White Outdoor 24AD595C190 Operator's Manual

OPERATOR’S MANUAL

Log Splitter

33-Ton

Model Number

24AD595C190

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-9722.

WHITE OUTDOOR PRODUCTS COMPANY P.O. BOX 361131 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

FORM NO.

770-10041D.fm

(7/01)

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices...................................................................3

Assembling Your Log Splitter.............................................................................5

Know Your Log Splitter ......................................................................................10

Operating Your Log Splitter................................................................................10

Adjusting Your Log Splitter.................................................................................12

Maintaining Your Log Splitter.............................................................................13

Conditions That Will Void Warranty ...................................................................15

Troubleshooting.................................................................................................15

Parts List............................................................................................................18

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new log splitter. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on

the model plate is very important if you need help from our Customer Support Department or

an authorized dealer.

• You can locate the model number by standing behind the unit and looking down at the hydraulic tank.

A sample model plate is explained below. For future reference, please copy the model number and

the serial number of the equipment in the space below.

(Model Number)

(Serial Number)

WHITE OUTDOOR

PRODUCTS COMPANY

P.O. B OX 36 11 31

CLEVELAND, OHIO 44136

Copy the model number here:

Copy the serial number here:

ENGINE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, powerrating, specifications, warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s

Manual packed separately with your unit for more information.

CALLING CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Dealer Referral Line.

Call 1- (800)-949-4483 to reach the Customer Dealer Referral Line. Please have your unit’s

model number and serial number ready when you call. See previous section to locate this

information. You will be asked to enter the serial number in order to process your call.

For more details about your unit, visit our website at www.whiteoutdoor.com

2

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could

endanger the personal safety and/or property of yourself and others. Read and follow all instructions in

this manual before attempting to operate this machine. Failure to comply with these instructions may

result in personal injury. When you see this symbol - heed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to State of California to cause cancer

and birth defects or other reproductiv e harm.

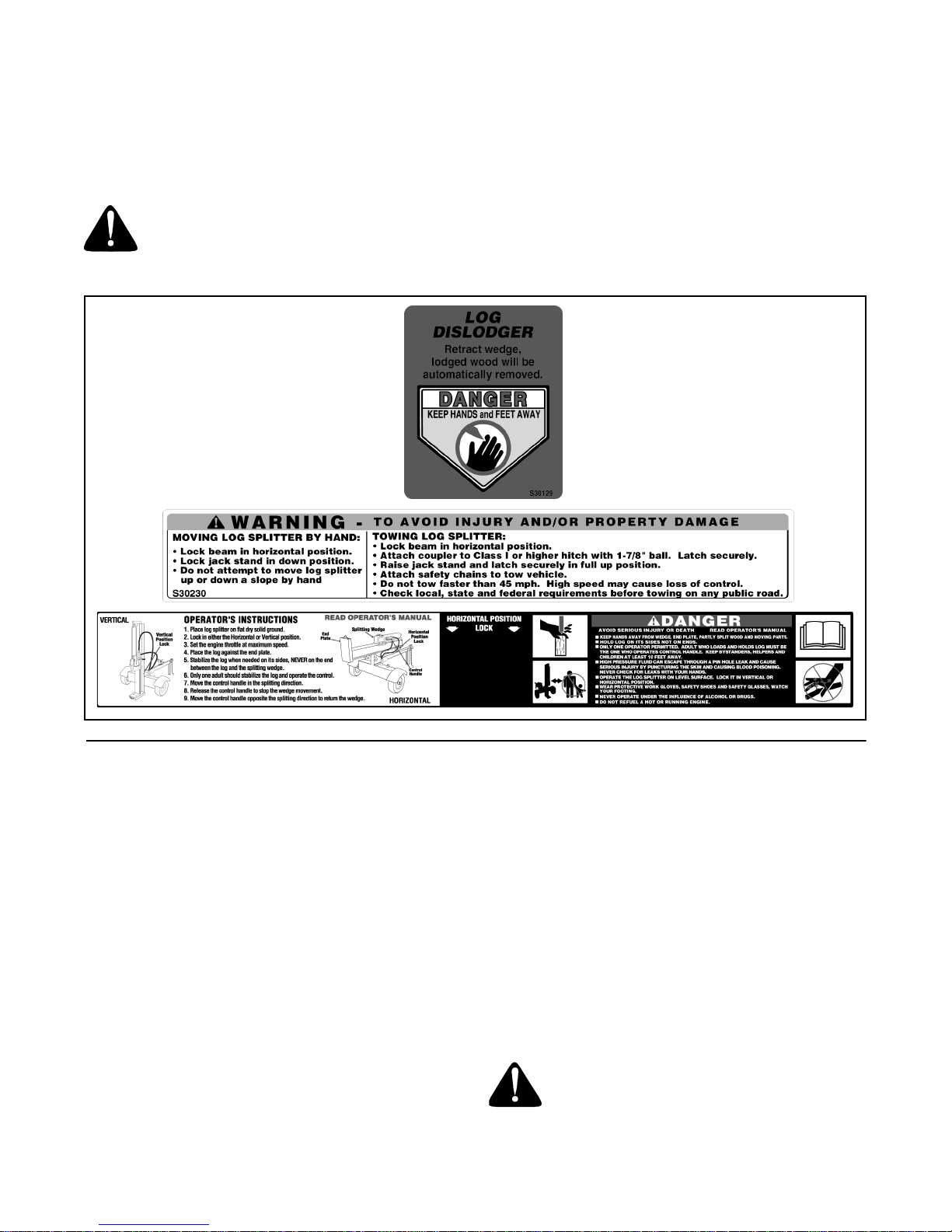

DANGER

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

: This machine was built to be operated according to the rules for safe operation in this

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe

place for future and regular reference and for

ordering replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 14 years old to operate

this machine. Children 14 years old and over

should read and understand the operation

instructions and safety rules in this manual and

should be trained and supervised by a parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Many accidents occur when more than one person

operates the machine. If a helper is assisting in

loading logs, never activate the control until the

helper is a minimum of 10 feet from the machine.

6. Keep bystanders, helpers, pets, and children at

least 20 feet from the machine while it is in

operation.

7. Never allow anyone to ride on this machine.

8. Never transport cargo on this machine.

9. Hydraulic log splitters develop high fluid pressures

during operation. Fluid escaping through a pin hole

opening can penetrate your skin and cause blood

poisoning, gangrene, or death. Give attention to the

following instructions at all times:

a. Do not check for leaks with your hand.

b. Do not operate machine with frayed, kinked,

cracked, or damaged hoses, fitting, or tubing.

c. Stop the engine and reli eve hydraul ic system

pressure before changing or adjusting

fittings, hoses, tubing, or other system

components.

d. Do not adjust the pressure settings of the

pump or valve.

10. Leaks can be detected by passing cardboard or

wood, while wearing protective gloves and safety

glasses, over the suspected area. Look for

discoloration of cardboard or wood.

11. If injured by escaping fluid, see a doctor

immediately. Serious infection or reaction can

develop if proper medical treatment is not

administered immediately.

12. Keep the operator zone and adjacent area clear for

safe, secure footi ng.

13. If your machine is equipped with an internal

combustion engine and it is intended for use near

any unimproved forest, brush, or grass covered

land, the engine exhaust should be equipped with a

spark arrester . Make su re you com ply wit h

applicable local, state, and federal codes. Take

appropriate firefighting equipment with you.

14. This machine should be used for splitting wood

only, do not use it for any other purpose.

15. Follow the instructions in the manual(s) provided

with any attachment(s) for this machine.

PREPARA TION

1. Always wear safety shoes or heavy boots.

2. Always wear safety glasses or safety goggles

during operating this machine.

3. Never wear jewelry or l oos e cloth ing t hat mi ght

become entangled in moving or rotating parts of the

machine.

4. Make sure this machine is on level surface before

operating.

5. Always block the machin e as requir ed to prev ent

unintended movement, and lock in either the

horizontal or vertical position.

6. Always operate this machine from the operator

zone(s) specified in the manual.

7. Logs should be cut with square ends prior to

splitting.

8. Use your log splitter in daylight or under good

artificial light.

3

9. To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change immediately.

a. Use only an approved gasoline container.

b. Extingu ish all ciga rettes , cigars, pi pes, and

other sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes

before refueling.

f. Never overfill the fuel tank. Fill tank to no

more than 1/2 inch below bottom of filler neck

to provide space for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine

and equipment. move machine to another

area. Wait 5 minutes before starting the

engine.

i. Never store the machine or fuel container

inside where there is an open flame, spark or

pilot light as on a water heater, space heater,

furnace, clothes dryer or other gas

appliances.

j. Allow machine to cool at least 5 minutes

before storing.

OPERATION

1. Before starting this machine, review the “Safety

Instructions”. Failure to follow these rules may

result in serious injury to the operator or

bystanders.

2. Never leave this machine unattended with the

engine running.

3. Do not operate machine while under the influence

of alcohol, drugs, or medication.

4. Never allow anyone to operate this machine

without proper instruction.

5. Always operate this machine with all safety

equipment in place and working. Make sure all

controls are properly adjusted for safe operation.

6. Do not change the engine governor settings or

overspeed the engine. The governor controls the

maximum safe operating speed of the engine.

7. When loading a log, always place your hands on

the sides of the log, not on the ends, and never use

your foot to help stabilize a log. Failure to do so,

may result in crushed or amputated fingers, toes,

hand, or foot.

8. Use only your hand to operate the controls.

9. Never attempt to split more than one log at a time

unless the ram has fully extended and a second log

is needed to complete the separation of the first log.

10. For logs which are not cut square, the least square

end and the longest portion of the log should be

placed toward the beam and wedge, and the

square end placed toward the end plate.

11. When splitting in the vertical position, stabilize the

log before moving the control. Split as follows:

a. Place log on the end plate and turn until it

leans against the beam and is stable.

b. When spli tting ext ra large or uneven l ogs, the

log must be stabilized with wooden shims or

split wood between the log and the end plate

or ground.

12. Always keep fingers away from any cracks that

open in the log while splitting. They can quickly

close and pinch or amputate your fingers.

13. Keep your work area clean. Immediately remove

split wood around the machine so that you do not

stumble ove r it.

14. Never move this machine while the engine is

running.

15. This machine should not be towed on any street,

highway or public road without checking the

existing federal, state, or local vehicle

requirements. Any licensing or modifications such

as taillights, etc., needed to comply, is the sole

responsibility of the purchaser. If a “Statement of

Origin” is required in your state, see your local

dealer.

16. See the towing section in this manual for proper

towing instructions once all federal, local, or state

requirements are met.

MAINTENANCE AND STORAGE

1. Stop the engine, disconnect the spark plug and

ground it against the engine before cleaning, or

inspecting the machine.

2. Stop the engine and relieve hydraulic system

pressure before repairing or adjusting fittings,

hoses, tubing, or other system components.

3. To prevent fires, clean debris and chaff from the

engine and muffler areas. If the engine is equipped

with a spark arrester muffler, clean and inspect it

regularly according to manufacturers instructions.

Replace if damaged.

4. Periodically check that all nuts and bolts, hose

clamps, and hydraulic fittings are tight to be sure

equipment is in safe working condition.

5. Check all safety guards and shields to be sure they

are in the proper position. Never operate with

safety guards, shields, or other protective features

removed.

6. The pressure relief valv e is preset at t he factory. Do

not adjust the valve.

7. Never attempt to move this machi ne ov er hil ly or

uneven terrain without a tow vehicle or adequate

help.

4

8. For your safety, replace all damaged or worn parts

immediately with original equipment

manufacturer’s (O.E.M.) parts only. “Use of parts

which do not meet the original equipment

specifications may lead to improper performance

and compromise safety!”

WARNING: - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who read,

understand and follow the warnings and instr uctions in this manual and on the machine.

NOTE: Not all safety labels may apply to your log splitters.

9. Do not alter this machine in any manner, alterations

such as attaching a rope or extension to the control

lever, or adding to the width or height of the wedge

may result in personal injury.

SECTION 2: ASSEMBLING YOUR LOG SPLITTER

IMPORT ANT :

in the engine. Be certain to service engine with gasoline

and oil as instructed in the separate engine manual

before operating your machine.

NOTE: Reference to righ t or left hand side of the log

splitter is observed from the operating position.

Removing Unit From Carton

• Pry the top, sides, and ends off crate.

• Set panels aside to avoid tire punctures or personal

injury.

• Remove and discard plastic bag that covers unit.

• Remove wheels an d loose part s if include d with

unit (i.e., operator’s manual, etc.)

• Cut and remove straps which s ecure parts to

bottom of crate. Unbolt any remaining parts which

may be bolted to the bottom of the crate.

This unit is shipped without gasoline or oil

Loose Parts In Carton

• Reservoir Tank a nd En gine- Pump A ssembl y

• Engine-Pump Assembly Hardware

• Wedge, Beam, and Cylinder Assembly

• Tongue Assembly

• Wheels

• Hitch Assembly

• Beam Support/Latch Bracket

• Log Cradle Brackets and Hardware

• Fenders

• Adjustable Jack Stand Assembly

• Tail Light Kit

• 2 Hub Caps

WARNING: Use extreme caution unpacking this machine. Some components are

very heavy and will require additional people or mechanical handling equipment.

5

WARNING: Disconnect the spark plug wire

and ground against the engine to prevent

unintended starting.

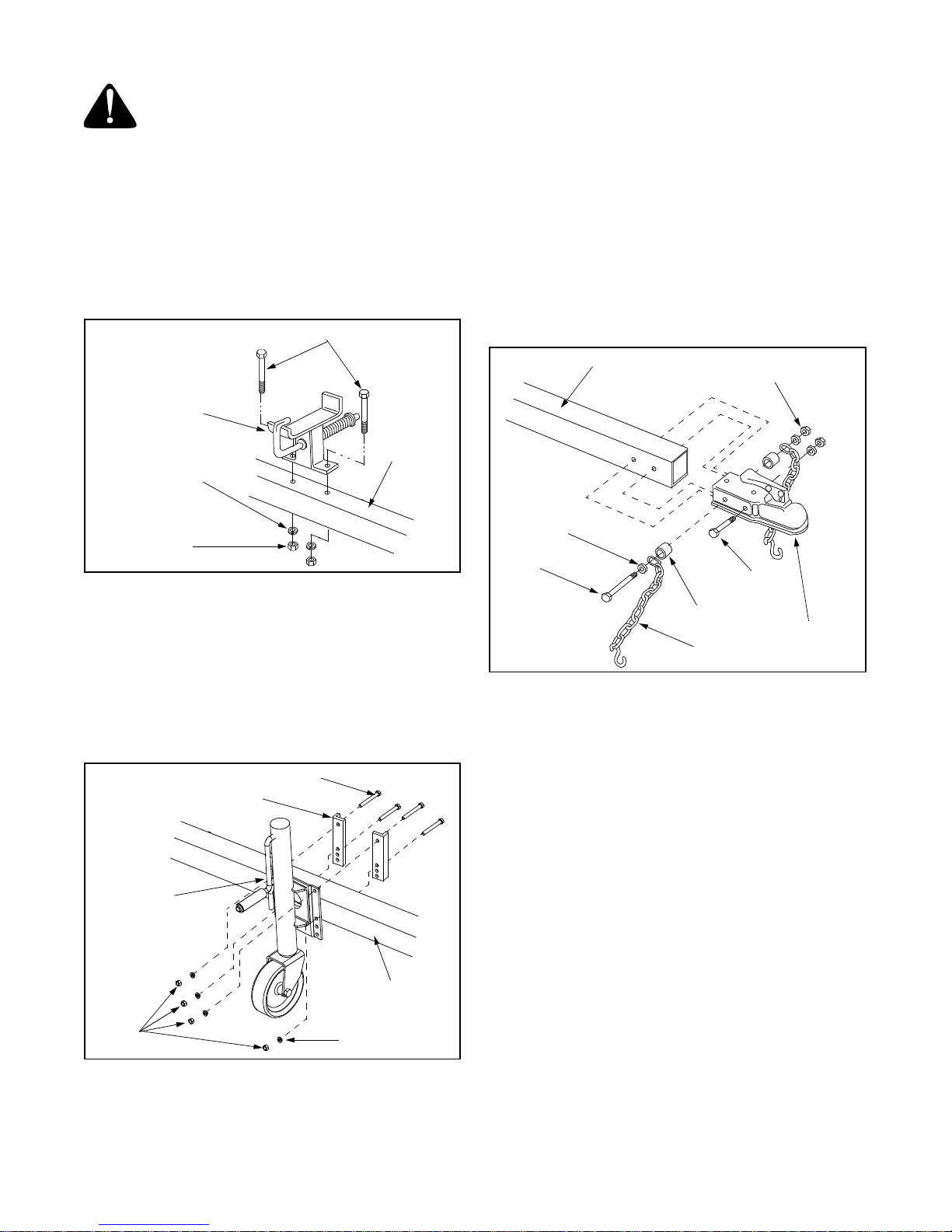

Assembling The Tongue

Attaching The Beam Support/Latch Bracket (See Fi gure 1)

• Remove two he x bol ts, loc k wash ers, an d hex nuts

from the tongue.

• Place the beam support/latch bracket on the

tongue and secure with the hex bolts, lock washers,

and hex nuts previously removed. Tighten securely.

Hex Bolts

Beam Support

Latch Bracket

• Insert hex bolts through upper holes in the bottom

of the mounting brackets and adjustable jack stand.

Secure with lock wa shers a nd hex nuts.

• The adjustable jack stand is raised by turning the

crank clockwise and lowered by turning counterclockwise.

Attaching The Hitch Assembly (See Figure 3)

• Remove the hardw are as sembl ed on the hitch

assembly and place the hitch on the end of the

tongue.

• Insert hex bolt through flat washer, end of safety

chain, spacer, and then rear hitch hole. Pivot the

end of safety ch ain so it fac es the bal l end of hit ch.

Tongue

Hex

Lock Nut

Lock

Washer

Hex Nut

Tongue

Figure 1

Attaching The Adjustable Jack Stand

(See Figure 2)

• Remove four hex bolts, lock washers, and hex nuts

that secure jack stand mounting brackets to

adjustable jack stand.

• Place adjustable jack stand halfway between beam

support/latch bracket and end of tongue.

Hex Bolts

Mounting

Brackets

Adjustable

Jack Stand

Tongue

Hex

Nuts

Lock Washer

Flat

Washer

Hex

Bolt

Spacer

Chain

Hex

Bolt

Hitch

Assembly

Figure 3

• Insert other spacer, safety chain, and flat washer

on the other end of the hex bolt and secure with hex

lock nut.

• Insert hex bolt through the front hole of hitch and

secure with flat washer and hex lock nut. Tighten

both hex nuts to 23 ft-lbs.

Assembling The Wheels, Tongue, and

Beam

Attaching The Wheels To The Reservoir Tank Assembly

(See Figure 4)

• Block up the reservoir tank assembly about eight to

twelve inches.

• Remove and discard plastic shipping caps on the

outside of the wheels.

• Remove the cott er pin, he x slotted nu t, and flat

washer from each axle.

Figure 2

• Insert hex bolts through top holes in jack stand

mounting brackets and holes in the adjustable jack

stand. Secure with lock washers and hex nuts.

NOTE: It is recommended that you polish the axles with

emery cloth before you install the wheels.

6

Loading...

Loading...