Whitehall Products E-27-S User Manual

E-27-S

S-90-S

STATIONARY WHIRLPOOL

OPERATION AND MAINTENANCE MANUAL

6900-194-000 Revised: November 2012

PLEASE READ THIS ENTIRE

European Union CE Mark

WARNING

To avoid electric shock, connect the instrument to properly earth-grounded, GFC I protected, 3-prong

receptacles only. Failure to observe this precaution can result in severe injury.

BOOKLET BEFORE OPERATING

! !

YOUR NEW WHIRLPOOL

Failure to follow these instructions could result in damage

to your new whirlpool and/or bodily injury

The presence of the CE Mark on Whitehall equipment means that it has been designed, tested and certified as complying

with all applicable European Union regulati ons and recommendations.

Waste Electrical and Electronic Equipment (WEEE)

This symbol on the product or on its packaging indicates that this product must not be disposed of w ith regular waste.

Instead, it is the user’s responsibil ity to dispose of waste equipment according to the local laws. Separate collection and

recyc ling of the waste equipment at the time of disposal will help conserve natural resources and ensure it is recycled in a

manner that protects human health and the environment. For information about where the user can drop off the waste

equipment for recycling, please contact your local waste collection authority. See Page 30 for instructions on how to

disassemble the equipment for recyc ling purposes.

General Warning or Caution

The Exclamation Sym bol appears in W arning and Caution statements. This symbol designates where personal injury or

damage to the equipment is possible.

Electric Shock

The Electric Shock Sym bol is used to indicate a hazard ari sing from dangerous voltage. Any mishandling could result in

irreparable damage to the equipment and/or personal injur y or death.

Ÿ WHIRLPOOLS intended for professional use only.

Ÿ 220v WHIRLPOOLS for export only.

Ÿ DO NOT operate appliance without properly filling with water. Under no conditions should the appliance be operated

without water. Fill appliance with water to the prescribed level before plugging into an electrical receptacle. Operating the

appliance without water may result in damage to the motor.

Ÿ IMPROPER USE of the whirlpool can cause injury. Use the whirlpool only for the purpose described in this manual.

Ÿ THE TURBINE is top-heavy. Improper handling can cause injury or damage. Handle the turbine with care.

Ÿ ATTACHING IMPROPER items to the whirlpool can cause injury to persons and damage to equipment. Use only Whitehall

approved items on the whirlpools.

Ÿ INCORRECT PARTS and service can cause injury to persons and damage equipment. Use only Whitehall parts and

Whitehall approved service on whirlpools.

3

3

a

WHITEHALL MANUFACTURING • P.O. Box 3527 • City of Industry, CA 91744-0527 U.S.A.

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

Table of Contents

Warning ................................................................................................................................................Page a

Table of Contents .................................................................................................................................Page 1

General Knowledge..............................................................................................................................Page 2

Operating Skills & Training..........................................................................................................Page 2

Patient Evaluation .......................................................................................................................Page 2

Inspecting Whirlpool ....................................................................................................................Page 2

Using The Whirlpool .............................................................................................................................Page 3

Installation & Operation ...................................................................................................................Pages 4-7

Fixture Installation Location Guide..............................................................................................Page 4

Combined Drain / Overflow .........................................................................................................Page 5

Separate Drain / Overflow...........................................................................................................Page 6

Slant Back ...................................................................................................................................Page 7

Repair Parts .................................................................................................................................Pages 8-26

Stationary Motor/Turbine Assembly.............................................................................................Page 8

Stationary "E" Series ...................................................................................................................Page 9

Stationary "H" Series .................................................................................................................Page 10

Stationary "L" Series..................................................................................................................Page 11

Stationary "P" Series .................................................................................................................Page 12

Stationary "S" Series .................................................................................................................Page 13

Motor Raising & Lowering Assembly (Small).............................................................................Page 14

Motor Raising & Lowering Assembly ........................................................................................Page 15

Motor Raising & Lowering Assembly (Slant Back) ....................................................................Page 16

Drain / Overflow Assembly - H/S Series....................................................................................Page 17

Drain / Overflow Assembly - "E" Series.....................................................................................Page 18

Drain / Overflow Assembly - (Lo-Boy) .......................................................................................Page 19

Drain / Overflow Assembly - Podiatry Series.............................................................................Page 20

Drain / Overflow Assembly - Slant Back....................................................................................Page 21

Separate Drain / Overflow Assembly - P-10, P/E-15/22............................................................Page 22

Separate Drain / Overflow Assembly - E-22-SP, E-27/45 ..........................................................Page 23

Separate Drain / Overflow Assembly - H-60/70/90, S-85/90 .....................................................Page 24

Butterfly Drain Valve ..................................................................................................................Page 25

Thermometers ...........................................................................................................................Page 26

Cleaning & Disinfecting ....................................................................................................................Pages 27

Care & Cleaning ...............................................................................................................................Pages 28

Maintenance & Troubleshooting.......................................................................................................Pages 29

Motor Information .............................................................................................................................Pages 29

WHITEHALL MANUFACTURING • P.O. Box 3527 • City of Industry, CA 91744-0527 U.S.A.

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

1

General Knowledge

OPERATOR SKILLS AND TRAINING

Skills:

Operators using the whirlpool need:

Ÿ a working knowledge of aquatic physical-therapy

procedures.

Ÿ the ability to assist the patient.

!

!

WARNING

WARNING

Untrained operators can cause injury or be injured.

Permit only trained personnel should operate the

whirlpool.

PATIENT EVALUATION

Require Each Patient To Be Evaluated

Patients who are electrically-susceptible (patients with

exposed, non-waterproof electric leads, monitors, etc.),

patients carrying infectious disease,

certain other medical, mental or physical conditions should

not receive treatment with the whirlpool.

The trained operator must evaluate and verify that each

patient is suitable for hydrotherapy treatment before

permitting the patient to begin hydrotherapy. If in doubt,

co nsul t a m edical pr ofessional before prov iding

hydrotherapy treatment.

or patients with

TRAINING

Operator trainees need to:

Ÿ be trained in aquatic-therapy protocols.

Ÿ be familiar with the types of patients who should or

should not receive this type of physical therapy (see

Patient Evaluation, below).

Ÿ read and understand this manual (and the manual for

the turbine, if used).

Ÿ be trained on the use of the whirlpool (and turbine, if

used).

Ÿ practice with the whirlpool (and turbine, if used) before

use with patient.

!

!

WARNING

WARNING

Certain medical conditions are incompatible with

hydrotherapy. The trained operator is responsible for

determining each user’s suitability for hydrotherapy

before beginning treatment.

Important

BLOODBORNE DISEASE NOTICE: To reduce the

risk of exposure to bloodborne diseases such as HIV-1

and hepatitis when using the whirlpool, read and

follow the disinfecting and cleaning instructions in this

manual thoroughly.

INSPECTING THE WHIRLPOOL

This Whitehall product has been carefully packaged at the

factory to minimize the possibility of damage during

shipping.

— Inspect the packaging for external signs of damage.

— Inspect the contents for damage.

If there is visible damage to the instrument upon receipt,

inform the shipping company and Whitehall immediately.

!

!

WARNING

WARNING

Do not attempt to operate this equipment if there is

evidence of shipping damage or you suspect the unit

is damaged. Damaged equipment may present

additional hazards to you. Contact Whitehall technical

support for advice before attempting to plug in and

operate damaged equipment.

Have your facility's equipment maintenance personnel

inspect the whirlpool regularly. Follow the checklist at right

and operate the whirlpool through all its functions as

described in this manual.

2

WHITEHALL MANUFACTURING • P.O. Box 3527 • City of Industry, CA 91744-0527 U.S.A.

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

Inspection Checklist

Ÿ

Are all components present?

Ÿ

Is the whirlpool free of excessive wear?

Ÿ

Does the turbine mount securely in place?

Ÿ

Is a properly-grounded and voltage-matched

hospital grade receptacle available for the turbine?

Ÿ

Is the outlet or turbine cord equipped with a

functioning GFI (or RCD)?

Ÿ

Can the turbine be raised, lowered and locked at the

desired height?

Ÿ

Does the drain valve open and close properly?

Ÿ

Is the thermometer present and is it legible?

Ÿ

Do the installed accessories operate without

interfering with whirlpool use or turbine operation?

USING THE WHIRLPOOL

Before Placing the Whirlpool In Service:

Operators using the whirlpool need:

Ÿ Personnel who will work with the whirlpool need to read

this manual.

Ÿ Have a plumbing professional install the whirlpool as

instructed in page 4. A rough-in

drawing is available to assist the installer. Contact

Whitehall Customer Service, bottom of page, for

additional installation not covered in this manual.

Ÿ Confirm that the whirlpool operates properly. See

Inspecting the Whirlpool , page 2.

Installing the Whirlpool,

Using The Whirlpool

General Guidelines for Use:

Ÿ Medical advice is beyond the parameters of this

manual.

Ÿ The whirlpool is for professional use only. A minimum of

one trained operator is required.

Ÿ The trained operator must evaluate and verify that the

patient is suitable for hydrotherapy treatment before

beginning hydrotherapy with whirlpool. See Patient

Evaluation, page 2.

Ÿ Follow your state and local hydrotherapy procedures

and, if the patient has one, the physician's order for

treatment (see Patient Evaluation, page 2).

Ÿ Stay with patient at all times.

Ÿ It is the operators responsibility to ensure safe practices

for the patient and themselves.

Ÿ If a turbine is used:

Plug the turbine cord only into a receptacle that is voltagematched, properly grounded and polarized. Verify that the

receptacle has GFI protection or order a GFCI plug for the

turbine cord.

Keep patient hair, gown strings and other loose items

away from the impeller housing to avoid entanglement

and injury.

Keep the area around the turbine clear. The turbine

requires a minimum of 24" (610mm) of clearance.

!

WARNING

Certain medical conditions are incompatible with

hydrotherapy. The trained operator is responsible for

determining each user's suitability for hydrotherapy

before beginning treatment.

Improper operation can cause injury. Operate the

whirlpool only as described in this manual.

An unattended patient can be injured. Stay with

patient at all times.

Loose items such as gown straps or gauze can be

pulled into the turbine impeller and cause injury. Keep

loose items away from the turbine impeller housing.

Important

Communicate with patient at all times. If a turbine is

used, tell the patient before starting or stopping the

turbine and before changing the water or aeration

level.

WHITEHALL MANUFACTURING • P.O. Box 3527 • City of Industry, CA 91744-0527 U.S.A.

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

3

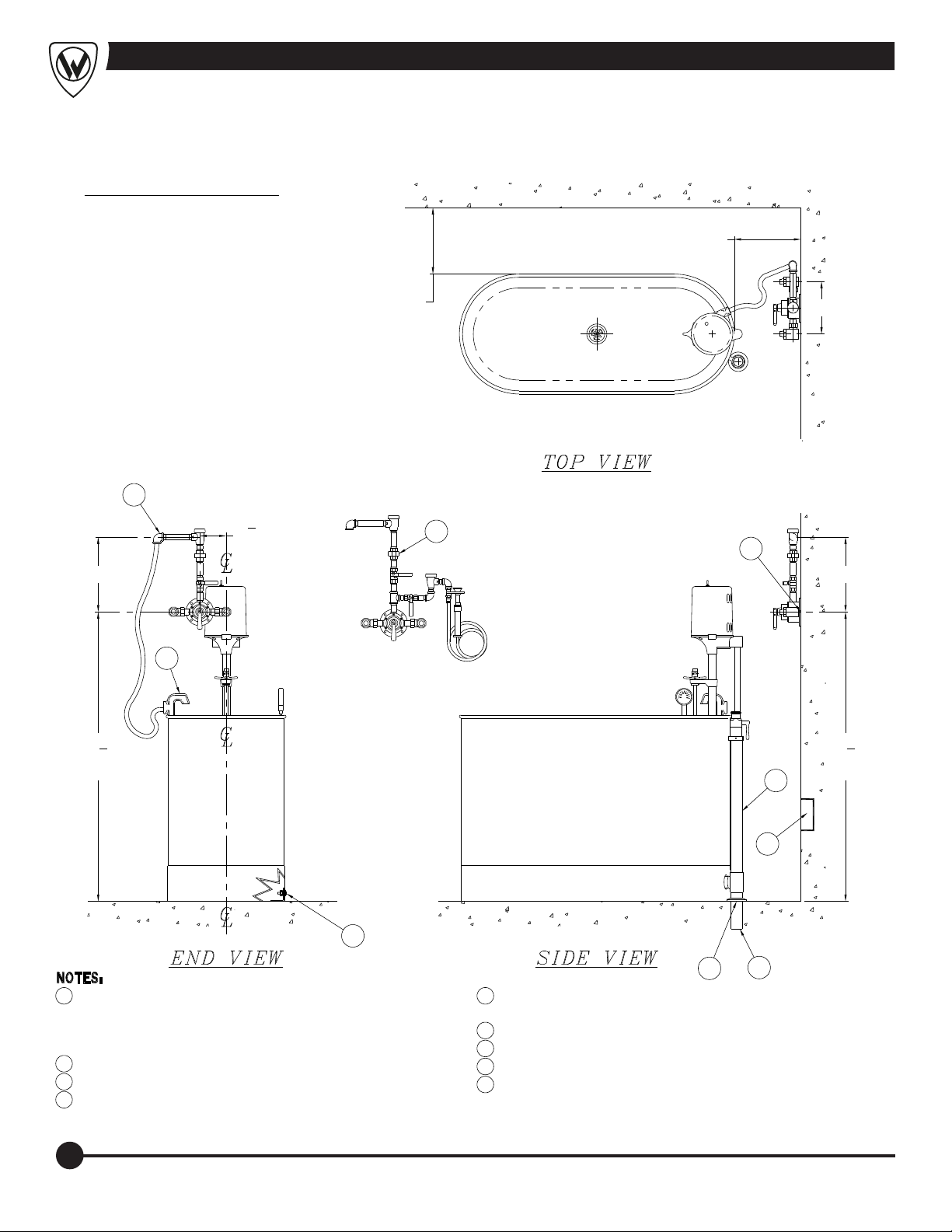

Fixture Installation Location Guide

DIMENSION DESCRIPTION

"A"

DISTANCE FOR:

MXT2 (MV2) 3/4" NPT

VALVE = 9-1/2"

MXT1 (MV1) 1/2" NPT

VALVE = 8-1/2"

"B"

DISTANCE FOR:

MXT2 (MV2) 3/4" NPT

VALVE = 13-1/2"

MXT1 (MV1) 1/2" NPT

VALVE = 13-3/4"

2

3

4

"

4

(120)

"B"

12"

(305)

REC. MIN.

12"

(305)

REC. MIN.

"A"

3

7

"B"

6

1

52

"

4

(1327)

9

ELECTRICAL REQUIREMENTS: 8 AMPS, 115 VOLTS. AT

1

WALL PROVIDE ONE 3 POLE RECEPTACLE HOSPITAL

GRADE WITH GROUND FAULT INTERRUPT FOR TURBINE

ASSEMBLY

THERMOSTATIC MIXING VALVES ARE OPTIONAL

2

OPTIONAL -MXWH (HA-WASHOUT ASSEMBLY)

3

2" x 5" TAIL PIECE FURNISHED WITH UNIT

4

5

1

8

2" COMBINATION DRAIN AND OVERFLOW ASSEMBLY

5

FURNISHED BY WHITEHALL

OVER RIM INLET

6

HOT & COLD WATER INLET

7

2" DRAIN

8

'L'-CLIPS FOR FLOOR MOUNTING

9

4

1

52

4

(1327)

"

4

WHITEHALL MANUFACTURING • P.O. Box 3527 • City of Industry, CA 91744-0527 U.S.A.

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

NOTE: THESE INSTALLATION

INSTRUCTIONS ARE USED FOR

ALL WHITEHALL OR DAKON

STATIONARY ALL MODELS.

REFERENCE DRAWINGS

ASSEMBLIES

MOTOR/TURBINE 8

RAISING/LOWERING/SM

RAISING/LOWERING 15

DRAIN OVERFLOW E

DRAIN OVERFLOW H/S

DRAIN OVERFLOW - L

THERMOMETER 26

PAGE NUMBER

14

18

17

19

20DRAIN OVERFLOW - P

3

"

4

2

1"

C

L

DETAIL "A"

(TOP VIEW)

7

Installation Instructions

13

1

5"

1

2

"

4

11

12

3

14

6

15

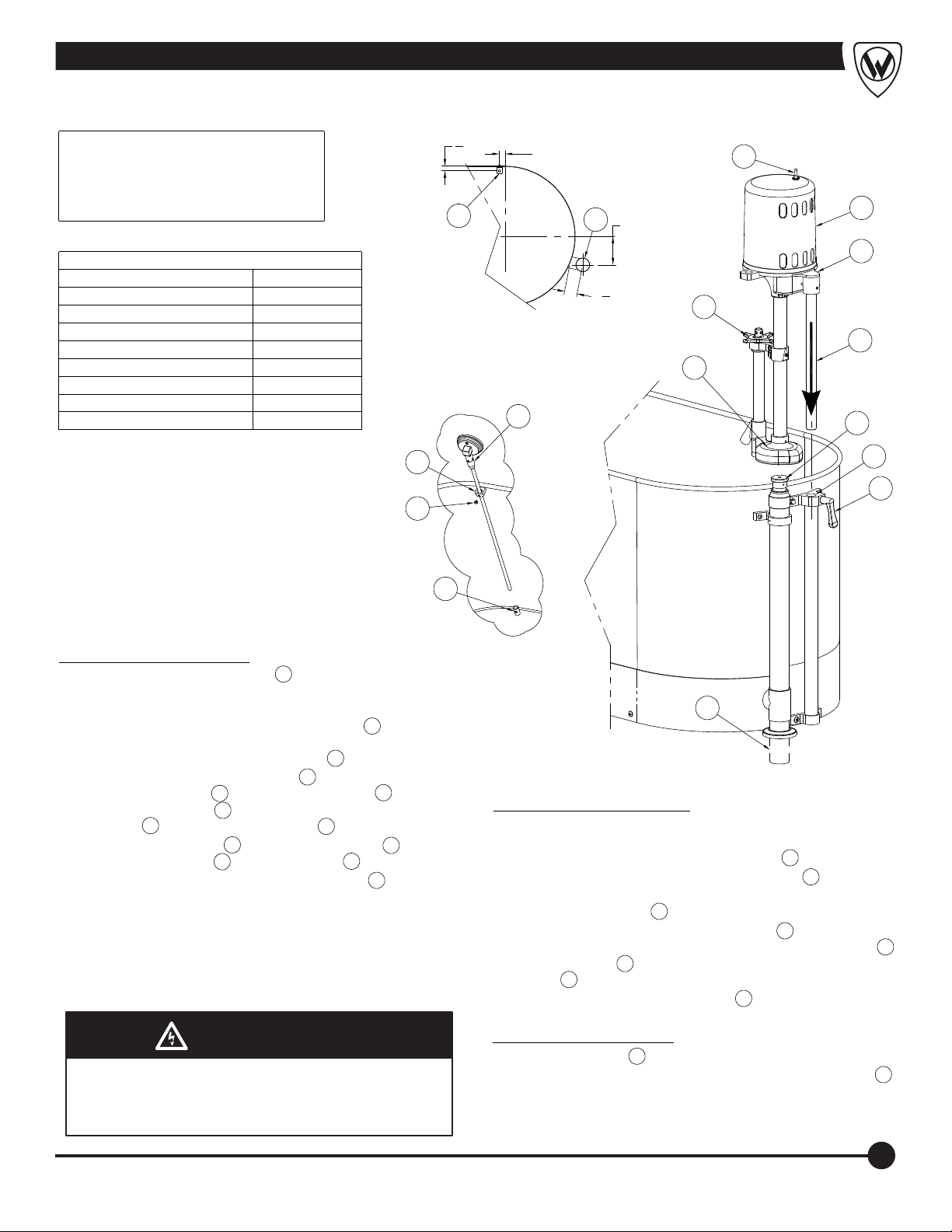

ASSEMBLY PROCEDURE:

A-

ROUGH-IN FOR 2" OD DRAIN LINE 1 AND WATER INLET VALVE.

(SEE DETAIL A) NOTE: FOR INFORMATION ON OPTIONAL

THERMOSTATIC MIXING VALVE CONTACT FACTORY.

B-

LOCATE TANK AND SECURE WITH "L" BRACKETS 2 , WITH

INSTALLER PROVIDED FLOOR ANCHORS AND ANCHORING

HARDWARE. MAKE WASTE CONNECTIONS 1 .

C-

INSTALL MOTOR/TURBINE ASSEMBLY 3 INTO RAISING AND

LOWERING ASSEMBLY 4 BY LOOSENING HANDLE 5 , SLIDING

MOTOR SUPPORT ROD 6 INTO RAISING AND LOWERING

ASSEMBLY 4 AND TIGHTENING HANDLE 5 .

D-

INSTALL THERMOMETER 7 THRU UPPER BRACKET 8 AND

INTO LOWER BRACKET 9 , TIGHTEN SCREW 10 .

E-

TURN THE PRESSURE CONTROL VALVE HANDLE 11 FULLY

CLOCKWISE, THEN FULLY COUNTERCLOCKWISE TO

COMPLETELY LUBRICATE THE PLUNGER ASSEMBLY.

F-

PROVIDE ELECTRICAL SERVICE AND PROPERLY INSTALLED,

GROUND FAULT CIRCUIT INTERRUPTER (GFCI) FOR MOTOR

SPECIFIED. MOTOR SPECIFICATIONS AVAILABLE ARE EITHER

120V AC / 60 HZ ON 15A CIRCUIT OR 240 V AC / 50 HZ ON 10A

WARNING

WARNING

Turbine assembly is provided with a 3-way plug. The

third prong functions as a built-in ground and must be

plugged into a matching grounded receptacle to

properly ground the product.

8

10

4

5

9

1

OPERATION PROCEDURE:

A-

FILL TUB AS DESIRED USING THERMOSTATIC MIXING VALVE.

WATER LEVEL SHOULD BE A MAXIMUM OF 4" BELOW THE RIM

AND A MINIMUM OF 6" ABOVE BOTTOM PUMP 12 .

B-

TURN THE PRESSURE CONTROL VALVE HANDLE 11 FULLY

CLOCKWISE, THIS PROVIDES MAX PRESSURE AND AGITATION.

C-

TURN ON THE SWITCH 13 .

D-

ADJUST RAISING AND LOWERING ASSEMBLY 4 BY SLOWLY

PUSHING DOWN ON TOP OF THE MOTOR SUPPORT CASTING 14

UNTIL THE PUMP 12 IS AT THE DESIRED LOCATION. TIGHTEN

HANDLE 5 . INTERNAL BUSHING MAY NEED ADJUSTMENT.

E-

ADJUST PRESSURE CONTROL VALVE 11 TO DELIVER DESIRED

LEVEL OF AGITATION AND PRESSURE.

DRAINING PROCEDURE:

A-

TURN OFF SWITCH 13 .

B-

LIFT COMBINATION DRAIN & OVERFLOW ASSEMBLY HANDLE 15 .

WHITEHALL MANUFACTURING • P.O. Box 3527 • City of Industry, CA 91744-0527 U.S.A.

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

5

Installation Instructions; -SDO Separate Drain Overflow

NOTE: THESE INSTALLATION

INSTRUCTIONS ARE USED FOR

ALL WHITEHALL OR DAKON

ALL STATIONARY -SDO MODELS.

REFERENCE DRAWINGS

ASSEMBLIES

MOTOR/TURBINE 8

RAISING/LOWERING/SM

RAISING/LOWERING 15

DRAIN OVERFLOW E

DRAIN OVERFLOW H/S

THERMOMETER

PAGE NUMBER

14

23

24

22DRAIN OVERFLOW - P

26

8

10

3

"

4

1"

13

3

2

14

C

L

7

7

"

8

1

3

"

2

1

11

6

DETAIL "A"

(TOP VIEW)

7

12

4

15

5

9

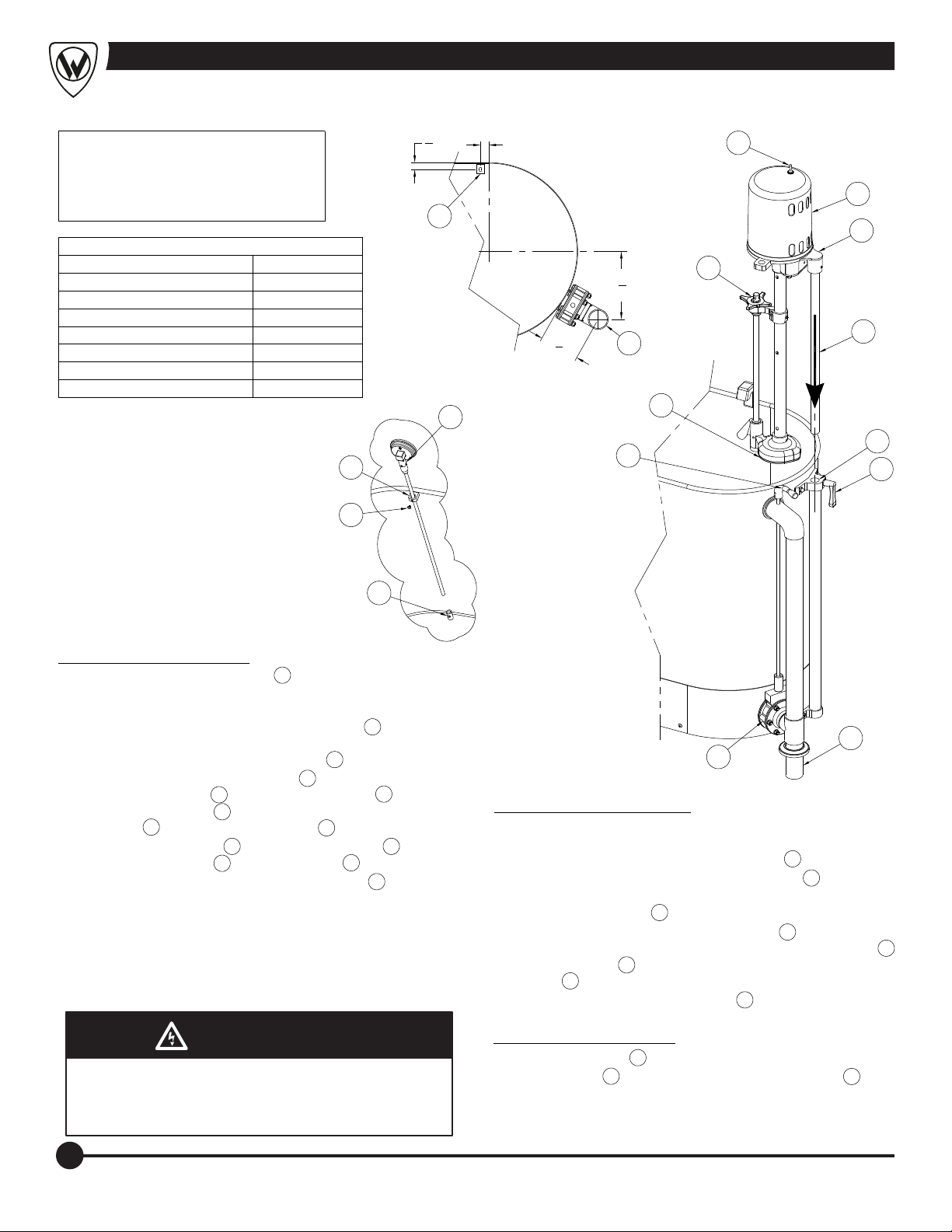

ASSEMBLY PROCEDURE:

A-

ROUGH-IN FOR 2" OD DRAIN LINE 1 AND WATER INLET VALVE.

(SEE DETAIL A) NOTE: FOR INFORMATION ON OPTIONAL

THERMOSTATIC MIXING VALVE CONTACT FACTORY.

B-

LOCATE TANK AND SECURE WITH "L" BRACKETS 2 , WITH

INSTALLER PROVIDED FLOOR ANCHORS AND ANCHORING

HARDWARE. MAKE WASTE CONNECTIONS 1 .

C-

INSTALL MOTOR/TURBINE ASSEMBLY 3 INTO RAISING AND

LOWERING ASSEMBLY 4 BY LOOSENING HANDLE 5 , SLIDING

MOTOR SUPPORT ROD 6 INTO RAISING AND LOWERING

ASSEMBLY 4 AND TIGHTENING HANDLE 5 .

D-

INSTALL THERMOMETER 7 THRU UPPER BRACKET 8 AND

INTO LOWER BRACKET 9 , TIGHTEN SCREW 10 .

E-

TURN THE PRESSURE CONTROL VALVE HANDLE 11 FULLY

CLOCKWISE, THEN FULLY COUNTERCLOCKWISE TO

COMPLETELY LUBRICATE THE PLUNGER ASSEMBLY.

F-

PROVIDE ELECTRICAL SERVICE AND PROPERLY INSTALLED,

GROUND FAULT CIRCUIT INTERRUPTER (GFCI) FOR MOTOR

SPECIFIED. MOTOR SPECIFICATIONS AVAILABLE ARE EITHER

120V AC / 60 HZ ON 15A CIRCUIT OR 240 V AC / 50 HZ ON 10A

WARNING

WARNING

Turbine assembly is provided with a 3-way plug. The

third prong functions as a built-in ground and must be

plugged into a matching grounded receptacle to

properly ground the product.

16

OPERATION PROCEDURE:

A-

FILL TUB AS DESIRED USING THERMOSTATIC MIXING VALVE.

WATER LEVEL SHOULD BE A MAXIMUM OF 4" BELOW THE RIM

AND A MINIMUM OF 6" ABOVE BOTTOM PUMP 12 .

B-

TURN THE PRESSURE CONTROL VALVE HANDLE 11 FULLY

CLOCKWISE, THIS PROVIDES MAX PRESSURE AND AGITATION.

C-

TURN ON THE SWITCH 13 .

D-

ADJUST RAISING AND LOWERING ASSEMBLY 4 BY SLOWLY

PUSHING DOWN ON TOP OF THE MOTOR SUPPORT CASTING 14

UNTIL THE PUMP 12 IS AT THE DESIRED LOCATION. TIGHTEN

HANDLE 5 . INTERNAL BUSHING MAY NEED ADJUSTMENT.

E-

ADJUST PRESSURE CONTROL VALVE 11 TO DELIVER DESIRED

LEVEL OF AGITATION AND PRESSURE.

DRAINING PROCEDURE:

A-

TURN OFF SWITCH 13 .

B-

TURN HANDLE 15 CLOCKWISE TO OPEN DRAIN VALVE 16 .

1

6

WHITEHALL MANUFACTURING • P.O. Box 3527 • City of Industry, CA 91744-0527 U.S.A.

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

Installation Instructions; Slant Back

REFERENCE DRAWINGS

ASSEMBLIES

MOTOR/TURBINE 8

RAISING/LOWERING

DRAIN OVERFLOW

THERMOMETER

2

PAGE NUMBER

1

1

"

4

TYP.

16

21

26

17"

TYP.

12

DETAIL "A"

(TOP VIEW)

7

8

10

9

1

"

8

7

6

"

8

13

3

14

11

6

12

15

5

4

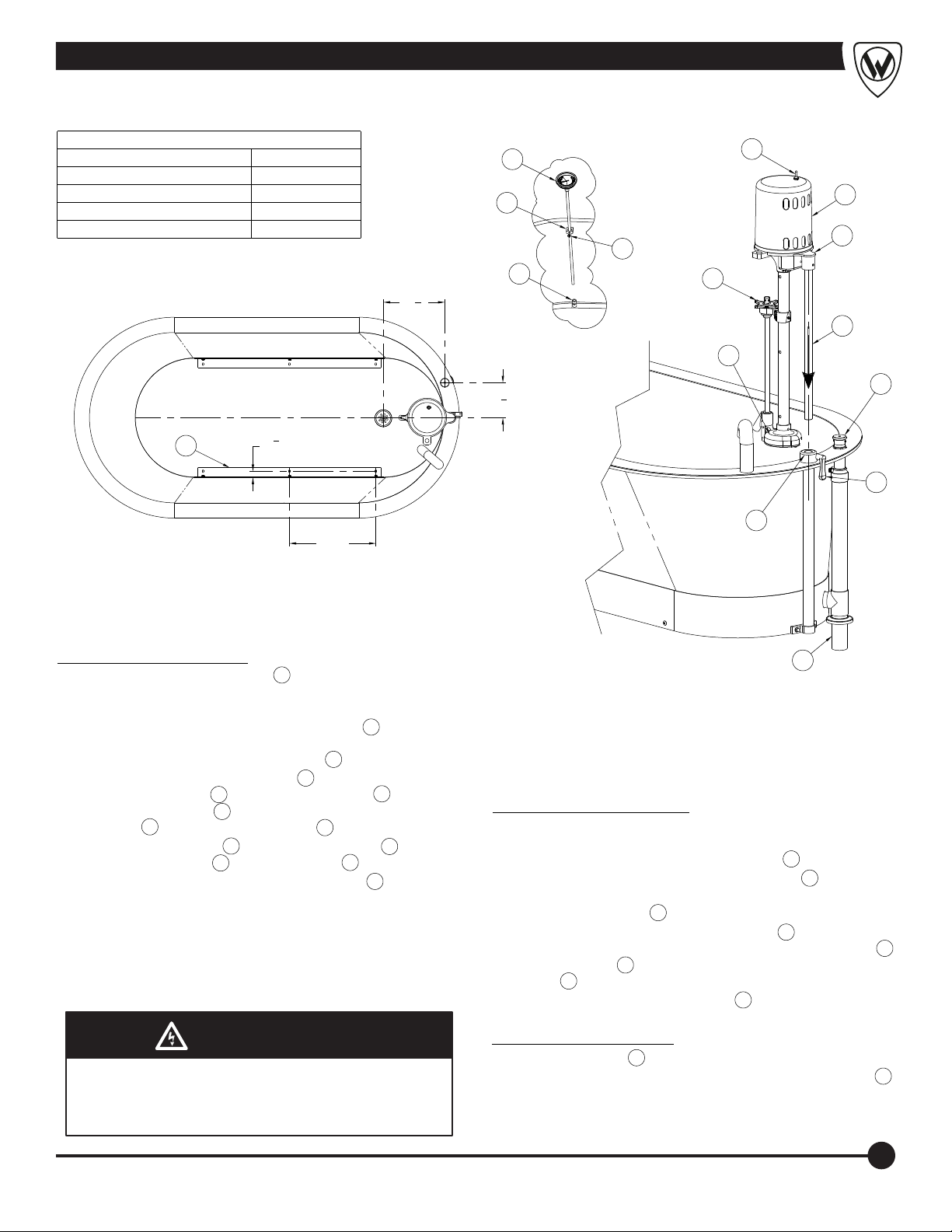

ASSEMBLY PROCEDURE:

A-

ROUGH-IN FOR 2" OD DRAIN LINE 1 AND WATER INLET VALVE.

(SEE DETAIL A) NOTE: FOR INFORMATION ON OPTIONAL

THERMOSTATIC MIXING VALVE CONTACT FACTORY.

B-

LOCATE TANK AND SECURE WITH "L" BRACKETS 2 , WITH

INSTALLER PROVIDED FLOOR ANCHORS AND ANCHORING

HARDWARE. MAKE WASTE CONNECTIONS 1 .

C-

INSTALL MOTOR/TURBINE ASSEMBLY 3 INTO RAISING AND

LOWERING ASSEMBLY 4 BY LOOSENING HANDLE 5 , SLIDING

MOTOR SUPPORT ROD 6 INTO RAISING AND LOWERING

ASSEMBLY 4 AND TIGHTENING HANDLE 5 .

D-

INSTALL THERMOMETER 7 THRU UPPER BRACKET 8 AND

INTO LOWER BRACKET 9 , TIGHTEN SCREW 10 .

E-

TURN THE PRESSURE CONTROL VALVE HANDLE 11 FULLY

CLOCKWISE, THEN FULLY COUNTERCLOCKWISE TO

COMPLETELY LUBRICATE THE PLUNGER ASSEMBLY.

F-

PROVIDE ELECTRICAL SERVICE AND PROPERLY INSTALLED,

GROUND FAULT CIRCUIT INTERRUPTER (GFCI) FOR MOTOR

SPECIFIED. MOTOR SPECIFICATIONS AVAILABLE ARE EITHER

120V AC / 60 HZ ON 15A CIRCUIT OR 240 V AC / 50 HZ ON 10A

WARNING

WARNING

Turbine assembly is provided with a 3-way plug. The

third prong functions as a built-in ground and must be

plugged into a matching grounded receptacle to

properly ground the product.

1

OPERATION PROCEDURE:

A-

FILL TUB AS DESIRED USING THERMOSTATIC MIXING VALVE.

WATER LEVEL SHOULD BE A MAXIMUM OF 4" BELOW THE RIM

AND A MINIMUM OF 6" ABOVE BOTTOM PUMP 12 .

B-

TURN THE PRESSURE CONTROL VALVE HANDLE 11 FULLY

CLOCKWISE, THIS PROVIDES MAX PRESSURE AND AGITATION.

C-

TURN ON THE SWITCH 13 .

D-

ADJUST RAISING AND LOWERING ASSEMBLY 4 BY SLOWLY

PUSHING DOWN ON TOP OF THE MOTOR SUPPORT CASTING 14

UNTIL THE PUMP 12 IS AT THE DESIRED LOCATION. TIGHTEN

HANDLE 5 . INTERNAL BUSHING MAY NEED ADJUSTMENT.

E-

ADJUST PRESSURE CONTROL VALVE 11 TO DELIVER DESIRED

LEVEL OF AGITATION AND PRESSURE.

DRAINING PROCEDURE:

A-

TURN OFF SWITCH 13 .

B-

LIFT COMBINATION DRAIN & OVERFLOW ASSEMBLY HANDLE 15 .

WHITEHALL MANUFACTURING • P.O. Box 3527 • City of Industry, CA 91744-0527 U.S.A.

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

7

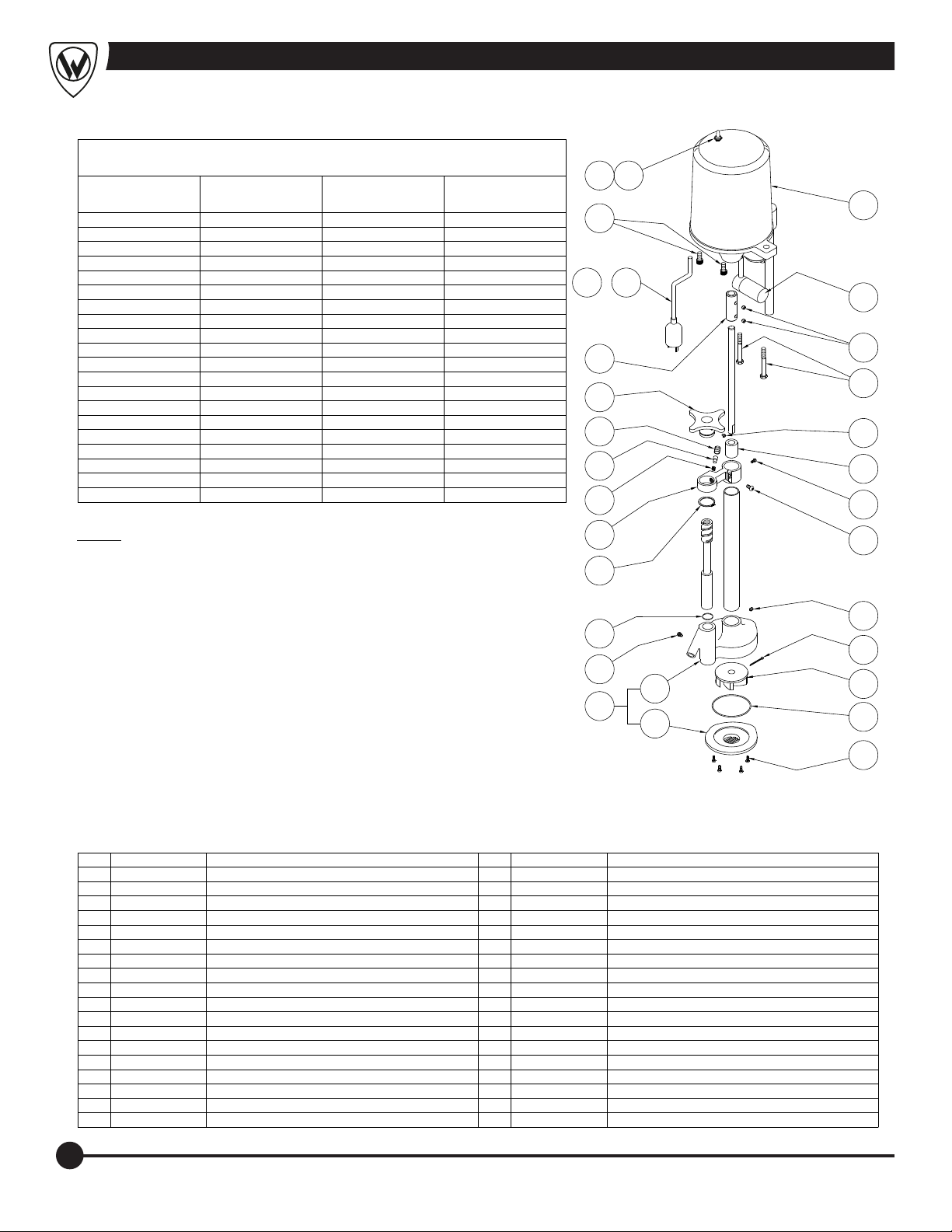

Stationary Motor/Turbine Assembly

THESE REPAIR PARTS ARE USED FOR THE

FOLLOWING MODEL NUMBERS ONLY:

WHITEHALL MODEL

NUMBERS

E-15-M-SDP

E-15-S

E-22-M-SDP

E-22-S

E-22-SP

E-27-M-SDP DD-2821

E-27-S DF-2821

E-36-M-SDP DD-2825

E-36-S DF-2825

E-45-M-SDP

E-45-S

H-60-M-SDP DD-3628

H-60-S

H-75-M-SDP

H-75-S

H-90-M-SDP

H-90-S

H-105-M-SDP DD-4828

H-105-S DF-4828

DAKON

MODEL NUMBERS

DD-2516

DF-2516

DD-2818

DF-2818

DF-3225

DF-3628

WHITEHALL MODEL

NUMBERS

L-75-M-SDP

L-75-S

L-90-M-SDP DD-6018

L-90-S DF-6018

L-90-SL

L-105-M-SDP DD-6618

L-105-S DF-6618

L-105-SL

P-10-S

P-15-M-SDP DD-2516

P-15-S DF-2516

P-22-M-SDP DD-2818

P-22-S DF-2818

S-85-M-SDP

S-85-S

S-90-M-SDP

S-90-S

S-110-M-SDP DDT-5625

S-110-S DFT-5625

SB-100-S

DAKON

MODEL NUMBERS

DDT-4825

DFT-4825

14 15

16

17A - 17H

18

19

20

21

22

13

12

11

10

9

8

7

NOTE: SEE ADDITIONAL DRAWINGS FOR

23

COMPLETE ASSEMBLY NUMBERS AND

DETAIL OF ITEMS NOT LISTED.

STATIONARY ''E'' SERIES

STATIONARY ''SB'' SERIES

Page 9

Page 9

STATIONARY ''H'' SERIES Page 10

STATIONARY ''L'' SERIES

STATIONARY ''P'' SERIES

STATIONARY ''S'' SERIES

Page 11

Page 12

Page 13

24

25

26

28

27

29

ITEM PART NUMBER DESCRIPTION ITEM PART NUMBER DESCRIPTION

1 6502-307-000 #8-32 x 1/2" PHIL FLAT HD SELF TAPPING

2 6504-501-199 17" PUMP GASKET

3 6525-518-000 TURBINE IMPELLER - PLASTIC

4 0341-101-000 COTTER PIN

5 6502-401-000 1/4"-20 x 5/16" HEX SOCKET SET SCREW

6 6502-042-000 1/4"-20 x 5/8" PHIL PAN HEAD SCREW

7 6502-300-000 #8-32 x 3/8" PHIL FLAT HEAD SELF TAPPING

8 6525-514-199 SHAFT BEARING

9 6502-410-000 1/4"-20 x 1/4" DOG SET SCREW

10 6502-352-000 3/8"-16 x 3" HEX CAP SCREW

11 6502-402-000 5/16"-16 x 1/4" HEX SOCKET SET SCREW

12 6502-020-001 CONDENSER ASSEMBLY

13 6525-600-000 PLASTIC MOTOR COVER

14 6505-025-000 DPST TOGGLE SWITCH

15 6505-035-000 WATERPROOF TOGGLE SWITCH CAP

16 6502-452-000 3/8"-16 x 3/4" HEX SOCKET CAP SCREW

17A 6505-030-000 10 FEET, 115VAC, 60Hz POWER CORD

17B 6505-034-001 DOMESTIC POWER CORD 220VAC, 60Hz

17C 6505-044-001 RUSSIAN POWER CORD, 250VAC, 50Hz

17D 6505-074-001 INDIA/S. AFRICA POWER CORD, 230VAC, 50Hz

17E 6505-043-001 EUROPEAN POWER CORD, 250 VAC, 50Hz

17F 6505-073-001 UK POWER CORD, 230VAC, 50Hz

17G 6505-070-001 ISRAEL POWER CORD, 250VAC, 50Hz

17H 6505-071-001 AUSTRALIAN POWER CORD, 250VAC 50Hz

18 6525-513-199

19 6525-584-199 HANDLE

20 6531-112-199 TENSION ADJUSTER

21 6531-111-199 FRICTION LOCK ROD

22 6531-113-000 SPRING

23 6525-570-199 AIR RING BRACKET

24 6502-620-000 1-3/8" RETAINING RING

25 6504-022-000 O-RING

26 6502-413-000 1/4"-20 x 5/16" DOG SETR SCREW

27 6525-509-001 PUMP BODY / COVER ASSEMBLY

28 6525-511-199 PUMP COVER

29 6525-510-199 PUMP BODY

SHAFT COUPLING

6

5

4

3

2

1

8

WHITEHALL MANUFACTURING • P.O. Box 3527 • City of Industry, CA 91744-0527 U.S.A.

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

Loading...

Loading...