Page 1

Page 2

INDEX

INDEX

REFERENCE

GUIDE

FEATURES

NEEDLE.ThREADFABRICSTITCHING

SETTING

WINDING

TO

TO

UPPER

SETTING

STITCH

SEWING

PREPARING

REMOVING

ADJUSTING

STRAIGHT

ADJUSTING

THE

THE

REMOVE

THREAD

THREADING

THE

LENGTH

IN

NEEDLE

BOBBIN

OR

REPLACE

THE

BOBBIN

STITCH

CHART

REVERSE

TO

SEW

THE

WORK

THE

TENSIONS

STITCHING

PRESSURE

BOBBIN

CASE

LENGTH

(APPROXIMATE)

AND

FEEDING

FABRIC

SEWING

DARNING

ZIGZAG

NEEDLE

CREATIVE

EMBROIDERY

SAMPLE

TWIN

NEEDLES-UpPER

OR

THIN

AND

LIGHT

MENDING

STITCHING

POSITION

CONTROL

EMBROIDERY

PATTERNS

EMBROIDERY

WEIGHT

PATTERNS

THREADING

SEWING

BUILT

BLIND

IN

DECORATIVE

HEMMING

STITCH

AND

PARTS.

GUIDE

CASE

OF

FABRICS

AND

DESIGNS

Page

2—

15

16

16

17

18

19

20

10

10

10

11

12

13

14

14

14

is’

1

3

4

5

6

7

8

9

BUTTONHOLES

SEWING

SEAM

NARROWHEMMER

LACE

LACE

FRENCH

HEMMINGACROSSASEAM

THE

FOOT

SEWINGINA

CARE

MACHINE

HOWTO

HOW

HOW

ACCESSORIES

TROUBLECHART

SOME

FORYQURMACHINE

ATTACHMENT

EDGESTITCHER

BINDER

FOLDED

TWO-TONE

HAND-CUT

THE

SETOF

HEMMER

ON

BUTTONS

GAUGE

OR

TRIMMED

EDGE

WITH

SEAM

ADJUSTABLE

ZIPPER

AND

MAINTENANCE

OILYQUR

TO

REPLACE

TO

CHANGE

OF

THE

ATTACHMENTS

FOOT

BINDING

BINDING

BIAS

HEMMERS

SET

CLOTH

HEM

INVISIBLE

CORDING

MACHINE

THE

THE

BELT

BINDING

GUIDE

OF

LIGHT

STITCHING

AND

ZIPPER

YOUR

BULB

AVAI

LABLE

Page

21—22

23

24

25

26

26

26

26

27

27

28

29

29

30

31

32—34

36

37

37—38

39

39

39

39

40

4041

Page 3

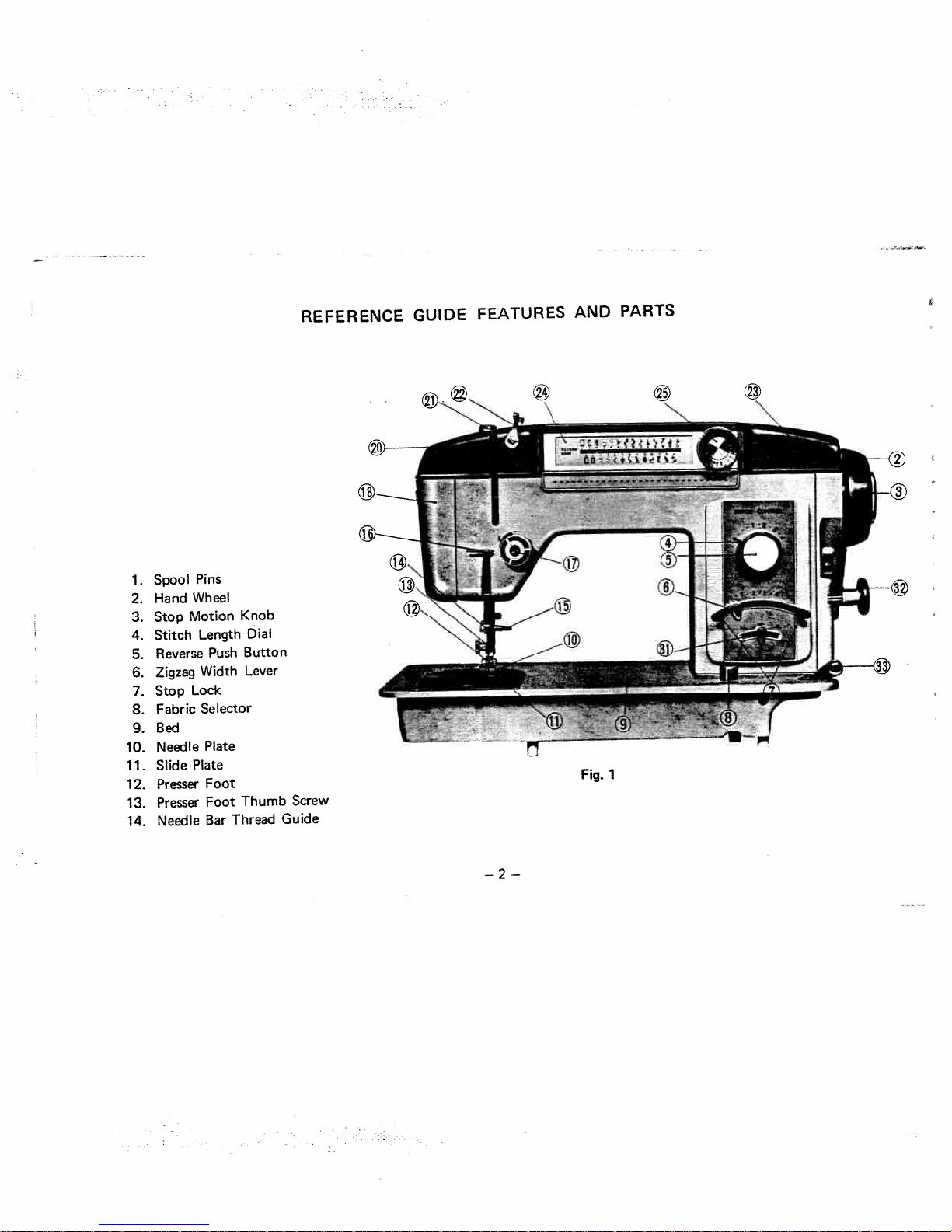

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Spool

Hand

Stop

Stitch

Reverse

Zigzag

Stop

Fabric

Bed

Needle

Slide

Presser

Presser

Needle

Pins

Wheel

Motion

Length

Push

Width

Lock

Selector

Plate

Plate

Foot

Foot

Bar

Knob

Dial

Button

Lever

Thumb

Thread

REFERENCE

Screw

Guide

GUIDE

FEATURES

AND

Fig.

PARTS

1

—2--

Page 4

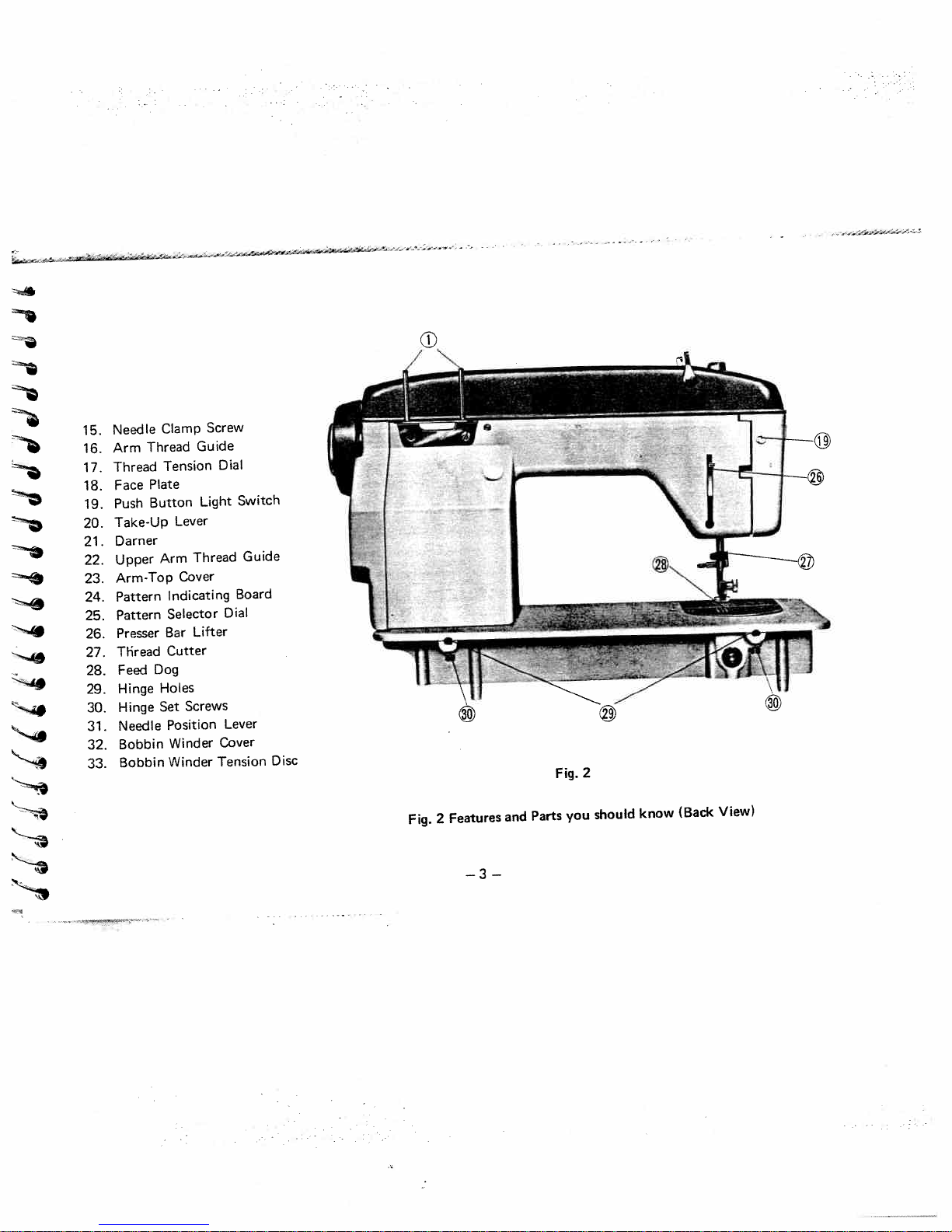

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

Needle

Thread

Arm

Thread

Plate

Face

Button

Push

Take-Up

Darner

Upper

Arm-Top

Pattern

Pattern

Presser

Tliread

Feed

Hinge

Hinge

Needle

Bobbin

Bobbin

Clamp

Tension

Lever

Arm

Cover

Indicating

Selector

Bar

Cutter

Dog

Holes

Screws

Set

Position

Winder

Winder

Screw

Guide

Dial

Light

Thread

Lifter

Cover

Tension

Switch

Guide

Board

Dial

Lever

Disc

N

z

—--=—

—

2

Fig.

View>

(Back

know

should

you

Parts

Fig.

Features

2

and

—3—

Page 5

Fabric

Extremely

tarpaulin,

canvas,

Heavy

fabric,

denim,

Medium

duck,

upholstery

ticking,

leatherette

velveteen,

fabric,

Suiting,

Medium

percale,

chintz,

shantung,

wool,

volie,

Sheer

dimity,

handkerchief

Plastic

sheer

Very

batiste,

ninon,

heavy

sacking,

etc.

heavy

terry,

felt,

brodcloth,

gingham,

taffeta,

lawn,

crepe,

etc.

film,

chiffon,

organdy,

lace,

marquisette,

net,

drapery

etc.

linen,

sheer

etc.

linen,

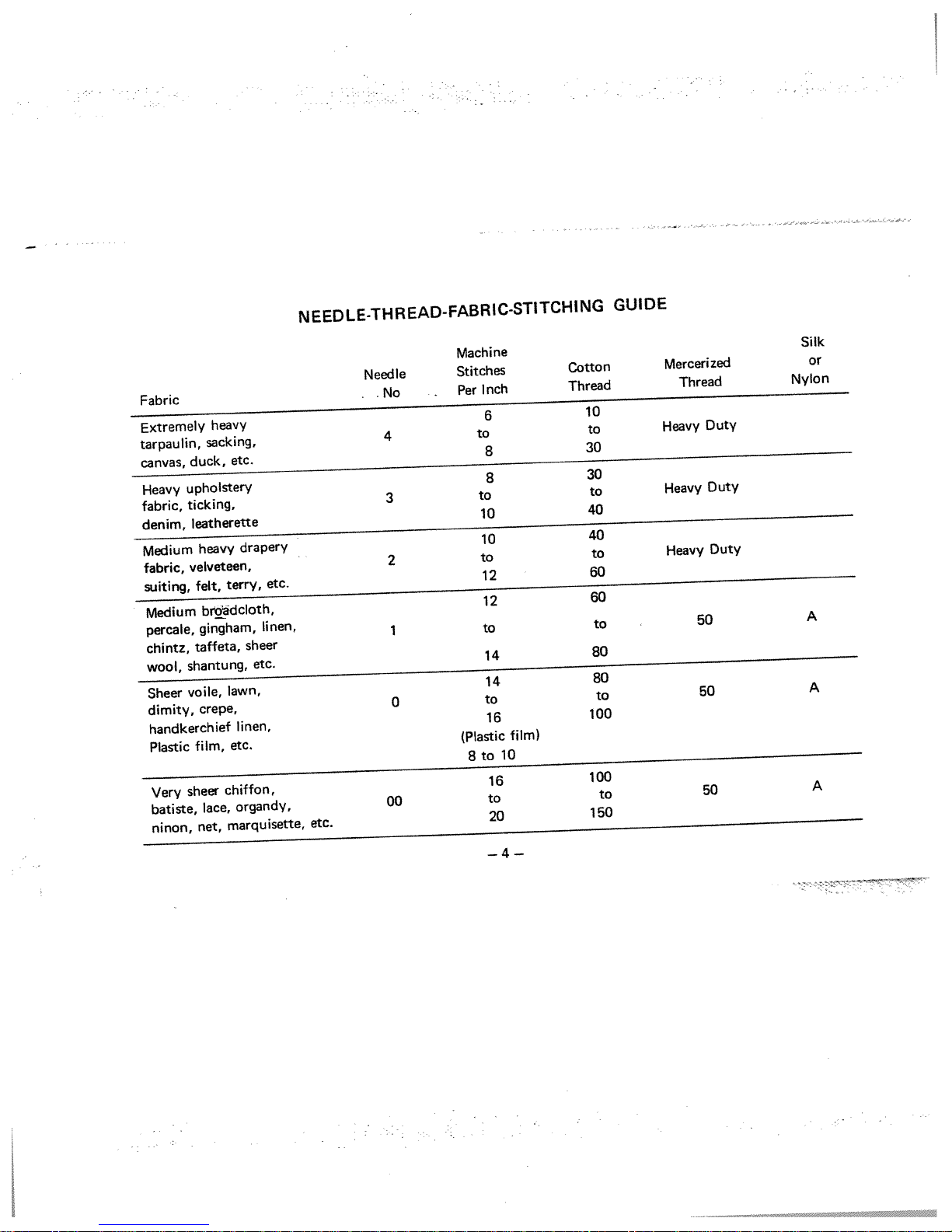

NEEDLE-THREAD-FABRIC-STITCHING

etc.

Needle

No

4

3

2

1

0

00

Machine

Stitches

Inch

Per

6

to

8

8

to

10

10

to

12

12

to

14

14

to

16

(Plastic

to

8

16

to

20

—4—

film)

10

Cotton

Thread

10

to

30

30

to

40

40

60

60

100

100

150

to

to

80

80

to

to

GUIDE

Mercerized

Thread

Duty

Heavy

Duty

Heavy

Duty

Heavy

50

50

50

Silk

or

Nylon

A

A

A

Page 6

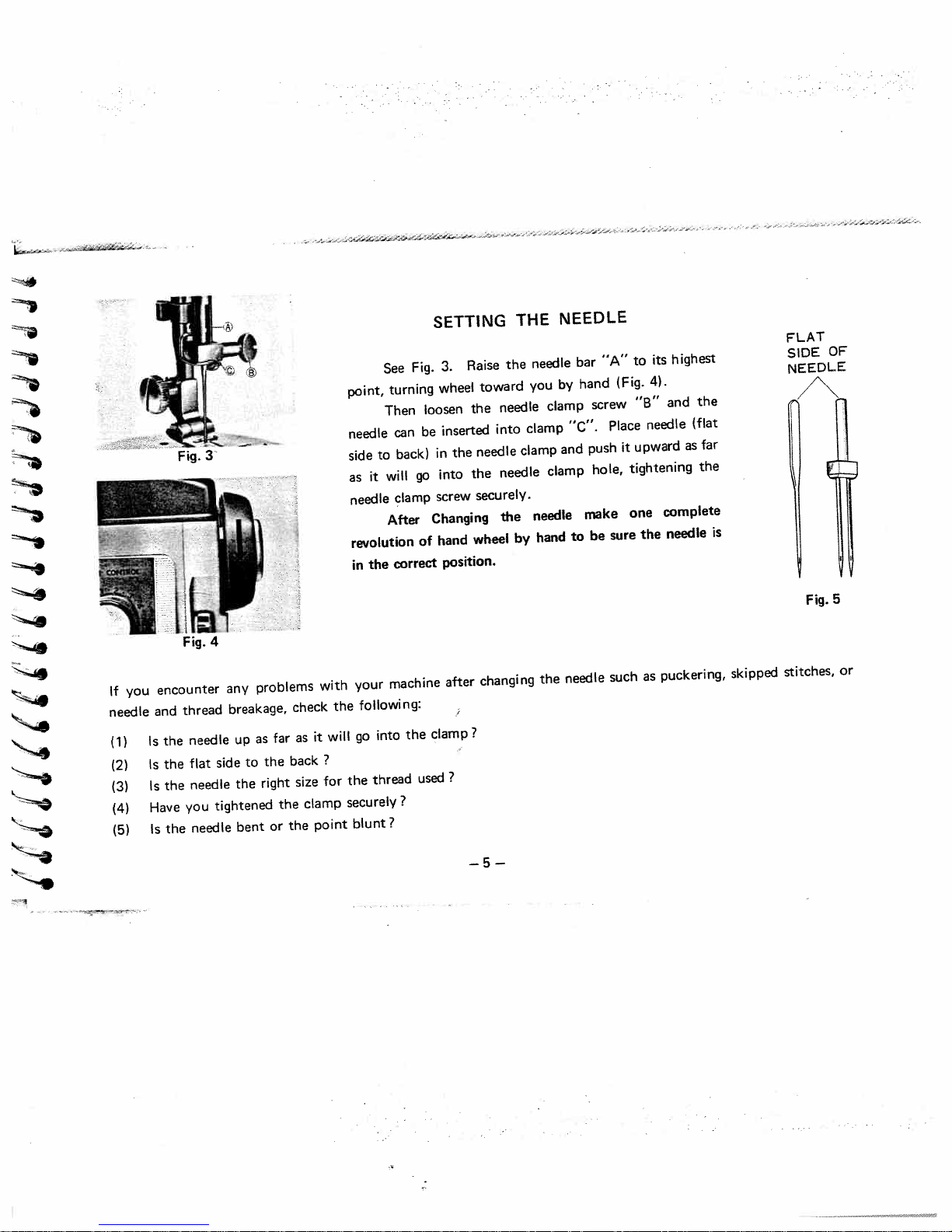

NEEDLE

toward

needle

the

into

needle

needle

the

securely.

the

wheel

the

by

THE

need’e

you

clamp

clamp

needle

clamp

clamp

hand

by

and

bar

hand

“C”.

to

“A”

screw

push

hole,

make

be

(Fig.

Place

it

tightening

one

sure

its

to

4).

“8”

needle

upward

the

highest

the

and

(flat

far

as

the

complete

needle

FLAT

OF

SIDE

NEEDLE

is

Hf

Fig.5

SETTING

Raise

3.

Fig.

See

can

back)

go

clamp

of

correct

wheel

loosen

inserted

be

the

in

into

screw

Changing

hand

position.

turning

point,

Then

needle

to

side

will

it

I

as

needle

After

revolution

the

in

If

you

needle

(1)

(2)

(3)

(4)

(5)

encounter

thread

and

the

Is

Is

the

the

Is

you

Have

the

Is

needle

flat

needle

needle

any

breakage,

up

to

side

the

tightened

bent

problems

check

as

far

as

back

the

size

right

the

the

or

with

it

?

for

clamp

point

the

will

the

securely?

machine

your

following:

into

go

thread

blunt?

the

clamp?

used?

after

changing

—5—

the

needle

such

puckering,

as

skipped

stitches,

or

Page 7

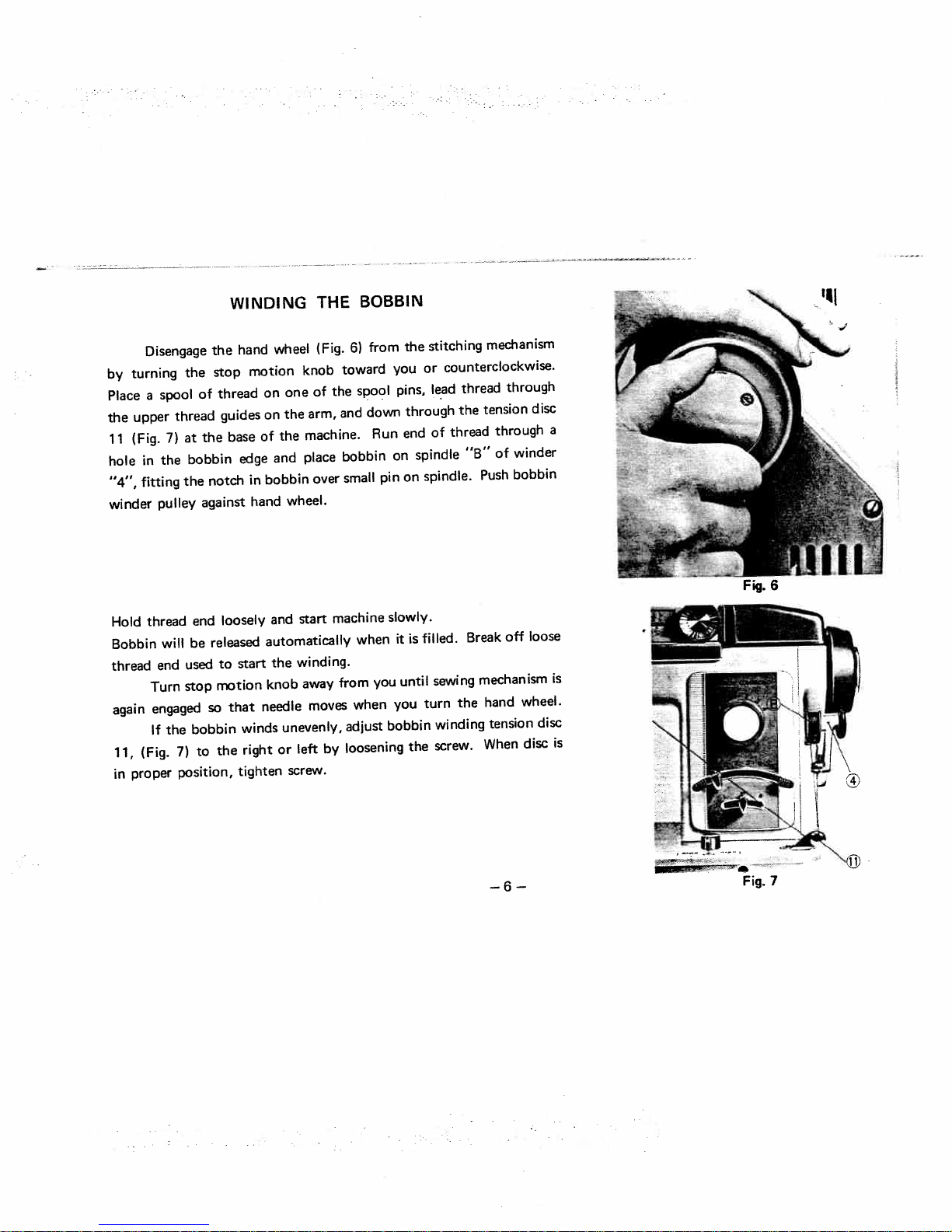

WINDING

THE

BOBBIN

turning

by

Place

the

(Fig.

11

hole

“4”,

winder

Hold

Bobbin

thread

again

11.

proper

in

Disengage

spool

a

upper

7)

the

in

fitting

pulley

thread

will

end

Turn

engaged

the

If

(Fig.

the

of

thread

the

at

bobbin

the

against

end

be

used

stop

bobbin

to

7)

position,

hand

the

stop

thread

guides

base

notch

loosely

released

start

to

motion

that

so

the

tighten

wheel

motion

on

on

the

of

and

edge

bobbin

in

hand

and

automatically

the

knob

needle

winds

or

right

(Fig.

knob

of

one

arm,

the

machine.

place

over

wheel.

start

winding.

away

moves

unevenly,

by

left

screw.

6)

toward

spool

the

down

and

bobbin

small

machine

when

from

when

adjust

loosening

from

Run

pin

you

the

you

pins,

through

end

spindle

on

on

slowly.

it

is

until

you

bobbin

the

stitching

or

lead

of

spindle.

filled.

sewing

turn

winding

screw.

mechanism

counterclockwise.

thread

tension

the

thread

“B”

Push

Break

mechanism

hand

the

tension

When

through

through

winder

of

bobbin

off

wheel.

disc

disc

a

loose

is

disc

is

—6—

Page 8

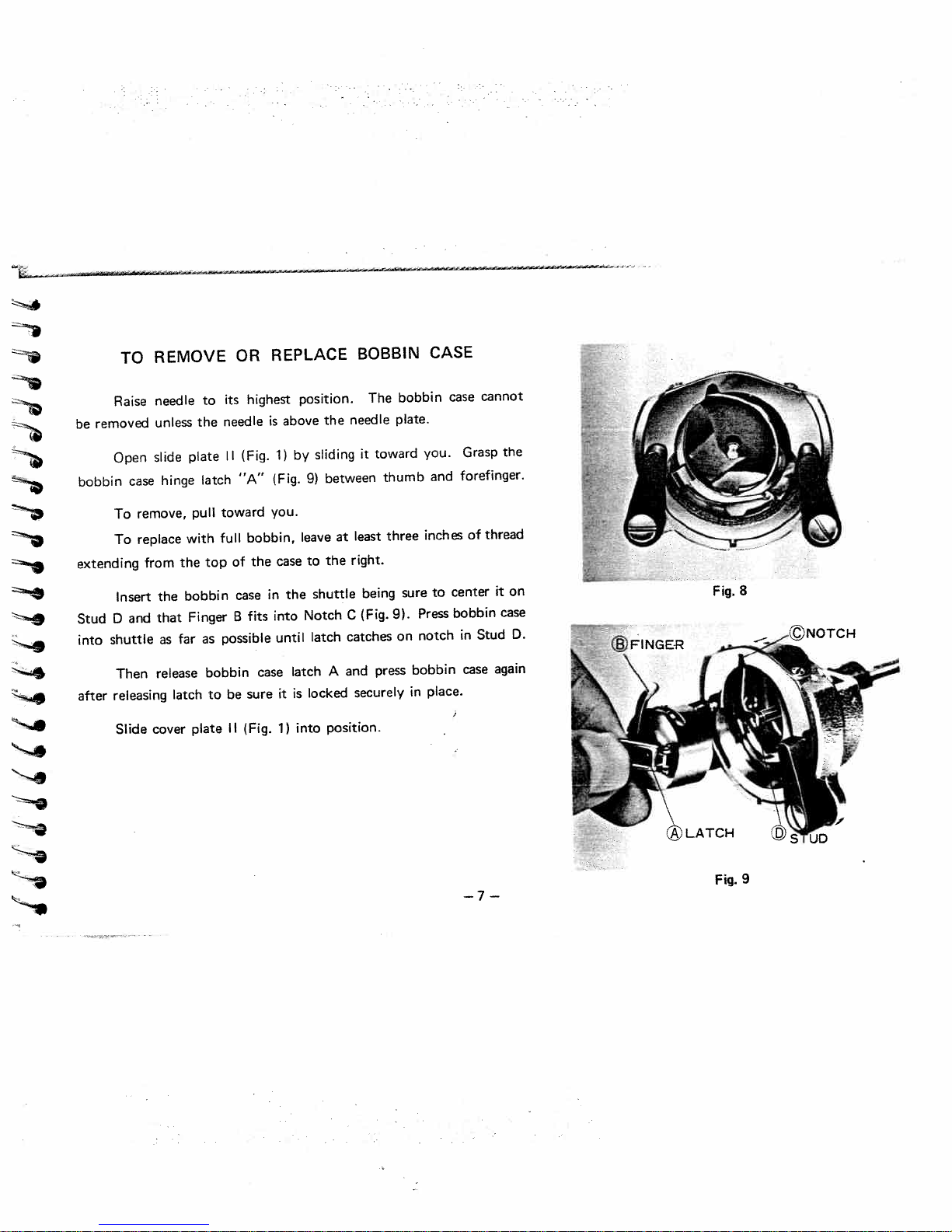

removed

be

bobbin

TO

Raise

Open

case

REMOVE

hinge

to

the

plate

latch

needle

unless

slide

OR

highest

its

needle

II

(Fig.

‘A”

REPLACE

position.

above

by

the

sliding

between

9)

is

1)

(Fig.

BOBBIN

The

needle

it

toward

thumb

bobbin

plate.

CASE

case

you.

and

cannot

the

Grasp

forefinger.

To

To

extending

Insert

D

Stud

shuttle

into

Then

releasing

after

Slide

remove,

replace

from

and

cover

the

the

that

far

as

release

latch

pull

with

top

bobbin

Finger

as

bobbin

to

plate

toward

full

bobbin,

the

of

case

fits

B

possible

sure

be

II

(Fig.

you.

in

case

case

into

until

it

1)

the

latch

is

leave

to

Notch

locked

into

the

shuttle

latch

A

position.

least

at

right.

C

catches

and

securely

being

(Fig.

press

three

sure

9).

on

inches

to

Press

notch

bobbin

place.

in

of

center

bobbin

Stud

in

case

—7—

thread

it

case

again

on

D.

FINGER

®

Fig.

I’—

LATCH

Fiq.9

8

©NOTCH

Page 9

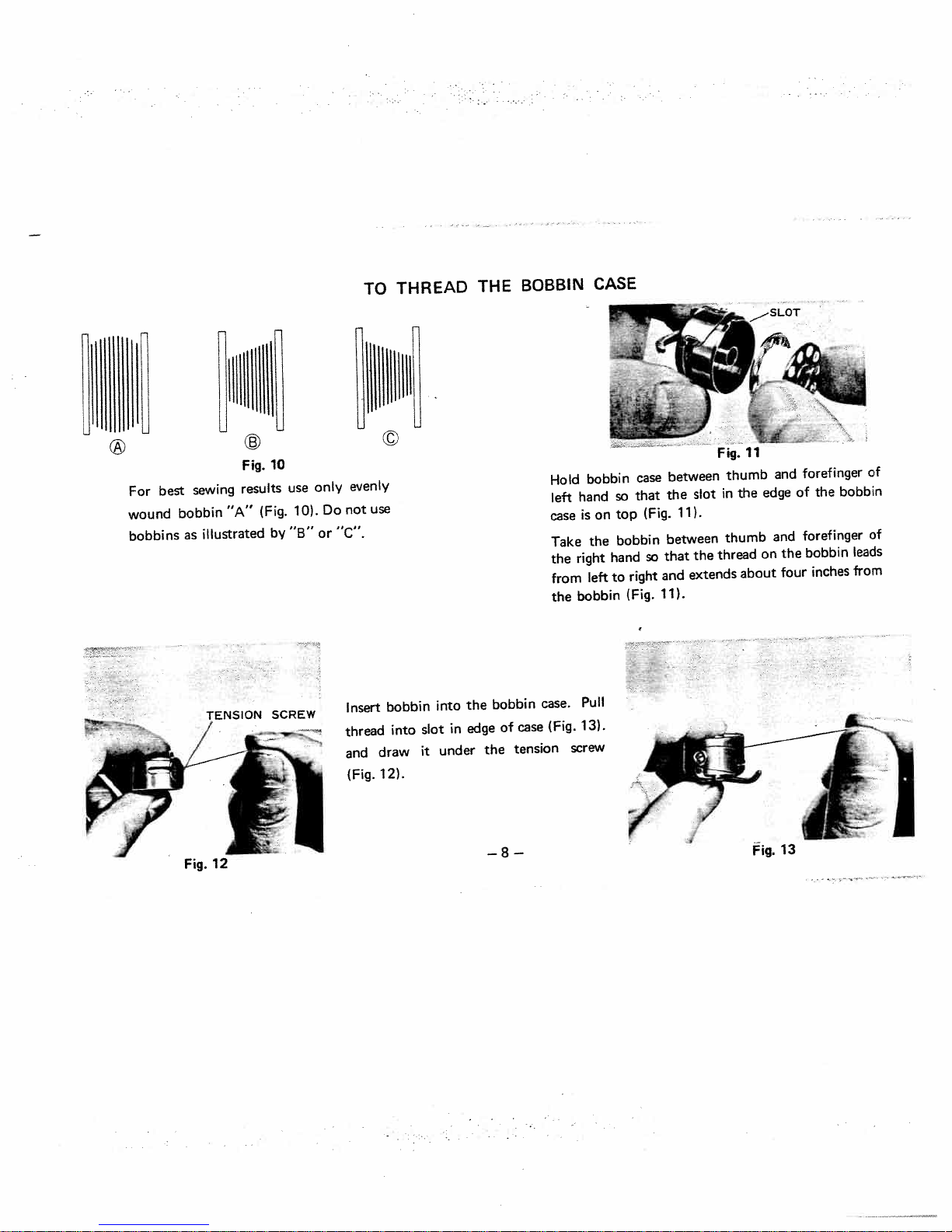

TO

THREAD

THE

BOBBIN

CASE

For

wound

bobbins

best

llllB

10

Fig.

sewing

bobbin

as

results

“A”

illustrated

TENSION

(Fig.

by

SCREW

use

10).

“B”

llllllll

evenly

only

use

not

Do

“C”.

or

the

into

slot

it

into

in

under

edge

Insert

thread

and

(Fig.

bobbin

draw

12).

bobbin

of

the

—8—

case.

case

tension

Hold

left

case

Take

the

from

the

(Fig.

bobbin

hand

is

the

right

left

bobbin

Pull

13).

screw

on

so

top

bobbin

hand

right

to

(Fig.

case

that

(Fig.

so

11).

between

the

11).

between

that

extends

and

slot

the

thumb

the

in

thumb

thread

about

edge

on

Fig.

and

and

the

four

13

forefinger

the

of

forefinger

bobbin

inches

of

bobbin

of

leads

from

Page 10

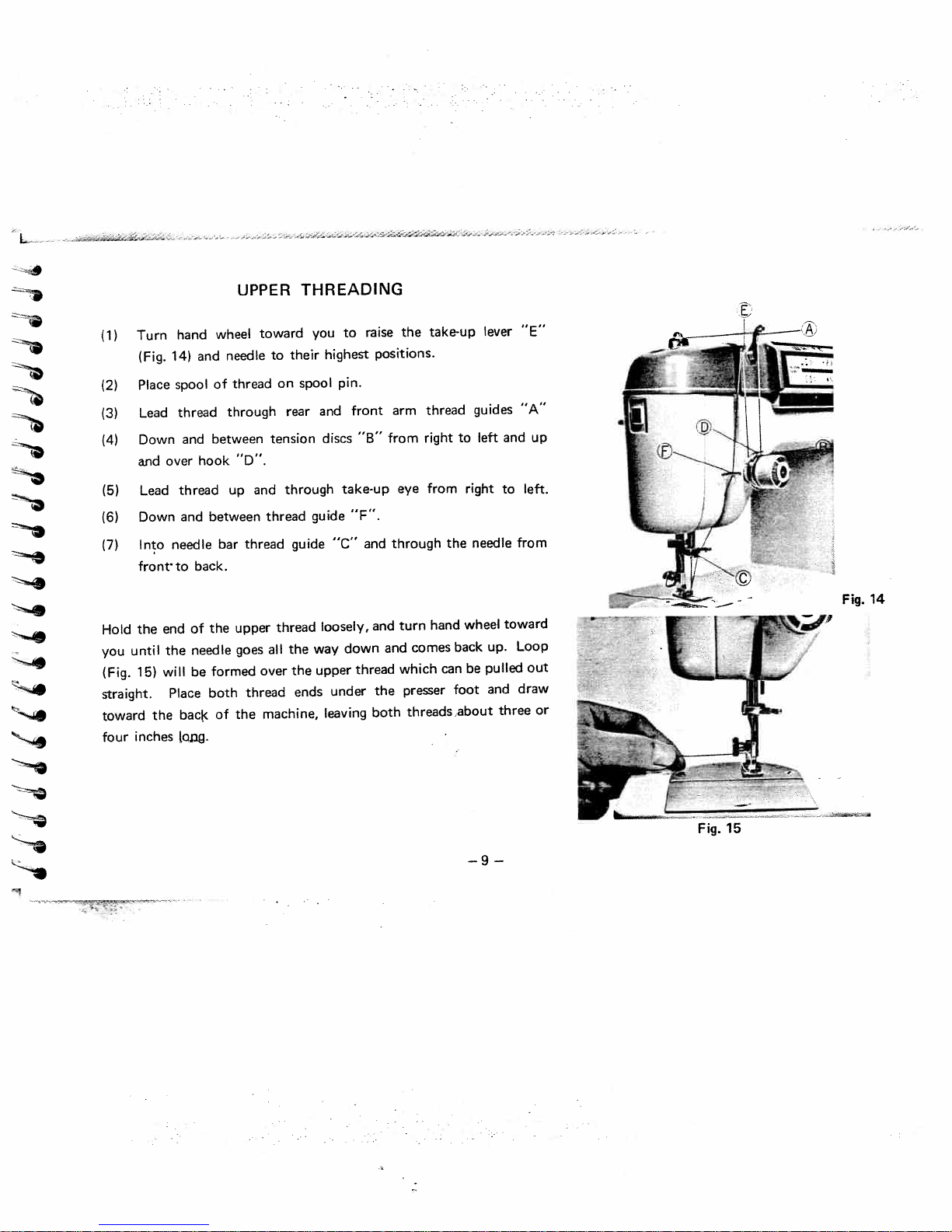

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Hold

until

you

(Fig.

straight.

toward

four

Turn

(Fig.

Place

Lead

Down

and

Lead

Down

Into

front-to

end

the

15)

will

the

inches

hand

14)

spool

thread

and

over

thread

and

needle

the

Place

bacK

to.

wheel

and

of

between

hook

between

back.

the

of

needle

formed

be

both

of

UPPER

needle

thread

through

“D”.

up

bar

upper

goes

the

toward

and

thread

thread

over

thread

machine,

THREADING

you

to

their

on

spool

rear

and

tension

through

guide

guide

thread

way

all

the

the

upper

ends

to

highest

pin.

front

discs

take-up

“F”.

“C”

loosely,

down

under

leaving

raise

positions.

“B”

and

and

thread

the

both

the

arm

from

eye

through

turn

and

which

presser

threads

take-up

thread

right

from

hand

comes

the

can

to

right

wheel

back

be

foot

about

lever

guides

left

needle

up.

pulled

and

and

to

from

toward

Loop

draw

three

“E”

“A”

up

left.

out

14

Fig.

or

—9—

Page 11

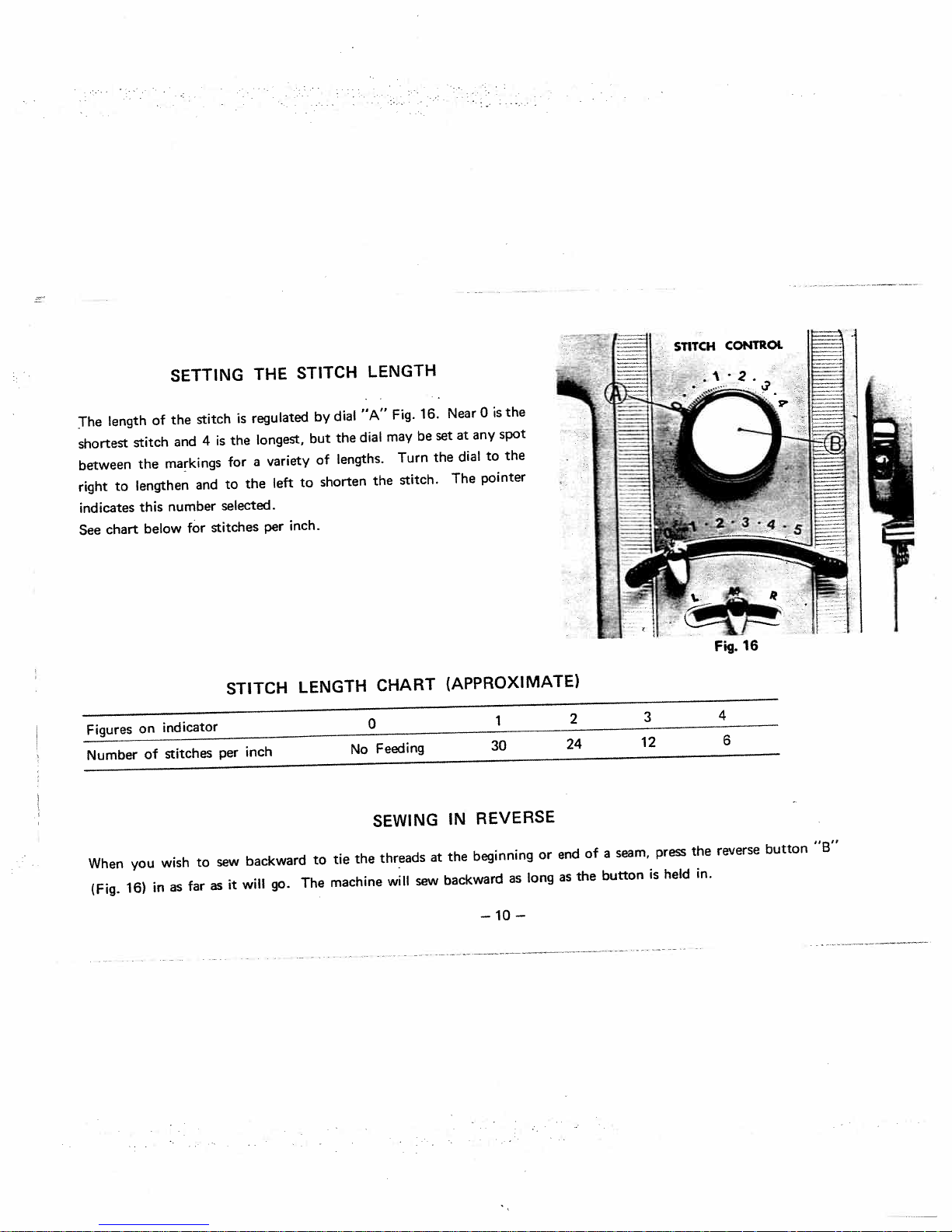

length

The

shortest

between

right

indicates

chart

See

to

of

stitch

markings

the

lengthen

number

this

below

SETTING

stitch

the

is

4

and

to

and

selected.

stitches

for

is

the

for

the

THE

regulated

longest,

variety

a

left

inch.

per

STITCH

dial

by

the

but

lengths.

of

shorten

to

LENGTH

Fig.

‘IA”

may

dial

Turn

stitch.

the

be

16.

set

the

Near

at

dial

The

is

0

any

to

pointer

the

spot

the

Figures

Number

When

(Fig.

you

16>

on

of

indicator

stitches

wish

as

in

far

to

as

STITCH

inch

per

backward

sew

will

it

go.

LENGTH

No

tie

to

machine

The

CHART

0

Feeding

SEWING

threads

the

will

(APPROXIMATE)

1

30

REVERSE

IN

beginning

the

at

backward

sew

—10—

seam,

a

button

12

3

press

is

held

2

24

of

end

or

the

as

long

as

the

in.

4

6

reverse

button

“B”

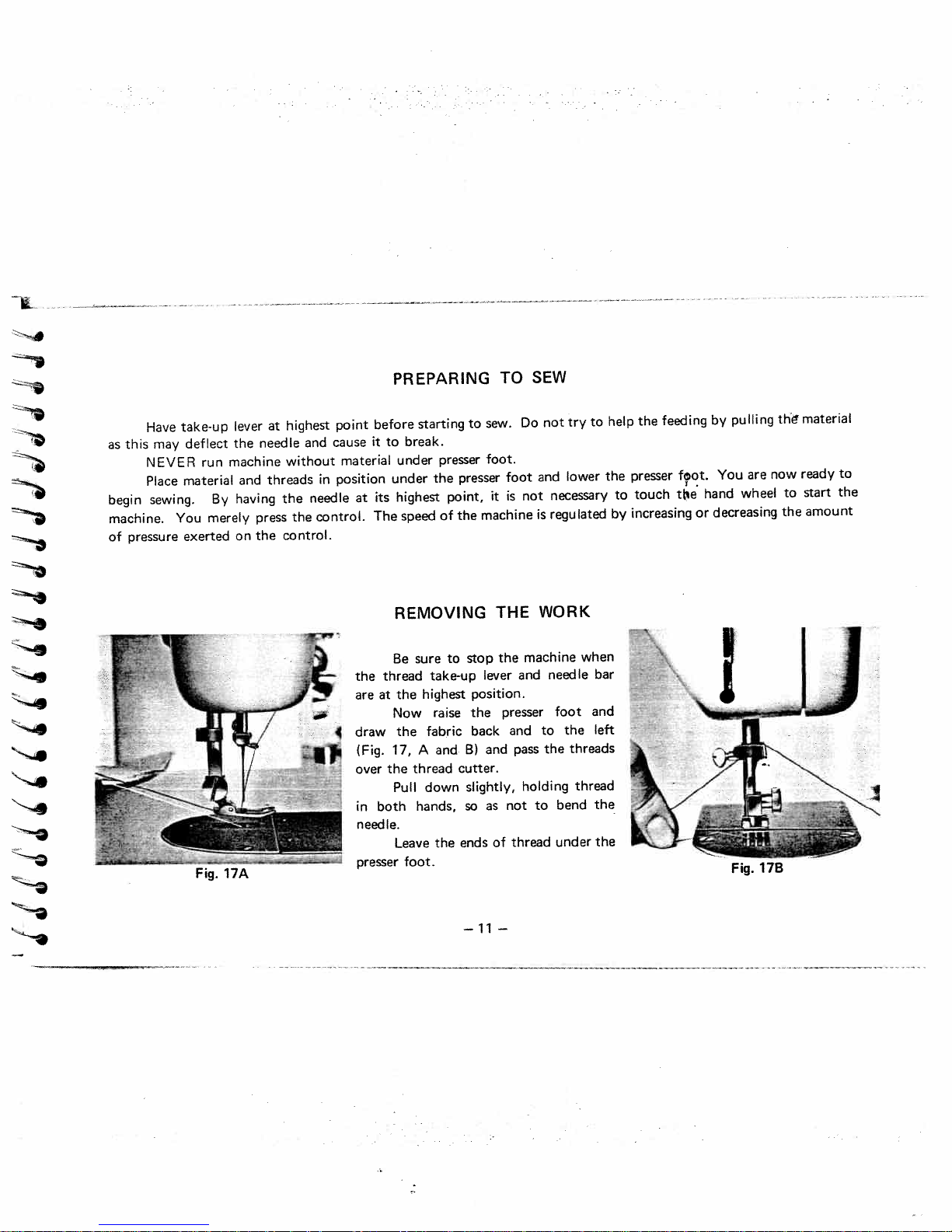

Page 12

-—-

SEW

to

presser

machine

the

sew.

foot.

it

THE

TO

foot

is

Do

and

not

is

try

not

lower

necessary

regulated

WORK

to

help

the

to

by

feeding

the

presser

touch

increasing

fot.

tte

by

You

hand

decreasing

or

pulling

are

wheel

th

now

the

to

material

ready

start

amount

to

the

this

as

begin

machine.

pressure

of

take-up

Have

may

NEVER

Place

sewing.

You

deflect

run

material

By

merely

exerted

lever

needle

the

machine

and

having

press

the

on

highest

at

without

threads

the

the

control.

and

in

needle

control.

point

cause

material

position

at

PREPARING

starting

before

ittobreak.

under

under

its

highest

The

speed

REMOVING

presser

the

point,

of

Be

the

thread

areatthe

Now

the

draw

17,

(Fig.

the

over

Pull

in

both

needle.

Leave

presser

sure

thread

hands,

foot.

take-up

highest

raise

fabric

and

A

down

the

to

cutter.

stop

lever

position.

the

back

and

B)

slightly,

as

so

ends

—11

the

presser

and

not

thread

of

—

machine

and

pass

holding

to

needle

foot

to

the

bend

under

when

the

threads

thread

bar

and

left

the

the

Page 13

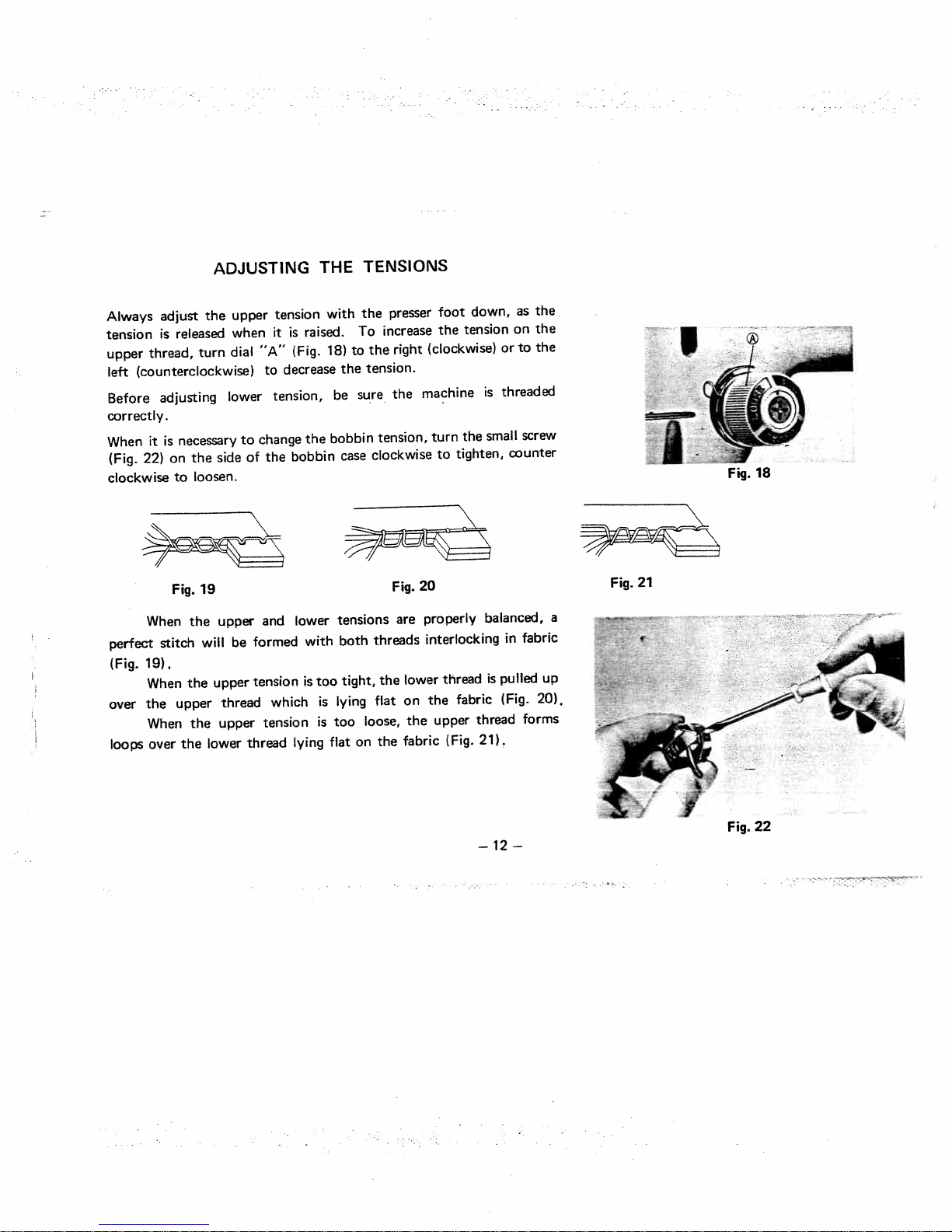

Always

tension

upper

left

Before

correctly.

When

(Fig.

clockwise

adjust

is

thread,

(counterclockwise)

adjusting

is

it

on

22>

Fig.

ADJUSTING

the

released

turn

necessary

the

loosen.

to

19

side

upper

when

dial

lower

to

of

tension

it

‘IA”

decrease

to

tension,

change

the

raised.

is

(Fig.

the

bobbin

THE

with

18)

the

be

bobbin

case

TENSIONS

presser

the

increase

To

right

the

to

tension.

the

sure

tension,

clockwise

Fig.

foot

the

(clockwise)

machine

the

turn

tighten,

to

20

down,

tension

is

small

as

the

the

on

the

to

or

threaded

screw

counter

Fig.

21

perfect

(Fig.

over

loops

When

stitch

19).

When

the

When

over

the

the

upper

the

the

will

upper

lower

upper

be

thread

upper

and

formed

tension

which

tension

thread

lower

with

is

lying

too

is

is

flat

tensions

both

tight,

lying

loose,

too

on

are

threads

the

flat

fabric

the

properly

interlocking

lower

the

on

upper

the

thread

fabric

(Fig.

balanced,

in

pulled

is

(Fig.

thread

21).

—12—

fabric

up

20).

forms

a

22

Fig.

Page 14

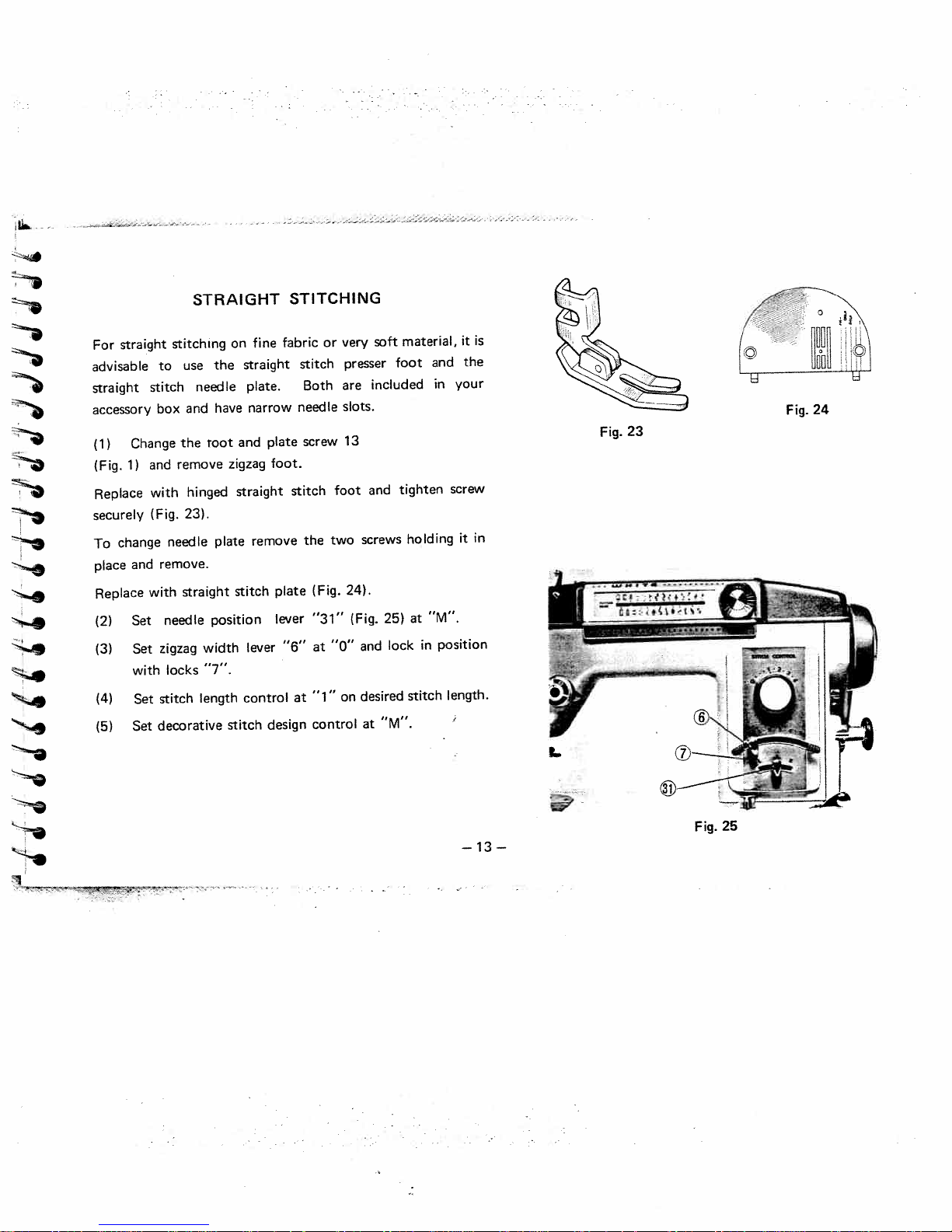

straight

For

advisable

straight

accessory

Change

(1)

(Fig.

1)

Replace

securely

change

To

and

place

Replace

Set

(2)

Set

(3)

with

(4)

Set

Set

(5)

stitching

use

to

stitch

and

box

the

remove

and

hinged

with

(Fig.

23).

needle

remove.

straight

with

needle

zigzag

locks

stitch

decorative

STRAIGHT

fine

on

straight

the

have

toot

plate

position

width

“7”.

length

plate.

narrow

and

zigzag

straight

remove

stitch

lever

control

stitch

needle

STITCHING

or

fabric

stitch

Both

needle

screw

plate

foot.

stitch

the

(Fig.

plate

lever

“31”

at

“6”

“1”

at

control

design

very

are

foot

two

“0”

on

presser

slots.

13

and

screws

24).

(Fig.

and

desired

at

material,

soft

foot

included

tighten

holding

25)

lock

“M”.

at

in

stitch

and

in

screw

“M”.

position

length.

it

the

your

it

is

LF1g.24

23

Fig.

in

a

—13—

Fig.

25

Page 15

(Fig.

way

GENERAL

at

is

27)

(Fig.

down

its

lowest

27)

ADJUSTING

SEWING.

position

Usually

and

PRESSURE

straight

for

feed

the

at

sewing

highest

its

AND

and

level-with

FEEDING

various

embroidery

drop

the

OF

feed

FABRIC

work,

button

the

pressure

marked

bar

UP

cap

ordarning

pressed

all

the

release

all

the

SEWING

When

or

silk

halfway

Release

(Fig.

Turn

In

order

mending

(Fig.

Turn

below

well

lighter

flimsy

down.

all

28)

drop

to

28)

drop

THIN

pressure

material,

way

the

then

and

feed

DARNING

the

move

monograming,

or

completely

knob

feed

needle

the

press

knob

OR

required

is

the

by

fabric

by

to

plate.

LIGHT

pressure

pressing

“B”

cap

(Fig.

“C”

AND

freely

release

pressing

down

WEIGHT

sew

to

bar

the

down

26)

MENDING

any

in

the

down

position

satisfactorily

should

cap

lock

snap

half-way

the

to

the

to

direction

presser

snap

the

on

drops

which

FABRICS

on

about

be

ring

position.

low

darning,

for

cap

bar

lock

the

thin

“A”

spot.

“B”

“A”.

feed

Fig.

26

Page 16

Be

(1)

(2>

(3)

sure

Set

By

right,

maintain

(Fig.

Left

controls

and

zigzag

needle

moving

29>

lock

moved

needle

it

will

determines

the

position

the

produce

selected

maximum.

to

the

ZIGZAG

and

plate

lever

width

zigzag

zigzag

widths

the

desired

STITCHING

“M”

lever

stitches

zigzag

of

can

position.

foot

position

“6”

presser

at

minimum

Locks

are

of

stitches,

width

be

(Fig.

ever

set

in

place.

(Fig.

29)

29)

increasing

stitch,

by

pressing

gradually

employ

while

width.

locks

right

in

slightly

I

the

to

To

“7”

j

lock

Fig.

29

needle

“31”

stitching

stitch

15—

CONTROL

position,

(Fig.

designs

to

and

1)

avoid

move

R—

tearing

desired

to

Position

blind

decorative

designs

fabric

the

position.

hemming

stitch

or

bending

the

M—

POSITION

adjusting

control

on

Position

straight

decorative

—

NEEDLE

when

its

highest

at

position

needle

be

for

on

pressing

by

buttons

sewing

stitch

designs

The

needle.

Select

needle

needle

L—

should

Position

buttonholes

sewing

twin

decorative

-

point

down

slightly

Page 17

stitch,

stitch

action.

needle

The

and

length

The

work.

satin

is

width

CREATIVE

stitch(Fig.

for

basis

the

“0”

near

as

be

may

EMBROIDERY

EMBROIDERY

31),which

embroidery,

most

possible

as

anywhere

set

just

really

is

obtained

is

without

from

stopping

“0”

PATTERNS

a

very

to

by

“5”

short

setting

the

feeding

for

zigzag

the

single

Fig.

Fig.

30

31

be

can

and

‘0”

yourself

machine,

hether

With

made

“5”

and

stitch

fast

the

machine

by

or

then

slow.

or

swinging

any

combination

proceed.

length

and

set

the

for

stitch

After

width

a

short

width

of

a

and

stitch

widths.

while

the

length,

lever

“6”

setting

Try

will

you

manipulation

different

(Fig.

the

become

—16—

30)

of

designs

between

locks

quite

lever

“1”

at

skillful,

“6”.

and

varying

Always

“5”,

run

“2”

your

the

“5”,etc.

and

designs

machine

by

at

Set

the

uniform

a

rhythm

a

speed

of

speed

for

the

Page 18

The

moderate

following

fast

or

patterns

speed.

will

SAMPLE

altered

be

EMBROIDERY

machine

the

by

speed.

PATTERNS

speed

slow

At

the

patterns

will

be

shorter

than

at

®

jiiM

__J\j_

WV’[”NVT

‘

Drop

-

E

fabric

stitch

H

feed,

on

width

®WM

lock

needle

at

4Vv’

WWV

Fig.

stitch

width

to

make

taking

and

“0”

next

lever

move

you

“1”,

slowly

fast.

to

machine

for

repeat.

setting

by

move

lever

“1”.

count

the

Pivot

quickly

then

width,

“4”

“0”

at

then

5,

at

speed.

Return

at

for

to

“21,4

operating

‘I

1

at

“1”

Stitch

stitch

fabric

in

is

complete.

short

a

establish

and

and

snap

and

“2-1/2”

at

to

period.

then

5”

machine

It

5

back

it

“4-1/2”,

“1”

at

“2-1/2”

left

side

Lock

rhythm.

a

move

rather

gradually

quickly

operate

while

“4-1/2”

and

and

of

stitches,

threads

stitches

few

a

Sew

-

A

to

back

lever

necessary,

width

width

width

moderate

“1,2,3”.

leave

flower

of

if

locks

setting,

.

1

to

count.

design

design.

loc.cs

lock

Then

needle

Count,

Set

-

B

between

Set

-

C

from

Set

-

D

at

same

stitches,

“4”

“3”

Continue

stitches

or

until

center

in

—

—

17

take

“5”,

at

petal.

daisy

“4”

or

“3”

Page 19

TWIN

1.

Be

Use

2.

Follow

3.

ceptions:

4.

Set

Zigzag

Straight

5.

the

NEEDLE-

sure

zigzag

only

left

threading

A

-

Place

spool

B-Pass

“16”

C

-

Down

between

discs.

D

-

Now

eye.

E-Pass

right

hand

lever

stitching

same

manner

needle

needle

thread,

pins.

threads

(Fig.

treat

one

zigzag

in

red

UPPER

position.

instructions

1)

around

the

both

thread

width

area

and

followed

as

THREADING

plate

and

matching

under

handle

one

thread

tension

back

discs

threads

through

stop

will

break

decorative

for

presser

Use

for

or

per

discs

and

as

each

at

needle.

stitch

single

foot

needles

single

contrasting

and

through

hole.

with

the

one,

until

needle

start

of

designs

threading.

AND

areinplace.

White

needle

in

arm

one

other

between

you

eye.

red area

can

SEWING

Part

with

color,

thread

thread

reach

(left

be

80999.

these

on

passing

the

the

needle

hand

produced

ex

both

guide

front

side).

Flat

side

of

the

shank

/

in

It

Fig.

34

Fig.35

..

....-..-......,-.

—18—

.-.,,

..-..

Page 20

BUILT

machine

Your

embroidery

the

sew

To

Select

(1)

The

Set

(2)

setting,

lever

For

(3)

feeding

DECORATIVE

IN

sews

designs

decorative

decorative

selected

design

width

zigzag

the

machine

no

“6”

best

the

action.

wide

a

with

stitch

stitch

lever

higher

pattern

variety

either

designs

design

indicated

is

“6”

will

than

designs,

STITCH

of

single

a

set

you

(Fig.

sew

“2-1/2”

set

beautiful

or

machine

desire

pattern

by

at

1)

straight

a

or

stitch

DESIGNS

and

twin

as

by

for

“5”

stitch

will

you

length

practical

needle.

foi

lows:

turning

indicator

designs

regardless

break

dial

pattern

“A”.

with

the

“4”

selector

the

of

needles.

(Fig.

greatest

pattern

the

as

1)

dial

close

“25”

width

to

(Fig.

single

for

selected.

“0”

36)

as

Fig.

36

to

needle

For

possible

either

twin

without

the

sewing.

needle

or

right

the

At

sewing

stopping

STITC

left.

“0”

set

the

Design

replacing

number

worn

“3”,

blanket

the

multiple

bindings

zigzag

and

/

stitch,

hundreds

\

v

Fig.

used

uses.

—19—

A

/

37

to

can

of

\

A

/,

v.

be

other

A

/

\

sew

V

stretch

A

\

/

\

to

fabrics,

sewing

elastic

waist

bands

skirts,

Page 21

Blind

stitch

pattern

number

“1”

(1)

(2)

(3)

(4)

Blind

comparable

and

Prepare

Step

Step

Step

Step

Use

Set

Set

Zigzag

smaller

stitch

the

STEP

1.

(Fig.

Turn

2.

Fold

3.

Place

4.

stitch

standard

stitch

pattern

width

the

hems

garment

39)

hem

hem

Make

zigzag

length

indicator

lever

sidewise

provide

hand

to

If

to

back

material

about

control

in

hem

the

every

blind

foot

to

stitch.

a

sewing.

the

with

depth

toward

under

(Fig.

“4”

for

suit

durable

same

STEP

folded

presser

3/4”

hem

38)

(Fig.

blind

material

hem

for

as

2

desired

right

an

of

as

hand

edge

side

foot,

inch

1)

hem

being

finish

and

of

follows

at

about

stitch

sewn

that

hemming.

is

used

baste

garment

with

sew

sewing.

of

“2.1/2”.

design

—

the

is

STEP

make

1/4”

stitch

lower

almost

Fig.

first

from

leaving

—

20

number

the

invisible

39

fold

upper

1/4”

length

—

“1”.

number,

3/8”

edge.

extended.

to

set

STEP

deep.

suit

the

Press

material

in

place.

being

COMPLETED

sewn

and

Fig.

make

38

wise

side

a

Page 22

I

dial.

the

To

the

to

which

thickness

used.

Various

“25”

establish

cutting

obtain

To

the

(B)

width

The

widths

(Fig.

space

button

of

Fig.

the

the

of

42

and

1).

the

for

length

passes,

button.

the

correct

BUTTON

lengths

length

tacks.

bar

the

of

measured

is

(Fig.

buttonhole

LES

HO

be

can

buttonhole

cutting

41)

sides

Set

number

lower

the

of

basting

one

rections

adjustments

1.

Replace

maximum

made

space,

adding

by

is

zigzag

“5”

number

Mark

buttonhole

line

on

below

automatically

required

the

the

governed

width

thick

for

for

beginning

the

or

tailor’s

fabric

scrap

to

are

correct.

presser

visibility

add

opening

width

the

by

lever

material

thin

fabric

on

chalk.

following

sure

be

foot

by

control

with

and

turning

inch

1/8

through

and

(A)

material

on

and

material.

end

and

with

Make

di

machine

special

allows

a

a

closely

purpose

spaced

Fig.

buttonhole

stitches

Fig.

to

40

41

foot.

feed

-Th

This

provides

evenly

(Fig.

40).

“L”

as

at

control

close

at

“A”.

to

position

needle

2.

Set

stitch

zigzag

3.

Set

the

4.

Stitch

Set

5.

widest

length

pattern

buttonhole)

selector

control

width

control

dial

position.

suit

to

as

0

material

possible

being

without

sewn

stopping

—21

for

buttonhole

of

width

or

feeding

the

—

action.

desired.

(Number

“5”

Page 23

Lower

6.

start

the

tack

bar

With

7.

position

buttonhole—forward

With

8.

“C”

With

9.

“D”

Reverse

Return

10.

stitches

4

11.

Cut

to

cut

Although

size

tarlaton

mercerized

50

If

you

on

You

procedure

needle

—“4”

the

and

the

position

the

position

stitching.

zigzag

buttonhole

the

the

plan

paper

can

noted

carefully

of

the

or

needle

sew

needle

and

needle

and

width

prevent

to

stitching.

buttonholes

are

to

under

make

above.

buttonhole.

stitches.

“5”

of

out

the

entire

stiching.

of

Out

the

sew

of

out

sew

control

ravelling.

opening

recommended

buttonholes

make

fabric

buttonholes

the

the

the

into

the

bar

can

which

length

cloth

cloth

right

to

with

by

the

Lower

pattern

tack

the

be

for

sewing

set

set

made

can

mark

of

—

hand

“0”

seam

best

on

be

on

presser

selector

the

pattern

4

or

pattern

side

position

ripper

with

results.

sheer

torn

the

the

left

selector

stitches.

5

selector

or

away

right

foot

of

most

soft

fabric

dial

hand

the

and

being

hand

indicating

and

at

side

dial

dial

buttonhole.

take

careful

any

material

after

side

the

sew

“B”

the

the

of

the

at

the

at

“3”

not

threads

place

stitching.

(reverse

or

stitching)

S

T

S

T

S

T

E

p

first

p

prefer

if

you

Fig.

44

by

p

just

S

T

E

p

reversing

the

22—

—

Page 24

SEWING

ON

BUTTONS

1.

2.

3.

4.

5.

6.

7.

8.

hooks

same

slightly

Remove

(Fig.

45).

drop

Turn

needle

Set

zigzag

Set

hand

hole

presser

zigzag

Move

down

Move

place.

enters

Correct

When

medium

at

needle

lock

To

at

width

may

you

two

the

toothpick

the

fasten.

Apply

and

snaps,

procedure

and

hinged

foot

exactly

left-hand

Turn

both

feed

position

stitch

comes

(Fig.

stitch

over

the

holes

presser

knob

width

directly

46).

width

zigzag

hand

in

lever

the

button

widthifnecessary.

needle

in

the

the

0,

holes,

the

move

speed,

place

above

above

into

goes

making

left

hole.

zigzag

take

and

a

rounded

sew

and

wind

and

method

If

etc.

a

for

fabrictopermit

Down

to

lever

right-hand

stitch

wheel

the

stitch

few

a

button

thread

four

the

two

foot

at

“L”.

under

lever

slowly

without

center

six

and

stitches

toothpick

to

hole

attach

and

position.

Place

0.

at

needle

the

right

the

to

hole

lever

width

by

deflecting

of

each

eight

or

prevent

in

the

fabricinregular

to

the

under

on

sew

button

button.

hole

stitching

(Fig.

the

then

until

in

the

stop

hand

hole

stitches,

ravelling,

same

the

over

button,

buttons

is

to

the

button

49).

button

gently

the

button

to

sure

to

be

needle.

run

stopping

hole.

button,

way.

forming

with

sewn,

be

lift

Now

remaining

sewing

needle

hold

the

set

If

four

follow

presser

two

its

so

lower

comes

(Fig.

lever

needle

the

machine

with

the

you

between

Remove

a

foot

left-

the

47).

the

stitch

wish

shank

holes,

the

foot

holes.

Fig.

45

in

Fig

46

Fig.

47

Fig.48

HIGH

.

.

(

I

LOW

Fig.

23

—

—

49

Page 25

SEAM

GAUGE

OR

CLOTH

GUIDE

top

stitching

threaded

regular

it

securely

zigzag

for

zigzag

position

the

Use

Fasten

hole

Narrow

presser

stitch

lever

seam

along

Gauge

in

Fig.

Hemmer:

foot

place.

in

width

stitched

at

gauge

edge

(Fig.

bed

50

with

lever

hem.

M”.

as

a

fabric

of

50)

of

machine.

NARROW

With

narrow

pattern

Set

0

for

at

Set

stitch

guide

with

needle

hemmer

straight

straight

for

(Fig.

52)

accompanying

Adjust

to

HEMMER

its

at

(Fig.

selector

stitched

length

control

seams

desired

Fig.

highest

53)

dial

screw

width.

being

at

hem

to

and

51

position

sure

manual

at

or

suit

rows

even

(Fig.

replace

to tighten

position,

number”3”

and

51)

needle

of

in

Fig.

52

Fig.

53

—

24

—

Page 26

Foraplain

two

inches

slip

underneath

fabric

bar lifter.

straight

Guide

through

The

or

any

along

forward

Gently

stitched

material slightly

scroll.

narrow

other

dainty

narrow

edge

hemmer.

to

end

pull

of

and

end

hem

fabric.

Bring

fasten

hem-Fig.55for

hem

provides

work.

make

Hold

foldupinto

with

of thread

zigzag

to

left

an

a

1/8

inch

each

the

pointofneedle.

as

you

start

stitched

anditwill

excellent

double

endofthe

scroll

stitching.

hem.)

takeadouble

finish

for

fold

two

of

hemmer,

edges

Lower

(Fig.

for

inch

of

about

fold,

draw

presser

for

54

turn

ruffles

Fig.

F.

54

55

—

25

—

Page 27

in

under

way.

the

To

slot

needle

sew

a

next

and

narrow

to

hem

LACE

hem

needle

into

TRIMMED

attach

and

(Fig.

56)

scroll.

Rick-rack

lace

sew

HEM

one

in

hem

may

stitching,

above

as

be

used

insert

guiding

the

in

lace

lace

same

insert

sew

and

wrong

the

material

of

hemmer

French

LACE

Hold

both

in

Place

scroll

seam.

lace

scroll

in

lace.

side.

material

1/8

EDGE

1/8

as

When

with

inch

allowing

For

WITH

inch

for

the

from

hem

cording

INVISIBLE

raw

from

narrow

plain

stitching

FRENCH

sides

right

hand

right

roll

to

effect,

edge

hem

completed

is

SEAM

facing

edge

over

use

catch

rolled

stitch.

chairs

ing

HEMMING

hemmer

the

edge

material

on

(Fig.

each

of

and

zigzag

both

hem

This

To

hold

to

slightly

right

sew

hem

STITCHING

side

hand

hem

let

57)

hem

the

and

other

piece.

lower

fabric

top

in

wide

stitch

of

edges

sew

and

used

be

can

forth

so

and

ACROSS

SEAM

A

across

gradually.

together

it

when

—

of

roll

pressed

is

top

the

Insert

enough

the

with

for

(Fig.

seam,

a

Press

and

hemming

—

26

fabric

over

to

piece

making

narrow

satin

cover

58).

cut

seam

for

in

to

the

added

over

seam

open.

the

*

folds

Stitch

firmness.

seam

.

at

(Fig.

-

an

across

It

may

59).

angle

—

0

Fig.

so

the

be

57

they

at

seam

necessary

will

the

lead

to

into

extreme

the

pull

Page 28

THE

This

insert

Loosen

or

right

over

cord.

so

foot

Machine

ADJUSTABLE

ZIPPER

AND

attachmentisused

thumb

left

needle

bastes

cording,

screwtoslide

needle.

of

Loosen

is

cord

covered

CORDING.

andtosew

Fold

thumb

centered

in

CORDING

FOOT

to

foottoeither

bias

strip

screw

in

place

make

in

of

needle

(Fig.

and

zippers.

fabric

set

and

hole.

61).

Fig.

61

and

so

center

(Fig.

closing.

is

needle

of

62).

more

To

stitches

L

Loosen

needle

Stitching

Adjust

convenient.

Fig.

62

sew

closer

hole.

should

to

-27-

covered

to

thumb

sew

cord

cord,

SEWING

screw

metal

Guide

closetozipper

be

from

and

either

on

and

of

edge

IN

zipper

right

of

A

slide

to

or

material,

to

reset

base

ZIPPER

foot

so

along

allow

left

adjustable

fabric.

needle

edge

easy

side,

foot

enters

foot

of

opening

whichever

Page 29

CLEANING

stitch

The

efficient

the

remove

To

1.

Turn

(Fig.

in

Remove

2.

Turn

3.

Clean

4.

Apply

5.

SHUTTLE

DRIVER

AND

operation

stitch

the

hand

63).

bobbin

two

the

the

drop

a

forming

wheel

Tilt

shuttle

of

OILING

mechanism

the

of

forming

until

head

case”E”.

shuttle

race,

oil

CARE

machine.

mechanism,

the

back

race

shuttle

with

AND

THE

MAINTENANCE

SHUTTLE

occasionaUybecomes

Cleaning

proceed

reaches

needle

hinges.

its

on

clamps

cover

shuttle

and

tip

SHUTTLE

A

Boo

to

Y

finger

its

“C”

outer

should

as

highest

outward

race

edge

clogged

be

follows:

position.

cover

of

done

and

by

shuttle.

YOUR

OF

with

a

with

The

remove

removing

BOBBIN

MACHINE

threads

loose

brush,

small

mechanism

shuttle

the

all

threads,

SHUTTLE

CASE

interfere

will

This

lint.

and

pointed

or

sharp

a

with

never

position

cover

etc.

COVER

the

“B”

BODY

and

‘SHUTTLE

RACE

covr

shuttle

assume

will

race

lint,

RACE

ASUrrLE

\\

\

with

tool.

illustrated

“A”.

Fig.

63

PIN

Fig.

64

—

28

—

Page 30

ii

a

65

Fig.

Use

gear

Lubricate only

HOW

Face

Open

correct

and

life

lubricant

when

TO

(Fig.

be

size,

HOW

at

removing

accessible

which

plate.

gears

on

machine

REPLACE

unscrew

65)

it

sure

OIL

TO

Avoid

over-oiling,

each

point.

Occasionally

screws

through

moving

To

oil

rarely

only

Oil

indicatedbywhite

seems

bulb

genuine

is

a

at

to

THE

spots

sew

LIGHT

and

remove

and

oil

parts

more

insert

White

YOUR

only

the

oil

holes.

inside

requires

indicated

arrows

slowly

BULB

new

part.

MACHINE

a

drop

top

moving

(Fig.

the

oiling,

in

in

than

one.

NUMBER

is

cover

parts

66)

face

(Fig.

(Fig.

For

needed

by

not

plate,

OPEN

65).

67)

usual.

long

6999

Fig.66

Fig.

4

67

-29-

Page 31

HOW

TO

CHANGE

THE

BELT

proceed

(1)

(2)

(3)

(4)

Ifitshould

follows:

as

Remove

Remove

Remove

small

out

lever

untilitcan

Before moving

will

as

it

ever

screws

rear cover.

motion

stop

screw

fall

off

Fig.

68

become

“A”

“C”.

be

hand

when

necessary

(Fig.

68)

knob “B”

Turn

lifted

off.

wheel,

changing

to

-

centerofhand

in

counter-clockwise

nut

positionoflips

note

the

belt.

(5)

(6)

(7)

(8)

(9)

and

wheel,

and replace

(10)

replace

Slide

“E”

Pull

the

old

(Fig.

hand

chine just

belttoslip

new

Put

wheel

hand

pulley.

Replace

position.

Replace

After

you

nism.

stop

doing

to

If

down

again

motion,

Replace

give

rear

—

on your

belt

wheel

(Fig.68)

holding

by

washer

on

over

belt

69).

wheel

away

far enough

over

wheel.

beltingrooved

then

and

motion

turn

needle

you

0

and

clutch toward

sewing

still

turn

washer

this,

disengage

the

as

remove

washer

the

“0”

nut.

cover.

30

—

the

“D”

motor

to

section

over

in

screw

a

machine,

taking

by

take-up

(Fig.

pulley

from

allow

motor

original

mecha

moves

the

the

half

69)

ma

the

of

“C”.

up

hand

stop

turn

Page 32

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

Plastic

Large

Small

Buttonhole

Package

ACCESSORI

Oiler

Screw

Screw

Needles

of

Twin

Package

Cloth

Thumb

Quilter

Presser

Button

Felt

Bobbins(3)

Buttonhole

Narrow

Needle

of

Guide

Screw

Guide

Foot

Sewing

Washes

Hemmer

Plate

(sealed

Driver

Driver

Cutter

for

(2)

Foot

for

ES

Needles

Straight

Foot

(for

Straight

and

Straight)

(5

spool

filled)

Sewing

pins)

Sewing

L4j

1

±L©

Fiq.71

—31

—

Page 33

TROUBLE

CHART

Trouble

If

Machine

Binds

Probable

Thread

race

way

in

case.

COVER

and

from

race

Correction

highest

NOTCH

remove

rim

cover.

case

all

of

by

position,

HOOK

race cover.

parts,

shuttle.

Snap

latch

tilt

CLAMPS

including

clamps

and

replace,

head

RACE

race.

into

back

place.

fitting

on

tongue

hinges

into

Cause

lint

in

or

.

-

1—With

remove

and

LATCH

2—Turn

3—Remove

4—Clean

5—Run

a

6—Replace

7—Grasp

notch

take-up

BOBBIN

CASE

clamps

hook.

thread

drop

shuttle,

threaded

of

race

lever

bobbin

BOBBIN

RACE

outward

and

of

oil

bobbin

cover.

ccc

lint

along

then

—32—

Page 34

Trouble

‘r

Bent

Probable

needle

Cause

Discard

and

Correction

replace.

4!

Skipping

stitches

Irregular

stitches

Uneven

stitches

Needle

clamp

Too

being

Upper

Improper

Bobbin

Pulling

Not

thread

Poor

Needle

used

placed

fine

used

thread

not

or

enough

quality

too

incorrectly

a

needle

tension

threading

wound

holding

tension

thread

fine

for

for

too

evenly

material

on

thread

in

thread

loose

upper

being

—

I

Avoid

Try

See

33

instruction

See

needle

See

Tighten

See

threading

Rewind

Increase

different

needle

—

upper

bobbin.

pulling

tension.

and

page

thread

and

tension.

instruction,

or

thread.

thread

No.

holding

chart,

material,

chart,

6.

page

page

page

No.

No.

just

No.

5.

and

9.

8

guide

it.

5.

Page 35

Trouble

Improperly

Probable

threaded

Cause

Refer

rethread

threading

to

machine.

Correction

instructions

see

page

No.

and

8

Upper

breaking

Material

puckering

thread

j

much

Too

Starting

correct

Improper

or

Bent

or

Bent

Tensions

Dull

needle

Stitch

tension

with

position

setting

eye

blunt

too

length

of

tight

too

take

of

needle

needle

tong

-

up

needle

too

in

sharp

in-

—

Loosen

tension

Always

position.

Refer

Try

Discard

new.

See

Change

Reduce

—

34

tension

knob

start

to

needle

new

a

all

tensions

needle.

stitch

on

lower

to

sewing

setting

needle.

blunt

adjustment

length.

upper

or

thread

number.

with

instructions

bent

page

take

needles

No.

up

by

10.

turning

lever

see

and

in

page

replace

thread

highest

No.

with

6.

Page 36

sewing

Your

this

book.

in

The following

machine comes

illustrate

pages

equipped with

additional

time

the

saving

basic

setofaccessories

attachments

that

described

have

been designed

earlier

available

are

your

specificaIIyfor

dealer

your

number.

formance

—

Ifasewing

cannot

Then

with

machine dealer

machine.

supply

willbeassuredofreceiving

you

your

machine.

WHITE

In

Canada

WHITE

SCARBOROUGH,

They

with

not

these

available

you

is

SEWING

11750

BEREA

CLEVELAND,

CONSOLIDATED

1470

BIRCHMOUNT

items,

mail

MACHINE

OHIO

ONTARIO,

modest

at

ask

him

to

the

genuine

inquiry

your

COMPANY

ROAD

44111

INDUSTRIES,

ROAD

CANADA

cost from

order

part

directly

LTD.

them

designed

to

your

for

dealer.

you

for

by

best

If

part

per

-35-

Page 37

SOME

OF

ATTACHMENTS

THE

AVAiLABLE

Fig.

72

I

FOR

YOUR

MACHINE

7/8

Ruffler

PART

Attachment

76552

Need’e

position

Foot

lever

must

PART

5/8

PART

be

1403

in

the

76552

left

PART

position

PART

Darning

Binder

Hemmers

when

—36—

74159

4990

Spring

using

3/8

these

PART

attachment.

76551

PART

76654

Edgestitcher

1/4

PART

76550

Page 38

ATTACHMENT

FOOT

The

lace

insertions,

The

in

sewing

If

you

or

lace

pieces

(Fig.

instance,

finished

and

the

edgestitcher

slots

together

want

and

of

material

75)

and

if

edge

lace

EDGESTITCHER

is

used

edgings

in

the

to

sew

tucked

the

you

of

in

slot

edgestitcher

various

lace,

strips

that

lower

are

sewing

fabric

“4”

and

will

fabric

place

(Fig.

piping.

pieces

lace

together,

be

the

in

making

serveasguides

of

material.

and

embroidery,

place

on

top

in

in

slot

“4’.’

lace

edging

fabric

in

74).

dainty

the

slot

For

to

slot

In

necessary

foot.

Mount

the

left

The

the

edge

before

1

a

1

to

order

to

(Fig.

73).

binder,

far

as

mounting

as

desired.

tightening

attach

remove

as

possible

slot

the

the

presser

edgestitcher

enables

Just

the

mounting

binder,

and

move

foot

or

tighten

you

the

screw.

edgestitcher

and

replaceitwith

hemmers,

screw.

to

sew

as

attachment

sliding

close

and

to

to

the

the

or

the

Fig.

hemmers,

the

attachment

attachment

far

as

correct

75

away

position

it

from

is

to

a

—37—

Page 39

Be

you

as

Rick-rack

To

place

Slot

See

sure

stitch.

trim

fabric

5

Fig.

to

with

may

76,

in

draw

Hold

can

slot

be

77,

the

be

wide

2

used

78

the

sewn

and

and

lace

fabric

to

piping,

the

a

as

79

and

the

folded

guide

for

material

the

in

edge

place

in

suggestions

under

left

of

fabric

the

edge

stitching

hand

the

of

the

the

material

in

the

French

a

how

on

needle

lace

in

solt’4’and

to

piping

seam.

use

to

in

and

the

the

the

back

right,

same

fold

the

right

edgestitcher.

the

the

of

being

manner.

of

slot”3’

in

edgestitcher

sure

piping

the

There

the

fabric

to

are

so

that

the

left

hundreds

the

overlaps

in

feed

the

slot”3’

other

of

will

lace

for

carry

slightly.

a

uses.

it

backward

narrow

piping

77

Fig.

Fig.

78

Fig.

—

38

—

79

Page 40

This

attachment

corresponding

open

The

point

Cut

a

under

and

slot

the

edge.

Two

bindings

used,

are

two

correct

binding

binder.

scroll.

,/

Cut

size

15/16

diagonally

Draw

Test

widths

mouth

folded

on

binder

Adjust

by

TWO-TONE

can

always

slot.

HAND-CUT

inch

back

stitching

bias

folds

commercially

of

binder

of

FOLDED

binding,

with

sliding

sewn

be

skip

bias

binding

toward

until

to

be

binding,

scroll

BINDING

strong

binder

on

one

BIAS

end,

opens

cut

sure

applies

folded

is

used

in

insert

pin.

right

to

BINDING

fabric

edge

between

size

BINDING

in

fold

almost

to

and

itison

it

to

bias

for

(Fig.

appropriate

stitching

Test

left.

or

(Fig.

alsoinone

widths,

foracouple

half

fold.

binding

the

BINDER

the

binding.

unfolded

82)

82)

(Fig.

Slip

encircles

edge

edge

bias

slot.

be

to

operation.

inserting

83)

of

fold

adjust

See

and

gestions

to

There

reds

of

Draw

sure

inches.

into

open

if

81

use

of

material

strips

through

it

each

center

end

necessary.

Fig.

for

on

binder.

the

hund

are

other

in

cut

is

on

When

in

Cut

of

of

80

sug

how

uses.

one

15/16

operation.

wide.

inch

Slots

on

scroll

are

binder

of

the

for

Fig.

I

80

Fig.

81

83

Fig.

—

39

—

Page 41

THE

SET

HEMMERS

OF

Before

pulled

is

turn

and

under

hemmer.

horizontally

loop

catch

material

Fold

of

fold.

material

in

stitching.

start

attaching

Then,

up.

handwheel

under

and

Slip

fold

back

can

You

Grasp

carry

to

of

any

with

hemmer

upper

suit

into

hemmer.

make

the

of

hemmerinplace,

one

bobbin

for

guide

a

full

toward

thread

two

and

hem

hemmers

turn

thread

inches

up

Draw

1/4”,

toward

back

to

over

forward

with

back.

along

spoon

3/8”,

sure

be

top

hold

you,

both

Bobbin

hemmer.

of

edge,

(Fig.

end

to

HEMMER

5/8”,

bobbin

thread

making

hands

hold

84).

of

or

thread

each

at

Fold

hem

7/8”

thread

loosely

a

and

and

in

loop

slip

will

end

hem

fasten

SET

width,

point

with

depending

of

upon

needle.

which

Fig.

Pull

hemmer

84

on

thereads

you

gentlyasyou

use.

—40

—

Page 42

‘3,,

85

Fig.

RUFFLER

Fig.

86

Fig.

—

87

The

ruffler

Ruffling

This

the

Use

Fig:

highly

ruffler

will

alsobedone

can

versatile

85

produce

making

for

yardsofdelicate

and

attachment

aprons,

sewn

despite

another

to

curtains,

ruffling

wide

its

pleating

Fig.

piece

range

86-A

—41—

precision

or

skirt,

a

of

fabric

of

use,

adding

pleating.

the

at

simple

is

fullness

same

to

to

time.

use.

the

bodice

Fig.

of

87-A

a

dress

and

etc.

Page 43

MEMO

Page 44

PART

SJH

4-70

*

I

OBTAIN

TO

YOUR

CARRYING

WITH

PRODUCrS.

MACNINE

YOUR

WHITE

OR

187€

PERFORMANCE

SURE

OTHER

ARE

SINCE

THE

CASE

MACHINE

BEST

BE

machines

THE

GENUINE

CABINET,

ITEMS

sewinil

FROM

USED

WHITE

Pthited

in

Japan

I.

Loading...

Loading...