WHITE

WHITE

MODEL

W1750C

Call

Toll

Free

www.whitesewing

D’LITE

800-331-3164

INSTRUCTION

.com

BOOK

CONTENTS

MAIN

PARTS

ACCESSORIES

OPENING

REMOVING

OPENING

DUST

CHANGING

REMOVING

INSERTING

CONNECTING

CONTROL

REVERSE

NEEDLE

SETTING

MACHINE

POLARIZED

WHERE

BOBBIN

WINDING

INSERTING

THREADING

THREADING

THREADING

THREADING

DRAWING

STARTINGTOSEW

STARTAND

REVERSE

TURNING

SEWING

SEWING

ADJUSTING

FABRIC,

STRAIGHT

ZIGZAG

FREE

OVERCASTING-OVERLOCKING

USING

COVER

BUTTONS

UP/DOWN

UP

ELECTRICAL

TO

USE

WINDING

THE

UP

STITCHING

CORNERS

HEAVY

OVER

THREAD

STITCH

STITCH

ARM

SEWING

THE

THE

ACCESSORY

THE

EXTENSION

ACCESSORY

THE

(OPTIONAL)

THE

PRESSER

THE

PRESSER

THE

NEEDLE

THE

STITCH

YOUR

PLUG

EACH

BOBBIN

THE

BOBBIN

THE

MACHINE

THE

UPPER

THE

TOP

THE

NEEDLE

THE

END

OF

FABRIC

OVERLAPPED

THE

THREAD

AND

SEWING

GENERAL

CASE

TABLE

CASE

FOOT

MACHINE

&DROP

BUTTON

BUTTON

WHITE

SEWING

CONNECTION

INFORMATION

STITCH

THREAD

THREAD

EYE

BOBBIN

THREAD

SEAM

AREAS

TENSIONS

NEEDLE

SEWING

PURPOSE

FOOT

HOLDER

FEED

TABLE

FOOT

LEVER

BLIND

2

BUTTONHOLE

4

MULTI-STITCH

4

ELASTIC

5

FEED

5

PATCH

5

APPLIQUE

6

INSERTING

6

SCALLOP

6

CONTINUOUS

7

8

CARING

8

8

HELPFUL

9

10

11

12

13

13

13

14

14

15

15

16

16

16

16

17

18

19

20

20

21

21

HEM

DOG

WORK

SEWING

FOR

CLEANING

HINTS

STITCHING

SEWING

ZIGZAG

STITCH

CONTROL

ZIPPERS

STITCH

DECORATIVE

LIGHT

WEIGHT

YOUR

THE

FEED

SEWING

FABRICS

MACHINE

DOGS

PATTERN

AND

HOOK

AREA

—1—

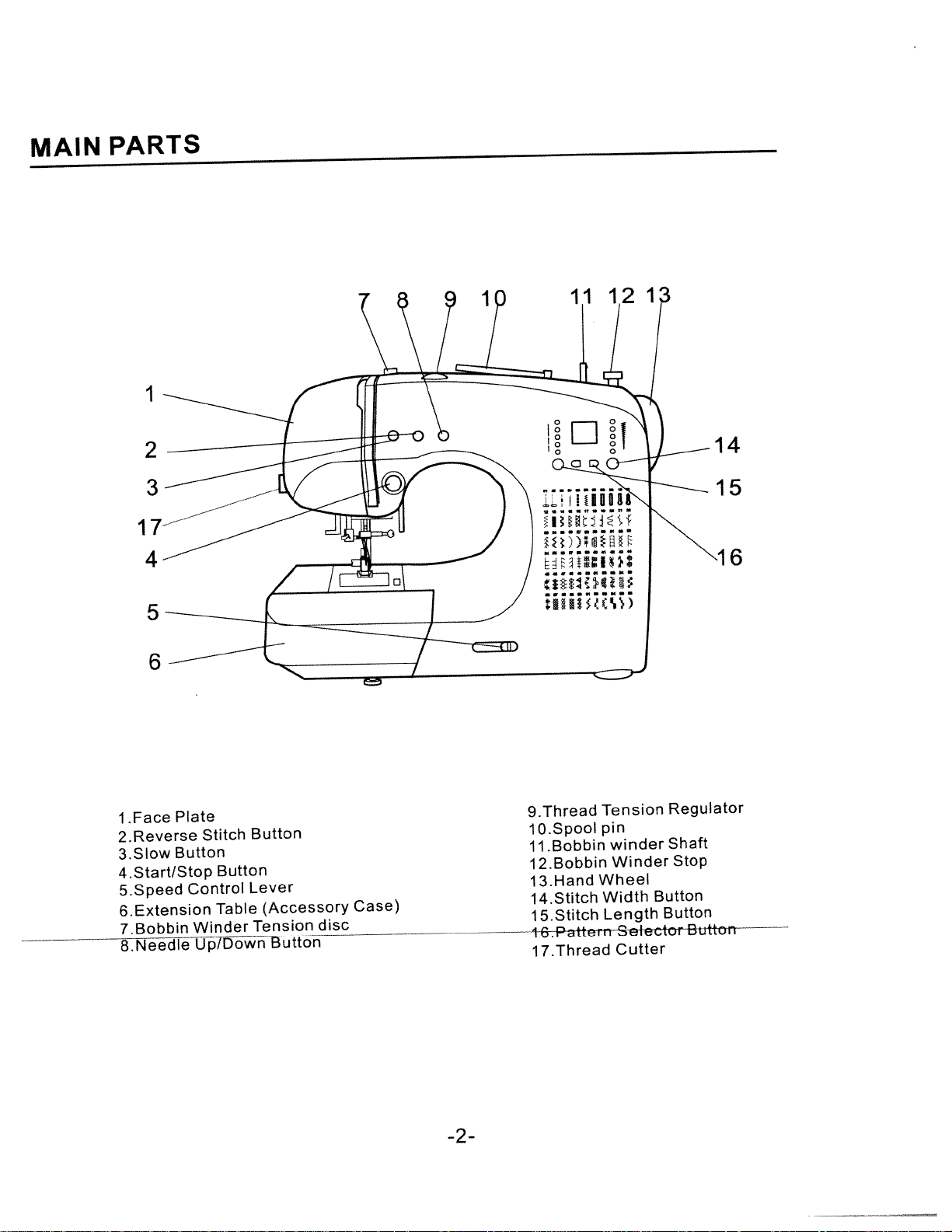

MAIN

PARTS

1

2

3

1

4

5

6

.Face

1

2.Reverse

3.Slow

4.StartlStop

5.Speed

6.Extension

7.Bobbin

8.Needle

Plate

Button

Stitch

Button

Control

Table

Winder

Up/Down

Button

Lever

(Accessory

Tension

Button

disc

Case)

9.Thread

lOSpool

11.Bobbin

12.Bobbin

13.Hand

14.Stitch

15.Stitch

iG.Pattern

17.Thread

Tension

pin

winder

Winder

Wheel

Width

Length

Button

SetectorButton

Cutter

14

15

16

Regulator

Shaft

Stop

Button

-2-

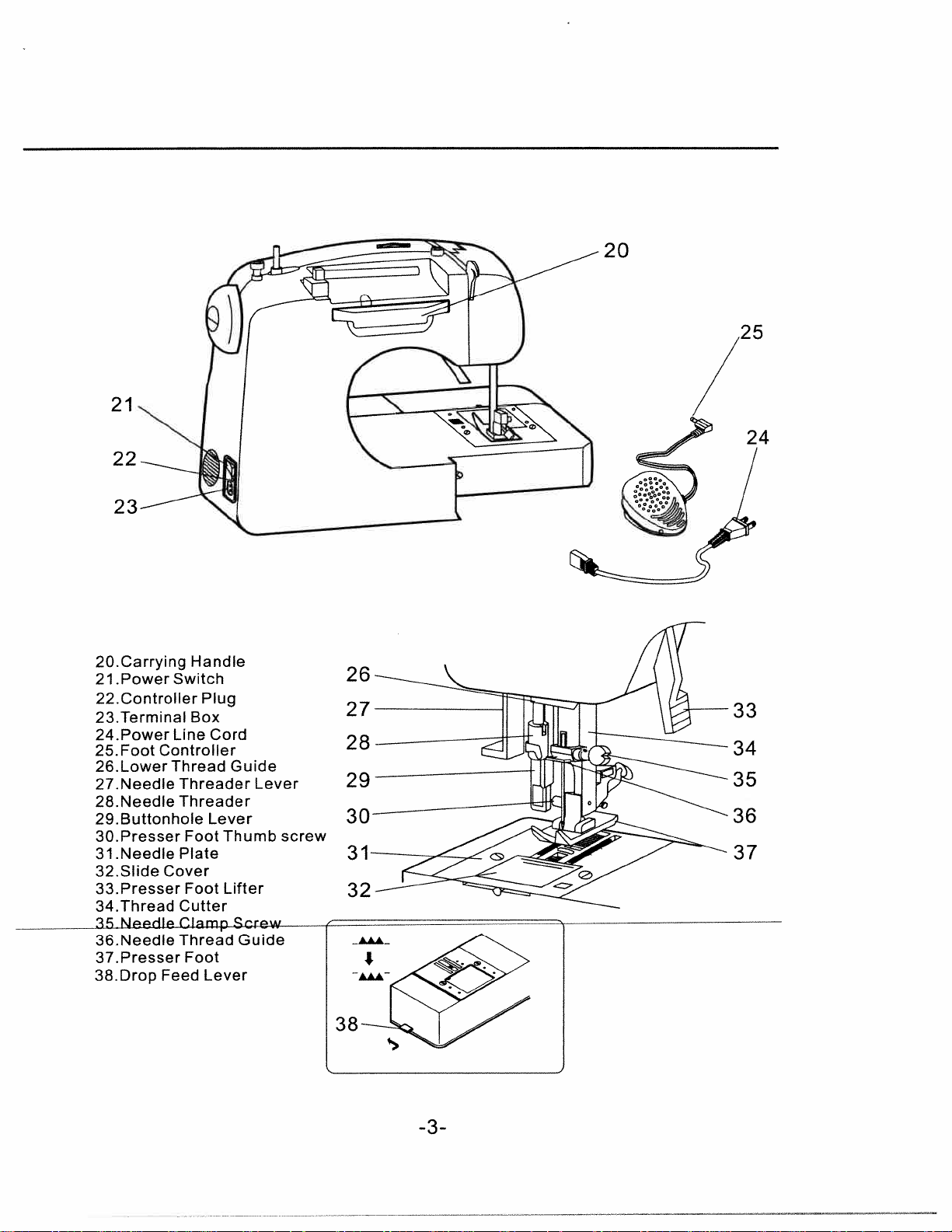

21

20

20.Carrying

.Power

21

22.Controller

23.Terminal

24.Power

25.Foot

26.Lower

27.Needle

28.Needle

29.Buttonhole

30.Presser

31

32.Slide

33.Presser

34.Thread

5

36.Needle

37Presser

38.Drop

Controfler

.Needle

Cover

NeedI

Feed

Handle

Switch

Plug

Box

Line

Thread

Threader

Threader

Foot

Plate

Foot

Cutter

Clamp

Thread

Foot

Lever

Cord

Guide

Lever

Thumb

Lifter

Lever

Screw

Guide

33

34

35

36

screw

37

38

-3-

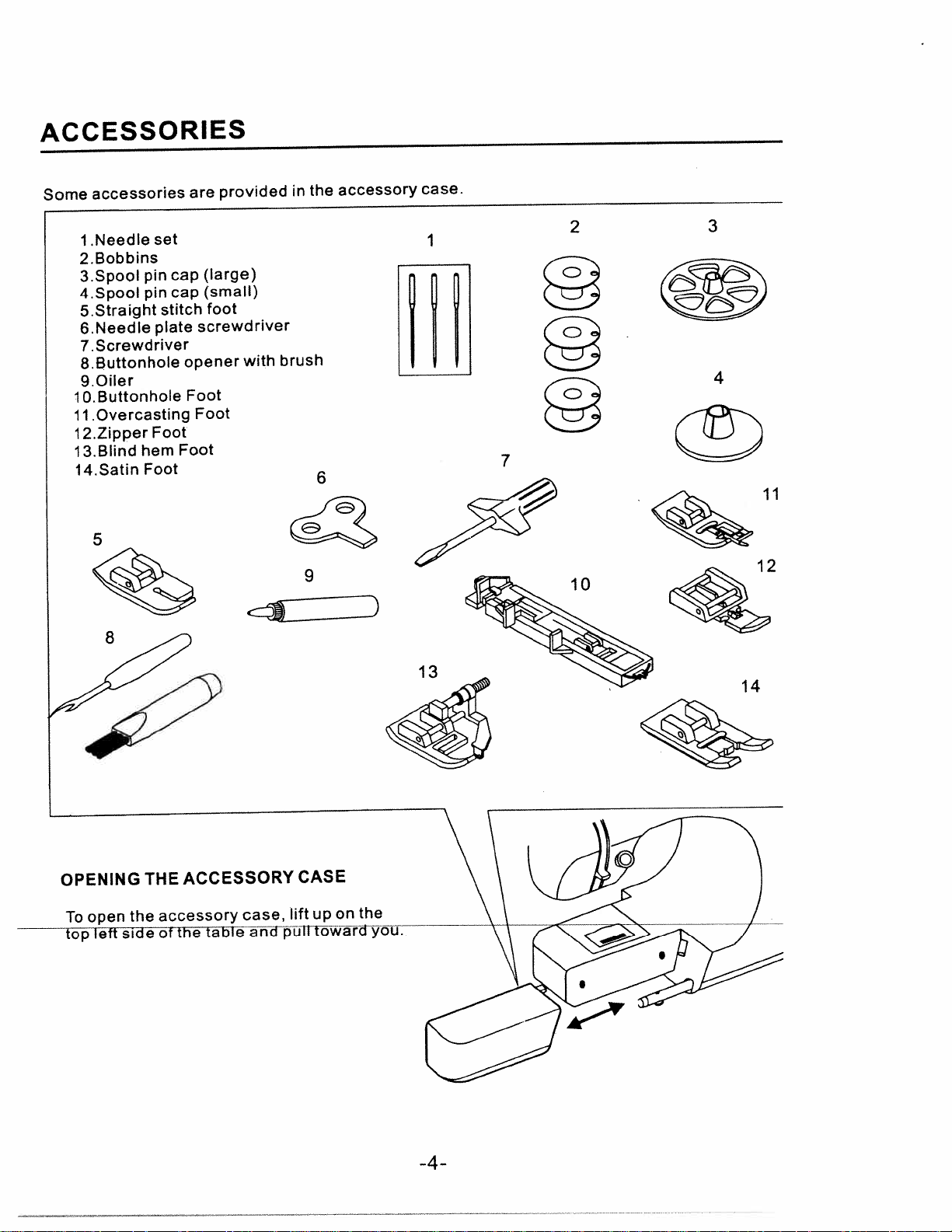

ACCESSORIES

Some

I

11

1

13.Blind

14.Satin

accessories

.Needle

I

2.Bobbins

3.Spool

4.Spool

5.Straight

6.Needle

Screwdriver

7.

8.6uttonhole

9.Oiler

O.Buttonhole

.Overcasting

2.Zipper

pin

pin

hem

Foot

set

cap

cap

stitch

plate

Foot

provided

are

(large)

(small)

foot

screwdriver

opener

Foot

Foot

Foot

the

in

brush

with

6

9

EEZED

accessory

case.

2

1

1H1

7

3

11

12

OPENING

To

ACCESSORY

THE

13

14

CASE

-4-

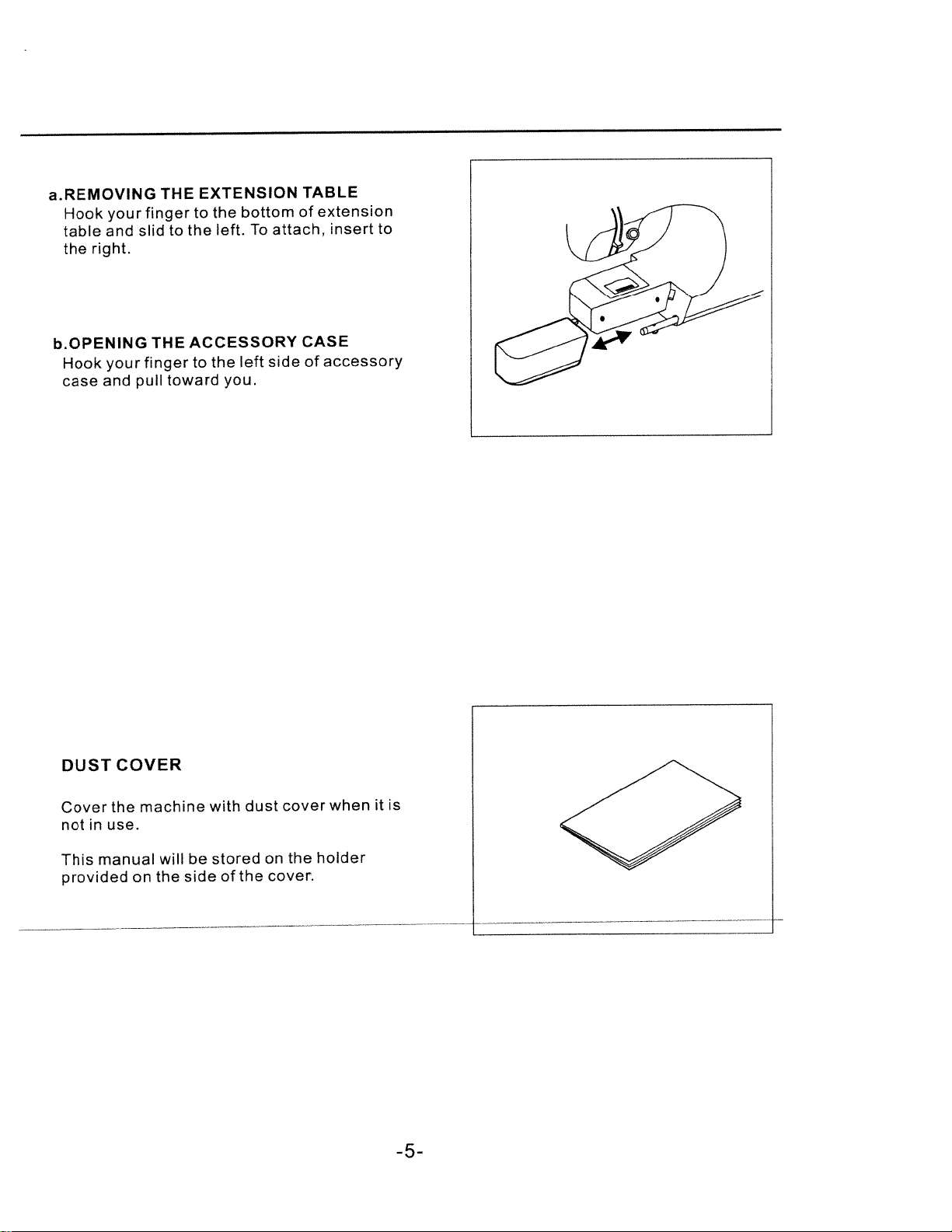

a.REMOVING

your

Hook

and

table

right.

the

finger

slid

THE

to

to

the

EXTENSION

bottom

the

attach,

To

left.

TABLE

extension

of

insert

to

b.OPENING

your

Hook

and

case

DUST

COVER

THE

finger

pull

ACCESSORY

the

to

toward

you.

left

side

CASE

accessory

of

Cover

in

not

manual

This

provided

the

use.

machine

will

the

on

be

side

with

stored

of

the

dust

cover

on

cover.

the

when

holder

is

it

-5-

_______

_______

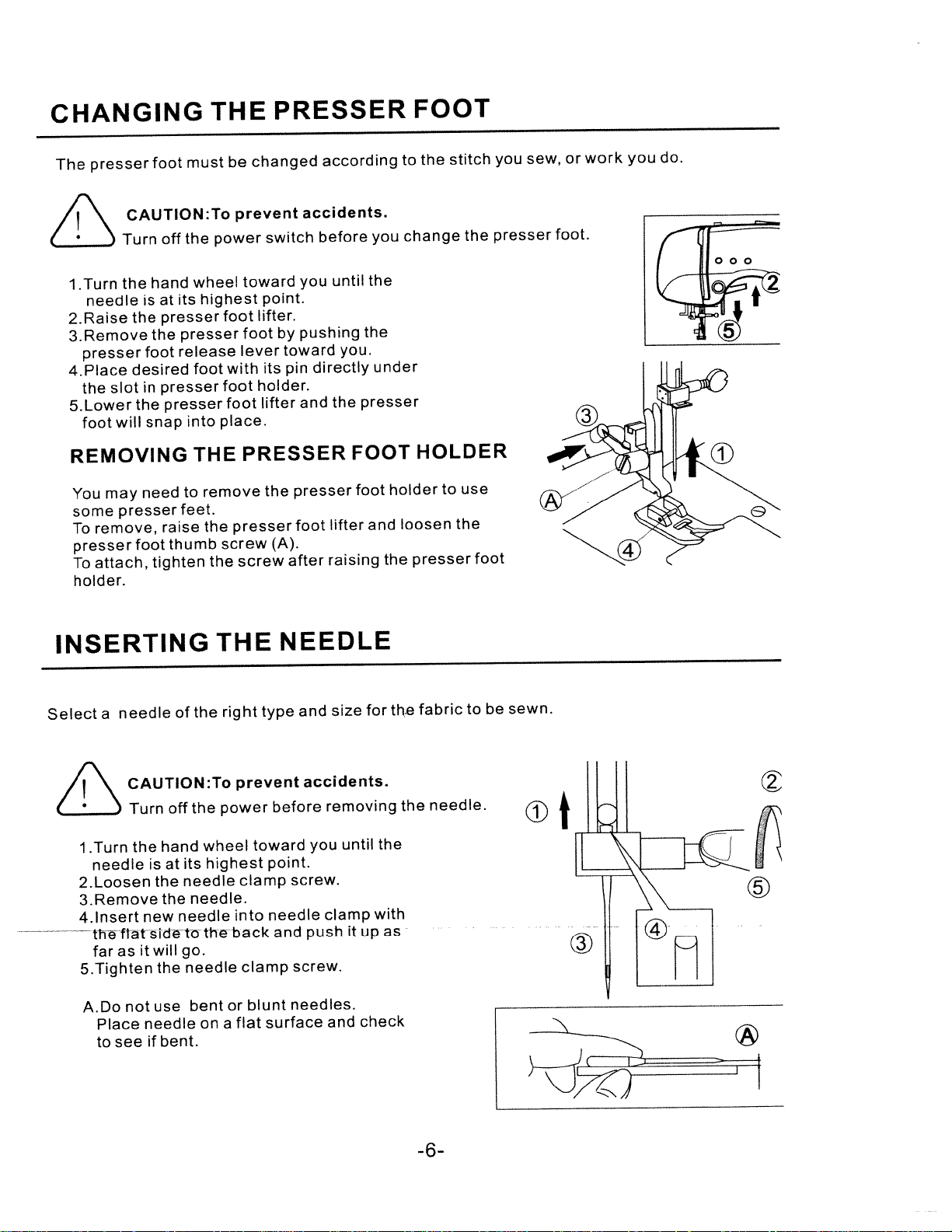

CHANGING

presser

The

.Turn

1

needle

2.Raise

3.Remove

presser

4.Place

the

5.Lower

foot

REMOVING

may

You

some

remove,

To

presser

attach,

To

Id

ho

foot

CAUTION:To

off

Turn

hand

the

at

is

presser

the

the

foot

desired

presser

in

slot

presserfoot

the

will

snap

need

presser

raise

foot

tighten

e

r.

thumb

must

the

wheel

highest

its

presser

release

foot

into

THE

remove

to

feet.

the

THE

be

prevent

power

toward

foot

foot

lever

with

foot

place.

PRESSER

presser

screw

screw

the

PRESSER

accidents.

you

pushing

by

toward

pin

and

presser

foot

after

according

before

directly

changed

switch

point.

lifter.

its

holder.

lifter

the

(A).

until

you.

the

FOOT

foot

lifter

raising

you

the

the

under

presser

holder

and

the

FOOT

stitch

the

to

change

HOLDER

to

loosen

presser

use

the

the

foot

you

presser

sew,

or

foot.

work

you

do.

INSERTING

needle

Select

a

1

.Turn

needle

2.Loosen

3.Remove

4.lnsert

t1ftatstdro

far

as

5.Tighten

A.Do

Place

see

to

CAUTION:To

Turn

hand

the

is

the

the

new

will

it

the

not

use

needle

bent.

if

of

off

at

needle

the

the

wheel

highest

its

needle

needle.

the

go.

needle

bent

onaflat

THE

right

prevent

power

toward

clamp

into

back

clamp

blunt

or

NEEDLE

and

type

accidents.

before

point.

needle

and

surface

removing

you

screw.

clamp

push

screw.

needles.

and

size

until

itupas

for

the

with

check

the

the

fabric

needle.

sewn.

be

to

N

-6-

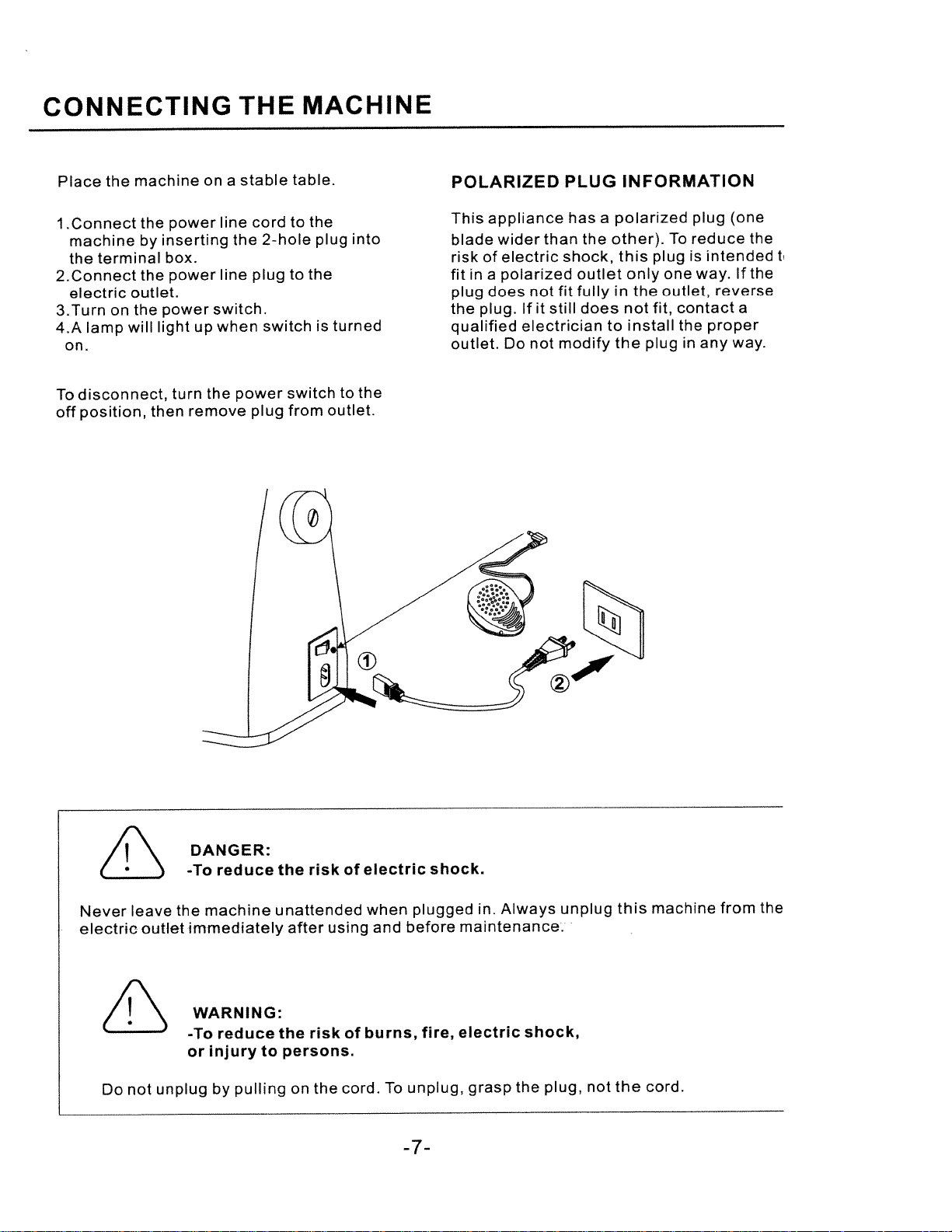

CONNECTING

THE

MACHINE

Place

1

.Connect

machine

terminal

the

2.Connect

electric

3.Turn

lamp

4.A

on.

disconnect,

To

position,

off

the

on

machine

the

by

the

outlet.

the

light

will

then

power

inserting

box.

power

power

up

turn

remove

on

line

line

switch.

when

the

stable

a

the

power

cord

2hole

plug

switch

plug

table.

the

to

the

to

switch

from

plug

is

outlet.

into

turned

to

the

POLARIZED

appliance

This

wider

blade

of

in

plug.

electric

polarized

a

does

Do

If it

electrician

risk

fit

plug

the

qualified

outlet.

not

not

than

fit

still

modify

PLUG

has

the

shock,

outlet

fully

does

INFORMATION

polarized

a

only

the

not

install

plug

fit,

plug

To

one

outlet,

contact

the

other).

this

in

to

the

plug

reduce

is

way.

in

any

(one

intended

If

reverse

a

proper

way.

the

t

the

AN

Never

electric

leave

outlet

AN

not

Do

DANGER:

-To

the

immediately

WARNING:

-To

or

unplug

reduce

machine

reduce

injury

pulling

by

the

unattended

after

the

persons.

to

on

risk

risk

the

of

using

of

cord.

electric

when

and

burns,

To

shock.

plugged

before

fire,

unplug,

-7-

in.

Always

maintenance

electric

grasp

the

shock,

plug,

unplug

not

this

the

machine

cord.

from

the

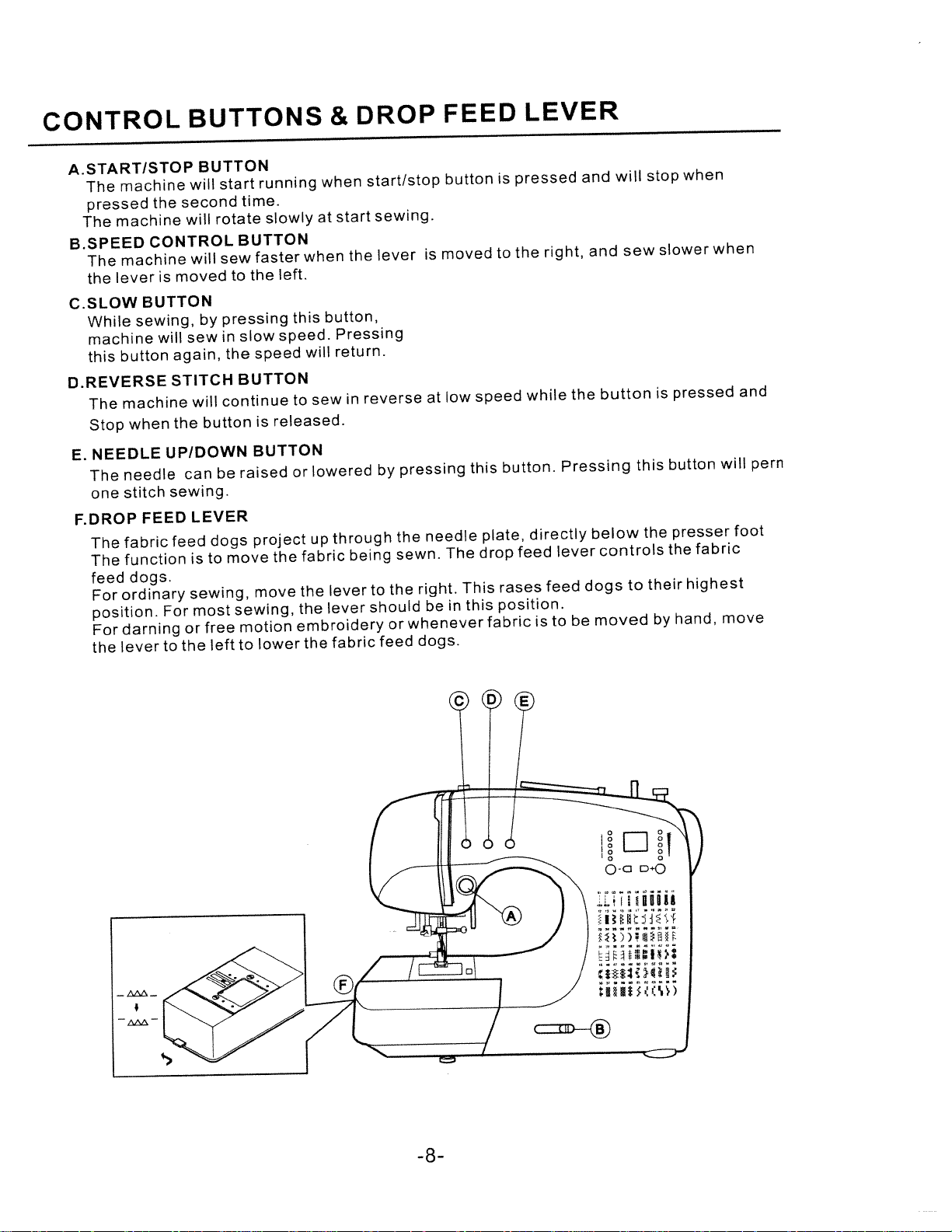

CONTROL

BUTTONS

DROP

&

FEED

LEVER

A.STARTISTOP

machine

The

pressed

The

B.SPEED

The

the

C.SLOW

While

machine

this

D.REVERSE

The

Stop

NEEDLE

E.

The

one

F.DROP

The

The

feed

For

position.

For

the

the

machine

CONTROL

machine

lever

BUTTON

sewing,

button

machine

when

needle

stitch

FEED

fabric

function

dogs.

ordinary

darning

lever

is

will

BUTTON

start

will

second

rotate

will

will

moved

by

sew

again,

STITCH

will

button

the

UP/DOWN

be

can

sewing.

LEVER

dogs

feed

is

to

sewing,

most

For

free

or

left

the

to

time.

BUTTON

faster

sew

the

to

pressing

slow

in

speed

the

BUTTON

continue

is

BUTTON

raised

project

move

move

sewing,

motion

lower

to

running

slowly

left.

this

speed.

to

released.

or

the

when

start

at

the

when

button,

Pressing

return.

will

in

sew

lowered

through

up

the

being

lever

lever

fabric

fabric

the

the

embroidery

start/stop

sewing.

lever

reverse

pressing

by

the

sewn.

the

to

should

or

feed

button

moved

is

low

at

needle

The

right.

in

be

whenever

dogs.

speed

this

This

this

is

to

plate,

drop

rases

position.

fabric

pressed

the

while

button.

directly

feed

right,

feed

is

the

Pressing

lever

to

be

and

and

button

below

controls

dogs

moved

will

sew

to

this

the

stop

slower

is

their

by

when

pressed

button

presser

fabric

the

highest

hand,

when

will

foot

move

and

pern

-8-

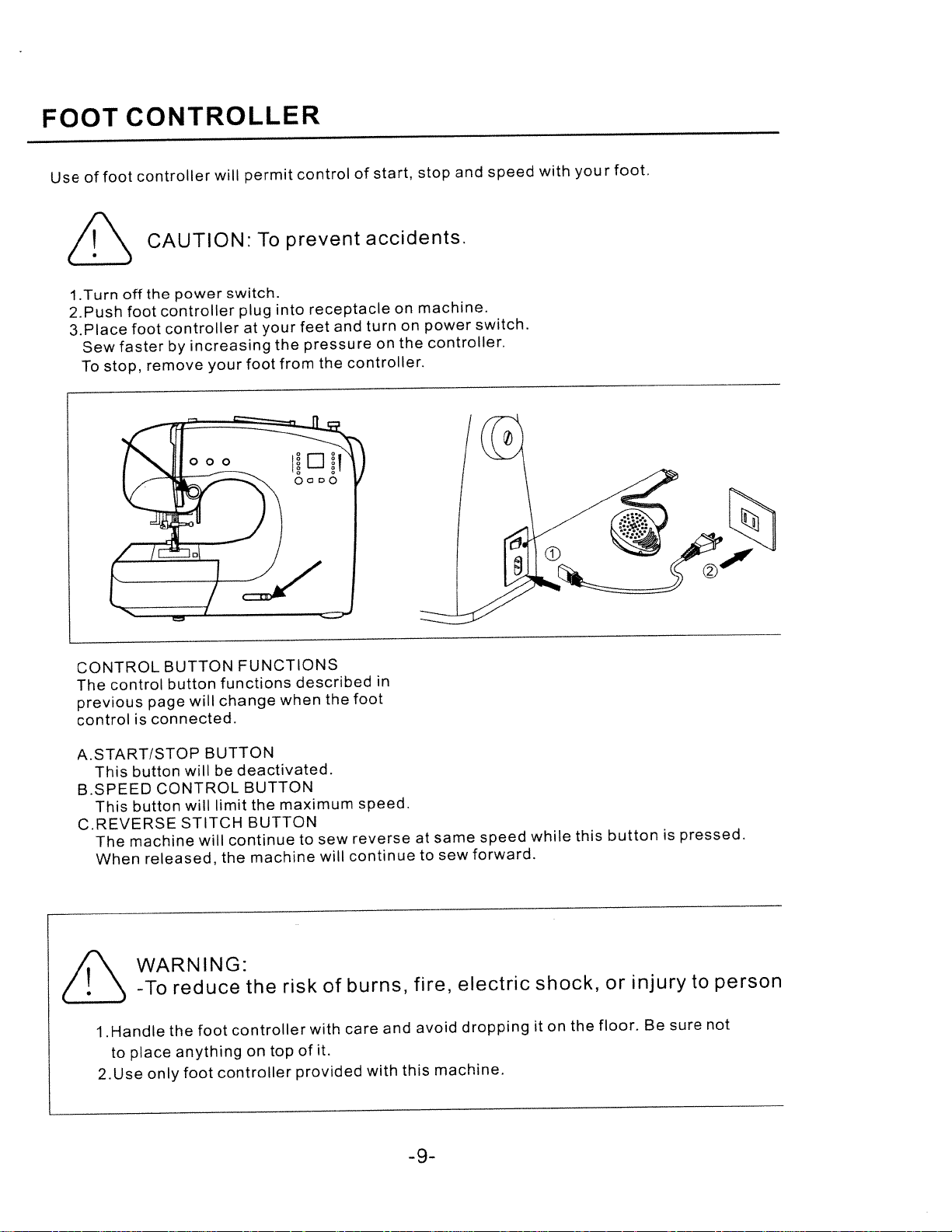

FOOT

of

Use

CONTROLLER

foot

controller

will

permit

control

of

start,

stop

and

speed

with

your

foot.

.Turn

1

2.Push

3,Place

faster

Sew

stop,

To

CONTROL

control

The

previous

control

CAUTION:

power

the

off

controller

foot

controller

foot

by

remove

BUTTON

button

page

connected.

is

switch.

plug

increasing

your

FUNCTIONS

functions

will

change

at

foot

To

your

the

prevent

receptacle

into

feet

pressure

from

described

when

and

the

the

accidents.

on

turn

on

controller.

in

foot

machine.

on

the

power

controller.

switch.

A.START/STOP

button

This

B.SPEED

button

This

C.REVERSE

machine

The

When

/\

WARNING:

-To

Handle

1

place

to

2.Use

will

CONTROL

will

STITCH

released,

reduce

the

anything

foot

only

BUTTON

deactivated.

be

limit

continue

will

the

controller

foot

controller

BUTTON

maximum

the

BUTTON

machine

risk

the

on

top

sew

to

will

of

with

it.

of

provided

speed.

reverse

continue

burns,

care

with

and

fire,

this

-9-

same

at

to

sew

avoid

machine.

speed

forward.

electric

dropping

while

shock,

on

it

the

this

button

or

floor.

is

injury

Be

pressed.

to

sure

person

not

Loading...

Loading...