Page 1

O W N E R S M A N U A L F O R

2004 AIR FORKS

580 N. Westgate Dr.

Grand Junction, CO 81505 USA

1.800.999.8277

www.whitebrotherscycling.com

A division of

PAGE 1

Page 2

TABLE OF CONTENTS

SAFETY.......................................................PAGE 2

INTRODUCTION........................................PAGE 2

FORK INSTALLATION..............................PAGE 3

TUNING.......................................................PAGE 4

MAINTENANCE........................................PAGE 5

TROUBLE SHOOTING..... ........................PAGE 6

EXPLODED VIEWS.............................PAGE 7,8,9

WARRANTY..............................................PAGE 10

IMPORTANT

CONSUMER SAFETY INFORMATION

WARNING: RIDING A BIKE IS DANGEROUS. NOT PROPERLY MAINTAINING OR INSPECTING YOUR BIKE AND

IT’S COMPONENTS IS EVEN MORE DANGEROUS. IT IS ALSO DANGEROUS TO NOT READ AND FOLLOW

THESE INSTRUCTIONS.

1. NEVER REMOVE STEERER TUBE FROM CROWN. THIS IS A PRESSED IN PART. REMOVING IT WILL

RENDER BOTH THE CROWN AND STEERER TUBE INOPERABLE.* MAKE SURE THE FORK CAPS AND ALL

FORK HARDWARE (pinch bolts, etc.) ARE TIGHT BEFORE EACH RIDE.

2. DO NOT PERFORM ANY MODIFICATIONS OR ADJUSTMENTS THAT ARE NOT OUTLINED IN THIS

MANUAL. SEE THE TUNING SECTION FOR MORE DETAILS.

3. INSPECT YOUR FORK BEFORE EVERY RIDE. INSPECT THE CROWN, TUBES, AND AXLE SEAT AREAS FOR

ANY SIGNS OF FATIGUE, BENDING, CRACKING OR OTHER DAMAGE. IF YOU NOTICE ANY TYPE OF

DAMAGE, DO NOT RIDE IT. RETURN IT TO YOUR DEALER OR TO WHITE BROTHERS FOR A COMPLETE

INSPECTION AND NECESSARY REPAIR.

4. THIS WHITE BROTHERS FORK IS DESIGNED WITH A LOCKOUT THAT TURNS OFF THE FORK’S

SUSPENSION. THE LOCKOUT IS ONLY DESIGNED TO BE USED ON SMOOTH TERRAIN. USING THE

LOCKOUT ON ROUGH TERRAIN, BUMPS OR DROP-OFFS CAN CAUSE SERIOUS DAMAGE TO THE FORK

AND COULD CAUSE SERIOUS PERSONAL INJURY OR DEATH.

5. PERFORM ALL RECOMMENDED MAINTENANCE ACCORDING TO THE MAINTENANCE SECTION OF THIS

MANUAL. FAILURE TO PERFORM MAINTENANCE COULD DRASTICALLY REDUCE THE FORK’S LIFE,

PERFORMANCE AND CAUSE YOUR FORK TO BE A SAFETY HAZARD.

6. WHITE BROTHERS RECOMMENDS THAT YOU WEAR PROPER SAFETY EQUIPMENT EVERY TIME YOU

RIDE, INCLUDING AN APPROVED BICYCLE HELMET. NEVER RIDE AT NIGHT WITHOUT LIGHTS.

7. ALWAYS USE GENUINE WHITE BROTHERS PARTS. USE OF AFTERMARKET REPLACEMENT PARTS AND

UPGRADES VOIDS THE WARRANTY AND COULD CAUSE STRUCTURAL FAILURE.

8.WHITE BROTHERS FORKS ARE DESIGNED FOR OFF ROAD USE ONLY. THEY ARE NOT EQUIPPED WITH

REFLECTORS FOR ROAD USE. IF YOU ARE GOING TO USE YOUR FORK ON THE ROAD, HAVE A DEALER

OR MECHANIC INSTALL REFLECTORS THAT MEET THE CONSUMER PRODUCT SAFETY COMMISSION’S

REQUIREMENTS.

*IF SERVICE BECOMES NECESSARY OR REMOVAL OCCURS, PLEASE CALL WHITE BROTHERS CUSTOMER SERVICE FOR PRODUCT

EVALUATION AND DIAGNOSIS.

INTRODUCTION

Thank you for purchasing your new White Brothers fork. Our forks are designed to help you perform at your absolute peak.

Your new White Brothers fork has oil damping and is air sprung for light weight performance. The air spring and damper is

set stock to satisfy a wide range of rider weights and riding styles. Fine tuning can be easily accomplished by changing air

pressure of the air spring. See the adjustment and maintenance section for rider weight verses air pressures settings. For very

heavy or very light riders the external damper can be adjusted to give a wide range of compression and rebound damping.

Steering accuracy is improved over conventional MTB forks by utilizing superior materials and design. These include

oversized 32mm fork tubes, a torsion box design steering crown with pressed in tubes, a one piece billet brake arch and extra

thick drop-outs. The WB forks bootless design allows a considerable amount more slider/stanchion overlap than competitor

forks which increases the fork steering accuracy. Fork travel has been chosen to offer the best performance possible for each

fork’s intended use. To ensure peak performance, proper installation and periodic maintenance is required. When riding on

public land, please respect the rights of others and stay on established paths and trails. By riding responsibly, you are helping

ensure the future of our sport.

PAGE 2

Page 3

FORK INSTALLATION

White Brothers forks feature a 1-1/8” threadless steer tube. If you have a threaded type fork on your bicycle, consult

your dealer for the appropriate upgrade parts necessary to convert to a 1-1/8” threadless steer tube.

1. Remove your old fork from the bicycle. Measure the diameter and length of your old forks steerer tube to ensure

that the White Brothers steerer tube is the correct diameter and sufficient length for the installation.

2. Remove the crown race from your old fork.

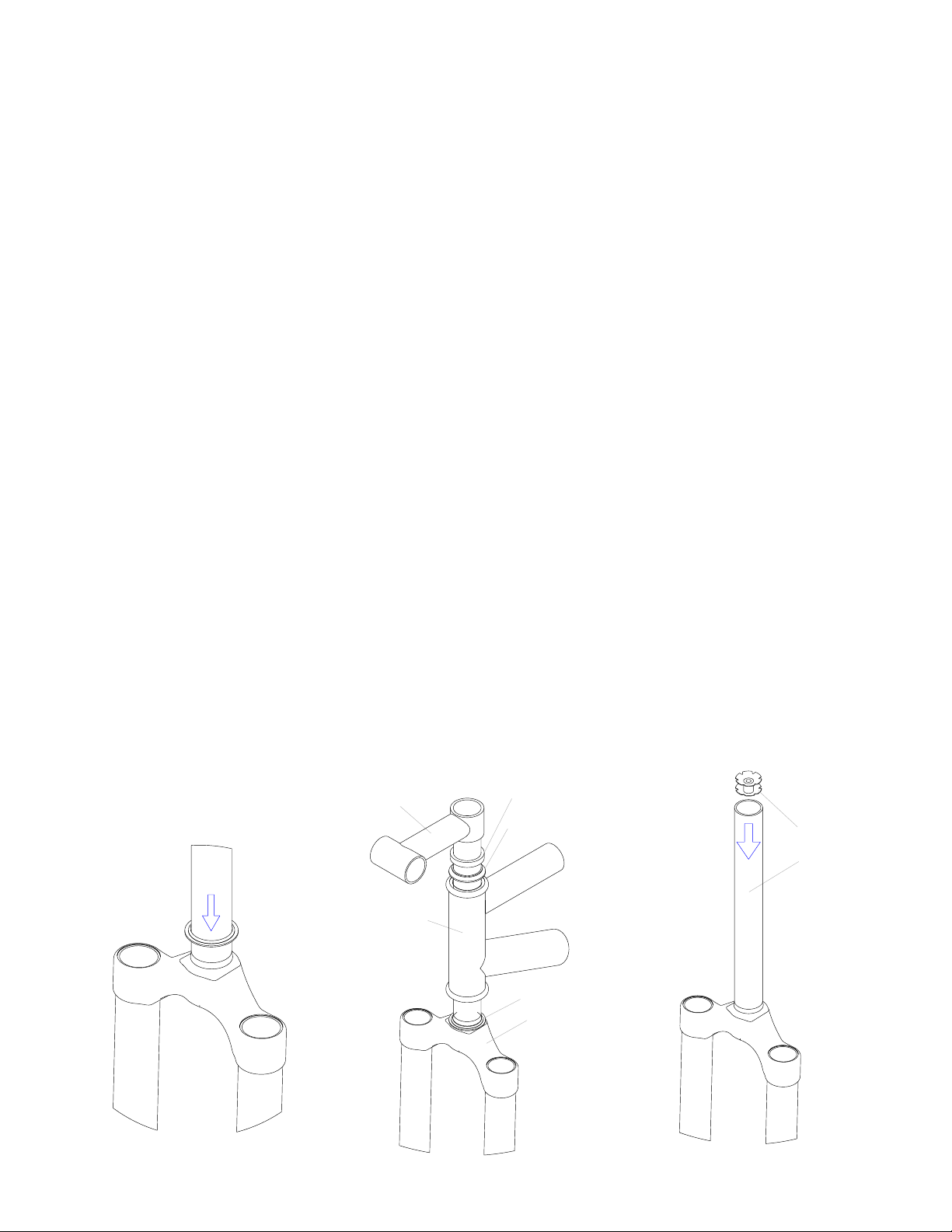

3. Press the crown race onto your new White Brothers fork.(see Figure #1)

4. Preassemble the headset by sliding the fork steerer tube through the bearings. Then install the headset upper race,

headset spacer (optional), and stem onto the fork steerer tube. Adjust with optional spacers to your preferred height.

(See Figure #2) Refer to the head set owner’s manual if there are any questions about the pre-assembly.

5. Mark the steerer tube at the top of the stem. The steerer tube will now need to be cut to the correct length.

Disassemble and cut 3mm (1/8”) below the mark. Consult your dealer or mechanic if you don’t have the proper

tools to cut the steer tube.

6. The star fangled nut must now be installed into the steer tube. If you don’t have the set tool, we recommend dealer

installation of this part. (See Figure #3)

7. Clean and grease all headset bearings and races to prepare them for assembly. Note: Replace the bearings if there

is any sign of wear or corrosion.

8. Now loosely assemble the headset, stem and handle bars as done in step four.

9. Install the headset top cap into the star fangled nut. Tighten until there is no play in the steering. The fork should

rotate freely in the head tube. Straighten the stem in relation to the front tire and tighten the pinch bolts on the stem.

If there are any questions consult your dealer or mechanic.

10. Install your front brake and adjust according to the manufacture’s instructions.

11. Adjust the quick release on the hub to clear the secondary catches on the drop-outs. Tighten the quick release after

the axle is properly seated in the drop-out. Ensure that there is sufficient thread engagement (5 or more threads with

the quick release in the lock position) due to the thicker White Brothers drop-outs. Install the front wheel per

manufactures specifications.

12. Check to see that the brakes are adjusted and properly working. Make sure that the brake cable does not interfere

with any part of the bike when the fork is compressed and released.

Warning: When installing the wheel or a new tire, check for minimum clearance. Measure from the highest point on

the tire to the under side of the crown. There must be 1/8” or 3mm more clearance than the fork’s travel to ensure

adequate clearance in all riding conditions. Any less clearance can result in the tire hitting the crown resulting in

serious injury or death.

Optional Headset Spacer

Headset Upper Race

Headset Lower Race

Fork Crown

Star Fangled Nut

Steerer Tube

Figure #3

Figure #1

Steering Stem

Frame with

Headset Cups

Figure #2

PAGE 3

Page 4

TUNING

To get the most out of your White Brothers fork, it is important that you tune the fork to

fit your weight, riding style and the terrain you ride.

INITIAL BREAK-IN PERIOD

Your new fork is designed to break-in over a period of 10 hours or more of riding. As

all the parts bed into each other, the stiction (friction) of the fork decreases and the

sensitivity increases. After the initial brake-in period, fine tuning the air pressure and

damping adjustments may be beneficial to achieve the best possible performance.

TOOLS NEEDED:

High pressure air pump

15/16” socket with ratchet.

6mm Allen wrench

AIR SPRING /CARTRIDGE DAMPER

Your new White Brothers fork is designed with air sprung support. The following guidelines

for checking and adjusting your air pressure will enable you to enjoy maximum

performance from your fork.

1. First, test ride the fork over easy terrain. If after riding the fork over varied terrain you

decide that more tuning is necessary, continue to the next step.

2. The compression or spring of the fork can be changed two ways: 1) by changing air

pressure and 2) adjusting the settings of the damper cartridge.

3. To change the air pressure remove the snap in dust cap (use a finger nail or small screw

driver) so that the schrader valve stem is exposed (see Figure #4).

4. You will need a high pressure shock pump to inflate the fork. Start with the stock setting

of 80 lbs. If the fork feels too soft or firm, fine tune the air pressure until the fork sag is

approximately 15 to 25 percent of the total travel. A small air pressure change will make a

large difference.

5. Test ride after each adjustment until the air pressure is at an adequate setting. Generally

you will want a higher pressure for a 80mm fork and a lower pressure for a 100mm fork.

Reinstall the dust cap.

Air Spring

Lockout /

Compression Adjuster

Rebound Adjuster

6. Compression adjustment (lockout) is done by turning the knob on the top of the right leg

and is a lockout when turned full clockwise. WARNING: The lockout is designed to be

used on smooth terrain only. DO NOT lockout the fork on rough terrain, bumps or dropoffs. Turning the knob counter-clockwise from lockout will provide less and less

compression damping. Less compression damping will increase the fork dive but will feel

smoother over small bumps. More compression damping will feel stiffer over small bumps

but will be more resistant to bottoming. The compression / lockout knob has ¾ of a turn of

adjustment. If more damping range is needed, contact White Brothers.

7. Rebound adjustment is done by turning the adjuster on the bottom of the right leg. Turn

the knob clockwise for slower rebound. To speed up rebound, turn the knob counterclockwise. Start with a middle setting and fine tune the rebound from there. Proper

rebound will allow the tire to track the ground over consecutive bumps. Rebound set too

slow will cause the fork to pack-up (feel stiff over consecutive bumps) while rebound set

too fast will cause the fork to top out. Adjustment range is 6 turns.

Figure #4

PAGE 4

Page 5

MAINTENANCE

Your White Brothers fork requires periodic maintenance to ensure peak performance and long life. Neglecting proper

maintenance will reduce the fork’s life. Internal build up of water and dirt or a lack of lubrication will cause excessive wear

and void the warranty.

BEFORE EVERY RIDE: Visually inspect your fork for bent or broken parts, loss of oil, abnormal sounds or other indications

of possible fork failure. Compress you fork to verify proper function. Check all other bicycle components to ensure proper

working order.

AFTER EVERY RIDE: Clean and dry the exterior of your fork. When cleaning the fork, do not direct the water spray at the

seals. Visually inspect your fork for damage.

*EVERY 30 HOURS OF RIDING: Your fork should be disassembled, inspected, cleaned and re-grease. If the fork appears to

be relatively clean, you can go 40 hours between servicing. If the fork appears excessively dirty you should service it every 20

hours. The three things that will effect the service interval and performance of your fork are water, mud and dust. How much

you use your fork in those conditions will determine how much service it requires.

*EVERY 100 HOURS OF RIDING: Complete service should include removing the lower fork legs cleaning and re-greasing

all shafts, bushings and seals. Check top cap assembly’s, damper cartridge, stanchion plug, brake post bolts and shaft bolts for

proper torque. At this time, the fork should be carefully inspected for wear and damage before reassembly. Contact White

Brothers for replacement parts and service. We recommend that this service be performed by a certified White Brothers

service center or by the factory.

*White Brothers recommends that you consult with a qualified technician before performing major service.

Basic Fork Disassembly and Inspection

1. Disconnect the front brake and remove the wheel as outlined in you bicycle owners manual. Important: Pop

the cap off the air side and deflate the system. (See Figure #4)

2. The cartridge damper locks out when the upper damper shaft is screwed down against a brass seat. This

provides a very durable and positive lockout that retains it’s seal over long periods of use, however if the

upper damper shaft is unscrewed several turns and detaches from the damper piston, the damper must be torn

down and rebuilt. Warning: To prevent the upper damper shaft from unscrewing when the fork lowers are

removed for lubrication or other maintenance, do not attempt to unscrew the compression screw at the bottom

of the right leg without first locking the fork out then removing the lockout knob and the cap and the hex key

from the crown on the damper side. After these parts are taken out, the compression screws can be loosened

and the lowers detached from the fork stanchions.

3. Pop out the damping adjuster knob from the bottom of the right dropout. Remove the allen bolts at the

bottom of the fork legs. (See figure #5) A light tap may be needed to free the control rod from the lower

assembly.

4. Simply slide the fork legs off the end of the inner stanchion tubes. Be careful not to damage the seals as they

come off the inner legs.

5. Clean all parts with a clean, non-abrasive rag. A mild grease cutting cleaner or solvent might make this an

easier task. Once clean, inspect the seals for tears or cracks. If okay, re-grease them with Slick Honey or

other suitable non-lithium grease. If your seals show signs of wear have them replaced.

6. The damper cartridge is threaded into the right fork stanchion. Inspect the cartridge for visible leakage. If

none, grasp the shaft while in the stanchion tube, un-lock the damper and operate back and forth to insure

smooth action. If the cartridge has visible leakage and/or the damping feels inconsistent as it is stroked,

return the cartridge to White Brothers or a dealer familiar with rebuilding the cartridge damper for service.

7. Check the DU bushings carefully for wear. This is done by looking at the color of the bushings. If the bushings are dark gray,

they are in good condition. If they are bronze/gold in areas, they are worn and can cause fork stanchion damage. If there is

noticeable movement back and forth when the legs are fully engaged on the fork stanchions, the DU bushings may need to be

replaced. Please note that special tools are required to remove and replace these bushings. This service can be performed by

certified White Brothers MTB service centers or directly through White Brothers.

8. Next, inspect the fork stanchion tubes for wear, nicks or scrapes. These will cause premature wear on the seals and DU

bushings. Check again for noticeable play between the stanchion tubes and the fork lower.

9. If everything is free of problems, coat all parts with a light coat of Slick Honey or other non-lithium grease. Be sure to lube

the DU bushings located inside the lower leg.

Figure #5

PAGE 5

Page 6

Basic Fork Reassembly

1. To re-attach the fork lowers, first push the lower damper shaft upward so that the hex key on the cap can be inserted into the

top damper shaft. Screw down the cap and re-attach the lockout knob by carefully fitting it on the top hex fitting of the key in

the cap and replacing the small screw in the center of the knob. Move the knob to the “7 o’clock” or “locked out “ position

and HOLD IT THERE. Pull the lower damper shaft downward as far as it will go and turn it clockwise, still holding the knob

in the ”locked out” position, until the shaft will not turn. The lock out is now engaged.

2. Make sure all the spacers and bottoming bumpers are installed on the control rods (see exploded views for proper installation).

With all parts cleaned and reinstalled with new grease, fit the lower assembly over the stanchion tubes and gently rock and

slide together until the control rods are touching the bottom of the lower assembly. Note: Do not tap the lower assembly

onto the stanchion tubes. The DU bushings can be dislodged. Thread the compression screws into the control rods starting

with the damper side and once again hold the lock out knob in the locked out position and firmly tighten. Adding air may be

needed to push the control rod down to the bottom of the leg. This will also help hold the rod from spinning as you tighten the

compression screw on the air side. Note: Ensure the compression screws are fully tight before riding.

3. Make sure the fork caps are fully tightened into the top of the stanchion tubes. Connect the front brake and wheel as outlined

in you bicycle owners manual.

4. Compress the fork to make sure it works smoothly and that the brake cable does not interfere with the operation of the fork.

TROUBLE SHOOTING

Loss of Air Pressure (In Excess of Normal Seepage):

Inflate the fork to 100 psi and spray a mixture of soap and water on the air cap with the dust cap removed. Check for any slow

bubbling.

1. Check the tightness of the air cap in the stanchion. It should be tight but not over tight.

2. Check the o-rings for damage, a fiber, hair or large dirt particle. Slow bubbling from the air cap usually indicates a

contaminated air cap o-ring. Remove suspect o-rings with a toothpick. If the o-ring is not cut or torn, cleaning and re-greasing

the o-ring usually repairs the leak.

3. Check the valve core for bubbles. Slow bubble formation at the top of the schrader valve (one bubble every 30-60 minutes) is

normal, more rapid bubbling indicates a loose or defective valve core. Tighten the valve core with a valve core wrench and see

if that stops the leak. If not replace the valve core.

4. If no leak can be seen after one minute, pressure loss probably occurs in use due to a worn or contaminated piston o-ring. To

check, let the fork sit at high pressure over night. Re-check pressure to see if there is a loss. If pressure loss happens, the piston

o-ring is easy to replace and is available through your local dealer or from White Brothers.

5. If none of these remedies solve the problem contact White Brothers for technical support.

Fork Feels Sticky:

This is usually caused by:

1. A lack of lubrication. Clean and lubricate the fork as outlined in the maintenance section.

2. Contamination inside the fork. Clean and lubricate the fork as outlined in the maintenance section.

3. Fork is not sufficiently broken in. Contact White Brothers for further technical information.

The Fork Bottoms Too Easily:

1. Incorrect air pressure. Add air pressure as outlined in the tuning section.

2. Insufficient compression damping. Add compression damping by turning the adjuster on the top of the right leg clock-wise.

The Fork Doesn’t Use Full Travel:

1. Incorrect air pressure. Remove air pressure as outlined in the tuning section.

2. Excessive compression damping. Reduce the compression damping by turning the adjuster on the top of the right leg counter

clock-wise.

Lockout and/or Damping Adjustment is Not Working

1. Damper may need servicing. Contact White Brothers for technical information.

PAGE 6

Page 7

23

19

11

22

21

10

14

13

Exploded Views

The following is an illustration and parts table

which gives you the exploded view of your White

Brothers fork. The parts table indicates the part

numbers for each individual part in the fork.

Reference these numbers when ordering

replacement parts. See your local dealer or contact

White Brothers to order the parts you require.

29

12

20

25

24

80mm Air Fork

W/ Oil Damper

26

1

28

ITEM NO. QTY. PART NO. DESCRIPTION

27

30

1 1 P1099-1 80mm Upper Assembly

2 1 100197,100198 80mm Lower Assbly (Red, Black)

3 1 100063S Compression Screw Solid

17

4 2 97-3668 Thread-In Brake Boss

5 2 100055 Washer .3125x.4375

18

6 1 100063 Compression Screw

7 1 100200 Damper Adjuster

8 1 100009 O-Ring 316

9 4 97-986 DU Bushing

15

9

9

16

34

33

10 1 100175 Compression Adjustment Knob

11 1 100195 Flat Head Screw M2.5x10

12 1 100217 80mm Damper Assembly

13 1 P4650 Dust Cap

14 1 97-9301 Star Nut

15 2 97-1351 Wiper Seal

16 1 100168 Dummy Shaft 80mm Air

32

17 1 P4600 Compression Rod Top

18 1 P2504 Compression Rod Bush

19 1 100291 Damper Leg Top Cap

4

31

20 1 100185 80mm Lockout Adj Hex

21 1 100201 Top Fitting for Lockout Key

22 1 100524 O-Ring 6x2mm

2

8

23 1 100506 Wave Washer

24 1 100134 Air Leg Top Cap

25 1 P3028 O-Ring 021

26 1 100572 Air Piston

27 1 100571 Piston Peg

28 1 100262 O-Ring -211

29 1 100054 Schrader Valve

30 1 P3000 Piston Band

6

5

31 1 100574 Stanchion Plug

32 5 100016 Negative Spring Series

33 1 100576 Bumper Guide

7

3

34 1 97-3342 Top Out Bumper

PAGE 7

Page 8

Exploded Views

The following is an illustration and parts table

which gives you the exploded view of your White

5

22

24

21

18

20

19

1

16

10

6

11

12

12

11

3

9

8

17

14

29

28

38

2

4

30

25

27

26

36

32

23

31

34

33

15

37

35

7

13

ITEM NO. QTY. PART NO. DESCRIPTION

6

Brothers fork. The parts table indicates the part

numbers for each individual part in the fork.

Reference these numbers when ordering

replacement parts. See your local dealer or contact

White Brothers to order the parts you require.

100mm Air Fork

W/ Oil Damper

1 1 100218 Damper Assm XC 1.0

2 1 P1139-1 Upper Assembly

3 1 100197,100199 Lower Assembly

4 2 100055 Washer .3125 x .4375

5 1 100195 Flat Head Screw M2.5x10

6 2 100009 O-Ring 316

7 1 ZTA-ORING-314 O-Ring 314

8 1 100200 Damper Adjuster

9 1 100063 Compression Screw

10 1 P3321 0.1" Delrin Washer

11 2 97-3668 Thread In Brake Boss

12 4 97-986 DU Bushing

13 1 100235 Stanchion Plug

14 1 P4650 Dust Cap

15 7 100016 Negative Spring

16 2 97-1351 Wiper Seal

17 1 97-9301 Star Nut

18 1 100291 Top Cap

19 1 100186 Damper Allen Key

20 1 100201 Hex Adapter

21 1 100033 O-Ring 010

22 1 100175 Adjuster Knob for Damper

23 1 100292 Compression Pad Holder

24 1 100506 Wave Washer

25 1 100572 Air Piston 04

26 1 P3000 Piston Ring

27 1 100262 O-Ring 211

28 1 100134 Air Cap 03

29 1 100054 Schrader Valve Assm.

30 1 100063S Compression Screw Solid

31 1 100169 Control Rod

32 1 P4600 Control Rod Top

33 1 100576 Topout Bumper Guide

34 1 97-3342 Bumper

35 1 100577 Topout Spacer

36 1 100596 Piston Peg XC 1.0

37 1 F-2402 O-Ring 313

38 1 P3028 O-Ring 021

PAGE 8

Page 9

Exploded Views

The following is an illustration and parts table

which gives you the exploded view of your White

14

13

26

24

21

23

22

17

16

36

34

35

31

32

Brothers fork. The parts table indicates the part

numbers for each individual part in the fork.

Reference these numbers when ordering

replacement parts. See your local dealer or contact

White Brothers to order the parts you require.

29” 80mm Air Fork

W/ Oil Damper

33

4

30

20

ITEM NO. QTY. PART NO. DESCRIPTION

1 1 100226 29" Lower Assembly

2 2 97-3668 Thread in Brake boss

3 4 97-986 DU Bushing

25

4 1 P1139-1 Upper Assembly

5 1 100227 Stanchion Plug

6 1 100220 29" 80mm Damper Assembly

19

6

7 2 F-2402 O-Ring 313

8 1 100009 O-Ring 316

9 2 100055 Washer .3125 x .4375

10 1 100063 Compression Screw

11 1 100200 Damper Adjuster

18

3

3

28

29

7

27

7

12 1 100063S Compression Screw Solid

13 1 100175 Adjuster Knob for Damper

14 1 100195 Flat Head Screw M2.5 x 10

15 5 100016 Negative Spring

16 1 P4650 Dust Cap

17 1 97-9301 Star Nut

18 2 97-1351 Wiper Seal

19 1 100169 Control Rod

15

2

37

38

20 1 P4600 Compression Rod Top

21 1 100291 Damper Leg Top Cap

22 1 100186 Damper Allen Key

23 1 100201 Hex Adapter

24 1 100524 O-Ring 6x2mm

25 1 100292 Compression Pad Holder

2

1

5

8

26 1 100506 Wave Washer

27 1 100578 Topout Spacer

28 1 97-3342 Bumper

29 1 100576 Topout Bumper Guide

30 1 100571 Piston Peg

31 1 100572 Air Piston 04

10

9

11

12

32 1 100262 O-Ring 211

33 1 P3000 Piston Ring

34 1 100134 Air Cap 03

35 1 P3028 O-Ring 021

36 1 100054 Schreader Valve

37 1 P3322 Barrel Spacer

38 1 P3310-1 Nylon Spring Shim

PAGE 9

Page 10

Owners Name:___________________________________________________________________________

Address:________________________________________________________________________________

_______________________________________________________________________________________

Phone:_________________________________________________________________________________

Purchase Date:___________________________________________________________________________

Purchase Location:________________________________________________________________________

Serial #: Located on lower back side of right axle clamp.__________________________________________

MAINTENANCE LOG

Date Service Performed Date Service Performed . Date Service Performed Date Service Performed . Date Service Performed Date Service Performed . Date Service Performed Date Service Performed . Date Service Performed Date Service Performed .

WARRANTY CLAIMS

White Brothers forks are the highest quality and as such are warranted to be free from defects in materials and workmanship for a

period of one year from the date of purchase for the original purchaser. On receipt of the fork, if it is found to be defective, White

Brothers will determine replacement or repair of the fork. This warranty is the sole and exclusive remedy. White Brothers shall not

be liable for any indirect, special or consequential damages. Warranty does not apply to any product that has been installed

improperly or adjusted using methods not outlined in this manual. Warranty also does not cover forks that have been misused, or

forks that have missing/altered serial numbers (located on the back of the right fork stanchion). The fork is not warrantied against

damage in the appearance of the fork or for modifications not outlined in this manual. This warranty does not cover breakage,

bending, or damage that may result from crashes, falls or abuse. Normal wear (i.e. seals, bushings, sliders finish, etc) and wear and

damage caused by lack of proper maintenance is not included. *The warranty registration card must be filled out and returned

within 30 days of purchase to activate and validate this warranty. A copy of the proof of purchase must be included with all

warranties. Customers in the US please contact your White Brothers or your dealer for a Return Authorization Number (RA#)

before returning the forks. All forks returned for inspection must be sent freight paid to:

580 N. Westgate Dr.

Grand Junction, CO 81505 USA

1.800.999.8277

www.whitebrotherscycling.com

A division of

*Consumers outside the US please contact the dealer or distributor in your area.

PAGE 10

Loading...

Loading...