Page 1

EXTREME

5000 / & 8000 /

OWNER’S MANUAL

The Coolest Thing In Wine Storage

Page 2

We manufacture, test and certify 100% of our wine cooling units in

the USA. By sourcing the best components and closely controlling our

manufacturing processes, we can assure the highest-quality, lowest

defect manufacturing rates in the industry.

Copyright © 2011. WhisperKOOL. All rights reserved.

This manual, the product design, and the design concepts are copyrighted by WhisperKOOL, with all rights reserved. Your rights

with regard to the hardware and manual are subject to the restrictions and limitations imposed by the copyright laws of the

United States of America. Under copyright laws, this manual may not be copied, reproduced, translated, transmitted, or reduced

to any printed or electronic medium or to any machine-readable form, for any purpose, in whole or in part, without the written

consent of WhisperKOOL.

Every eort has been made to ensure that the information in this manual is accurate. WhisperKOOL is not responsible for printing

or clerical errors.

WhisperKOOL reserves the right to make corrections or improvements to the information provided and to the related hardware

at any time, without notice.

Vinothèque and WhisperKOOL are registered trademarks, and ECE is a trademark of WhisperKOOL. All rights reserved.

Mention of third-party products is for informational purposes only and constitutes neither an endorsement nor a recommendation. WhisperKOOL assumes no liability with regard to the performance or use of these products.

11.01.11

Page 2

EXti 110111

Page 3

TABLE OF CONTENTS

Quick Reference Guide

Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Speed & Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

6

7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving & Inspecting The Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Start Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing the Wine Cellar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Through-the-Wall Installation

Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing the Installation Location . . . . . . . . . . . . . . . . . . . . . . .

Preparing the System for Installation . . . . . . . . . . . . . . . . . . . . . .

Optional Exterior Grille . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ducted Installation

Ducting Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ducting Congurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Duct Plenums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Controller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drain Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

9

10

11

14

15

16

18

20

21

22

24

25

27

Liquid Measuring Thermostat System . . . . . . . . . . . . . . . . . . . . . .

Multi Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Operation: Standard and Remote . . . . . . . . . . . . . . . . . .

Standard Control Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Wire Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Controller Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Wire Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Assistance & Accessories . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Terms and Conditions . . . . . . . . . . . . . . . . . . . . . . . . . .

28

29

30

31

34

35

38

39

40

42

44

Page 1

Page 4

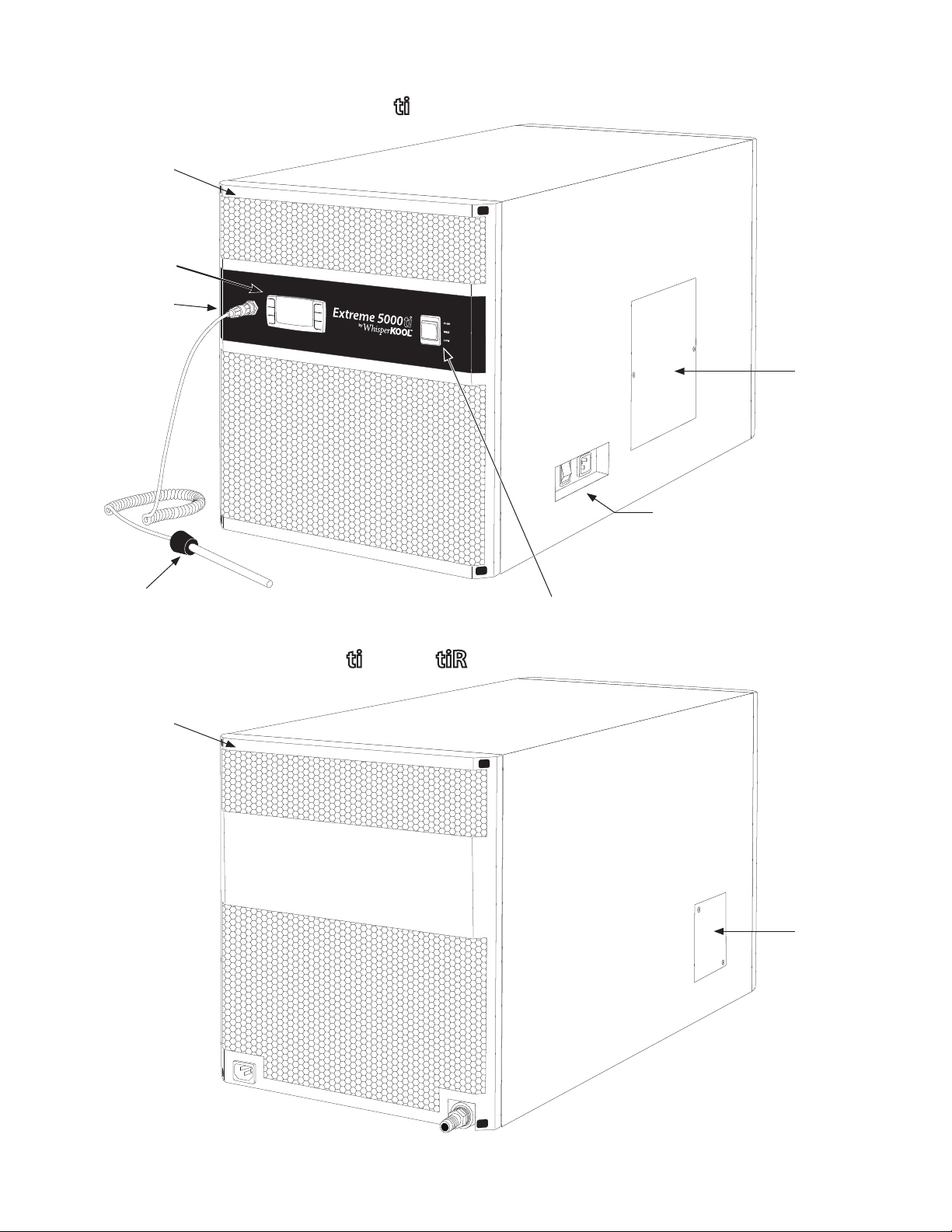

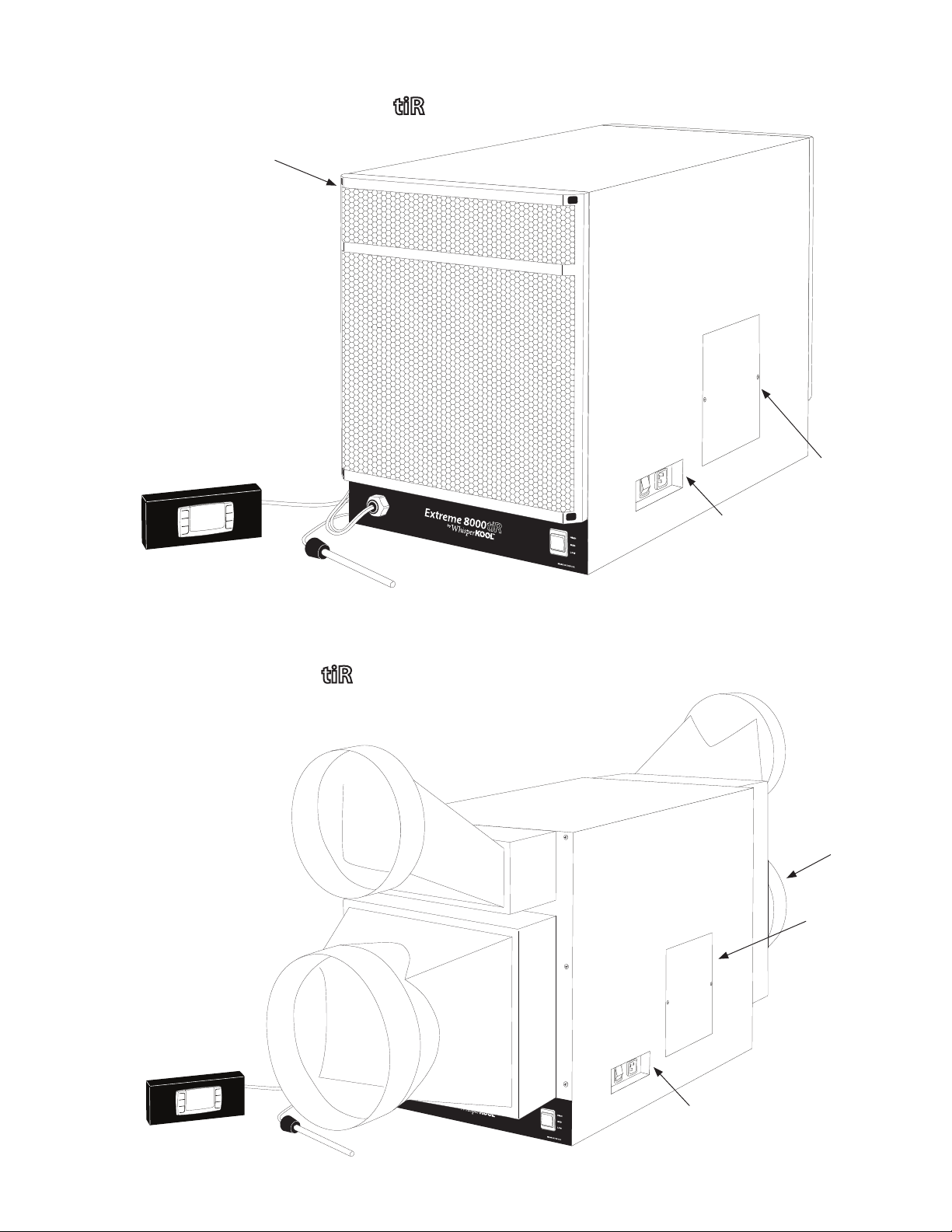

Grille w/Filter

Controller

Probe Input

QUICK REFERENCE GUIDE

5000 - Front / Side View

Bottle Probe

Grille w/Filter

5000

MADE IN THE USA

Fan Speed Control

/ 5000 - Rear / Side View

Compressor

Access Panel

Control Panel

(see page 14 for details)

Page 2

Drain Line

Access

Rear Power Option

Drain Port

EXti 110111

Page 5

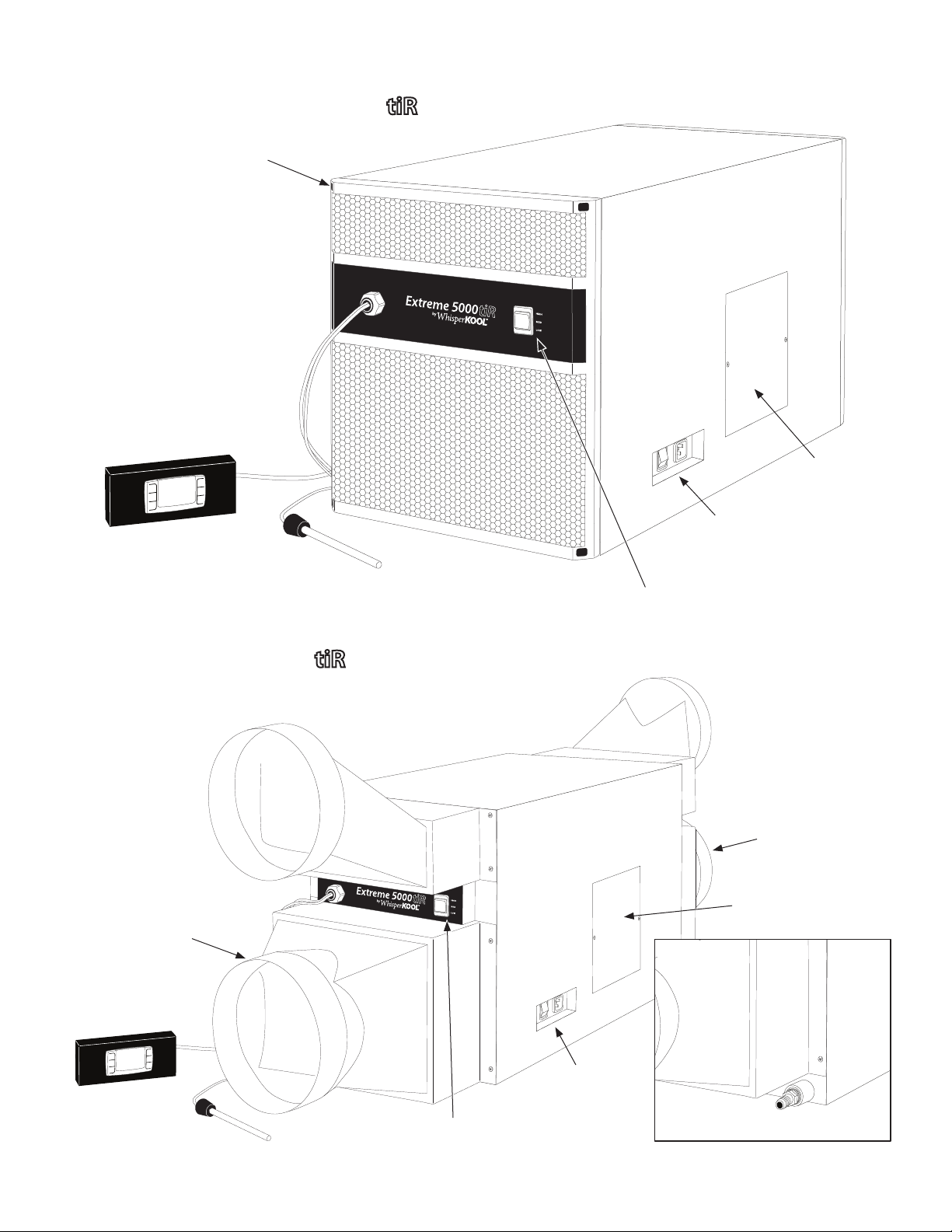

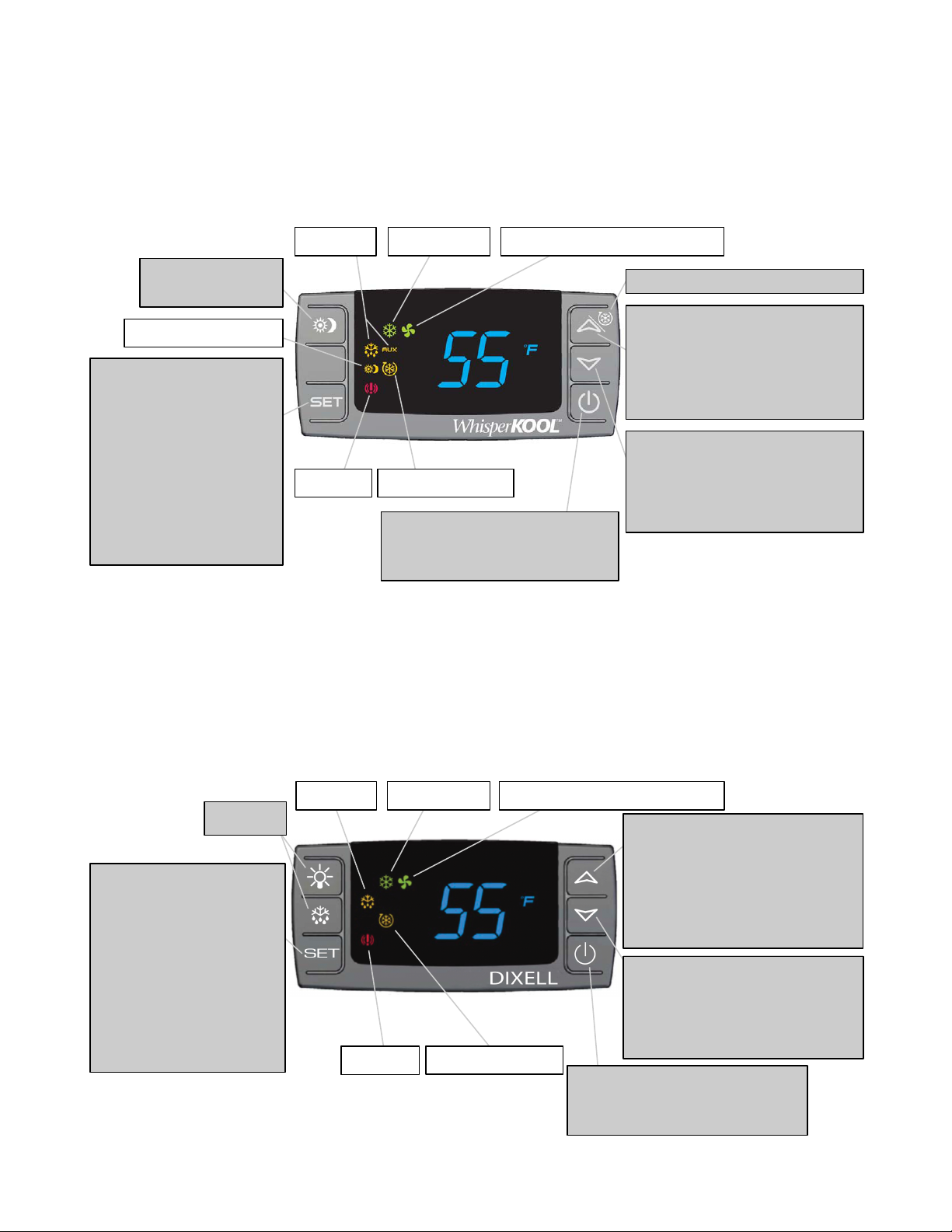

Grille w/Filter

Controller w/Remote Box

QUICK REFERENCE GUIDE

5000 - Front / Side View

R

MADE IN THE USA

Compressor

Access Panel

Supply Plenum

Return Plenum

Bottle Probe

5000

Fan Speed Control

Fully Ducted - Front / Side View

R

Rear

Control Panel

(see page 14 for details)

Exhaust Plenum

Intake Plenum

Compressor

Access Panel

Controller w/Remote Box

Bottle Probe

Fan Speed Control

Control Panel

(see page 14 for details)

Drain Port

Page 3

Page 6

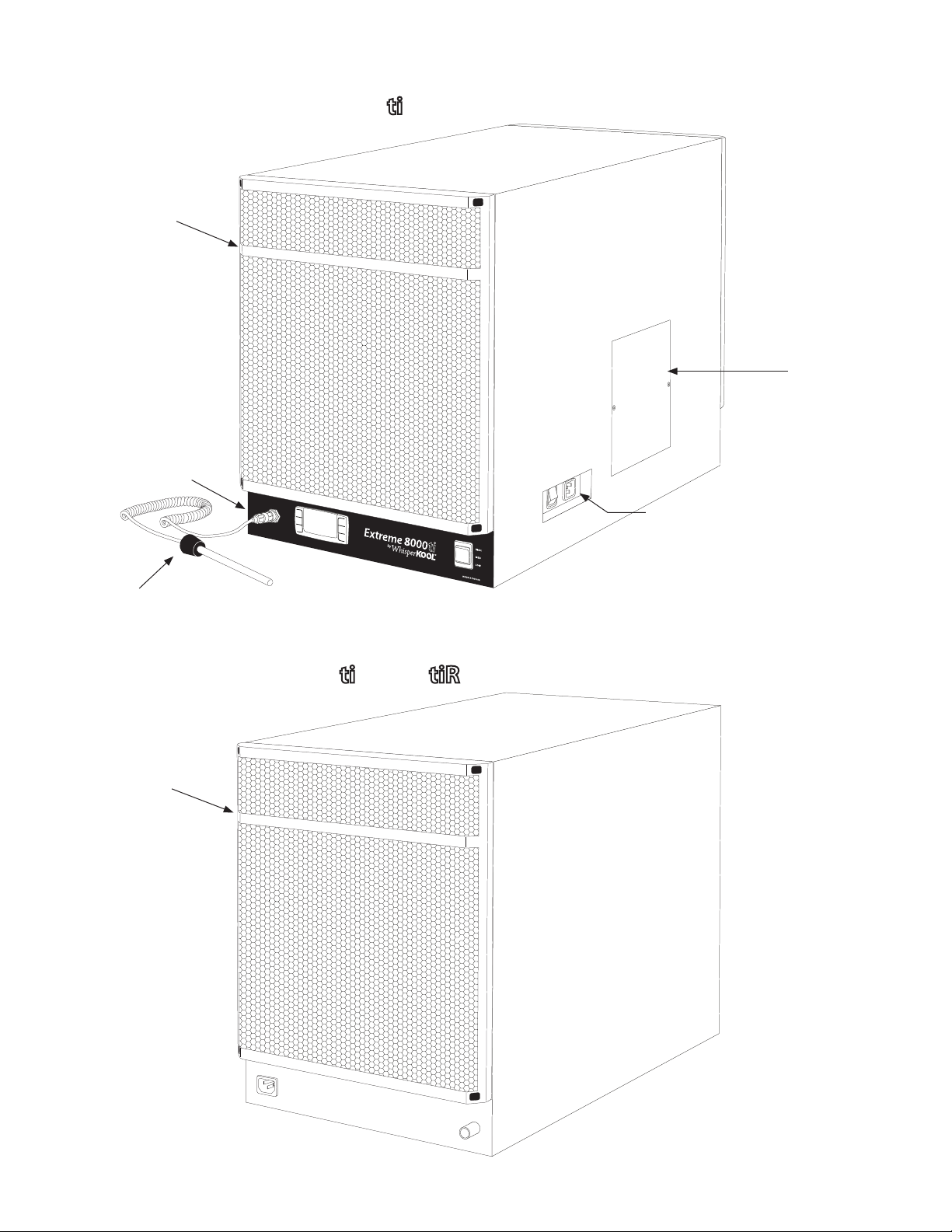

Grille w/Filter

Probe Input

QUICK REFERENCE GUIDE

8000 - Front / Side View

Compressor

Access Panel

Control Panel

(see page 14 for details)

Bottle Probe

Grille w/Filter

Controller

8000

Fan Speed Control

/ 8000 - Rear / Side View

Page 4

Rear Power Option

Drain Port

EXti 110111

Page 7

Grille w/Filter

QUICK REFERENCE GUIDE

8000 - Front / Side View

Controller w/Remote Box

Bottle Probe

Supply Plenum

8000

Compressor

Access Panel

Control Panel

(see page 14 for details)

Fan Speed Control

Fully Ducted - Front / Side View

Exhaust Plenum

Intake Plenum

Compressor

Access Panel

Return Plenum

Controller w/Remote Box

Bottle Probe

Control Panel

(see page 14 for details)

Fan Speed Control

Page 5

Page 8

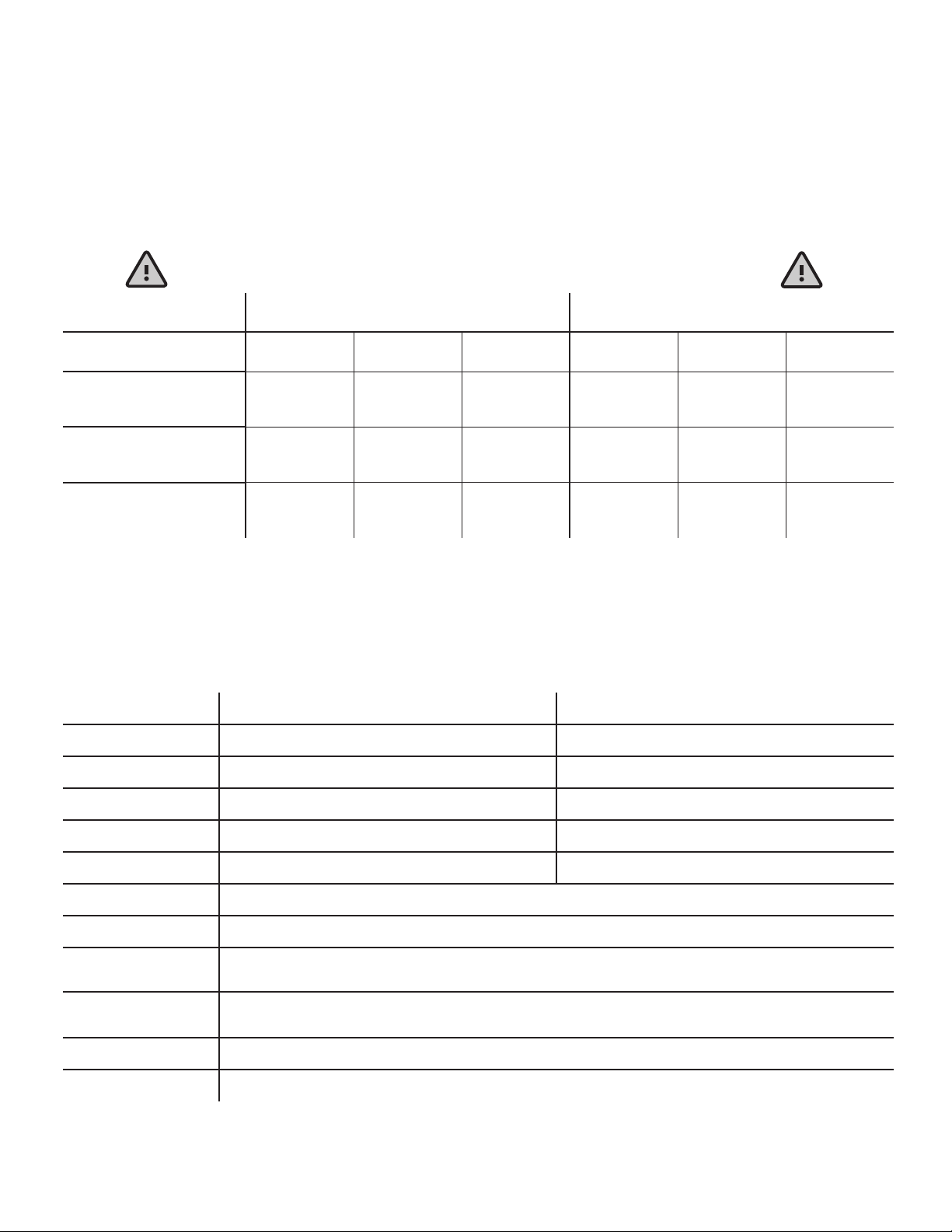

Evaporator and Condenser Fan

•

•

•

•

ALARM

Pre-Chill Display

Control “ON/OFF” Buon

•

Turns the Cooling Unit

“ON/OFF”

1

An Frost

Compressor

Energy Reducon

Hi Bole Temp History & Scroll

Buon

1

Low Bole Temp History & Scroll

Buon

Push to see the min. stored temperature.

In programming mode use to browse the

parameter codes or decrease

the displayed value.

1

Energy Saving

Buon

1

Cellar “Pre-Chill” Buon

3-5

Push to see the max stored temperature.

In programming mode use to browse the

parameter codes or increase the display

value. Hold for 3 seconds to start fast

freezing cycle.

Set Buon

View Set Point

1

Change Set Point

3-5

SET + Down = CPSM

10-15

Reset Hi & Lo Buon

3-5

Display and modify set point. In

programming mode it selects a

parameter conrms an operation. Hold for 3 seconds when

the min or max temperature is

displayed to RESET.

Evaporator and Condenser Fan

Set Buon

•View Set Point

1

•Change Set Point

3-5

•SET + Down = CPSM

3 - 5

•Reset Hi & Lo Buon

3-5

ALARM Pre-Chill Display

Control “ON/OFF” Buon

•

Turns the Cooling Unit

“ON/OFF”

1

An Frost Compressor

Hi Bole Temp History & Scroll

Buon

1

Cellar “Pre-Chill” Buon

3-5

Low Bole Temp History & Scroll

Buon

Push to see the min. stored temperature.

In programming mode use to browse the

parameter codes or decrease

the displayed value.

1

Inacve

Display and modify set point. In

programming mode it selects a

parameter conrms an operation. Hold for 3 seconds when

the min or max temperature is

displayed to RESET.

Push to see the max stored temperature.

In programming mode use to browse the

parameter codes or increase the display

value. Hold for 3 seconds to start fast

freezing cycle.

QUICK REFERENCE GUIDE

Standard Controller Layout

*If your unit is installed through the wall and does not have a remote keypad you have the Standard Controller*

Note: The 1 or 3-5 qualies the amount of time in seconds that the button must be pushed to activate the feature.

Refer to page 30 for complete listing of buttons and symbols.

Note: The 1 or 3-5 qualies the amount of time in seconds that the button must be pushed to activate the feature.

Page 6

Remote Controller Layout

*If your unit has a remote keypad then you have the Remote Controller*

Refer to page 34 for complete listing of buttons and symbols.

EXti 110111

Page 9

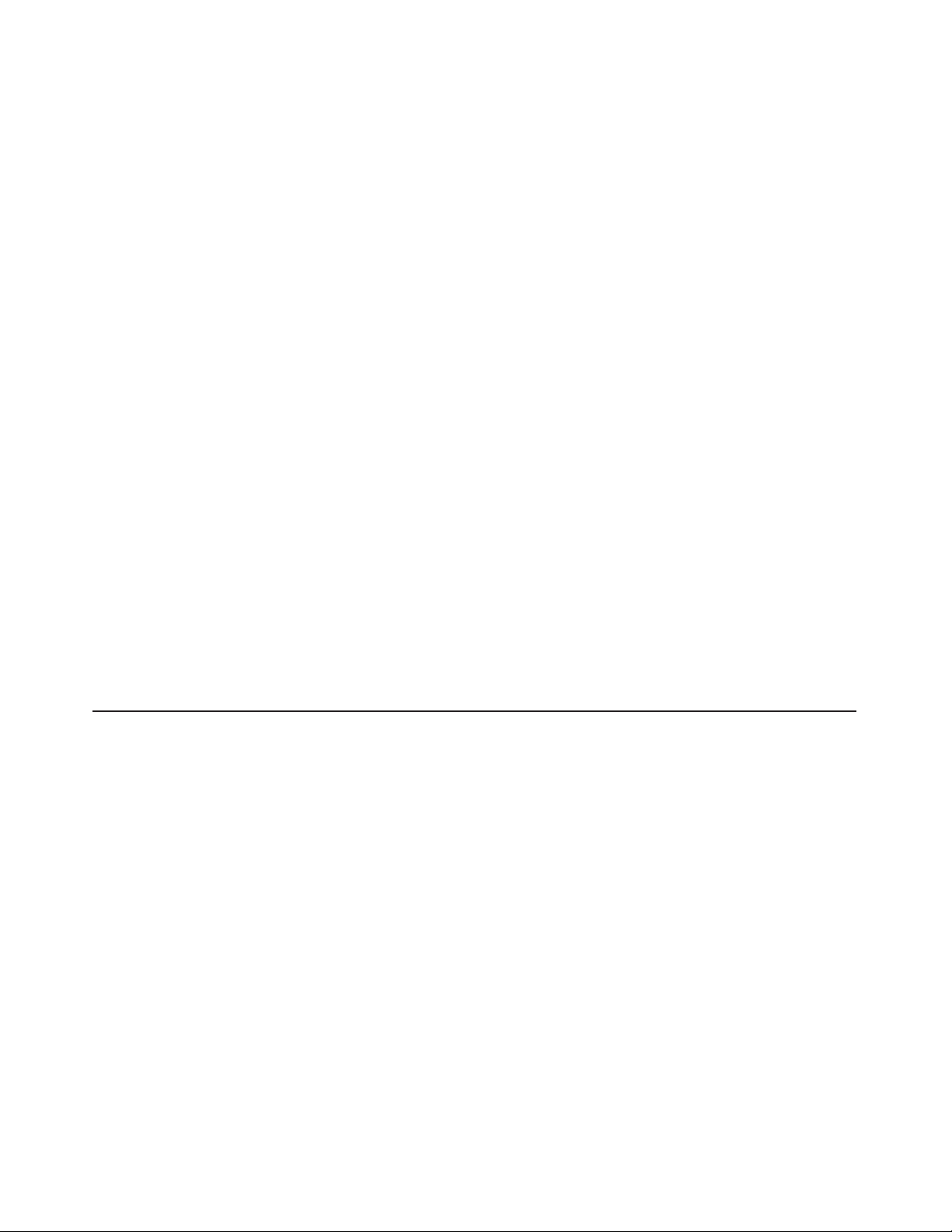

FAN SPEED REFERENCE

Your fan speed selection will depend on the amount of heat that needs to be removed from the cellar and the application of the unit (through a wall or fully ducted). Fan speed selection will depend on the cellar size, insulation

factor, door seal and desired wine temperature. When initially installing the unit, set the fan speed to High setting

for a quick chill down. Once the temperature of the cellar reaches the desired temperature, you may be able to select

a lower fan speed to handle the normal load. In the event the temperature outside goes above 90 degrees, (when

exhausting to the outside) you may need to select the higher fan speed.

Fully ducted systems need to be set and stay in the High fan speed position.

Model

Speed Selection

Air Flow

(CFM)

Sound

(dBA In Cellar / Out of Cellar)

Cooling Capacity

(BTU/h)

* To get a feeling for decibels, a food blender at 3ft is 90 dBA, garbage disposal at 3ft is 85 dBA, vacuum cleaner at

10ft is 75 dBA, normal speech at 3ft is 79 dBA, dishwasher in the next room is 55dBA, Quiet night is 35dBA

Low Med High Low Med High

147 180 256

51/51 58/57 66/65

2967 3142 3360

5000ti & 5000tiR 8000ti & 8000tiR

274 318 333

57/57 59/59 60/61

5140 5606 5760

UNIT SPECIFICATIONS

Model 5000ti & 5000tiR 8000ti & 8000tiR

Cellar Size 1000 cu. ft. 2000 cu.ft

Dimensions 14.25”W x 15.75”H x 28”D 14.25”W x 22”H x 28”D

Weight 96 lbs 110 lbs

AMPS

(running) 9 10

dBA 51 low 58 med 66 high 57 low 59 med 61 high

Installation Through-the-Wall, Partially Ducted, Fully Ducted

Thermostat Digital Control Display

Temp. Delta

Outside Venting

Ducting Options Unit can be fully ducted.

Warranty 2 year parts and labor / 5 year compressor

55°F temperature dierential

(maintains proper cellar temperature when exhaust environment does not exceed 110°F)

Can be done if the outside temperature does not exceed 110°F, the external grille cover is

required.

Page 7

Page 10

INTRODUCTION

Customer Service

Thank you for purchasing a WhisperKOOL Extreme Series cooling unit. We strive to provide the highest quality products and the best possible customer service. If you have any questions about your WhisperKOOL unit, please call us

at 1(800) 343-9463.

Using the Manual

This User’s Manual is intended to assist in the proper installation and maintenance of the WhisperKOOL Extreme cooling system. In order to ensure the longevity of your cooling unit, the equipment should be installed properly and

have a proper care and maintenance schedule. Please read and review this manual carefully and keep it for future

reference.

What Is the WhisperKOOL Extreme Series Cooling System?

The WhisperKOOL Extreme Series system is a specialized refrigeration unit designed for one purpose only: to maintain the optimal temperature and humidity levels conducive to the proper storage and aging of ne wines. It is a

self-contained cooling unit designed to be used as a forced-air through-the-wall unit or as a remote mount unit with

external ductwork connections.

How Does the WhisperKOOL Extreme Series Work?

The WhisperKOOL Extreme Series cooling system is especially designed for the use and application to maintain

optimal conditions for wine storage and aging. The system is fully self-contained and can be installed as a “ThroughThe-Wall’ application, or the unit is capable of an even more exible “Ducted” application, which allows the unit to be

placed in an indoor remote site, resulting in a quiet airow. The standard “Through-the-Wall” and ducted units are

temperature controlled via a bottle probe, and the ducted system comes standard with a remote key board that can

be located up to 50 ft from the cooling system (Note: Remote Unit comes standard with a 50 ft bottle probe and 50 ft.

of cable for the remote keypad, additional lengths are optional).

Temperature Setting

The WhisperKOOL Extreme unit can be set at any temperature within the acceptable wine-aging range of 50°F to

67°F. It is designed to cool up to 55°F cooler than the ambient temperature of the space to which it is exhausting.

Page 8

EXti 110111

Page 11

RECEIVING & INSPECTING THE UNIT

Receiving and Inspecting the Unit

• Lift only at the designated hand hold locations on the shipping container or fully support the unit from un-

derneath. A shipment may include one or more boxes containing accessories.

• Before opening the container, inspect the packaging for any obvious signs of damage or mishandling.

• Write any discrepancy or visual damage on the Bill of Lading before signing.

• Place the box containing the WhisperKOOL unit on a tabletop to prepare it for testing prior to installing.

• Sit upright for 24 hours.

Note: WhisperKOOL Extreme units are manufactured in the USA and tested prior to shipment.

Review the Packing Slip to Verify Contents

• Check the model number to ensure it is correct.

• Check that all factory options ordered are listed.

If any items listed on the packing slip do not match your order information, contact WhisperKOOL Customer Service

immediately.

Check the Box for the following contents:

5000 / 5000

Single Piece Mounting Bracket

Accessory Kit One:

• WhisperKOOL Extreme Series Owner’s Manual

Accessory Kit Two:

• Power Cord

• Mounting Bracket Insulation Foam 16” (2)

• Mounting Bracket Insulation Foam 17” (2)

• Bottle Temperature Probe (Standard Unit)

Accessory Kit Three:

• 1 ¾ Standard Screws (9)

• ½ Self-Tapping Screws (5)

• ½ x ½ Barbx MNPT Fitting

• Drain Line tube (1)

• Connection “T” (1)

Please leave the WhisperKOOL unit in its original box until you are ready for installation. This will allow you to move

the product safely without damaging it. When you are ready to remove the product from the box, refer to page 12 for

installation instructions.

Mounting Flanges (4)

Accessory Kit One:

• WhisperKOOL Extreme Series Owner’s Manual

Accessory Kit Two:

• Power Cord

• Mounting Bracket Insulation Foam 16” (2)

• Mounting Bracket Insulation Foam 22” (2)

• Bottle Temperature Probe (Standard Unit)

Accessory Kit Three:

• 1 ¾ Standard Screws (9)

• ½ Self-Tapping Screws (9)

• Drain Line tube (1)

• Tube Clamp (1)

• Connection “T” (1)

8000 / 8000

TIP: Save your box and all packaging materials. They provide the only safe means of transporting/shipping the unit.

Page 9

Page 12

QUICK START GUIDE

This guide is meant to serve as a quick reference for installation of the WhisperKOOL unit. The remainder of this

Owner’s Manual will provide more detailed information and instructions.

Upon receiving the WhisperKOOL unit:

1. Inspect the unit before installation. If damage is found, please contact your distributor or WhisperKOOL

Customer Service at 1.800.343.9463 ext 799.

2. The unit should remain in an upright position for 24 hours prior to operation.

3. The WhisperKOOL unit requires a dedicated 115-volt 20-amp circuit. Use a surge protector with the

WhisperKOOL unit. Do not use a GFI (Ground Fault Interrupter) line.

4. For your convenience, the WhisperKOOL unit has two power inlets, one on the side of the unit and the other on the

back. Use the selector switch, located on the right side of the unit, to select the inlet you would like to use.

5. The unit is designed to gently cool down the temperature of the cellar over time by cycling cooler and cooler air

throughout. Test the unit prior to installation. Operate unit for twenty minutes. While the unit is running and

working properly, the air discharged from the front should be 10 - 15°F cooler than the air in the room. This

means that in an environment where the air is 80°F, the unit will discharge air that is 65-70°F.

6. It is REQUIRED to install a drain line to remove condensation from the unit.

7. The WhisperKOOL unit is intended for use in properly designed and constructed wine cellars. Hire a

professional wine storage consultant with a valid contractor’s license to build your wine cellar. Refer to the “How to

Build a Wine Cellar” video available on the WhisperKOOL website at www.whisperkool.com.

8. Install the foam strips along the inside edge of the unit’s flange to assure a proper seal against the wall.

Never try to open the WhisperKOOL unit, repair it yourself, or use a service company

without WhisperKOOL’s authorization. This will void your warranty.

If you encounter a problem with your WhisperKOOL unit, please refer to the Troubleshooting Guide on page 36.

If you have any further questions, concerns, or need assistance, please contact WhisperKOOL Customer Service at

1.800.343.9463 ext. 799. Please be sure all testing has been completed prior to contacting Customer Service. Please

have your results ready for your representative.

Page 10

EXti 110111

Page 13

PREPARING THE WINE CELLAR

The performance and life of your WhisperKOOL unit is contingent upon the

steps you take in preparing the wine cellar.

Note: Improperly preparing your enclosure or incorrectly installing your WhisperKOOL

unit may cause unit failure, leaking of condensation, and other negative side eects.

IT IS HIGHLY RECOMMENDED THAT YOU OBTAIN THE ASSISTANCE

OF A WINE STORAGE PROFESSIONAL.

Wine storage professionals work with licensed contractors, refrigeration technicians, and racking companies to build

well-insulated, beautiful, and protective wine cellars. WhisperKOOL has put together some useful tips to assist in the

installation process. Our recommendations are meant to act as a guide in the process of building a proper enclosure.

Your intended location may have specic needs that we do not address.

How to Build a Wine Cellar Instructional Video

WhisperKOOL has a construction tutorial available on line at our website: www.whisperkool.com. This tutorial will walk

you through the steps of constructing a properly built wine cellar and the installation of our WhisperKOOL product line.

Wall & Ceiling Framing

Build wine cellar walls using standard 2x4 or 2x6 construction methods and ceiling joists following the guidelines of

local and state codes in your area. As a general rule, the thicker the walls and the higher the insulation value in your

cellar, the better it will be at maintaining a consistent temperature.

Insulation

Insulation is REQUIRED with the use of the WhisperKOOL product. Standard berglass or rigid foam insulation is normally used in cellar construction or, in some cases, “blown-in” insulation is used. It is very important that all walls and

ceilings are insulated to keep the cellar temperature as consistent as possible during the summer and winter months.

The R-value, or quality of insulation, is determined by the rate at which heat passes through the insulation. The

higher the R-value, the more resistant the insulation is to conducting heat. Using higher R-values in insulation will

lower your operating costs and unit run time. (R-13 minimum, R-19 recommended, R-30 for ceiling and exterior walls.)

Vapor Barrier

A vapor barrier is REQUIRED to prevent the intrusion of water vapor so that the cellar can be kept at the correct

temperature and humidity. 6 mm plastic sheeting (recommended) should be applied to the warm side of the cellar

walls. The vapor barrier must also be applied to the outside walls and ceiling. If it is impossible to reach the outside,

then the plastic must be applied from within the cellar. The most common method is to wrap the entire interior, leaving the plastic loose in the stud cavity so the insulation can be placed between each stud. All of the walls and ceiling

must be wrapped in plastic for a complete vapor barrier.

In areas of high humidity, such as Southern and Gulf States, the vapor barrier will prevent inltration of warm moist

air. The moist air can cause mold to form, and standing water in drain pans promote microbial and fungal growth that

cause unpleasant odors and indoor air quality problems. If mold is found, remove it immediately and sanitize that

portion of the unit.

Page 11

Page 14

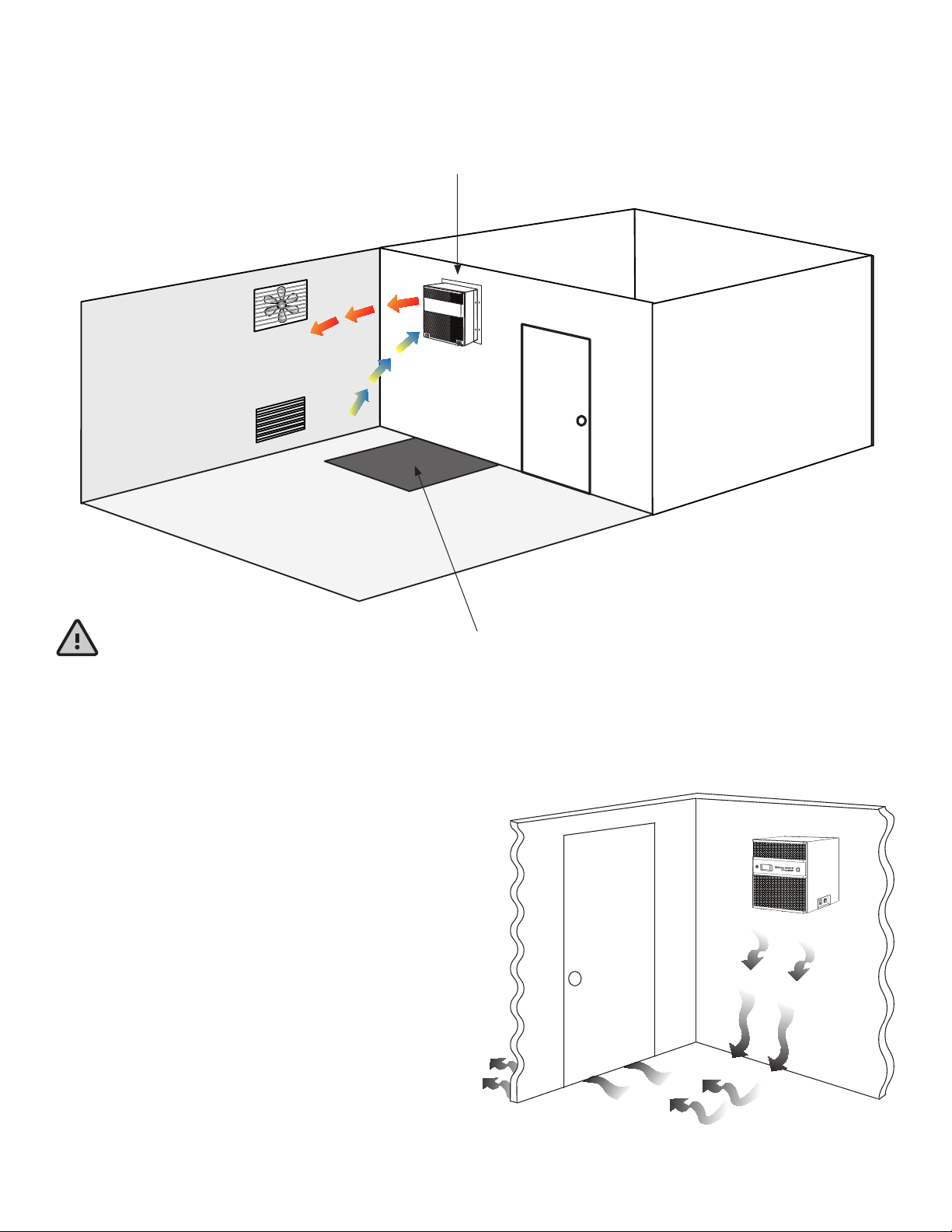

Mounting the Unit

The unit must be mounted within 18“ of the top of the room in order to achieve sucient cooling. As the room cools

down, the warm air will rise to the ceiling. Mounting the WhisperKOOL high in the room will create a consistently

cool environment by capturing the warm air and replacing it with cool air. Mounting the unit low in the room will

result in a temperature variation in the room due to the unit’s inability to draw warm air from the ceiling of the cellar

to the unit itself, and cold air settling to the oor.

Wine Cellar

Exhaust Fan/Vent

(optional)

Air Intake

(optional)

Keep Clear

Exhaust Area

Unobstructed Airow

Unobstructed airflow too and from the unit is critical for the unit’s overall performance and life-span. A minimum three-foot clearance (five foot is ideal) area is crucial. The air the fans blow needs to circulate and either dissipate or absorb heat from the space, the more air to exchange the more efficient the system will operate.

Note: Avoid attempting to camouflage the unit. This will restrict airflow and thus the unit’s ability to work efficiently.

Door and Door Seal

An exterior grade (1 3/4”) door must be installed as a cellar

door. It is very important that weather stripping is attached to all 4 sides of the doorjamb. A bottom “sweep” or

threshold is also required. The door must have a very good

seal to keep the cool cellar air from escaping out of the

cellar. One of the most common problems with cooling

units running continually is due to the door not sealing

properly. In cases where glass doors are used and the

room size is close to the recommended unit size, the

next larger size WhisperKOOL should be used. This will

compensate for the insulation loss due to the lower insulating rating of glass.

HIGH

MED

LOW

Page 12

EXti 110111

Page 15

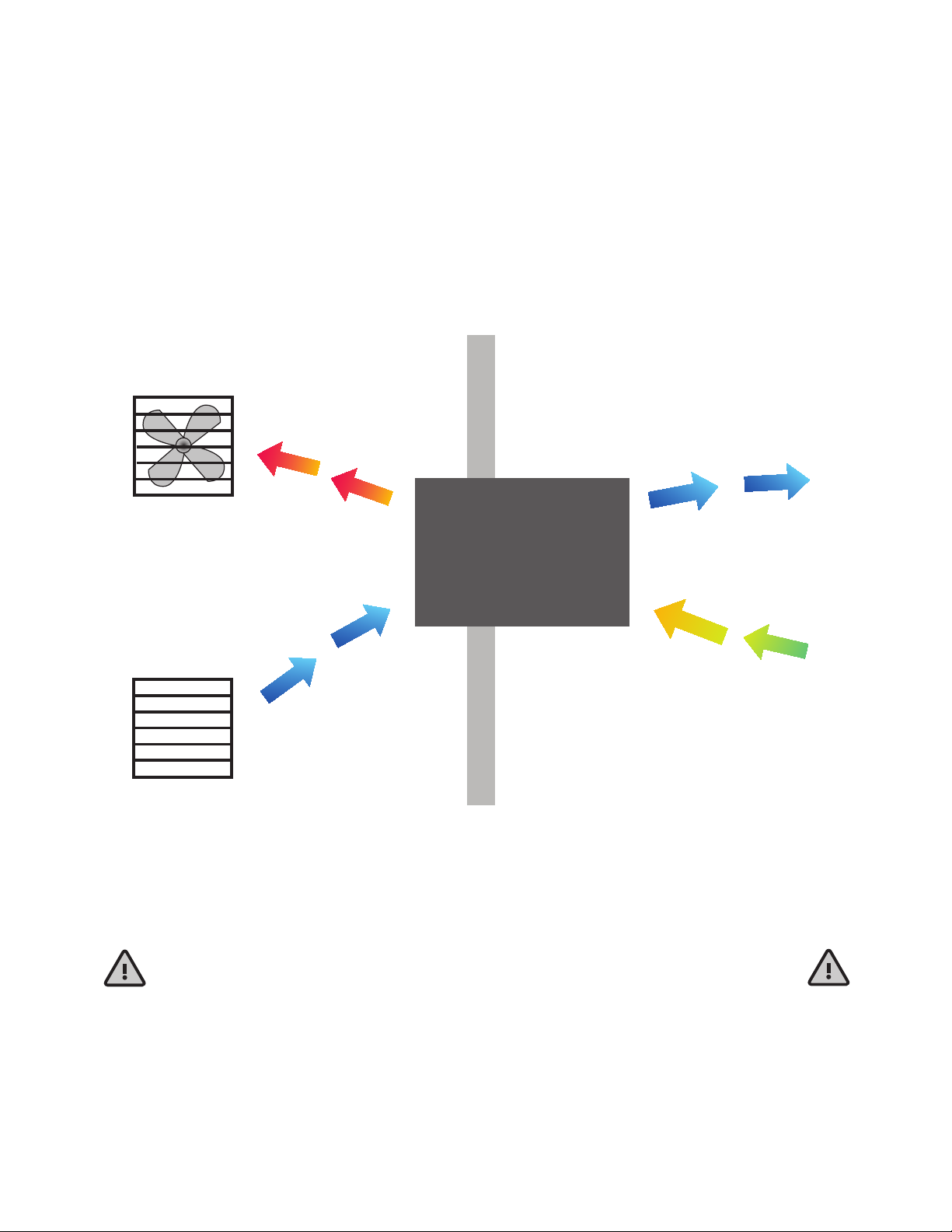

Ventilation

The necessity of dissipating heat away from the unit is critical to the unit’s performance and cannot be overstated. As

the unit operates and cools, a greater amount of heat is generated on the exhaust side of the unit. Adequate ventilation is required in order to dissipate heat away from the unit. If ventilation is inadequate, the exhaust will heat up the

area or room and adversely aect the unit’s ability to cool. In some cases, it may be advisable to install a vent fan to

dissipate heat within the exhaust area on the backside of the unit. However, you must have a fresh air inlet as well. If

your unit requires ducting, please contact WhisperKOOL to obtain a specially designed ducting plenums for the unit.

Using any other ducting system will void the warranty.

Note: If you are unsure about having adequate ventilation in your install location, please

contact us to assess your specic installation at support@whisperkool.com or 1.800.343.9463.

Back - Exhaust Room

Front

-

Wine Cellar

Exhaust Fan

WhisperKOOL

(side view)

110ºF 55ºF

Air Intake Cellar Wall

Ambient Temperature Factor

The cooling system has the ability to cool a wine cellar eciently to 55°F as long as the ambient temperature of the

area that it is exhausting to does not exceed 110°F. Therefore, you want to exhaust the unit in a room which will not

exceed 110°F. Otherwise the unit will not have the capacity to keep the wine at a desirable 55°F.

Warning, allowing your system to operate in high ambient temperatures for extended

periods of time will greatly decrease the life of your system and void your warranty.

Page 13

Page 16

PRE-INSTALLATION

TEST THE UNIT PRIOR TO INSTALLATION

To prepare it for testing before installation in wall:

• Unit needs to be in the upright position for 24 hours before starting.

• Remove unit from box

• Place unit on tabletop

• Plug in unit to electrical outlet

• Plug in bottle probe

• Turn on to test (Should be 10°F- 15°F across coils) approximately 20-30 minutes

• Turn o after test

• Remove bottle sensor

Electrical Needs

The WhisperKOOL Extreme System requires a dedicated 115-volt 20-amp circuit. The unit draws a large amount

of amps at initial start up. By designating a dedicated circuit breaker, you will guarantee the unit has enough power

to run eectively. Contact an electrician for assistance with the installation of this dedicated electrical circuit:

• Match the electrical outlet to the plug provided on the WhisperKOOL unit.

• Provide a dedicated circuit and wiring for the unit.

• Provide a weatherproof plug for units connected outside.

Plug your WhisperKOOL unit into a surge protector or power conditioner. As with any sensitive electrical equipment,

the WhisperKOOL electrical equipment may be damaged by power surges and spikes. Power surges and spikes are

not covered under warranty.

WE RECOMMEND THAT YOU DO NOT USE A GROUND FAULT INTERRUPTER (GFI) WITH THIS PRODUCT.

Electrical Inlets

The unit is equipped with two power inlets: One is located on the right side of the unit; (inside the cellar) the other is

located on the rear of the unit (outside of the cellar). Use the selector switch located on the right side of the unit to

select which power inlet you would like to utilize. (Meaning if you would like to plug the unit into a socket outside

of the cellar, set the selector switch to rear; if you would like to plug the unit into a socket inside of the cellar, set the

selector switch to the front position. When placed in either position power can only enter the unit utilizing the power

inlet you’ve selected.)

In case the unit should lose power, check the home/main circuit breaker. If the unit does not respond properly, refer

to the Troubleshooting section on page 39.

Front / Rear

Power Switch

FRONT

Power Inlet

REAR

Page 14

EXti 110111

Page 17

PREPARING THE INSTALLATION LOCATION

Through-the-Wall

Minimum Tools Needed

Level

Hammer SawScrewdriver

Locate the desired installation location (no lower than 18” inches from the

ceiling). Using a stud nder, locate the studs on either side of the center

point, and mark them with vertical lines.

Using a level and a pencil, mark a horizontal line on the wall between the two

studs, no less than 1 1/2” and no more than 18” from the ceiling.

Using a ruler or measuring tape, measure 16” down (5000ti/tiR) or 22.25”

down (8000 ti/tiR), and mark another horizontal line parallel to the rst one.

Using a saw, cut along the uppermost horizontal line until your saw reaches

the stud. Turn the saw around, inserting it into the cut you have just made,

and cut toward the opposite stud so that you have a clean horizontal cut between the two studs. Be careful not to cut into the studs themselves.

Now make the second horizontal cut from stud to stud on the line 16” below

the rst cut.

Once the horizontal lines have been cut, make vertical cuts using the inside

edge of the studs as a guide. Once you have made both vertical cuts, you

should have a rectangular hole in the sheetrock. Now you have to make the

same hole on the other side of the wall. Since you already have one hole,

this is an easy process. Using a nail, mark all four corners of the rst hole by

making nail holes through the sheetrock. Then on the other side of the wall,

connect the holes with a pencil mark and cut.

Once the horizontal lines have been cut, make vertical cuts using the inside

edge of the studs as a guide. Once you have made both vertical cuts, you

should have a rectangular hole in the sheetrock. Now you have to make the

same hole on the other side of the wall. Since you already have one hole,

this is an easy process. Using a nail, mark all four corners of the rst hole by

making nail holes through the sheetrock. Then on the other side of the wall,

connect the holes with a pencil mark and cut.

Sheetrock alone cannot support the weight of a 96-pound cooling system.

Therefore, it is necessary to frame the hole that you have just cut with upper

and lower supports. These supports also provide solid material for the mounting bracket screws.

Using two 2x4s at 14.5” in length and eight 6d nails, secure the upper and

lower supports to the right and left studs, just inside the sheetrock. Make sure

that the internal height remains at 16” (5000ti/tiR) or 22.25” (8000 ti/tiR) so

that the WhisperKOOL system will t snugly through the framed cut-out.

Page 15

Page 18

PREPARING THE SYSTEM FOR INSTALLATION

5000 / 5000

Single Piece Mounting Bracket

The 5000ti/tiR utilizes a single piece mounting bracket, this sturdy bracket frames the installation location and secures the unit to the wall. WhisperKOOL has also designed the

bracket to hold the system at a 2º degree angle, this helps project the air into the space

and aids in condensation drainage.

Applying Insulation Tape

Locate the (4) precut pieces of black foam tape included with the system, two larger

pieces and two smaller pieces. To apply, simply peel back the white-paper adhesive covering and place on the mounting bracket. The large pieces are applied to the top and

bottom while the smaller pieces are for the sides. This foam creates a tight seal between

the bracket and the wall.

Mounting Bracket Installation

Select your desired bracket mounting location (see diagram below), this location determines the depth of the installation. For example, position #1 keeps most of the system out of the cellar while position #4 makes the back of the

system near ush on the exterior wall. Slide bracket onto unit, pay special attention to the TOP label on the bracket

and the anges for mounting to the unit are towards the back. Use the (4) supplied 1/2” self tapping screws to fasten

the bracket to the unit. It is imperative to not use self tapping screws longer than 1/2” in length.

If you are installing through an exterior wall, please review page 18 for

specic instructions on exterior grill installation.

5” inch thick wall

(wall thickness may vary)

Wine Cellar Exhaust Area

Mounting Bracket

Page 16

7.5-8.5” inches In Cellar

11.5-12.5” inches In Cellar

15.5-16.5” inches In Cellar

19.5-20.5” inches In Cellar

#

1

#

2

#

3

#

4

EXti 110111

Page 19

PREPARING THE SYSTEM FOR INSTALLATION

8000 / 8000

Mounting Flanges

Your system utilizes mounting anges (4) to frame the installation location and secure

the unit to the wall.

Applying Insulation Tape

Locate the (4) precut pieces of black foam tape included with the system, two larger

pieces and two smaller pieces. To apply, simply peel back the white-paper adhesive

covering and place on the mounting ange. The small pieces are applied to the top

and bottom while the larger pieces are for the sides. This foam creates a tight seal

between the ange and the wall.

Mounting Flange Installation

Select your desired ange mounting location (see diagram below), this location determines the depth of the installation. For example, position #1 keeps most of the system out of the

cellar while position #3 makes the back of the system near ush on the exterior wall. Use the (8) supplied 1/2” self tapping screws to fasten the anges to the unit. It is imperative to not use self tapping screws longer than 1/2” in length.

If you are installing through an exterior wall, please review page 19 for

specic instructions on exterior grill installation.

Mounting Flange

Wine Cellar Exhaust Area

5” inch thick wall

(wall thickness may vary)

11.5-12.5” inches In Cellar

15.5-16.5” inches In Cellar

19.5-20.5” inches In Cellar

#

1

#

2

#

3

Page 17

Page 20

OPTIONAL EXTERIOR GRILLE

5000 / 5000

Exterior Grille Installation

The exterior grille is required on all installations where the exhaust side of the unit is exposed to the outside of the

dwelling (i.e. rain and weather).

Non-Flush Installation

Install the system according to the standard through-the-wall procedure. After the system is installed, place the exterior grille over the exhaust side ler grille and line up the screw holes on the top, bottom, and sides. Use the supplied

(8) self tapping screws to fasten the grille to the unit.

Flush Installation

This installation is slightly dierent because you are utilizing the same holes for both the mounting bracket and exterior grille.

1. Slide the mounting bracket onto the unit followed by the exterior grille, bring the two pieces together by sliding the exterior grille over the mounting bracket side anges.

2. Align the (2) top screw holes of the exterior grill with the top screw locations on the system, use the supplied

self tapping screws to fasten the grille.

3. Repeat step 2 on the bottom of the system.

4. You will notice the side holes do not line up, use the supplied self tapping screws to fasten the grille and

bracket to the system ensuring the bracket stays perpendicular/square.

5. Continue through-the-wall installation.

It is required to use self tapping screws provided. Do not drill screws into unit.

Page 18

Non-Flush Installation

Flush Installation

EXti 110111

Page 21

OPTIONAL EXTERIOR GRILLE

8000 / 8000

Exterior Grille Installation

The exterior grille is required on all installations where the exhaust side of the unit is exposed to the outside of the

dwelling (i.e. rain and weather).

Non-Flush Installation

Install the system according to the standard through-the-wall procedure. After the system is installed, remove the

exhaust side lter grille and place the exterior grille over the system. Line up the screw holes on the top, bottom, and

sides. Use the supplied (8) self tapping screws to fasten the grille to the unit.

Flush Installation

This installation is slightly dierent because you are utilizing the same holes for both the mounting anges and exterior grille.

1. Slide the exterior grille onto the system and align the screw holes of the exterior grill with the screw locations

on the system.

2. Place the top mounting ange and use the supplied self tapping screws to fasten the ange and grille to the

system.

3. Repeat step 2 on the bottom and sides of the system.

4. Continue through-the-wall installation.

It is required to use self tapping screws provided. Do not drill screws into unit.

Non-Flush Installation

Flush Installation

Page 19

Page 22

THROUGH-THE-WALL INSTALLATION

Installing the System

Slide the unit from the outside wall into your wine cellar with the outer ange ush to the wall. Secure the ange to

the wall through the pre-drilled holes. The screws should penetrate the studs as well as the upper and lower supports to provide adequate support for the WhisperKOOL system (see illustration). Seal all cracks and gaps around the

WhisperKOOL Extreme unit with an air-tight sealant or caulking to prevent air leakage.

Note: If you use decorative moulding, it should be attached to the walls and never to the cooling unit itself.

The moulding itself should be removable incase the unit needs servicing

2x4 Upper Support

Mounting Flange

Wall Stud

Rear Power

Back of Unit

2x4 Lower Support

Drain Port

Page 20

EXti 110111

Page 23

DUCTING OVERVIEW

Use of Ductwork

Use ductwork to connect the unit to the supply and return outlets in the wine cellar. Use only insulated ductwork to minimize cooling losses, prevent sweating and reduce noise. Use ductwork on the condenser section to

redirect or absorb sound, bring in outside air to the unit inlet, and/or exhaust the hot air.

Note: Do not exceed a total of 25’ for each length of ductwork run

and a total of 50’ combined for both the supply and return lengths.

Avoid crimping the exible ducts. This chokes down the inside area and reduces the airow causing the unit to

operate improperly. Be sure all duct work and outer surfaces in contact with the airow are insulated and have

a vapor barrier on the outside. Un-insulated supply and return ducts may cause bare, exposed metal surfaces to

sweat, further degrading the insulation and equipment cooling capacity.

DO NOT ALLOW FLEXIBLE DUCTING TO GET SQUEEZED OR ALLOW THE INSIDE

DIAMETER DECREASE DUE TO VERY SHARP TURNS.

General Duct Recommendations

•

Provide support for the exible duct to prevent sags and bends.

• 5000tiR Duct Size: 8” Supply and Return

• 8000tiR Duct Size: 8” Supply and 10” Return

• Stretch out the duct to make a smoother interior which reduces air resistance.

• Maximum duct length is 25’.

• For 90° bends, use a 90° adjustable elbow.

• No more than two 90° bends on each duct. Sweep 90° bends are recommended rather than sharp 90° bends.

• Generously apply duct sealant to all metal seams to ll in gaps that can leak air. Allow sealant to dry until rm

to the touch before applying berglass insulation.

• Do not squeeze or reduce the inside diameter of the ducts as this will reduce airow.

• Use short and straight ductwork where possible.

• Check that all fan blades move freely.

• Keep air paths free of loose foreign objects and debris.

• To provide adequate airow the fan speed must be set to high when the unit is ducted.

Location of Supply and Return Grilles

Locate the supply and return grilles inside the cellar to create an airow pattern that maximizes air circulation in

the room. Avoid short circulation of the air.

Do not:

• Install through-the-wall return air grilles at oor level, as they will collect dust from the oor.

• Mount the unit lower than 18” from the ceiling.

• Locate the supply or return air grille where it is blocked by bottles, boxes or cases.

Page 21

Page 24

DUCTING CONFIGURATIONS

There are a variety of ways to duct this system, please review the dierent congurations to determine a basis

for your particular installation. Remember to contact a wine cellar professional if you have any questions.

Half Duct Conguration

Wine Cellar

Cold Air Supply Cellar Side

Return Air-Cellar Side

Three-Quarter Duct Conguration

Cold Air Supply Cellar Side

Wine Cellar

Adjacent Room

Condenser Exhaust

Condenser

Intake

Page 22

Return Air-Cellar Side

Adjacent Room

EXti 110111

Page 25

Fully Ducted

Cold Air Supply-Cellar

Return Air-Cellar Side

DUCTING CONFIGURATIONS

Heat Exhaust

Condenser Intake

Attic Mounted System

It is recommended to use our Insulation Box and Condensate Pan for this application.

Insulation Box

Cold Air

Condenser

Intake

Return Air

Condenser Exhaust

Fresh Air

Intake

Page 23

Page 26

INSTALLING THE DUCT PLENUMS

STEP 1:

Remove the lter grill from the unit by

unscrewing the screws that hold it in

place.

STEP 2:

Move the Ducting Adapters into place

STEP 3:

Screw the ducting adapters into place

using the supplied screws.

Page 24

EXti 110111

Page 27

TM

TM

REMOTE CONTROLLER INSTALLATION

The WhisperKOOL Extreme Series can be congured with a remote controller system. If you have a unit with a remote controller, please review this section.

The controller can be installed up to 50 feet away from the cooling unit, or up to 300 feet away with the extended

connection wire available from WhisperKOOL.

First you will need to determine how you will be routing the connection wire into the controller box.

TM

TM

Connection wire in Side Mount conguration Connection wire in Rear Mount conguration

Attach the connection wire as shown below, with the red wire in the upper connection slot and the black wire in the

lower slot.

Red Wire

Black Wire

Page 25

Page 28

Remove the mounting bracket and secure the bracket to the wall in the desired location. Reattach the controller to

the bracket.

Mounting Bracket

Below is an illustration of one possible way to congure

the remote controller in a wine cellar.

Cooling Unit

Bottle Probe

Remote

Controller

Page 26

EXti 110111

Page 29

DRAIN LINE

Condensation Drain Line Tube

The condensation drain line tube is used to remove excess condensation from the unit to a proper discharge location.

It is important that the drain line tube is properly connected and used to prevent leakage and other problems associated with excess condensation.

Failure to use the condensation drain line tube will void the warranty on the unit.

Drain Line

All units come with a drain line for additional

removal of excessive condensate. It is mandatory

to install the drain line with “T” fitting. During

operation, the cooling unit will strip excess water

from the air in order to maintain the proper level

of humidity within the cellar. However in extreme

humidity, additional condensate will be removed.

Thus the drain line will prevent overflow and leaking by allowing for discharge of the additional

condensate.

WRONG: Drain line is under water.

Drain Line

T-Fitting

Failure to install the drain line voids the

warranty.

To prevent mold from growing, allow the

drain line to hang above the water line.

Page 27

Page 30

LIQUID MEASURING THERMOSTAT SYSTEM

The WhisperKOOL Series cooling units come equipped with a liquid temperature measuring thermostat system.

This system incorporates the following advantages:

Self-Calibrating Probe

The probe contains a sensor chip, which actually communicates back and forth to the thermostat. This results in

a consistent temperature setting and accuracy.

Measuring liquid temperature has a few unique advantages:

1. Wine temperature is kept in a very precise controlled environment. This assures a consistent temperature.

2. By measuring the liquid temperature rather than air, the unit will operate 75- 80% of the time.

Liquid Measuring Thermostat System

To assure a consistent temperature, place bottle probe approximately 3 feet away from the air output and not in the flow of

the air.

To Use the thermostat:

1. Locate an empty wine bottle.

2. Fill 3/4 full with room temperature tap water.

3. Place bottle probe securely into bottle.

4. Place bottle with probe level and to the side of the unit in your

wine cellar. It is recommended that it is placed in a central location

of your wine cellar. Avoid pulling too much on the probe cord. It

may become disconnected resulting in non-operation of the unit.

Note: The thermostat can be set between 50°F

and 67°F.

Remember: The WhisperKOOL System is based on the temperature

of the water. Do not be misled by thermostats reading air temperature. The air temperature in the cellar will be cooler than the liquid

temperature of the wine while it is coming to optimum balanced

temperature.

Page 28

EXti 110111

Page 31

MULTI FAN SPEED CONTROL

Designed for wine cellars up to 1000 and 2000 cubic feet, the Extreme 5000ti/tiR and 8000ti/tiR feature multispeed fans with a “high” setting for maximum performance in high-temperature (+110°F) environments and a

“low” setting for super-quiet operation.

Fan Speed Selector Switch (Low/Med/High): The cooling unit fans operate on 3 speed settings: Low, Medium,

and High. For optimum sound and energy eciency, select the lowest fan speed that will maintain the desired

cellar temperature. If the relative humidity is low, a higher fan speed will cause less moisture to be removed

during cooling. High speed is recommended for initial cellar cool down, extreme temperature conditions and

ducted installations.

MADE IN THE USA

Your fan speed selection will depend on the amount of heat that needs to be removed from the cellar and the application of the unit (through a wall or fully ducted). Fan speed selection will depend on the cellar size, insulation

factor, door seal and desired wine temperature. When initially installing the unit, set the fan speed to High setting

for a quick chill down. Once the temperature of the cellar reaches the desired temperature, you may be able to select

a lower fan speed to handle the normal load. In the event the temperature outside goes above 90 degrees, (when

exhausting to the outside) you may need to select the higher fan speed.

Fully ducted systems need to be set and stay in the High fan speed position.

Model

Speed Selection

Air Flow

(CFM)

Low Med High Low Med High

147 180 256

5000ti & 5000tiR 8000ti & 8000tiR

274 318 333

(dBA In Cellar / Out of Cellar)

Sound

Cooling Capacity

(BTU/h)

* To get a feeling for decibels, a food blender at 3ft is 90 dBA, garbage disposal at 3ft is 85 dBA, vacuum cleaner at

10ft is 75 dBA, normal speech at 3ft is 79 dBA, dishwasher in the next room is 55dBA, Quiet night is 35dBA

51/51 58/57 66/65

2967 3142 3360

57/57 59/59 60/61

5140 5606 5760

Page 29

Page 32

SYSTEM OPERATION:

Standard and Remote Controls

Initial Start-Up

When power is applied to the unit, the control will

briey display all symbols, and the Compressor symbol will be displayed (if unit is calling for cooling).

There may be a brief delay prior to the evaporator and

condenser fans turning on. When the evaporator and

condenser fans are activated the “FAN” symbol will

turn on.

Normal System Cycle

After the bottle probe has reached the set point (all

units are shipped with the set point of 55°F and a

dierential of 1°F), the unit will turn o. The WhisperKOOL Humidity Management (WHM) is an adjustable feature which allows the customer the convenience of managing the humidity enhancement of

their wine cellar. The WHM is one of the many Customer Preference Selection features which allow the

customer the ability to ne tune the controls. Feature

is o from the factory but can be turned on with the

“FON” parameter.

Anti Short Cycle

The Anti Short Cycle ensures that the compressor

will remain o for a period of 3 minutes after the unit

has reached the set point to allow the pressure in the

refrigeration system to equalize prior to starting the

compressor.

Bottle Probe Failure Protection

In the event that a bottle probe should fail, the APST

(Advance Product Safety Technology) will automatically transition the Refrigeration Compressor cycles

to a pre-determined time series (based on detailed

laboratory testing), which will ensure that the product

is kept within the safe range.

Remote Control (optional)

The control panel can be installed or mounted separately from the cooling unit itself (remotely), using the

supplied cable. This option provides unique exibility

for installing the Extreme Series cooling unit in your

wine cellar. The remote option must be specied when

the unit is ordered.

Note: Remote Control is generally standard with a

“Ducted Unit”.

Ducting and Ventilation Options

The ventilation system is ideal for ducting. The optional collars t standard ventilation ducting allowing the

installer to vent air to and from the unit for optimum

performance (please see specications for details).

Anti Frost Cycle

The Anti Frost Cycle is a precautionary measure, as

icing or frosting of the coil does not occur during

normal operation. The system will go through an anti

frost cycle when the evaporator temperature reaches

26°. During the Anti Frost cycle, the unit will stop

cooling and run the indoor fan to provide air ow

across the indoor coil, which will melt any frost accumulation.

Page 30

EXti 110111

Page 33

STANDARD CONTROLLER FUNCTIONS

If your unit is installed through the wall and does not have a remote keypad you will have the Standard Controller.

Button/Symbol Normal Functions

ON/OFF • The ON/OFF button allows the customer the convenience of turning the refrigeration

system ON or OFF, from the control panel. This feature does not disconnect power from

the unit. In order for the power to be shut o from the unit, the power cord must be

unplugged from the wall receptacle.

• Press the ON/OFF button once for button application.

Up and Down

Arrows

Cellar PreChill (CPC) The CPC Feature is activated by pressing the Up button for 3-5 seconds, and the CPC logo

Energy Reduction

• Use these buttons to scroll up or down the CPSM (Customer Preference Selection Mode)

menu.

• Displays the Highest and Lowest temperature sensed by the Bottle Probe. This feature

allows the customer instant access to the recorded data applicable to the Bottle Probe

Temperatures, it can be easily reset to reect current temperatures.

1. Press the “UP” arrow, or the “Down” arrow once, and the Highest or Lowest Temperature

(Hi/Lo) sensed by the Bottle Probe, will be displayed.

2. To reset the Hi/Lo, press and hold the “Set” button when the Hi/Lo value is displayed on

the Digital Display, continue to hold the “Set” button until “rst” appears on the digital

display and then blinks. This will erase the past recorded “Temperature Data History” and

start recording, from the current time and temperature, forward. Temperatures displayed

would reect Bottle Probe Temperatures from that point in time, and beyond.

3. The Hi/Lo feature should be reset at initial “Start-Up” and after the Cellar or Cabinet has

obtained normal operating temperatures, which is generally 55°F.

will be displayed on the digital display. The CPC feature can be terminated by pressing the

Up button for 3-5 seconds, or the feature will self terminate after 6 hrs.

1. The (CPC) Feature may be used to Pre-Chill the Cellar prior to loading it with Warm

Product. The feature will shift the Set Point down to a lower setting of 52°F, for the next 6

hours. After the 6 hour time period, the Set Point will automatically return to the original

Set Point.

2. The CPC feature can be conveniently adjusted to the customer’s specic needs, by accessing the “Customer Preference Select Mode” (CPSM). See Customer Preference Select

Mode Instructions.

1. The ER feature is activated by pressing the ER button one time, and the ER logo will ap-

(ER)

pear on the digital display.

2. The purpose of the ER feature is to reduce energy cost, by shifting the Set Point up by 4

degrees, which will allow the cooling system to run for shorter periods of time, resulting

in a reduction in energy cost.

3. The ER feature allows for Energy Savings at any time - During periods of high ambient

temperatures, vacations or business travel.

4. To deactivate the ER feature, press the ER button one time, and the ER logo will turn o.

5. The ER feature can be conveniently adjusted specic need by accessing the “Customer

Preference Select Mode” (CPSM). See CPSM Instructions on page 32.

Page 31

Page 34

SET 1. Press the “Set” button once and it will display the Set Point. After approximately 5 sec-

onds, the display will return to normal operation and display the Bottle Probe temperature.

2. Standard Controller - Press and hold the “Set” button for 3-5 seconds until the set point

is displayed and the °F symbol starts blinking. Next press the “UP or Down” arrows to

change the Set Point. Next press the “Set” button once and the Set Point numbers and

the °F on the display will blink to conrm the new Set Point setting.

3. Press and hold the “Set” button during the display of the Hi/Low “Temperature Data History” (hold button unit “rst” blinks on display), and it will erase the past recorded data le

and start recording, from the current time and temperature.

4. Press the “Set” and the “Down Arrow” buttons simultaneously, for 10-15 seconds, and

you will access the “Customer Preference Selection Mode” (CPSM). The CPSM allows the

customer to “Fine Tune” the Control Operating System to their applicable choice.

Anti-Frost The Anti-Frost Cycle is automatically activated when the evaporator temp has reached a low

temp of 26° and has sustained that temp for a period of ve minutes. During this cycle the

compressor and condenser fans will turn o and the evaporator fans will continue to run.

Once the temperature of the evaporator gets back up to 40° the cycle will deactivate and

the system will revert back to normal operating conditions.

At the beginning of the cycle the symbol will be illuminated and the symbol is

illuminated during the anti-frost cycle.

Alarm The Alarm symbol is shown when the system encounters an issue that needs attention, the

displayed alarm codes are explained below.

Alarm Codes

Message Cause Solution

Bottle Probe is Unplugged Attach Bottle Probe to Unit

“P1”

“P2” Faulty Evaporator Probe

“HA” Defective Bottle Probe Replace the Bottle Probe

“LA”

“POF” The keypad is locked Hold “Up” and “Down” buttons for 3 to 5 seconds to disable, “PON”

Faulty Bottle Probe Connection 1. Check Bottle Probe attachment at circular connector

2. Check Bottle Probe connection at green terminal block on

back of controller

Defective Bottle Probe Replace the Bottle Probe

Check Evaporator Probe connection at green terminal block on back of

Connection

Defective Evaporator Probe Replace the Evaporator Probe

The Bottle Probe is sensing a

temperature of 4° below the set

point

Defective Bottle Probe Replace the Bottle Probe

controller

Allow the room to warm up which will increase the temperature of the

wine

should appear

Page 32

EXti 110111

Page 35

CPSM Mode Press the “Set” and the “Down Arrow” buttons simultaneously, for 10-15 seconds, and you will access

the “Customer Preference Selection Mode” (CPSM). The CPSM allows the customer to “Fine Tune” the

Control Operating System to their applicable choice.

The following CPSM options are available for adjustment:

Fon – Humidity Management Enhancement: This parameter is normally set at 0, which should provide adequate relative humidity for the cellar.

• An increase in this parameter will increase the Humidity Enhancement (%RH), and a decrease in

the parameter will decrease Humidity Enhancement (%RH).

• Adjustments should be made in increments of 5, with a maximum of 15, and a minimum of 0.

• After any adjustment to Humidity Enhancement, you should wait a minimum of three days

before making any additional adjustments. This will allow the cellar sucient time to acclimate

to the new setting.

Fof - Humidity Management Enhancement: This parameter is normally set at 15. This parameter

should not be adjusted, as it simply provides an OFF cycle time for the fan, during the compressor

OFF cycle. However, the parameter is located within the CPSM as a convenience to the customer,

should it need to be adjusted.

CCS – Cellar Pre-Chill Set Point: This parameter is set at 52°f, but can be adjusted to a set point between 50°f - 67°f.

CCT - Cellar Pre-Chill Duration: This parameter is set to 6 hours, but can be changed between 0-23.5

hours.

Con/Cof – Compressor On time (Con) and O time (Cof) with a Probe 1 failure/Alarm. These parameters are set at Con 40 min/Cof 10 min. In the event that there is a Probe 1 failure/Alarm, the compressor/refrigeration system automatically starts a predetermined ON/OFF cycle, which is controlled by

the Con and the Cof parameters. The customer can adjust these parameters to maintain the desired

Bottle temperature.

Hes – Dierential for Energy Reduction – This parameter is set at 4° above the set point, during the

Energy Reduction mode. A decrease in this setting will decrease the set point, and an increase in this

feature will increase the set point.

Page 33

Page 36

STANDARD WIRE SCHEMATIC

1

Evap.

7 8 6

NC C NO

DEFR

3 4 2

11 12

9 10

2

3 4 2

7 8 6

NC C NO

1

0

0

5

3

1

4

6

COMP

Cond

Fan

Evap

Fan

!

8 A

120V

6 7 8

Rear

Front

5

8 A

16/60

5 A

Cmp

Fan

1 2 3 4

20A

Max

Receptacle

Receptacle

Line

Compressor

Page 34

EXti 110111

Page 37

REMOTE CONTROLLER FUNCTIONS

If your unit has a remote keypad then you will have the Remote Controller.

High Temp / Pre-Chill

Low Temp

Display

Set Point

ON / OFF

TEMPERATURE

Button Normal Functions

ON/OFF • The ON/OFF button allows the customer the convenience of turning the refrigeration

system ON or OFF, from the control panel. This feature does not disconnect power from

the unit. In order for the power to be shut o from the unit, the power cord must be

unplugged from the wall receptacle.

• Press the ON/OFF button once for button application.

Up and Down

Arrows

• Use these buttons to scroll up or down the CPSM (Customer Preference Selection Mode)

menu.

• Displays the Highest and Lowest temperature sensed by the Bottle Probe. This feature

allows the customer instant access to the recorded data applicable to the Bottle Probe

Temperatures, it can be easily reset to reect current temperatures.

1. Press the “UP” arrow, or the “Down” arrow once, and the Highest or Lowest Temperature

(Hi/Lo) sensed by the Bottle Probe, will be displayed.

2. To reset the Hi/Lo, press and hold the “Set” button when the Hi/Lo value is displayed on

the Digital Display, continue to hold the “Set” button until “rst” appears on the digital

display and then blinks. This will erase the past recorded “Temperature Data History” and

start recording, from the current time and temperature, forward. Temperatures displayed

would reect Bottle Probe Temperatures from that point in time, and beyond.

3. The Hi/Lo feature should be reset at initial “Start-Up” and after the Cellar or Cabinet has

obtained normal operating temperatures, which is generally 55°F.

Cellar PreChill (CPC) The CPC Feature is activated by pressing the Up button for 3-5 seconds, and the CPC logo

will be displayed on the digital display. The CPC feature can be terminated by pressing the

Up button for 3-5 seconds, or the feature will self terminate after 6 hrs.

1. The (CPC) Feature may be used to Pre-Chill the Cellar prior to loading it with Warm

Product. The feature will shift the Set Point down to a lower setting of 52°F, for the next 6

hours. After the 6 hour time period, the Set Point will automatically return to the original

Set Point.

2. The CPC feature can be conveniently adjusted to the customer’s specic needs, by accessing the “Customer Preference Select Mode” (CPSM). See Customer Preference Select

Mode Instructions.

Page 35

Page 38

Set 1. Press the “Set” button once and it will display the Set Point. After approximately 5 sec-

onds, the display will return to normal operation and display the Bottle Probe temperature.

2. Press the “Set” button once and it will display the Set Point. Press the up and down arrows to change the set point. Press the Set button again and the numbers will blink,

conrming the change in Set Point.

3. Press and hold the “Set” button during the display of the Hi/Low “Temperature Data History” (hold button unit “rst” blinks on display), and it will erase the past recorded data le

and start recording, from the current time and temperature.

4. Press the “Set” and the “Down Arrow” buttons simultaneously, for 3-5 seconds, and you

will access the “Customer Preference Selection Mode” (CPSM). The CPSM allows the customer to “Fine Tune” the Control Operating System to their applicable choice.

Alarm The Alarm symbol is shown when the system encounters an issue that needs attention, the

displayed alarm codes are explained below.

Alarm Codes

Message Cause Solution

Bottle Probe is Unplugged Attach Bottle Probe to Unit

“P1”

“P2” Faulty Evaporator Probe

“HA” Defective Bottle Probe Replace the Bottle Probe

“LA” The Bottle Probe is sensing a

“POF” The keypad is locked Hold “Up” and “Down” buttons for 3 to 5 seconds to disable,

Faulty Bottle Probe Connection 1. Check Bottle Probe attachment at circular connector

2. Check Bottle Probe connection at green terminal block on

back of controller

Defective Bottle Probe Replace the Bottle Probe

Check Evaporator Probe connection at green terminal block on

Connection

Defective Evaporator Probe Replace the Evaporator Probe

temperature of 4° below the set

point

Defective Bottle Probe Replace the Bottle Probe

back of controller

Allow the room to warm up which will increase the temperature

of the wine

“PON” should appear

Page 36

EXti 110111

Page 39

CPSM Mode Press the “Set” and the “Down Arrow” buttons simultaneously, for 3-5 seconds, and you will

access the “Customer Preference Selection Mode” (CPSM). The CPSM allows the customer to

“Fine Tune” the Control Operating System to their applicable choice.

The following CPSM options are available for adjustment:

Fon – Humidity Management Enhancement: This parameter is normally set at 0, which

should provide adequate relative humidity for the cellar.

• An increase in this parameter will increase the Humidity Enhancement (%RH), and a

decrease in the parameter will decrease Humidity Enhancement (%RH).

• Adjustments should be made in increments of 5, with a maximum of 15, and a minimum

of 0.

• After any adjustment to Humidity Enhancement, you should wait a minimum of three

days before making any additional adjustments. This will allow the cellar sucient time

to acclimate to the new setting.

Fof - Humidity Management Enhancement: This parameter is normally set at 15. This parameter should not be adjusted, as it simply provides an OFF cycle time for the fan, during the

compressor OFF cycle. However, the parameter is located within the CPSM as a convenience

to the customer, should it need to be adjusted. CCT - Cellar Pre-Chill Duration: This parameter is set to 6 hours, but can be changed between 0-23.5 hours.

Con/Cof – Compressor On time (Con) and O time (Cof) with a Probe 1 failure/Alarm. These

parameters are set at Con 40 min/Cof 10 min. In the event that there is a Probe 1 failure/

Alarm, the compressor/refrigeration system automatically starts a predetermined ON/OFF

cycle, which is controlled by the Con and the Cof parameters. The customer can adjust these

parameters to maintain the desired Bottle temperature.

Page 37

Page 40

REMOTE WIRE SCHEMATIC

COMP

NC C

NO

3

4 2

7 8 6

1

0

Line

Front

Receptacle

Rear

Receptacle

Cond

Fan

Evap

Fan

Compressor

2

1

3

5

4

6

Line

Neutral

Page 38

EXti 110111

Page 41

Monthly 1. Check lters

2. Check for unusual noise or vibration

3. Check the drain line to see if it is above the waterline if draining into a vessel.

MAINTENANCE SCHEDULE

Quarterly 1.

2. Replace Filters on ducted systems

3. Open access door and add chlorine tablets to drip tray. (5000 ti/tiR only)

Annually

1. Replace lters if worn or plugged beyond cleaning.

2. Use a vacuum with brush attachment to clean coils. Be careful not to crush coil ns

when cleaning.

3. Inspect for corrosion.

4. Check wiring connections and integrity of cords.

5. Examine duct work for cracks or possible leaks.

6. Pour a 50/50 bleach solution into the drain line every spring.

Clean Filters

Page 39

Page 42

TROUBLESHOOTING GUIDE

Unit has ice forming on the evaporator

Possible Cause

Evaporator lter and/or coil are dirty.

Solution

Clean lter and coil with a vacuum.

If coil is very dirty, use a small hand spray with a small amount

of liquid dish washer detergent. Spray coil, let set for 5 min, then

ush with fresh water.

There is something blocking the supply and or return air

The evaporator fan is not turning on.

The unit has not gone through its anti-frost sequence, yet.

If unit continues to ice.

Unit does not run/power up

Possible Cause

Unit is not plugged in

Power switch not on

Line voltage is incorrect rating for unit

Bottle at set point

Thermostat not calling for cooling

Power select switch in wrong position

Faulty thermostat or wiring

Cellar Temperature is to Warm

Possible Cause

The temperature or the room unit is exhausting to has

exceeded 110°

The unit is undersized for the cellar.

There is something blocking the supply and/or return air,

on evaporator or condenser side of the unit

Unit is mounted too low in the cellar

Remove blockage

Call a service tech to troubleshoot

Check for ice in the depth of the coil. Melt with blow drier until

coil is warm to the touch. Soak up water with a towel.

Observe ice formation pattern. If only part way up the coil face,

unit could be low on refrigerant. If all the way up, the coil may be

dirty or airow is blocked.

Solution

Make sure the unit is plugged into an outlet

Turn unit on by pressing the power button on the control

Check line voltage to make sure there is 110v/120v

Lower set point

Lower set point

See page 14 for correct switch position

Call Customer Service at 800-343-9463

Solution

Intake temperature needs to drop below 110°.

Order correct size unit

Remove air ow obstruction

Re-Locate unit so the distance from the ceiling and top of the

unit is no more than 18”

One or more of the fans is not turning on.

Compressor is not turning on.

Compressor keeps cycling on overload

Poor seal around door.

Controller set too high

Evaporator coil is frosted or iced up

Page 40

Call Customer Service at 800-343-9463

Call Customer Service at 800-343-9463

Make sure all fans are working and there are no airow obstruction.

Make sure there are no air gaps around the door. If door seal is

damaged, replace it.

Lower the set point.

Observe ice formation pattern. If only part way up the coil face,

unit could be low on refrigerant. If so, call Customer Service at

800-343-9463

EXti 110111

Page 43

TROUBLESHOOTING GUIDE

Unit leaks water

Possible Cause

Unit is not level

Drain line clogged or kinked

Drain is clogged preventing water form escaping

Drain line does not have a downward slope

Coil is iced causing drain pan ice and water overowing

Unit runs but does not cool

Possible Cause

Lack of air ow

Compressor not running

Unit undersized

Compressor is overheating

Solution

Unit should be level in wall to prevent leaking

Check drain line to make sure water can ow freely.

Disconnect drain and clear out, open access door and

check drain for blockage

Fix Drain line so there is a downward slope from the unit to the drain.

Melt ice with blow drier. Soak up with a towel

Solution

Make sure fan is unobstructed; clean evaporator if necessary

Call Customer Service at 800-343-9463

Call Customer Service at 800-343-9463

Shut unit o for 1 hour to allow compressor to cool. Turn

back on and check for cooler air ow out. If compressor

runs, check for and clean condenser coil as possible cause

of compressor overheating. If problem repeats, call customer service.

Evaporator fan runs but compressor does not

Possible Cause

Running an Anti-Frost Cycle

Compressor and/or starting components faulty

Unit may be performing the WHM function

Compressor may have overheated.

Compressor runs but evaporator fan does not

Possible Cause

Faulty fan motor

Faulty Controller

Compressor short cycles

Possible Cause

Evaporator blows on bottle probe

Unit low on refrigerant charge

Condensing fan motor/capacitor faulty

Compressor and /or starting components faulty

Solution

Check evaporator coil temp.

Call Customer Service at 800-343-9463.

Allow cooling unit to revert back to cooling mode.

Shut unit o for 1 hour to allow compressor to cool. Turn

back on and check for cooler air ow out. If compressor

runs, check for and clean condenser coil as possible cause

of compressor overheating. If problem repeats, call customer service.

Solution

Call Customer Service at 800-343-9463

Call Customer Service at 800-343-9463

Solution

Move bottle probe to a more central location.

Call Customer Service at 800-343-9463

Call Customer Service at 800-343-9463

Call Customer Service at 800-343-9463

Humidity in cellar too low

Possible Cause

Not enough moisture

Solution

Raise the Fon setting to increase the humidity level

Page 41

Page 44

TECHNICAL ASSISTANCE

WhisperKOOL Customer Service is available Monday through Friday from 8:00 a.m. to 4:00 p.m. Pacic Time.

The customer service representative will be able to assist you with your questions and warranty information more

eectively if you provide them with the following:

• The model and serial number of your WhisperKOOL Series Unit.

• Location of unit and installation details, such as ventilation, ducting, construction of your wine cellar, and

room size.

Contact WhisperKOOL Customer Service

1738 E. Alpine Avenue

Stockton, CA 95205

www.whisperkool.com

Email: support@whisperkool.com

Phone: (209) 466-9463

US Toll Free (800) 343-9463

Fax (209) 466-4606

ACCESSORIES FOR COOLING UNITS

WhisperKOOL offers accessories to enhance and customize your Extreme wine cooling unit.

Exterior Grille

Protects the systems from the weather elements when placed on the exhaust side.

• Small Exterior Grille (used for Extreme 5000ti & 5000tiR)

• Large Exterior Grille (used for Extreme 8000ti & 8000tiR)

Condensate Pump Kit

The condensate pump kit is designed as an automatic condensate removal pump for water dripping out of our cooling

units’ drain line. The pump is controlled by a float/switch mechanism that turns the pump on when approximately

2-1/4” of water collects in the tank, and automatically switches off when the tank drains to approximately 1-1/4”. The

condensate pump kit allows the excess condensate to be pumped up to 20ft away from the unit.

Extreme Ducting Plenum

This plenum allows either side of the unit to be ducted. Duct the cold air through a vent into the cellar, duct the hot

exhaust air out of the home. This plenum allows for total installation flexibility.

Accessories can be purchased at www.whisperkool.com

Page 42

EXti 110111

Page 45

INSTALLATION TERMS AND CONDITIONS

WhisperKOOL Cooling System

WHISPERKOOL PRODUCT BASE TERMS

WhisperKOOL Corporation (“WhisperKOOL”) is in the business of manufacturing and selling wine cabinets, cooling units and

related goods; each such wine cabinet, cooling unit and related good is referred to herein as a “Product”. As used herein, the

term “WhisperKOOL” includes any Product sold under the names WhisperKOOL, Vinotheque and CellarCool. “Purchaser” means

the original purchaser of a WhisperKOOL Product. “End User” means the consumer who has installed and is actually using a

WhisperKOOL Product. Every sale of a Product from WhisperKOOL to a Purchaser is made subject to these Terms and Conditions

of Sale (“Terms and Conditions”).

Product prices are specied in the WhisperKOOL published price list that is current at the time WhisperKOOL receives

Purchaser’s particular order. Prices are subject to change at any time prior to WhisperKOOL’s acceptance of Purchaser’s particular

order. No contract of sale exists until WhisperKOOL has accepted Purchaser’s order and provided Purchaser with a written

acknowledgment of Purchaser’s order. Prices are exclusive of, and Purchaser shall pay, all taxes, duties, levies or fees imposed

on WhisperKOOL or Purchaser by any taxing authority related to Purchaser’s order. Payment for a WhisperKOOL Product must

be made in lawful money of the United States of America in immediately available funds. WhisperKOOL accepts all major credit

cards. WhisperKOOL may change payment terms for unlled orders if, in WhisperKOOL’s reasonable opinion, Purchaser’s nancial

condition, previous payment record or relationship with WhisperKOOL merits such change.

All Purchaser orders, whether written or verbal, are governed by these Terms and Conditions and are subject to acceptance

by WhisperKOOL. Any term or condition which may be included on any Purchaser’s purchase order, or in any form of

communication (whether verbal or in writing) from any Purchaser to WhisperKOOL, that is not identical with these Terms

and Conditions, is hereby expressly objected to and rejected by WhisperKOOL, and shall NOT become a part of the contract

of sale of any Product. WhisperKOOL’s failure to object to any such conicting term and/or condition of sale contained in

any communication (including a purchase order) from a Purchaser shall not be considered as acceptance of such term and/

or condition or as a waiver of these Terms and Conditions. The only language in which WhisperKOOL states these Terms and

Conditions is English. WhisperKOOL reserves the right, in its sole discretion, to change these Terms and Conditions at any time,