White Outdoor ZT Zero 17, 17AA5A4G790, 1E154G20133, ZT Zero 22 Service Manual

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

Service Manual

ZT Zero Turn Rider

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outd oor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete and accura te as possible at the time of publication. However, du e to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

MTD Products Inc. - Product Training and Education Department

© Copyright 2005 MTD Products Inc. All Rights Reserved

www.mymowerparts.com

FORM NUMBER - 769-01421

12/2004

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

TABLE OF CONTENTS

General Information .............................................................................................................. 1

deck leveling .........................................................................................................................1

PTO/Deck Belt Replacement ............................................................................................... 2

Deck Removal ...................................................................................................................... 2

Blade Drive Belt Removal .................................................................................................... 2

Idler Arm Removal ................................................................................................................ 2

Blade Spindle Removal ........................................................................................................ 3

Drive Belt Replacement ........................................................................................................ 3

Servicing Electric PTO Clutch .............................................................................................. 3

Transmission Replacement .................................................................................................. 4

Steering Linkage: Adjustment .............................................................................................. 6

Pivot Bar ............................................................................................................................... 9

Seat Removal ..................................................................................................................... 10

Console Removal ............................................................................................................... 11

Battery Removal ................................................................................................................. 13

Fuel Tank Removal ............................................................................................................ 14

Control Shaft Replacement ................................................................................................ 15

Deck Lift Shaft Replacement .............................................................................................. 16

Electrical System Components .......................................................................................... 19

Relays ................................................................................................................................ 21

www.mymowerparts.com

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

White Outdoor ZT 17

17AA5A4G790

1E154G20133

GENERAL INFORMATION

2004 is the first year for the ZT. There are two models

ZT17 and ZT22. New for the ‘05 model year is a Kohler

Command 19 HP model with a 50” cutting deck.

1. DECK LEVELING

1.1. To adjust the deck pitch, front to back, loosen or

tighten the jam nuts located on the front stabilizer bracket using a 15/16” socket and a 15/16”

wrench. The correct deck pitch should be 1/8” to

1/4” lower in the front than in the back, as measured from the blade tips. See Figure 1.1.

Jam Nuts

Front deck stabilizer bracket

Figure 1.1

This series of riders has the unique feature of not having to reset the PTO switch if the end us er tries to mow

in reverse. Once one lapbar is moved in to neutral or

forward the PTO will turn back on.

The “ZT 17” has a 17 HP Briggs & Stratton Intek which

is a single cylinder engine with full pressure lubrication.

The engine drives the dual Hydro-gear Hydrostatic

transmissions and the electric PTO. The PTO runs the

3-in-1blades on the 42” twin blade stamped deck. On

the front of the stamped frame is a large pivoting front

axle.

The “ZT 22” is very similar to the ZT 17 except for the

twin cylinder, 22 HP Briggs & Stratton Intek. Th ere are

also 4 wheels, instead of 2, on the 50” triple blade

stamped deck.

1.2. To level the deck, side to side, loosen the screw

on the left side adjustment gear using a 1/2”

socket. Using a 3/4” wrench, run the gear up or

down as necessary until each outside blade tip

is the same distance from the ground.

See Figure 1.2.

Deck hanger rod

Deck adjustment gear

Figure 1.2

www.mymowerparts.com

1

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

2. PTO / DECK BELT REPLACEMENT

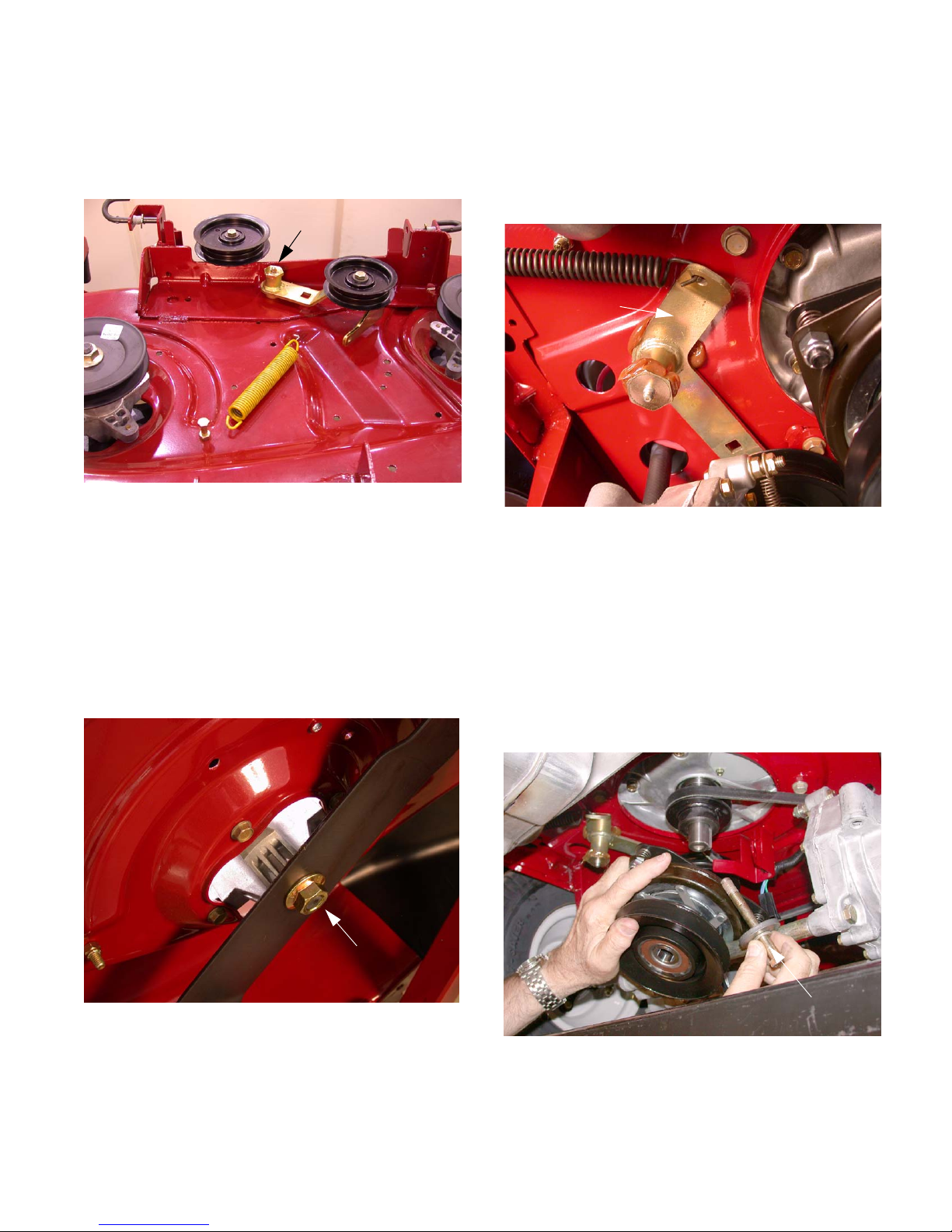

2.1. Insert a 1/2” breaker bar into the square hole in

the tensioner arm located on top of the deck.

See Figure 2.1.

Idler arm

1/2” Breaker bar

Figure 2.1

2.2. Pivot the tensioner arm and pulley to slacken the

belt.

3. DECK REMOVAL

3.1. Release the deck J pins from the rear hanger

arms. See Figure 3.1.

Deck hanger rod

“J” Pin

Figure 3.1

3.2. Slide the deck forward until the front stabilizer

bar can be lifted away from the front mounting

bracket.

2.3. Remove the belt from the two stationary idler

pulleys and spindle pulleys.

NOTE: The spindle covers do not need to be

removed.

2.4. Remove the belt from the clutch.

3.3. Slide the deck out from underneath the unit.

4. BLADE DRIVE BELT REMOVAL

4.1. Remove the deck from the unit.

4.2. Remove both belt covers. These belt covers are

identical and interchangeable. See Figure 4.2.

Belt Covers

Figure 4.2

www.mymowerparts.com

4.3. Remove the belt from around the pulleys.

4.4. Install the new belt. A belt routing diagram label

is adhered to the deck housing.

5. IDLER ARM REMOVAL

2

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

5.1. Remove the cutting deck from the unit.

5.2. Remove the shoulder screw and hex lock nut

securing the idler to the deck housing. See Figure 5.2.

Idler

Figure 5.2

5.3. Remove the idler and inspect for wear or damage.

6. BLADE SPINDLE REMOVAL

6.1. Remove the deck from the unit.

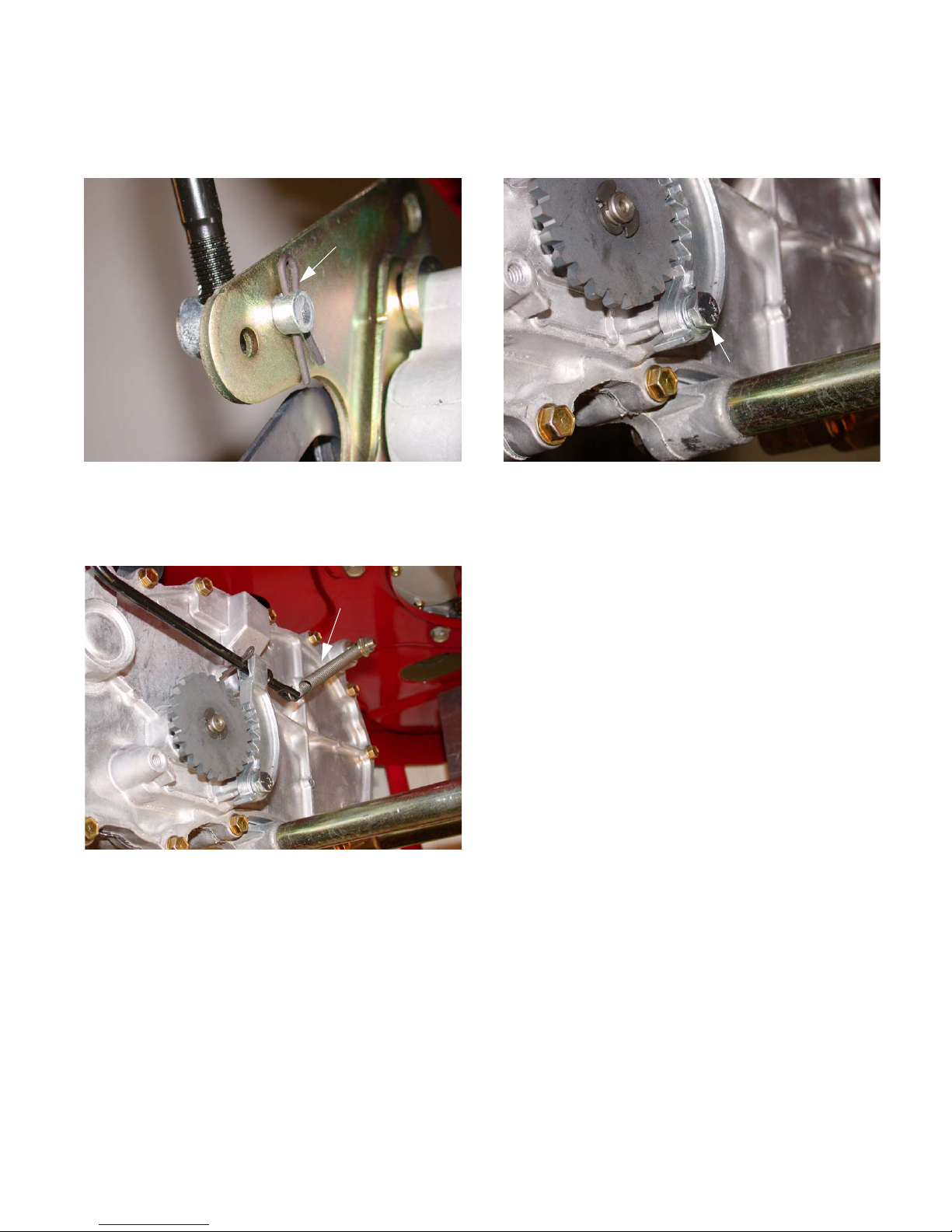

7.1. Insert a 3/8” breaker bar into the square hole on

the tensioner arm.

7.2. Pull the breaker bar to the right until it can be

braced in position at the pivot point of the tensioner arm. See Figure 7.2.

Idler arm

Figure 7.2

7.3. Remove the belt from the transmission pulleys,

tensioner pulley and the crankshaft pulley. Belt

is part number 754-04043

6.2. Remove the spindle covers and blade drive belt.

6.3. Using an impact wrench, remove the hex flange

nut securing the blade to the spindle assembly.

See Figure 6.3.

Hex Flange Lock Nut

Figure 6.3

6.4. Remove the four hex washer head tapp screws

securing the spindle assembly to the deck housing.

7. DRIVE BELT REPLACEMENT

8. SERVICING ELECTRIC PTO CLUTCH

8.1. Using a small flat blade screwdriver, unplug the

electrical connector on the PTO clutch.

8.2. Using a 5/8” socket and an impact wrench,

remove the clutch bolt. See Figure 8.2.

Clutch Bolt

Figure 8.2

8.3. Lower the clutch off of the crankshaft.

8.4. Remove the crankshaft key.

www.mymowerparts.com

3

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

8.5. Remove the crankshaft pulley. See Figure 8.5.

Crankshaft pulley

Key

Figure 8.5

8.6. Use a 9/16” socket to adjust the air gap on the

clutch to between.010” and.015”.

See Figure 8.6.

.012 Feeler gage

9.3. Remove the belt from the transmission pulleys,

tensioner pulley and the crankshaft pulley.

9.4. Using a 3/4” socket and impact wrench, remove

the four lug nuts securing the rear wheel to the

axle hub.

NOTE: Insure the lap bar control rods and b rake

rods are not rubbing against the frame.

9.5. Remove the cotter pin securing the bypass rod

to the transmission bypass arm. Remove the

bypass rod. See Figure 9.5.

Cotter Pin

Bypass rod

Figure 8.6

NOTE: Clutch adjustment can be done with the

clutch in the unit. If a new clutch is being put in

the adjustment can be done on the bench.

9. TRANSMISSION REPLACEMENT

9.1. Insert a 1/2” breaker bar into the square hole on

the tensioner arm.

9.2. Pull the breaker bar to the right until it can be

braced in position at the pivot point of the tensioner arm.

Figure 9.5

9.6. Mark the lap bar control rod threads near the ferrule. See Figure 9.6.

Control Rod

Ferrule

Marking Paint

Figure 9.6

www.mymowerparts.com

4

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

9.7. Remove the hairpin securing the lap bar control

rod ferrule to the transmission return assembly. See Figure 9.7.

Hairpin

Figure 9.7

9.8. Disconnect the brake return spring from the

brake arm. See Figure 9.8.

9.9. Remove the bolt securing the brake arm to the

transmission using a 7/16” socket.

See Figure 9.9.

Brake Arm Bolt

Figure 9.9

NOTE: A spacer is located between the brake

arm and transmission housing.

Figure 9.8

Brake Return Spring

NOTE: During installation, the bottom ridge of

the brake arm needs to be below the embossment on the transmission housing. Improper

installation will prevent the brake from engaging.

9.10. Remove both bolts securing the tubular transmission brace using a 5/8” socket.

NOTE: When installing the brace bolts use loctite 242.

9.1 1. Remove the front transmission mounting bolt

using a 1/2” wrench and a 1/2” socket.

NOTE: Secure the transmission or use another

technician to support the transmission while performing the next step.

www.mymowerparts.com

5

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

9.12. Remove both transmission mounting bolts

securing the transmission to the mounting

bracket using two 1/2” wrenches.

See Figure 9.12.

Transmission Mounting Bolts

Figure 9.12

9.13. Rotate the transmission out and down until the

fan is clear of the front transmission mounting

bracket, and remove it from the frame.

9.14. Installation notes:

• Lift transmission into place a nd start a ll threaded

fasteners before tightening any individual fasteners.

10. STEERING LINKAGE: ADJUSTMENT

10.1. Begin to adjust the steering by confirming that

both hydros are correctly adjusted for neutral

control. See Figure 10.1.

Neutral Return Assembly

Figure 10.1

10.2. Lift and safely support the rear of the mower.

10.3. Disconnect the ferrule at the hydro end of each

lap bar control rod from the neutral return

assembly on each of the hydros. The ferrules

are secured to the neutral return assemblies with

hairpin clips. See Figure 10.3.

• Install the axle horn bolts from the top down,

tighten nuts to a torque of 90-120 in-lbs.

• Install the torque bracket bolt from the bottom

up, and tighten the nut to a torque of 90-120 inlbs.

• Install the bolts in the tubular transmission

braces and tighten them to a torque of 90-120 inlbs.

• The remainder of the installation process consists of reversing the removal process.

• Tighten the lug nuts to a torque of 350-500 inlbs.

• Tighten the center wheel hub nut to 100-160 Ft.

Lbs.

Ferrule

Figure 10.3

NOTE: In the course of normal service, it is very

unusual for the neutral return assemblies to

require adjustment unless someone has prev iously tampered with it. It is necessary to check

the adjustment because the rest of the proce-

www.mymowerparts.com

6

Loading...

Loading...