovery early to reach the program setpoint at

the program start time. A selection of Off will start the

recovery period at the program start time.

8) Outdoor Remote Sense. A selection of On enables the

display of outdoor temperature with the connection of

F145-1378 outdoor remote sensor to the control.

9) Auxiliary Off. When condenser is heat pump configured

and outdoor sensor is connected, the option of locking

out the auxiliary heat based on outdoor ambient temperature becomes available. Default is Off with a selection range from 80 degrees to 35 degrees in 1 degree

increment. When outdoor ambient is above the selected

temperature the auxiliary stages are disabled.

10) Dual Fuel Config. When condenser is heat pump and

indoor heat is gas and outdoor sensor is connected. A

selection from 0 to 50 in one degree increment is available. The Auxiliary/fossil fuel system is enabled, the heat

pump is disabled when the outdoor ambient temperature

is at or below the selection.

11) Dehumidification. Select from Off (default) to a setting

range from 40% to 80% Rh. If Rh is above setting, a

cooling call is initiated. To turn this feature Off raise setting to its highest level 80%

12) Independent Dehumidification. Selection of Off (default) or On. When On is selected the DHM2 output is

active when humidity level is above the desired dehumidification setting.

13) Humidification. Select from Off (default) to a setting

range from 20% to 60% Rh. If Rh is below setting HM2

output is active with a call for heat. To turn this feature Off

lower setting to its lowest level 20%.

14) Independent Humidification. Selection of Off (default)

or On. When On is selected the HM2 output operates

when humidity level is below the desired humidification

setting.

15) Compressor Lockout. Selection of Off (default) or On.

When On is selected the control will invoke a 5 minute

delay between compressor cycles.

After Advanced Installer Configuration, LEDs on the control

will indicate the selections of the thermostat. The following

tables show the LED indications. Remove control cover to

Fig. 10 - LED locations

W/E

7-Segment

LED for Comfort

Alert and

Communication

Codes

System

6

Configuration Plug-In tool

RJ-11 Connection for

W2

Y

Y2

G

O/B

HM

DHM

view LEDs. To view LEDs with cover installed, break off tab

on inside of cover.

Fig. 11 - Inside of front cover

Break tab

to have LEDs

on with cover

installed

Page 7

INSTALLER/CONFIGURATION MENU

LED Indicator legend:

= Amber

= Green

Off = Off

LED’s will be on constant to show configuration.

LED’s will flash to indicate the terminal output is active.

Table 1 - System Configuration

No. of Stages –

System

Type

Conventional

Heat Pump

Dual Fuel

AC Cool

Gas Heat

Electric Heat

Electric System

HP Only (HO)

Fan Only

Outdoor

Equipment

Type

AC 1 Gas 1 Off Off

AC 1 Gas 2 Off

AC 2 Gas 1 Off

AC 2 Gas 2

HP 1 Elec 1 Off Off

HP 1 Elec 2 Off

HP 2 Elec 1

HP 2 Elec 2

HP 1 Gas 1 Off

HP 1 Gas 2 Off

HP 2 Gas 1

HP 2 Gas 2

AC 1 Elec 0 Off Off Off

AC 2 Elec 0 Off Off

No Outdoor

Unit – Gas 1 Off Off Off

No Outdoor

Unit – Gas 2 Off Off

No Outdoor

Unit – Elec 1 Off Off Off

No Outdoor

Unit – Elec 2 Off Off

AC 1 Elec 1 Off Off

AC 1 Elec 2 Off

AC 2 Elec 1 Off

AC 2 Elec 2

HP 1 Elec 0 Off Off Off

HP 2 Elec 0 Off Off

No Outdoor

Unit – Elec 0 Off Off Off Off

Outdoor

Equipment

Type

Indoor

Equipment

Type

No. of Stages –

Indoor

Equipment

Type Y Y2 W/E W2 G

Table 2 - DHM Bi-Color LED Table

DHM DRY

Switch Position

RH

DHM2

DHM LED

Table 3 - HM Bi-Color LED Truth Table

HM DRY

Switch Position

RH

HM2

HM LED

Table 4 - O/B Bi-Color LED Truth Table

Reversing Valve

Configuration

O mode

B mode

O/B LED

7

Page 8

TROUBLESHOOTING

Reset Operation

If a voltage spike or static discharge blanks out the display or

causes erratic thermostat operation, you can reset the system

by removing batteries for 2 minutes. After resetting the

system, replace the batteries. If the system has been reset

and still does not function correctly perform a power reset.

Note: Be sure to review the installer configuration menu

settings.

Symptom Possible Cause Correction Action

No Heat/No Cool/No Fan

(common problems)

No Heat

No Cool

Heat, Cool or Fan

Runs Constantly

Thermostat Setting &

Thermostat Thermometer

Disagree

Furnace (Air Conditioner)

Cycles Too Fast or Too

Slow (narrow or wide

temperature swing)

1. Blown fuse or tripped circuit breaker.

2. Power switch to OFF.

3. Furnace blower compartment door or

panel loose or not properly installed.

4. Loose connection to system.

1. Pilot light not lit.

2. Furnace Lock-Out Condition. Heat

may also be intermittent.

3. Heat pump system requires service.

See fault code table Comfort Alert.

1. Cooling system requires service.

See fault code table Comfort Alert.

1. Possible short in wiring.

2. Possible short in thermostat.

3. Possible short in heat/cool/fan system.

4. FAN Switch set to Fan ON.

1. Thermostat display setting

requires adjustment.

1. The location of the thermostat and/or

the size of the Heating System may

be influencing the cycle rate.

Note: When thermostat is reset, installer configuration menu

settings and programming will reset to factory settings.

To reset the programming, clock and configuration

settings, press and and the SYSTEM touch keys

simultaneously. The thermostat should go blank and then all

segments will be displayed momentarily.

Replace fuse or reset breaker.

Turn switch to ON.

Replace door panel in proper position to engage safety

interlock or door switch.

Check connections.

Re-light pilot.

Many furnaces have safety devices that shut down when

a lock-out condition occurs. If the heat works intermittently

contact the furnace manufacturer or local HVAC service

person for assistance.

Check each wire connection to verify they are not shorted

or touching together. No bare wire should stick out from

under terminal block. Try resetting the thermostat as

described above. If the condition persists the manufacturer

of your system or service person can instruct you on how

to test the Heat/Cool system for correct operation. If the

system operates correctly, replace the thermostat.

The display can be adjusted +/- 5 degrees. See

Temperature Display Adjustment in the Configuration Menu

section.

Digital thermostats provide precise control and cycle faster

than older mechanical models. The system turns on and off

more frequently but runs for a shorter time so there is no

increase in energy use. If you would like an increased cycle

time, choose SL for slow cycle in the Configuration menu.

White-Rodgers is a division

of Emerson Electric Co.

The Emerson logo is a

trademark and service mark

of Emerson Electric Co.

8

Comfort Alert™ Fault Codes

Number Displayed in

7 Segment LED

P Tr i p

1 Long Run Time

2 System Pressure Trip

3 Short Cycling

4 Locked Rotor

5 Open Circuit

6 Open Start Circuit

7 Open Run Circuit

8 Welded Contactor

9 Low Voltage

System Communication Codes

E Communication Error

C For 30 seconds after Communication

www.white-rodgers.com

www.emersonclimate.com

Comfort Alert Fault

established, then blank

Loading...

Loading...