Page 1

Manual available online at wkfluidhandling.com

CPT-1 Product Manual

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 2

Table of Contents

1. System Recommendations .................................................................................................................................1

1.1 Precautions .......................................................................................................................................................1

1.2 System Environment Recommendations/Requirements ..................................................................................1

1.3 Getting Started ..................................................................................................................................................1

2 Parts List ..................................................................................................................................................................2

2.1 CPT-1 Cycle Rate Translator ............................................................................................................................2

2.2 Power Adapter with Crimp Pins ........................................................................................................................3

2.3 Cable: 44-Pin HD D-Sub to Wire Leads ...........................................................................................................3

2.4 Breakout Board: 44-Pin HD D-Sub to Screw Terminal .....................................................................................3

2.5 Din Rail Power Supply ......................................................................................................................................3

2.6 Quick Connect: 44-Pin HD D-Sub to Connectors .............................................................................................3

3 System Overview .....................................................................................................................................................3

4 Power and Communication .....................................................................................................................................4

4.1 Powering the CPT-1 ..........................................................................................................................................4

4.2 Ethernet Connection: ........................................................................................................................................5

4.3 RS-232 Connection: ..........................................................................................................................................5

5 Digital I/O Setup .......................................................................................................................................................5

5.1 Power Digital Ports ...........................................................................................................................................5

5.2 Digital Inputs: ....................................................................................................................................................5

5.3 Digital Outputs:..................................................................................................................................................7

5.4 Wiring Configurations ........................................................................................................................................8

6 PC to CPT-1 Communication: .................................................................................................................................9

6.1 Ethernet Connection: ........................................................................................................................................9

6.2 RS-232 Connection: ..........................................................................................................................................9

7 Software Setup: .......................................................................................................................................................9

7.1 Installation: ........................................................................................................................................................9

7.2 Using the Software: ...........................................................................................................................................9

7.3 Software Inputs: ............................................................................................................................................. 10

8 Troubleshooting Q & A: ........................................................................................................................................ 12

8.1 Issues connecting to CPT-1 via Ethernet: ..................................................................................................... 12

8.2 Issues Connecting to CPT-1 via RS-232: ...................................................................................................... 12

9 Appendix 1: Complete Wiring Guide Table .......................................................................................................... 13

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 3

10 Appendix 2: Dimensional Diagrams ................................................................................................................... 16

DO NOT OPEN CONTROL BOX

Do not open up the control box. White Knight is not responsible for any damage caused by opening the

control box.

Environmental Temperature

This product is rated to withstand environmental temperatures up to 70°C.

Grounding

All electrical components must be ground to minimize risk of sparks. Follow proper procedures for

grounding all products in the system.

11 Ordering Instructions .......................................................................................................................................... 17

1. System Recommendations

1.1 Precautions

1.2 System Environment Recommendations/Requirements

1.3 Getting Started

Installing the CPT-1 for the first time it is recommended that you follow these steps:

1) Verify that you received all of the components that you ordered. Note: cables and breakout board for the

controller are options that can be selected at the time of purchase.

2) Check that you have a compatible power supply to power the controller. See Section 4.1

3) Check that you have a compatible communication cable for setting up the controller. See Sections 4.2 and 4.3

4) Download the setup software from www.wkfluidhandling.com/cpt-1.

5) Verify that your computer is able to connect to the controller.

a) Power up the controller with correct power source

b) Connect the communication cable correctly. (Ethernet cables should go from the controller to a network

switch, not your PC)

c) Install and launch the Smart Control Software.

d) The connections dialog should appear at launch. Verify that your controller appears on the list and click

the connect button. See Section 7

e) Once connectivity is verified disconnect from the software, and disconnect power and communication

cable.

6) Install CPT-1 in the desired location.

7) Connect 44-pin connector and use the wiring guide in Section 5 to connect system.

8) Connect to controller (same as before) and configure the CPT-1 settings to match your system needs.

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 4

2 Parts List

Quantity of parts for each configuration callout

Part Numbers

Description

CPT-1

-W

-S

-Q

-P

8600-XX-0011

Translator Controller

1

8600-XX-0020

2 Pin Molex Connector

1

-1

8600-XX-0021

Molex Crip Pin

2

-2

8600-XX-0013

44 Pin Cable to Wire Leads

1

8600-XX-0018

Screw Terminal Breakout Board

1

14910-XX-0007

Controller Power Jumper Assembly

1 8600-XX-0061

44 Pin Quick Connection Board

1 8600-XX-0063

2 Pin Quick Connector

1

8600-XX-0064

4 Pin Quick Connector

16

10010-NY-0002

#4-40 ½” Thumb Screw

2 8600-XX-0015

24 VDC Power Supply

1

Power port

Ethernet

Indicator Lights

44-Pin

Connector

Figure 1: The CPT-1 Controller and communication ports.

RS-232

Part list by configuration options:

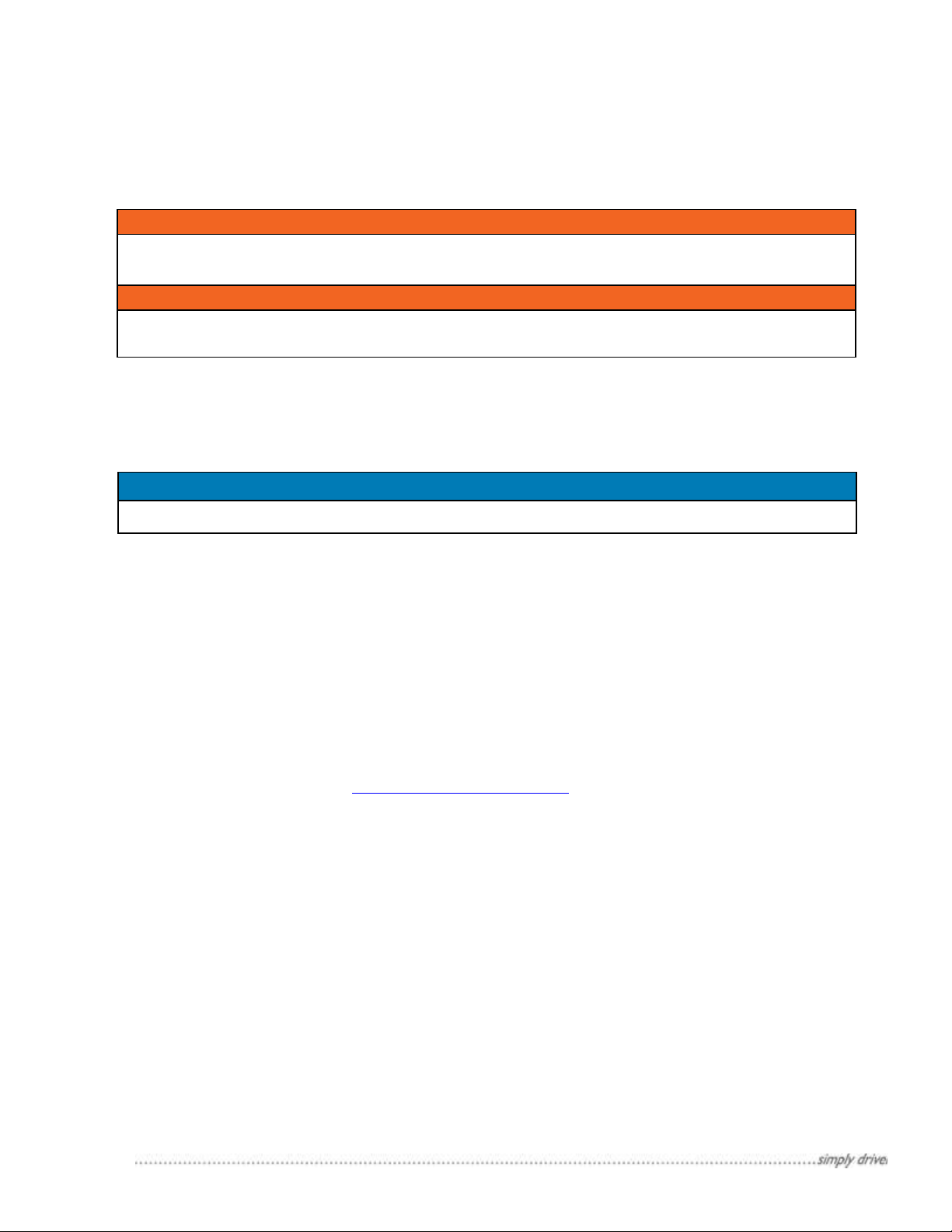

2.1 CPT-1 Cycle Rate Translator

The CPT-1 control box is a small I/O communication device that converts the pump’s cycle rate to the cycle rate

that works with the tool’s algorithm. The control box has:

• 44-pin HD D-Sub Connector: Sends and receives digital signals.

• Indicator Lights: Show when each digital signal is active.

• Power Port: Takes 18-36 VDC input to power the controller.

• Ethernet Connector: This is used by the setup software to configure the controller.

• RS 232 serial communication: This is an alternate method of connecting to configure the controller.

Figure 1 shows an image of the WK CPT-1 controller with the above features labeled.

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 5

2.2 Power Adapter with Crimp Pins

2.6 Quick Connect: 44-Pin HD D-Sub to Connectors

(Pin reference start at one from top as shown in image below)

2.4 Breakout Board: 44-Pin HD D-Sub

to Screw Terminal

2.3 Cable: 44-Pin HD D-Sub to Wire

2.5 Din Rail Power Supply

Power Connector:

• Pin 2: 24 VDC Power

Digital Output Connector:

Pin 1: 24 VDC Power

Type) Output

Digital Output Connector:

• Pin 1: 24 VDC Power

• Pin 2: Ground

• Pin 3: High Reference

(NPN Type) Input

• Pin 4: Low Reference

(PNP Type) Input

3 System Overview

•

• Pin 2: Ground

• Pin 3: Source (PNP

Type) Output

• Pin 4: Sink (NPN

• Pin 1: Ground

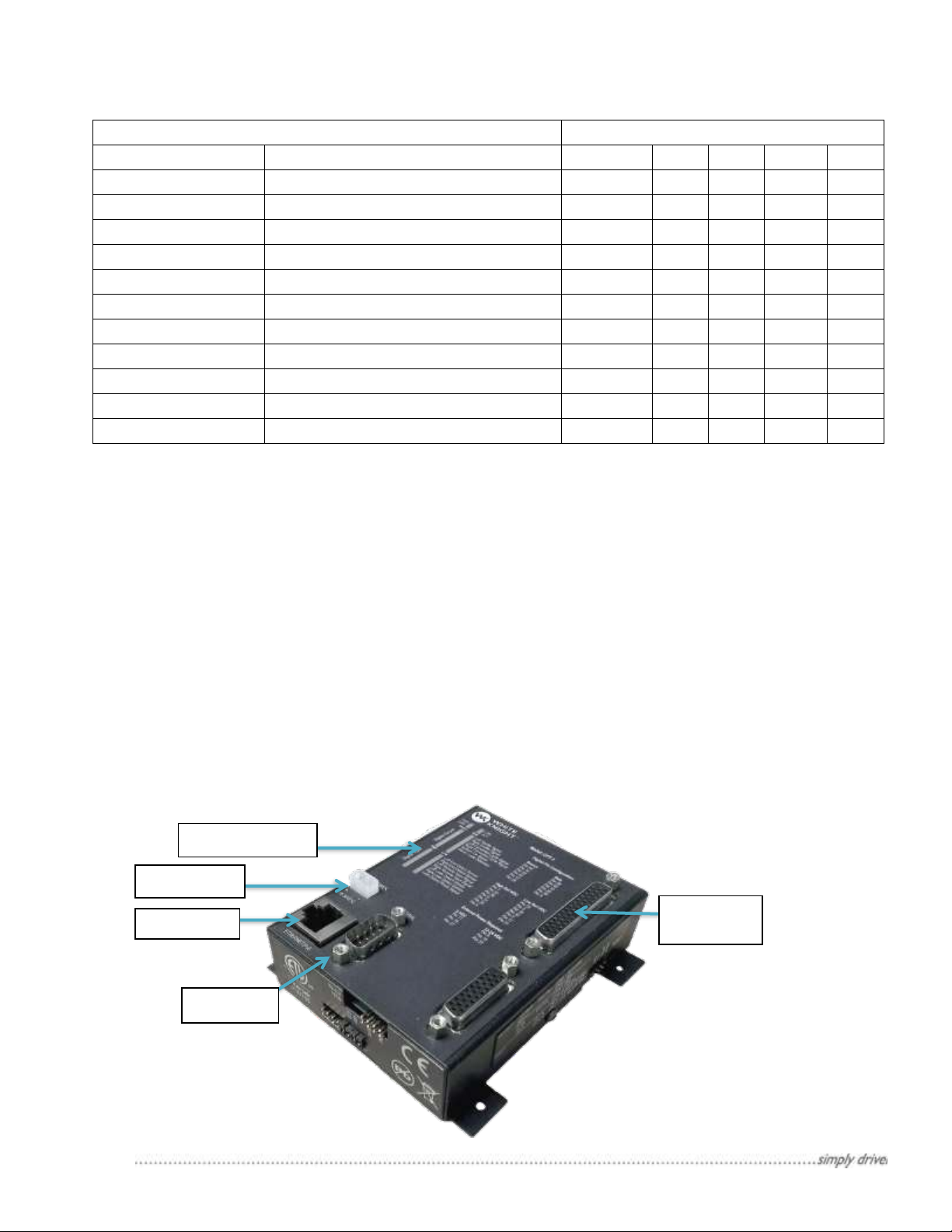

The CPT-1 has been designed to be an interface between the tool’s algorithm and a pneumatic pump. This interface

is needed when inserting an alternate pump into an existing tool; frequently the alternate pump will have a different

cycle rate than the previous pump which may cause the tool to alarm out.

The CPT-1 is able to operate the pneumatic pump at the cycle rate that is optimal for the pump. Then, the CPT-1

will scale the pump’s cycle rate by a factor set by the user and send the scaled cycle rate back to the tool. The CPT1 can be configured to work with any system setup.

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 6

PoE EXT

The Tool sees the scaled

CPT-1.

The pump operates in

or End Stroke/Oscillate

WK CPT-

1

Tool

Algorithm

WK Pump

Scaled Cycle Rate Operation

Figure 2: Illustration of how the CPT-1 maintains two separate communication loops. The CPT-1

will run the pump and calculate its cycle rate (shown with black arrows). The CPT-1 will scale the

cycle rate and communicate the scaled cycle rate back to the tool (shown with gray arrows)

Figure 4: External power/Power over Ethernet selection jumpers.

Shown in figure is the default setup supporting external power

Figure 3: External power connector.

cycle rate from the WK

the current mode: End

Stroke Detect, Oscillate,

4 Power and Communication

4.1 Powering the CPT-1

There are two methods of powering the CPT-1: 18-36 VDC power connector and Power over Ethernet (PoE).

By default the CPT-1 is setup to use the external power adapter. Simply connect an appropriate DC power to the

connector as shown in Figure 3.

To setup PoE, find the jumpers labeled EXT and PoE on the bottom face of the controller. See figure 4. Move the

jumpers from EXT to PoE locations. POE can now be used.

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 7

4.2 Ethernet Connection:

Pin Name

Pin #

Wire Color

Designation

Levels

Notes

Power:

Source

Outputs

15 Red/

Black Stripe

Power Source

12-24 VDC

The voltage input into these pins power

all of the source type outputs.

* The voltage input will equal the voltage

output from these ports.

27

Red/

White Stripe

Ground Reference

0 VDC

Power:

Sink Outputs

8

Green

Power Source

12-24 VDC

The voltage input into these pins will

power the sink type outputs.

11

Orange

Ground Reference

0 VDC

Power:

Input High

37

Violet/

Red Stripe

Reference Voltage

High

12-24 VDC

The Voltage input into this pin will be the

reference for all digital high inputs.

Power:

Input Low

19

Orange/

Black Stripe

Reference Voltage

Low

0 VDC

The Voltage input into this pin will be the

reference for all digital low inputs.

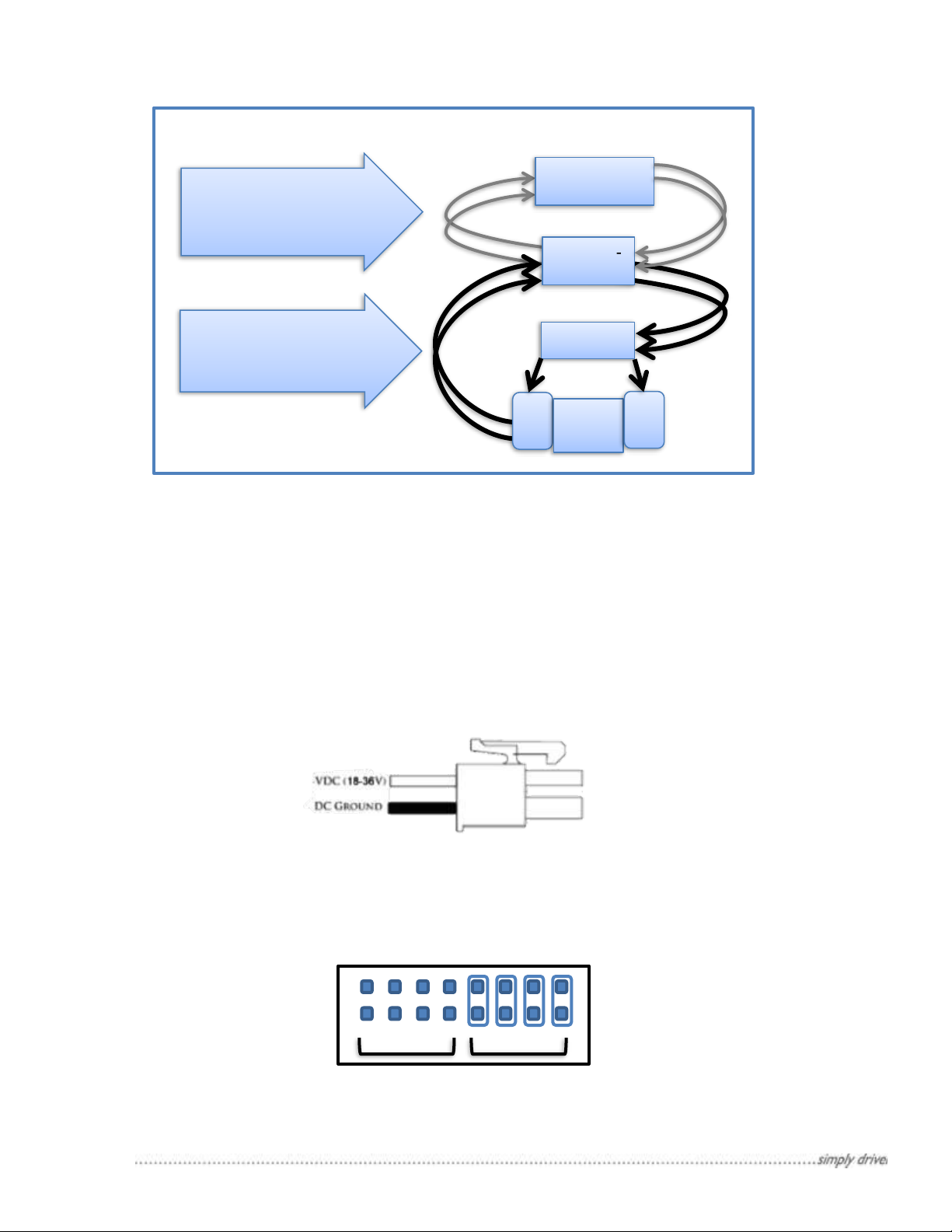

Table 1: Wire connections for powering the digital ports. All ports should be connected

The Ethernet connection is available for PC to CPT-1 communications. These communications are available for

setting up the software, and for on screen controls. After the controller has been setup the settings can be saved

and disconnected to be run as a standalone unit. The CPT-1 uses two industry standard Ethernet connection

protocols TCP/IP and UDP/IP, the controller will automatically respond in the format in which it is connected.

When connecting to the WK Controller to a local network. The WK Controller will look to the server to assign it an

IP address; this is supported on both DHCP and BOOT-P server protocols.

4.3 RS-232 Connection:

An RS-232 connection can be created through the 9 pin serial port on the box. When opening the software the

RS-232 port will show as a COM port and will give two baud rate options, 19200 and 115000. The default baud

rate is 115000, however the slower 19200 baud rate can be selected by placing a jumper on the connection

labeled 19.2 on the upper right side of the control box.

5 Digital I/O Setup

5.1 Power Digital Ports

The digital ports are not powered by the controller. An external power supply is required for the digital ports to be

active. Use Table 1 for digital port power connections.

* Note: When using the quick connection board simply connect power to one of the power ports, then power will

be distributed to all of the correct locations. See markings on the board for power and ground pins. The second

power port is to jumper power to the controller.

5.2 Digital Inputs:

Each digital input can be wired into either a high or low voltage reference see Table 2.

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 8

Pin Name

Pin #

Wire Color

Designation

Levels

Note

Digital Input:

Remote Left

[DI_2]

36

Yellow/

Red Stripe

High VDC Reference

24 V = Not Active

0 V = Active

When one of these

connections becomes active,

the CPT-1 will turn on and start

controlling the pneumatic

pump. Disconnect the left and

right inputs from the shuttle

and connect these signals to

the appropriate high or low

voltage reference on the CPT-1.

18

Green/

Black Stripe

Low VDC Reference

0 V = Not Active

24 V = Active

Digital Input:

Remote Right

[DI_3]

6

Blue

High VDC Reference

24 V = Not Active

0 V = Active

32

Gray/

Red Stripe

Low VDC Reference

0 V = Not Active

24 V = Active

Digital Input:

End Detect Left

(Full Cycle Signal)

[DI_0]

7

Brown

High VDC Reference

24 V = Not Active

0 V = Active

The left end detect is used to

count each full cycle. If using a

shuttle-operated pump,

connect a pressure switch or

end detect sensor to the left

end detect signal.

If using a solenoid valve-

operated pump, connect both

the left and right end detect

sensors such that the signal is

active when the sensor is

triggered.

33

Light Green/

Red Stripe

Low VDC Reference

0 V = Not Active

24 V = Active

Digital Input:

End Detect Right

[DI_1]

22

Gray/

Black Stripe

High VDC Reference

24 V = Not Active

0 V = Active

3

Red

Low VDC Reference

0 V = Not Active

24 V = Active

Digital Input:

Leak Detect Left

[DI_4]

21

Brown/

Black Stripe

High VDC Reference

24 V = Not Active

0 V = Active

For systems that do not

support a leak detect function

to turn off the pump when

leaks are detected, leak detect

signals can be brought into

these digital inputs. When the

leak detect signal is active, the

CPT-1 will stop the pump and

wait for the reset signal before

the pump will restart.

2

White

Low VDC Reference

0 V = Not Active

24 V = Active

Digital Input:

Leak Detect Right

[DI_5]

35

Pink/

Red Stripe

High VDC Reference

24 V = Not Active

0 V = Active

17

Violet/

Black Stripe

Low VDC Reference

0 V = Not Active

24 V = Active

Digital Input:

Alarm Reset

[DI_6]

5

Violet

High VDC Reference

24 V = Not Active

0 V = Active

When alarms are enabled: leak

detect, or speed alarms it is

recommended that the alarm

reset signal is connected. This

can be wired into the tool or to

a physical button located near

the pump. f

31

Blue/

White Stripe

Low VDC Reference

0 V = Not Active

24 V = Active

Table 2: List of all digital input connections with a description of behaviors

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 9

5.3 Digital Outputs:

Pin Name

Pin #

Wire Color/

Stripe

Designation

Levels

Note

Digital Output:

Left Solenoid

[DO_0]

26

Orange/

White Stripe

Sink

Relay Open = Not Active

Relay Closed = Active

The CPT-1 will turn

on the left and right

solenoid signals to

control a solenoid-

operated pump. If

using a shuttleoperated pump

these connections

are not required.

44

Light Green/

Green Stripe

Source

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Right Solenoid

[DO_1]

40

Red/

Green Stripe

Sink

Relay Open = Not Active

Relay Closed = Active

14

White/

Black Stripe

Source

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Left Translated

Cycle Rate

[DO_2]

10

Light Blue

Sink

Relay Open = Not Active

Relay Closed = Active

This is the output to

tell the tool about

the modified cycle

rate. If the tool is

only looking for one

signal indicating a

full cycle rate, only

connect one of these

to the tool.

Otherwise connect

both left and right to

the tool.

29

Brown/

White Stripe

Source

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Right Translated

Cycle Rate

[DO_3]

25

Pink/

Black Stripe

Sink

Relay Open = Not Active

Relay Closed = Active

43

Light Blue/

Green Stripe

Source

Relay Open = Not Active

Relay Closed = Active

Digital Output:

System On

[DO_4]

39

Orange/

Green Stripe

Sink

Relay Open = Not Active

Relay Closed = Active

This is to indicate

that the system is

on. This input is

required when

operating a shuttle

pump. However this

can also be used as

verification that the

system is

operational.

13

Pink

Source

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Leak Alarm

[DO_5]

9

Gray

Sink

Relay Open = Not Active

Relay Closed = Active

This output is to alert

the user that a leak

was detected.

28

Violet/

White Stripe

Source

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Over Speed

Alarm

[DO_6]

24

Light Green/

Black Stripe

Sink

Relay Open = Not Active

Relay Closed = Active

This output is to alert

the user that the

pump was operating

faster than the set

threshold

42

Brown/

Green Stripe

Source

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Under Speed

Alarm

[DO_7]

38

Gray/

Green Stripe

Sink

Relay Open = Not Active

Relay Closed = Active

This output is to alert

the user that the

pump was operating

slower than the set

threshold

12

Light Green

Source

Relay Open = Not Active

Relay Closed = Active

Table 3: List of digital output wiring with designations

The CPT-1 sends out signals to control or be read by other devices. There are two types of digital outputs, voltage

source or a voltage sink. The CPT-1 will turn on both corresponding voltage source and sink when it turns on an

output. Generally, components that may have a higher current draw should be connected to the voltage s ink.

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 10

Tool Communication

Pump Type

Leak Detection**

End

Stroke

Detection

On-Off

with Cycle

Counter

Cycle

Counter

Only

Solenoid

Pump

Shuttle

Pump

Tool

CPT-1

Digital Input

Remote Left

From Tool

From Tool

Hard

Wire

Active

Remote Right

From Tool

End Detect Left

From

Pump

From

Pump

End Detect Right

From

Pump

Leak Detect Left

From

Pump

Leak Detect Right

From

Pump

Leak Reset

From

Physical

Button or

Tool

Digital Output

Left Solenoid

To

Solenoid

Right Solenoid

To

Solenoid

Left Translated Cycle Rate

To Tool

To Tool

To Tool

Right Translated Cycle Rate

To Tool

System On

To Air

Valve*

Leak Alarm

To Tool

or Alarm

Over Speed Alarm

(Optional)

To Tool

or Alarm

To Tool

or Alarm

Over Speed Alarm

(Optional)

To Tool

or Alarm

To Tool

or Alarm

Table 4: Wiring Selection table

5.4 Wiring Configurations

The CPT-1 works within a variety of configurations. Use Table 4 to learn which wiring connections should be

connected when setting up the CPT-1. These connections have been divided into 3 sections that need to be

selected.

• Tool Communications – The tool will need to send a signal to tell the CPT-1 to turn on-off and will need

to receive a signal from the CPT-1 for the cycle rate.

• Pump Type - The CPT-1 will send signals to open valves to operate the selected pump, and expects to

receive end detect signals from the pump.

• Leak Detection – In the case where the tool already handles leak errors from a pump, there is no need to

connect leak detection to the CPT-1; however, if the tool does not handle leak detection, this can be wired

into the CPT-1.

Select one column from each section that matches the system configuration, and then use the rows in the table to

determine how the system should be wired.

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 11

* In the case where the tool varies the air pressure to a shuttle-operated pump, there is no need to connect the

CPT-1 Connected via Ethernet

CPT-1 Connected via RS-232

Figure 5: Connections Window

system on signal to an additional air valve.

** See Pump manual for wire leak detection.

6 PC to CPT-1 Communication:

6.1 Ethernet Connection:

An Ethernet connection is only needed for using the CPT-1 setup software. After the controller has been setup, the

settings can be saved and disconnected to be run as a standalone unit. The CPT-1 uses two industry standard

Ethernet connections TCP/IP and UDP/IP the controller will automatically respond in the format to which it is

connected. When connecting the CPT-1 to a local network, it will look to the server to assign it an IP address. This

is supported on both DHCP and BOOT-P server protocols.

6.2 RS-232 Connection:

An RS-232 connection can be created through the 9-pin serial port on the box. When opening the software, the

RS-232 port will show as a COM port and will give two baud rate options, 19200 and 115000. The default baud

rate is 115000, but the slower 19200 baud rate can be selected by placing a jumper on the connection labeled

19.2 on the upper left side of the control box.

7 Software Setup:

7.1 Installation:

Download the CPT-1 setup software at wkfluidhandling.com/cpt-1. Run the installers by double-clicking on the

installer executable (.exe) file, and follow the on screen prompts. Software requires Windows XP or newer version

of Windows.

7.2 Using the Software:

1. Open “WK Cycle Rate Translator.exe”.

2. Wait for the connections window to show. If you have a CPT-1 connected to the computer via RS-232 or to

the network via Ethernet, it will show in the connections window. See Figure 5 for an image of the

connections window.

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 12

3. Select your controller and click “Connect”. (If the controller does not show, you can click “Cancel” and

Figure 6: Controls Window

proceed to the next screen where you can try connecting again.)

4. Wait for the Controls window to show. See Figure 6 for screen shot of controls window.

5. Set the desired controls parameters. See section 7.3 for more information about individual parameters.

6. When done, click “Save Defaults”. Note: if the settings are not saved, new settings will be lost when the

controller restarts.

7.3 Software Inputs:

Operation Mode: This controller can control the pump in three ways. To change between operation modes, move

the knob to the desired operation mode.

• Simulation Mode - Calibration mode runs the pump as a simple timer. Simulation mode has two functions:

1. Fiber-optic end stroke detection: To calibrate the fiber-optic sensors, set a slow cycle rate

Manual Version 1.3.1 Manual Part# 18200-LM-0038

(Recommended settings 16 CPM at 20-25 PSI). Then, turn on Simulation mode, and calibrate the

Page 13

fiber-optic sensors. After the fiber-optic sensors have been calibrated, switch the operation mode

out of Simulation mode.

2. System experimentation: When no pump is connected to the CPT-1 simulation mode can be used

to simulate how the system would operate if the pump were running at a set speed. Simulation

mode is ideal for testing that the connections are wired correctly, and for verifying how the tool will

react to different cycle rates without actually swapping out different pumps.

Warning: Simulation mode should never be used for long term operation of a pump. This will result

in premature damage to the pump.

• End Stroke Mode – End Stroke mode sends out a signal to open a valve that will cause one side of the

pump to pressurize and will wait for an end of stroke signal before switching to the other side. End Stroke

mode is recommended for applications where cycle rates may fluctuate due to variance in air supply

pressure. When operating a shuttle pump, it is required to use End Stroke mode.

• End Stroke/Timer – End Stroke/Timer mode sends out a signal to open a valve that will cause one side of

the pump to pressurize and when either the cycle timer or the end stroke is detected then the pressure will

switch to the other side. This is a specialized operation mode that is ideal for systems that expect the set

cycle rate to occur. This mode will also help protect the pump if an end detect sensor fails. This mode is

not for shuttle-operated pumps.

Cycle Rate: The cycle rate sets the default cycle rate. When the system turns on, it will start up with the default

cycle rate, and if the operation mode is set to End Stroke/Timer mode, this cycle rate will be forced as the slowest

cycle rate allowed by the system.

Scale Value: The scale value changes the speed of the converted signal back to the tool. The number represents

the ratio [Converted Cycle Rate] / [Actual Cycle Rate], thus if the scale is greater than one, the converted cycle rate

will be faster than the actual cycle rate. If the scale is less than one, the emulated cycle rate will be slower than the

actual cycle rate.

Output Percent: The output percent changes the duration of the converted signal as a percent of its duration. For

example if the signal should stay on until the signal from the opposite side turns on, set the output percent to 100%,

or if the signal should turn off shortly after turning on, set the percentage to a smaller value. Some experimentation

may be necessary to determine what output duration the tool’s algorithm is expecting.

Off Delay: The CPT-1 expects either the right or left remote signal from the tool to be on. In some cases there may

be a delay between the signal switching. The off delay will keep the system on for a set time without any signal

being sent. The default setting is one second, but can be changed from the user interface.

Dual Detect Mode: For the majority of pumps this mode should be turned off. This mode should only be turned on

in two cases:

1. A single probe dual detect pump is to be operated. In this case it is recommended that the CPT-1’s

operation mode also be set to End Stroke/Timer mode; this is recommended because it will prevent the

pump from getting out of sync in its oscillations when the pump is at dead head. Thus it is also

recommended that the cycle rate variable be set to a slower than the normal operation cycle rate so that

timer doesn’t affect normal operation.

2. A pressure switch is being used for end of stroke sensing where a double signal is being detected.

A double signal may be seen if the pressure switch is connected to an exhaust port. In this case the dual

detect mode will only count every other signal as an end of cycle signal.

Leak Alarm: When connecting leak detect through the CPT-1, the leak alarm will light up when leaks are detected

and the pump will turn off. In order to turn the pump back on, the leak reset needs to be sent.

Over Speed/Under Speed Alarms: These alarms can be configured in the alarm settings. The following describe

the alarm settings that can be configured.

• Enabled – If alarm is enabled then the alarm is allowed to occur, if disabled then the alarm will never occur.

• Threshold – The cycle rate that if passed the alarm will occur.

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 14

• On Delay – The duration in milliseconds that the over speed/under speed alarm condition is allowed to be

true before the alarm actually occurs. (This might be needed for start-up conditions)

• Auto Stop – When the alarm occurs and auto stop is enabled, then the pump will be shut down until the

reset signal has been received.

• Auto Recover – When an alarm occurs and the cycle rate returns to an acceptable operation the alarm will

turn itself off. Note: this feature will not work if the auto stop is enabled.

Save Defaults: Saving the defaults will tell the controller that the current settings are to be used as the defaults

when there are power outages. It is recommended to save the defaults after modifying any settings. If the defaults

are not saved, the controller will lose all changes made to the settings.

Reset: This action clears the alarms and enabled the pump to startup from normally. This action can be performed

in the software interface, or using the digital alarm reset button.

Connect/Disconnect: If connection was lost or when it is desired to connect to a different control box, use the

Connect and Disconnect buttons. The software can only be connected to one device at a time, so when switching

communications from one controller to another, the user should first disconnect from the current connection and

then connect to the new connection.

Command Line Entry: This tool enables specific commands to be issued to the controller and check the response

sent back from the controller.

Set IP Address: By default the control box is set to look for an IP address to be set from the DHCP network.

However, this tool can be used to force an IP address to the box independent of the network.

Update Firmware: If there is a discrepancy in the software version and the controller firmware version, then this

tool can be used to update the controller to the compatible version.

8 Troubleshooting Q & A:

8.1 Issues connecting to CPT-1 via Ethernet:

• Check that all wires are connected correctly.

• Check that the network is assigning an IP Address. (Contact system administrator for help).

• Press the Reset button on the controller, wait a moment for system restart, and try connecting again.

• If still unable to connect, contact White Knight at Tech.Support@wkfluidhandling.com

8.2 Issues Connecting to CPT-1 via RS-232:

• Ensure wires are connected correctly.

• Ensure serial port uses RS-232 connection protocol.

• Go to the device manager on your computer.

o Verify that your computer assigned a COM port for the device.

o Verify that the COM port is set to a baud rate of 115000

• Try power cycling the control box by pressing the Reset button on the control box.

• If still unable to connect, contact White Knight at Tech.Support@wkfluidhandling.com

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 15

9 Appendix 1: Complete Wiring Guide Table

Pin Name

[Quick Connect Port]

Pin # Wire

Color/Stripe

Designation

Levels

Note

Power:

Source Outputs

15

Red/Black

Power Source

12-24 VDC

The voltage input into these

pins will be the voltage output

for all Source type output pins.

27

Red/White

Ground Reference

0 VDC

Power:

Sink Outputs

8

Green

Power Source

12-24 VDC

The voltage input into these

pins will power the sink type

output pins.

11

Orange

Ground Reference

0 VDC

Power:

Input High

37

Violet/Red

Reference Voltage

High

12-24 VDC

The voltage input into this pin

will be the reference for all

digital high inputs.

Power:

Input Low

19

Orange/Black

Reference Voltage

Low

0 VDC

The voltage input into this pin

will be the reference for all

digital low inputs.

Digital Input:

Remote Left

[DI_2]

36

Yellow/Red

Reference High VDC

24 V = Not Active

0 V = Active

When one of these

connections becomes active,

the CPT-1 will turn on and start

controlling the pneumatic

pump. Disconnect the left and

right inputs from the shuttle

and connect these signals to

the appropriate high or low

voltage reference on the CPT-

1.

18

Green/Black

Reference Low VDC

0 V = Not Active

24 V = Active

Digital Input:

Remote Right

[DI_3]

6

Blue

Reference High VDC

24 V = Not Active

0 V = Active

32

Gray/Red

Reference Low VDC

0 V = Not Active

24 V = Active

Digital Input:

End Detect Left, or

Full Cycle Signal

[DI_0]

7

Brown

Reference High VDC

24 V = Not Active

0 V = Active

The left end detect is used to

count each full cycle. If using a

shuttle operated pump,

connect a pressure switch or

end detect sensor to the left

end detect signal.

If using a solenoid valve-

operated pump, connect both

the left and right end detect

sensors such that the signal is

active when the sensor is

triggered.

33

Light Green/Red

Reference Low VDC

0 V = Not Active

24 V = Active

Digital Input:

End Detect Right

[DI_1]

22

Gray/Black

Reference High VDC

24 V = Not Active

0 V = Active

3

Red

Reference Low VDC

0 V = Not Active

24 V = Active

Digital Input:

Leak Detect Left

[DI_4]

21

Brown/Black

Reference High VDC

24 V = Not Active

0 V = Active

For systems that do not

support a leak detect function

to turn off the pump when

leaks are detected, leak detect

signals can be brought into

these digital inputs. When the

leak detect signal is active, the

CPT-1 will stop the pump and

wait for the reset signal before

the pump will restart.

2

White

Reference Low VDC

0 V = Not Active

24 V = Active

Digital Input:

Leak Detect Right

[DI_5]

35

Pink/Red

Reference High VDC

24 V = Not Active

0 V = Active

17

Violet/Black

Reference Low VDC

0 V = Not Active

24 V = Active

Digital Input:

Leak Reset

[DI_6]

5

Violet

Reference High VDC

24 V = Not Active

0 V = Active

When using a leak detect

sensor through the CPT-1, it is

required to connect this leak

detect signal. This can be wired

into the tool or to a physical

button located near the pump.

31

Blue/White

Reference Low VDC

0 V = Not Active

24 V = Active

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 16

Digital Output:

Left Solenoid

[DO_0]

26

Orange/White

Sink: Connect To

ground when closed

Relay Open = Not Active

Relay Closed = Active

The CPT-1 will turn on the left

and right solenoid signals to

control a solenoid operated

pump. If using a shuttle

operated pump, these

connections are not required.

44

Light

Green/Green

Source: Connect to

power when closed

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Right Solenoid

[DO_1]

40

Red/Green

Sink: Connect To

ground when closed

Relay Open = Not Active

Relay Closed = Active

14

White/Black

Source: Connect to

power when closed

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Left Translated

Cycle Rate

[DO_2]

10

Light Blue

Sink: Connect To

ground when closed

Relay Open = Not Active

Relay Closed = Active

This output tells the tool about

the modified cycle rate. If the

tool is only looking for one

signal indicating a full cycle

rate, only connect one of these

to the tool. Otherwise connect

both left and right to the tool.

29

Brown/White

Source: Connect to

power when closed

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Right Translated

Cycle Rate

[DO_3]

25

Pink/Black

Sink: Connect To

ground when closed

Relay Open = Not Active

Relay Closed = Active

43

Light Blue/Green

Source: Connect to

power when closed

Relay Open = Not Active

Relay Closed = Active

Digital Output:

System On

[DO_4]

39

Orange/Green

Sink: Connect To

ground when closed

Relay Open = Not Active

Relay Closed = Active

This is to indicate that the

system is on. This input is

required when operating a

shuttle pump. However, this

can also be used as verification

that the system is operational.

13

Pink

Source: Connect to

power when closed

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Leak Alarm

[DO_5]

9

Gray

Sink: Connect To

ground when closed

Relay Open = Not Active

Relay Closed = Active

This output is to alert the user

that a leak was detected.

28

Violet/White

Source: Connect to

power when closed

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Under Speed

Alarm

[DO_7]

38

Gray/

Green Stripe

Sink

Relay Open = Not Active

Relay Closed = Active

This output is to alert the user

that the pump was operating

slower than the set threshold

12

Light Green

Source

Relay Open = Not Active

Relay Closed = Active

Digital Output:

Over Speed Alarm

[DO_6]

24

Light Green/

Black Stripe

Sink

Relay Open = Not Active

Relay Closed = Active

This output is to alert the user

that the pump was operating

faster than the set threshold

42

Brown/

Green Stripe

Source

Relay Open = Not Active

Relay Closed = Active

Figure 7: Pin out diagram for 44-pin connector

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 17

Controller Label

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 18

10 Appendix 2: Dimensional Diagrams

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 19

11 Ordering Instructions

CPT-1 (Cycle Rate Translator) Ordering Instructions

- - -

W QS

White Knight Fluid Handling, Inc.

435-783-6040

Optional Configurations

= 44 male pin to 1-

Meter Wire Lead Cable

W①P

②

CPT-1

To configure your Cycle Rate Translator with different connection methods, a power supply or request a specific revision level,

please select options from the appropriate additional options (1-3).

www.wkfluidhandling.com

③ Revision Level : Contact factory for copy exact code activation information.

Rev

③

= 44 male pin to Screw

Terminals

① Connection Method

② Power Supply

P

= 24V/60W Power

Supply

Required

Configurations

Additional

Options

= Quick Connect Plugs

(Registered by Galil Motion Control, Inc.)

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Page 20

Manual Version 1.3.1 Manual Part# 18200-LM-0038

Loading...

Loading...