Page 1

Gas Tumble dryer BG 43A_

INSTALLATION AND SERVICE INSTRUCTIONS

Keep this booklet for future reference.

The dryer must be fitted by a competent person. In the U.K. CORGI Registered Installers undertake

to work to safe and satisfactory standards.

The dryer must be installed in accordance with the Gas Safety (Installation and Use) Regulations

1998.

Guidance may be obtained from the relevant parts of B.S. 6172: B.S. 5440 parts 1 and 2,

B.S. 7624:2004, B.S. 6891: current editions, I.E.E. Wiring Regulations, and relevant Building

Regulations.

Failure to install the appliance correctly could invalidate the warranty liability claims and could lead to

prosecution.

FOR USE IN GREAT BRITAIN AND EIRE WITH NATURAL GAS ONLY.

GAS CATEGORY I

2H

GAS SUPPLY PRESSURE 20 MBAR.

THE INSTALLER MUST LEAVE THIS BOOKLET WITH THE CUSTOMER

Page 2

2

Page

Technical Data . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Service instructions . . . . . . . . . . . . . . . . . . . 6

Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . 8

Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . 12

Exploded views . . . . . . . . . . . . . . . . . . . . . . 13

Parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Contents

WARNING

THIS APPLIANCE SHALL BE

INSTALLED IN ACCORDANCE WITH

THE LOCAL REGULATIONS IN

FORCE AND ONLY IN A WELL

VENTILATED SPACE. READ THE

INSTRUCTIONS BEFORE USING OR

INSTALLING THIS APPLIANCE.

THIS APPLIANCE CONFORMS TO THE FOLLOWING EEC DIRECTIVES.

LOW VOLTAGE DIRECTIVE LVD 73/23/EEC: EN60 335-1, EN60 335-2.11.

GAS APPLIANCE DIRECTIVE (GAS) 90/396/EEC: BS 5258: PART 17: 1992. EN 1458-1, 2000

ELECTROMAGNETIC COMPATIBILITY DIRECTIVE 89/336/EEC: EN55014, EN 61000 - 3 - 2,

EN 61000 - 3 - 3, EN 50366

Page 3

3

TECHNICAL DATA

GENERAL

Front loading tumble dryer with gas heating. Reverse

action drum tumble. Time control. 2-temperature exhaust

thermostat control. Induced air flow enters dryer through

front grille, some passes through the gas burner into the

rear ducting and some into the cooling passages, this

mixed air enters the drum through the rear perforations,

passes through the clothes, lint filter, and the fan and is

discharged through the vent at the rear.

CONNECTIONS

Gas pressure: Rp 1/2(1/2” B.S.P. parallel internal thread).

Nominally 20mb

Electric: 230V. 50 Hz, earthed supply, 13A fuse.

(wall socket must have efficient earth

connection and correct polarity)

DIMENSIONS

Height 85 cms. (33

1

/

2

”)

Width 59.6 cms. (23

1

/

4

”)

Depth 57 cms. (22

1

/

2

”)

Depth when rear vent hose assembled 60cms. (23

5

/

8

”)

WEIGHT

With packing 37 kg

Without packing 36 kg

SUPPORT

Machine rests on 2 rear positioned rollers and 2 non

adjustable feet.

AIR-FLOW

Approximately 120 cubic metres per hour with capacity

clothes load.

IDENTITY

Manufacture date, and serial number are displayed on a

plate revealed when machine door is open.

The first 4 numerals identify year and week of manufacture.

The last 6 numerals identify the machine. ALL

INFORMATION FROM THIS PLATE SHOULD BE

QUOTED IN ANY SERVICE COMMUNICATION.

COMPONENTS

DRIVE MOTOR

Permanent split capacitor (8μF) 4 pole—Approx.

1

/

8

HP

Overload protection approx. 130°C

BURNER

Pressed steel with slotted flame perforations.

Heat input: 3.0kW (10235 Btu/hr). Injector 1.32 mm dia.

CONTROL

Type: Pactrol full sequence flame control, P16A GTD(CE)

414601. Ignition electrode gap to burner 3 to 4mm Flame

failure electrode (4213 078 52641). Height from heater

base to centre of electrode 27.0±0.5mm.

INLET THERMOSTAT

(Brown wires identification)

Bi-metal contacts normally closed.

Contacts open if airflow restricted.

Contacts open 130˚C ± 3˚C

Contacts reset 100˚C ± 5˚C

INLET TEMPERATURE LIMITER

(White wires identification)

Bi-metal contacts normally closed.

Contacts open if INLET THERMOSTAT fails.

Contacts open 143˚C ± 3˚C

Contacts reset 100˚C ± 5˚C

EXHAUST THERMOSTATS

Bi-metal contacts normally closed.

Normal Fabrics: Contacts open 60˚C ± 3˚C

60˚C (green spot Contacts reset 49˚C ± 4˚C

identification)

Delicate Fabrics: Contacts open 50˚C ± 3˚C

50˚C (red spot Contacts reset 35˚C ± 3˚C

identification)

DRUM

Volume 105 litres

Speed approx. 50/59 r.p.m.

Capacity 5 kg dry cotton

Rotation clockwise 6 mins., anticlockwise 10 secs

TRANSMISSION

Poly-vee belt driven by vee-grooved motor pulley to

outer circumference of drum.

TIMER

Electric 140 minutes combined forward and reverse 6

min cycle with 10 seconds reverse.

HEATER SWITCH

Single pole, ON/OFF

R.F.I. FILTER

0.1μF + 2x2400pF + 2x5mH + 2M2

ACCESSORIES

VENT HOSE ASSEMBLY 0312 001 01001

WALL/WINDOW VENT KIT 0312 005 01001

STACKING KIT 0312 003 01001

RESTRAINING KIT 0312 006 01001

Page 4

4

1 INSTALLATION

The dryer is designed for installation using a flexible gas

connection with tubing in accordance with B.S. 669.

Ensure that the supply gas sizing is adequate.

When installing, position the appliance so that the plug is

accessible.

An electric supply cord with moulded-on 13 Amp. plug is

fitted at the back of the dryer. The length is 1.5 m. (5ft.).

If there are any other appliances that are relatively high

rated (eg a central heating boiler) fed from the same gas

supply branch. It is advisable to perform the verification of

inlet pressure with both appliances in operation.

Prior to installation, check that the local distribution

conditions, nature of gas and pressure and adjustment of

the dryer are compatible.

2 AIR SUPPLY

The tumble dryer shall be installed in a room or internal

space having an openable window, or equivalent. The

customer must be advised that this must be kept open

during use.

Purpose provided ventilation of 100cm

2

shall also be

provided where the room volume is less than 3.7m

3

/kw of

appliance rated heat input.

Additional guidance on the provision of air supply may be

obtained from BS5440 parts 1 and 2 and BS 7624:2004

If the dryer is to be installed in a room or internal space that

already contains one or more fuel burning appliances, the

ventilation requirements above, together with any

additional requirements of BS5440-2:2000, 5,5 shall be

applied.

3 POSITION

The dryer must not be installed in a bedroom, bathroom or

shower room.

Great care is required in the location of the dryer in

premises where concentrations of flammable vapours may

accumulate, e.g. commercial garages and associated

workshops.

The dryer can be placed against a wall, other appliances,

kitchen furniture and similar surfaces.

4 VENTING

The dryer must be fitted with an exhaust vent hose and the

end either hung out of a window or fitted to a wall/ window

vent connection.

Note; Do not obstruct or add a mesh to the vent hose

outlet during use and ensure that it cannot be blocked or

bent sharply which obstruct the air flow.

It is recommended that the interior of the hose be

periodically inspected and cleaned if necessary.

PERMANENT VENTING

Accessory wall/window vent kit CL005 is available:

See illustration for necessary hole through wall. Dim A =

200mm and Dim B = 100mm for direct alignment.

Note Dim B may be increased to 200mm to facilitate easier

drilling if required.

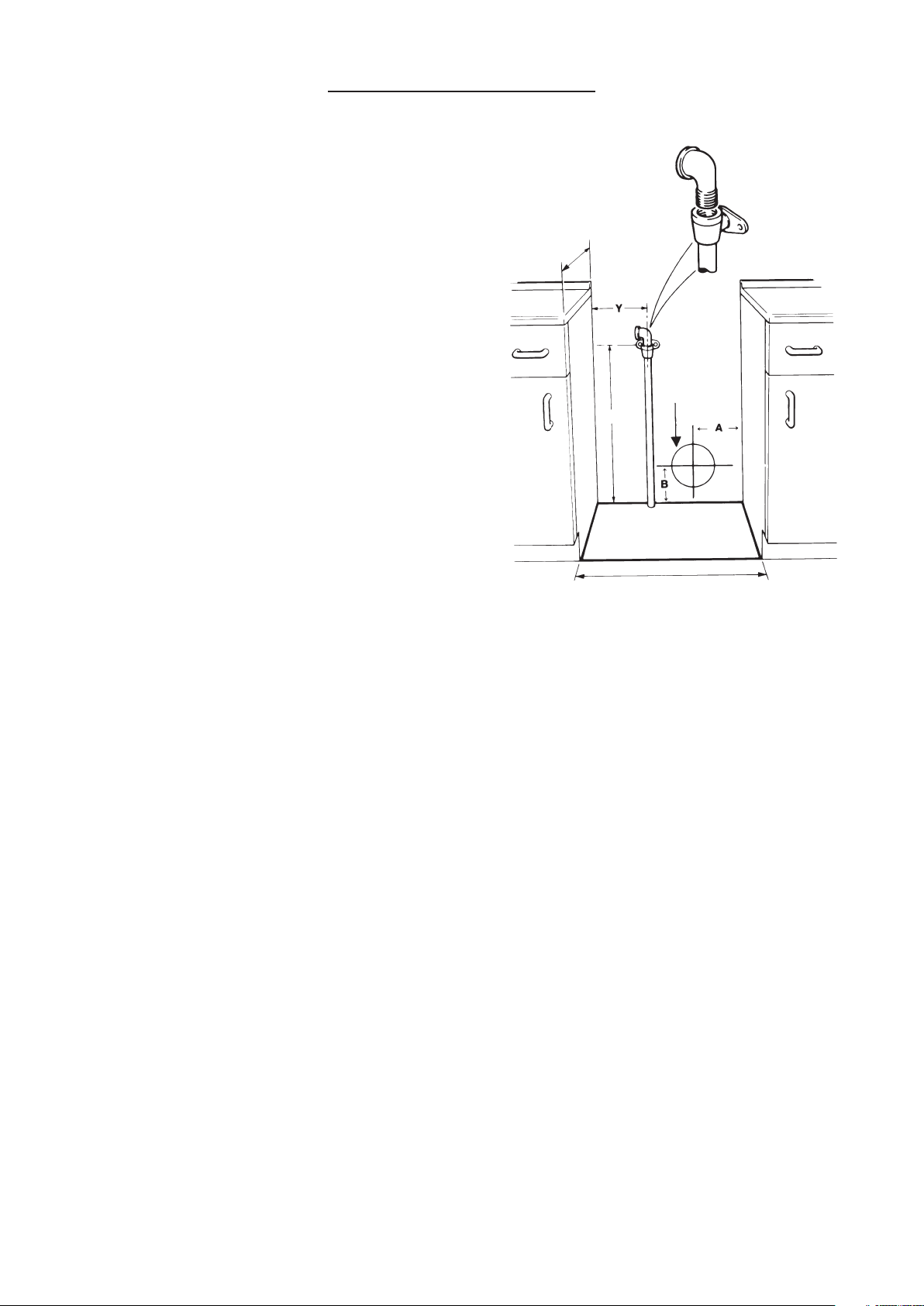

5 POSITION OF DRYER AND CONNECTIONS

The illustration shows the minimum space required by the

dryer and the position of the gas wall connector. It is not

acceptable to use a forward facing mounting plate

because of the space limitation. The sideways facing

assembly must be used and this should be fitted so that

the flexible hose hangs down from the bayonet connector.

A 13 Amp socket must be provided within a distance of 1.4

m (55 in.) of the cable entry into the dryer. The socket must

have an efficient earth connection.

If the dryer is to stand on a surface above the floor or on

top of a washing machine (using the Stacking Kit) then the

750 mm dimension is measured above the supporting

surface.

If the dryer is installed under a worktop there must be a

minimum gap of 15 mm between the top of the dryer and

the underside of the worktop to allow for ventilation.

If it is intended to move the dryer regularly for use then the

Restraining Kit must be fitted to prevent possible damage

to the gas connection.

We also recommend the fitting of a restraining kit to any

dryer which is stacked.

If using accessories:

Wall/Window Vent Kit

Stacking Kit

Restraining Kit

See separate fitting instructions included with each Kit.

Y = 150 to 330 mm

600mm

750mm

600mm

115-125 mm

diameter

INSTALLATION

Page 5

5

6. OPERATIONAL CHECK

6.1 Remove the pressure test point screw from the gas

tee connection at the back of the dryer and connect

a gas pressure gauge.

6.2 Check that the dryer timer is in the 'off' position, and

that the heat switch is set to 'high'.

Remove anything from inside the drum, check that

the lint filter is fitted, shut the dryer door.

6.3 Turn on the gas, push the electric plug into the socket

and switch on the electricity supply.

6.4 Turn the timer clockwise past the dotted line marking

the cool-down period to a setting of at least 30 mins.

Check for ignition. If the gas fails to remain lit then

repeatedly turn the timer on and off (or open and

close the door) for periods of at least 30 seconds

until the air is removed from the system and burning

is continuous. Note that gas is not lit when the drum

is turning anti-clockwise.

6.5 With the gas burning ensure that the pressure is as

detailed in the Technical Data. Turn off and replace

the pressure test point screw. Check for soundness.

6.6 Switch on again and re-start so that the gas is

burning.Disconnect the flexible gas hose and check

that the solenoids can be heard to close. After 30

seconds turn on the gas and check that there is no

re-ignition. Switch the machine off and on again and

check for reignition.

6.7 Check that the operation of the machine does not

cause spillage of products of combustion from any

open flued gas appliance in the same room, or from

appliances in adjoining rooms, e.g. a gas fire or

central heating boiler.

6.8 In the event of an electrical fault after installation of

the appliance, preliminary electrical system checks

must be carried out (i.e. earth continuity, polarity and

resistance to earth).

6.9 IMPORTANT INFORMATION RE-FUNCTIONING

OF THE FULL SEQUENCE FLAME CONTROL

BOX.

THE FULL SEQUENCE FLAME CONTROL BOX

ON THIS APPLIANCE REQUIRES A 6 SECOND

RE-SET PERIOD FOLLOWING EACH

INTERRUPTION OF INPUT VOLTAGE.

6 SECONDS DELAY IS REQUIRED BETWEEN

EACH ATTEMPT TO RESTART THE APPLIANCE

FOLLOWING SWITCHING IT OFF, OR AFTER

OPENING THE DOOR.

7 AIRFLOW

It is most important that airflow to the plinth is not

restricted.

8 MAINTENANCE

It is recommended that the appliance is serviced

annually by a person competent to service gas fired

tumble dryers.

9 STACKING

Instructions for stacking, if required, are supplied

with the stacking kit.

PROGRAMME

Clockwise rotation of the control knob closes switch

contacts within the timer to: a) energise the drive motor,

and b) energise the full sequence flame controller.

The timer switch controlling the drive motor and the timer

motor, remains closed until the timer motor mechanism

returns the control knob to the '0' position. The timer

switch controlling the full sequence flame controller

opens 12 minutes earlier to provide a cool-down period.

The full sequence flame controller opens the tandem

solenoid gas valves after a delay time of about 8 seconds

and operates the pulsing spark ignition. If the flame is not

detected by the flame failure electrode within 10 seconds

then the valves are closed. The system must then be reset by switching the machine off and re-starting.

The heat selector switch provides options for either 60°C,

or 50°C, exhaust thermostat control. This results in the

burner cycling on and off giving Ionger than anticipated

drying times. Drying times vary depending on the weight

and size of the articles, type of fabric, dampness etc.

These thermostats turn off the heating towards the end of

the chosen cycle and so avoid waste of energy. The

lower temperature thermostat prevents delicate fabrics

from getting too hot with possible risk of damage.

An inlet thermostat is fitted in the ducting at the back of

the dryer. It may also operate under certain other

conditions of restriction of the air-flow, for example, an

overloaded drum or blocked lint filter. This thermostat

switches off the flame controller. This will result in the

burner cycling on and off giving longer than anticipated

drying times. Drying times vary depending on the weight

and size of the articles, type of fabric, dampness etc.

Should the thermostat fail there is an inlet cut-out

connected in circuit with the gas valves. After operation,

the cut-out must be re-set to restore heating but a service

call may be required to correct the initial fault.

The conditions of failure of the air flow, blow-back, or of

gas interruption are detected by the flame failure

electrode and the system is shut-down.

Both drum rotation and heater control are switched off

when the door is opened and switched on when the door

is reclosed.

For programme times see chart on dryer control panel.

Note: Do not allow fluff to accumulate around the dryer.

Page 6

6

RECOMMENDATIONS FOR DISMANTLING

Note: Re-assembly should be done in reverse

sequence to these instructions.

HEATER ASSEMBLY REMOVAL

Heater Assy. (32), Solenoid Coil (45 or 45A), Flame

failure Electrode (33), lgnition Electrode (39).

Withdraw the 2-screws securing the Plinth (199) to the

Cabinet, unhook the bottom edge fixing, and remove it.

Separate the 4-way Housing (31 ) to release the wiring

from the Heater Assy. to the Cabinet.

Lay the dryer flat on its front, supported to take the

weight from the door and controls.

Withdraw the 6-screws securing the Cover Piate (19) to

the Back Panel (24) and remove it. Pull out the Exhaust

Tube (30).

Withdraw the 4-screws securing the Hot Air Elbow Assy.

(20) to the Back Panel (24) and remove it.

Disconnect the External Feed Pipe (15) from the Tee

Piece (27).

Pull the connectors off the Flame failure Electrode (33)

and the ignition Electrode (39).

SERVICE INSTRUCTIONS

Heat

Heat

Page 7

7

Withdraw the 3-screws and shakeproof vvashers (13)

securing the Flame Tube Assy. (34) to the Cabinet base.

Note: On re-assembly the shakeproof washers must be

replaced to ensure a good earth connection.

Lift out the Heater Assy.

To remove either solenoid coil (45 or 45A) disconnect the

electrical connectors, unscrew the nut (44) or remove circlip

(52) from the top of the valve and lift off. When removing

solenoid coil (45A), take care not to misplace the spring (53).

To remove the sensing electrode (33), withdraw the screw

(41) lockwasher (482) and nut (411 ) securing it to the Flame

Tube Assy. (34). Note on re-assembly the lockwasher (482)

must be replaced to ensure a good earth connection.

To remove the Ignition Electrode (39), withdraw the screw

securing it to the top of the Heater Tube Assy. (34).

If there is a fault in the valves, burner or other parts of the

gas line, then the Heater Assy. (32) must be replaced.

INLET THERMOSTAT & THERMAL OVERLOAD CUTOUT (TOC) REMOVAL

Lay the dryer flat on its front, supported to take the weight

from the door and controls.

Withdraw the 6-screws securing the Cover Plate (19) to the

Back Panel (24) and remove it. Pull out the Exhaust Tube

(30). Disconnect the Faston connectors from the 4-way

Terminal Block (142) as necessary (see wiring Diagram for

colour code). Cut off the 2-Cable Ties (387). Note: on

reassembly these must be replaced by new components to

secure thermostat wiring away from contact with the Drum.

Withdraw the 16-screws securing the Rear Banjo (18) and lift

it off.

Withdraw the screws securing the Thermostat (230) and/or

TOC (38) and pull the connecting wires through the

Grommet (25).

Note: Operation of the TOC should only occur if the

thermostat has failed. If the TOC should also fail this results

in high temperatures in the dryer.

Assembly

(359)

Page 8

8

FAULT FINDING

In the event of an electrical fault carry out the preliminary electrical system checks i.e. earth

continuity, polarity, and resistance to earth.

Use each chart to locate the fault causing the dryer to operate incorrectly as follows:

Chart No.

1 Motor does not run.

2 Motor runs but full sequence control does not produce ignition spark.

3 Motor runs, Full Sequence Control produces ignition sparks, but gas does not ignite.

4 Motor runs, gas ignites but burns for only a short period.

Chart 1. Motor does not run

Page 9

9

Chart 2.

Motor runs but full

sequence control does not

produce ignition spark

START

Exchange timer, Does control spark?

Does control spark with low heat

selected?

Change 50˚C exhaust thermostat

Does control spark?

Check continuity of red wire between

timer B2 and heat selector switch.

Are connections clean and tight.

Does control spark?

Exchange heat selector switch.

Does control spark?

Exchange both exhaust thermostats

(50˚C and 60˚C) and inlet thermostat

130˚C (brown wires)

Does control spark?

Exchange full sequence control unit.

Does control spark?

With timer ON (30 min) is voltage between output

B2 on timer and TB-N 230v?

Does control spark with high

heat selected?

Disconnect both red wires at timer B2. Reconnect

only red wire from heat selector to timer B2.

Caution the other red wire is live. Is voltage

between heat selector switch and TB-N 230V?

With red wire still disconnected is voltage between

output of heat selector switch and TB-N 230V at

high heat setting and zero volts at low setting.

Is voltage between brown wire in control box

multiway connector and TB-N 230V?

Check HT lead is connected to control and

electrode. Does control spark?

Check condition of ignition electrode and spark

gap is correct by removing heater assembly.

Does control spark?

Does gas light?

Does gas stay on?

Machine operating. Instruct

users as necessary

Yes

Yes

No

Yes

No

No

No

No

Refer to chart 3

No

Refer to chart 4

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

Yes

Yes

No

No

No

Yes

Yes

Yes

Page 10

10

Chart 3. Motor runs Full Sequence Control produces ignition sparks, but gas does not ignite

Page 11

11

Chart 4. Motor runs, gas ignites but stays on for only short period

Before proceeding, ensure polarity of 13 Amp supply socket and earthing is correct.

Is weight of load suitable?

Is filter clean? Is vent

hose or terminal

unobstructed? Is vent

terminal unaffected by

wind conditions that may

cause back pressure?

Is flame failure electrode

correctly positioned, and

undamaged? Is wire to

terminal 9 undamaged and

connections tight? Is rear

drum seal complete? Is rear

elbow and plinth attached

correctly?

Exchange full sequence

control and/or gas control

relay PCB and/or

thermostats as necessary

until gas stays on.

Machine operating.

Instruct user as necessary.

Yes

Yes

Yes

Start

Check gas pressure with all

other appliances in operation

does gas stay ON?

No

Yes

Rectify as necessary

does gas stay ON?

Yes

No

No

No

Page 12

12

WHITE KNIGHT BG 43A_

CROSSLEE P.L.C.

Page 13

13

WHITE KNIGHT BG 43A_

CROSSLEE P.L.C.

EXPLODED VIEW 1

Page 14

14

WHITE KNIGHT BG 43A_

CROSSLEE P.L.C.

EXPLODED VIEW 2

REAR ASSEMBLY VIEWED FROM FRONT

Page 15

15

WHITE KNIGHT BG 43A_

CROSSLEE P.L.C.

EXPLODED VIEW 3

INTERNALS VIEWED FROM REAR

Page 16

WHITE KNIGHT BG 43A_

CROSSLEE P.L.C.

EXPLODED VIEW 4

INTERNALS VIEWED FROM REAR

16

Page 17

17

WHITE KNIGHT BG 43A_

CROSSLEE P.L.C.

EXPLODED VIEW 5

HEATER ASSEMBLY

Page 18

18

Page 19

19

Page 20

BG 43A_ Installation/Service Book 4213 094 67791

Manufactured by: Crosslee plc. Lightcliffe Factory, Hipperholme, Halifax, West Yorkshire HX3 8DE.

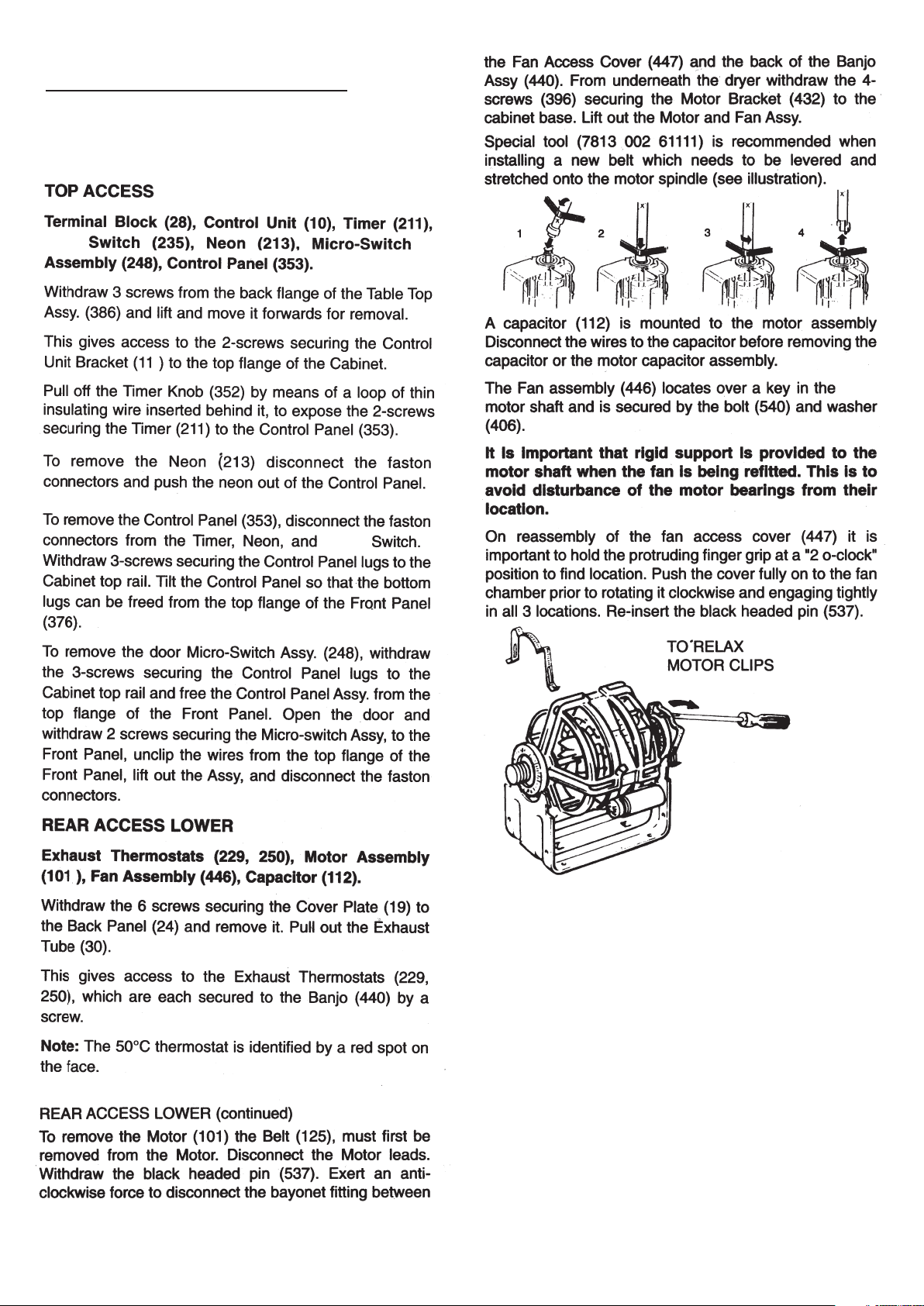

Loading...

Loading...