Page 1

AIR ENGINEERED

OPERATING AND INSTALLATION INSTRUCTIONS

FOR WHISPAIR RANGEHOODS

UTILISING REMOTE FAN MOTOR UNITS

Page 2

Page 3

CONGRATULATIONS

Congratulations and thank you for choosing a

Whispair rangehood.

To avoid the risks that are always present when you

use an electrical appliance it is important that the

rangehood is installed correctly and that you read

the safety instructions carefully to avoid misuse and

hazards.

We recommend that you keep this instruction

booklet for future reference and pass it on to any

future owners.

IMPORTANT INFORMATION

ENVIRONMENTAL TIP

Information on disposal for users

Most of the packing materials are recyclable. Please

dispose of those materials through your local

recycling depot or by placing them in a appropriate

collection bin.

If you wish to discard this product, please contact your

local authorities and ask for the correct method of

disposal.

AFTER UNPACKING THE RANGEHOOD

PLEASE REVIEW YOUR NEW ITEM TO ENSURE

THAT IT HASN’T BEEN DAMAGED IN TRANSIT

OR IS MISSING ANY COMPONENTS. FAILURE

TO REPORT ANY ISSUE WITHIN 72 HOURS OF

RECEIPT OF YOUR ITEM MAY RESULT IN

ADDITIONAL CHARGES.

TO AVOID THE RISK OF INJURY OR

DAMAGE TO THE PRODUCT IT IS

ESSENTIAL TO READ THESE

INSTRUCTIONS PRIOR TO

INSTALLATION AND USE

1

Page 4

PRODUCT DESCRIPTION & CARTON CONTENTS

CARTON 1 - HOOD UNIT

You will be supplied with one of the four hood unit options detailed below.

OPTION 1 - INTEGRATED HOOD

MODELS INCLUDED:

X3M06S5, X3M09S5, X3M12S5, X3MD09S5, X3MD12S5 and X3W12S5

INCLUDED IN THE CARTON:

1. Main hood housing including switch control and led lighting

2. Bafe lters

3. Grease trap

4. Cabinet installation screws

5. Operating & installation guide

OPTION 2 - WALL HUNG CANOPY HOOD

MODELS INCLUDED:

X5L09S5, X5S09S5, X5V09S5, X5R09S5, X5R09W5, X5M10S5, X5V12S5, X5N12S5 and X5N15S5

INCLUDED IN THE CARTON:

1. Main hood housing including switch control and led lighting

2. Bafe lters

3. Grease trap

4. Stainless steel chimney (2x)

5. Chimney bracket

6. Wall mounting bracket

7. Fixing screws

8. Operating & installation guide

OPTION 3 - ISLAND HUNG CANOPY HOOD

MODELS INCLUDED:

7C12S5, X7P04B5, X7P04W5, X7S09S5, X7V09S5, X7R09S5 and

X

X7N12S5 INCLUDED IN THE CARTON:

1. Main hood housing including switch control and led lighting

2. Bafe lters

3. Grease trap

4. Stainless steel chimney (1x)

5. Ceiling (island) mounting plate

6. Mounting Beams (2x)

7. Threaded rod (4x) and nuts

8. Fixing screws

9. Operating & installation guide

2

Page 5

OPTION 4 - CEILING MOUNT CASSETTE AND UNIVERSAL HUNG HOOD

MODELS INCLUDED:

X9C12S5

, X9B12S5, X9B15S5 and X5C10S5

INCLUDED IN THE CARTON:

1. Main hood housing including switch control and led lighting

2. Bafe lters

3. Grease trap

4. Mounting Beams (2x)

5. Threaded rod (4x) and nuts

6. Fixing screws

7. Operating & installation guide

3

Page 6

PRODUCT DESCRIPTION & CARTON CONTENTS

CARTON 2 - FAN MOTOR UNIT

You will be supplied with one of the two fan motor unit options detailed below.

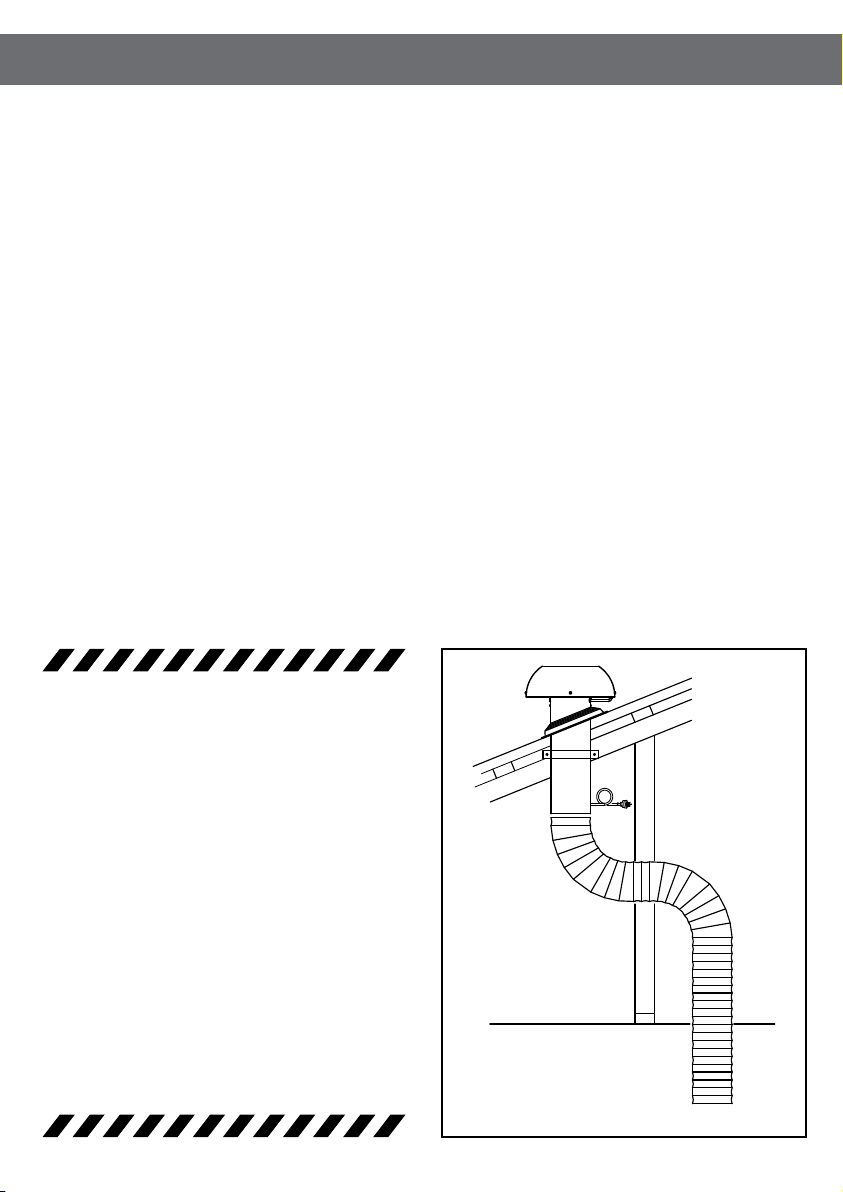

OPTION 1 - INLINE FAN SOLUTION (FIG. A)

MODELS INCLUDED:

IL-800 and IP-1140

Unit designed to be located in a roof space and then

ducted to an external vent to the outside atmosphere.

INCLUDED IN THE CARTON:

1. KLEENAIR Inline fan motor unit

2. Mounting bracket

3. Mounting screws for vent and fan motor unit

4. Pipe Clamps - 200mm (4x)

5. 200mm Flexi-duct (5 meters in length)

6. Aluminium powder coated wall / eave vent

7. Foam liner for wall / eave installation

OPTION 2 - EXTERNAL FAN SOLUTION (FIG. B)

MODELS INCLUDED:

EL-800, EP-1140 and EPP-2010.

Unit designed to be mounted externally either on an

external wall vertically mounted or penetrating through

the roof horizontally mounted.

Fig. A

INCLUDED IN THE CARTON:

1. KLEENAIR External fan motor unit

Pipe Clamps - 200mm (2x)

2.

3. 200mm Flexi-duct (5 meters in length)

4. Mounting screws for wall installation

5. Foam liner for wall installation

OPTIONAL INSTALLATION ACCESSORIES:

1. HBX200TILE - 200mm Tile Roof Install Kit

Includes roof ashing for tile roof, 200mm duct mounting

brackets (2x), threaded rod (2x) and nuts (4x).

2.

HBX200MET

Includes roof ashing for metal roof, 200mm duct mounting

brackets (2x), threaded rod (2x) and nuts (4x).

HBX200DUCT

3.

Includes 200mm Flexi-duct (5 meters length), 200mm inner

connector and pipe clamps (2x).

- 200mm Metal Roof Install Kit

- 200mm Duct Extension Kit

Fig. B

4

Page 7

CONDITIONS OF USE AND MAINTENANCE

This rangehood is a domestic appliance which has been manufactured and tested to comply with Australian and New Zealand

Standard AS/NZS 60335.2.31 and is designed to work under Australian and New Zealand conditions. The hoods are designed

to remove bi-products of cooking – heat, steam, grease and odour.

This appliance is intended for domestic application only. Any other usage is at the owner’s risk and could be dangerous. The

manufacturer cannot be held liable for damage resulting from incorrect or improper use or operation. This unit is approved for

electrical safety (Please refer RCM E4759).

WHISPAIR reserves the right to change the specication without notice.

All WHISPAIR performance gures are based upon standards developed by the Haus Group, which either comply or are in excess

of the government regulated standards.

SAFETY

WARNING: The installation of WHISPAIR rangehoods must comply with the information in this guide. Failure to

install the rangehood in accordance with these installation instructions may result in electrical hazards, injury,

damage to your appliance and loss of warranty. Specically, failure by the installer to install the screws or xing

devices in accordance with these installation instructions may result in electrical hazards. Please install the

appliance as detailed in these instructions.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

There shall be adequate ventilation of the room when the range hood is used at the same time as appliances

burning gas or other fuels (not applicable to appliances that only discharge the air back into the room).

Exhausted air must not be discharged into a chimney or ue which may carry combustion products from other

sources.

There is a re risk if cleaning is not carried out in accordance with the instructions.

Bafe lters and grease trap must be regularly cleaned to reduce the risk of re.

CAUTION: Accessible parts may become hot when used with cooking appliances and stainless steel baffle filter

edge's can be sharp when handling and cleaning.

Ensure the rangehood is switched off and power source cable unplugged before carrying out maintenance, to

avoid any possibility of electric shock.

Always use non-ammable materials to minimize the risk of re.

Do not ambé under the range hood.

Always cover lit gas burners with pots or pans when cooker hood is in use.

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualied

persons in order to avoid a hazard.

Please ensure the hood is securely xed to the support as detailed in this guide. The method of xing stated is

not to depend on the use of adhesives as they are not a means of reliable xing.

The height of the underside of the hood body must be a minimum of 600mm above an electric cooktop, for a

gas cooktop a minimum of 600mm above the highest part of the highest burner and a minimum height of

1200mm above BBQ cookers. If the instructions of the hob specify a greater distance than the minimum

detailed, this shall be the minimum height for installation.

5

Page 8

DUCTING AND EXTRACTION LEVELS

WHISPAIR ducting is designed to ensure optimum performance for your rangehood. Please follow the installation instructions

carefully.

Every WHISPAIR rangehood must be ducted to the Inline or Externally mounted KLEENAIR fan motor unit by the use of

non-ammable ducting. The rangehood must not be ducted into a wall cavity or a ceiling space where a build-up of grease can

occur and become a potential re risk. Ensure the external outlet on the KLEENAIR unit is not covered and the air ow is not

restricted in any way as this may result in reduced performance.

The duct must at all times have a cross sectional surface area equivalent to the hood outlet. The hood outlet has a circular cross

section of 200mm in diameter or an approximate area of 31,400mm. Do not reduce the duct size at any time and avoid sharp

bends. If the duct run is longer than six (6) metres, it may be necessary to enlarge the duct size to ensure optimum performance.

The manufacturer does not guarantee performance when the duct length is greater than six (6) metres.

Ensure that all ducting is correctly tted and sealed with pipe clips, duct tape or silicone to ensure that fumes do not escape prior

to reaching the KLEENAIR fan motor unit.

The WHISPAIR extraction calculations are based upon a 50pa change of head of pressure loss and are used to factor the variance

of air ow resistance through the ducting. 50pa is equivalent to approximately four (4) metres (the recommended length) of exi

ducting with one gentle bend, which is above and beyond the industry standard of one straight metre of ducting. The KLEENAIR

LITE offers a powerful 800 cubic metres per hour (223 litres per second) of air movement. The KLEENAIR PRO offers 1140 cubic

metres per hour (317 litres per second) whilst for serious users the KLEENAIR PRO PLUS boasts a market leading 2010 cubic

metres per hour (558 litres per second).

THE RECOMMENDED DUCT

LENGTH (INSTALLATION DISTANCE)

IS 4 METRES.

THE MINIMUM INSTALLATION

DISTANCE IS 3.5 METRES.

GENTLE BENDS IN THE DUCTING

ARE RECOMMENDED AS IT ASSISTS

IN MUFFLING NOISE FROM THE

REMOTE FAN UNIT.

Gentle Bend

In Ducting

To Rangehood Unit

6

Page 9

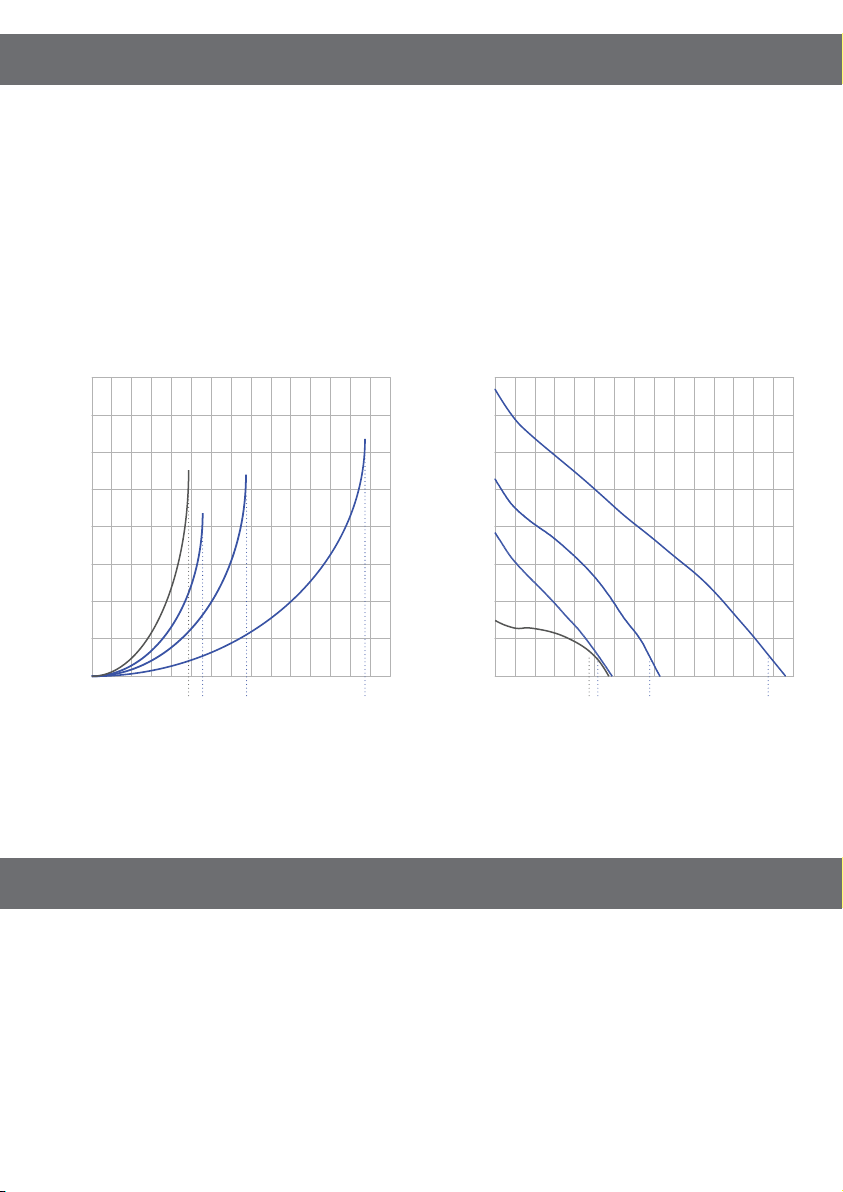

NOISE LEVELS & EXTRACTION LEVELS

All KLEENAIR fan motor unit operates at maximum external sound pressure level between 43dB(A) and 76dB(A). The internal

operation of the systems will have a varying sound level dependent on the style of hood, the motor option selected, the acoustics

of the environment and the installation method used. It was established through testing, in accordance with the Australian

Standards, that the internal noise level varied between 33dB(A) and 65dB(A) on the air movement settings available.

It is important to understand that whilst WHISPAIR rangehoods offer quieter operational noise levels due to the positioning of the

motor remotely to the primary cooking environment, the noise levels as a consequence of air movement or ‘wind’ noise are

equivalent to other premium hoods in the Australian and New Zealand market place, although it must be noted that the extraction

levels are signicantly higher.

Extraction Level versus Noise Level

[dB]

70

60

50

40

30

Sound Pressure Level

20

10

0

A.700 B.800 C.1140 D.2010

Cubic Meters / Hour of Air Movement

A. Standard premium rangehood found in the Aus/NZ market offering 700 m/hr

B. KleenAir Lite Unit offering 800 m/hr

C. KleenAir Pro Unit offering 1140 m/hr

D. KleenAir Pro Plus Unit offering 2010 m/hr

SERVICING

Extraction Level Comparison

[Pa]

700

600

500

400

300

Change in Pressure

200

100

[m/hr]600 1200 1800

0

A.700 B.800 C.1140 D.2010

Cubic Meters / Hour of Air Movement

[m/hr]600 1200 1800

The installation and tting of the rangehood should be done in such a way that will allow the unit to be removed if service is

required. Additional costs incurred in the removal, such as damage to walls, are not covered under warranty.

It is expected that the stainless steel is cleaned with a quality non-abrasive stainless steel cleaner. The bafe lters and grease

trap are removable and dishwasher safe. It is recommended that these items be cleaned regularly.

The KLEENAIR unit should be checked regularly to ensure that nothing is obstructing the air ow from the housing.

7

Page 10

PART 1: HOOD INSTALLATION GUIDE

Integrated Hood

Models included: X3M06S5, X3M09S5, X3M12S5,

DIMENSIONS ARE ACCURATE AT THE TIME OF PRINTING, HAUS GROUP RESERVES THE RIGHT TO

CHANGE SPECIFICATIONS WITHOUT NOTICE. FOR BUILDING PURPOSES THE UNIT SHOULD BE

PROVIDED TO THE CABINET MAKER / BUILDER / KITCHEN DESIGNER FOR EXACT MEASUREMENTS.

X3MD09S5, X3MD12S5 and X3W12S5

WARNING

STEP 1:

To install into your overhead cupboard, several holes may need to be cut into

shelves to enable the ducting to exit the cabinetry. Ensure the hood is mounted

as close to the centre of the cooking surface as possible.

NOTE:

The height of the underside of the hood body must be a minimum of 600mm

above an electric cooktop, for a gas cooktop a minimum of 600mm above the

highest part of the highest burner and a maximum height of 1000mm. If the

instructions of the hob specify a greater distance than the minimum detailed,

this shall be the minimum height for installation.

A comfortable installation height would be 700 – 750mm gap between the

base of the rangehood and the highest part on your cooktop.

For installation over a BBQ, the hood must be installed a minimum of

1200mm above the cooking surface. Building codes that stipulate a

minimum dimension may vary from state to state, please check with your

local council prior to installation.

STEP 2:

Refer to Part 2: Motor Installation Guide.

STEP 3:

Remove the three (3) screw xings from within the Main Chassis of the

rangehood located along the rear chassis wall (located above the grease trap),

along with two (2) screws on the left side and two (2) screws on the right side.

Once the screws are removed, the Fascia will separate away from the Main

Chassis.

Outlet

Fascia

Step 3: Remove Fascia from Chassis

Bafe Filters Grease Trap

Fixing Holes

Main Chassis

STEP 4:

Fixing Holes are located on the returns of the main chassis. These Fixing Holes

are used to secure the main chassis to the cabinetry.

STEP 5:

Place the Main Chassis in the cabinet ensuring that the hood is level and the

controls and display will be visible when standing in front of the unit.

8

Step 4: Locate the Fixing Holes of the Main Chassis

Page 11

PART 1: HOOD INSTALLATION GUIDE

STEP 6:

Using the ten (10) xing holes, screw the Main Chassis into position.

STEP 7:

Once the Main Chassis is secured into the cabinetry, the Fascia can then be slid

back inside the Main Chassis. Replace the screws (removed in Step 3) to x the

Fascia back into positon.

STEP 8:

Attach the male power plug of the rangehood unit to mains power supply. Note to

electricians: Standard 10 Amp General Power Outlet (GPO) required. Position GPO

as close to the hood unit as possible.

Step 7: Insert Fascia into Main Chassis

INSTALLING THE GREASE TRAP AND BAFFLE FILTERS:

Top Ledge

Bafe Filter Grease Trap

All WHISPAIR hoods utilise removable bafe lters and grease trap. This ltration

system is used to catch by-products such as grease and moisture from the air ow.

To install the bafe lters, simply locate the lter on the top ledge of the hood and

then slide the lter on a downward angle to rest in the channel of the grease trap.

Ensure the lter vane are aligned towards the rear of the hood.

Front Rear

Bafe Filter and Grease Trap Position

Most by-products are captured and stored directly in the bafe lters however the grease trap may begin to ll when excess amounts of

grease and condensate build up in the lter vanes.

The grease trap can be removed for cleaning by removing the two (2) screw xings in the channel.

To clean your bafe lters and grease trap please wash with warm soapy water or simply place in the dishwasher for convenience. Please

note, baffle filter edge's can be sharp and caution must be taken when removing and when cleaning by hand.

It is recommended the bafe lters and grease trap are cleaned every 4 weeks to reduce the risk of re.

9

Page 12

PART 1: HOOD INSTALLATION GUIDE

Wall Hung Canopy Hood

Models included: X5L09S5, X5S09S5, X5V09S5, X5V12S5,

DIMENSIONS ARE ACCURATE AT THE TIME OF PRINTING, HAUS GROUP RESERVES THE RIGHT TO

CHANGE SPECIFICATIONS WITHOUT NOTICE. FOR BUILDING PURPOSES THE UNIT SHOULD BE

PROVIDED TO THE CABINET MAKER / BUILDER / KITCHEN DESIGNER FOR EXACT MEASUREMENTS.

STEP 1:

Measure the height (H1) of the hood from the base to the top of the Mounting

Hooks. Ensure the hood is mounted as close to the centre of the cooking surface

as possible.

NOTE:

The height (H2) of the underside of the hood body must be a minimum of

600mm above an electric cooktop, for a gas cooktop a minimum of 600mm

above the highest part of the highest burner and a maximum height of

1000mm. If the instructions of the hob specify a greater distance than the

minimum detailed, this shall be the minimum height for installation.

A comfortable installation height would be 700 – 750mm gap between the

base of the rangehood and the highest part on your cooktop.

For installation over a BBQ, the hood must be installed a minimum of 1200mm

above the cooking surface. Building codes that stipulate a minimum dimension

may vary from state to state, please check with your local council prior to

installation.

X5R09S5, X5R09W5, X5M10S5 and X5N12S5

WARNING

2

3

H1

1

H2

5

4

STEP 2:

Using a spirit level mark a vertical centre line on the wall where the Mounting

Bracket needs to be positioned. It is recommended to centre the hood unit to the

cooktop below.

STEP 3:

Mark a horizontal line on the wall for the Mounting Bracket position. Centre and

mark the four (4) xing points in the vertical section on the left and right side of

the bracket. Drill and plug holes with suitable sized wall plugs (not provided).

STEP 4:

Fix the Mounting Bracket with four (4) suitable screws into the wall at the

positions marked in step 3 to allow the body of the hood to be hung on the wall.

STEP 5:

Hang the hood on the wall ensuring the Mounting Hooks are securely positioned

into the Mounting Bracket.

10

Wall Mounting Bracket

Hood Fixing Holes (5x) - Step 6

Wall Fixing Holes (4x) - Step 4

Page 13

PART 1: HOOD INSTALLATION GUIDE

STEP 6:

Secure the hood to the wall by screw xing through the ve (5x) holes on the

Chimney Bracket Chimney Fixing Points

horizontal plate of the Mounting Bracket.

STEP 7:

Secure the Chimney Bracket to the wall.

STEP 8:

Refer to Part 2: Motor Installation Guide.

STEP 9:

Place the stainless steel chimney on the hood and secure to the Chimney Bracket

with the two (2) screws supplied. If the chimney is required to be shortened, new

holes may need to be drilled to secure the chimney cover.

Step 9: Chimney Installation

STEP 10:

Attach the male power plug of the rangehood unit to mains power supply. Note to

electricians: Standard 10 Amp General Power Outlet (GPO) required. Position GPO

as close to the hood unit as possible.

INSTALLING THE GREASE TRAP AND BAFFLE FILTERS:

Top Ledge

All WHISPAIR hoods utilise removable bafe lters and grease trap. This ltration

system is used to catch by-products such as grease and moisture from the air ow.

Bafe Filter Grease Trap

To install the bafe lters, simply locate the lter on the top ledge of the hood and

then slide the lter on a downward angle to rest in the channel of the grease trap.

Ensure the lter vane are aligned towards the rear of the hood.

Front Rear

Bafe Filter and Grease Trap Position

Most by-products are captured and stored directly in the bafe lters however the grease trap may begin to ll when excess amounts of

grease and condensate build up in the lter vanes.

The grease trap can be removed for cleaning by removing the two (2) screw xings in the channel.

To clean your bafe lters and grease trap please wash with warm soapy water or simply place in the dishwasher for convenience. Please

note, baffle filter edge's can be sharp and caution must be taken when removing and when cleaning by hand.

It is recommended the bafe lters and grease trap are cleaned every 4 weeks to reduce the risk of re.

11

Page 14

PART 1: HOOD INSTALLATION GUIDE

Island Hung Canopy Hood

Models included: X7C12S5, X7P04B5, X7P04W5, X7S09S5, X7V09S5, X7R09S5, X7R09W5 and X7N12S5

WARNING

DIMENSIONS ARE ACCURATE AT THE TIME OF PRINTING, HAUS GROUP RESERVES THE RIGHT TO

CHANGE SPECIFICATIONS WITHOUT NOTICE. FOR BUILDING PURPOSES THE UNIT SHOULD BE

PROVIDED TO THE CABINET MAKER / BUILDER / KITCHEN DESIGNER FOR EXACT MEASUREMENTS.

STEP 1:

Using a weighted string line (plumb line), determine the central position of

hood on the ceiling. Ensure the

hood is mounted as close to the centre of

the cooking surface as possible. Mark the position. Before making the cut

out, check for obstructions like electrical cables, etc.

NOTE:

The height of the underside of the hood body must be a minimum of 600mm

above an electric cooktop, for a gas cooktop a minimum of 600mm above the

highest part of the highest burner and a maximum height of 1000mm. If the

instructions of the hob specify a greater distance than the minimum detailed,

this shall be the minimum height for installation.

A comfortable installation height would be 700 – 750mm gap between the

base of the rangehood and the highest part on your cooktop.

300mm

For installation over a BBQ, the hood must be installed a minimum of 1200mm

above the cooking surface. Building codes that stipulate a minimum dimension

may vary from state to state, please check with your local council prior to

installation.

STEP 2:

Place the two (2) supplied supporting metal beams (1000mm long) with

pre-drilled xing holes perpendicular (90) to the roof trusses.

STEP 3:

Fit the four (4) supplied 10mm threaded rod through the holes provided on the

supporting metal beams and secure with nuts and washers provided. Ensure

the rod drop height is sufcient to attach the hood and nut xings but is not

excessive that is will impede the placement of the lters.

STEP 4:

Feed the Ceiling Plate up the threaded rod and x into position with nuts

provided ensure a rm t to the ceiling.

STEP 5 (OPTIONAL):

For additional stability add a second Ceiling Plate (optional) half way between the

ceiling and the hood. This will give the mounting additional stability which may

be benecial for longer chimney runs.

12

Supporting Metal Beams

Ceiling Plate

Threaded Rod

Step 4

Page 15

PART 1: HOOD INSTALLATION GUIDE

STEP 6:

Refer to Part 2: Motor Installation Guide.

STEP 7:

Lift the stainless steel chimney into position and secure to the Ceiling Bracket with

the four (4) screws supplied. If the chimney is required to be shortened, new holes

may need to be drilled to secure the chimney cover.

STEP 8:

Attach the exi-ducting to the top of the hood unit and x into place with a stainless

steel clamp (provided).

STEP 9:

Lift and attach the hood unit to the base of the threaded rod with the provided nuts

and washers. Level the unit off by tensioning the 10mm nuts. Being mindful not to

over tighten.

Minimise how much threaded rod is below the nut. Excess

threaded rod may interfer with the bafe lters.

STEP 10:

Feed any excess exi-ducting back into the ceiling space ensuring that any excess

gathering of ducting is pulled tight. Loose and gathered ducting will reduce the

extraction levels.

STEP 11:

Attach the male power plug of the rangehood unit to mains power supply. Note to

electricians: Standard 10 Amp General Power Outlet (GPO) required. Position GPO

as close to the hood unit as possible.

Hood Mounting Points

INSTALLING THE GREASE TRAP AND BAFFLE FILTERS:

Top Ledge

All WHISPAIR hoods utilise removable bafe lters and grease trap. This ltration

system is used to catch by-products such as grease and moisture from the air ow.

Lift Chimney

Into Position

(Step 7)

Lift Hood

Into Position

(Step 9)

Bafe Filter Grease Trap

To install the bafe lters, simply locate the lter on the top ledge of the hood and

then slide the lter on a downward angle to rest in the channel of the grease trap.

Ensure the lter vane are aligned towards the rear of the hood.

Front Rear

Bafe Filter and Grease Trap Position

Most by-products are captured and stored directly in the bafe lters however the grease trap may begin to ll when excess amounts of

grease and condensate build up in the lter vanes.

The grease trap can be removed for cleaning by removing the two (2) screw xings in the channel.

To clean your bafe lters and grease trap please wash with warm soapy water or simply place in the dishwasher for convenience. Please

note, baffle filter edge's can be sharp and caution must be taken when removing and when cleaning by hand.

It is recommended the bafe lters and grease trap are cleaned every 4 weeks to reduce the risk of re.

13

Page 16

PART 1: HOOD INSTALLATION GUIDE

Ceiling Mounted Cassette and Universal Hung Hood

Models included: X9C12S5, X9B12S5, X9B15S5 and X5C10S5

WARNING

DIMENSIONS ARE ACCURATE AT THE TIME OF PRINTING, HAUS GROUP RESERVES THE RIGHT TO

CHANGE SPECIFICATIONS WITHOUT NOTICE. FOR BUILDING PURPOSES THE UNIT SHOULD BE

PROVIDED TO THE CABINET MAKER / BUILDER / KITCHEN DESIGNER FOR EXACT MEASUREMENTS.

STEP 1:

Using a weighted string line (plumb line), determine the central position of

hood on the ceiling. Ensure the

the cooking surface as possible. Mark the position. Before making the cut

out, check for obstructions like electrical cables, etc.

NOTE:

The height of the underside of the hood body must be a minimum of

600mm above an electric cooktop, for a gas cooktop a minimum of 600mm

above the highest part of the highest burner. If you are installing a BBQ Alfresco

specific model above a BBQ it must be installed at a minimum 1200mm above

the BBQ cooking surface. The maximum recommended height for a

cassette unit is 1500mm above the cooktop. If the instructions of the hob

specify a greater distance than the minimum detailed, this shall be the minimum

height for installation.

Building codes that stipulate a minimum dimension may vary from state to state,

please check with your local council prior to installation.

hood is mounted as close to the centre of

Supporting Metal Beams

STEP 2:

Place the two (2) supplied supporting metal beams (500mm long) with

pre-drilled xing holes perpendicular (90) to the roof trusses.

STEP 3:

Fit the four (4) supplied 10mm threaded rod through the holes provided on the

supporting metal beams and secure with nuts and washers provided. Ensure

the rod drop height is sufcient to attach the hood and nut xings but is not

excessive that is will impede the placement of the lters.

STEP 4:

Refer to Part 2: Motor Installation Guide.

STEP 5:

Attach the exi-ducting to the top of the hood unit and x into place with a pipe

clamp (provided).

14

Threaded Rod

Page 17

PART 1: HOOD INSTALLATION GUIDE

STEP 6:

Lift and attach the hood unit to the base of the threaded rod with the provided nuts

and washers. Secure the hood cassette rmly to the underside of the ceiling. Level

the unit off by tensioning the 10mm nuts. Being mindful not to over tighten.

Minimise how much threaded rod is below the nut. Excess threaded rod may

interfer with the bafe lters.

STEP 7:

Feed any excess exi-ducting back into the ceiling space ensuring that any excess

gathering of ducting is pulled tight. Loose and gathered ducting will reduce the

extraction levels.

STEP 8:

Attach the male power plug of the rangehood unit to mains power supply. Note to

electricians: Standard 10 Amp General Power Outlet (GPO) required. Position GPO

as close to the hood unit as possible.

Lift Hood

Into Position

INSTALLING THE GREASE TRAP AND BAFFLE FILTERS:

Top Ledge

Bafe Filter Grease Trap

All WHISPAIR hoods utilise removable bafe lters and grease trap. This ltration

system is used to catch by-products such as grease and moisture from the air ow.

To install the bafe lters, simply locate the lter on the top ledge of the hood and

then slide the lter on a downward angle to rest in the channel of the grease trap.

Ensure the lter vane are aligned towards the rear of the hood.

Front Rear

Bafe Filter and Grease Trap Position

Most by-products are captured and stored directly in the bafe lters however the grease trap may begin to ll when excess amounts of

grease and condensate build up in the lter vanes.

The grease trap can be removed for cleaning by removing the two (2) screw xings in the channel.

To clean your bafe lters and grease trap please wash with warm soapy water or simply place in the dishwasher for convenience. Please

note, baffle filter edge's can be sharp and caution must be taken when removing and when cleaning by hand.

It is recommended the bafe lters and grease trap are cleaned every 4 weeks to reduce the risk of re.

15

Page 18

PART 2: FAN MOTOR INSTALLTION GUIDE

EXTERNAL KLEENAIR

MOTOR SOLUTION

Roof (Upper) and

Wall (Lower) Mounted

108

702

60

Roof

Flashing to suit

Metal or Tile Roof

(Optional Accessory)

Housing Mounts

(Optional Accessory)

Fan Power Supply

Attached to Internal Hood Unit

Ducting Pulled Tight

Gentle Bend In Ducting

440

185

17

200mm Ducting

Attached to Internal

Hood Unit Outlet

Wall

Fan Power Supply

Attached to Internal Hood Unit

Gentle Bend In Ducting

Ducting Pulled Tight

200

Attached to Internal Hood Unit Outlet

200mm Ducting

INLINE KLEENAIR

MOTOR SOLUTION

Eave (Upper) and

Wall (Lower) Vented

159

Roof

Ducting Pulled Tight

Attached to Internal Hood Unit Outlet

200mm Ducting

Gentle Bend In Ducting

Fan Power Supply

Attached to Internal Hood Unit

Vent & Eave

390

200

Fan Power Supply

Attached to Internal Hood Unit

363.5

30

Gentle Bend In Ducting

Wall

Ducting Pulled Tight

12

70

314

143.5 125

16

200mm Ducting

Attached to Internal

Hood Unit Outlet

Vent

Page 19

PART 2: FAN MOTOR INSTALLTION GUIDE

Inline Solution

Models included: IL-800 and IP-1140

Positioning your KLEENAIR Unit:

It is recommended that the KLEENAIR INLINE unit be mounted

OutletMounting Bracket

in a roof space or wall cavity. Please ensure that the KLEENAIR

unit is positioned in an environment that is free of other gases

to enable an efcient expulsion of the cooking by-products

and to ensure that back draft of external gases doesn’t take

place.

Please ensure the fan motor is positioned away from other

exhausts such as chimneys, gas ues, etc. The inline unit can

be mounted so that it ducts directly through the wall or eave

vent.

STEP 1:

Establish a suitable position in the roof or wall cavity for the

KLEENAIR unit, ensuring that the distance between the

KLEENAIR unit and the outside vent is no greater than

Inlet

800mm. The KLEENAIR unit must be located a minimum

of 3 metres from the hood unit.

STEP 2:

Using the mounting bracket and screws, mount the KLEENAIR unit to a beam, truss or another appropriate structures in the roof

or wall space through the rubber grommets. Hang the fan motor unit from the mounting bracket ensuring the mounting bracket

is located at the top of the unit. Ensure the direction of airow is toward the outside. The direction of airow is marked on the

KLEENAIR unit.

STEP 3:

Cut a 200mm diameter hole in the wall or eave to enable the mounting of the external vent. Please ensure that the hole is cut in

a practical position to enable the exi-duct to be secured. Attach the exi-duct to the vent and then mount vent to the wall or

eave.

STEP 4:

Attach the exi-duct from the external vent to the outlet of the KLEENAIR unit using pipe clamps. To minimise inefciencies and

noise ensure the duct is pulled tight and the 200mm diameter is maintained.

STEP 5:

Attach exi-duct from the KLEENAIR unit to the rangehood using pipe clamps. Ensure that the duct is pulled tightly to ensure that

exi-duct remains rm and stable during operation. Avoid sharp bends in the duct.

recommended as it assists in mufing noise from the fan motor unit back to the rangehood

Gentle bends in the ducting are

. If the exi-duct needs to be

extended attach two exi-duct ends using a rigid duct insert and secured by pipe clamps (Optional installation accessories

HBX200DUCT).

STEP 6:

Attach the male plug of the KLEENAIR unit to the female plug of the rangehood to enable power supply to the fan motor unit. An

extension lead (not supplied) of up to ve meters may be added if required.

17

Page 20

PART 2: FAN MOTOR INSTALLTION GUIDE

External Solution - Wall Mounted

Models included: EL-800, EP-1140 and EPP-2010

Positioning your KLEENAIR Unit:

It is recommended that when the KLEENAIR EXTERNAL UNIT is

WALL mounted, it is positioned a minimum 1800mm above

the ground surface with a downward clearance of 1200mm

and with a radial clearance of 600mm. Please ensure that the

KLEENAIR unit is positioned in an environment that is free of

other gases to enable an efcient expulsion of the cooking

bi-products and to ensure that back-draft of external gases

doesn’t take place.

Please ensure the fan motor is positioned away from other

exhausts such as chimneys, gas fuses, etc. The unit can be

mounted so that it ducts directly through the wall.

STEP 1:

Cut a 200mm diameter hole in the wall to enable the rigid duct

on the back of the KLEENAIR unit to protrude. Please ensure

that the hole is cut in a practical position to enable sufcient

clearance around the fan motor unit.

STEP 2:

Remove the mounting bracket from your KLEENAIR unit by

twisting the cover in an anti-clockwise direction. Mark at least

four mounting points on the wall and pre-drill the holes

required.

Inlet

Cover

Outlet

Mounting Holes

Secondary Wall

Mounting Bracket (Optional)

STEP 3:

The rigid duct may require cutting to suit your particular wall

thickness. Attach the exi-duct to the rigid duct on the back of

the mounting bracket using the pipe clamps supplied.

STEP 4:

Fix the mounting bracket to the wall using the screws and wall

plugs provided. Making sure to secure it at 90 degree’s to the

horizontal. A secondary mounting bracket (HBXP24) is

available is additional clearance between the wall and outlet is

Primary Wall

Mounting Bracket (Supplied)

Locking Screw

required.

STEP 5:

Feed the power cable through the centre of the mounting bracket and return the KLEENAIR unit onto the mounting bracket and

x it by rotating the cover in a clockwise direction noting the locating points. Lock the cover into position by tightening the locking

screw.

STEP 6:

Attach the male plug of the KLEENAIR unit to the female plug of the rangehood to enable power supply to the fan motor unit. An

extension lead (not supplied) of up to ve meters may be added if required.

18

Page 21

PART 2: FAN MOTOR INSTALLTION GUIDE

External Solution - Roof Mounted

Models included: EL.800, EP

Positioning your KLEENAIR Unit:

It is recommended that when the KLEENAIR EXTERNAL UNIT is ROOF

mounted, it is positioned a minimum 2100mm above the ground surface

with a radial clearance of 600mm. Please ensure that the KLEENAIR unit is

positioned in an environment that is free of other gases to enable an efcient

expulsion of the cooking by-products and to ensure that back-draft of

external gases doesn’t take place.

Please ensure the fan motor is positioned away from other exhausts such as

chimneys, gas fuses, etc. The unit can be mounted so that it ducts directly

through the roof and is mounted below the highest point of the roof line.

STEP 1:

Cut a 200mm diameter hole in the roof to enable the rigid duct on the base

of the KLEENAIR unit to protrude down into the roof space. Please ensure

that the hole is cut in a practical position to enable sufcient clearance

around the fan motor unit. Afx the ashing (optional accessory

X1IK.200TILE or X1IK.200MET) to the roof surface. Please ensure that

the ashing is sealed thoroughly onto the rigid duct with silicone to prevent

water leaks.

STEP 2:

Using standard 200mm pipe mounts (optional accessory), mount the rigid

duct to beams, trusses or other appropriate structures in the roof space.

Ensure the rigid duct protrudes past the top of the ashing by at least 75mm.

.1140 and EPP.2010

Outlet

Mounting

Bracket

Rigid Duct

Inlet

STEP 3:

Remove the mounting bracket from your KLEENAIR unit by rotating the cover

in an anti-clockwise direction.

min 75mm,

max 150mm,

STEP 4:

Fix the mounting bracket to the rigid duct using the screws provided.

STEP 5:

Feed the power cable through the centre of the mounting bracket and return the KLEENAIR unit on to the mounting bracket and

x it by rotating the cover in a clockwise direction. Lock the cover into position by tightening the locking screw, which is located

between the outlet and the mounting bracket.

STEP 6:

Attach the exi-duct to the rigid duct using the pipe clamps supplied.

STEP 7:

Attach

exi-duct from the KLEENAIR unit to the rangehood using pipe clamps. Ensure that the duct is pulled tightly to ensure that

exi-duct remains rm and stable during operation. Avoid sharp bends in the duct. Gentle bends in the ducting are recommended

as it assists in mufing noise from the fan unit back to the rangehood. If the exi-duct needs to be extended, attach the two

exi-duct ends using a rigid duct insert, secured by pipe clamps or duct tape. (Optional Accessory - X1IK.200DUCT)

STEP 8:

Attach the male plug of the KLEENAIR unit to the female plug of the rangehood to enable power supply to the fan motor unit. An

extension lead (not supplied) of up to ve meters may be added if required.

19

Page 22

OPERATION

Operating your 4-button control panel

Models included: Electronic Control or Touch Control

TURNING THE EXTRACTION FUNCTION ON OR OFF:

• In standby mode, press button 2 or 3 to change the speed.

• The hood has three speed options and a 4th boost speed (4 spe

• The LED indicators directly above the buttons indicates the s

• To turn hood off, press button 2 repeatedly until hood return

peed setting selected.

s to standby mode.

eds in total).

• Auto off function: After 2 hour of operation without alterati

TURNING THE LIGHT FUNCTION ON OR OFF:

Press button 1 to turn on or turn off the light independently in standby mode.

TURNING THE TIMER FUNCTION ON OR OFF:

In operating mode, press button 4 to engage the timer function, then press button 2 or 3 to adjust the delay time.

The default timer is set to 10mins and can be increased in increments of 10mins up to 1 hour (i.e. 4 pushes of button 3 will result

in timer set to 50mins before shut off).

When the timer is rst activated, the LED positioned behind button 4 (timer) will ash quickly to indicate the time setting i.e. for

30mins remaining the LED will blink 3 times quickly. When the timer function is engaged the (timer) LED positioned behind button

4 (timer) will blink slowly until the timer expires.

on the fan motor will turn off (returned to standby).

1 2 3 4

20

Page 23

PRODUCT CARE

It is recommended that your WHISPAIR rangehood and all of its items be cleaned regularly.

Before any cleaning or maintenance work, disconnect the cooker hood from the mains power supply.

CLEANING THE STAINLESS STEEL HOOD UNIT

• It is expected that the stainless steel is cleaned with a quality non-abrasive stainless steel cleaner.

• Use a soft cloth for application.

• It is recommended that this is performed every 4 weeks.

CLEANING THE KLEENAIR FAN MOTOR UNIT

• The KLEENAIR unit should be checked regularly to ensure tha

• If there are obstructions, please remove the debris ensurin

condition.

CLEANING THE BAFFLE FILTERS AND GREASE TRAP

• The bafe lters and grease trap can be removed from the mounted position within the hood and washed in the dishwasher

or by hand.

• Use hot water and liquid detergent.

• After cleaning, leave the lters and trap to dry before pla

WARNING WHEN CHANGING THE LED LAMP

Please be aware that whilst in use LED lighting units may become hot and the surrounding area may remain hot for some time

after switching off. Please allow the lamp area to cool before operating near the lighting.

t nothing is obstructing the air ow from the housing.

g the product returns to the manufacturer’s intended operating

cing back in the hood.

REPLACEMENT OF LED LAMP

•

Make sure the main power supply into hood is disconnected at the GPO.

• Using a ne at blade, wedge the LED unit from the insert whilst applying pressure to the locking tab.

Disconnect the 12V connectors.

•

•

Replace with a new unit and push back inside the cut outs in the fascia.

Please replace only with a genuine unit available from Haus Group Australia Pty Ltd.

•

21

Page 24

WARRANTY

Every WHISPAIR rangehood comes with a 5-Year parts and labour warranty. This warranty is conditional upon the appliance

being used only for personal, domestic and household purposes and installed and operated in accordance with WHISPAIR

instructions.

The consumer is responsible for any charges associated with removal of the faulty unit and installation of the new unit.

The customer may also be responsible for any freight charges incurred in this change over process.

The installation of WHISPAIR rangehoods must comply with the information in the guide. Installation of the rangehood must be in

a covered area, to avoid direct weathering. Failure to follow the guidelines will result in loss of warranty.

We recommend our customers use an authorised WHISPAIR installer.

Any imperfections in the nishes or in the natural materials used should not be considered as faults but a typical characteristic

of these crafted products.

Should you ever need to make a warranty related enquiry about your WHISPAIR product, in Australia simply call Haus Group

Australia on +61 (0) 3 8593 9600 or New Zealand on +64 (0) 9 887 6959 to speak with our friendly customer service team

consultants. We suggest you have the following information close at hand to make the process as easy as possible:

1. Model number of your complete rangehood and motor unit

2. A copy of your WHISPAIR proforma invoice

3. Address details of where the appliance has been installed

Any associated or ancillary costs to be incurred by you as a result of replacement or repair of your WHISPAIR rangehood under

this guarantee shall, in all cases, be previously approved by Haus Group Australia Pty Ltd.

Please note: The benets provided under this warranty are additional to other rights and remedies available to the customer

under the Australian Customer Law.

YOUR STATUTORY RIGHTS

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement

or a refund for a major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled

to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major

failure.

22

Page 25

NOTES

23

Page 26

NOTES

24

Page 27

Page 28

Print Version: W_16_S5_01

Haus Group Australia Pty Ltd

CARRUM DOWNS Victoria Australia 3201

t. (AU) 03 8593 9600 f. (AU) 03 8593 9699

t. (NZ) 09 887 6959 f. (NZ) 09 887 6958

e. info@hausgroup.com.au

w. www.hausgroup.com.au

e. info@hausgroup.co.nz

w. www.hausgroup.co.nz

head office.

2/2 Network Drive

Australia.

New Zealand.

Loading...

Loading...