Page 1

OPERATOR’S MANUAL

ZERO TURN TRACTOR

Model Numbers

ZT 17 w/42" Mower Deck

ZT 22 w/50" Mower Deck

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning:

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

PRINTED IN U.S.A.

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

FORM NO. 769-01148

(8/04)

Page 2

TABLE OF CONTENTS

TRACTOR PREPARATION .................................................................................................... 2

IMPORTANT SAFE OPERATION PRACTICES ..................................................................... 3

SAFETY DECALS AND LABELS ..................................................................................... ....... 6

RECORDING MODEL AND SERIAL NUMBER INFORMATION .......................................... . 8

CUSTOMER SUPPORT ......................................................................................................... 8

TO THE OWNER ..................................................................................................................... 8

SECTION 1: CONTROLS AND FEATURES ...... ... .... ... .......................................... ................. 9

SECTION 2: OPERATION .................................................................................................... 13

SECTION 3: ADJUSTMENTS ............................................................................................... 20

SECTION 4: MAINTENANCE ............................................................................................... 21

SECTION 5: MOWER DECK ................................................................................................ 26

SLOPE GAUGE .............................................. ... ... .... ... ... ....................................... ... ... .... ... .. 31

SECTION 6: ENGINE MANUAL ................................................... ... .... ... ... ... ......................... 33

WARRANTY ......................................................................................................... BACK PAGE

TRACTOR PREPARATION

Remove the upper crating material from the shipping

pallet, and cut any bands or tie straps secu ring the t ractor to the pallet. Use the lift ha ndle to raise the d eck to

its highest position; engage the transmission bypass

rods (Refer to SECTION 1, CONTROLS AND FEATURES); and carefully roll the tractor off the shipping

palltet. Disengage the bypass rods.

CONNECT THE BATTERY

WARNING

Battery posts, terminals and related accessories

contain lead and lead compounds. Wa sh hands

after handling.

The tractor is shipped with an activated sealed battery,

with the positive battery cable factory connected. The

negative cable must be connected.

Note: Make sure the ignition switch is in the "OFF" position before attaching the battery cable.

1. Pull the protective cap off the negative terminal of

the battery, and remove the hex cap screw and nut

from the free end of the negative battery cable.

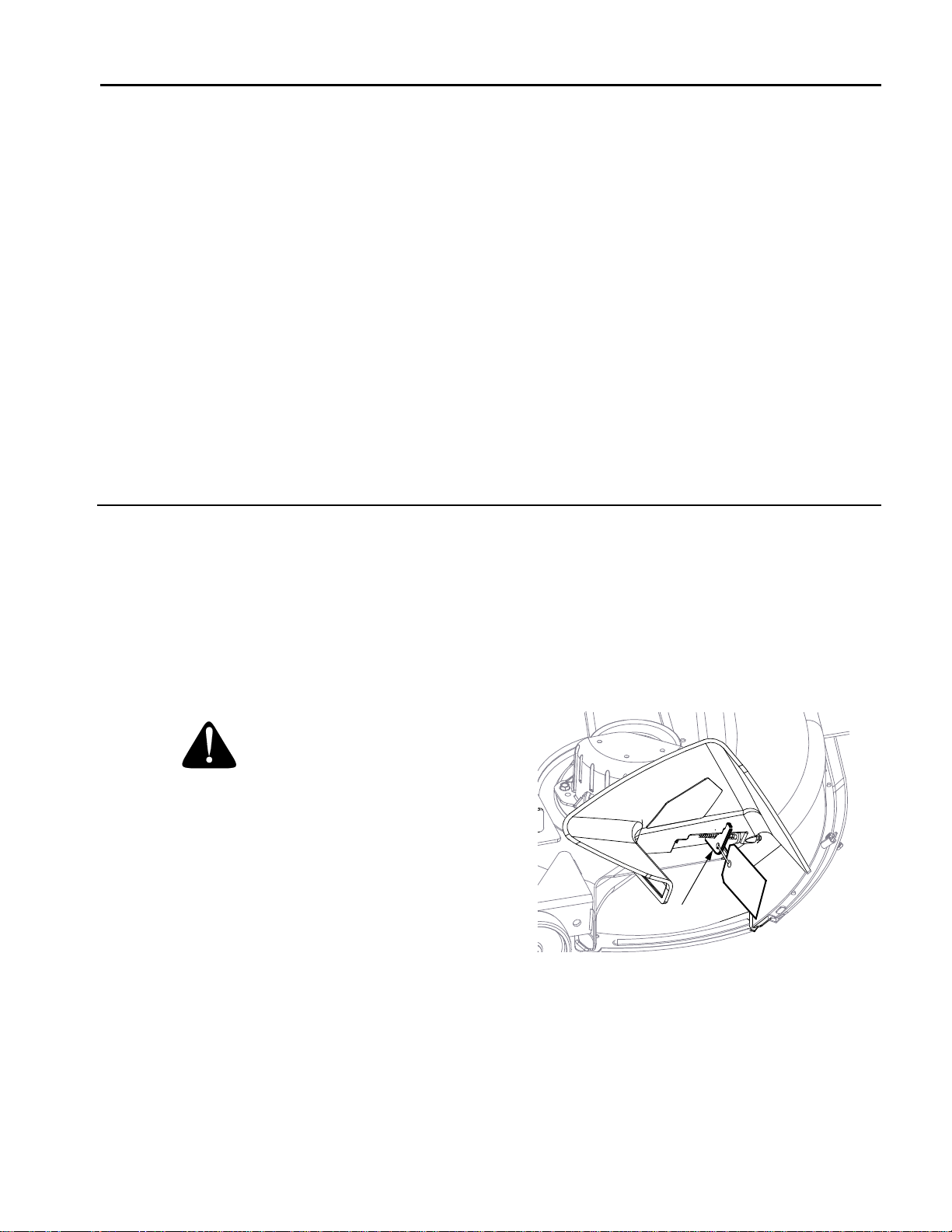

MODEL ZT 17 ONLY

Remove The Chute Stop

• Locate the chute stop on the right side of th e

mower, between discharge chute and cutting deck.

• While holding the discharge chute up, rotate the

chute stop clockwise and remove.

• Discard the chute stop.

Chute Stop

2. Connect the negative battery cable (heavy black)

to negative terminal (NEG) of the battery using the

hex cap screw and nut. Slide the black terminal

cover over the negative terminal of the battery.

2

Page 3

WARNING

• The engine exhaust, some of its constituents, and certain vehicle compone nts contain or emit chemicals known

to the State of California to cause cancer, birth defects or other reproductive harm.

• This unit is equipped with an internal combustion engine and should not be used on or near any unimproved

forest-covered, brush-covered, or grass-covered land unless the engine’s exhaust system is equipped with a

spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

• In the State of California, the above is required by law (Section 4442 of the California Public Resources Code).

Other States may have similar laws. Federal laws apply to federal lands. A spark arrester muffler is available

at your nearest engine authorized service center.

IMPORTANT

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED,

COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND

OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING

TO OPERATE YOUR UNIT. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT

IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL— HEED ITS WARNING.

Your lawn mower was built to be operated according to the rules for safe operation

in this manual. As with any type of power equipment, carelessness or error on the

DANGER

I. GENERAL OPERATION

1. Read, understand and follow all instructions in the

manual and on the machine before starting. Keep

this manual in a safe place for future and regular

reference.

2. Only allow responsible individuals familiar with

the instructions to operate the machine. Know the

controls and how to stop the machine quickly.

3. Do not put hands or feet under the cutting deck or

near rotating parts.

4. Clear the area of objects such as rocks, toys,

wire, etc. which could be picked up and thrown by

the blades. A small object may have been

overlooked and could be accidentally thrown by

the mower in any direction and cause injury to

you or a bystander. To help avoid a thrown

objects injury, keep children, animals, bystanders

and helpers at least 75 feet from the mower while

it is in operation. Always wear safety glasses with

side shields or safety goggles during operation or

while performing an adjustment or repair, to

protect eyes from foreign objects. Stop the blades

when crossing gravel drives, walks or roads.

part of the operator can result in injury. This lawn mower is capable of amputating

hands and feet or throwing objects. Failure to observe the following safety

instructions could result in serious injury or death.

SAFE OPERATION PRACTICES

5. Be sure the area is clear of other people before

mowing. Stop machine if anyone enters the area.

6. Never carry passengers.

7. Disengage the blades before shifting into reverse

and backing up. Always look down and behind

before and while backing.

8. Be aware of the mower and attachment discharge

direction and do not point it at anyone. Do not

operate the mower without either the entire grass

catcher or the chute guard in place.

9. Slow down before turning. Operate the machine

smoothly. Avoid erratic operation and excessive

speed.

10. Never leave a running machine unattended.

Always turn off the blades, place the transmission

in neutral, set the parking brake, stop the engine

and remove key before dismounting.

11. Turn off blades when not mowing.

12. Stop the engine and wait until the blades come to

a complete stop before (a) removing the grass

catcher or unclogging chute, or (b) making any

repairs, adjusting or removing any grass or debris.

3

Page 4

13. Mow only in daylight or good artificial light.

14. Do not operate the machine while under the

influence of alcohol or drugs.

15. Watch for traffic when operating near or crossing

roadways.

16. Use extra care when loading or unloading the

machine into a trailer or truck. This unit should not

be driven up or down a ramp onto a trailer or truck

under power, because the unit could tip over

causing serious personal injury. The unit must be

pushed manually on a ramp to load or unload

properly.

17. Never make a cutting height adjustment while the

engine is running if the operator must dismount to

do so.

18. Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Do not wear loose fitting

clothes or jewelry. They can be caught in moving

parts. Never operate a unit in bare feet, sandals

or sneakers.

19. Check overhead clearance carefully before driving

under power lines, wires, bridges or low hanging

tree branches, before entering or leaving

buildings, or in any other situation where the

operator may be struck or pulled from the unit,

which could result in serious injury.

20. Disengage all attachment clutches, set the

parking brake in the on position, and put the lap

bars to the neutral or out position before

attempting to start the engine.

21. Your mower is designed to cut normal residential

grass of a height no more than 10”. Do not

attempt to mow through unusually tall, dry grass

(e.g. pasture) or piles of dry leaves. Debris may

build up on the mower deck or contact the engine

exhaust presenting a potential fire hazard.

22. Use only accessories approved for this machine

by White Outdoor. Read, understand and follow

all instructions provided with the approved

accessory.

II. SLOPE OPERATION

Slopes are a major factor related to loss of contro l and

tip-over accidents, which can result in severe injury or

death. All slopes require extra caution. If you cannot

back up the slope or if you feel uneasy on it, do not

mow it.

For your safety, use the slope gauge included as part

of this manual to measure slopes before operat ing this

unit on a sloped or hilly area. If the slope is greater

than 15° as shown on the slope gauge, do not operate

this unit on that area or serious injury could result.

DO:

Mow across slopes, not up and down.

Remove obstacles such as rocks, limbs, etc.

Watch for holes, ruts or bumps . Uneven terrain could

overturn the machine. Tall grass can hide obstacles.

Use slow speed. Choose a low enough speed so that

you will not have to stop while on the slope.

Follow the manufacturer’s recommendations for coun-

terweights with attachments to improve stability.

Use extra care with grass catchers or other attach-

ments. These can change the stability of the machine.

Keep all movement on the slopes slow and gradual.

Do not make sudden changes in speed or direction.

Rapid acceleration or deceleration could cause the

front of the machine to lift and rapidly flip ove r backwards, which could cause serious injury.

Avoid starting or stopping on a slope. If the tires lose

traction, disengage the blades and proceed slowly

straight down the slope.

DO NOT:

Do not turn on slopes unless necessary; if mowing

slopes, turn slowly and gradually uphill, if possible.

Do not mow near drop-offs, ditches or emb ankme nts.

The mower could suddenly turn over if a wheel is over

the edge of a cliff or ditch, or if an edge caves in.

Do not mow on wet grass. Reduced traction could

cause sliding.

Do not try to stabilize the machine by putting your foot

on the ground.

Do not use the grass catcher on steep slopes.

III. CHILDREN

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the machine and the mowing activity.

Never assume that children will remain where you

last saw them.

1. Keep children out of the mowing area and in

watchful care of an adult other than the operator.

2. Be alert and turn the machine off if children enter

the area.

3. Before and when backing up, look behind and

down for small children.

4. Never carry children, even with the blades off.

They may fall off and be seriously injured or may

interfere with safe machine operation.

4

Page 5

5. Never allow children under 14 years old to

operate the machine. Children 14 years and over

should only operate the machine under close

parental supervision and proper instruction.

6. Use extra care when approaching blind corners,

shrubs, trees or other objects that may obscure

your vision of a child or other hazard.

7. Remove the key when the machine is left

unattended to prevent unauthorized operation.

IV. SERVICE

1. Use extreme care in handling gasoline and other

fuels. They are extremely flammable and the

vapors are explosive.

a. Use only an approved container.

b. Never remove fuel cap or add fuel with the en-

gine running. Allow the engine to cool at least

two minutes before refueling.

c. Replace the fuel cap securely and wipe off any

spilled fuel before starting the engine as it may

cause a fire or explosion.

d. Extinguish all cigarettes, cigars, pipes and oth-

er sources of ignition.

e. Never refuel the machine indoors because fuel

vapors will accumulate in the area.

f. Never store the fuel container or machine

inside where there is an open flame or spark,

such as a gas hot water heater, space hea ter

or furnace.

2. Never run a machine inside a closed area.

3. To reduce fire hazard, keep the machine free of

grass, leaves or other debris build-up. Clean up

oil or fuel spillage. Allow the machine to cool at

least 5 minutes before storing.

4. Before cleaning, repairing or inspecting, make

certain the blade and all moving parts have

stopped. Disconnect the spark plug wire, and

keep the wire away from the spark plug to prevent

accidental starting.

5. Check the blade and engine mounting bolts at frequent intervals for proper tightness. Also visually

inspect blades for damage (e.g., excessive wear,

bent, cracked). Replace with blades which meet

original equipment specifications.

6. Keep all nuts, bolts and screws tight to be sure

the equipment is in safe working condition.

7. Never tamper with safety devices. Check their

proper operation regularly. Use all guards as

instructed in this manual.

8. After striking a foreign object, stop the engine,

remove the wire from the spark plug and

thoroughly inspect the mower for any damage.

Repair the damage before restarting and

operating the mower.

9. Grass catcher components are subject to wear,

damage and deterioration, which could expose

moving parts or allow objects to be thrown. For

your safety protection, frequently check the

components and replace with manufacturer’s

recommended parts when necessary.

10. Mower blades are sharp and can cut. Wrap the

blades or wear gloves, and use extra caution

when servicing blades.

11. Check the park brake operation frequently. Adjust

and service as required.

12. Muffler, engine and belt guards become hot

during operation and can cause a burn. Allow to

cool down before touching.

13. Do not change the engine governor settings or

overspeed the engine. Excessive engine speeds

are dangerous.

14. Observe proper disposal laws and regulations.

Improper disposal of fluids and materials can

harm the environment and the ecology.

a. Prior to disposal, contact your local

Environmental Protection Agency to

determine the proper method for disposing of

the waste. Recycling centers are established

to properly dispose of materials in an

environmentally safe fashion.

b. Use proper containers when draining fluids.

Do not use food or beverage containers that

may mislead someone into drinking from

them. Properly dispose of the containers immediately following the draining of fluids.

c. DO NOT pour oil or other fluids into the

ground, down a drain or into a stream, pond,

lake, or other body of water. Observe Environmental Protection Agency regulations when

disposing of oil, fuel, coolant, brake fluid, filters, batteries, tires and other harmful waste.

15. We do not recommend the use of a pressure

washer or garden hose to clean your unit. They

may cause damage to electrical components;

spindles; pulleys; bearings; or the engine. The

use of water will result in shortened life and

reduce serviceability.

WARNING - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who

read, understand and follow the warnings and instructions in this manual and on the machine.

5

Page 6

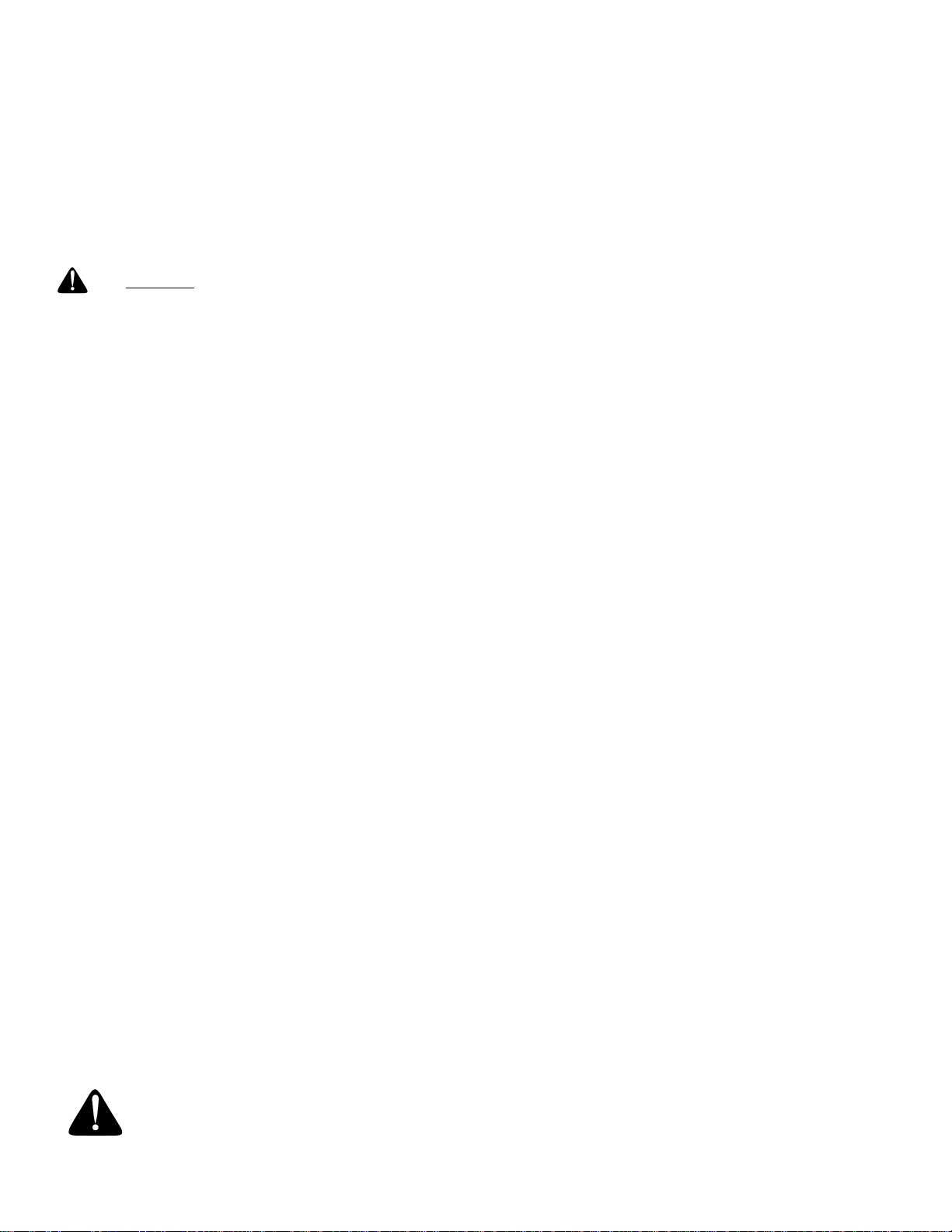

SAFETY DECALS AND LABELS

Keep product safety graphics (decals) clean. Replace any safety graph ic that is damaged, destroyed, missing, painted over or can no longer be read. Replacement safety graphics are available through your dealer.

START

NEUTRAL

FORWARD

REVERSE

STARTING INSTRUCTIONS

•

To START, PARK BRAKE must be set.

•

P.T.O. switch in OFF (down) position.

•

Lap bars in NEUTRAL and outward positions.

•

Throttle set properly, CHOKE position if "cold".

•

Turn key to ON, then START, release when engine r uns.

GENERAL SAFETY INSTRUCTIONS

– LOCATED ON LEFT CONSOLE

ASIDE OPERATOR’S SEAT

START

FORWARD

NEUTRAL

REVERSE

GENERAL OPERATING INSTRUCTIONS

– LOCATED ON RIGHT CONSOLE

ASIDE OPERATOR’S SEAT

FOR FIRST-TIME OPERATORS

•

Start Off In A Flat, Open Area.

•

Keep Bystanders Away.

•

Set Throttle At A Low Speed.

•

Practice Maneuvering, (Forward, Reverse,

Left, Right) Without Deck Engaged.

ON

•

PTO

Bars Are Moved Too Far Into Revers e

PTO Automatically Reengages Wh en Levers Are

•

Returned To The Neutral Or Forward Positions.

NOTICE

Automatically Disengages When Both Lap

.

ZT 17

ZT 22

CHOKE

CUTTING

HEIGHT

DECK HEIGHT INDICATOR

– LOCATED ON RIGHT SIDE

OF SEAT BOX FRAME

P

PARK

BRAKE

OFF

PARK BRAKE INDICATOR

– LOCATED ON LEFT SIDE

OF SEAT BOX FRAME

6

FAST

SLOW

SLOW

THROTTLE CONTROL

INDICATOR – LOCATED ON

LEFT CONSOLE

FAST

Page 7

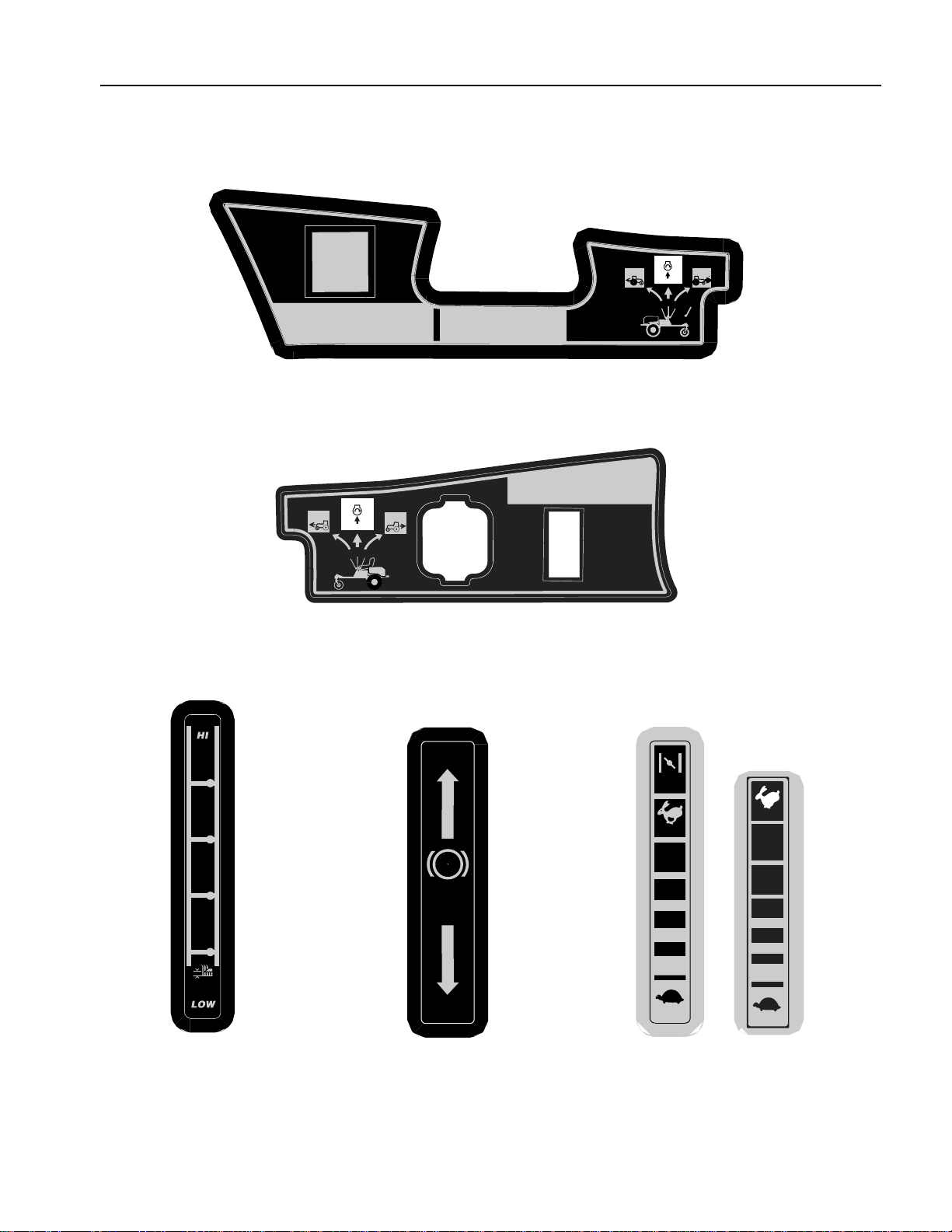

SAFETY DECALS AND LABELS

WARNING

AVOID SERIOUS INJURY OR DEATH

• Read The Operator's Manual.

• Go Across Slopes, Not Up And Down.

•

If Machine Stops Going Uphil l, Stop Blade And Back Down Slowly .

• Avoid Sudden Turns.

• Do Not Mow When Children Or Others Are Around.

• Never Carry Children Even With Blades Off.

• Look Down And Behind Before And While Backing.

•

Keep Safety Devices (Guards, Shields, Switches, Etc.) In Place And Working.

• Remove Objects That Could Be Thrown By The Blade.

•

Do Not Operate Unit Where It Could Slip Or Tip.

• Know Location And Function Of All Controls.

•

Be Sure Blades And Engine Are Stopped Before Placing Hands Or Feet Near Blades.

•

Before Leaving Operator Po sition, Disengage Blad es, Place In Neutral,

Engage Parking Brake, Shut Off And Remove Key.

•

When Using The Optional Grass Bagging Attachment , The Front Counter

Weight Included With Bagger Must Be Installed.

WARNING

• Do not add fuel while the engine is hot or running.

•

Stop engine, disconnect spark plug before adjusting or servicing.

• Before leaving operator's position:

DISENGAGE IMPLEMENT DRIVE.

•

•

Place speed controls in neutral and set parking brake.

•

Wait for all movement to stop.

• Do not allow operation by untrained personnel.

GENERAL SAFETY INSTRUCTIONS

WARNING – LOCATED IN CENTER

OF SEAT BOX FRAME

TO REDUCE THE RISK OF INJU R Y, DO NOT

OPERATE

UNLESS DISCHARGE COVER OR

GRASS CATCHER IS IN ITS PROPER PLACE.

IF

DAMAGED, REPLACE IMMED IATELY.

HANDS AND FEET SAFETY GRAPHIC–

LOCATED ON DEFLECTOR CHUTE

DEFLECTOR and SAFETY GRAPHIC –

LOCATED ON RIGHT SIDE OF DECK

ZT 22

KEEP HANDS AND FEET AWAY FROM

ROTATING PARTS

REMOVE OBJECTS THAT CAN BE

THROWN BY THE BLADE IN ANY

DIRECTION. WEAR SAFETY GLASSES.

DO NOT MOW WHEN CHILDREN OR

OTHERS ARE AOUND. NEVER CARRY

CHILDREN

USE EXTRA CAUTION ON SLOPES. DO

NOT MOW SLOPES GREATER THAN 15°.

MOW UP AND DOWN, NOT ACROSS

READ OPERATOR'S MANUAL. KEEP SAFETY DEVICES WORKING.

AVOID SUDDEN TURNS, USE LOW GEAR

.

.

.

.

SAFETY GRAPHIC – LOCATED ON

LEFT SIDE OF MOWER DECK

ZT 17

INFORMATION GRAPHIC – BELT

ROUTING LOCATED ON

LEFT SIDE OF MOWER DECK

7

Page 8

RECORDING MODEL AND SERIAL NUMBER

This Operator’s Manual is an important part of your new lawn tractor. It will help you assemble, prepare and

maintain the unit for best performance. Please read and under stand what it says.

Before you start assembling your new equipmen t, please locate the m odel plate under the seat of the

tractor and copy the information in the space provided below. A sample model plate is also given below.

This information will be necessary to use the manufacturer’s web site and/or help from the Customer Support Department or an authorized service de ale r

XXXXXXXXXXX XXXXXXXXXX

Model Number Mfg. Date

Copy the model number here:

MTD LLC

P. O. BOX

www.whiteoutdoor.com

DEALER LOCATOR PHONE NUMBER:

CLEVELAND,OH

361131

44136

800-949-4483

Copy the serial number here:

CUSTOMER SUPPORT

If you have difficulty assembling this product or have any questions re garding the controls, oper ation or

maintenance of this unit, you can seek help from the expert s. Choose from the options below:

Visit whiteoutdoor.com for many useful suggestions. Click on Customer Support button and

you will get the four options reproduced here. Click on the appropriate button and help is

immediately available.

The answer you are

looking for could be just

a mouse click away!

The answer you are

looking for could be just

a mouse click away!

If you prefer to reach the Customer Dealer Referr al Line, please call 1(800) 949- 4483.

Engine

Manual

The engine manufacturer is responsible for all engine-related issues with regards to

performance, power-rating, specifications, wa rranty and service. Please refer to the engine

manufacturer’s Owner’s/Operator ’s Manual, packed seperate ly in crate, for more information.

TO THE OWNER

Your local authorized White Outdoor dealer is inte rested in the perfor mance you r eceive from your tra ctor, and with

the maintenance needed to ensure the satisfacto ry operation of your tr actor. The dealer has trained service personnel familiar with the latest servicing information, is equipped with the latest tools, and has a complete line of genuine

White Outdoor service parts which assure proper fit and high quality.

All references to LEFT, RIGHT, FRONT, and REAR, unless specifically stated otherwise, indicate that relative po-

sition on the tractor when facing forward while seated in the operator’s seat.

CAUTION: DO NOT tow your Model ZT-17 or ZT-22 tractor. To wing may caus e severe dam age the transmissio ns.

Place the tractor on a Level Surface before pulling the transmission bypass rods to the engaged position (transmission disengaged).

8

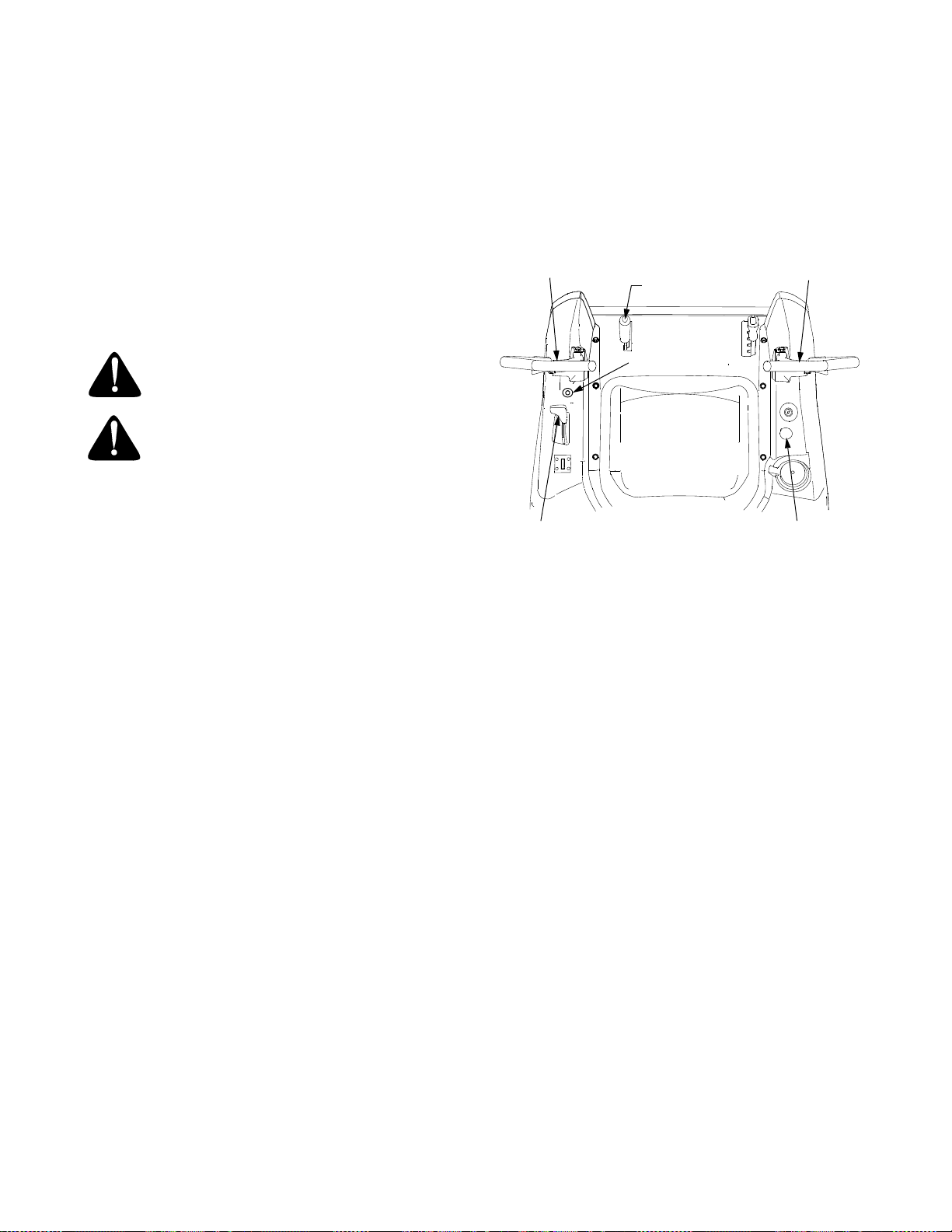

Page 9

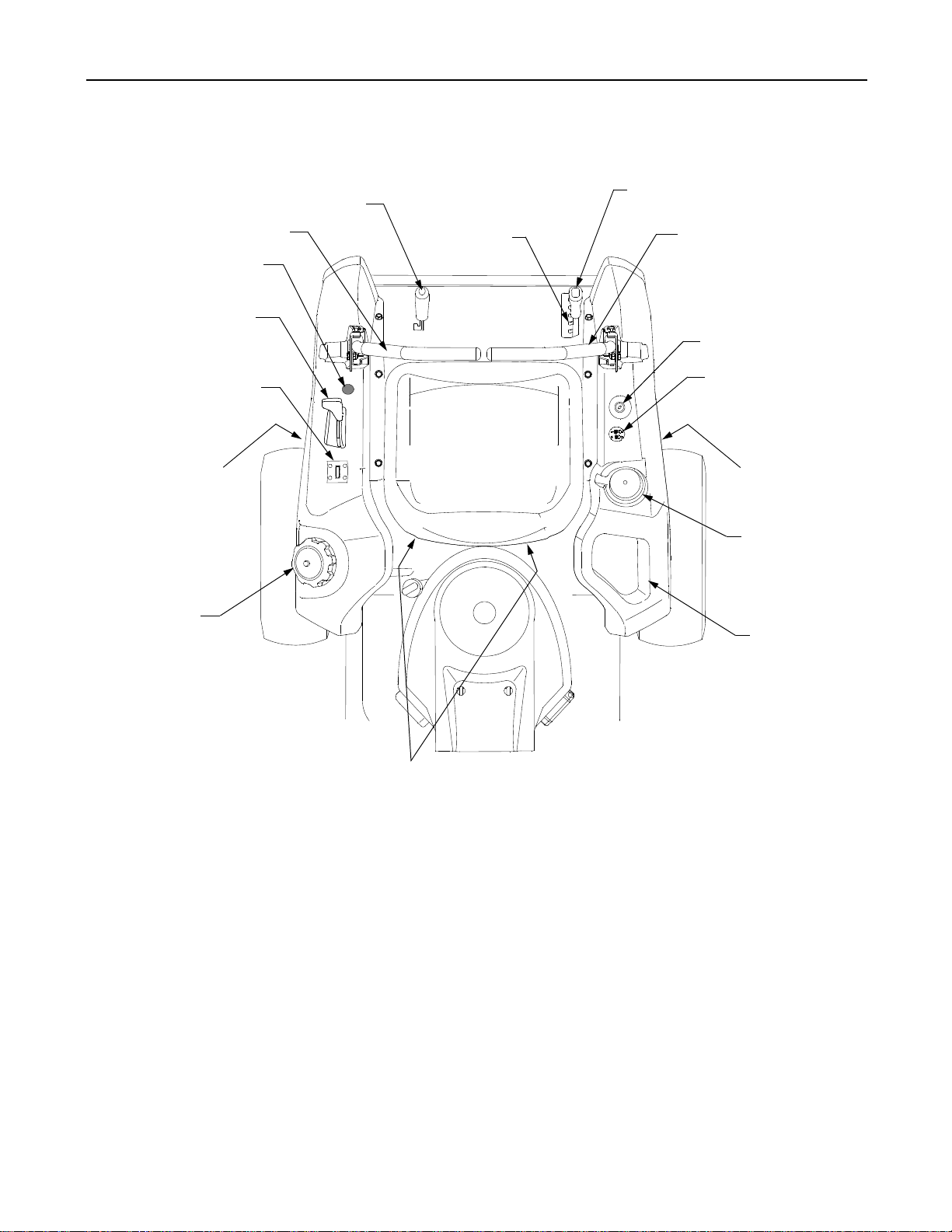

SECTION 1: CONTROLS AND FEATURES

O

C

N

M

L

F

K

A

B

C

D

E

F

G

H

A.

B.

Deck Lift Handle

C.

RH and LH Drive Control Levers

D.

Ignition Switch

E.

PTO Switch

F.

Transmission Bypass Rod (Not Shown)

G. Cup Holder

J

Figure 3

H.Deck Height Index

Storage Tray

J.

Seat Adjustment Wing Knobs (Not Shown)

K.

Fuel Tank Cap

L.

Hour Meter/Indicator Panel

M.

Throttle Control

N.

Choke Control — Model ZT22 ONLY

O. Parking Brake Engagement Lever

9

Page 10

NOTE: References to LEFT, RIGHT, FRONT, and

REAR indicate that position on the tractor when

facing forward while seated in the operator’s seat.

START - The starter motor will turn over the engine.

Release the key immediately when the

engine starts

A. Deck Height Index

The deck height index consists of six index notches

located on the front/right of the seat box frame. Each

notch corresponds to a 1/2 inch change in the deck

height position ranging from 1-1 /2 inches at the lowest notch to 4 inches at the highest notch.

B. Deck Lift Handle

The deck lift handle is located on the front/right of the

seat box frame, and is used to raise and lower the

mower deck.

Pull the handle to the left out of the index notch and

push downward to lower the deck, or pull upward to

raise the deck. When the desired height is attained,

move the lift handle to the right until fully in the index

notch.

C. RH and LH Drive Control Levers

The RH and LH control levers are located to each

side of the operator’s seat. These hinged levers open

out to the side in the neutral position to permit the

operator to be seated or to leave the tractor seat. The

levers must be fully opened out in the neutral position

to start the tractor engine.

Each lever controls the respective RH or LH transmission. Consequently, these levers control all of the

movements of the tractor. Driving and steering utilizing these control levers is quite different from

conventional tractors, and will take some practice to

master. Refer to SECTION 2: OPERATION for

instructions on using the control levers.

D. Ignition Switch

The ignition switch is located on the RH console to

the right of the operator’s seat.

The ignition switch has three positions as follow:

OFF

STOP

ON

START

NOTE: To prevent accidental starting and/or battery

discharge, remove the key from the ignition switch

when the tractor is not in use.

E. Power Take-Off (PTO) Switch

The PTO switch is located on the RH console to the

right of the operator’s seat.

Figure 5

The PTO switch operates the electric PTO clutch

mounted on the bottom of the engine crankshaft. Pull

the switch knob upward to engage the PTO clutch, or

push the knob downward to disengage the clutch.

The PTO switch must be in the "disengaged" position

when starting the engine.

F. Transmission Bypass Rods (Not Shown)

The transmission bypass rods (one for each the RH

and LH transmission) are located beneath the frame

platform, just inside each rear wheel.

When engaged, the two rods open a bypass within the

hydrostatic transmissions, which allows the tractor to

be pushed short distances by hand. Refer to

SECTION 2: OPERATION for instructions on using

the bypass feature.

WARNING: Never tow your tractor.

Towing the tractor with the rear wheels

on the ground may cause severe damage

to the transmissions.

G. Cup Holder

The cup holder is located toward the rear of the RH

console to the right of the operator’s seat.

Figure 4

OFF - The engine and electrical system is turned off.

ON - The tractor electrical system is energized.

H. Storage Tray

The storage tray is located at the rear of the RH

console.

10

Page 11

J. Seat Adjustment Wing Knobs (Not Shown)

The seat adjustment wing knobs are located

underneath the seat hinge bracket. The wing knobs

allow for tool free adjustment of the fore and aft

position of the operator’s seat. Refe r to SECTION 3:

ADJUSTMENTS for instructions on adjusting the seat

position.

K. Fuel Tank Cap

The fuel tank cap is located at the rear of the LH

console. Turn the cap counterclockwise to unscrew

and remove from the fuel tank. Always re-install the

fuel cap tightly onto the fuel tank after removing.

WARNING: Never fill the fuel tank when

the engine is running. If the engine is hot

from recently running, allow to cool for

several minutes before refueling. Highly

flammable gasoline could splash onto

the engine and cause a fire.

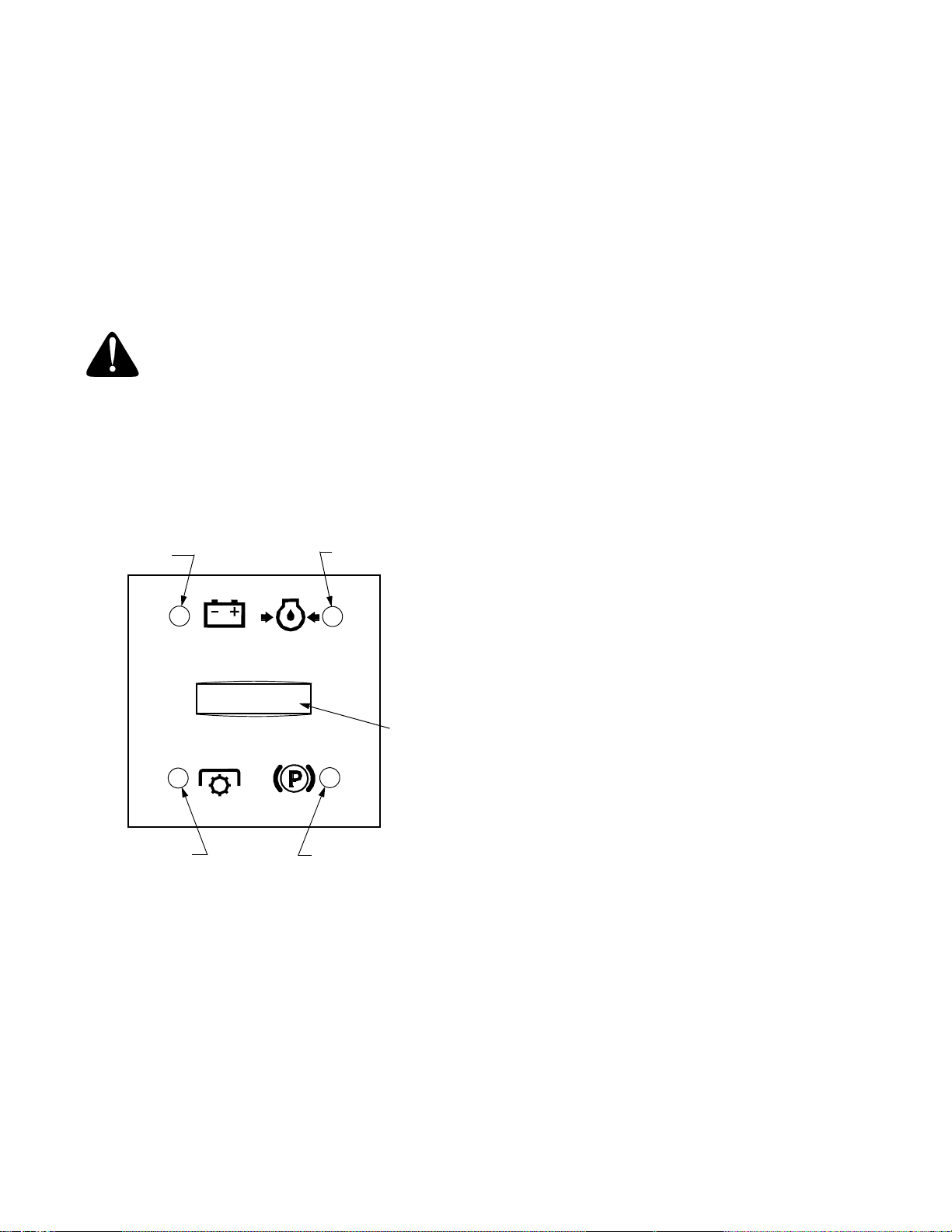

L. Hour Meter/Indicator Panel

The hour meter/indicator panel is located on the LH

console to the left of the operator’s seat.

Battery

Indicator

Oil Pressure

Indicator

this, a record of the actual hours of operation

should be kept to assure all maintenance

procedures are completed according to the

schedule in this manual and the engine manual.

• When key is turned to the "ON" position, the

battery indicator light briefly illuminates and the

battery voltage is briefly displayed. The display

then changes to the accumulated hours.

Indicator Panel Features

Battery Indicator (Refer to Figure 6)

• Illuminates and the battery voltage is displayed

briefly when the ignition switch it turned to the

"ON" position.

• Illuminates to indicate the battery voltage has

dropped below 11.5 (+0.5/-1.0) volts. The battery

voltage is also displayed on the hour meter. If this

indicator and display come on during operation,

check the battery and charging system for possible causes and/or contact your White Outdoor

dealer.

Oil Pressure Indicator (Refer to Figure 6)

• This warning lamp indicates low engine oil

pressure. If the indicator comes on while the

engine is running, stop the engine immediately

and check for possible causes. Do not run the

engine while this indicator is illuminated. Contact

your White Outdoor dealer to have the tractor and

engine inspected.

Hour

Meter

PTO Engaged

Indicator

Parking Brake

Engaged Indicator

Figure 6

Hour Meter Feature

The purpose of the hour meter is to record the hours

(tenths of an hour-right most digit) that the tractor has

been operated.

• The hour meter is activated whenever the ignition

switch is turned to the "ON" position. Because of

NOTE: The oil pressure indicator may illuminate

when the ignition switch is in the ON position, but

should turn off when the engine is started.

PTO Engaged Indicator (Refer to Figure 6)

• This indicator illuminates any time the PTO switch

is pulled upward in the "ENGAGED" position and

the ignition switch is in the "ON" or "START"

position. Check this indicator if the engine will not

crank with the ignition switch in the "START"

position; then move the PTO switch to the

"DISENGAGED" position if necessary.

Parking Brake Engaged Indicator (Refer to Figure 6)

• This indicator illuminates any time the parking

brake is in the "ENGAGED" position and the ignition switch is in the "ON" or "START" position.

When starting the engine, the parking brake must

be engaged and this indicator should be

illuminated.

11

Page 12

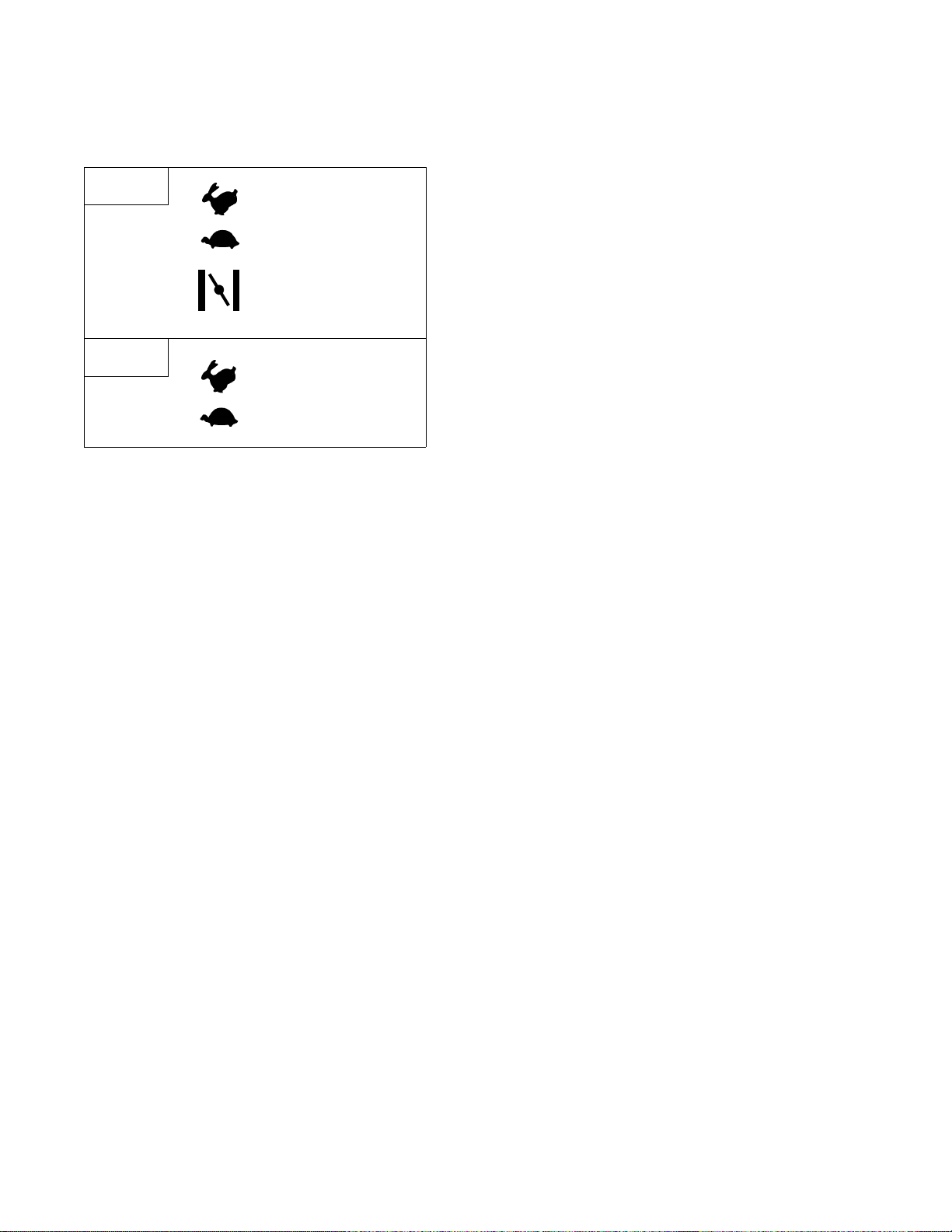

M. Throttle Control

The throttle control is located on the LH console to

the left of the operator’s seat. When set in a given

position, a uniform engine speed will be maintained.

ZT17

CHOKE

ZT22

This symbol indicates the

fast position.

This symbol indicates the

slow position.

This symbol indicates the

choke position.

This symbol indicates the

fast position.

This symbol indicates the

slow position.

Figure 7

• Push the control handle forward to increase the

engine speed. The tractor is designed to operate

with the control handle in the fast position (full

throttle) when the tractor is driven and the mower

deck is engaged.

• Pull the control handle rearward to decrease the

engine speed.

• Model ZT17 ONLY — When starting the engine,

push the control handle fully forward into the

"CHOKE" position. See Figure 7. After starting

and warming the engine, move the control handle

rearward until you feel it move past the choke

detent.

N. Choke Control - Model ZT22 ONLY

The choke knob controls the position of the engine

choke. Pull the knob out to choke the engine; push t he

knob in to open the choke.

O. Parking Brake Engagement Lever

The parking brake engagement lever is located on

the front/left of the seat box frame, and is used to

engage the parking brake.

• Pull the lever fully upward and to the left and

lower into the "J" slot to engage the parking

brake.

• Pull the lever up out of the "J" slot and to the

right; then lower completely to disengage the

parking brake.

IMPORTANT: If the LH and RH drive control levers

are not fully opened out in the ne utral position when

engaging the parking brake, the engine will stop. The

parking brake must be placed in the engaged position

when starting the tractor engine.

12

Page 13

SECTION 2: OPERATION

GENERAL SAFETY

• RECEIVE INSTRUCTION - Read the operator’s

manual. Learn to operate this machine SAFELY.

Don’t risk INJURY or DEATH. Allow only those

who have become competent in its usage to

operate this tractor .

• Familiarize yourself with the operations of all the

instruments and controls.

• Before starting the engine or beginning operation,

be familiar with the controls. The operator should

be in the operator’s seat. The PTO switch must

be in the disengaged position, the parking brake

engaged, and the RH and LH drive control levers

moved fully outward in the neutral position.

• Keep all shields in place. Keep away from moving

parts.

• NO RIDERS! Keep all people and pets a safe

distance away. Look behind to both sides before

backing up.

• DO NOT direct the mower discharge at people.

• Avoid slopes where possible. Never operate on

slopes greater than 15°. Slopes with a greater

incline present dangerous operating conditions.

Tractors can be rolled over.

• Before leaving the operator’s seat: Shut off the

PTO, mov e the RH and LH drive control levers

fully outward in the neutral position, engage the

parking brake, shut off the engine and remove

the ignition key. Wait for all movement to stop

before servicing or cleaning.

• Operate the drive control levers smoothly and

avoid any sudden movements of the levers

when starting and stopping. Keep a firm grip on

the control levers; do not allow the levers to

return to neutral on their own.

• Be careful when operating near roadways. Stop

the tractor motion and wait for vehicles to pass

before operating along the road.

• Do not operate the tractor with the mower deck

removed. Removal of the deck will change the

balance of the tractor, and could contribute to a

tractor rollover.

• Avoid operation or use extreme care if the

traction surface is unstable or slippery.

• Slow down before turning and come to a

complete stop before any zero turn maneuver.

• Do not stop the tractor or park the tractor over

combustible materials such as dry grass, leaves,

debris, etc.

• Do not fill the fuel tank when the engine is

running or while the engine is hot. Allow the

engine several minutes to cool before refueling.

Tighten the fuel cap securely.

BEFORE OPERATING YOUR TRACTOR

• Before you operate the tractor, study this manual

carefully. It has been prepared to help you

operate and maintain your tractor efficiently.

• Familiarize yourself with the operations of all the

instruments and controls.

• This engine is certified to operate on unleaded

gasoline. For best results, fill the fuel tank with

only clean, fresh, unleaded gasoline with a pump

sticker octane rating of 85 or higher. Unleaded

gasoline is recommended because it leaves less

combustion chamber deposits.

Some fuels are gasoline blended with alcohols or

ethers. Excessive amounts of the these blends

can damage the fuel system or cause engine

performance problems. If undesirable operating

symptoms occur, use gasoline with a lower

percentage of alcohol or ether. Do not use

gasoline that contains Methanol.

• Check the engine oil level. See Engine Manual.

IMPORTANT: Your tractor is shipped with mo tor

oil in the engine. However, you MUST check the

oil level before operating. The capacity of the

engine and oil filter is approximately 48 oz. (1.4

liters) for the model ZT17 and 64 oz. (1.9 liters).

for the model ZT22. Be careful not to overfill.

• Clean the air cleaner element if necessary. See

Engine Manual.

• Check the tire inflation pressures.

• Adjust the seat for operator’s maximum comfort,

visibility, and for maintaining complete control of

the tractor.

SAFETY INTERLOCK SYSTEM

This tractor is equipped with a safety interlock system

for the protection of the operator. If the interlock system

should ever malfunction, do not operate the tractor.

Contact your authorized White Outdoor Dealer.

• The safety interlock system prevents the engine

from cranking or starting unless the RH and LH

drive control levers are moved fully outward in the

neutral position, the parking brake is engaged,

and the PTO is disengaged.

• To avoid sudden movement when disengaging

the parking brake, the safety interlock system will

shut off the engine if the RH and/or LH drive

control levers are moved to a position other than

the fully out in neutral position when the parking

brake is engaged

• The safety interlock system will shut off the

engine if the operator leaves the seat before

engaging the parking brake.

13

Page 14

• The safety interlock system will shut off the

engine if the operator leaves the seat with the

PTO engaged, regardless of whether the parking

brake is engaged.

NOTE: The PTO switch must be moved to the

“OFF” position to restart the engine.

• The safety interlock system will shut off the PTO

and the mower blades will stop if both driv e control levers are moved into the reverse position.

The PTO will re-engage when one or both of the

levers are moved back to the neutral or forward

position.

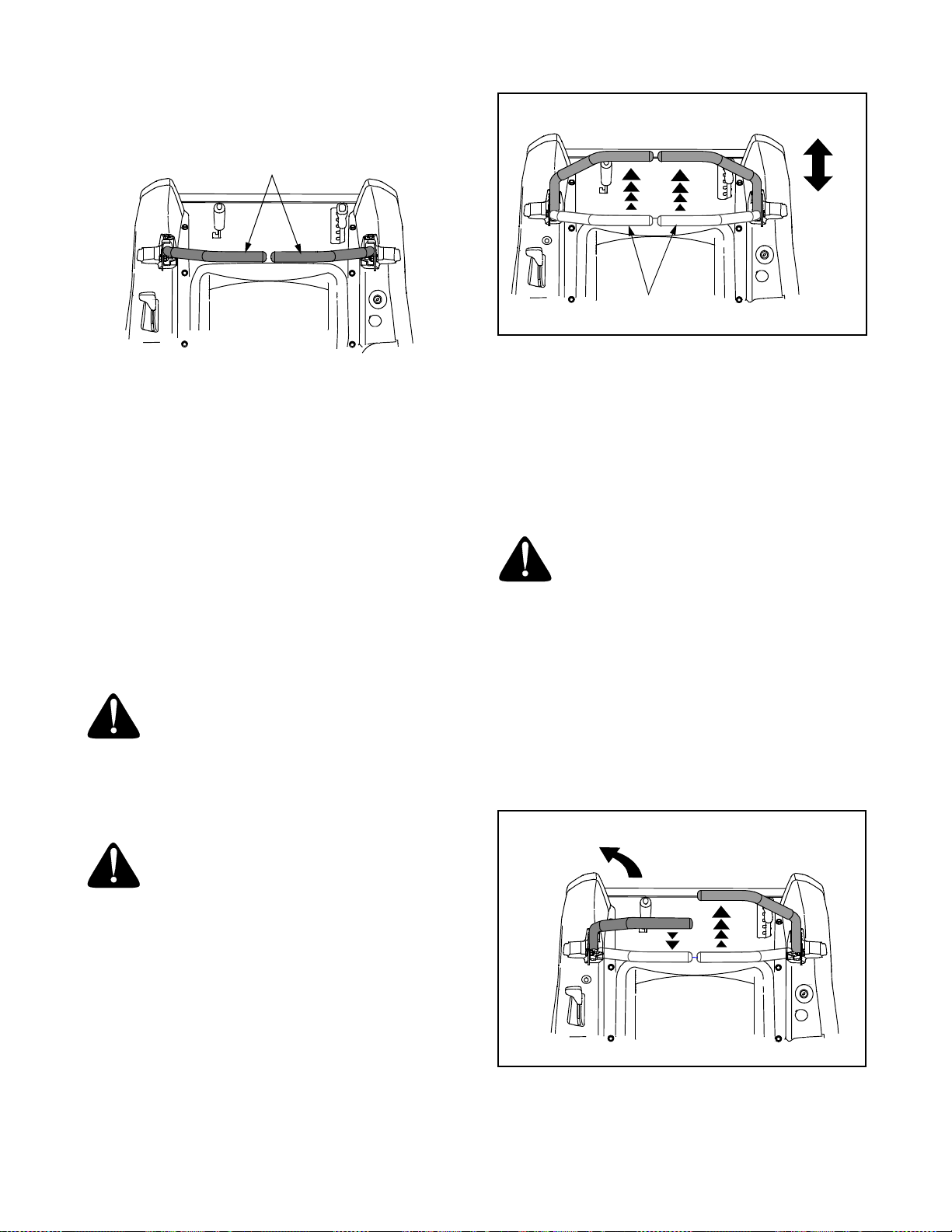

STARTING THE ENGINE

WARNING: For personal safety, the

operator must be sitting in the tractor

seat when starting the engine.

WARNING: This unit is equipped with a

safety interlock system designed for the

protection of the operator. Do not operate the tractor if any part of the interlock

system is malfunctioning. Periodically

check the functions of th e interlock system for proper operation.

• Move the RH and LH drive control levers fully

outward in the neutral position. Refer to Figure 8.

• Operator must be sitting in the tractor seat.

• Engage the parking brake. Refer to Figure 8.

• Make certain the PTO switch is in the disengaged (down) position. Refer to Figure 8.

• Model ZT17 ONLY

1. Move the throttle control lever fully forward

into the "CHOKE" position. NOTE: If the

engine is warmed up, it may not be ne cessary

to place the throttle control in the choke

position.

2. Turn the ignition key clockwise to the “START”

position and release it as soon as the engine

starts; however, do not crank the engine

continuously for more than 5 seconds at a

time. If the engine does not start within this

time, turn the key to “OFF” a nd wait a minute

to allow the engine’s starter motor to cool. Try

again after waiting. If after a few at tempts the

engine fails to start, do not k eep trying to start

it with the choke closed as this will cause

flooding and make starting more difficult.

3. As the engine warms up, gradually pull the

throttle control lever rearward past the choke

detent position. Do not use the choke to enrich

the fuel mixture, except as nec essary to start

the engine.

• Model ZT22 ONLY

1. Pull the choke control knob upward to the full

choke position. NOTE: If the engine is warmed

up, it may not be necessary to choke the

engine.

2. Move the throttle control lever fully forward to

the "fast" position.

LH Control Lever

Out in Neutral

ZT17 - Move Throttle

Control to Choke

ZT22 - Move Throttle

Control to "FAST"

Parking Brake

Engaged

ZT 22 - Pull Choke

RH Control Lever

Out in Neutral

PTO Switch in Down

(Disengaged) Position

Figure 8

3. Turn the ignition key clockwise to the “START”

position and release it as soon as the engine

starts; however, do not crank the engine

continuously for more than 5 seconds at a

time. If the engine does not start within this

time, turn the key to “OFF” and wait a minute

to allow the engine’s starter moto r to cool. Try

again after waiting. If after a few attempts the

engine fails to start, do not keep trying to start

it with the choke closed as this will cause

flooding and make starting more difficult.

4. As the engine warms up, gradually push the

choke knob downward to open the choke. Do

not use the choke to enrich the fuel mixture,

except as necessary to start the engine.

• Allow the engine to run for a few minutes at mid

throttle before putting the engine under load.

• Observe the hour meter/indicator panel. If the

battery indicator light or oil pressure light come

on, immediately stop the engine. Have the tractor

inspected by your White Outdoor dealer.

14

Page 15

COLD WEATHER STARTING

Be sure to use the proper oil for the expected

temperatures (check the table in the engine manual).

Follow the normal engine starting instructions above.

However, allow the engine ample time to warm up

before putting the tractor under load.

USING JUMPER CABLES TO START ENGINE

WARNING: Batteries contain sulfuric acid

and produce explosive gasses. Make

certain the area is well ventilated, wear

gloves and eye protection, and avoid

sparks or flames near the battery.

If the battery charge is not sufficient to crank the

engine, recharge the battery. If a battery charger is

unavailable and the tractor must be started, the aid of

a booster battery will be necessary. Connect the

booster battery as follows:

• Connect the end of one cable to the disabled

tractor battery’s positive terminal; then connect

the other end of that cable to the booster

battery’s positive terminal.

• Connect one end of the other cable to the booster

battery’s negative terminal.

• Connect the other end of that cable to the frame

of the disabled tractor, as far from the battery as

possible.

• Start the disabled tractor following the normal

starting instructions previously provided; then

disconnect the jumper cables in the exact reverse

order of their connection.

• Have the tractor’s electrical system checked and

repaired as soon as possible to eliminate the

need for jump starting.

STOPPING THE ENGINE

• Place the PTO switch in the “OFF” position.

• Engage the parking brake.

• Move the RH and LH drive control levers fully

outward in the neutral position.

• Model ZT17 ONLY — Place the throttle control

lever to the fast (high idle) position.

• Model ZT22 ONLY — Place the throttle control

lever to the slow (idle) position.

• Turn the ignition key to the “OFF” position and

remove the key from the ignition switch.

NOTE:

switch to prevent accidental starting or battery

discharge if the equipment is left unattended.

PRACTICE OPERATION (INITIAL USE)

Operating a zero-turn tractor is not like operating a

conventional type riding tractor. Although and because a zero-turn tractor is more maneuverable, getting used to operating the control levers takes some

practice.

We strongly recommend that you locate a reasonably large, level and open "practice area" where there

are no obstructions, pedestrians, or animals. You

should practice operating the tractor for a minimum of

30 minutes.

Carefully move (or have moved) the tractor to the

practice area. When performing the practice session,

it not necessary operate with the PTO engaged.

While practicing, operate the tractor at approximately

1/2 throttle and at less than full speed in both forward

and reverse.

Carefully practice maneuvering the tractor using the

instructions in the following section "Driving the Tractor." Practice until you are confident that you can

safely operate the tractor.

DRIVING THE TRACTOR

• Adjust the operator’s seat to the most

• Release the parking brake.

Always remove the key from the ignition

WARNING: Avoid sudden starts, excessive speed and sudden stops.

WARNING: Do not leave the seat of the

tractor without disengaging the PTO,

moving drive control levers fully outward

in the neutral position, and engaging the

parking brake. If leaving the tractor

unattended, turn the ignition key off and

remove key.

comfortable position that allows you to operate

the controls. See seat adjustment in the

ADJUSTMENTS section.

15

Page 16

• Move the RH and LH drive control levers inward

in the neutral position. See Figure 9.

Control Lever Moved

Inward and in Neutral

DRIVING FORWARD

Faster

Slower

Neutral

Position

Figure 10

Figure 9

• Move the throttle control lever forward to the full

throttle position (3500-3600 RPM).

IMPORTANT: The tractor and engine are designed to

run at full throttle. However, if performing a prac-

tice session, the tractor should be operated at

half throttle (approximately 2500-2600 RPM). This

only applies to practice operation.

NOTE: For Model ZT17, make certain the throttle

control has not been moved t oo far forward into the

"Choke" position.

• To drive the tractor, firmly grasp the respective

drive control levers with your right and left hands

and proceed as follows :

WARNING: Always maintain a firm grip

on the control levers. DO NOT release the

control levers to slow or stop the tractor;

move the levers to the neutral position

using your hands.

Driving the Tractor Forward

WARNING: Keep all movement of the

drive control levers slow and smooth.

Abrubt movement of the control levers

can affect the stability of the tractor and

could cause the tractor to flip over,

which may result in serious injury or

death to the operator.

• Slowly and evenly move both drive control levers

forward. The tractor will start to move forward.

See Figure 10.

• As the control levers are pushed farther forward

the speed of the tractor will increase.

• To slow the tractor move the controls lever

rearward to attain the desired speed, or move the

levers to the neutral position to stop the tractor .

IMPORTANT: Always maintain your grasp on the

drive control levers. Do not release the levers to

slow the tractor or to return to neutral.

Turning the Tractor While Driving Forward

WARNING: When reversing the direction

of travel, we recommend performing

gradual ‘U’ turns where possible.

Sharper turns increase the possibility of

turf defacement, and could affect control

of the tractor. ALWAYS slow the tractor

before making sharp turns.

• To turn the tractor while driving forward, move the

control levers as necessary so that one lever is

rearward of the other. The tractor will turn in the

direction of the rearward control lever.

- To turn to the left, move the left drive control

lever rearward of the right lever. See Figure 11.

FORWARD LEFT TURN

Figure 11

16

Page 17

- To turn to the right, move the right drive control

lever rearward of the left lever. See Figure 1 2.

FORWARD RIGHT TURN

Figure 12

• The greater the fore-to-aft distance between the

two levers, the sharper the tractor will turn.

• To execute a "pivot turn," move the turn side

drive control lever to the neutral position, while

moving the other control lever forward.

IMPORTANT: Making a "pivot turn" on grass

will greatly increase the potential for

defacement of the turf.

IMPORTANT: Always maintain your grasp on the

drive control levers. Do not release the levers to

slow the tractor or to return to neutral.

Turning While Driving Rearward

• To turn the tractor while driving rearward, move

the control levers as necessary so that one lever

is forward of the other. The tractor will turn in the

direction of the forward control lever.

- To turn to the left while traveling in reverse,

move the left drive control lever forward of the

right lever. See Figure 14.

REARWARD LEFT TURN

Driving the Tractor In Reverse

WARNING: Always look behind and

down on both sides of the tractor before

backing up. Always look behind while

traveling in the reverse direction.

• Slowly and evenly move both drive control levers

rearward. The tractor will start to move in the

reverse direction. See Figure 13.

DRIVING REARWARD

Neutral

Position

Slower

Faster

Figure 13

• As the control levers are pushed farther re arward

the speed of the tractor will increase.

• To slow the tractor move the controls lever

forward to attain the desired speed, or move the

levers to the neutral position to stop the tractor.

Figure 14

- To turn to the right while traveling in reverse,

move the right drive control lever forward of the

left lever. See Figure 15.

REARWARD RIGHT TURN

Figure 15

• The greater the fore-to-aft distance between the

two levers, the sharper the tractor will turn.

• To execute a "pivot turn," move the turn side

drive control lever to the neutral position, while

moving the other control lever rearward.

IMPORTANT: Making a "pivot turn" on grass

will greatly increase the potential for

defacement of the turf.

17

Page 18

Executing a Zero Turn

WARNING: When executing a zero turn,

the tractor MUST BE STOPPED.

Executing a zero turn while the tractor is

moving can significantly reduce your

control of the tractor and will cause

severe turf defacement to occur.

• Stop the forward or rev erse motion of the tractor

by moving the two drive control levers to neutral.

• To turn clockwise, slowly move the left control

lever forward while simultaneously moving the

right control lever rearward. See Figure 16.

CLOCKWISE ZERO TURN

STOPPING THE TRACTOR

• Move both drive control levers to the neutral

position to stop the motion of the tractor.

• Push the PTO switch downward to the

disengaged position.

• Use the deck lift handle to raise the deck to its

highest position.

• If dismounting the tractor:

- Move the drive control handles fully outward in

the neutral position.

- Engage the parking brake.

- Move the throttle control lever to the fast

position if operating a ZT17 tractor, or to the

slow position if operating a ZT22 tractor.

- Turn the ignition switch to “OFF’” and remove

the key from the switch.

DRIVING ON SLOPES

Refer to the SLOPE GAUGE on page 31 to help

determine slopes where you may not operate safely.

WARNING: Do not operate on inclines

with a slope in excess of 15 degrees (a

rise of approximatel y 2-1/2 feet every 10

feet). The tractor could overturn and

cause serious injury.

Figure 16

• To turn counterclockwise, slowly move the right

control lever forward while simultaneously moving

the left control lever rearward. See Figure 17.

COUNTERCLOCKWISE ZERO TURN

Figure 17

• Always drive across slopes, NEVER UP AND

DOWN.

• Always turn uphill where possible. Start at the

bottom of a slope and work upward.

• Always slow down before turning.

• Avoid turning downhill if possible. Use extra care

and go slowly when turning downhill.

OPERATING THE PTO

Operate the PTO clutch as follows:

• Move the throttle control lever to approximately

the mid throttle position.

• Pull the PTO switch upward to the “ENGAGED”

position.

• Advance the throttle lever to the operating speed

(full engine speed).

• The operator must remain in the tractor seat at all

times. If the operator should leave the seat

without turning off the power take-off switch, the

tractor’s engine will shut off.

• The PTO clutch cannot be operated when the

tractor is driving in the reverse direction. The

PTO will disengage when both drive control

levers are moved to the reverse position, and will

re-engage when one (or both) control levers are

moved to the neutral or forward position.

18

Page 19

USING THE MOWER DECK

WARNING: Make certain the area to be

mowed is free of debris, sticks, stones,

wire or other objects that can be thrown

by the rotating blades.

• Mow across slopes, not up and down. If mowing

a slope, start at bottom and work upward to

ensure turns are made uphill.

• On the first pass pick a point on the opposite side

of the area to be mowed.

• Lower the mower deck to the desired height

setting using the lift handle.

• Engage the PTO clutch using the PTO switch and

move the throttle control to the fast position.

• Slowly and evenly push the RH and LH drive

control levers forward to move the tractor

forward, and keep the tractor headed directly

toward the alignment point.

NOTE: The speed of the tractor will affect the

quality of the mower cut. Mowing at full speed

with adversely affect the cut quality. Control the

ground speed with the control levers.

• When approaching the other end of the strip,

slow down or stop before turning. A U-turn is

recommended unless a pivot or zero turn is

required.

• Align the mower with an edge of the mowed strip

and overlap approximately 3 inches.

• Direct the tractor on each subsequent strip to

align with a previously cut strip.

• To prevent rutting or grooving of the turf, if

possible, change the direction that the strips are

mowed by approximately 45° for the next and

each subsequent mowing.

WARNING: Be careful when crossing

gravel paths or driveways. Disengage

the PTO and raise the deck to the

highest position before crossing.

CHECKING THE SAFETY INTERLOCK CIRCUITS

Periodically check the safety interlock circuits to

ensure they are working properly. If a safety circuit is

not working as designed, contact you White Outdoor

dealer to have the tractor inspected. DO NOT operate

the tractor if any safety circuit is not functioning

properly. To check the safety circuits, proceed as

follows:

• Sitting in the tractor seat with both drive control

levers opened fully outward, disengage the

parking brake and momentarily turn the ignition

switch to the start position. T he eng ine s hould not

crank.

• Engage the parking brake and pull the PTO

switch upward to the engaged position.

Momentarily turn the ignition switch to the start

position; the engine should not crank.

• Push the PTO switch downward to the disengaged position and engage the parking brake.

Start the engine and move one of the drive control levers from the fully outward neutral position.

The engine should stop running. Repeat the procedure with the opposite control lever.

• Move both control levers fully outward in the neutral position and disengage the parking brake;

then lift upward from the operator’s seat. The

engine should stop.

• With both control levers fully outward in the neutral position and the parking brake engaged,

engage the PTO. Lift upward from the operator’s

seat; the engine should stop.

• Start the tractor, disengage the parking brake,

and move the control levers inward to the neutral

operating position. Engage the PTO and move

both control lever slowly into the slow reverse

position; the PTO should disengage and the

mower deck should stop until one or both of the

control levers are moved to the neutral or forward position.

19

Page 20

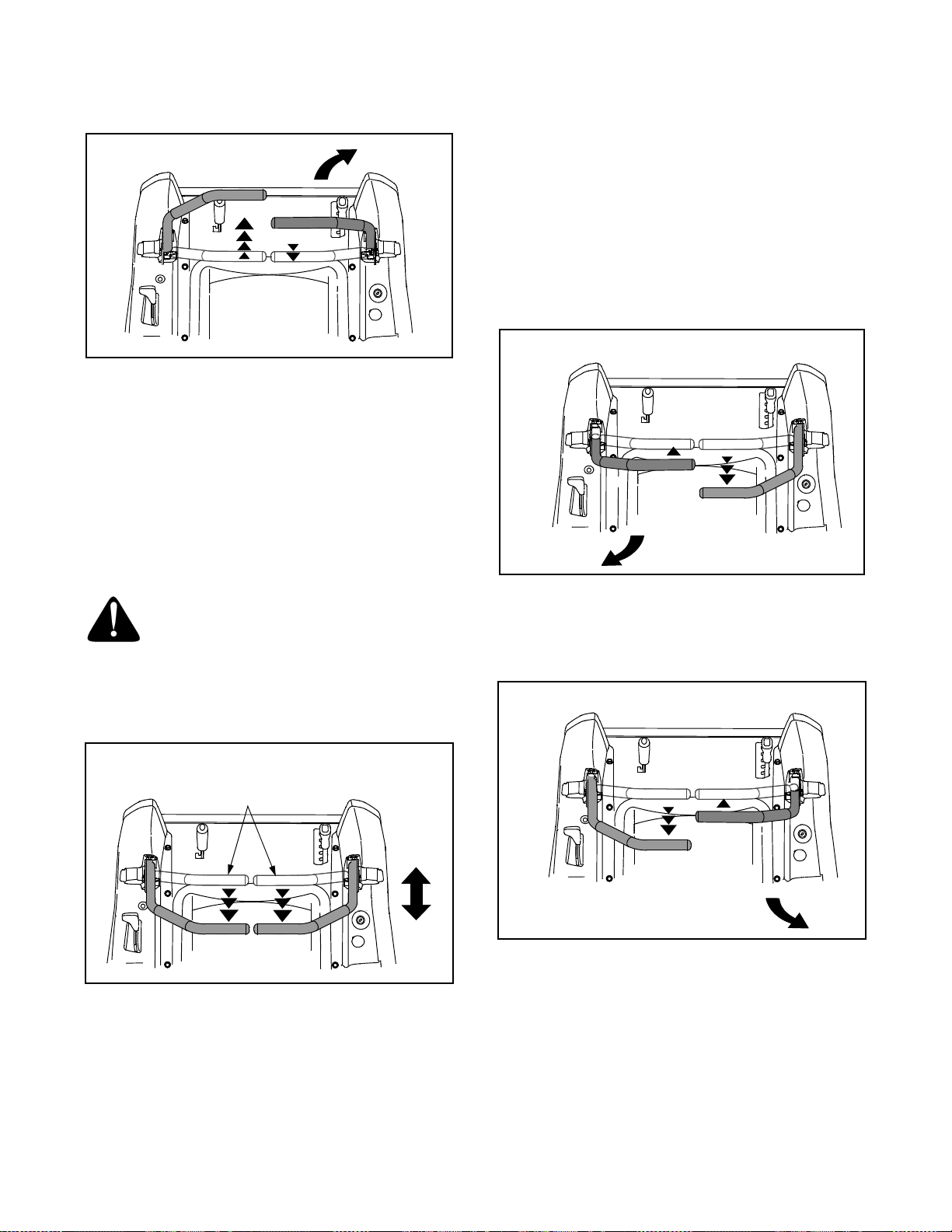

SECTION 3: ADJUSTMENTS

ADJUSTING THE OPERATORS SEAT

The seat may be adjusted f ore and af t for the com fort

of the operator. To adjust the seat proceed as follows:

• Pivot the seat partially forward and hold in a

position that allows you to access the wing knobs

on the bottom of the seat.

• Loosen the two wing knobs and slide the seat

forward or backward in the adjustment slots to

the desired position, then retighten the wing

knobs. See Figure 18.

Wing Knobs

Seat

• Remove the two hex insert lock nuts securing the

hex cap screws fastening the control lever to the

control pivot bracket. Refer to Figure 19.

• While holding the hex cap screws in the control

lever mounting bracket, remove the control lever

w/screws from the control pivot handle and

reposition by inserting the screws in the other pair

of holes.

• If repositioning the control levers forward or

rearward proceed to the next step. If not, fully

tighten the hex cap screws and hex insert lock

nuts to secure the contro l levers.

Hex Insert

Lock Nut

Pivot Bracket

Control Lever

Flat Washer

Hex Cap Screw

Adjustment

Slots

Figure 18

ADJUSTING RH & LH DRIVE CONTROL LEVERS

The RH and LH drive control levers can be adjusted

up or down and fore-and-aft for the comfort of the

operator. The drive control levers can be placed in

either of two height positions, or can be moved

forward or rearward within the range of the upper

slots on each control lever mounting bracket.

To adjust the drive control lever height, proceed as

follows:

Slot

Hgt. Adjust Holes

Figure 19

To adjust the drive control lev ers forw ard or rearward ,

proceed as follows:

• Loosen the two hex insert loc k nuts and hex cap

screws securing the control lever to the control

pivot bracket. Refer to Figure 19.

• Rotate the control lever either forward or

rearward to the desired position.

• Tight the two hex insert lock nuts and hex cap

screws to secure in the control lever.

20

Page 21

SECTION 4: MAINTENANCE

ENGINE MAINTENANCE

Engine maintenance procedures and schedules can

be found in the engine manual found at the back of

this manual. Follow these schedules for performing

engine maintenance.

Using the Engine Oil Drain Valve

• Locate the oil drain valve on the left side of the

engine.

• Pop open the protective cap on the end of the oil

drain valve to expose the oil drain port. See

Figure 20.

• Push the oil drain hose (packed with this manual) onto the oil drain port. Route the opposite

end of the hose into an appropriate oil collection

container with a capacity great enough to collect

the used oil (48 oz.- ZT17; 64 oz.- ZT22).

Protective

Cap

Oil Drain

Hose

Turn and

Pull Out

Oil Drain

Valve

Figure 20

• Push the oil drain valve in slightly, then rotate

counterclockwise and pull outward to begin

draining oil. See Figure 20.

HYDROSTATIC TRANSMISSION MAINTENANCE

The zero turn tractor is equipped with dual integrated

hydrostatic pumps, motors, and transaxles that are

sealed and do not require regular maintenance. All

service work on the hydrostatic transmissions should

be performed by your White Outdoor dealer.

GENERAL BATTERY INFORMATION

WARNING:

• Battery posts, terminals and related accessories

contain lead and lead compounds. Wash hands

after handling.

• Should battery acid accidentally splatter into the

eyes or onto the skin, rinse the affected area

immediately with clean cold water. If there is any

further discomfort, seek prompt medical attention.

• If acid spills on clothing, first dilute it with clean

water, then neutralize with a solution of ammonia/

water or baking soda/water.

• NEVER connect (or disconnect) battery charger

clips to the battery while the charger is turned on,

as it can cause sparks.

• Keep all sources of ignition (cigarettes, matches,

lighters) away from the battery. The hydrogen

gas generated during charging can be

combustible.

• As a further precaution, only charge the battery in

a well ventilated area.

• Always shield eyes and protect skin and clothing

when working near batteries.

WARNING: Batteries contain sulfuric

acid and may emit explosive gases. Use

extreme caution when handling batteries. Keep batteries out of the reach of

children.

BATTERY REMOVAL

WARNING: Battery posts, terminals and

related accessories contain lead and

lead compounds. Wash hands after

handling.

The battery is located on the right/rear of the tractor

beneath the seat box frame.

To remove the battery:

• Grasp the bottom of the battery holddown strap

and pull downward and rearward to release it

from the tab in the frame.

• Remove the hex ca p screw and sems nut securing the black negative battery lead to the negative

battery post (marked NEG). Move the cable away

from the negative battery post.

• Remove the hex ca p screw and sems nut securing the red positive battery lead to the positive

battery post (marked POS).

• Carefully lift the battery out of the tractor.

Install the battery by repeating the above steps in the

reverse order.

WARNING: Always connect the positive

lead to the battery before connecting the

negative lead. This wil l prevent sparking

or possible injury from an electrical short

caused by contacting the tractor body

with tools being used to connect the

cables.

21

Page 22

CHARGING THE BATTERY

Test and, if necessary, recharge the battery after the

tractor has been stored for a period of time.

• A voltmeter or load tester should read 12.6 volts

(DC) or higher across the battery terminals.

• Charge the battery with a 12-volt battery charger

at a MAXIMUM rate of 10 amps.

Voltmeter

Reading

12.7 100% Full Charge

12.4 75% 90 Min.

12.2 50% 180 Min.

12.0 25% 280 Min.

State of

Charge

Charging

Time

BATTERY MAINTENANCE

The battery is filled with battery acid and then sealed

at the factory. However, even a “maintenance free”

battery requires some maintenance to ensure its

proper life cycle.

• Spray the terminals and exposed wire with a

battery terminal sealer, or coat the terminals with

a thin coat of grease or petroleum jelly, to protec t

against corrosion.

• Always keep the battery cables and terminals

clean and free of corrosion.

• Avoid tipping. Even a sealed battery will leak

electrolyte when tipped.

GOOD

BAD

Figure 21

Relays and Switches

There are several relays and safety switches in the

electrical system. If a functi on of the safety interlock

system described earlier is not functioning properly,

have the electrical system checked by your White

Outdoor dealer.

LUBRICATION

• Using a pressure lubricating gun, lubricate the

front castor axles with a No. 2 multi-purpose

lithium grease after every 10 hours of service.

• From underneath the left rear of the tractor,

locate the tractor drive belt idler pulley and idler

bracket. Using a pressure lubricating gun,

lubricate the idler bracket with No. 2 multipurpose lithium grease after every 10 hours of

service.

• Refer to the "MOWER DECK" section later in this

manual for deck lubrication procedures.

• Periodically lubricate all other pivot points with a

quality lubricating oil.

BATTERY STORAGE

• When storing the tractor for extended periods,

disconnect the negative battery cable. It is not

necessary to remove the battery.

• All batteries discharge during storage. Keep the

exterior of the battery clean, especially the top. A

dirty battery will discharge more rapidly.

• The battery must be stored with a full charge. A

discharged battery can freeze sooner than a

charged battery. A fully charged battery will store

longer in cold temperatures than hot.

• Recharge the battery before returning to service.

Although the tractor may start, the engine charging

system may not fully recharge the battery.

SERVICING ELECTRICAL SYSTEM

A fuse is installed to protect the tractor’s electrical

system from damage caused by excessive amperage. Always use the same capacity fuse for

replacement. If the electrical system does not function, check for a blown fuse. See Figure 21

If you have a recurring problem with blown fuses,

have the tractor’s electrical system checked by your

White Outdoor dealer.

TIRE MAINTENANCE

Check the tire air pressure after every 50 hours of

operation or weekly. Keep the tires inflated to the

recommended pressures. Improper inflation will

shorten the service life of a tir e. See the tire si de wall

for proper inflation pressures. Observe the following

guidelines:

• Do not inflate a tire above the maximum pressure

shown on the sidewall of the tire.

• Do not reinflate a tire that has been run flat or

seriously under inflated. Have a qualified tire

mechanic inspect and service the tire.

USING THE TRANSMISSION BYPASS RODS

If for any reason the tractor will not drive or you wish

to move the tractor, the two hydrostatic transmissions are equipped with bypass rod that will allow you

to manually move the tractor short distances.

WARNING: Do not tow the tractor, even

with the bypass rod engaged. Serious

transmission damage will result from

doing so.

22

Page 23

• From just in front of the two rear tires, locate the

transmission bypass rods. See Figure 22.

• Pull one rod toward the front of the tractor until

the flange on the rod is forward of the keyhole

slot in the frame assembly.

• Lower the bypass rod into the keyhole slot and

release so the rod flange is against the front of

the frame bracket.

• Repeat the above procedure to engage the other

bypass rod.

• If only one wheel is rotating, locate the transmission control rod beneath the frame at the front of

the rear tire. If both wheels rotate, locate both

control rods. See Figure 23.

RH Transmission

Control Rod

Internal

Cotter Pin

RH Transmission

Bypass Rod

Pull out

Bypass Rod

Then Lower

In Slot

Keyhole

Slot

Figure 22

• After moving the tractor, disengage both bypass

rods. Lift the rod and guide the flange of the rod

back through the larger circular opening of the

keyhole, then release the rod.

IMPORTANT: The tractor will not drive with the

bypass rods in the engage position.

TRACTOR CREEPING

Creeping is the slight forward or backward movement

of the tractor when the engine is running at high idle

and the drive control levers are opened out in the

neutral position.

If after operating the tractor for some time, it be gi ns to

creep while in the neutral position, adjust the

transmission control rods as follows.

• Place the front of the tractor against an

immovable object (e.g. wall, post, etc.).

• Jack up the rear of the tractor so that both rear

wheels are approximately one inch of the gr ou n d.

• With the engine running at high idle and the drive

control levers opened out in the neutral position,

and the parking brake disengaged, check the rear

wheels for rotation.

Ferrule

Transmission

Control Arm

Figure 23

• Remove the internal cotter pin securing the

ferrule to the transmission control arm and

withdraw the ferrule. Wheel rotation should stop.

If it does not, contact your White Outdoor dealer.

• If the rotation stops, adjust the ferrule up or down

the control rod as necessary to align with the hole

in the transmission control arm. Re-insert the

ferrule into the hole in the control arm and secure

with the internal cotter pin.

• If necessary, repeat the previous two steps to

adjust the other transmission control rod.

• Lower the tractor and remove the jack.

TRACTOR HIGH SPEED TRACKING

If the tractor tracks to one side with both drive control

levers fully forward, adjust the control levers as

follows:

• Check for proper and balanced air pressure in

both front and rear tires. Refill tires if necessary.

• Perform the first three steps in the previous subsection, Tractor Creeping, to verify that the tractor

is not creeping. If creeping, adjust following the

instructions in that sub-section.

• Recheck the tracking after making any adjustments to the transmission control rods.

• If uneven tracking persists, note which direction

the tractor is tracking.

- If the tractor tracks to the right, adjust the

control lever stop bolt on the left side.

- If the tractor tracks to the left, adjust the control

lever stop bolt on the right side.

23

Page 24

• Locate the applicable stop bolt on the left or right

console. See Figure 24.

Console

Jam Nut

Transmission

Drive Pulley

Idler

Pulley

Stop Bolt

Figure 24

• Loosen the jam nut on the stop bolt, then turn the

stop bolt counterclockwise to make it longer.

Recheck the tracking and fine tune the adjustment as necessary.

NOTE: If the stop bolt is adjusted too far, the

tracking problem will change sides. Make fine

tuning adjustments by shortening the same bolt.

• Tighten the jam nut against the console and reposition the control lever if necessary.

TRANSMISSION DRIVE BELT

If the transmission drive belt becomes worn and

causes the drive transmissions to slip, the drive belt

must be replaced. To replace the drive belt, proceed

as follows:

• Remove the deck drive belt from the PTO clutch

on the bottom of the engine following the ins tructions in Deck Removal, SECTION 5: MOWER

DECK.

• From beneath the rear of the tractor, insert a 3/8

inch drive ratchet into the square hole of the drive

idler bracket. See Figure 25.

Square

Hole

Idler

Bracket

Idler Brkt.

Spring

Engine

Pulley

Drive

Belt

PTO

Pulley

Figure 25

• Using the ratchet for leverage, pivot the idler

bracket and idler pulley away from the backside

of the ‘V" belt; then lift the belt off and above the

engine pulley and off the idler pulley.

• With the belt loose, lift the belt off, up and over

the two transmission drive pulleys. Remove the

belt from the engine and idler pulleys.

• Loop the new belt and slide over and onto the

two transmission pulleys.

• Route the belt above the idle r bracket back to the

engine drive pulley. Lift the belt over th e PT O pu lley and above the engine drive pulley.

• Using the ratchet for leverage, pivot the idler

bracket and idler pulley against the spring tension; then slip the belt down into the engine drive

pulley and onto the idler pulley.

• Release the idler bracket so that the idler pulley

tightens against the back side of the belt and tensions the drive belt.

• Reinstall the deck drive belt.

24

Page 25

TRACTOR STORAGE

If your tractor is not going to be operated for an

extended period of time (thir ty days to approximately

six months), the tractor should be prepared for storage. Store the tractor in a dry and protected location.

If stored outside, cover the tractor (including the tires)

to protect it from the elements. The procedures outlined below should be performed wh en ever the tractor

is placed in storage.

1. Change the engine oil and filter following the

instructions provided in the engine information at

the back of this manual.

WARNING: Never store the tractor with

fuel in the tank indoors or in poorly ventilated enclosures, where fuel fumes may

reach an open flame, spark or pilot light

as on a furnace, water heater, clothes

dryer, etc.

WARNING: Fuel left in the fuel tank deteriorates and will cause serious starting

problems.

2. If storing the tractor for 30 days or more:

To prevent gum deposits from forming inside the

engine’s carburetor and causing possible malfunction of the engine, the fuel system must be either

completely emptied, or the gasoline must be

treated with a stabilizer to prevent deterioration.

Using a fuel stabilizer:

• Read the product manufacturer’s instructions

and recommendations.

• Add to clean, fresh gasoline the correct amount

of stabilizer for the capacity (approximately 3

gallons) of the fuel system.

• Fill the fuel tank with treated fuel and run the

engine for 2-3 minutes to get stabilized fuel into

the carburetor.

Emptying the fuel system:

• Prior to putting the tractor in storage, monitor

fuel consumption with the goal of running the

fuel tank empty.

• Run the engine until it begins to stall. Use the

choke to keep the engine running until all fuel in

the carburetor has been exhausted.

3. Clean the engine and the entire tractor

thoroughly.

4. Fully charge the battery, then disconnect the negative cable at the battery to prevent possible

discharge. Recharge the battery periodically

when in storage.

NOTE: Remove the battery if exposed to prolonged

periods of sub-freezing temperatures. Store in a cool,

dry location where temperatures are above freezing.

5. Lubricate all lubrication points.

NOTE: We do not recommend the use of a pressure

washer or garden hose to clean your unit. They may

cause damage to electrical components; spindles;