Page 1

Trouble Shooting & Safety Guide

Wiring Diagram

Exploded Views

Parts List

September 2016

8kg

Condenser Tumble Dryer

UK

White Knight - B96M8W

SERVICE MANUAL

Note: Please read before servicing the unit. Any problems: contact your service centre

Page 2

CONTENTS – B96M8W

2. User error checklist

3. Control panel connection diagram

3.1 Lack of display on control panel

3.2 Drum does not turn but the control panel displays correctly

3.3 Heating system failure

3.4 The drum turns but the appliance fails to dry

3.5 The dryer makes an abnormal noise when operating

3.6 The dryer produces an abnormal smell when operating

3.7 The LED displays when the dryer is operating

3.8 Error warning codes

4.1 Disassembly warnings

4.2 Disassembly methods

5. Wiring diagram

6. Exploded view

2. User error checklist – please check prior to service

Symptoms

The drum does not rotate

The dryer gives out abnormal

heat

The clothes are creased or

shrunk

Check whether:

There is power to the appliance

The door is closed

The correct program has been selected and the start button has been

pressed

The heat exchanger is assembled and fit correctly

The maintenance cover is locked in place

The door is sealed correctly

The dryer is overloaded

The correct program has been selected

Page 3

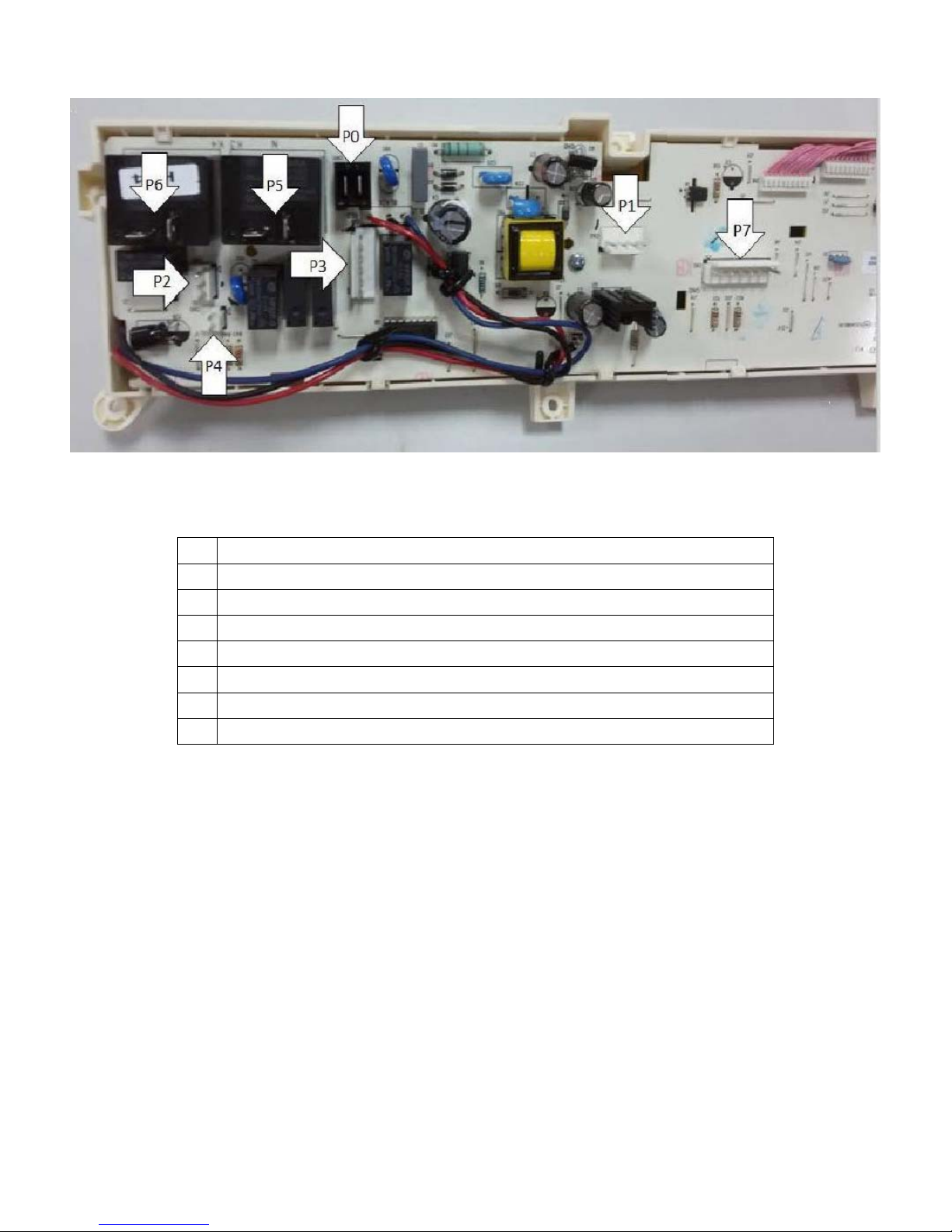

3. Control panel connection diagram

P0 Live and neutral

P1 Load moisture sensor

P2 Motor L + heater (700W) L

P3 Drum light and pump

P4 Door switch

P5 Heater N+ motor N

P6 Heater (1600W) L

P7 Water level sensor, Inlet thermistor and Exhaust thermistor

Page 4

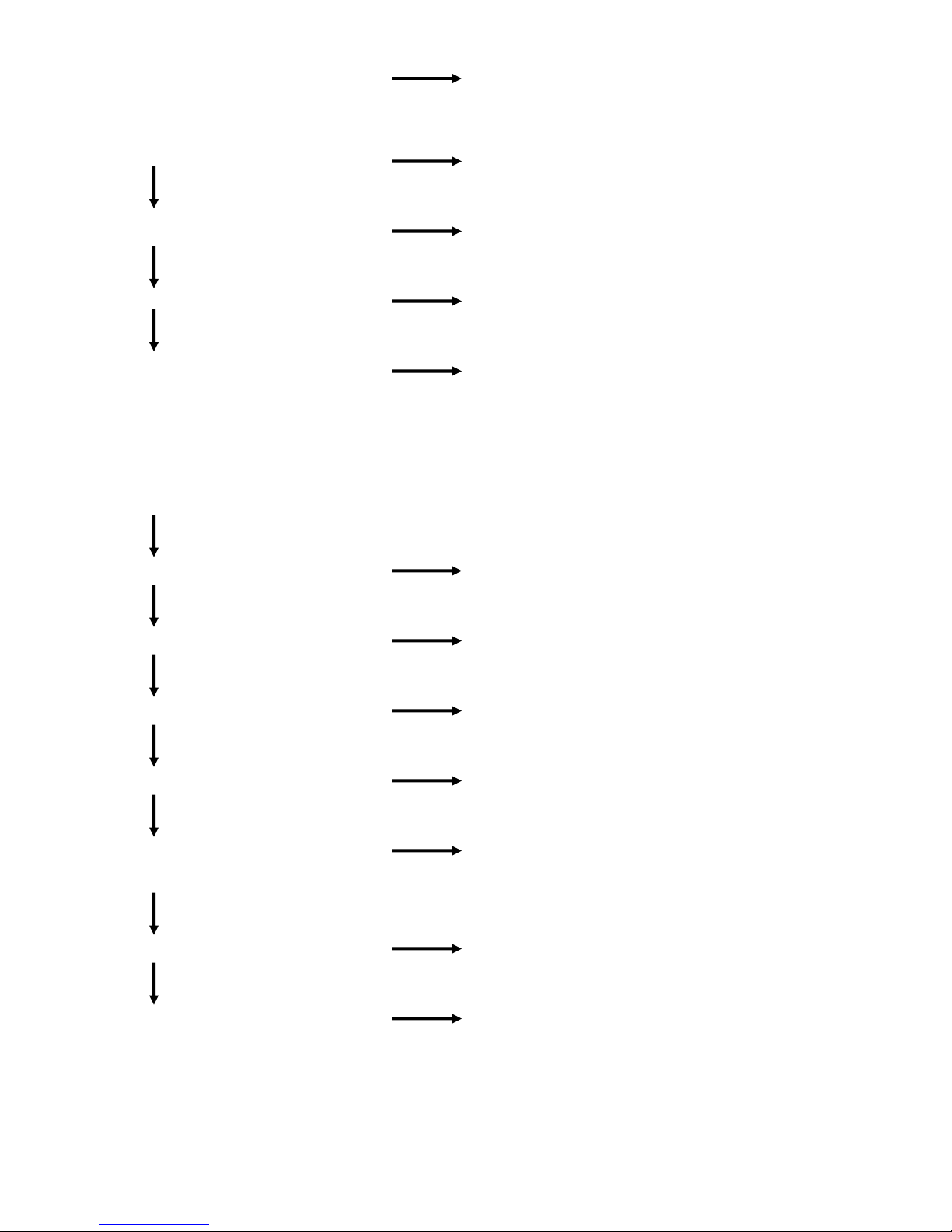

3. FAULT FINDING

3.1 Lack of display on control panel

Check if power is NO YES

getting to the appliance Check fuse for continuity Replace fuse

YES

Switch off the appliance NO Check power cord and YES Replace the mains cable

Check for 230V between loom harness for damage or loom harness as necessary

pins P0 on PCB

YES YES

Replace the PCB Check the RFI filter for damage

3.2 Drum does not turn but the control panel displays correctly

YES

Check if the belt is loose or damaged Re-fit or replace belt

NO

YES

Check if the terminals of P2 are loose Ensure that the terminals are connected correctly

NO

YES

Check the front support wheel for damage Replace the front support wheel (including wheel shaft)

NO

YES

Check if the capacitor has correct value Insert or replace capacitor

and is connected to the loom

NO

YES

Check if the tension spring Install or replace the tension spring

NO

YES

Check the motor for damage Replace the motor

NO

YES

Check for blockage/binding when drum rotates Check and remove blockage

NO

YES

Check for damage to the drum bearing Replace the drum bearing assembly

NO

YES

Check any damage to door switch Replace the door switch

NO

YES

Page 5

Check loose connections or damage to loom Re-assemble or replace the loom

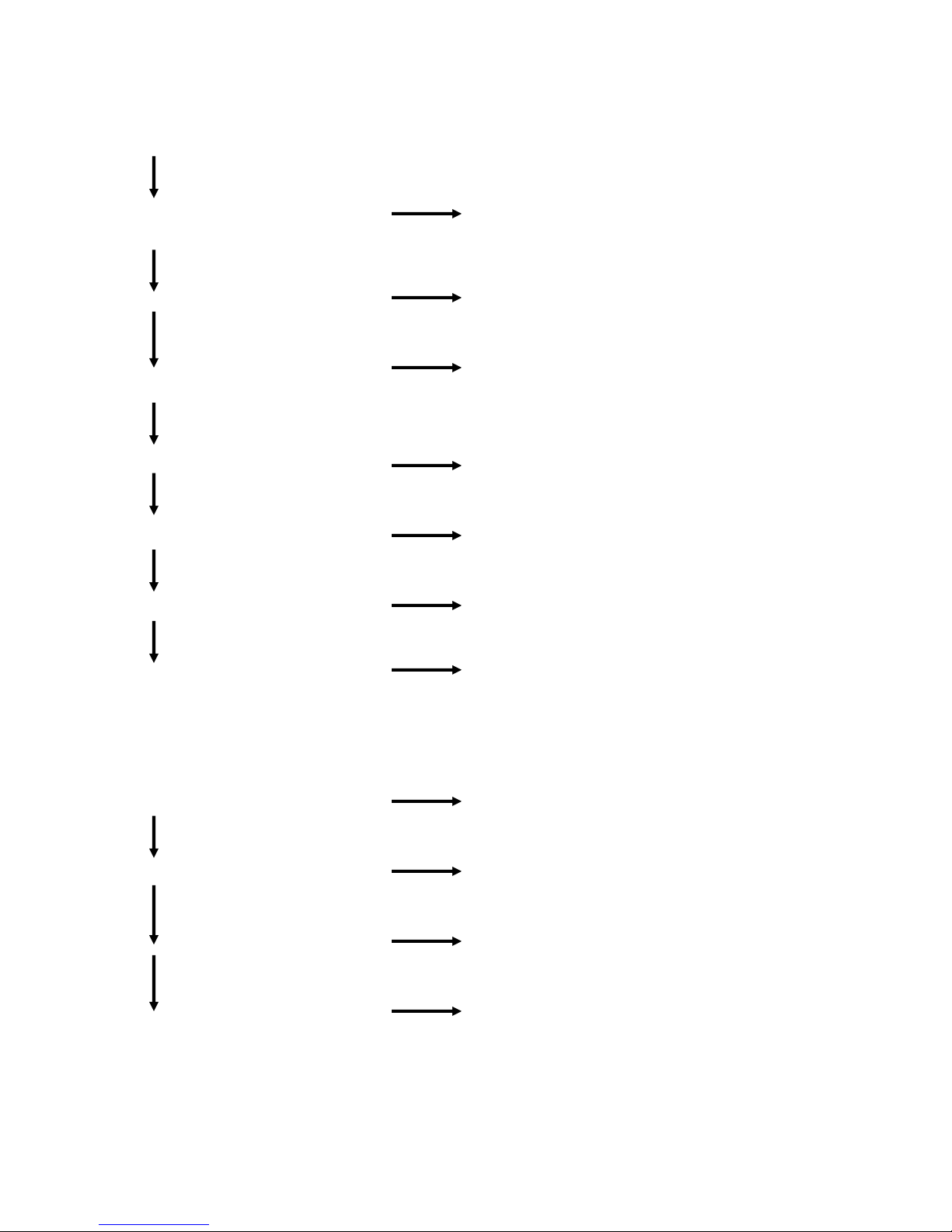

3.3 The heating system does not work

YES

Check if the “cool” program is in operation Re-test the appliance in a heating program

NO

YES

Check if terminal P4 is loose Re-attach terminals

NO

YES

Check if the loom is damaged Replace the loom harness

NO

YES

Check if the Inlet thermostat on the heater Replace the heater subassembly

assembly is damaged

3.4 The drum turns but the appliance fails to dry

Is the ambient temperature higher than 35°C

NO

YES

Check the correct program has been selected Select the correct program

NO

YES

Check if the dryer is overloaded The load placed in the drum must not exceed the

maximum load rating stated in the instruction book

NO

YES

Check that the filter is clean Clean the filter

NO

YES

Is the heat exchanger blocked Clean the heat exchanger

NO

YES

Is the Inlet thermostat damaged or has the thermal Reset the thermal cut-out if tripped. Replace the heater

cut-out tripped subassembly if damaged

NO

YES

Is the heater damaged Replace the heater subassembly

NO

YES

Check the load moisture sensors Clean and then check. If still faulty, replace.

Page 6

3.5 The dryer makes an abnormal noise when operating

Check to find the source of the noise

YES

Check if the screws holding the lifter to the drum Tighten the screws accordingly

are loose

NO

YES

Is the front support wheel damaged Replace the front support wheel subassembly including

shaft

NO

YES

Is the tension spring connected between the Reassemble the tension spring

motor and the base

NO

YES

Is the motor noisy Replace the motor

NO

YES

Check if the fan is loose or damaged Reassemble or replace the fan

NO

YES

Is the drum bearing/drive shaft damaged Replace the drum assembly

NO

YES

Does either the drainage or overflow Ensure the hoses are positioned correctly

pipe rub on the rotating drum

3.6 The dryer produces an abnormal smell when operating

YES

Is there any sign of deposits on the heater Clean the heater

NO

YES

Is the main drive belt slipping Replace the main drive belt. Check the spring providing

tension (between the motor and base)

NO

YES

Has the motor stalled Check for any signs as to why the motor stalled (e.g.

drum jammed). Replace motor if no issues found.

NO

YES

Check for any signs of overheating of electrical Replace any parts as necessary

components

Page 7

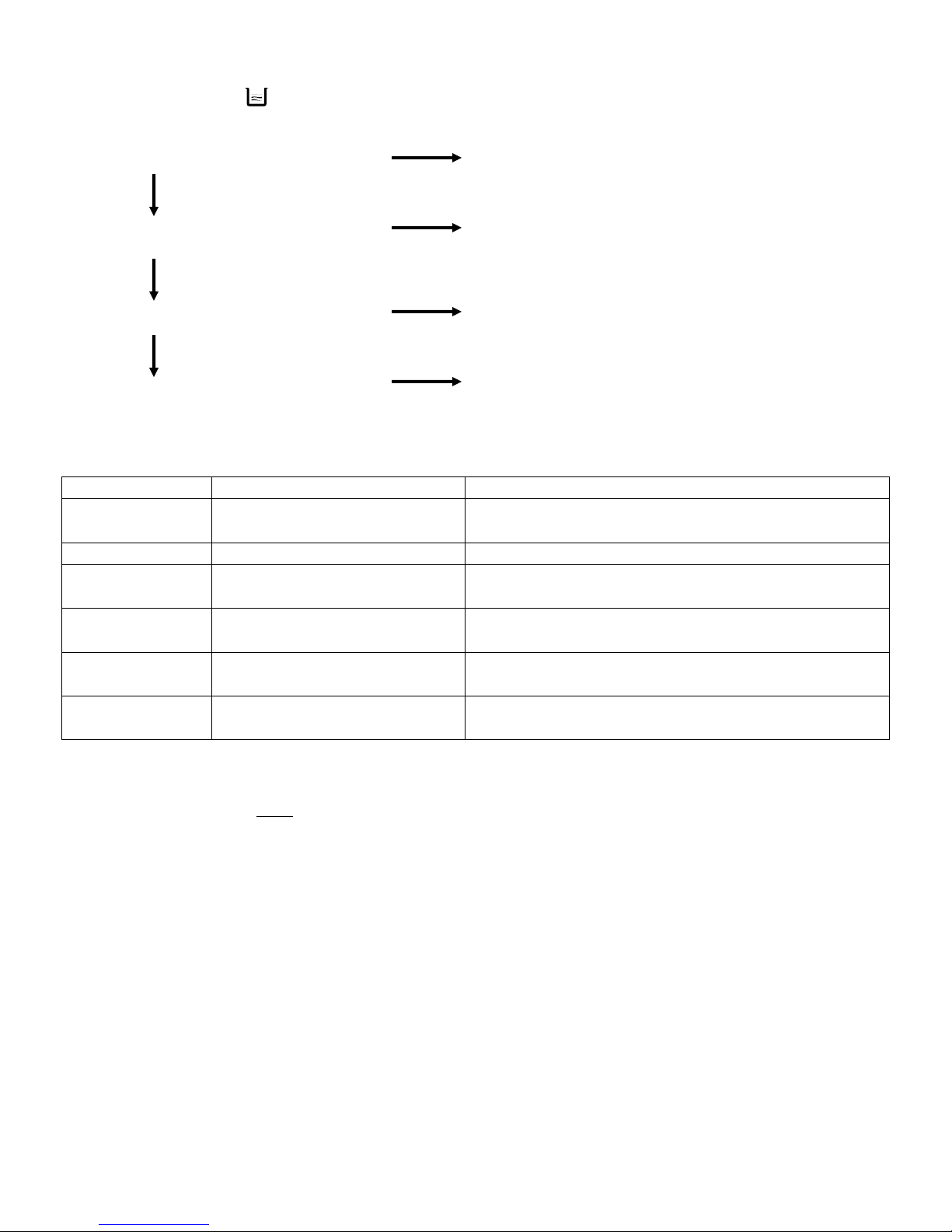

3.7 The LED displays when the dryer is operating

YES

Check if the bottle is full Empty the bottle

NO

YES

Check if the pump is connected correctly Attach the terminals accordingly or replace the loom

Check PCB for any signs of damage Check connections on PCB and replace if necessary

NO

YES

Check if the pump is damaged or blocked Replace or clean the pump

NO

YES

Check if the water level sensor is damaged Replace the water level sensor

3.8 Error warning codes

Error ‘code’ Error description Parts to check

Bottle full

indicator lit

Bottle is full of water

and bottle full indicator is lit

Check the water container, pump and water level

sensor

E30 Heater not working Check the heater and motor

Clean filter

indicator lit

E32

E33

E34

Filter mesh is blocked Clean the filter mesh and restart the machine

Load moisture sensor not

working

Inlet thermistor not functioning

correctly

Exhaust thermistor not

functioning correctly

Check the moisture sensors and restart the machine

Check the inlet thermistor (on heater assembly) and

check associated connections

Check the exhaust thermistor (below filter) and check

associated connections

4.1 Disassembly warnings

The mains cable must

be disconnected from the power supply when disassembling or repairing the

machine.

The loom harness and terminals used must be for the correct wire size and the correct tools must be

used to crimp any terminals onto the harness. Insulation tape must be used where appropriate.

When attaching terminals to the mating connectors, always ensure that they are pushed fully on.

When attaching a wire via a screw terminal, ensure that sufficient wire is underneath the screw

terminal. Ensure that the screw is tightened satisfactorily.

The loom harness should not touch any moving parts or sharp edges. The wiring route around high

temperature objects (e.g. motor) should be followed as per the initial construction.

Always use the specified screws

Page 8

4.2 Disassembly methods

1. Control panel assembly disassembly

1. Unfasten the two screws at the rear of the

top cover and slide top cover backwards

2. Remove the bottle

3. Remove 4 screws at the front of the dryer

from the control panel and cross brace

4. Remove 2 screws inside the slots on the

control panel

5. Remove all of the connections from the

back of the PCB

Page 9

6. Remove the screws holding the PCB to the

control panel. The PCB’s can be removed by

unscrewing and unclipping where necessary.

2. Disassembling the RFI filter and water level sensor

Disassembling the RFI filter:

Remove the loom terminals from the filter. Unfasten

the two screws from the filter in order to remove the

filter from the upper bracket.

Disassembling the water level sensor:

Remove the top cover (screws at rear of appliance)

and left-hand side panel (screws along top, at rear

and underneath appliance) from the appliance.

(1) Pull out the drainage hose connector from the

pump cover.

(2) Remove the pump cover(s)

(3) Remove the nut on water level sensor to

allow the water level sensor to be removed

from the pump cover. Unclip the wires.

3. Disassembling the door

1) Remove the screws holding the hinge to the front

panel. Lift the door to extract the hinge from the

panel and place on a soft surface to avoid scratching

the door.

2) Remove the screws on the inside of the door.

3) The door should now be able to be stripped into

its constituent parts.

Page 10

4) Push the two pins of the hinge to separate the

hinge..

4. Disassembling the heater

1) Remove the screws from the rear panel

2) Remove the screws from the air ductwork below

the heater

3) Remove the top cover by unscrewing the screws

at the back of the appliance.

4) Disconnect the loom harness from the RFI filter

5) Disconnect the terminal from the heater connector

Page 11

6) Remove the cable clamp holding the wires to the

backpanel

7) Remove the screws from the heater

5. Disassembling the drum

1) With the side panels and the top cover of the

appliance removed, remove the bracing struts

between the front and backpanels. Remove the

screws which hold the metal backpanel to the plastic

base. The drum and the backpanel should now come

away as one item.

2) Remove the main drive belt from the drum

subassembly.

3) Remove the two screws from the bearing cover

4) Remove the ring seal from the bearing cover

Page 12

5) Remove the nut with adjustable wrench or similar

6) Remove the drum shaft ring

7) Remove the backpanel from the drum

8) Remove the other two shaft rings

Page 13

5. Wiring Diagram

1-Pump 2-Drum light 3-Door Switch 4-Moisture level sensor 5-Mains cable 6-RFI filter

7-Motor 8-Capacitor 9-Heater 10-Inlet thermistor 11-Water level sensor 12-Exhaust thermistor

6. Exploded View

Page 14

Exploded View Base

Page 15

Exploded View Front Support

Page 16

Exploded View Control Panel & Water Bottle

Page 17

Exploded View Drum

Page 18

Exploded View Front Panel

Page 19

Exploded View Door

Page 20

Parts for Model White Knight B96M8W

ITEM No DESCRIPTION CODE BOM code

1.1 Handle Assembly 4213 092 69251 301160760440

1.2 Base Assembly NOT AVAILABLE 301160760035

1.2.1 Condenser Cover 4213 092 65211 301160700025

1.2.2 Sump Cover 4213 092 65341 301160700024

1.3 Capacitor 4213 092 65291 302460700011

1.4 Leg 4213 092 65311 301160700027

1.5.1 Short Belt 4213 092 65271 302760700002

1.5.2 Motor Support 4213 092 65251 301160700033

1.5.3 Motor 4213 092 65241 302460760017

1.6 Pump Protection Cover 4213 092 65191 301160760011

1.7 Pump Cover 4213 092 65181 301160700028

1.9 Drain Hose Joint 4213 092 65901 301160700030

1.10 Drain Pump 4213 092 65171 302460700014

1.11 Water Level Sensor 4213 092 65201 302460700015

1.12 Noise Absorber 4213 092 65321 302160700006

1.13 Fan Assembly 4213 092 65231 301160760030

1.14 Fan Assembly 4213 092 65261 301160760029

1.15 Tensioner Spring 4213 092 65281 302960700002

1.16 Condenser Assembly 4213 092 65001 301560760002

1.17 Cover Fan 4213 092 65221 301160700026

2.1 Front Support Seal 4213 092 65111 302160700003

2.2 Humidity Sensor 4213 092 65101 302460700024

2.3 Bracket Humidity Bar 4213 092 69261 301160700038

2.4 Noise Absorb Cotton 4213 092 69271 302160700005

2.5 Holder Lamp 4213 092 65071 302460700013

2.6 Lamp 4213 092 65091 302460700012

2.7 Front Support Assembly 4213 092 65061 301160700037

2.8 & 2.9 Cover Lamp & Seal 4213 092 65081 301160700039

2.10 Lint Filter 4213 092 65051 301160700070

2.11 Wheel Assembly 4213 092 65121 302960860008

2.12 Temperature Sensor 4213 092 65151 302411600802

2.13 Seal Thermistor 4213 092 65141 302760700003

2.14 Nut 4213 092 65741 302560700003

3.1 PCB 4213 092 64891 302460860001

3.2 Control Panel Assembly 4213 092 64881 3011607A0145

3.3 Knob 4213 092 64871 301160760018

4.1 Drum 4213 092 66091 301160760105

4.2 Cover Bearing 4213 092 66111 301260700013

4.3 Seal Cover Bearing 4213 092 66101 302760700007

4.4 Nut NOT AVAILABLE 302502000102

4.5 Cover Back NOT AVAILABLE 301260700016

4.6 Seal Back Assembly 4213 092 65391 302160700004

4.7 Bearing House Assembly 4213 092 65361 301260760022

4.8 Drum Assembly 4213 092 65401 301260760044

4.9 Lifter NOT AVAILABLE 301160700045

4.10 Cover Basket NOT AVAILABLE 301160700046

4.11 Heater Assembly 4213 092 65371 302460700016

5.1 Front Panel 4213 092 65561 301260700011

5.2 Door Lock Assembly - up to WK1537 4213 092 65591 301160700021

5.2 Door Lock Assembly - from WK1538 4213 092 68531 302460860004

5.3 Positioning Pin NOT AVAILABLE 301160760023

5.4 Cover Switch 4213 092 68531 302411500061

www.whiteknightspares.co.uk www.whiteknightrange.co.uk

Page 21

6 Door Assembly - up to WK1537 4213 092 64901 301160700018

6 Door Assembly - from WK1538 4213 092 69281 12138200A02721

6.1 Outer Frame 4213 092 64911 301160700053

6.2 Protect Cover 4213 092 64921 301160700057

6.3 Inner Ring Seal 4213 092 64941 302760700005

6.4 Door Plunger - up to WK1537 4213 092 64961 302960700011

6.4 Door Plunger - from WK1538 4213 092 68541 302960700015

6.5 Inner Ring (2 Ribs) - up to WK1537 4213 092 64951 301160700054

6.5 Inner Ring (No Ribs) - from WK1538 4213 092 68561 301160700054

6.6 Door Hinge Pedestal 4213 092 64981 301160700058

6.7 Parallel Pin NOT AVAILABLE 302960700010

6.8 Hinge Support 4213 092 64971 302960700009

6.9 Window Door 4213 092 64931 301160700056

7 Top Cover Assembly 4213 092 65491 301160700015

8 Upper Support 4213 092 65441 301160700012

9 Bottle Assembly 4213 092 65431 301160700069

10 Housing Bottle 4213 092 65451 301160700011

11 Water Bottle Handle And Printing 4213 092 65421 3011608A0038

12 Top Bracket 4213 092 65601 301260700009

13 Bracket Side 4213 092 65461 301260700006

14 Right Top Bracket 4213 092 65471 301260700007

15 Air Inlet Grill NOT AVAILABLE 301160760146

16 Long Belt 4213 092 65511 302760700001

17 Cover Back NOT AVAILABLE 301260700012

18 Side Panel 4213 092 65551 301260700008

19 Maintenance Cover 4213 092 65571 301160760145

20 UK Power Cord 4213 092 65501 302460760022

21 Electric Filter 4213 092 65481 302360700001

22 Door Gasket - up to WK1537 4213 092 65581 301160700007

22 Door Gasket - from WK1538 4213 092 68551 302760860001

23 Overflow Hose 4213 092 65411 301160700010

24 Drain Hose 4213 092 65331 302760700008

25 Inlet Duct 4213 092 65531 301260700010

www.whiteknightspares.co.uk www.whiteknightrange.co.uk

Loading...

Loading...