Whirlpool WFE500M4HS, YWFE50M4HS Installation Instructions

INSTALLATION INSTRUCTIONS 24" (61.0 CM)

FREESTANDING ELECTRIC RANGES

INSTRUCTIONS D’INSTALLATION

POURCUISINIÈRES ÉLECTRIQUES

AUTOPORTANTES DE 24PO(61,0CM)

Table of Contents / Table des matières

RANGE SAFETY .............................................................................2

INSTALLATION REQUIREMENTS .................................................3

Tools and Parts .............................................................................3

Location Requirements ................................................................3

Electrical Requirements ...............................................................5

INSTALLATION INSTRUCTIONS ...................................................7

Unpack Range..............................................................................7

Backguard Assembly ...................................................................7

Install Anti-Tip Bracket .................................................................8

Electrical Connection - U.S.A. Only .............................................9

Verify Anti-Tip Bracket Is Installed

and Engaged ..............................................................................13

Level Range ................................................................................14

Storage Drawer ..........................................................................14

Complete Installation .................................................................14

Moving the Range ......................................................................15

SÉCURITÉ DE LA CUISINIÈRE ...................................................16

EXIGENCES D’INSTALLATION ...................................................17

Outils et pièces ...........................................................................17

Exigences d’emplacement .........................................................17

Spécications électriques ..........................................................19

INSTRUCTIONS D’INSTALLATION .............................................21

Déballage de la cuisinière ..........................................................21

Dosseret .....................................................................................21

Bride antibasculement ...............................................................22

Raccordement électrique – É.-U. seulement .............................23

Vérier que la bride antibasculement est bien installée et en-

gagée ..........................................................................................27

Réglage de l’aplomb de la cuisinière .........................................28

Tiroir de remisage .......................................................................28

Terminer l’installation .................................................................. 28

Déplacement de la cuisinière .....................................................29

IMPORTANT:

Save for local electrical inspector’s use.

IMPORTANT :

Conserver ces instructions à l’usage de l’inspecteur des installations électriques local.

W11169656B

RANGE SAFETY

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

Range Foot

Anti-Tip

Bracket

To verify the anti-tip bracket is installed and engaged:

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

• Slide range back so rear range foot is under anti-tip bracket.

• See installation instructions for details.

2

INSTALLATION REQUIREMENTS

A

B

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

■ Tape measure

■ Flat-blade screwdriver

■ Phillips screwdriver

■ Level

■ Hammer

■ Hand or electric drill

■ Wrench or pliers

■ Marker or pencil

■ Masking tape

■ 3/8" (1 cm) and 5/16" (7.9 mm) nut driver

■ 1/8" (3.2 mm) drill bit (for wood oors)

Parts Supplied

Check that all parts are included.

C

A. Anti-tip bracket

B. #12 x 1" screws (2)

C. Plastic Anchors (2)

■ Anti-tip bracket must be securely mounted to oor or wall.

Thickness of ooring may require longer screws to anchor

bracket to oor.

Parts needed

If using a power supply cord kit:

■ A UL listed power supply cord kit marked for use with

ranges. The cord should be rated at 250 V minimum, 40A

or 50 A that is marked for use with nominal 1³⁄8" (3.5 cm)

diameter connection opening and must end in ring terminals

or open-end spade terminals with upturned ends.

■ A UL listed strain relief.

Check local codes. Check existing electrical supply. See

“Electrical Requirements” section.

It is recommended that all electrical connections be made

by a licensed, qualied electrical installer.

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

■ It is the installer’s responsibility to comply with the installation

clearances specied in this installation instructions. The

model/serial/rating plate is located under the storage drawer.

See the installation instructions on instructions on how to

remove the storage drawer.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

■ The anti-tip bracket must be installed. To install the anti-tip

bracket shipped with the range, see “Install Anti-Tip Bracket”

section.

■ Grounded electrical supply is required. See “Electrical

Requirements” section.

IMPORTANT: To avoid damage to your cabinets, check with your

builder or cabinet supplier to make sure that the materials used

will not discolor, delaminate or sustain other damage. This oven

has been designed in accordance with the requirements of UL

and CSA International and complies with the maximum allowable

wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280). When such standard is

not applicable, use the Standard for Manufactured Home

Installations, ANSI A225.1/NFPA 501A or with local codes.

In Canada, the installation of this range must conform with

the current standards CAN/CSA-Z240-latest edition, or with local

codes.

Mobile home installations require:

■ When this range is installed in a mobile home, it must be

secured according to the instructions in this document.

■ Four-wire power supply cord or cable must be used in a

mobile home installation. The appliance wiring will need to be

revised. See “Electrical Connection - U.S.A. Only” section.

3

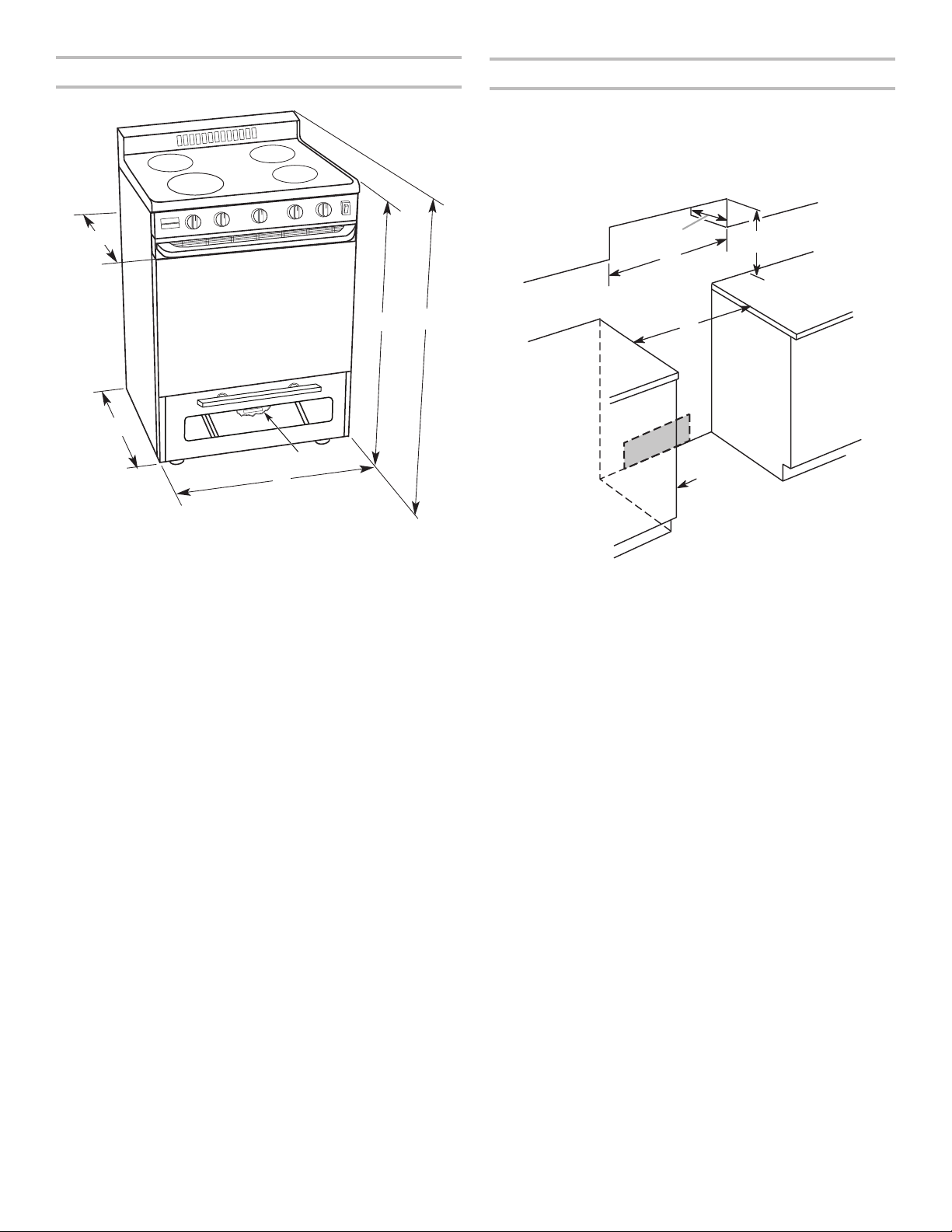

Product Dimensions

SURFACE

A

OVEN

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth and

36" (91.4 cm) countertop height.

A freestanding range may be installed next to combustible walls

with zero clearance.

A

B

B

C

D

C

XX

E

F

D

A. 28" (71.1 cm) maximum depth with handle

B. 377/8" (96.2 cm) overall height (maximum) with leveling legs

screwed all the way in*

C. 36" (91.4 cm) cooktop height (maximum) with leveling legs

screwed all the way in*

D. 24" (60.9 cm) width

E. 253/8" (64.4 cm) depth - back of range to front of cooktop**

F. Model/serial/rating plate is located under the storage drawer

IMPORTANT: Range must be level after installation. Follow the

instructions in the “Level Range” section. Using the cooktop as

a reference for leveling the range is not recommended.

*Range can be raised approximately 3/4" (1.9 cm) by adjusting

the leveling legs.

**Front of door and drawer may extend further forward

depending on styling.

E

F

A. 13" (33.0 cm) maximum upper cabinet depth

B. 24" (61.0 cm) minimum opening width

C. For minimum clearance to top of cooktop, see NOTE*

D. 243/16" (61.5 cm) minimum opening width

E. Outlet - 3" (7.6 cm) from either cabinet, 8" (20.3 cm)

maximum from oor.

F. Cabinet door or hinges should not extend into the cutout.

*NOTE: 24" (61.0 cm) minimum when bottom of wood or

metal cabinet is covered by not less than 1/4" (0.64 cm) ame

retardant millboard covered with not less than No. 28 MSG

sheet steel, 0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm)

aluminum or 0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking

platform and the bottom of an uncovered wood or metal cabinet.

4

Electrical Requirements

Electrical Requirements - U.S.A. Only

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrical installer determine that

the ground path and wire gauge are in accordance with local

codes.

Do not use an extension cord.

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code, ANSI/

NFPA 70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualied electrician or service technician if you are in doubt as to

whether the appliance is properly grounded. Do not modify the

power supply cord plug. If it will not t the outlet, have a proper

outlet installed by a qualied electrician.

Electrical Connection

To properly install your range, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

■ Range must be connected to the proper electrical voltage

and frequency as specied on the model/serial rating

plate. The model/serial rating plate is located under the

storage drawer. See the installation instructions on how to

remove the storage drawer. Refer to the gures in “Product

Dimensions” in the “Location Requirements” section.

■ This range is manufactured with the neutral terminal

connected to the cabinet. Use a 3-wire, UL listed, 40 or 50A

power supply cord (pigtail) (see the following Range Rating

chart). If local codes do not permit ground through the

neutral, use a 4-wire power supply cord rated at 250 V, 40 or

50 A and investigated for use with ranges.

Specied Rating of

Range Rating*

Power Supply Cord Kit

and Circuit Protection

120/240 V 120/208 V A

8.8 - 16.5 kW

16.6 - 22.5 kW

7.8 - 12.5 kW

12.6 - 18.5 kW

40 or 50**

50

*The NEC calculated load is less than the total connected

load listed on the model/serial rating plate.

**If connecting to a 50 A circuit, use a 50 A rated cord with

kit. For 50 A rated cord kits, use kits that specify use with

a nominal 1³⁄8" (34.9 mm) diameter connection opening.

■ A circuit breaker is recommended.

■ The range can be connected directly to the circuit breaker

box (or fused disconnect) through exible or nonmetallic

sheathed, copper or aluminum cable. See the “Electrical

Connection - U.S.A. Only” section.

■ Allow 2 to 3 ft (61.0 cm to 91.4 cm) of slack in the line so that

the range can be moved if servicing is ever necessary.

■ A UL listed conduit connector must be provided at each end

of the power supply cable (at the range and at the junction

box).

■ Wire sizes and connections must conform with the rating of

the range.

■ The wiring diagram is located on the back of the range.

If connecting to a 4-wire system:

This range is manufactured with the ground connected to the

neutral by a link. The ground must be revised so the green

ground wire of the 4-wire power supply cord is connected to the

cabinet. See “Electrical Connection - U.S.A. Only” section.

Grounding through the neutral conductor is prohibited for new

branch-circuit installations (1996 NEC); mobile homes; and

recreational vehicles, or an area where local codes prohibit

grounding through the neutral conductor.

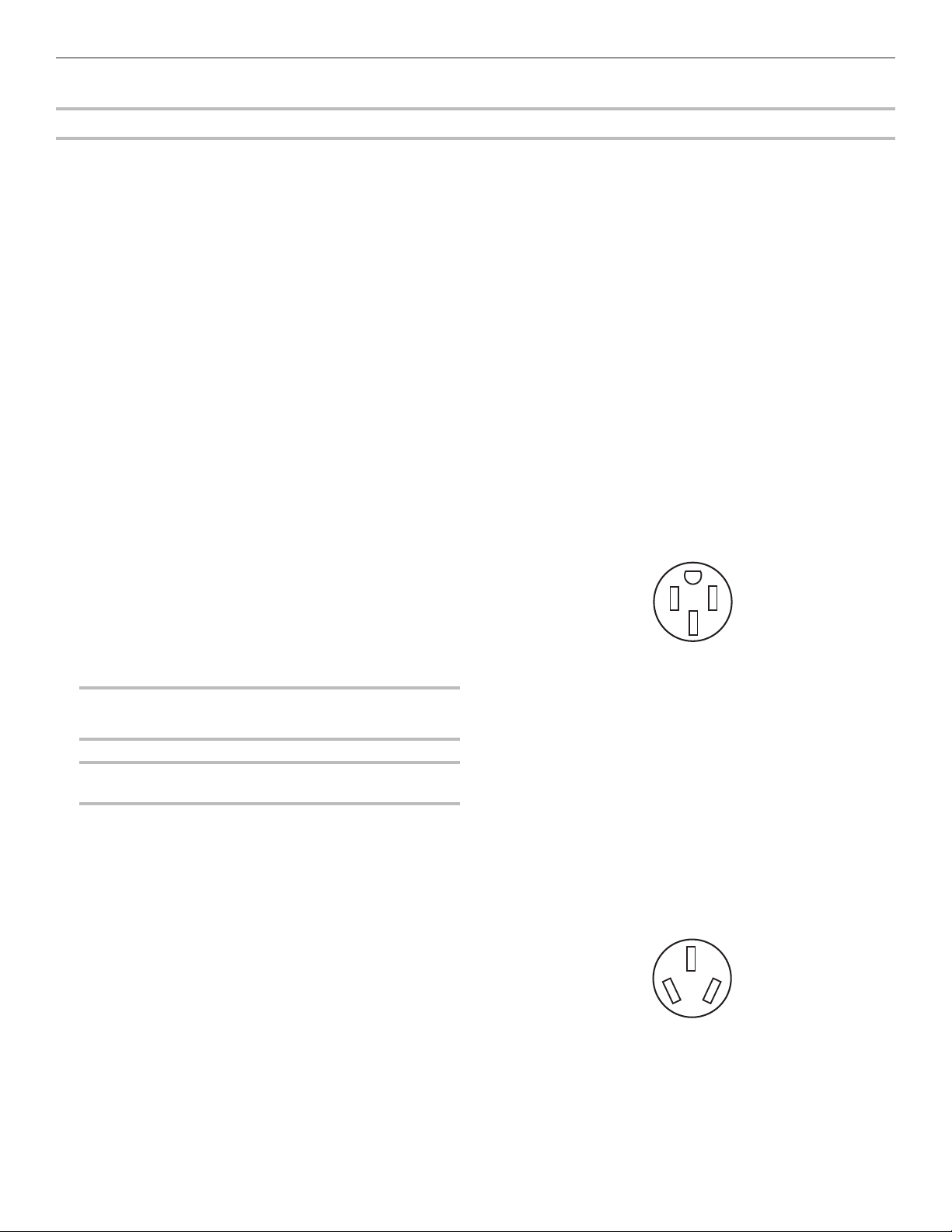

When a 4-wire receptacle of NEMA Type 14-50R is used, a

matching UL listed, 4-wire, 250 V, 40 or 50 A, range power

supply cord (pigtail) must be used. This cord contains 4 copper

conductors with ring terminals or open-end spade terminals with

upturned ends, terminating in a NEMA Type 14-50P plug on the

supply end.

The fourth (grounding) conductor must be identied by a green

or green/yellow cover and the neutral conductor by a white

cover. Cord should be Type SRD or SRDT with a UL listed strain

relief and be at least 4 ft (1.22 m) long.

4-wire receptacle (14-50R)

The minimum conductor sized for the copper 4-wire power cord

are:

40 A circuit

2 No.-8 conductors

1 No.-10 white neutral

1 No.-8 green grounding

If connecting to a 3-wire system:

Local codes may permit the use of a UL listed, 3-wire, 250 V, 40

or 50 A range power supply cord (pigtail). This cord contains

3copper conductors with ring terminals or open-end spade

terminals with upturned ends, terminating in a NEMA Type

10-50P plug on the supply end. Connectors on the appliance

end must be provided at the point the power supply cord enters

the appliance. This uses a 3-wire receptacle of NEMA Type

10-50R.

3-wire receptacle (10-50R)

5

WARNING

Electrical Requirements - Canada Only

■ Check with a qualied electrical installer if you are not sure

the range is properly grounded.

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrical installer determine that

the ground path is adequate and wire gauge are in accordance

with local codes.

Be sure that the electrical connection and wire size are adequate

and in conformance with CSA Standard C22.1, Canadian

Electrical Code, Part 1 - latest edition, and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

Range Rating*

120/240 V 120/208 V A

8.8 - 16.5 kW

16.6 - 22.5 kW

*The NEC calculated load is less than the total connected load

listed on the model/serial/rating plate.

**If connecting to a 50 A circuit, use a 50 A rated cord with kit.

For 50 A rated cord kits, use kits that specify use with a nominal

13/8" (34.9 mm) diameter connection opening.

■ A time-delay fuse or circuit breaker is recommended.

■ This range is equipped with a CSA International Certied

Power Cord intended to be plugged into a standard 14-50R

wall receptacle. Be sure the wall receptacle is within reach of

range’s nal location.

■ Do not use an extension cord.

7.8 - 12.5 kW

12.6 - 18.5 kW

Specied Rating of

Power Supply Cord Kit

and Circuit Protection

40 or 50**

50

6

INSTALLATION INSTRUCTIONS

A

B

Unpack Range

WARNING

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Remove shipping materials, tape and lm from range.

2. Remove oven racks and parts package from inside oven and

on top of range.

3. Do not remove the shipping base at this time.

A. Shipping base

Remove the storage drawer. See the “Storage Drawer”

section. Use a wrench or pliers to lower front leveling legs

one-half turn.

Backguard Assembly

Tools Required:

Phillips Screwdriver

1. Lower Backguard down while guiding the Backguard slots

down between the range top and the locking nuts.

2. Use the two assembly screws to attach the back corners of

the Backguard to the side panels.

Parts Supplied:

(2) Assembly Screws# lOA x

1/2 Phillips Pan Hd Screw

A

B

C

B

A

A. Wrench or pliers

B. Front leveling leg

A. Backguard slot

B. Assembly screw

C. Locking nut

7

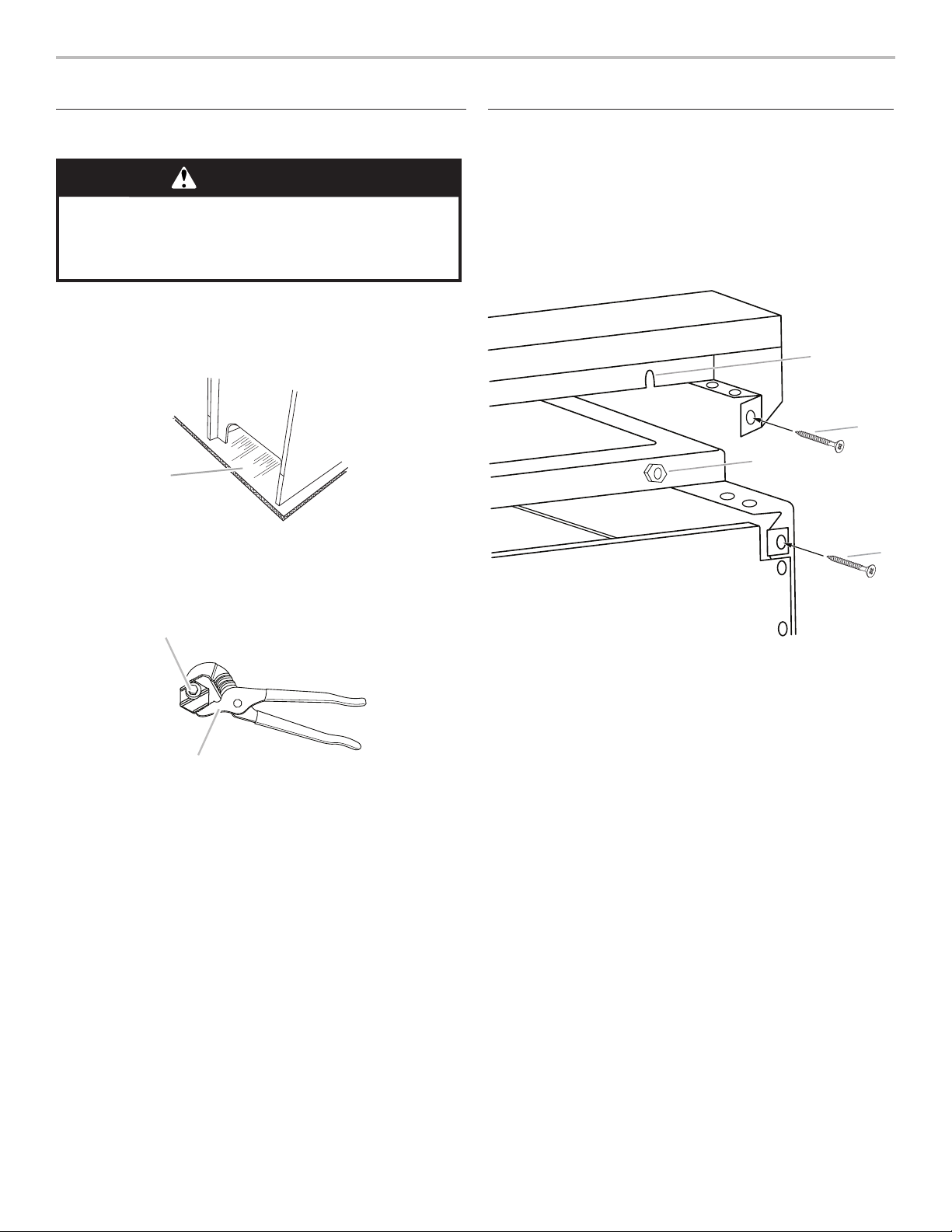

Install Anti-Tip Bracket

WARNING

Edge A

3. It is necessary to determine the nal location of the range

before you can locate the anti-tip bracket. If the range is

going to be located between cabinets, place the bracket so

that Edge A sits at against the rear wall. Edge B should just

touch the side of the cabinet sitting to the right side of the

range.

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Remove the anti-tip bracket from inside the literature bag

assembly located in the oven.

2. Determine which mounting method to use: oor or wall.

If you have a stone or masonry oor, you can use the wall

mounting method. If you are installing the range in a mobile

home, you must secure the range to the oor.

Location C

If there are no adjacent cabinets, align Edge B of the bracket

with the edge of the range side. After the bracket has been

placed mark the hole locations with a marker.

4. The anti-tip bracket can be attached to the oor or the wall.

For wall mount application use Location C. When using

location C, the screws must penetrate the wall sill plate

located within the wall. For oor mount application use

Location D or E. One screw on each side of the bracket is

sufcient.

5. To mount anchor bracket to concrete or ceramic oor, use a

drill with a 3/16" masonry bit to drill the two holes. Tap plastic

anchor into mounting holes in oor with hammer. Line up

holes in anti-tip bracket to holes in oor. Use the two screws

provided to fasten anti-tip bracket to oor.

6. Unscrew the rear leg levelers approximately 1/2" so that the

rear leg levelers will slide in under the anti-tip bracket. Slide

range into the nal position after completing the gas and

electrical connections to the range.

Anti-Tip Bracket

Location C

Edge B

Location D

Location E

8

B

A

A

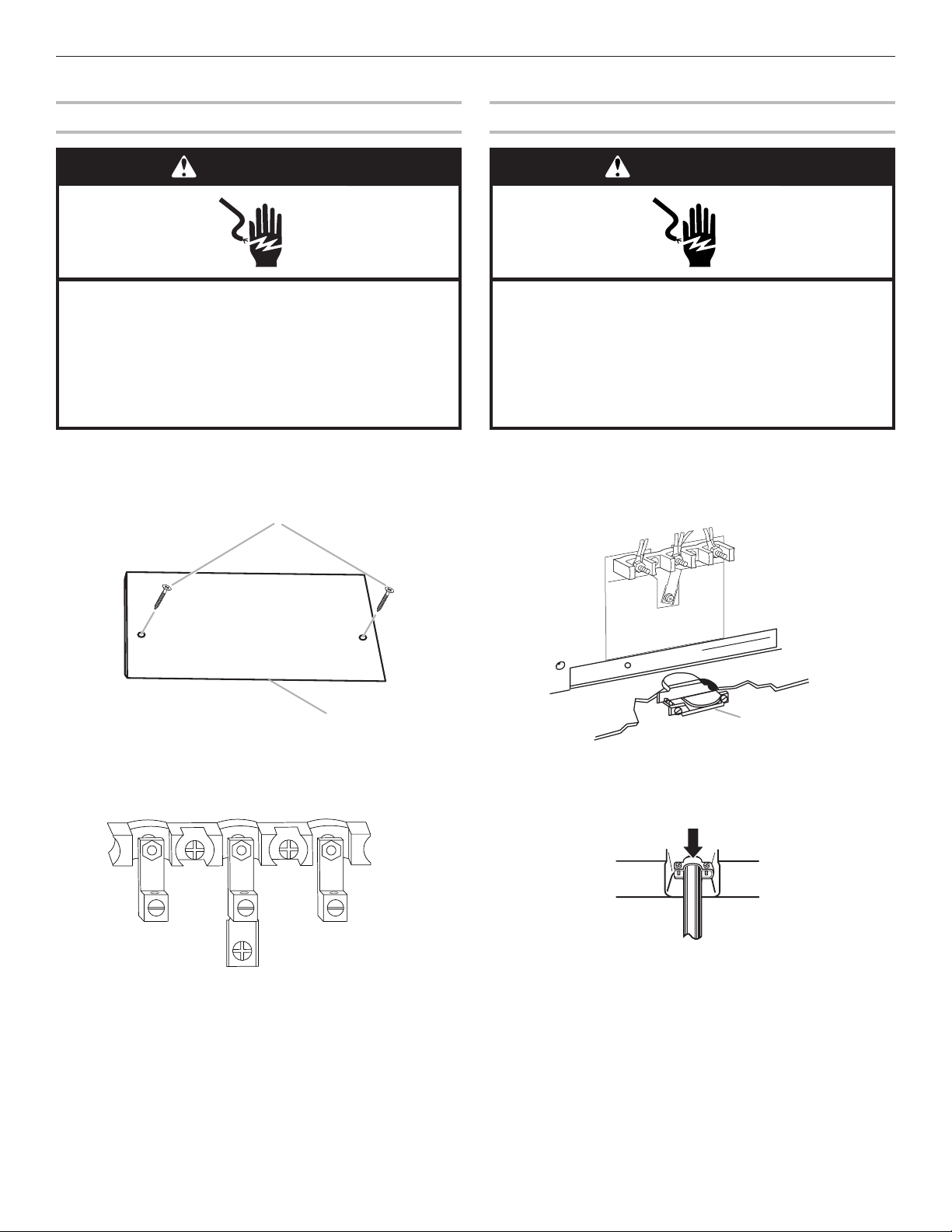

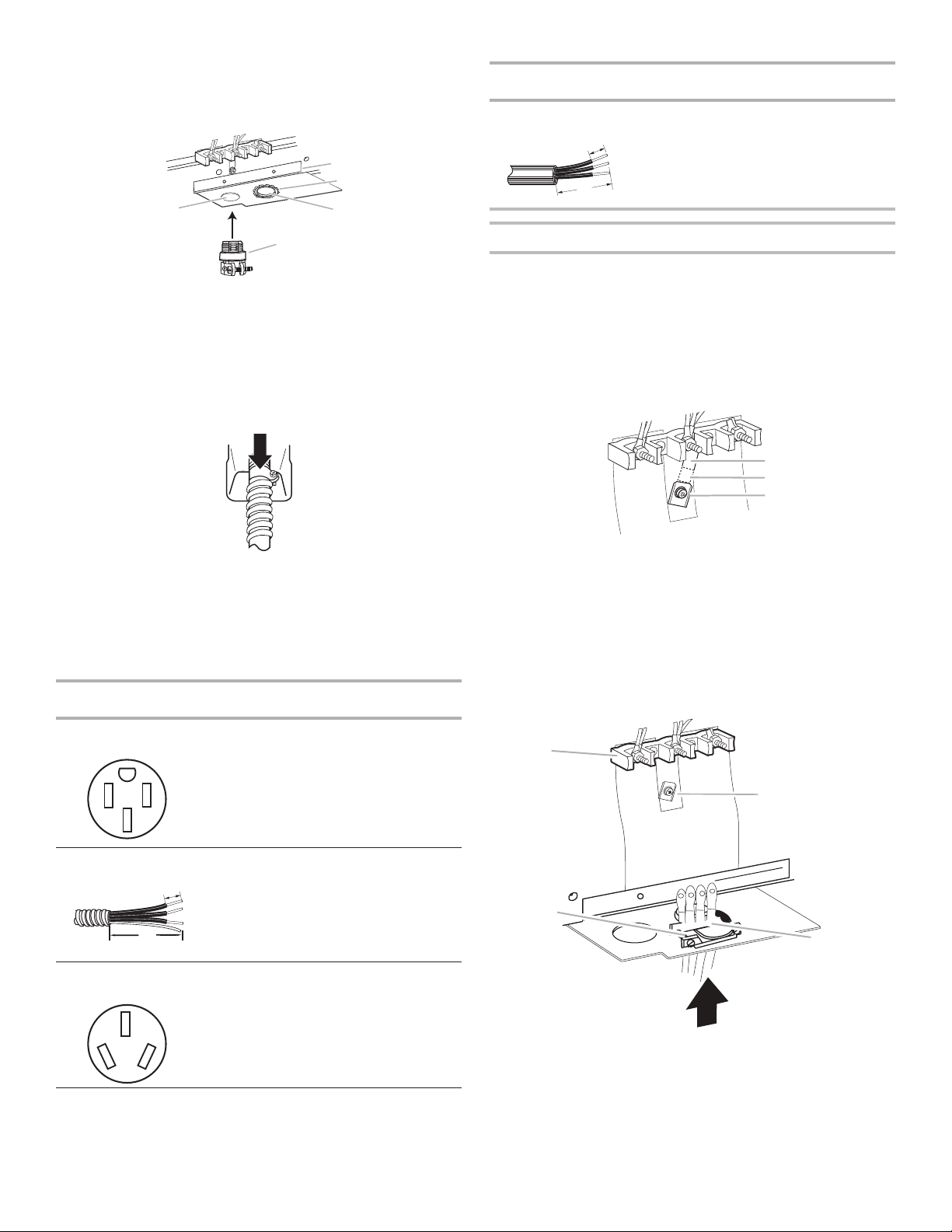

Electrical Connection - U.S.A. Only

WARNING

Power Supply Cord

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Use a new 40 A power supply cord.

Plug into a grounded outlet.

Failure to follow these instructions can result in death,

fire, or electrical shock.

1. Disconnect power.

2. Remove the terminal block cover screws located on the back

of the range.

Direct Wire

Electrical Shock Hazard

Disconnect power before servicing.

Use 8 gauge copper or 6 gauge aluminum wire.

Electrically ground range.

Failure to follow these instructions can result in death,

fire, or electrical shock.

3. Add strain relie f.

Style 1: Power supply cord strain relief

■ Assemble a UL listed strain relief in the opening that is

centered beneath the conduit bracket.

A. Terminal block cover

B. Phillips screws (2)

Remove the top 10-31 hex nut and lugs from each of the 3

terminal blocks and set aside.

A. UL listed strain relief

■ Tighten strain relief screw against the power supply cord.

9

Style 2: Direct wire strain relief

A

D

(7.6 cm)

A

C

A

■ When direct wiring, relocate the conduit bracket so the left

hole is centered beneath the terminal block.

■ Assemble a UL listed conduit connector in the opening.

C

E

If your home has: And you will be

connecting to:

3-wire direct A circuit breaker

3/8"

(1.0 cm)

3"

box or fused

disconnect

Go to Section:

3-wire connection:

Direct wire

B

A. Removable retaining nut

B. Conduit

C. Conduit bracket

D. Direct wire strain relief

E. Power cord strain relief

NOTE : When direct wiring, use the hole on the left.

■ Tighten strain relief screw against the exible conduit.

4. Complete installation following instructions for your type of

electrical connection:

■ 4-wire (recommended)

■ 3-wire (if 4-wire is not available)

Electrical Connection Options

If your home has: And you will be

Go to Section:

connecting to:

4-wire receptacle

(NEMA type 14-50R)

A UL listed,

250 V minimum,

4-wire connection:

Power supply cord

40 A, range

power supply cord

4-wire connection: Power Supply Cord

Use this method for:

■ New branch-circuit installations (1996 NEC)

■ Mobile homes

■ Recreational vehicles

■ In an area where local codes prohibit grounding through the

neutral

1. Part of metal ground strap must be cut out and removed.

B

A. Metal ground strap

B. Discard

C. Ground-link screw

2. Use a 5/16" (7.9 mm) nut driver to remove the ground-link

screw from the back of the range. Save the ground-link

screw and the end of the ground link under the screw.

3. Feed the power supply cord through the strain relief on the

cord/conduit plate on bottom of range. Allow enough slack

to easily attach the wiring to the terminal block.

B

4-wire direct A circuit breaker

3/8"

(1.0 cm)

box or fused

disconnect

4-wire connection:

Direct wire

C

5"

3-wire receptacle

(NEMA type 10-50R)

(12.7 cm)

A UL listed,

250 V minimum,

3-wire connection:

Power supply cord

D

40 A, range

power supply cord

A. Terminal block

B. Ground-link screw

C. UL listed strain relief

D. Power supply cord wires

10

4. Use a 5/16" (7.9 mm) nut driver to connect the green ground

wire from the power supply cord to the range with the

ground-link screw and ground-link section. The ground wire

must be attached rst.

Loading...

Loading...