White Mountain DVP36FP30-3 LP, DVP36FP30-3 NAT, DVP36FP70-3 LP, DVP36FP70-3 NAT, DVP36FP93-3 LP User Manual

...Page 1

INSTALLATION INSTRUCTIONS

GAS-FIRED

AND

OWNER’S MANUAL

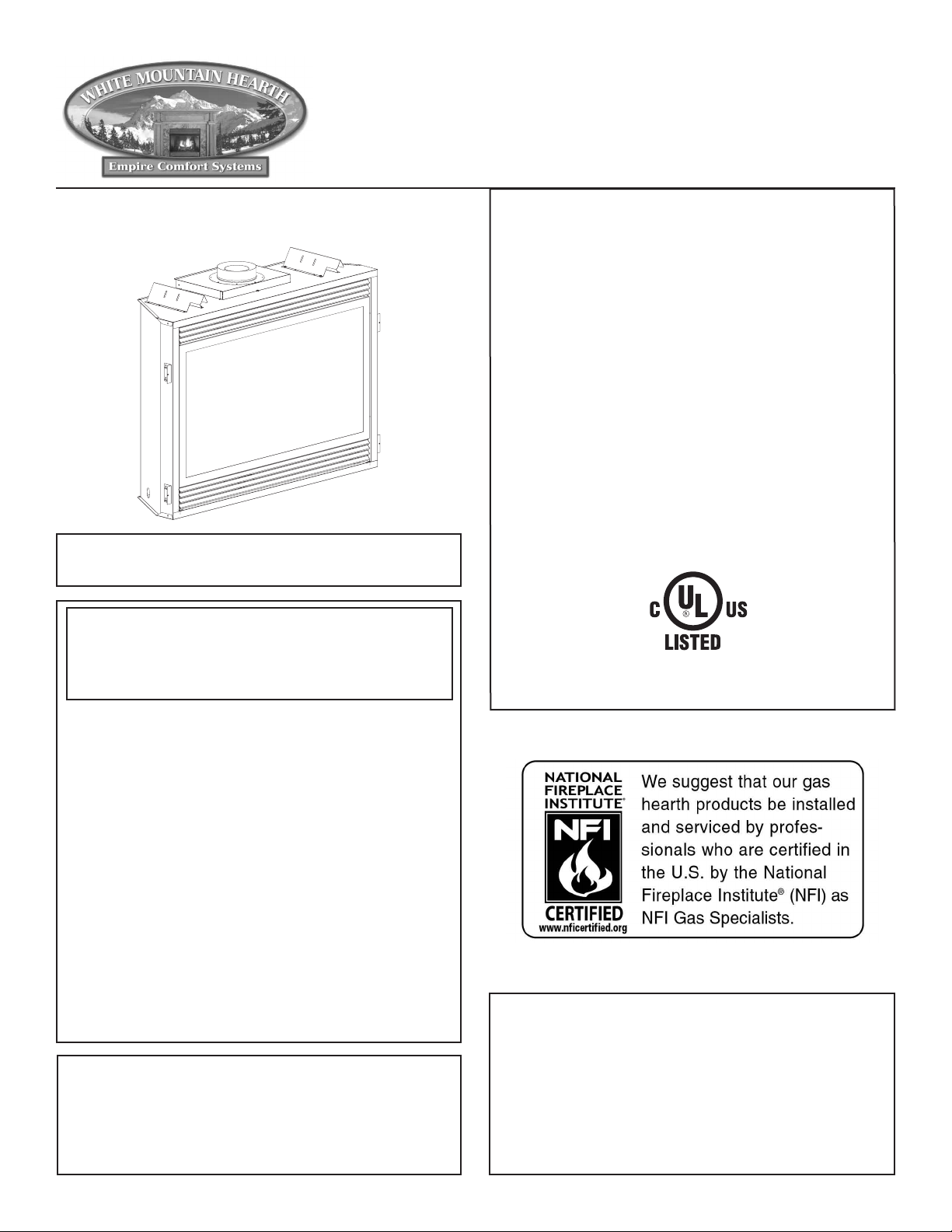

The Tahoe Direct Vent Zero Clearance Gas

Fireplace Heater

Installer: Leave this manual with the appliance.

Consumer: Retain this manual for future reference.

WARNING: If the information in these instructions

are not followed exactly, a fire or explosion may result causing property damage, personal injury or

loss of life.

DIRECT VENT

GAS FIREPLACE HEATER

MODEL SERIES

MILLIVOLT STANDING PILOT

DVP36FP3(0,1,2,3)-3 NAT

DVP36FP3(0,1,2,3)-3 LP

INTERMITTENT PILOT

DVP36FP7(0,1,2,3)-3 NAT

DVP36FP7(0,1,2,3)-3 LP

REMOTE RF MODELS

DVP36FP9(1,3)-3 NAT

DVP36FP9(1,3)-3 LP

UL FILE NO. MH30033

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

— Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

WARNING: If not installed, operated and maintained

in accordance with the manufacturer’s instructions,

this product could expose you to substances in fuel or

from fuel combustion which can cause death or seri

ous illness.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA only)

or mobile home, where not prohibited by state or local

codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is not

-

convertible for use with other gases, unless a certified

kit is used.

Page 1

Page 2

TABLE OF CONTENTS

Section Page

Important Safety Information .........................................................................................................................................3

Safety Information for Users of LP Gas .........................................................................................................................

Requirements for Massachusetts .....................................................................................................................................5

Introduction ..................................................................................................................................................................... 6

Specifications ..................................................................................................................................................................

Fireplace Dimensions ......................................................................................................................................................7

Clearances .......................................................................................................................................................................8

Locating Fireplace ..........................................................................................................................................................8

Gas Supply ......................................................................................................................................................................9

Rear Vent Conversion ...................................................................................................................................................

Special Vent Systems ....................................................................................................................................................

Installation ................................................................................................................................................................11-14

Venting Fireplace - Top (LP and Nat models) ........................................................................................................

DVVK-4FV Direct Vent Termination Kit ...............................................................................................................

Examples - Top Vent Run .............................................................................................................................................

Venting Fireplace - Rear (Nat models only) .................................................................................................................

Examples - Rear Vent Run ............................................................................................................................................

Termination Clearances ................................................................................................................................................

Vent Clearances .............................................................................................................................................................

Vent System Identification ............................................................................................................................................

Framing and Finishing ............................................................................................................................................ 31-32

Horizontal Termination .................................................................................................................................................

DVVK-4RE Vent Kit Installation Instructions .......................................................................................................

DVVK-4F Flex Vent Instructions .................................................................................................................................

Vertical Termination ................................................................................................................................................

Log Placement - 4 Log Set ............................................................................................................................................40

Operating Instructions ............................................................................................................................................. 41-42

Standing Pilot Wiring Diagram .....................................................................................................................................

Standing Pilot Lighting Instructions ............................................................................................................................. 44

Standing Pilot Troubleshooting ....................................................................................................................................

Intermittent Pilot Operating Instructions ......................................................................................................................46

Intermittent Pilot Wiring Diagram ................................................................................................................................

Intermittent Pilot Lighting Instructions ........................................................................................................................47

Intermittent Pilot Troubleshooting ..........................................................................................................................

RF Standing Pilot Operating Instructions .....................................................................................................................53

RF Transmitter Functions .............................................................................................................................................

RF Wiring Diagram .......................................................................................................................................................

RF Standing Pilot Lighting Instructions .......................................................................................................................56

Maintenance and Service .............................................................................................................................................. 57

Parts View .....................................................................................................................................................................

Parts List ................................................................................................................................................................. 59-60

FBB4 Optional Variable Speed Blower Installation ...............................................................................................

Junction Box Wiring Installation Instructions ..............................................................................................................

Optional Brick Liner Installation Instructions .............................................................................................................. 63

Accessories ...................................................................................................................................................................64

How to Order Repair Parts ............................................................................................................................................65

Service Notes .......................................................................................................................................................... 65-67

4

7

10

10

15-17

18-24

25

26

27

28

29

30

33

34-36

37

38-39

43

45

46

48-52

54

55

58

61-62

63

23340-4-0608Page 2

Page 3

IMPORTANT SAFETY INFORMATION

Before enclosing the vent pipe assembly, operate the appliance to ensure it is venting properly.

DO NOT OPERATE THIS APPLIANCE WITHOUT GLASS FRONT PANEL INSTALLED

• If this appliance is installed directly on carpeting,

tile or other combustible material other than wood

flooring the appliance shall be installed on a metal

or wood panel extending the full width and depth of

the appliance.

The base referred to above does not mean the fireproof

base as used on wood stoves. The protection is for rugs

that are extremely thick and light colored tile.

• Children and adults should be alerted to the hazards

of high surface temperatures and should stay away

to avoid burns or clothing ignition.

• Young children should be carefully supervised when

they are in the same room as the appliance.

• Clothing or other flammable material should not be

• Due to high temperatures the appliance should be

located out of traffic and away from furniture and

draperies.

• The glass front or any part removed for servicing

the appliance must be replaced prior to operating

the appliance. Work should be done by a qualified

service person.

• Keep burner and control compartment clean.

• Vent cap is hot while fireplace is in operation.

• Installation and repair should be done by a

QUALIFIED SERVICE PERSON. The appliance

should be inspected before use and at least annually

by a qualified service person. More frequent

cleaning may be required due to excessive lint from

carpeting, bedding materials, etc. It is imperative

that control compartments, burners and circulating

air passageways of the appliance be kept clean.

placed on or near the appliance.

• Adequate accessibility clearances for servicing and

proper operation.

• This appliance must not share or be connected to a flue

serving a separate solid-fuel burning appliance.

• Keep the area around your appliance clear of

combustible materials, gasoline and other flammable

vapor and liquids.

• Under no circumstances should any solid fuels (wood,

coal, paper or cardboard etc.) be used in this appli

ance.

• The flow of combustion and ventilation air must not

be obstructed in any way.

• DO keep the appliance area clear and free from

combustible material, gasoline and other flammable

vapors and liquids.

• DO examine venting system periodically and replace

damaged parts.

• DO make a periodic visual check of pilot and burners.

Clean and replace damaged parts.

• CAUTION: The glass used in your fireplace is

tempered glass. If the glass is cracked or damaged in

any way, it should be replaced only with a complete

glass frame assembly from Empire. See parts list on

Pages 59 and 60 for ordering.

• DO NOT use this fireplace if any part has been under

water. Immediately call a qualified service technician

to inspect the heater and to replace any part of the

control system and any gas control which has been

under water.

-

• DO NOT put anything around the fireplace that will

obstruct the flow of ventilation air.

• Clearance in accordance with local installation codes

and the requirements of the gas supplier.

23340-4-0608 Page 3

• Any safety screen or guard removed for servicing an

appliance must be replaced prior to operating the

appliance.

Page 4

SAFETY INFORMATION FOR USERS OF LP GAS

Propane (LP-Gas) is a flammable gas which can cause fires

and explosions. In its natural state, propane is odorless and

colorless. You may not know all the following safety precau

tions which can protect both you and your family from an

accident. Read them carefully now, then review them point

LP-GAS WARNING ODOR

If a gas leak happens, you should be able to smell the gas because of the odorant put in the LP-Gas.

That’s your signal to go into immediate action!

• Do not operate electric switches, light matches, use your phone.

Do not do anything that could ignite the gas.

• Get everyone out of the building, vehicle, trailer, or area. Do

that IMMEDIATELY.

• Close all gas tank or cylinder supply valves.

• LP-Gas is heavier than air and may settle in low areas such as

basements. When you have reason to suspect a gas leak, keep

out of basements and other low areas. Stay out until firefighters

declare them to be safe.

NO ODOR DETECTED - ODOR FADE

Some people cannot smell well. Some people cannot smell the

odor of the chemical put into the gas. You must find out if you

can smell the odorant in propane. Smoking can decrease your

ability to smell. Being around an odor for a time can affect your

sensitivity or ability to detect that odor. Sometimes other odors

in the area mask the gas odor. People may not smell the gas odor

or their minds are on something else. Thinking about smelling a

gas odor can make it easier to smell.

The odorant in LP-Gas is colorless, and it can fade under some

circumstances. For example, if there is an underground leak, the

movement of the gas through soil can filter the odorant. Odorants

by point with the members of your household. Someday

when there may not be a minute to lose, everyone’s safety

will depend on knowing exactly what to do. If, after read

ing the following information, you feel you still need more

information, please contact your gas supplier.

• Use your neighbor’s phone and call a trained LP-Gas service

person and the fire department. Even though you may not

continue to smell gas, do not turn on the gas again. Do not

re-enter the building, vehicle, trailer, or area.

• Finally, let the service man and firefighters check for escaped

gas. Have them air out the area before you return. Properly

trained LP-Gas service people should repair the leak, then

check and relight the gas appliance for you.

in LP-Gas also are subject to oxidation. This fading can occur if

there is rust inside the storage tank or in iron gas pipes.

The odorant in escaped gas can adsorb or absorb onto or into walls,

masonry and other materials and fabrics in a room. That will take

some of the odorant out of the gas, reducing its odor intensity.

LP-Gas may stratify in a closed area, and the odor intensity could

vary at different levels. Since it is heavier than air, there may be

more odor at lower levels. Always be sensitive to the slightest gas

odor. If you detect any odor, treat it as a serious leak. Immediately

go into action as instructed earlier.

-

SOME POINTS TO REMEMBER

• Learn to recognize the odor of LP-Gas. Your local LP-Gas

Dealer can give you a “Scratch and Sniff” pamphlet. Use it to

find out what the propane odor smells like. If you suspect that

your LP-Gas has a weak or abnormal odor, call your LP-Gas

Dealer.

• If you are not qualified, do not light pilot lights, perform service,

or make adjustments to appliances on the LP-Gas system. If

you are qualified, consciously think about the odor of LP-Gas

prior to and while lighting pilot lights or performing service

or making adjustments.

• Sometimes a basement or a closed-up house has a musty smell

that can cover up the LP-Gas odor. Do not try to light pilot

lights, perform service, or make adjustments in an area where

the conditions are such that you may not detect the odor if

there has been a leak of LP-Gas.

• Odor fade, due to oxidation by rust or adsorption on walls of

new cylinders and tanks, is possible. Therefore, people should

be particularly alert and careful when new tanks or cylinders

are placed in service. Odor fade can occur in new tanks, or

reinstalled old tanks, if they are filled and allowed to set too

long before refilling. Cylinders and tanks which have been

out of service for a time may develop internal rust which will

cause odor fade. If such conditions are suspected to exist, a

periodic sniff test of the gas is advisable. If you have any

question about the gas odor, call your

periodic sniff test of the LP-Gas is a good safety measure

under any condition.

• If, at any time, you do not smell the LP-Gas odorant and you

think you should, assume you have a leak. Then take the same

immediate action recommended above for the occasion when

you do detect the odorized LP-Gas.

• If you experience a complete “gas out,” (the container is under

no vapor pressure), turn the tank valve off immediately. If the

container valve is left on, the container may draw in some air

through openings such as pilot light orifices. If this occurs,

some new internal rusting could occur. If the valve is left

open, then treat the container as a new tank. Always be sure

your container is under vapor pressure by turning it off at the

container before it goes completely empty or having it refilled

before it is completely empty.

LP-Gas dealer. A

23340-4-0608Page 4

Page 5

REQUIREMENTS FOR MASSACHUSETTS

For all side wall horizontally vented gas fueled equipment installed

in every dwelling, building or structure used in whole or in part

for residential purposes, including those owned or operated by the

Commonwealth and where the side wall exhaust vent termination

is less than seven (7) feet above finished grade in the area of

the venting, including but not limited to decks and porches, the

following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS.

At the time of installation of the side wall horizontal vented

gas fueled equipment, the installing plumber or gasfitter shall

observe that a hard wired carbon monoxide detector with an

alarm and battery back-up is installed on the floor level where

the gas equipment is to be installed. In addition, the installing

plumber or gasfitter shall observe that a battery operated

or hard wired carbon monoxide detector with an alarm is

installed on each additional level of the dwelling, building or

structure served by the side wall horizontal vented gas fueled

equipment. It shall be the responsibility of the property owner

to secure the services of qualified licensed professionals for

the installation of hard wired carbon monoxide detectors

a. In the event that the side wall horizontally vented gas

fueled equipment is installed in a crawl space or an attic,

the hard wired carbon monoxide detector with alarm and

battery back-up may be installed on the next adjacent

floor level.

b. In the event that the requirements of this subdivision can

not be met at the time of completion of installation, the

owner shall have a period of thirty (30) days to comply

with the above requirements; provided, however, that

during said thirty (30) day period, a battery operated

carbon monoxide detector with an alarm shall be

installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each

carbon monoxide detector as required in accordance with the

above provisions shall comply with NFPA 720 and be ANSI/

UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be

permanently mounted to the exterior of the building at a

minimum height of eight (8) feet above grade directly in line

with the exhaust vent terminal for the horizontally vented gas

fueled heating appliance or equipment. The sign shall read,

in print size no less than one-half (1/2) inch in size,

VENT DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side

wall horizontally vented gas fueled equipment shall not

approve the installation unless, upon inspection, the inspector

observes carbon monoxide detectors and signage installed in

accordance with the provisions of 248 CMR 5.08(2)(a) 1

through 4.

(b) EXEMPTIONS: The following equipment is exempt

from 248 CMR 5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10 entitled

“Equipment Not Required To Be Vented” in the

most current edition of NFPA 54 as adopted by the

Board; and

2. Product Approved side wall horizontally vented gas

fueled equipment installed in a room or structure

separate from the dwelling, building or structure

used in whole or in part for residential purposes.

(d) MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of a Product Approved side

wall horizontally vented gas fueled equipment does not

provide the parts for venting the flue gases, but identifies

“special venting systems”, the following requirements

shall be satisfied by the manufacturer:

1. The referenced “special venting system” instructions

shall be included with the appliance or equipment

installation instructions; and

2. The “special venting systems” shall be Product

Approved by the Board, and the instructions for

that system shall include a parts list and detailed

installation instruction.

(e) A copy of all installation instructions for all Product

Approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists for

venting instructions, and/or all venting design instructions

shall remain with the appliance or equipment at the

completion of the installation.

“GAS

23340-4-0608 Page 5

Page 6

INTRODUCTION

Instructions to Installer

1. Installer must leave instruction manual with owner after

installation.

2. Installer must have owner fill out and mail warranty card supplied

with the fireplace.

3. Installer should show owner how to start and operate the

fireplace.

This direct vent gas fireplace heater is designed to operate with all

combustion air being siphoned from the outside of the building

and all exhaust gases expelled to the outside of the building. The

information contained in this manual pertains to all models and gas

control systems unless otherwise noted.

Warning: This unit is not for use with solid fuels.

Appliance Certification

This fireplace is design certified in accordance with American

National Standard/CSA Standard ANSI Z.21-88/CSA 2.33 and by

Underwriters Laboratories as a Direct Vent Gas Fireplace Heater

and shall be installed according to these instructions.

Consult your local building code agency, prior to installation,

to ensure compliance with local codes-including permits and

inspections.

The fireplace, when installed, must be electrically grounded in

accordance with local codes or, in absence of local codes, with the

National Electric Code ANSI/NFPA 70 or Canadian Electric code,

CSA C22.1, if an external electrical source is utilized.

These models may be installed in a bedroom or bed-sitting room

in the U.S.A. and Canada.

Qualified Installing Agency

Installation and replacement of gas piping, gas utilization equipment

or accessories and repair and servicing of equipment shall be

performed only by a qualified agency. The term “qualified agency”

means any individual, firm, corporation or company which either in

person or through a representative is engaged in and is responsible

for (a) the installation or replacement of gas piping or (b) the

connection, installation, repair or servicing of equipment, who is

experienced in such work, familiar with all precautions required

and has complied with all the requirements of the authority having

jurisdiction.

State of Massachusetts: The installation must be made by

a licensed plumber or gas fitter in the Commonwealth of

Massachusetts.

The installation must conform with local codes or, in the absence of

local codes, with the National Fuel Gas Code ANSI Z223.1/NFPA

54* Natural Gas and Propane Installation Code, or CSA B149.1

in Canada. *Available from the American National Standards Institute, Inc. 11

West 42nd St., New York, N.Y. 10036.

Warning: ANY CHANGE TO THIS FIREPLACE OR ITS

CONTROLS CAN BE DANGEROUS.

Improper installation or use of the fireplace can cause

serious injury or death from fire, burns, explosions, or

carbon monoxide poisoning.

Any alteration of the original design, installed other than as

shown in these instructions or use with a type of gas not shown on

the rating plate is the responsibility of the person and company

making the change.

Important

All correspondence should refer to complete Model Number, Serial

Number and type of gas.

High Altitude

When installing this unit at an elevation above 2000 feet (in the

United States) it may be necessary to decrease the input rating by

changing the existing burner orifice to a smaller size. Generally,

input should be reduced 4 percent for each 1000 feet above sea

level. However, if the heating value of the gas has been reduced,

this general rule may not apply. Check with local gas utility for

proper orifice size identification.

Canadian High Altitude

Altitude: 0-4500 feet (0-1370 m)

When installing this unit at an elevation above 4500 feet (in Canada),

check with local authorities.

Consult your local gas utility for assistance in determining the

proper orifice for location.

Preparation

This direct vent gas fireplace and its components are tested and safe

when installed in accordance with this Installation Manual. Report

to your dealer any parts damaged in shipment, specifically check

glass condition. Do not install unit with damaged, incomplete, or

substitute parts. Read all instructions before starting installation

and follow these instructions carefully during installation to insure

maximum benefit and safety. Failure to follow them will void your

warranty and may present a fire hazard.

The warranty will be voided by, and the warranter disclaims any

responsibility for the following actions:

• Installation of any damaged fireplace or vent system

component.

• Modification of the fireplace or direct vent system.

• Installation other than as instructed by Empire Comfort Systems,

Inc.

• Improper positioning of the logs, glass door or decorative

rock.

• Installation and/or use of any component part not manufactured

or approved by manufacturer.

23340-4-0608Page 6

Page 7

RIGHT SIDE VIEW

J

H

K

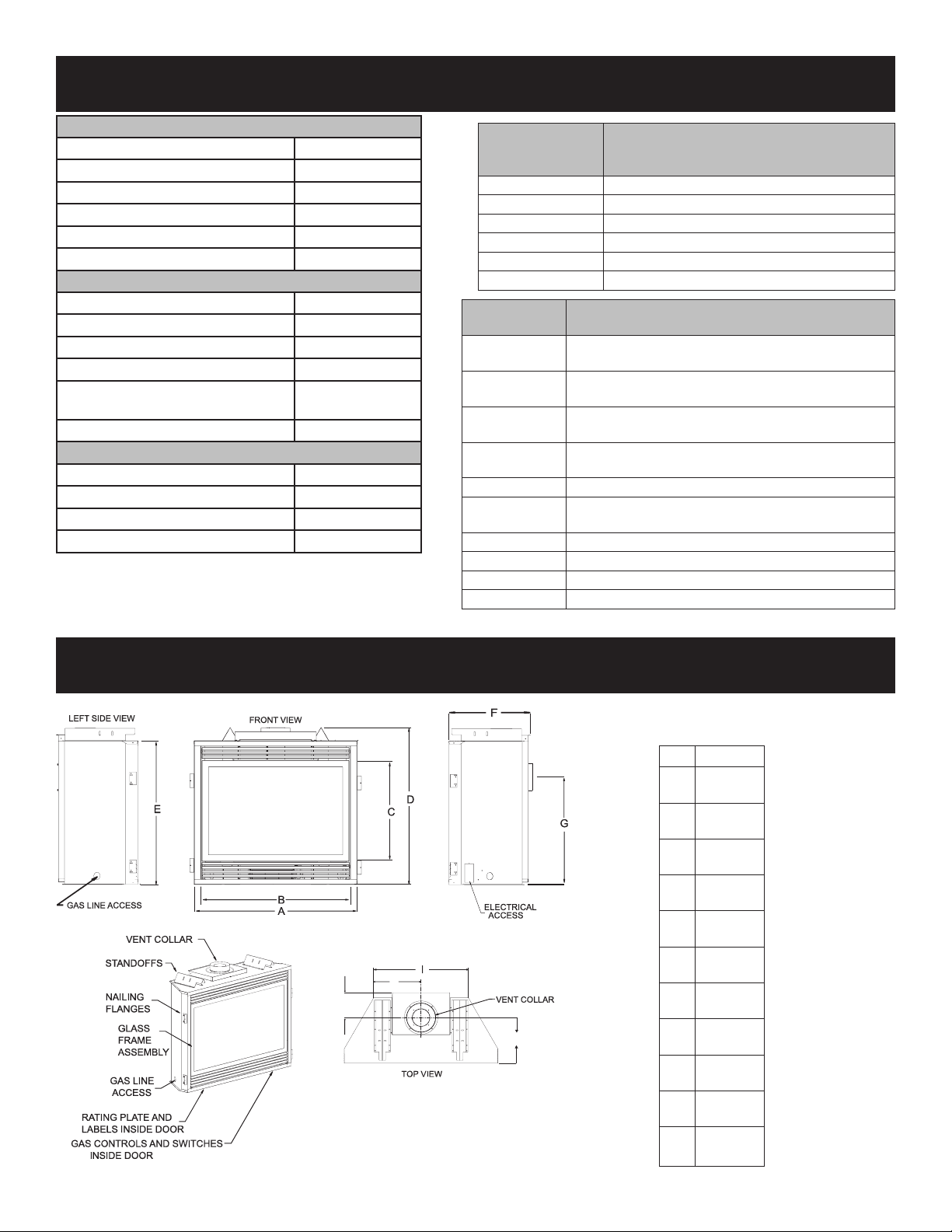

SPECIFICATIONS

DVP36 Nat Models

Input Btu/hr Maximum 25,000

Btu/hr Minimum (millivolt only) 18,000

KWH (Maximum) 7.3

(Minimum) 5.2

Orifice

#41

Air Shutter Opening 1/8"

DVP36 LP Models

Input Btu/hr Maximum 27,000

Btu/hr Minimum (millivolt only) 19,000

KWH (Maximum) 7.9

(Minimum) 5.2

Orifice

1.55mm

P-258

Air Shutter Opening FULL OPEN

DVP36 Nat and LP Models

Height without standoff

Width

34 3/4"

39"

Depth 19 7/8"

Gas Inlet Shutoff Valve (pipe)

1/2" NPT

NOTE: Air shutter settings are factory minimum settings. Some

venting configurations may require minor air shutter adjustments

for optimum performance.

Remote Control

Description

Options &

Accessories

FRBC Millivolt Batt. Remote ON/OFF

FRBTC Millivolt Batt. Remote T-Stat

TMW Millivolt Wireless Wall Thermostat

TRW Millivolt Reed Switch Wall Thermostat

FWS-1 Direct Ignition/Millivolt Wall Switch

FREC Electric Remote

Venting

Description

Options

DVVK-4TSP

Top Vent Kit (Horz.) - 4½" to 6" wall thickness

(DVVK-4TS)

DVVK-4TP

Top Vent Kit (Horz.) - 8" to 12" wall thickness

(DVVK-4T)

DVVK-4RP

Rear Vent Kit (Horz.) - 5" to 7" wall thickness

(DVVK-4R)

DVVK-4VP

Vertical Vent Kit

(DVVK-4V)

DVVK-4F Horizontal Flex Vent Kit (4' Flex)

DVVK-4RE Horizontal Round Termination wall thickness

(up to 11 7/16")

DV822 Vinyl Siding Kit for DVVK-4RE

DVVK-4FV Vertical Flex Vent Kit

DVEK-10 10' Vent Extension Kit

DVEK-25 25' Vent Extension Kit

Note: Rear vent installation can only be vented on natural gas.

FIREPLACE DIMENSIONS

DVP36

Figure 1

23340-4-0608 Page 7

A 39"

99.1 cm

B 36"

91.4 cm

C 25 1/16"

63.7 cm

D 37 5/8"

96 cm

E 34 3/4"

88 cm

F 19 7/8"

50.5 cm

G 26 1/2"

66 cm

H 7 1/8"

18.1 cm

I 27"

68.6 cm

J 13 1/2"

34.6 cm

K 12 3/4"

32.4cm

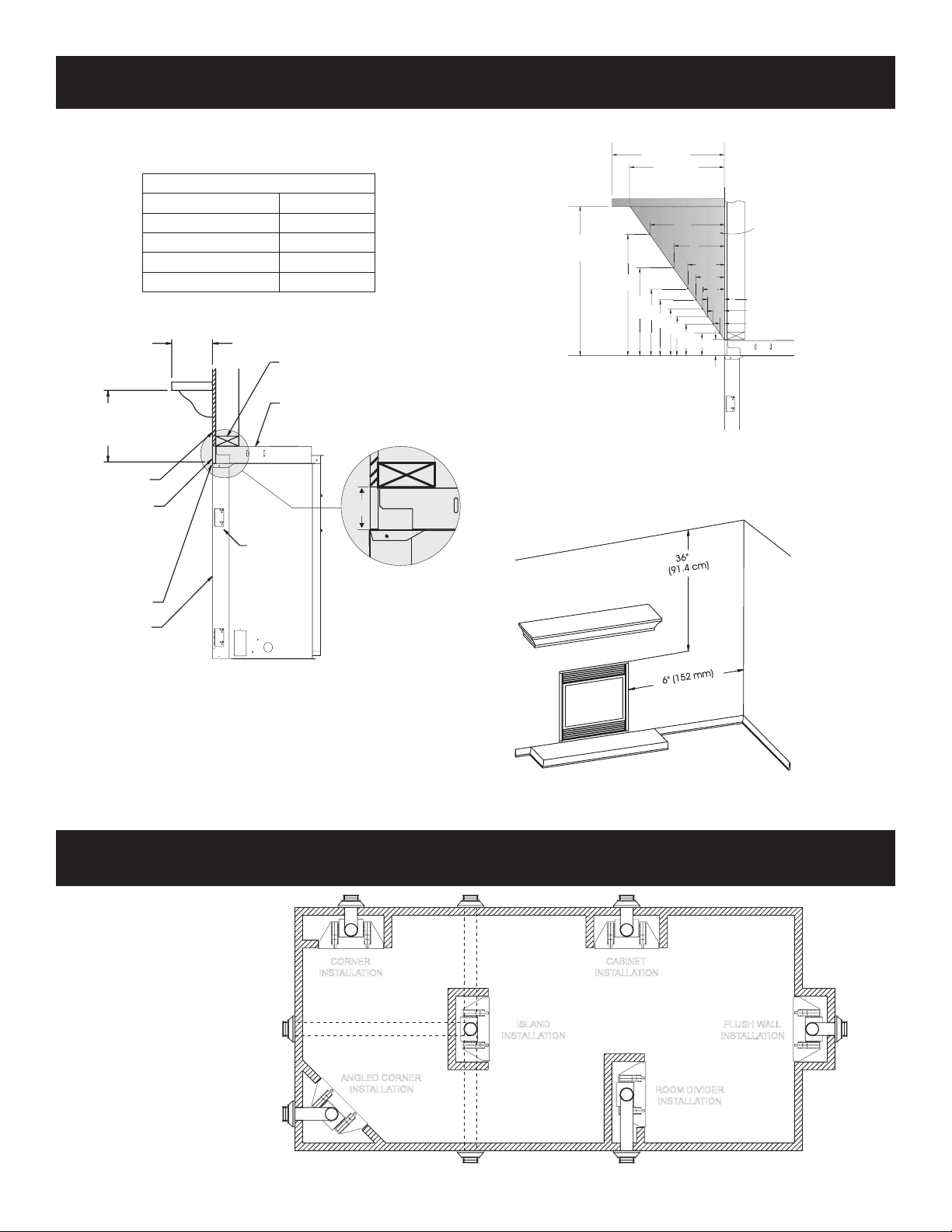

Page 8

15”

(381mm)

TO

P EDGE OF FIREPLACE

12” (305mm)

10” (254mm)

MANTEL

COMBUSTIBLE TRIM

AND MANTELS

ALLOWED

IN SHADED AREA

4”

5”

6”

7”

8”

9”

11”

13 3/4”

3/4”

1 ½

”

2 1

/4”

3”

3 3

/4”

4 ½”

6”

8”

3”

CABINET

INSTALLATION

FLUSH WALL

INSTALLATION

ROOM DIVIDER

INSTALLATION

CORNER

INSTALLATION

ANGLED CORNER

INSTALLATION

ISLAND

INSTALLATION

Clearance to Combustibles

SEE MANTLE CHART FOR

MAXIMUM MANTLE DEPT

H

NON-COMBUSTIBLE

FIRST 3 (SEE MAGNIFFIED

VIEW)

”

NAILIN

G

FLANGES

GLASS FRONT

TOP FRAMING

LEDGE

FINISHED WALL

(COMBUSTIBLE

)

SEE MANTLE CHART

FOR MINIMUM HEIGHT

OF MANTLE ABOVE UNI

T

2" x 4" HEADE

R

STAND

OFF

3" (76 mm) HEIGHT

ABOVE T

OP OF

FIREPLAC

E

3"

Back 0" (0 mm)

Side 0" (0 mm)

Floor 0" (0 mm)

Top Stand-off

0" (0 mm)

Top Framing Edge 3" (76 mm)

CLEARANCES

Mantel Chart (Figure 3)

Figure 3

Clearances (Figure 4)

Clearance from top of fireplace to ceiling is 36"

Clearance from side of fireplace to adjacent sidewall is 6".

Combustible Material

No greeting cards, stockings or ornamentation of any type should

be placed on or attached to the fireplace. The flow of heat can

ignite combustibles.

Note:** Island (C) and Room

Divider (D) installation is possible

as long as the horizontal portion

of the vent system (H) does not

exceed 20 feet with a minimum

vertical run of 8 feet. See details

in Venting Section.

*When you install your Direct Vent

Fireplace in (D) Room divider or

(E) Flat on wall corner positions,

a minimum of 6 inches clearance

must be maintained from the

perpendicular wall and the front

edge of the appliance.

Figure 2

LOCATING FIREPLACE

Figure 5

Figure 4

23340-4-0608Page 8

Page 9

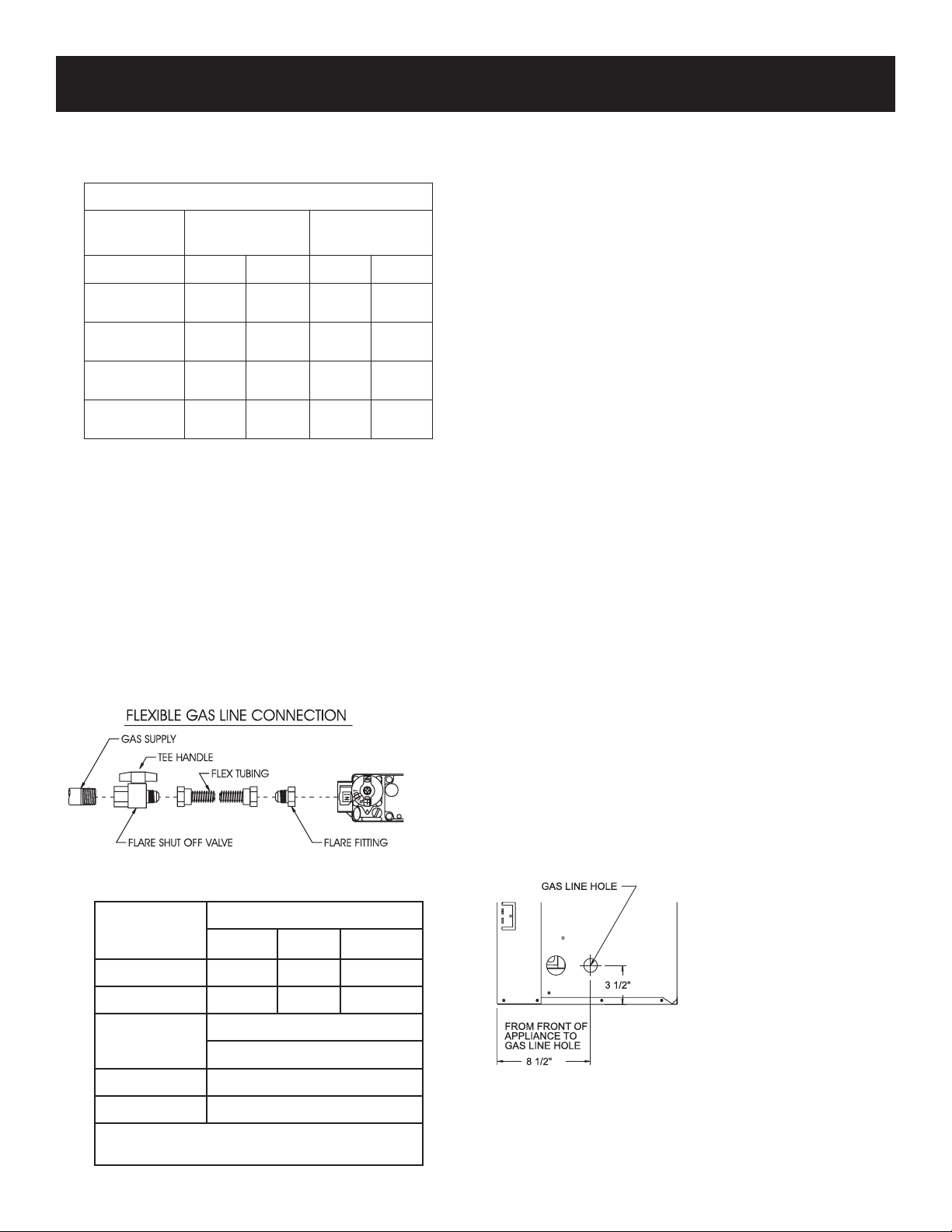

GAS SUPPLY

The gas pipeline can be brought in through the right or left side of

the appliance. Consult the current National Fuel Gas Code, ANSI

Z223.1 CAN/CGA-B149 (.1 or .2) installation code.

Recommended Gas Pipe Diameter

Pipe Length Schedule 40 Pipe

Inside Diameter

Nat. L.P. Nat. L.P.

0-10ft

0-3m

11-40ft

4-12m

41-100ft

13-30m

101-150ft

31-46m

1/2"

12.7mm

1/2"

12.7mm

1/2"

12.7mm

3/4"

19mm

3/8"

9.5mm

1/2"

12.7mm

1/2"

12.7mm

1/2"

12.7mm

Tubing, Type L

Outside Diameter

1/2"

12.7mm

5/8"

15.9mm

3/4"

19mm

7/8"

22.2mm

3/8"

9.5mm

1/2"

12.7mm

1/2"

12.7mm

3/4"

1.9 mm

Note: Never use plastic pipe. Check to confirm whether your

local codes allow copper tubing or galvanized.

Note: Since some municipalities have additional local codes, it is

always best to consult your local authority and installation code.

The use of the following gas connectors is recommended:

— ANS Z21.24 Appliance Connectors of Corrugated Metal Tubing

and Fittings.

— ANS Z21.45 Assembled Flexible Appliance Connectors of

Other Than All-Metal Construction

The above connectors may be used if acceptable by the authority

having jurisdiction. The state of Massachusetts requires that a flexible

appliance connector cannot exceed three feet in length.

Figure 6

Installing a New Main Gas Cock

Each appliance should have its own manual gas cock.

A manual main gas cock should be located in the vicinity of the unit.

Where none exists, or where its size or location is not adequate, contact

your local authorized installer for installation or relocation.

Compounds used on threaded joints of gas piping shall be resistant

to the action of liquefied petroleum gases. The gas lines must be

checked for leaks by the installer. This should be done with a soap

solution watching for bubbles on all exposed connections, and if

unexposed, a pressure test should be made.

Never use an exposed flame to check for leaks. Appliance must

be disconnected from piping at inlet of control valve and pipe

capped or plugged for pressure test. Never pressure test with

appliance connected; control valve will sustain damage!

NOTE: The millivolt gas controls are equipped with a captured

screw type pressure test point, therefore it is not necessary to provide

a 1/8" test point up stream of the control.

On direct ignition valves, hex plugs may be replaced with hose fittings

for pressure checks, then reinstalled before operating fireplace.

When using copper or flex connector use only approved fittings.

The appliance and it’s individual shut off valve must be disconnected

from supply piping system during any pressure testing of that system

at test pressures in excess of 1/2 psig (3.5kPa).

The appliance must be isolated from the gas supply piping system

by closing its individual manual shut off valve during any pressure

testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig (3.5kPa).

Attention! If one of the procedures results in pressures in excess

of 1/2 psig (14" w.c.) (3.5 kPa) on the fireplace gas valve, it will

result in a hazardous condition.

Checking Manifold Pressures

Both Propane and Natural gas valves have a built-in pressure

regulator in the gas valve. Natural gas models will have a manifold

pressure of approximately 3.5" w.c. (.871kPa) at the valve outlet

with the inlet pressure to the valve from a minimum of 4.5" w.c.

(1.120kPa) for the purpose of input adjustment to a maximum of

14.0" w.c. (3.484kPa). Propane gas models will have a manifold

pressure approximately 10.0" w.c. (2.49kPa) at the valve outlet

with the inlet pressure to the valve from a minimum of 10.8" w.c.

(2.68kPa) for the purpose of input adjustment to a maximum of

14.0" w.c. (3.484kPa).

Gas Supply Pressure (inches w.c.)

Minimum Normal Maximum

Natural Gas 4.5" 7.0" *14.0"

LP (Propane)

Natural Gas 3.5"

LP (Propane)

10.8" 11.0" *14.0"

Manifold Pressure (inches w.c.)

Normal (HI)

Figure 7

10.0"

*Note: Remote "RF" Models - 10.5" w.c.

maximum

23340-4-0608 Page 9

Page 10

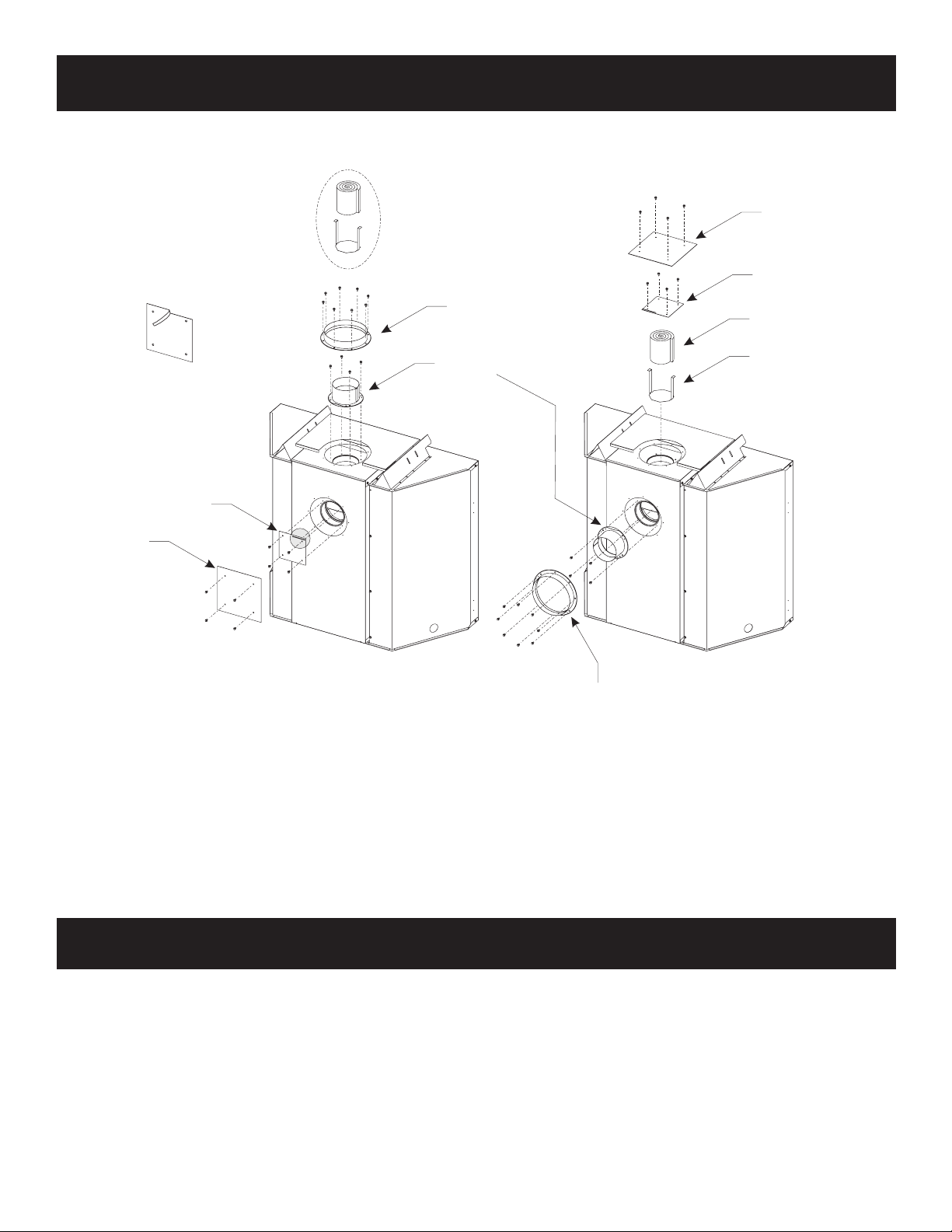

REAR VENT CONVERSION

Note: Discard insulation

& retainer when using

vertical venting off

VERTICAL VENTING

HORIZONTAL VENTING

FLUE INSULATION

INSULATION

RETAINER

INLET VENT COLLAR

INLET VENT COLLAR

FLUE OUTLET

COLLAR

FLUE COVER PLATE

(See note above)

INLET VENT

COVER PLATE

FLUE COVER PLATE

INLET VENT

COVER PLA

TE

Note: It is recommended that the

flue cover plate tab be pulled

outward prior to removal.

This will ensure that the plate

is not accidentally dropped

inside the rear air chamber.

Note: Discard insulation

& retainer when venting off

top of fireplace.

LP and Nat models

Nat models only

Converting flue take-off to rear venting

When switching out the flue and inlet vent collars to run horizontally

off the rear vent, the following steps must be taken.

1. Remove the inlet vent collar (8 screws) and flue collar (4 screws)

from the top of the fireplace, and set to the side.

2. Remove the inlet cover plate and flue cover plate located on the

back of the fireplace. These will be used to close the top flue

and inlet openings.

3. Insert the insulation retainer bracket and insulation into the top

flue pipe before reinstalling the flue cover plate over the top flue

The following vent systems are acceptable for use with the DVP36 series fireplaces:

Simpson Duravent® GS 4" - 6 ⅝", refer to page 30.

American Metal Products 4" - 6 ⅝"

Selkirk Direct-Temp® 4" - 6 ⅝"

Security Secure Vent® 4" - 6 ⅝"

Empire Horizontal Round Termination Kit DVVK-4RE, refer to page 34.

Empire Flexvent Kit DVVK-4F, refer to page 37.

Empire Flexvent Kit DVVK-4FV Vertical Flex Vent Kit, refer to page 18.

SPECIAL VENT SYSTEMS

with 4 screws.

4. Reinstall the inlet cover plate over the top inlet opening with 4

screws. See illustration above..

5. Install the flue collar assembly to the rear flue with 4 screws.

6. Install the inlet vent collar to the rear of the fireplace with 8

screws.

7. This completes the conversion for a rear vent application.

Note: for top vented installations, the insulation and retainer are

to be removed from the flue pipe and discarded.

23340-4-0608Page 10

Page 11

VENT PIPE

1" MINIMUM CLEARANCE AROUND VENT PIPE

Top of Vent

Combustibles

NOT

allowed in shaded

area

1"

1"

3"

(25

mm)

7” Diameter

intake vent

4” Diameter flue

(25 mm)

(76 mm)

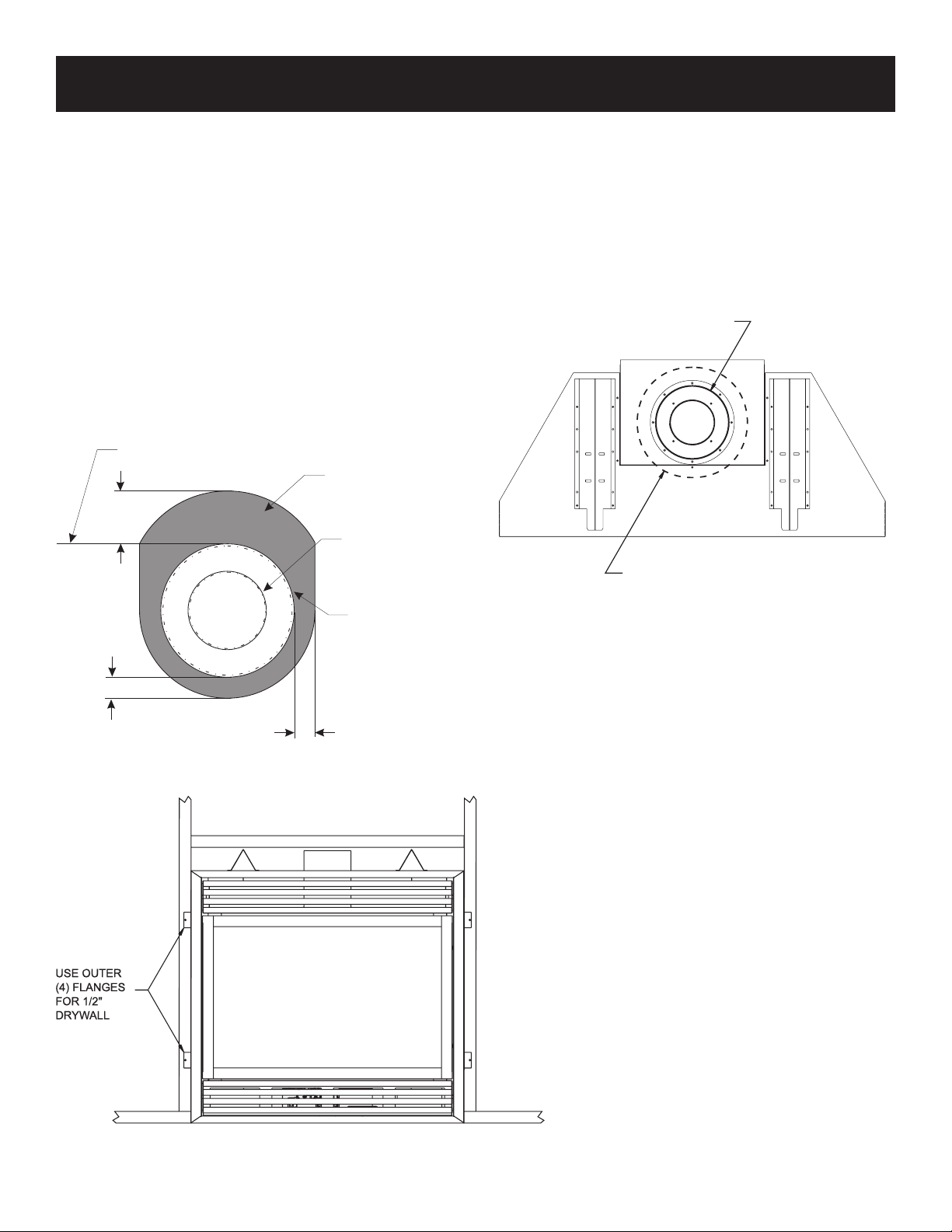

INSTALLATION

Framing and Finishing

1. Choose unit location.

2. Frame in fireplace with a header across the top. It is important to

allow for finished face when setting the depth of the frame.

3. Attach fireplace to frame using adjustable frame. Preset depth to

suit facing material (adjustable to 1/2", 5/8" or 3/4" depths).

4. Use (8) 1/2" hex-head screws supplied in hardware package,

to screw through slotted holes in drywall strip and then screw

into pre-drilled holes on fireplace side. Measure from face of

fireplace to face of drywall strip to determine final depth.

Vent Pipe Clearance

Note: Maintain one inch (1") of clearance around vertical vent

pipe. See Figure 9. For horizontal vent, maintain a minimum 1"

clearance to the bottom and sides of the vent, and 3" clearance to

combustibles above the vent pipe. See Figure 10.

Figure 8

Figure 10

23340-4-0608 Page 11

Figure 9

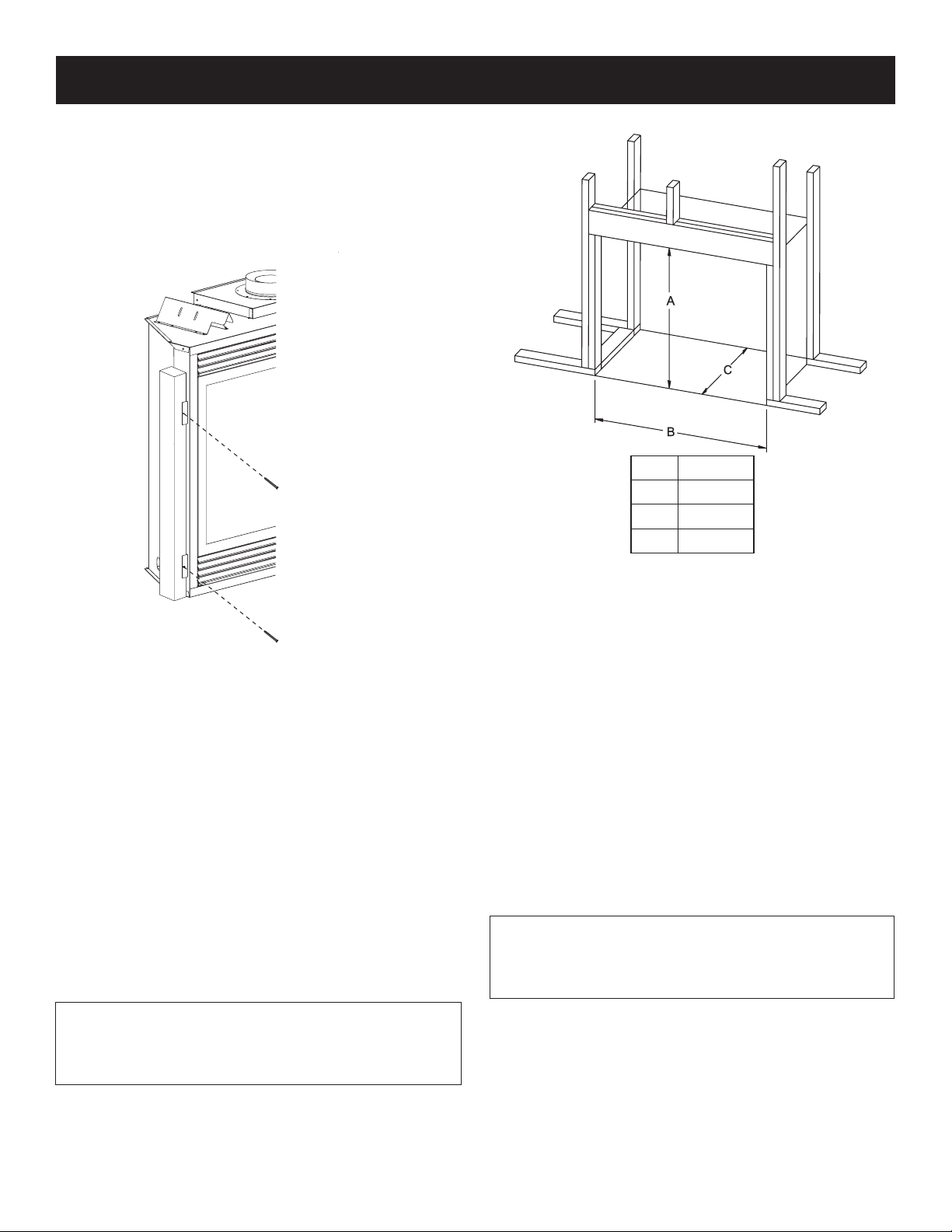

Page 12

NAIL OR OTHER SUITABLE FASTENER

INSTALLATION (continued)

Flush Mount Mantel Installation (Figure 11)

The fireplace must extend 3/4" beyond finished wall surface when

using a flush mount mantel. Refer to Figure 11 to locate nailing

flanges on fireplace sides. Mark and drill two (2) 1/8" holes into

fireplace side to mount each nailing flange. Use eight (8) 1/2" hexhead screws supplied in hardware package to attach nailing flanges

to fireplace sides.

Note: For finishing to top of fireplace, refer to Figure 12.

DVP36

"A" 37 3/4"

"B" 39 3/8"

"C" 19 7/8"

Figure 11

Attention: When fireplace is installed in optional full cabinet mantel

or corner mantel the (4) four nailing flanges shown in Figure 11 will

not be installed on the side of outer casing. The fireplace will be

attached to the full cabinet mantel or corner mantel with the (2) two

nailing flanges located on the top of the outer casing assembly.

Framing (Figure 12)

Fireplace framing can be built before or after the fireplace is set in

place. Framing should be positioned to accommodate wall covering

and fireplace facing material. The fireplace framing should be

constructed of 2 x 4 lumber or heavier. The framing headers may

rest on the fireplace standoffs. Refer to Figure 12 for minimum

framing dimensions.

CAUTION: MEASURE FIREPLACE DIMENSIONS AND

VERIFY FRAMING METHODS, AND WALL COVERING

DETA ILS B EFO R E F R AMI N G C O NST R UC T I ON

BEGINS.

Framing dimension "A" includes a three inch clearance for

standoffs on firebox. After installing firebox into framing,

the finished wall surface must cover the three inch opening

above the firebox.

Figure 12

Attention: Add 3-3/4" to “A” dimensions when using a flush

mantel base.

Attention: If a base or mantel is not used and the appliance is

installed directly on carpeting, tile or other combustible material

other than wood flooring, it shall be installed on a metal or wood

panel extending the full width and depth of the appliance. The

vertical dimension in Figure 12 must be adjusted when a metal or

wood panel is placed beneath the appliance.

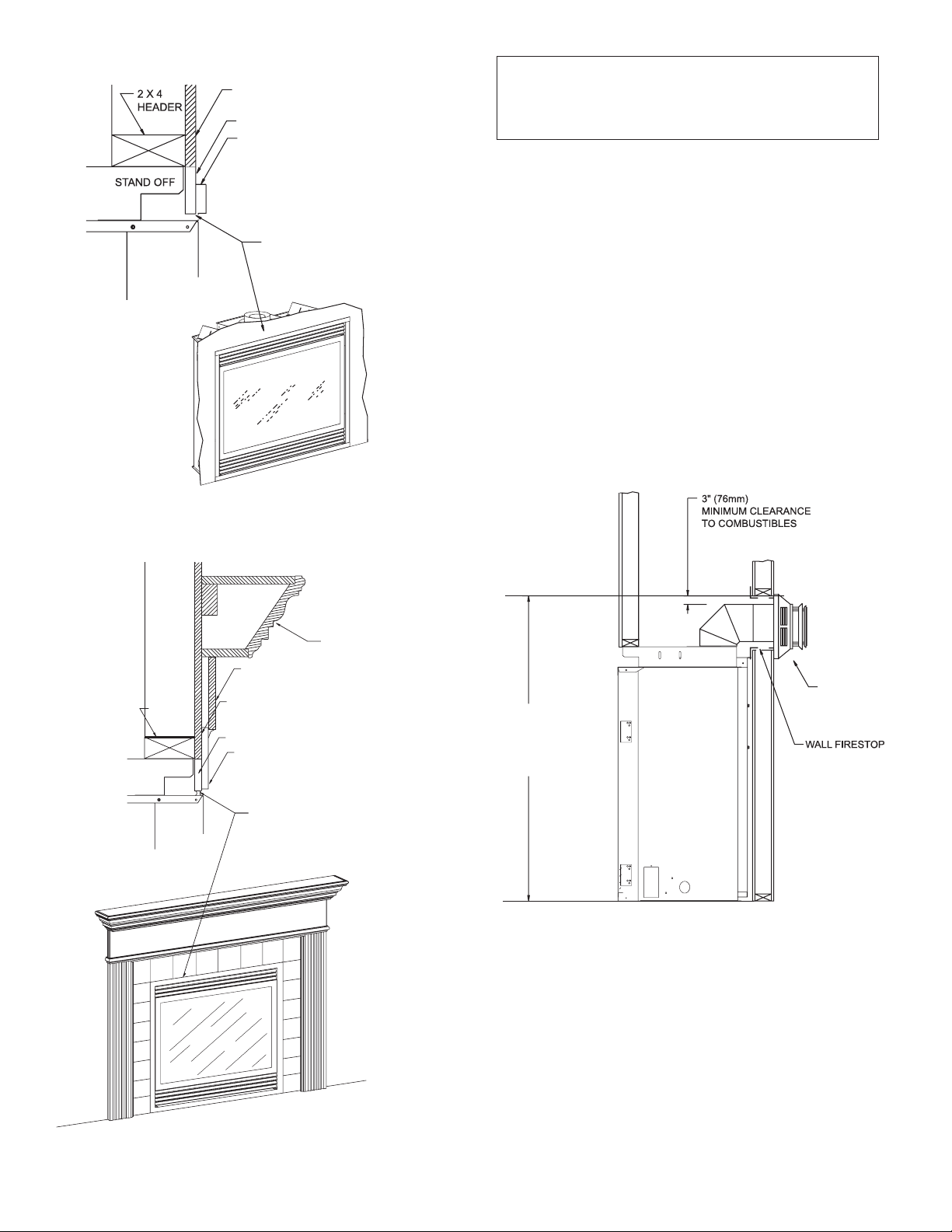

Finishing (Figures 13 and 14)

Finish the walls with the material of your choice. Figure 3 on

page 8 shows the minimum vertical and corresponding maximum

horizontal dimensions of mantels or other combustible projections

above the top front edge of the fireplace.

Only non-combustible materials may be used to cover the black

fireplace front.

Warning: When finishing the fireplace never obstruct

or modify the air inlet/outlet louvers in any manner.

Provide adequate clearances around air openings into the

combustion chamber.

Caution: If the joints between the finished wall and the fireplace

surround (top and sides) are sealed, a 300°F minimum sealant

material must be used. These joints are not required to be sealed.

Only non-combustible material (using 300°F minimum adhesive if

needed), can be applied as facing to the fireplace surround.

23340-4-0608Page 12

Page 13

Flush Wall Installation

3! OF NON-COMBUSTIBLE MATERIAL

FINISHED WALL

FRONT TRIM O

R NONCOMBUSTIBLE MA TERIAL

(INSTALLATION IS OPTIONAL)

JOINT BETWEEN FINISHED

WALL AND UNIT SEALED

WITH 300° F, 149° C SEALANT

MATERIAL

(Sealant is optional)

DVP36

49 ½”

(126

mm)

TO BOTT

OM

OF UNIT

VENT CAP/

THIMBLE

THIMBLE

3! OF NON-COMBUSTIBLE MATERIAL

FINISHED WA

LL

FRONT TRIM

OR NON-COMBUSTIBLE

MATERIAL (INSTALLATION I

S OPTIONAL)

JOINT BETWEEN FINISHED WA

LL AND

UNIT SEALED WITH

300° F 149

MATERIAL (SEALANT IS OPTIONAL

)

° C

SEALANT

COMBUSTIBLE SURROUND

MANTELSHELF

2 X 4

HEADER

STAND OFF

Attention: Cold climate installation recommendation: When

installing this unit against a non-insulated exterior wall, it is

recommended that the outer walls be insulated to conform

to applicable insulation codes.

Vent Runs (Figures 15, 16, 17, 18, and 19)

In planning the installation for the fireplace, it is necessary to

install certain components before the appliance is completely

positioned and installed. These include the direct vent system,

gas piping for the appliance and the electrical wiring. (If the fan

option is used.)

The appliance can be mounted on any of the following surfaces:

1. A flat, hard combustible (burnable) surface.

2. A raised wooden platform.

3. Four (4) corner supports. (Example: Four (4) concrete masonry

blocks.) These supports must be positioned so they contact all

four (4) perimeter edges on the bottom of the unit.

VERTICAL, 90° ELBOW WITH HORIZONTAL

TERMINATION

Figure 13

Combustible Surround Installation

LP and Nat models

Figure 15

Figure 14

23340-4-0608 Page 13

Page 14

WALL FIRESTOP/

THIMBLE

VENT CAP

A

"

PIPE LENGTH

WALL FIRESTOP/

THIMBLE

"

WALL FIRESTOP/

THIMBL

E

VENT

CAP

WALL FIRESTOP/

THIMBLE

INSTALLATION (continued)

HORIZONTAL ONLY, STRAIGHT OUT THE BACK

Nat models only

"A" "B"

6" 5 1/8" to 6 1/2"

9" 8 1/8" to 9 1/2"

12" 11 1/8" to 12 1/2"

Figure 16

VERTICAL, 90° ELBOW TO

HORIZONTAL OUT THE WALL

CORNER INSTALLATION VERTICAL, 90° ELBOW TO

HORIZONTAL OUT THE WALL

LP and Nat models

Dim. DVP36

44 7/8" (114 cm)

A

31 3/4" (81 cm)

B

13 7/16" (34 cm)

C

63 7/16" (161 cm)

D

Figure 18

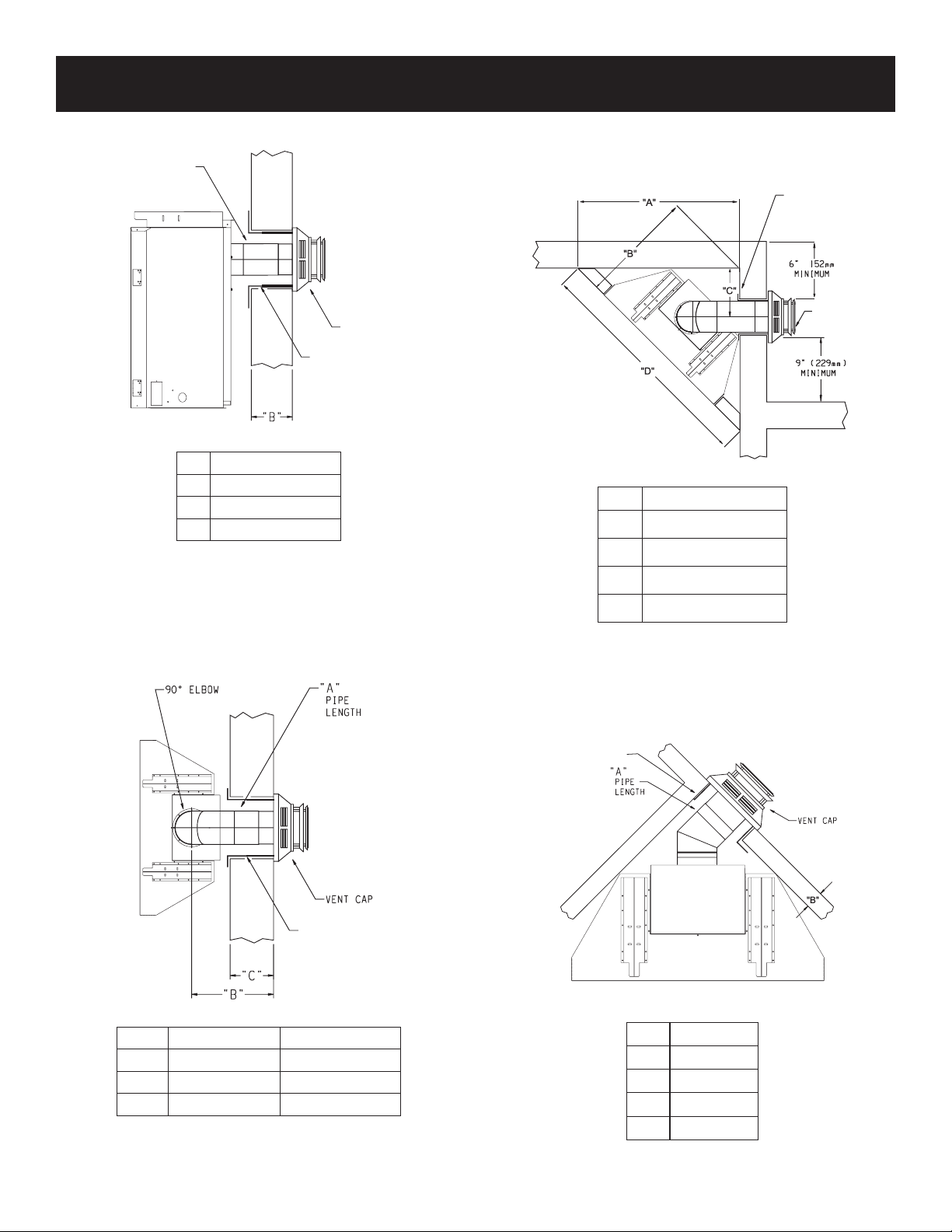

LP and Nat models

"A" "B" "C"

6" 11 1/4" to 12 3/4" 4 3/4" to 6 1/4"

9" 14 1/4" to 15 3/4" 7 3/4" to 9 1/4"

12" 17 1/4" to 18 3/4" 10 3/4" to 12 1/4"

Figure 17

CORNER INSTALLATION HORIZONTAL, 45° ELBOW

TO HORIZONTAL OUT THE WALL

Nat models only

DVP36

"A" "B"

6" 4" to 5 1/2"

9" 6" to 7 1/2"

12" 9" to 10 1/2"

Figure 19

23340-4-0608Page 14

Page 15

VERTICAL

DIMENSION

FROM

THE

BOTTOM

OF

THE

UNIT

TO

THE

CENTER

OF

THE

FLUE

OUTLET

WITH

VERTICAL

OR

HORIZONTAL

TERMINATION

CAPS

VENTING FIREPLACE - TOP (LP & NAT MODELS)

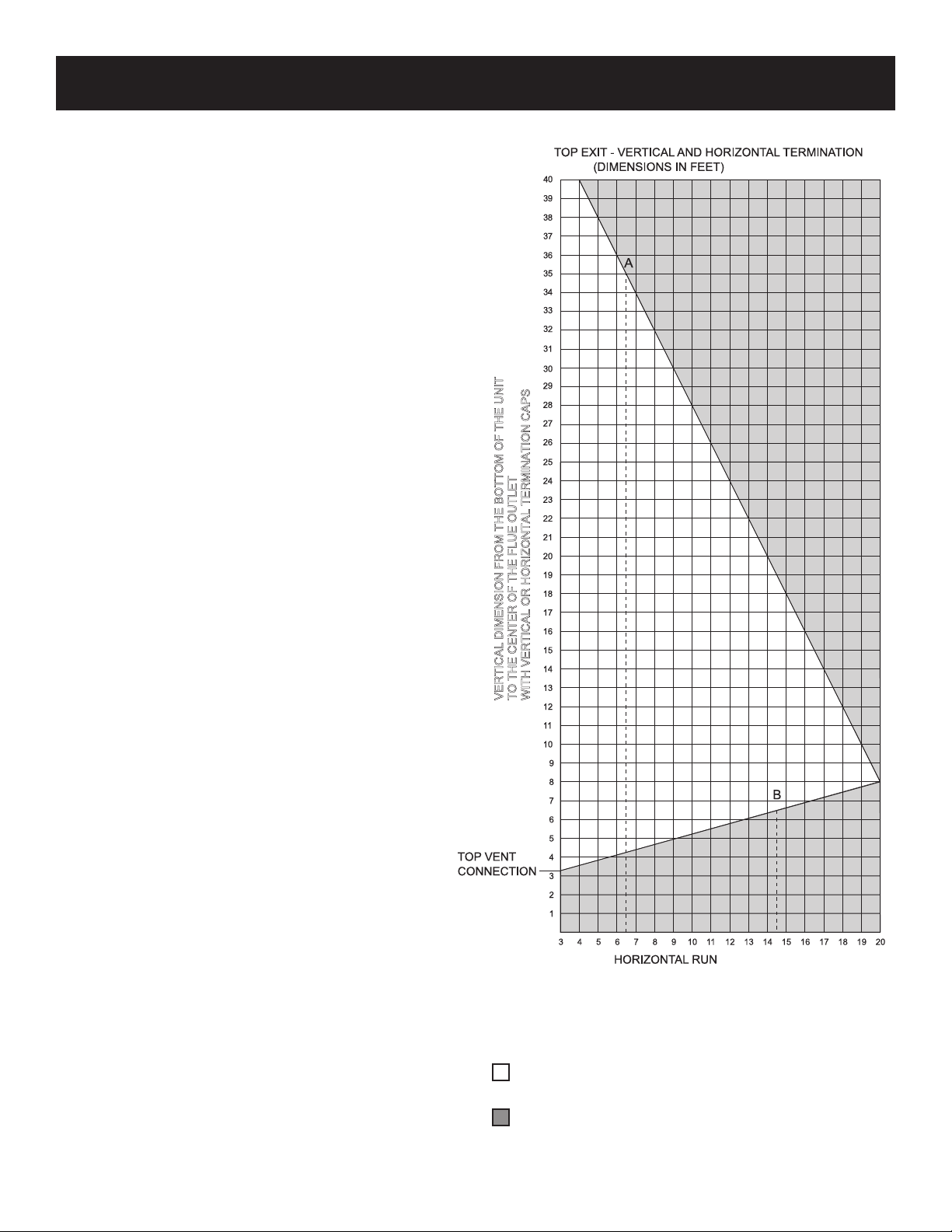

To Use the Vent Graph (Figure 20)

1. Determine the height of the center of the horizontal vent

pipe. Using this dimension on the Sidewall Vent Graph,

locate the point it intersects with the slanted graph

line.

2. From the point of this intersection, draw a vertical line

to the bottom of the graph.

3. Select the indicated dimension, and position the unit in

accordance with same.

EXAMPLE A:

If the vertical dimension from the floor of the unit is 35

feet, the horizontal run to the outer wall flange must not

exceed 6.5 feet.

EXAMPLE B:

If the vertical dimension from the floor of the unit is 6.5

feet, the horizontal run to the outer wall flange must not

exceed 14.5 feet.

SPECIAL NOTE: For each 45 degree elbow installed in

the horizontal run, the length of the horizontal run MUST be

reduced by 18" (45cm). This does not apply if the 45 degree

elbows are installed on the vertical part of the vent system.

Reduce 3' for every 90° elbow.

Example: According to the chart the maximum horizontal

vent length is 20' and if two 45 degree elbows are required

in the horizontal vent it must be reduced to 17'.

The maximum number of 45 degree elbows permitted per

side wall installation is two (2). These elbows can be installed

in either the vertical or horizontal run.

Note: On vertical venting the first elbow does not get

counted.

Note: LP and Nat gas models can be top vented.

Venting Graph (Dimensions in Feet)

Figure 20

Acceptable vertical and horizontal vent run.

(40' maximum vertical and 20' maximum horizontal)

Unacceptable vertical and horizontal vent run.

23340-4-0608 Page 15

Page 16

VENTING FIREPLACE - TOP (continued)

Below Grade Installation

When it is not possible to meet the required vent terminal clearances

of 12" (305mm) above grade level, a snorkel kit is recommended.

It allows installation depth down to 7" (178mm) below grade level.

The 7" (178mm) is measured from the center of the horizontal vent

pipe as it penetrates through the wall.

Ensure the sidewall venting clearances are observed. If venting

system is installed below ground, we recommend a window well

with adequate and proper drainage to be installed around the

termination area.

Firestop at

Ceiling Level

LP and Nat models

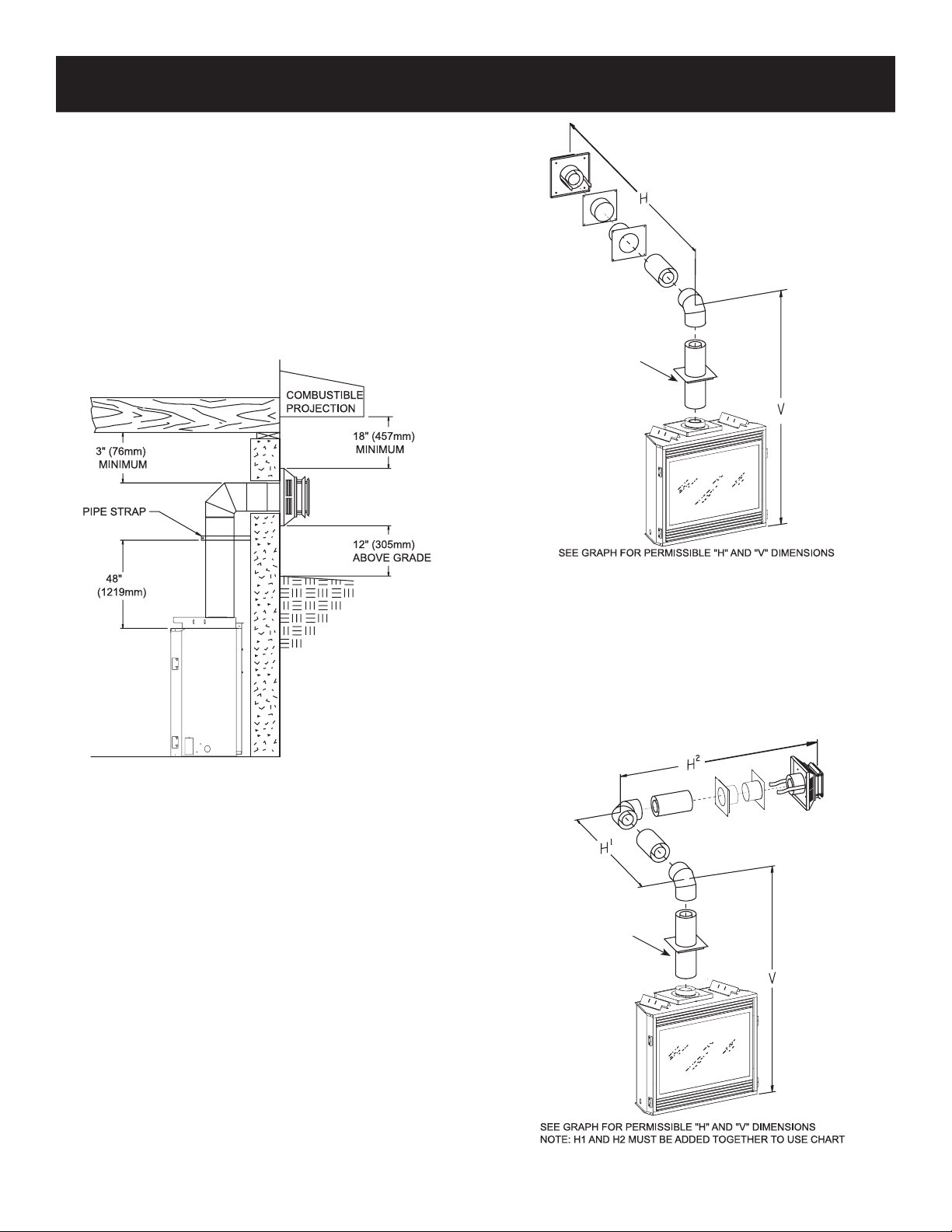

TYPICAL BASEMENT INSTALLATION

Figure 21

Examples of possible venting systems using one (1) 90° elbow.

Eight (8) feet is listed as minimum vertical vent run with 20 feet

of maximum horizontal vent run. Vertical dimensions are based on

centerline to centerline of pipe. Horizontal dimensions are based

on centerline of pipe to end of termination.

LP and Nat models

Figure 22

Examples of possible venting systems using two (2) 90° elbows. V

is listed as minimum vertical dimensions and H1 + H2 is listed as

total of maximum horizontal dimensions. The maximum vertical

and horizontal distances for two (2) 90° elbows as shown in Figure

23 is 20 feet.

Attention: Refer t o Fi g u r e 20 for addit i o n a l ve n t ing

requirements.

Firestop at

Ceiling Level

LP and Nat models

Figure 22

23340-4-0608Page 16

Page 17

LP and Nat models

10”

(254mm)

10

”

(254mm)

MAXIMUM HORIZONTAL

RUN WITH NO VERTICAL

RISE AND 90° ELBOW

MAXIMUM HORIZONTAL

RUN WITH MINIMUM

VERTICAL RISE AND

90° ELBOW

minimum

Figure 24

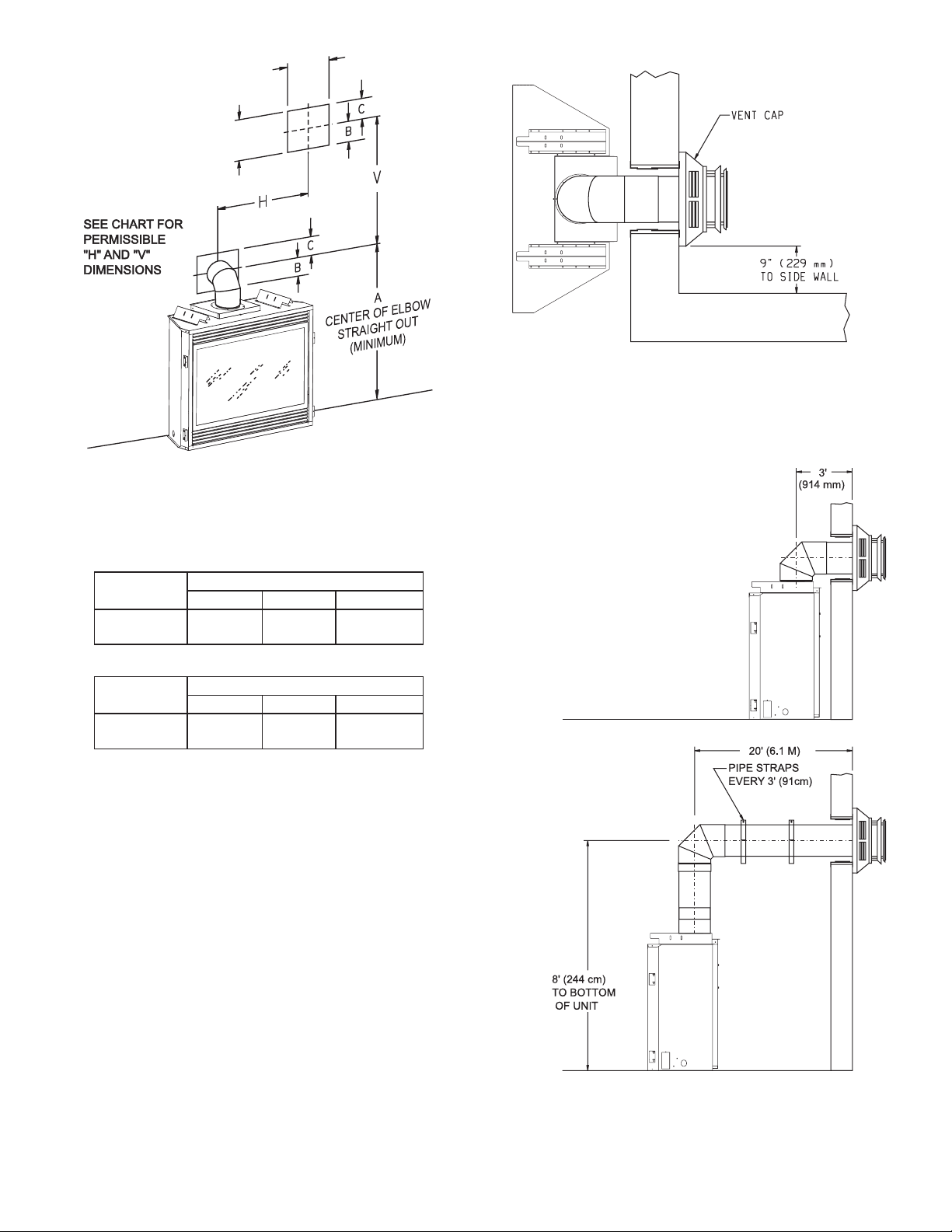

MINIMUM HOLE LOCATION DIMENSIONS FOR THROUGH THE WALL

HORIZONTAL INSTALLATIONS WITH 90 DEGREE ELBOW OFF TOP OF

FIREPLACE

LP and Nat models

Figure 25

FIREPLACE

SERIES

DVP36FP 43-1/2"

FIREPLACE

SERIES

36FP 45"

Positioning the Fireplace

Determine the exact position of the appliance so the direct vent termination

will be centered (if possible) between two (2) studs. This will avoid any

extra framing. All vent kit pipes should be assembled on the unit after the

unit is moved into the final position.

Cutting the Hole (Figures 24)

After the fireplace has been positioned in its permanent location, the hole

through the exterior wall of the house can be cut. This hole must be 10"

(254mm) high x 10" (254mm) wide with its center line determined by the

amount of vertical rise and horizontal run of the termination. See Figure

24. When locating the hole it must be noted that the bottom of the cap

must be 12" (305mm) above the ground level, and top of the cap must

be no less than 18" (457mm) below a combustible projection, and no

closer than 9" (229mm) to any wall running parallel to vent termination.

See Figure 25.

HARD ELBOW DIMENSIONS

"A" "B" "C"

4"

(1105mm)

FLEX PIPE 90 DEGREE BEND

"A" "B" "C"

(1143mm)

(102mm)

4-1/2"

(114mm)

6"

(152mm)

6-1/2"

(165mm)

LP and Nat models

Figure 26

23340-4-0608 Page 17

Page 18

DVVK-4FV DIRECT VENT TERMINATION KIT

Installation Instructions

This termination kit can only be used with Empire Comfort Systems direct vent fireplaces listed for use with

DVVK-4FV Vertical Flex Vent Kit. Please review the instructions packaged with your fireplace and verify the

fireplace model number. Check that this flex vent system is listed for use with your fireplace model prior to

starting the installation.

This vent kit may be installed as an OEM installation in a manufactured home (USA only) or mobile

home and must be installed in accordance with the manufacturer’s instructions and the manufactured

home construction and safety standard, Title 24 CFR, Part 3280 or Standard for Installation in Mobile

Homes, CAN/CSA Z240 MH.

CAUTION

All Fireplaces listed for use with the DVVK-4FV will operate safely when installed in accordance with this instruction manual. Read

all instructions before starting installation, then follow these instructions carefully to maximize fireplace performance and safety.

Report damaged parts to your dealer.

WARNING

Any common venting of the gas appliance using the DV vent kit with other gas appliances is not allowed. Do not connect this appli

ance to a chimney flue servicing a separate solid fuel-burning appliance.

-

WARNING

Failure to follow these instructions may create a possible fire hazard and will void the warranty.

WARNING

Always maintain minimum clearances around vent systems. The minimum clearance to combustibles for horizontal runs of vent pipe

is 3 inches from the top, and 1 inch from the sides and bottom of the vent system. Do not pack the open air spaces around the fireplace

or flue with insulation or other materials. Any horizontal run must have a 1/4” rise for every one (1) foot of run towards the vent ter

mination. The vent above the roof must terminate vertically.

WARNING

Contact your Local Building and Fire Officials about restrictions and installation inspections in your area.

IMPORTANT SAFETY INFORMATION

• The vertical termination cap MUST be vented directly to the

outside. The termination kit MUST NEVER be connected to

a chimney flue(s) servicing a separate solid-fuel burning appliance or any other appliances.

• Termination cap MUST NOT be mounted horizontally.

• The flexible vent pipe cannot be intermingled with any of the

rigid vent pipe section(s). DO NOT connect two sections of

flexible vent pipe together to achieve a longer length without

the use of approved connectors.

• The installation must conform with local codes or in the absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1 (in the United States) or with the current installation

code CAN/CGA B149 (in Canada).

• Only Direct Vent fireplaces approved for use with Empire

Comfort Systems, Inc. DVVK-4FV termination kit shall be

used. See PARTS LIST/ILLUSTRATIONS section for vent

component identification.

• Horizontal vent runs must be supported every 2 feet using

wall straps. Vertical runs must be supported every 3 feet using wall straps. Slip wall straps loosely on to pipe. Attach

installer provided straps to framing members using nails or

screws.

• The fireplace and venting system should be inspected before

initial use and at least annually by a qualified field service

person. Inspect the external vent cap on a regular basis to

make sure that no debris is interfering with the airflow. Inspect entire venting system to ensure proper function.

• Please refer to the fireplace instructions for information on

Termination Cap clearances.

-

23340-4-0608Page 18

Page 19

PRE-INSTALLATION INFORMATION:

Items Required For Installation:

Tools Building Supplies

Phillips Screwdriver

Hammer

Saw and/or saber saw

Level

Measuring Tape

Electric Drill and Bits

Pliers

Square

Tin Snips

Before You Start:

Plan your installation. Read these instructions and the fireplace installation manual before installing unit and vent system. Set unit in

place and survey how best to vent the unit. After the vent configuration has been decided, stretch the flex pipe components out, then trim

off what will not be needed.

Refer to the fireplace installation manual for information on vertical venting requirements. The maximum length of vent when using flex

venting is 35 feet total. Contact your dealer or distributor for information on flex vent extension kits that may be added to the DVVK4FV kit, in order to terminate up to 35 feet. Available extension kits include the DVEK-10 (10’ Flex) or the DVEK-25 (25’ Flex) exten

sion kits. The extension kits include connection hardware.

Installation of the Vertical Flex Termination Kit

Framing Materials

Wall Finishing Materials

Caulking Material (Noncombustible)

Support Strap supplies

-

WARNING

Ensure that the venting system exits the structure through the roof and does not terminate less than 12 inches (305mm) above the

roof.

WARNING

Refer to your fireplace homeowner’s manual for the minimum and maximum venting requirement of your fireplace prior to installa

tion. Failure to do so may cause a fire hazard.

WARNING

This flexible pipe termination kit is ONLY for vertical terminations.

WARNING

Any horizontal run section must have a 1/4” rise for every one (1) foot of run towards the vent termination. Never allow the vent pipe

to run downward. This could cause high temperatures and may present a fire hazard. This vertical kit may incorporate two (2) 90 de

gree bends, but must terminate vertically.

CAUTION

This flex vent kit can be installed either vertically or horizontally off of Direct Vent Series fireplaces but must only terminate vertically.

WARNING

Because of sharp edges, always use gloves when handling the flex vent components.

CAUTION

Vent connections should overlap a minimum of 1” for proper sealing.

-

-

CAUTION

Always stretch and secure venting with metal strapping secured with nails (nails and strapping not supplied) to ensure that the flex

vent runs remain true.

INSTALLATION NOTE:

If space permits, it is generally easier to attach venting in the top vent configuration.

23340-4-0608 Page 19

Page 20

NAILS

(4) REQ'D

.

THIMBLE

FIRESTOP

CEILING FRAMING

9½” Min.

(241mm)

9½” Min.

(241mm)

NOTE: ADDITIONAL

HOLES FOR ADJUSTING

THIMBLE UP OR DOWN

AS NEEDED

FLEX OUTER

AIR INTAKE PIPE

SPACER SPRINGS

FLEX

FLUE PIPE

SPACER SPRINGS

4" FLEX

VENT PIPE

12”

305m

m

12

”

305m

m

12

”

305m

m

12

”

305m

m

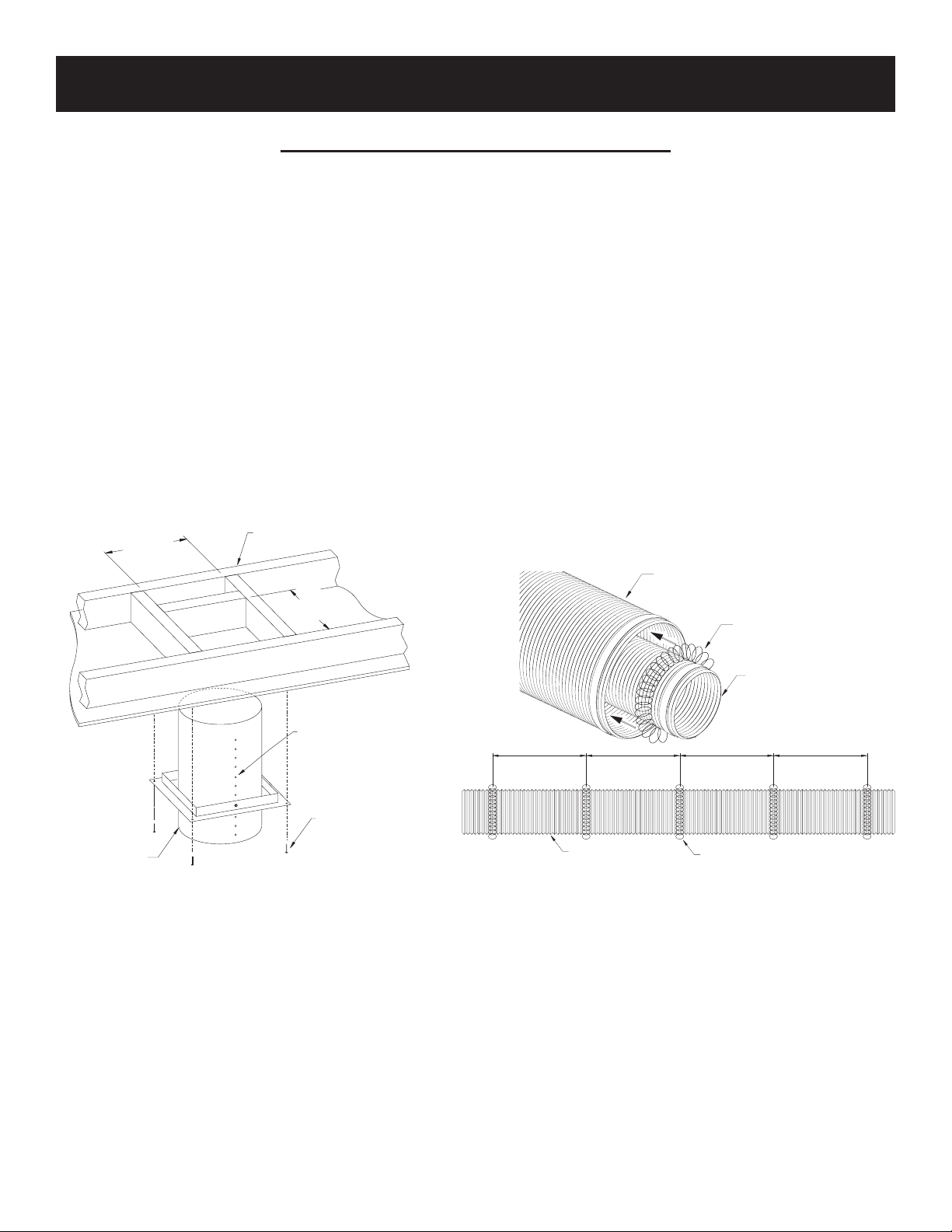

DVVK-4FV DIRECT VENT TERMINATION KIT (continued)

Step-By-Step Installation For Flex DV Kit

1. Unpack vent components and check all items for shipping

damage.

2. For this venting system to operate as designed it is dependent on the use of all parts and procedures detailed in these

instructions. Failure to follow these instructions may potentially affect the performance of this vent system and the attached appliance.

3. As per the fireplace manufacturer’s instructions, replace the

existing 6 5/8” diameter fireplace vent adapter with the 7”

diameter flex vent fireplace adapter included in the vent kit.

Install the adapter collar with the screws removed from the

standard fireplace collar. Refer to the fireplace manual for additional information on the vent collar removal and installation.

4. Once the fireplace location has been determined, mark the

ceiling where the flex vent will pass through. Cut an opening

for installation of the firestop thimble assembly. The opening must measure a minimum of 9-1/2” x 9-1/2” square. See

Figure 27.

5. Next, determine the location for the cutout in the roof open

ing. This opening must be large enough to provide a minimum 1” air space clearance from the vertical vent pipe to any

combustible framing.

6. Install the Firestop/Thimble assembly to the framed opening

in the ceiling using common nails or screws.

Note: The thimble assembly is adjustable up or down as

needed within the firestop. It is also designed with a pivoting

firestop for use with 0 - 3/12 pitch cathedral ceilings.

7. To begin vent system assembly, first layout all the vent components on the floor in the order in which they will be assembled.

8. Stretch the 4” diameter inner flex flue and 7” diameter outer

flex vent to the maximum length of 6 feet.

9. Install the spring spacers provided around the 4” diameter

flex flue at 1 foot intervals, then slide the flue pipe with spacers into the 7” diameter outer flex vent pipe. Make sure the

springs are spaced evenly starting at 12 inches from the fireplace collar. See Figure 28.

-

Figure 27

Figure 28

23340-4-0608Page 20

Page 21

10. With the flex vent assembly and the 48” long hard pipe

WING NUT (2)

PIPE CLAMP

ROOF BRACKET (2)

NUT (2)

SCREW (2)

H

X

12

ROOF PITCH IS X/12

H (Min.) - Minimum height from

roof to lowest discharge opening

DISCHARGE

LOWEST

OPENING

VENT CAP

GAS VENT

components laid out on the floor, begin securing these parts

together. First, apply a generous bead of silicone sealant to

the inside of the 4” diameter flex flue (not the end with the

pre-installaed connector), then slide the flex flue over the 4”

diameter hard pipe flue. Be sure to overlap at least 1-1/4”. Secure this connection with a 4” diameter band clamp provided.

Be careful not to damage or tear the flex flue when tightening

clamp.

11. Repeat the connection process for the outer 7” diameter flex

vent to hard pipe connection. Use silicone sealant at this joint

also, overlap at least 1-1/4”, then secure the joint with the 7”

diameter band clamp provided. Be careful not to damage or

tear the flex vent pipe when tightening the clamp.

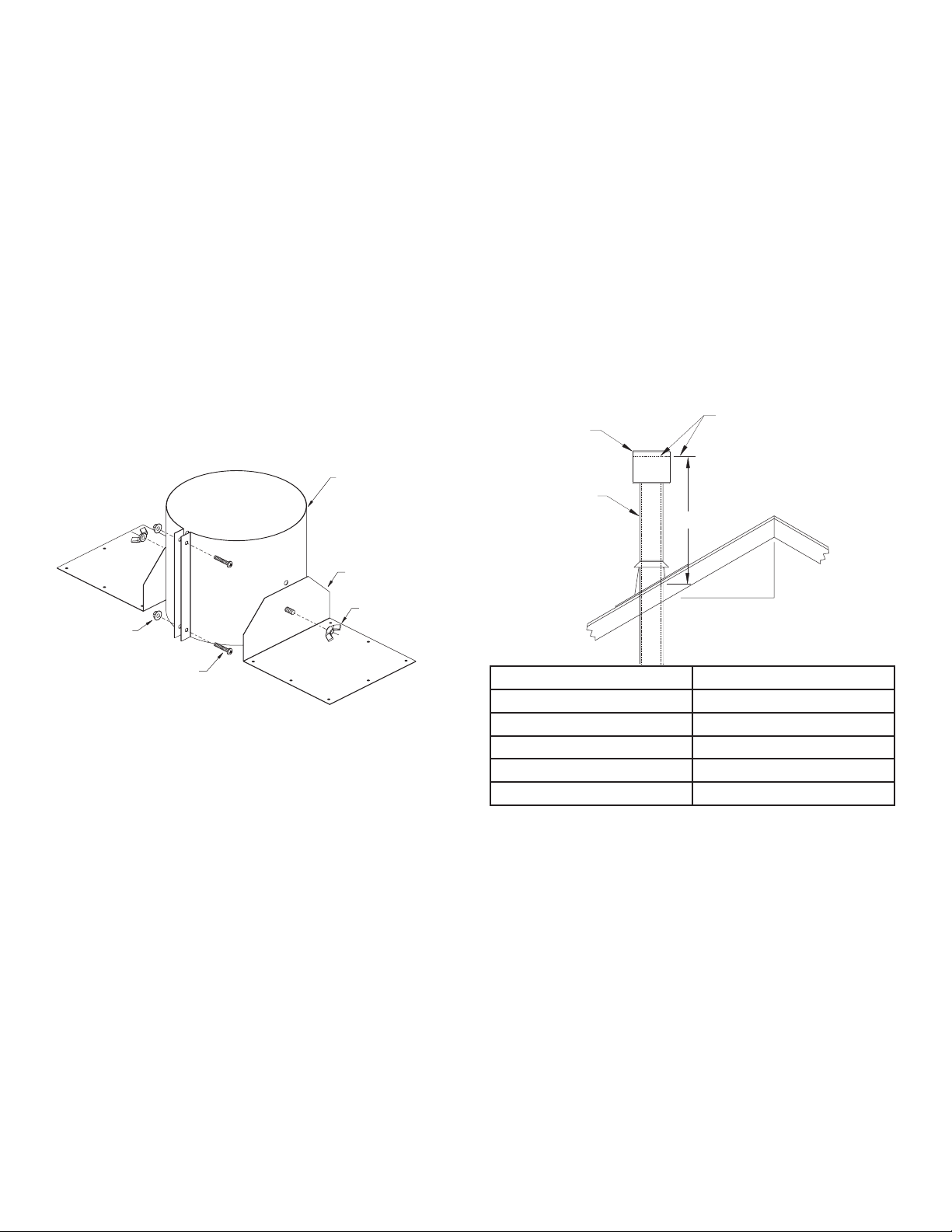

12. While the venting is still on the floor, assemble the roof jack

components as shown in Figure 29 and pre-install the roof

jack assembly to the hard pipe approximately 18” from the

top end of the hard pipe.

13. Now the pre-assembled vent system may be carried to the

roof, then lowered through the roof cutout opening (see step

5). Feed the flex vent end down through the roof opening and

firestop/thimble assembly installed in steps 4 through 6.

14. Secure the roof support assembly to the roof sheathing with

at least (4) nails/screws through each support bracket. Check

that the combustible clearances through the roof framing will

maintain at least a 1” clearance from the vent pipe.

15. Determine how high the vent terminal should be located

above the roof line based on the roof pitch information shown

in Figure 30. Adjust the vent system height by loosening the

pre-installed roof support pipe clamp and sliding the vent

pipe up or down as pre-determined, then re-tighten the pipe

clamp. Install a couple of sheet metal screws through the pipe

clamp into the outer hard vent pipe to lock in place.

16. Check to make sure that the bottom end of the flex vent is

long enough to reach the fireplace adapter collars. If too long,

trim off the extra flex vent not needed.

ROOF PITCH H (Min.)

Flat to 6/12 12” (305mm)

Figure 29

6/12 to 7/12 15” (381mm)

Over 7/12 to 8/12 18” (457mm)

Over 8/12 to 16/12 24” (610mm)

Over 16/12 to 21/12 36” (914mm)

Figure 30

23340-4-0608 Page 21

Page 22

BAND CLAMP

APPLY HIGH

TEMPERATURE

SEALANT

(WITH GASKET)

ADAPTER COLLAR

7" DIA. INLET

4" DIA. FLU

E

ADAPTER

COLLAR

FLUE PIP

E

4" DIA. FLEX

7” DIA. FLEX AIR

INTAKE PIPE

Vent Cap

Storm

Minimum

Clearance to

Combustibles

Collar

Exterior

Roof

Roof

Flashing

Support

Roof

Assembly

7"(178mm) Dia.

Must Extend

7"(178mm) Dia.

Hard Pipe

Through Roof

Flashing

1” (25mm)

Flex

DVVK-4FV DIRECT VENT TERMINATION KIT (continued)

17. To attach the vent connections at the fireplace, be sure the 7”

diameter adapter collar has been installed per step 3. Apply

a bead of silicone sealant to the 4” diameter flex connector,

then slide the flex pipe adapter collar into the fireplace flue

collar and secure by installing a minimum of two (2) screws

through the flue collar and into the adapter. See Figure 31.

18. Apply sealant to the 7” diameter adapter collar, slide outer

flex vent over the collar, then secure with a 7” diameter band

clamp. See Figure 31.

19. Once the lower connections are made and the flex pipe is

secured with support bands as required (3 feet minimum between supports) then the roof flashing can be installed. See

Figure 32.

20. Install the roof flashing, and seal using common constructions practices.

21. An additional storm collar band is provided in kit that may be

used as an attic insulation shield. The collar can be installed

around the flex pipe (or hard pipe) just above the firestop

thimble. This collar will act as a shield to prevent blown insulation from entering the thimble.

22. To complete the vent installation, install the vent termination

cap to the top of the hard vent pipe assembly. Mate up the flue

and outer telescopes with the hard pipe assembly, then secure

by installing a minimum of two (2) sheet metal screws into

the overlapped flanges of the cap and pipe.

23. Figure 33 shows a completed installation with components

identified and other installation information such as heights

and clearance to combustibles.

LP and Nat models

Figure 31

Figure 32

23340-4-0608Page 22

Page 23

Storm

Clearance to

Combustibles

Collar

Exterior

Roof

Roof

Flashing

Roof Jack

Adjustable

Assembly

4' Long Rigid Pipe

Direct Vent

Fireplace

Required From

Vent Pipe

Firestop/Thimble

Ceiling

Straps (As Req'd.)

Venting Support

With Gasket & Clamps

7" Dia. Adapter Collar

4" Dia. Flue Connector

Assembly

Firestop/Thimble

Adjustable

Storm Collar (Use TO

Keep Insulation Out Of

Inlet Vent Connections

Clamps

At Flue &

Vertical Termination

Thimble Assembly)

35 ft. Max

Note: DVVK-4VF Kit

Maximum Height

(including fireplace) Is

13’. To

Extend Vent

Run, an Additional

Ve

nt Extension Kit

Is Necessary

Figure 33

23340-4-0608 Page 23

Page 24

DVVK-4FV DIRECT VENT TERMINATION KIT (continued)

Vertical Flex Termination Kit

Item

Number Item Description Repair Part No.

1 4”/7” Vertical Termination Cap MF100038 1

2 Roof Support Kit MF100503 1

3 2 Ply Alum Flex 4” Diameter by 6 ft. MF04ALA2F006 1

4 2 Ply Alum Flex 7” Diameter by 6 ft. MF07ALA2F006 1

5 4”/7” x 48” Rigid Pipe Assembly MF100554 1

6 Firestop Thimble Assembly MF100124 1

7 Roof Flashing (0/12 to 6/12) MF100091 1

8 7” Flex Adapter Collar with Gasket MF100524 1

9 7” Storm Collar MF100147 2

10 Spring Spacers MF100548 5

N/S Clamp 4” Diameter MF100330 2

N/S Clamp 7” Diameter MF100534 2

N/S #8 x 1/2” Self Drilling Screws N/A 20

N/S HT Silicone N/A 1

N/S #8 x 5/8” Self Drilling Screws N/A 10

Quantity

Supplied

23340-4-0608Page 24

Page 25

24”

24” MINIMUM

CLEARANCE TO

COMBUSTIBLES

EXAMPLES - TOP VENT RUN

LP and Nat models

Figure 34

LP and Nat models

Figure 35

LP and Nat models

Figure 36

23340-4-0608 Page 25

Page 26

VERTICAL

DIMENSION

FROM

THE

BOTT

OM

OF

THE

UNIT

TO

THE

CENTER

OF

THE

FLUE

OUTLET

WITH

VERTICAL

OR

HORIZONT

AL

TERMINA

TION

CAPS

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

HORIZONTAL RUN

REAR EXIT - VERTICAL AND HORIZONTAL TERMINATION

(DIMENSIONS

IN FEET)

REAR HORIZONTAL

VENT CONNECTION

B

A

VENTING FIREPLACE - REAR (NAT GAS MODELS ONLY)

To Use the Vent Graph (Figure 37)

1. Determine the height of the center of the

horizontal vent pipe. Using this dimension on

the Sidewall Vent Graph, locate the point it

intersects with the slanted graph line.

2. From the point of this intersection, draw a vertical

line to the bottom of the graph.

3. Select the indicated dimension, and position the

unit in accordance with same.

EXAMPLE A:

If the vertical dimension from the floor of the unit

is 12 feet, 4 inches the horizontal run to the outer

wall flange must not exceed 12 feet, 3 inches.

EXAMPLE B:

If the vertical dimension from the floor of the unit

is 6 feet, 9 inches, the horizontal run to the outer

wall flange must not exceed 6 feet, 6 inches.

SPECIAL NOTE: For each 45 degree elbow

installed in the horizontal run, the length of the

horizontal run MUST be reduced by 18" (45cm).

This does not apply if the 45 degree elbows are

installed on the vertical part of the vent system.

Reduce 3' for every 90° elbow.

Example: According to the chart the maximum

horizontal vent length is 20' and if two 45 degree

elbows are required in the horizontal vent it must

be reduced to 17'.

The maximum number of 45 degree elbows

permitted per side wall installation is two (2).

These elbows can be installed in either the vertical

or horizontal run.

Note: Only natural gas models can be rear

vented.

Venting Graph (Dimensions in Feet)

Figure 37

Acceptable vertical and horizontal vent run.

Unacceptable vertical and horizontal vent run.

23340-4-0608Page 26

Page 27

EXAMPLES - REAR VENT RUN

Nat models only

Figure 40

Model Maximum Pipe

Length H1

DVP36 24"

Nat models only

Figure 38

Model Maximum Pipe

DVP36 24"

Nat models only

Figure 39

Length H1

Nat models only

Figure 41

23340-4-0608 Page 27

Page 28

TERMINATION CLEARANCES

Termination clearance for buildings with combustible and noncombustible exteriors.

Figure 42

Vertical Sidewall Installations

Important! Minimum clearance between vent pipes and combustible materials is three (3

and sides.

Important! When vent termination exits through foundation less than 20" below siding outcrop, the vent pipe must extend outward so

that the horizontal vent terminal is located flush to, or beyond the outcrop siding.

Information on Various Venting Routes and Components

Important: It is always best to locate the fireplace in such a way that minimizes the number of offsets and horizontal vent length.

Since it is very important that the venting system maintain its balance between the combustion air intake and the flue gas exhaust, certain

limitations as to vent configurations apply and must be strictly adhered to.

The graph showing the relationship between vertical and horizontal side wall venting will help to determine the various vent lengths

allowable.

The horizontal vent run refers to the total length of vent pipe from the flue collar of the fireplace to the face of the outer wall.

The maximum horizontal vent run is 20 feet (457 cm) when the vertical vent rise is 8 feet (244 cm). See Figure 20.

Venting terminals shall not be recessed into wall or siding.

") (76mm) on top, and (1") (25mm) on bottom

23340-4-0608Page 28

Page 29

VENT CLEARANCES

Figure 43

A = *Clearance above grade, veranda, porch, deck or balcony

[*12 inches (30cm) minimum]

B = clearance to window or door that may be opened [*12 inches

(30cm) minimum for appliances < 100,000 Btuh (30kW)

C = clearance to permanently closed window [minimum 12

inches (30cm) recommended to prevent condensation on

window]

D = vertical clearance to ventilated soffit located above the

terminal within a horizontal distance of 24 inches (60 cm) from

the center of the terminal [18 Inches (46 cm) minimum

E = clearance to unventilated soffit [12 inches 30cm)

minimum]

F = clearance to outside corner. See Page 28.

G = clearance to inside corner. See Page 28.

H = *not to be installed above a meter/regulator assembly

within 3 feet (90cm) horizontally from the center-line of

the regulator

I = clearance to service regulator vent outlet [*6 feet (1.8m)

minimum]

J = clearance to non-mechanical air supply inlet to building or

the combustion air inlet to any other appliance [*12 inches

(30cm) minimum for appliances ≤ 100,000 Btuh (30 kW)

36 inches (90cm) minimum for appliances > 100,000 Btuh

(30kW)]

K = clearance to a mechanical air supply inlet [* 6 feet (1.8m)

minimum]

L = †clearance above paved sidewalk or a paved driveway located

on public property [*7 feet (2.1m) minimum]

M = clearance under veranda, porch, deck, or balcony [*12 inches

(30cm) minimum ¥]

† a vent shall not terminate directly above a sidewalk or

paved driveway which is located between two single family

dwellings and serves both dwellings*

¥ only permitted if veranda, porch, deck, or balcony, is fully

open on a minimum of 2 sides beneath the floor*

* as specified in CGA B149 Installations Codes or ANSI

Z223.1. Note: Local Codes or Regulations may require

different clearances.

23340-4-0608 Page 29

Page 30

WALL THIMBLE

(MAXIMUM

OF

THREE 90 ELBOWS)

(MAXIMUM OF

TWO 90 ELBOWS)

VENT SYSTEM IDENTIFICATION

Installing Vent Components (Figure 44)

Begin the vent system installation by installing the first Simpson Duravent

component, 90° elbow to the starting collars or straight pipe on the top of

the appliance, then the straight pipe length and then horizontal or vertical

termination kit.

NOTE: All outer connection joints must be sealed with aluminum

tape, screws or silicone sealant rated above 300°F/149°C. The inner

flue joints do not require any sealant.

Simpson Duravent vent system components lock into place by sliding the

concentric pipe section with four (4) equally spaced interior beads onto

the appliance collar or previously installed component end with four (4)