Page 1

OWNERS MAN UAL

series

SC72UL#

SC92UL

Page 2

Owners Name:

Address:

Phone:

Purchase Date:

Purchase Location:

Serial #

: Located on backside of right fork leg

Fork Model:

Steer Tube Length:

Bike Brand:

Frame Size:

Safety

1.) NEVER REMOVE STEER TUBE FROM CROWN. THIS IS A PRESSED IN PART,

REMOVING IT WILL RENDER BOTH CROWN AND STEERER INOPERABLE*.MAKE

SURE YOUR FORK CAPS AND ALL FORK HARDWARE (brake studs,pinch bolts,

etc.) ARE TIGHT

2.) DO NOT PERFORM ANY MODIFICATIONS OR ADJUSTMENTS THAT ARE NOT

OUTLINED IN THIS MANUAL.SEE THE TUNING SECTION OF THE MANUAL FOR

MORE DETAILS.

3.) INSPECT YOUR FORKS BEFORE EVERY RIDE.INSPECT THE CROWN,TUBES AND

AXLE SEAT AREAS FOR ANY SIGNS OF FATIGUE,BENDING,CRACKING OR OTHER

DAMAGE.IF YOU NOTICE ANY TYPE OF DAMAGE,DO NOT RIDE ON THEM.

RETURN THEM TO YOUR DEALER FOR A COMPLETE INSPECTION AND NECESSARY

REPAIR OR WARRANTY STEPS.PLEASE REFER TO THE WARRANTY SECTION OF

THIS MANUAL.

4.) PERFORM ALL RECOMMENDED MAINTENANCE ACCORDING TO THE MAINTENANCE

SECTION OF THIS MANUAL.FAILURE TO PERFORM MAINTENANCE COULD

DRASTICALLY REDUCE YOUR FORKS LIFE AND PERFORMANCE.

5.) WHITE BROTHERS RECOMMENDS THAT YOU WEAR PROPER SAFETY EQUIPMENT

EVERY TIME YOU RIDE,INCLUDING A APPROVED BICYCLE HELMET.NEVER RIDE

AT NIGHT WITHOUT LIGHTS!

* IF SERVICE BECOMES NECESSARY OR REMOVAL OCCURS, PLEASE CALL WHITE BROTHERS CUSTOMER SERVICE

FOR PRODUCT EVALUATION AND DIAGNOSIS.

Fork Log

Page 3

1

TABLE OF CONTENTS:

SECTION ONE...................Applications..............................................PAGE 1

SECTION TWO

.................Fork Installation.................................PAGE 2

SECTION THREE

..............Tuning.................................................................PAGE 3-5

SECTION FOUR

................Maintenance.............................................PAGE 6-8

SECTION FIVE

...................Exploded Views...................................PAGE 9-10

SECTION SIX

......................Warranty..........................................................P A GE 13

Applications

Thanks for purchasing your new White Brothers Fork. You are in for the best ride of your

life. Our forks are designed to give you the level of performance you need to ride at your

absolute peak.

The White Brothers Ultra Light Series forks features a lightweight air damper design. This

damper is very easily adjusted for a wide range of riding requirements. Additional tuning can

be accomplished by adjusting negative spring preload or changing the negative springs to a

different style. Steering accuracy is improved over conventional MTB forks by the utilization of

superior materials and design. These include oversized 31.75mm fork tubes,a torsion box

design steering crown with pressed-in tubes (SC72/92UL models),an extruded magnesium

heavy duty brake bridge,and extra-thick machined drop-outs. Fork travel has been chosen to

offer the best performance possible for each forks intended use.

Every possible effort has been made to make the White Brothers Forks very light in weight

and perform at a level superior to other forks on the market. To insure peak performance,

proper installation and periodic maintenance is required. Please read this manual in its entirety to familiarize yourself with the fork and insure your satisfaction with this product.

White Brothers Forks are designed for offr

oad use only. They are not equipped with proper

reflectors for on-road use. If you are going to use your forks for road use,have your dealer or

mechanic install reflectors that meet the Consumer Product Safety Commission’s (C.P.S.C.)

requirements for bicycle standards. If you have any questions concerning C.P.S.C.Standards,

please talk to your dealer.

When using your forks on public land and trails,please respect the rights of other users and

stay on established paths and trails. By mounting biking responsibly,you help to insure the

future of our sport.

Page 4

Fork Installation

White Brothers Ultra Light Series forks features a 1 1/8” threadless steerer tube. If you have a

threaded type fork on your bicycle,consult your dealer for the appropriate upgrade parts nec-

essary to convert to a 1 1/8”threadless steerer tube.

1.) Remove old forks from the bicycle. See your bicycle’s owners manual. Measure the diameter and

length of your old forks steerer tube to insure that the White Brothers fork steerer tube is the correct

diameter and has sufficient length for the installation.

2.) Remove the cr o wn r ac e from your old forks.Note:Replace the bearings if there are any signs of wear

or corrosion

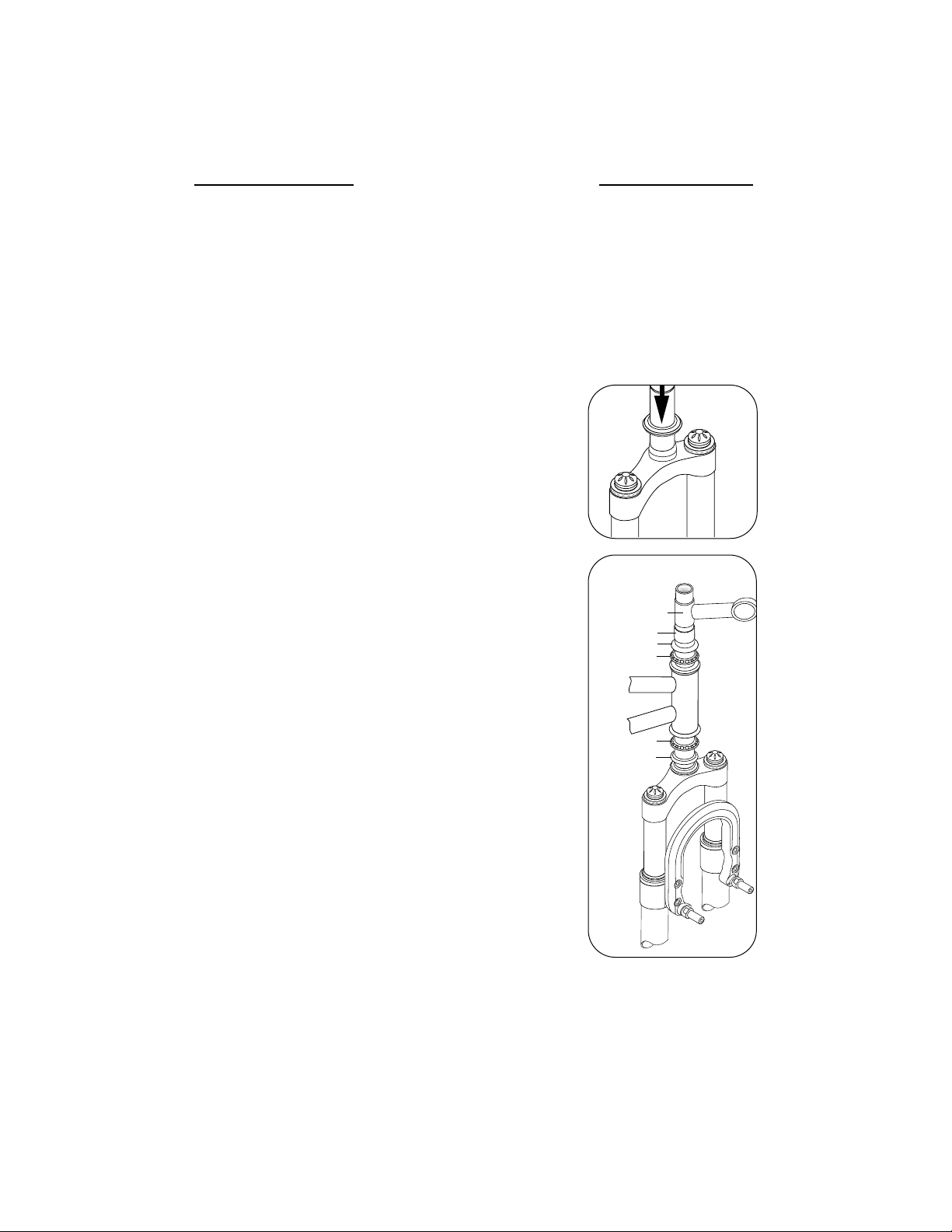

3.) P ress the cro wn rac e onto the steer er of y our White Brothers fork (figure 1).

4.) Preassemble headset by: Sliding fork steerer tube through headset

bearings.Then install top headset, stem spacer (optional),and steering stem onto fork steerer tube. Refer to headset owners manual if

you have any questions about this preassembly.

5.) Mark steerer tube at top of steerer stem. Steerer must then be cut

3mm (1/8”) below this mark. Consult a dealer or mechanic if you do

not have the proper tools for cutting the steerer tube.

6.) The special star fangled nut must now be installed into the steerer.

We recommend dealer installation of this part since a special tool is

required.

7.) Clean and grease all headset bearings and races to prepare them for

assembly.

8.) Now assemble headset as done in Step 4 (figure 2).

9.) Install the steering stem (threadless type is required) and handle-

bars. Set your bars to your desire height.

10.) Install the threadless mounting cap. Tighten the top threadless

stem bolt until there is no play in the fork tube. The forks should

rotate freely in the head tube. S ecure the pinch bolts on the steering stem. Consult the installation instructions for your threadless

bearing set to insure correct installation and tension of the headset.

11.) Install your front brakes and adjust following the manufactures

specifications.

12.) Adjust quick release hub on your front wheel to clear the secondary catches of the forks. The quick release must be tightened after it

is properly seated into the dropout counter bores. Insure that there

is sufficient thread engagement (5 or more threads with the release

adjusted to lock) due to the thicker White Brothers fork dropouts.

Install front wheel to bicycle per manufacturers specification.

13.) Check to see that your br akes are adjusted and w orking.Make

sure brake cable doesn’t foul on any part of bicycle when fork is com-

pressed and released.

2

headset bearings

lower race

top race

steering stem

headset bearings

spacer (optional)

figure 1

figure 2

Page 5

3

Tuning

To get the most from your White Brothers Pro Forx it is important that you tune the forks to fit your style of

riding and the conditions you ride in.

Initial break-in period

Your new fork is designed to break-in over a period of 10 hours or more of riding. As all of the parts bed

into each other, the stic tion (friction) of the forks will reduce and the forks will absorb the bumps better.

After this initial break-in,fine tuning the spring preload and car tridge damper may be beneficial to achieve

the best possible fork performance for your weight and riding style.

Adjustment and Maintenance

.Valve wrench (provided)

.4mm allen wrench

.rear shock pump or other high pressure pump (WB pn 97-725)

.Air Tight Adapter (WB pn 97-726)

.Neutral Shaft Retainer Pin Spanner (WB pn 97-716)

The White Brothers Ultra Light Series forks has been fitted with Total Air cartridges for spring and damping. Total Air cartridges are lightweight, adjustable air-sprung shock absorbers which screw into the fork

stanchions at the crown. The following guidelines for checking and adjusting your cartridges will enable you

to enjoy maximum performance from your fork.

1) IMPORTANT! Always before riding the fork, push down on the bars hard with all your body weight to

check for sufficient air pressure in your Total Air cartridges. The fork should not bottom out easily (if more

pressure is needed,see No.4 through 6 below).

2) Test ride the fork first over easy terrain. If after riding over a variety of terrain you decide that tuning is

necessary,go on to the next section. Before beginning,make sure you have the necessary tools.

Compression Adjustment

3) The compression or overall “spring”of the fork can be changed two ways;by changing air pressure and by

resetting the adjuster. Either change requires re-inflation of the cartridges. Rebound adjustment is done

by changing adjusters.

4) If the forks feels too soft or firm,try changing the air pressure as follows:

SC72UL

Rider Wt.(lbs.) Plush Ride Firm Ride

100-120 110-140 psi 125-150 psi

120-140 130-155 psi 140-160 psi

140-160 140-165 psi 150-170 psi

160-180 150-175 psi 160-180 psi

180-200 160-185 psi 170-190 psi

200-220 170-190 psi 180-200 psi

220- 180-195 psi 190-210 psi

SC92UL

Rider Wt.(lbs.) Plush Ride Firm Ride

100-120 105-110 psi 115-125 psi

120-140 110-125 psi 125-135 psi

140-160 125-140 psi 140-150 psi

160-180 140-155 psi 155-165 psi

180-200 155-165 psi 165-175 psi

200-220 165-170 psi 175-185 psi

220- 170-180 psi 185-195 psi

Page 6

4

5) Unscrew each of the dome-shaped dustcaps so that the schrader valve

stem is exposed

(figure 3).

6) A high pressure shock pump is the best way to inflate cartridges. WB recommend you purchase the BTI High Pressure Air Pump (pn 97-725) and

the BPP Air Tight Adapter (pn 97-726). Install the male part of the BPP Air

Tight Adapter into th ehose end of the BTIHigh Pressure Air Pump. The

pump is ready to use. Thread the pump with adapter onto the fork’s

schrader valve stem(figure 4). Pump the BTI High Pressure Air Pumpuntil

the air pressure is up to pressure recommended on the chart (page 3) for

your weight prefrence and type of fork. Unthread the Air Pump from the

schrader valve stem. Repeat this procedure on the other fork leg. After

pressurizing is completed,reinstall dome-shaped dustcaps.

7) Further tuning can be done by resetting the damping adjuster in each

cartridge. Deflate both cartridges. Brush away any dirt or sand around

the schrader valve and unscrew it with the tubular socket wrench provided. Set the schrader valve aside only on a dust-free surface.

8) The adjuster setting is measured in “turns out”,or counterclockwise turns

from the fully closed position. Your adjusters are preset at 6 turns out.

9) Insert the long end of a 4mm allen wrench through the schrader valve

hole (figure 5). Rotate it slightly while pushing down until you feel it

seat in the top of the adjuster. Turn the wrench clockwise counting the

turns until you reach to fully seated position. NOTE: Do not turn the

adjuster hard clockwise against its seat,only turn it until it lightly touches its closed position. Failure to follow these instructions can damage

the adjuster spring.

10) Now, screw the adjuster counter clockwise to the setting you need.

Fewer “turns out”will result in a firmer ride,more turns out will provide a

plusher ride. The following guidelines may be useful. NOTE:Never set

the adjuster at more than 8 turns out from bottom.

SC72UL

Rider Wt.(lbs.) Plush Medium Firm

100-120 8 6 1/2 5

120-140 7 1/2 6 4 1/2

140-160 7 5 1/2 4

160-180 6 1/2 5 3 1/2

180-200 6 4 1/2 3

200-220 5 1/2 4 2 1/2

220- 5 3 1/2 2

SC92UL

Rider Wt.(lbs.) Plush Medium Firm

100-120 8 7 6

120-140 7 1/2 6 1/2 5 1/2

140-160 7 6 5

160-180 6 1/2 5 1/2 4 1/2

180-200 6 5 4

200-220 5 1/2 4 1/2 3 1/2

220- 5 4 3

11) When replacing the schrader valve in the air cap,make sure that

the o’ring on the schrader valve is free of dust or hair and in good

condition. Warning: Use only the tubular wrench to tighten

the schrader valve;ordinary wrenches or pliers can overstress

the threads in the nylon air cap.

Adjuster

Piston O-Ring

Air Cap O-Ring

Adjuster O-Ring

Compression Valve

Valve Spring

Negative Spring

Spring Spacer

figure 3

figure 4

figure 5

Page 7

5

12) Rebound is governed by the size of a small hole in the adjuster. The

adjusters installed in your cartridges are rated for “medium”

rebound. In the small bag included in the package are adjusters

rated for “slow”and for “fast”rebound damping.

13) Adjusters are coded to distinguish them. Slow rebound adjusters

are marked #1, medium are marked #2, and fast are marked #3

(figure 6).

14) To change an adjuster, deflate both cartridges and remove the

schrader valve stems. Insert the long end of a 4mm allen wrench

through the hole and into the top of the adjuster . Rotate the adjuster

counterclockwise several times until it finally comes loose. When the

adjuster is free,it can be withdrawn on the end of the allen wrench by

tilting the wrench slightly and pulling it up through the valve stem

hole (figure 7). Caution: Just under the adjuster are the compres-

sion valve and spring; these may fall out if the fork is turned

upside-down while the adjuster is out. If they do fall out, first install

the spring, then seat the tapered end of the compression valve in

the adjuster and carefully re-install the adjuster into the cartridge.

15) Insert the new adjuster through the schrader valve hole in the air cap. Follow Steps 9 and

10 for installing and positioning the adjuster.

16) Reinstall the schrader valve,inflate the cartridges and replace the dust cap. The standard

rebound settings should suit most applications when the proper air pressure has been used,

since damping medium increases with pressure.

By increasing or decreasing preload,and/or changing negative springs,the

action of the White Brothers Ultra Light Series forks can be altered. White

Brothers has designed each model of the Ultra Light Series forks to be tuneable for a very plush initial ride or adjusted for a firmer, with less pedal

induced bio-pacing type of ride. Below list the negative spring

tuning options for each fork.

SC72UL: As delivered, the SC72UL fork is equipped with a long negative

spring and guide system (Std.Kit, figure 8) that offers a plush,

responsive initial ride. This system is recommended for most riders. Included

with the SC72UL is the (Pro Kit, figure 9). The Pro Kit consist of a short

negative spring and nylon spacer (replaces the long negative spring and

nylon guide). With the Pro Kit installed, the forks are quite stiff at the top of

the travel. Bobbing while climbing and pedal induced bio-pacing is reduced

with the Pro Kit installed. See figure 8 and 9 for proper installation of the

negative spring system.

SC92UL/DC120UL: As delivered, the SC92 and DC120UL fork is equipped

with a long negative spring and guide system. This system is recommended

for most riders. Optional spacers are included with each fork that will increase

the preload on the negative springs and offer a plusher,more responsive initial

ride. Normally, we recommend installation of these spacers only when the fork pressure has

been adjusted to a very high setting for heavy riders. Install one or three spacers (the more spacers,the softer the initial fork travel) under the negative spring inside the bottom out cap (figure

10). NOTE: Never install more than three spacers under the negative spring,fork travel will

be reduced. See exploded view for proper installation of the negative spring system.

plush

firm

Negative Spring Adjustments

figure 6

figure 7

figure 9

figure 8

Rebound Adjustments

Page 8

Maintenance

Your White Brothers fork requires periodic maintenance to insure peak performance and long

life. Moisture and contamination may build up inside the fork. We suggest you disassemble your

forks,inspect, clean and re-grease them after 30 hours of use. If the forks appear to be relatively

clean,you can probably go 40 hours between servicing. If the forks appear dirty,you should service them every 20 hours. The three things that will most effect the service inter val and per formance of your forks is water,mud and dust. D epending on how much time you use your forks in

those conditions will determine how much service they require.

NOTE: When cleaning the fork,it is not recommended to direct water spray at the seals.

NOTE: Neglecting proper fork maintenance will reduce the forks life. Internal build up of water

and dirt,or a lack of lubrication will cause excessive wear to the forks.

Maintenance (Total Air Cartridges)

1) Check and top up pressure in the cartridges after approximately 10 hours of typical riding

(more often in the case of racing or very hard riding) or if the bike has not been ridden for two

weeks or more. Lubricate the cartridge shaft every two months using WB/Englund

Suspension Lube or Englund Slick Honey.

2) If unusual pressure loss occurs,remove the cartridges,inflate to at least 150 psi and immerse

in water for several minutes with the dust caps removed. Slow bubbling from inside or underneath the air cap usually indicates a contaminated schrader valve o’ring or air cap o’ring.

Remove suspect o’rings with a toothpick. If the o’ring is not cut or torn,cleaning and regreasing the o’ring and o’ring seats will usually repair the leak. Slow bubble formation at the top of

the schrader valve (one bubble every 30-60 minutes) is normal,more rapid bubbling indicates

a loose or defective valve core.

If no leak can be seen after fifteen minutes of immersion,pressure loss probably occurs in use

due to a worn or contaminated cartridge body o’ring. The body o’ring is easy to replace with

a “Cartridge Body Seal Kit”available through your local dealer or from White Brothers.

Disassembly/Assembly Negative Spring System

1) Let air out of Total Air Cartridges by removing dome-shaped dust caps and compressing

valve core.

2) See Basic Fork Disassembly/Assembly for how to remove and reinstall lower fork legs from

fork stanchions.

3) With fork legs removed,loosen nylon bottom out cap from fork stanchion. NOTE:A proper

fitting pin spanner or WB pn 97-716 tool is required. Remove entire dummy shaft assembly

noting order of parts. Adjust negative spring preload and/or spring per Negative Spring

Adjustments above, or simply remove the travel limiter and compression bumper and slide

assembly out the top crown with

cartridges and top caps removed.

4.) To install Pro Kit remove long negative spring and guide. Then install shor t spring and

spacer supplied in kit.

5.) Reinstall in reverse order.

6

Page 9

* White Brothers recommends that you consult with a qualified technician before performing the following:

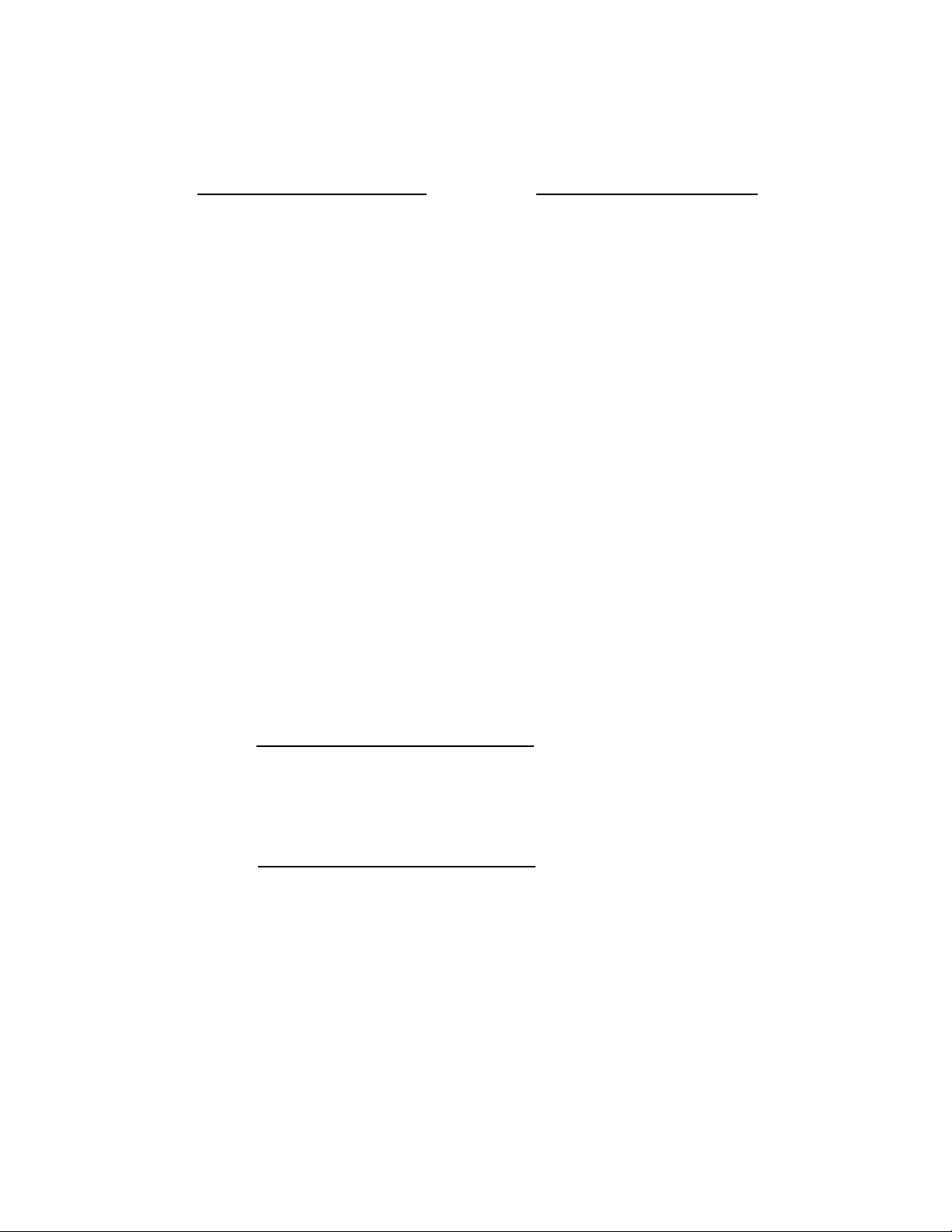

Basic Fork Disassembly

1) Disconnect front brake and remove wheel as outlined in your

bicycle’s owners manual.

2) Remove allen head bolts at the bottom of the forks using a

6mm allen wrench (figure 1).

3) Simply slide the lower fork legs off the end of the inner stanchion tubes. Be careful not to damage the seals as you pull

inner legs out (figure 2).

4) At this point clean all parts with a clean,non-abrasive rag. A

mild grease cutting cleaner or solvent might make this an

easier task.

Once clean,inspect seals for tears or cracks. If okay,regrease

them with White Brothers Suspension Lube or other suitable,

non-lithium grease. If your seals are no longer serviceable,

check the General Disassembly Parts Table section of this

manual for the proper replacement part numbers. Also,check

carefully the DU bushes for wear. This is done by looking at

the color of the bushes. If they are dark grey, the bushes are

okay. If they are bronze/gold in areas, they are worn and

can cause fork stanchion damage. Your dealer will be able

to order any replacement parts you might need.

5) Next, inspect the fork stanchion tubes for wear, nicks or

scrapes. If there is noticeable play between lower fork legs

and fork stanchions,the DU bushes located inside the lower

fork legs may require replacement. Consult your dealer for

service options.

6) If ever ything is free of problems, coat all parts with a light

coating of White Brothers/Englund Suspension Lube or other

suitable,non-lithium grease. Also lube the DU bushings that

are located inside lower fork legs by dipping a socket extension in grease and applying the grease into the inside of the

fork stanchion on the DU bushings.

READ PRIOR TO FORK ASSEMBLY: White Brothers Ultr a Light

Series forks feature a triple lip seal system with wiper seal.15

cc’s of 30wt. Motor oil is also added through top of fork to

keep fork internals lubricated and reduce maintenance requirements. An optional Slick Kit System is included with each WB Ultra Light Fork. Kit consists of

foam wiper that replaces the triple lip seals installed in the fork legs. The slick kit reduces seal

tension and decreases stiction in the fork. Since the only the foam wipers are oiled,weight

(approx.30 grams) is saved because additional lubricating only is not added to the fork. The

Slick Kit System is recommended for dry conditions and requires more frequent fork

disassembly and maintenance schedules.

7

figure 1

figure 2

Page 10

8

Basic Fork Assembly

7a) WITH STD. TRIPLE LIP SEAL SYSTEM, (figure 3): Install cone

shaped compression bumper and nylon travel limiter (see

parts breakdown drawings on page 8 for correct installation of

these parts). Carefully install fork legs over fork stanchion

tubes rocking legs slightly allowing fork stanchion tubes to

engage DU bushings inside of fork legs. Fully compress f orks so

that 6mm allen bolts can be installed into bottom fork legs and

engage internal rods. NOTE: Do not tap fork legs onto stanchions, DU bushings can be dislodged. Slide both fork stanchions into lower fork legs and fully compress. Fully tighten

6mm allen bolts in lower fork legs. Remove complete Total Air

Cartridges from top of fork legs and add 15cc’s of 30wt motor

oil per side. Reinstall and tighten fully the Total Air Cartridges.

7b) WITH SLICK KIT SYSTEM, (figure 4): Remove the top wiper

seals and triple lip seals (triple lip seals will not be reinstalled)

with a tire tool prying upward. NOTE: Remove top wiper seal

tension spring prior to prying seals upward. Be careful not to

damage seal or scratch aluminum seal housing. Slide fork seals

and Slick Kit foam wipers over both fork stanchion tubes. S eals

should be greased and wipers should be oiled prior to assembly. Install cone shaped compression bumper and nylon travel

limiter (see parts breakdown drawings on pages 8 through 10

for correct installation of these parts). Carefully install fork legs

over fork stanchion tubes rocking legs slightly allowing fork

stanchion tubes to engage DU bushings inside of fork legs.

Fully compress forks so that 6mm allen bolts can be installed

into bottom fork legs and engage internal rods. NOTE: Do not

tap fork legs onto stanchions,DU bushings can be dislodged.

Slide both fork stanchions into lower fork legs and fully compress. Fully tighten 6mm allen bolts in lower fork legs. Slide the

foam ring into each lower fork leg carefully tucking it in on all

sides. Finish reassembly by snapping into place the fork seals

(figure 5).

8) Make sure fork caps and cartridges are fully tightened into top

of fork stanchion tubes. Connect front wheel and brakes as outlined in your bicycles owners manual.

9) Compress your forks to make sure they work smoothly and brake

cable doesn’t foul on fork in anyway.

figure 3

figure 4

figure 5

Page 11

9

7

8

6

5

4

3

2

1

9

10

OPT.

OPT.

STD.

11

31

30

29

28

27

26

25

24

22

21

20

19

15

14

16

17

18

11

23

12

13

1

WIPER SEAL 97-1350

2

FOAM RING 97-1358

3

OIL SEAL P3060

4

DU BUSH 97-986

5

TI BRAKE MOUNT STUD 97-3662

6

BRAKE SPRING RETAINER 97-3663

7

BRACE BOLT (6M) P4001

8

BRACE P1602

9

LEG ASSEMBLY (LH) P1502

10

LEG ASSEMBLY (LH W/ BRAKE MOUNT) P1500

11

SHAFT BOLT(8mm) P4000

12

SEALING WASHER P4000-1

13

LEG ASSEMBLY (RH) P1501

14

1

1/8"

STAR NUT 97-9301

15

AIR DAMPENING SYSTEM (75mm) 97-875

16

TOP FORK CAP 97-3655

17

0-RING P3023

18

CROWN ASSEMBLY P1140

19

COMPRESSION PAD 97-858-30

20

PLUG, PUSHER P2501

21

DUMMY PUSHER '99 P2500

22

0-RING F-2402

23

PRELOAD SHIM (AS REQIURED) P3310-1

24

NEGATIVE SPRING GUIDE P3310

25

NEGATIVE SPRING P3202

26

BOTTOM OUT CAP P3306

27

PRO KIT SPRING P3202-1

28

PRO KIT SPACER P3202-2

29

DUMMY SHAFT P2020

30

COMPRESSION BUMPER P3290

31

TRAVEL LIMITER 97-3900

The SC72ul Exploded View

The following illustration and parts

table gives you the exploded view of

the SC72ul fork. The parts table lists

the part number for each individual

part in the fork and is the reference

you will need if ordering replacement

parts. See your local dealer to order

the parts that you require.

Page 12

10

7

8

6

5

4

3

2

1

9

OPT.

STD.

10

27

26

25

24

23

21

22

20

19

18

14

13

15

16

17

7

11

12

1

WIPER SEAL 97-1350

2

FOAM RING 97-1358

3

OIL SEAL P3060

4

DU BUSH 97-986

5

STEEL BRAKE MOUNT STUD 97-3665

6

BRAKE SPRING RETAINER 97-3663

7

BRACE BOLT (6M) P4001

8

BRACE P1602

9

LEG ASSEMBLY (LH W/ BRAKE MOUNT) P1500

10

11

SHAFT BOLT(8mm) P4000

12

SEALING WASHER P4000-1

13

LEG ASSEMBLY (RH) P1501

14

1

1/8"

STAR NUT 97-9301

15

AIR DAMPENING SYSTEM (95mm) 97-876

16

TOP FORK CAP 97-3655

17

0-RING P3023

18

CROWN ASSEMBLY P1142

19

COMPRESSION PAD 97-858-30

20

PLUG, PUSHER P2501

21

DUMMY PUSHER '99 P2500

22

0-RING F-2402

23

PRELOAD SHIM (AS REQIURED) P3310-1

24

NEGATIVE SPRING GUIDE P3310

25

NEGATIVE SPRING P3203

26

BOTTOM OUT CAP P3306

27

DUMMY SHAFT P2021

COMPRESSION BUMPER P3290

The SC92ul Exploded View

The following illustration and parts

table gives you the exploded view of

the SC92ul fork. The parts table lists

the part number for each individual

part in the fork and is the reference

you will need if ordering replacement

parts. See your local dealer to order

the parts that you require.

Page 13

11

Notes

Page 14

12

date service performed

Maintenance Log

date service performed

Page 15

WARRANTY RETURNS

White Brothers forks are designed to enhance riding please and as such are

warranted to be free from defects in materials and workmanship for a period

of six months from the date of purchase. On receipt of the forks by White

Brothers,if they are found to be defective,White Brothers will determine

replacement or repair of the forks. This warranty is the sole and exclusive remedy. White Brothers shall not be liable for any indirect,special or consequential damages.

Warranty does not apply to any product that has been installed improperly

or adjusted using methods not outlined in this manual. Warranty also does

not cover forks that have been misused,or forks that are missing or have

altered serial numbers (located on the backside of the right fork stanchion).

The forks are not warranted against damage in the appearance of the fork or

for modifications not outlined in this manual. This warranty does not cover

breakage,bending,or damage that may result from crashes,falls or abuse.

Normal wear (i.e.seals,bushings,slider finish, etc.) and wear and damage

caused by lack of proper maintenance is not included.

A copy of the proof of purchase must be included with all warranties.

Customers in the USA please contact your dealer for a Return Authorization

Number (RA#) before returning the forks. All forks returned for inspection

must be sent freight paid to:

WHITE BROTHERS

A division of EKO Sport Inc.

580 N. Westgate Dr.

Grand Junction, CO 81505

Phone (800) 999-8277 Fax (970) 241-3529

http://www.whitebrotherscycling.com

*Customers outside the USA please contact the dealer or distributor in your area

13

Loading...

Loading...