Whirlpool YLTE5243DQ5, YLTE5243DQ4 Installation Guide

24IN.(6ICM)ELECTRICWASHER/DRYER

INSTAILATIONINSTRUCTIONS

INSTRUCTIONSPOURL'INSTAILATIONDELA

p p

LAVEUSF_ECHEUSEELECTRIQUEDE24PO(61CM)

TableofContents/Tabledes matibres

WASHER/DRYER SAFETY .............................. 1

INSTALLATION INSTRUCTIONS .................... 2

Tools and Parts.............................................. 2

Alternate Parts ............................................... 2

Location Requirements ................................ 2

Drain System ................................................. 3

Electrical Requirements ................................. 4

Venting Requirements ................................... 5

Install Leveling Legs ...................................... 5

Remove Foam Packing ................................. 5

Connect Drain Hose ...................................... 6

Connect Inlet Hoses ...................................... 6

Secure Drain Hose ........................................ 7

Plan Vent System .......................................... 7

Install Vent System ........................................ 9

Level Washer/Dryer ....................................... 9

Connect Vent ................................................. 9

Complete Installation ..................................... 9

SF:CURITte DE LA LAVEUSE/SF:CHEUSE.... 10

INSTRUCTIONS D'INSTALLATION .............. 10

Outillage et pi_oes n_oessaires ................... t 0

Autres pieces ............................................... 11

Emplacement d'installation ........................ 11

Systeme de vidange .................................... 12

Sp6cifications _lectriques ........................... 12

Exigences concernant I'_vacuation ............ 13

Installation des pieds de nivellement .......... 14

Enlever I'emballage en mousse .................. 14

Connexion du tuyau de vidange ................. 14

Raccordement des tuyaux d'alimentation .. 15

Immobilisation du tuyau de vidange ........... 16

Planification du systeme d'_vacuation ....... 16

Installation du conduit d'_vacuation ........... 18

Nivellement de la laveuse/s_cheuse ........... 18

Conduit d'6vacuation .................................. 18

Achever I'installation .................................... 19

WASHER/DRYERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

8542749

INSTAILATIONINSTRUCTIONS

Check that you have everything necessary for correct installation.

Proper installation is your responsibility.

Tools needed:.

• #2 Phillips and flat-blade • Knife

screwdriver

• Adjustable wrench that

opens to 1 in. (2.5 cm) or • Vent clamps

9/16in. (14 mm) open-end • Caulking gun and

wrench (for adjusting compound (for installing

dryer feet) new exhaust vent)

• Level • Gloves

• 1/4in. nut driver or socket • Pliers

wrench

• Wood block(for leveling)

• Ruler or measuring tape installations)

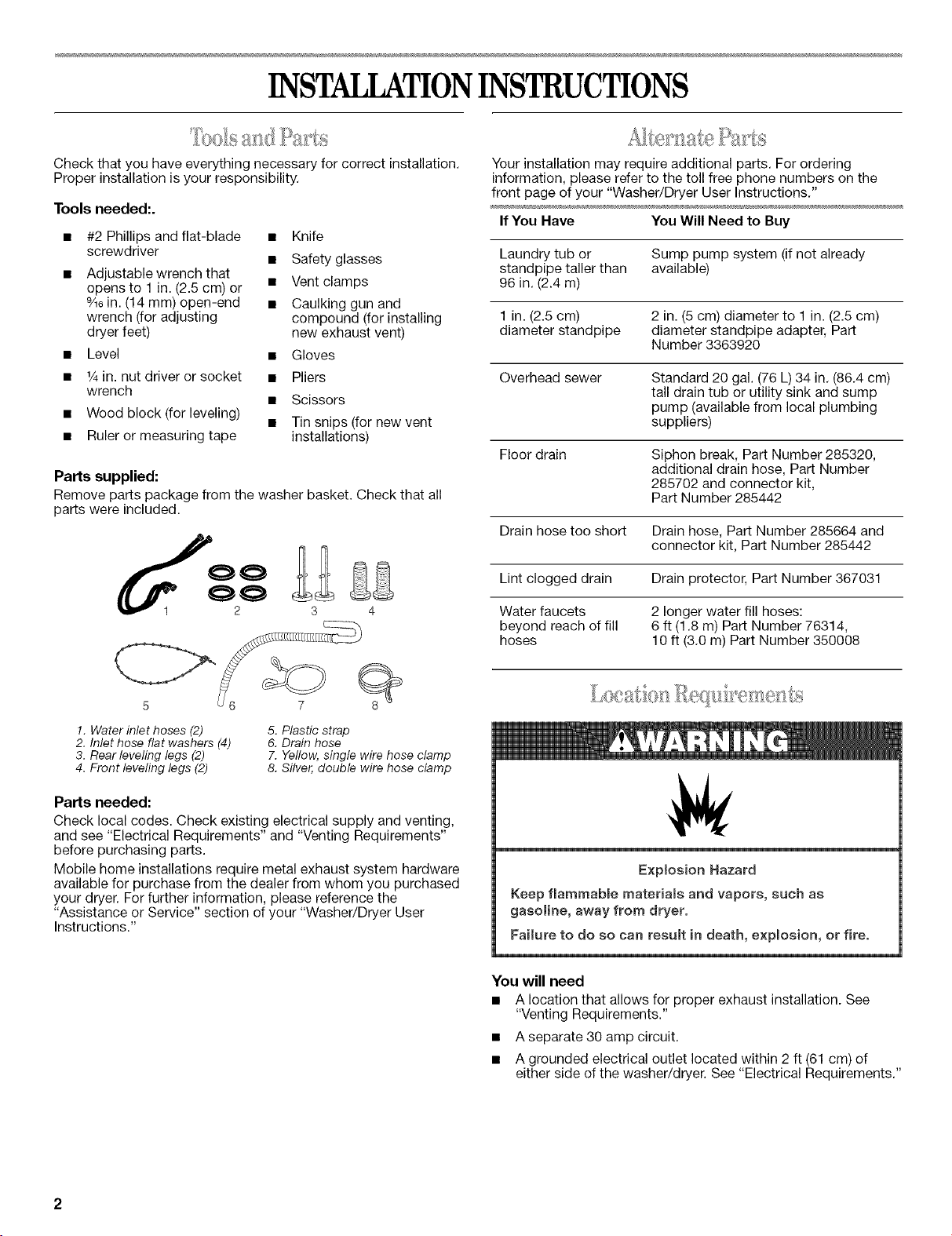

Parts supplied:

Remove parts package from the washer basket. Check that all

parts were included.

• Safety glasses

• Scissors

• Tin snips (for new vent

3 4

Your installation may require additional parts. For ordering

information, please refer to the toll free phone numbers on the

front page of your "Washer/Dryer User Instructions."

If You Have You Will Need to Buy

Laundry tub or Sump pump system (if not already

standpipe taller than available)

96 in. (2.4 m)

1 in. (2.5 cm) 2 in. (5 cm) diameter to 1 in. (2.5 cm)

diameter standpipe diameter standpipe adapter, Part

Number 3363920

Overhead sewer Standard 20 gal. (76 L) 34 in. (86.4 cm)

tall drain tub or utility sink and sump

pump (available from local plumbing

suppliers)

Floor drain Siphon break, Part Number 285320,

additional drain hose, Part Number

285702 and connector kit,

Part Number 285442

Drain hose too short Drain hose, Part Number 285664 and

connector kit, Part Number 285442

Lint clogged drain Drain protector, Part Number 367031

Water faucets 2 longer water fill hoses:

beyond reach of fill 6 ft (1.8 m) Part Number 76314,

hoses 10 ft (3.0 m) Part Number 350008

5 6

1. Water inlet heses (2)

2. Inlet hose flat washers (4)

3. Rear leveling legs (2)

4. Front leveling legs (2)

Parts needed:

Check local codes. Check existing electrical supply and venting,

and see "Electrical Requirements" and "Venting Requirements"

before purchasing parts.

Mobile home installations require metal exhaust system hardware

available for purchase from the dealer from whom you purchased

your dryer. For further information, please reference the

"Assistance or Service" section of your "Washer/Dryer User

Instructions."

7

5. Plastic strap

6. Drain hose

7. Yellow, single wire hose clamp

8. Silver, double wire hose clamp

Explosion Hazard

Keep flammabme materiams and vapors, such as

gasoline, away from dryer.

Failure to do so can result in death, expmosion, or fire.

You will need

• A location that allows for proper exhaust installation. See

"Venting Requirements."

• A separate 30 amp circuit.

• A grounded electrical outlet located within 2 ft (61 cm) of

either side of the washer/dryer. See "Electrical Requirements."

• Asturdyfloortosupportthewasher/dryerweight(washer/

dryer,waterandload)of500Ibs(226.8kg).

• Alevelfloorwithamaximumslopeof1in.(2.5cm)under

entirewasher/dryer.Clothesmaynottumbleproperlyand

automaticsensorcyclesmaynotoperatecorrectlyifwasher/

dryerisnotlevel.Installingoncarpetisnotrecommended.

• Awaterheatersettodeliver120°F(49°C)watertothewasher.

• Hotandcoldwaterfaucetslocatedwithin4ft(1.2m)ofthe

hotandcoldwaterfillvalves,andwaterpressureof5-100psi

(34.5-689.6kPa).

Thewasher/dryermustnotbeinstalledorstoredinanareawhere

itwillbeexposedtowaterand/orweather.

Donotoperateyourwasherintemperaturesatorbelow32°F

(O°C).Somewatercanremaininthewasherandcancause

damageinlowtemperatures.See"Washer/DryerCare"inyour

"Washer/DryerUserInstructions"forwinterizinginformation.

Donotoperateyourdryerattemperaturesbelow45°F(7°C).At

lowertemperatures,thedryermightnotshutoffattheendofan

automaticcycle.Thiscanresultinlongerdryingtimes.

Checkcoderequirements.Somecodeslimit,ordonotpermit,

installationofthewasher/dryeringarages,closets,mobilehomes,

orsleepingquarters.Contactyourlocalbuildinginspector.

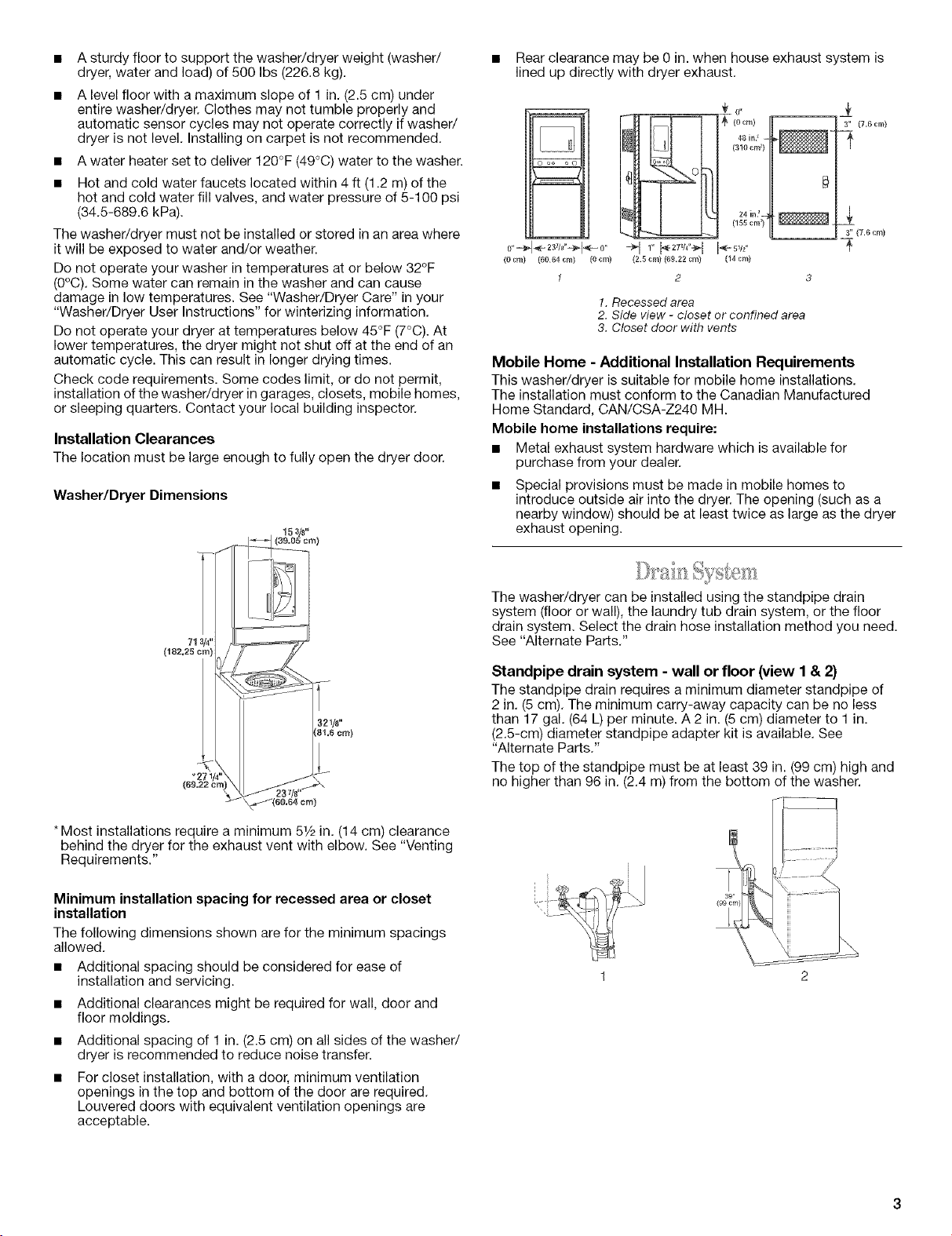

Installation Clearances

The location must be large enough to fully openthe dryer door,

Washer/Dryer Dimensions

• Rear clearance may be 0 in. when house exhaust system is

lined up directly with dryer exhaust.

48in _ q

o _o o o

24 in._

3" (7 6 cm)

(0 cm) (8064 cm) (0 era) (2.£ era) (59 22 cm)

1. Recessed area

2. Side view - closet or confined area

3. Closet door with vents

Mobile Home - Additional Installation Requirements

This washer/dryer is suitable for mobile home installations.

The installation must conform to the Canadian Manufactured

Home Standard, CAN/CSA-Z240 MH.

Mobile home installations require:

• Metal exhaust system hardware which is available for

purchase from your dealer.

• Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

(14 cm)

\/(60.64 cm)

* Most installations require a minimum 5V2in. (14 cm) clearance

behind the dryer for the exhaust vent with elbow. See "Venting

Requirements."

Minimum installation spacing for recessed area or closet

installation

The following dimensions shown are for the minimum spacings

allowed.

• Additional spacing should be considered for ease of

installation and servicing.

• Additional clearances might be required for wall, door and

floor moldings.

• Additional spacing of 1 in. (2.5 cm) on all sides of the washer/

dryer is recommended to reduce noise transfer.

• For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

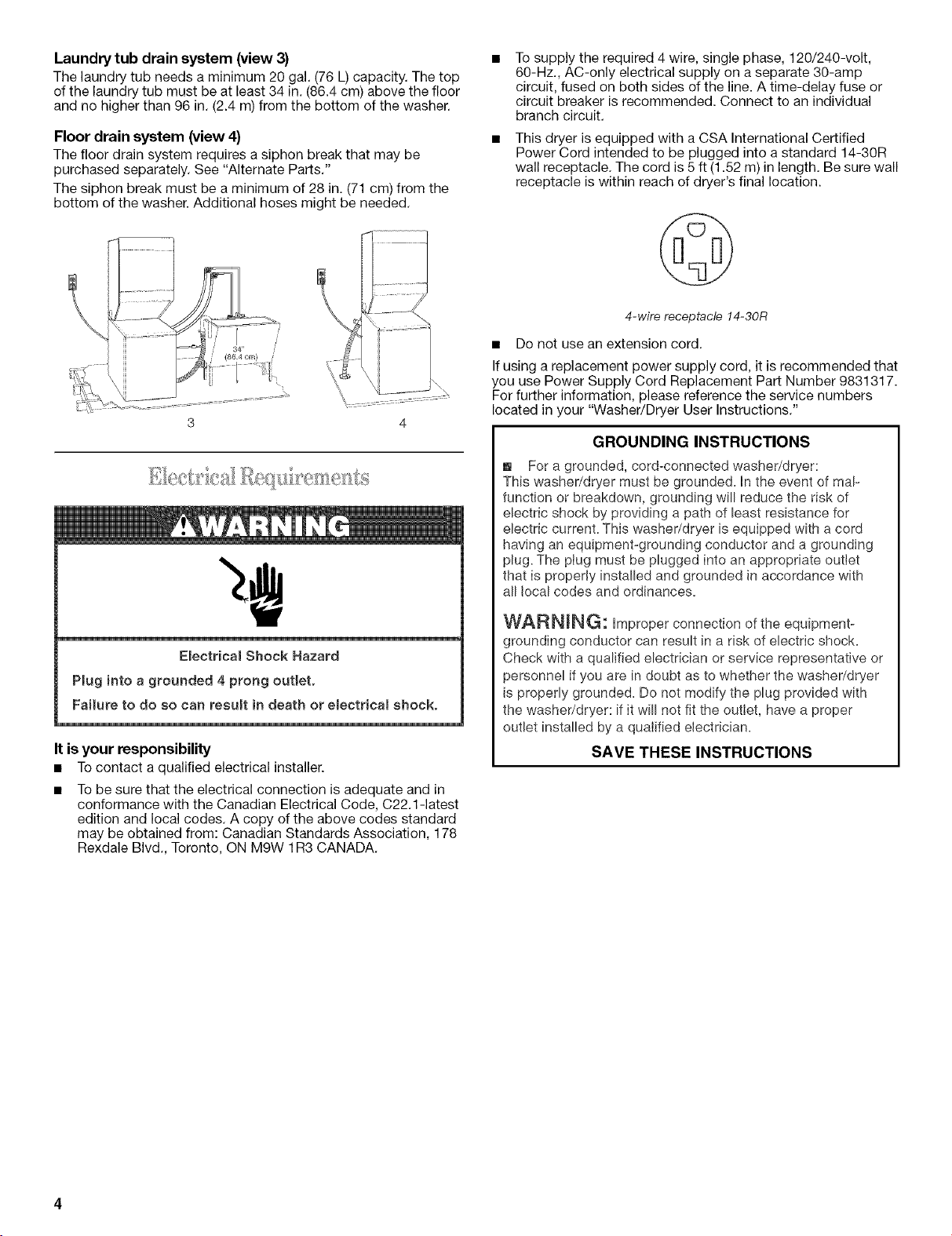

The washer/dryer can be installed using the standpipe drain

system (floor or wall), the laundry tub drain system, or the floor

drain system. Select the drain hose installation method you need.

See "Alternate Parts."

Standpipe drain system - wall or floor (view I & 2)

The standpipe drain requires a minimum diameter standpipe of

2 in. (5 cm). The minimum carry-away capacity can be no less

than 17 gal. (64 L) per minute. A 2 in. (5 cm) diameter to 1 in.

(2.5-cm) diameter standpipe adapter kit is available. See

"Alternate Parts."

The top of the standpipe must be at least 39 in. (99 cm) high and

no higher than 96 in. (2.4 m) from the bottom of the washer.

Laundry tub drain system (view 3)

The laundry tub needs a minimum 20 gal. (76 L) capacity. The top

of the laundry tub must be at least 34 in. (86.4 cm) above the floor

and no higher than 96 in. (2.4 m) from the bottom of the washer.

Floor drain system (view 4)

The floor drain system requires a siphon break that may be

purchased separately. See "Alternate Parts."

The siphon break must be a minimum of 28 in. (71 cm) from the

bottom of the washer. Additional hoses might be needed.

To supply the required 4 wire, single phase, 120/240-volt,

60-Hz., AC-only electrical supply on a separate 30-amp

circuit, fused on both sides of the line. A time-delay fuse or

circuit breaker is recommended. Connect to an individual

branch circuit.

This dryer is equipped with a CSA International Certified

Power Cord intended to be plugged into a standard 14-30R

wall receptacle. The cord is 5 ft (1.52 m) in length. Be sure wall

receptacle is within reach of dryer's final location.

4-wire receptacle 14-30R

• Do not use an extension cord.

If using a replacement power supply cord, it is recommended that

you use Power Supply Cord Replacement Part Number 9831317.

For further information, please reference the service numbers

located in your "Washer/Dryer User Instructions."

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected washeddryer:

This washer/dryer must be grounded. In the event of mal-

function or breakdown, grounding will reduce the risk of

electric shock by providing a path of least resistance for

electric current. This washer/dryer is equipped with a cord

having an equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate outlet

that is properly installed and grounded in accordance with

all local codes and ordinances.

Emectrical Shock Hazard

Plug into a grounded 4 prong outlet.

Failure to do so can resumt in death or emectrica_ shock.

It is your responsibility

• To contact a qualified electrical installer.

• To be sure that the electrical connection is adequate and in

conformance with the Canadian Electrical Code, C22.1-1atest

edition and local codes. A copy of the above codes standard

may be obtained from: Canadian Standards Association, 178

Rexdale Blvd., Toronto, ON M9W 1R3 CANADA.

WARNmNG: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative or

personnel if you are in doubt as to whether the washer/dryer

is properly grounded. Do not modify the plug provided with

the washer/dryer: if it will not fit the outlet, have a proper

outlet installed by a quaIified electrician.

SAVE THESE INSTRUCTIONS

Fire Hazard

Use a heavy metal vent,

Do net use a plastc vent,

Do net use a metamfoil vent.

Falure to folow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this washer/dryer

MUST BE EXHAUSTED OUTDOORS.

4 in. (10.2 cm) heavy metal exhaust vent and clamps must be

used. DURASAFE TM venting products are recommended.

DURASAFF Mvent products can be purchased from your dealer

or by calling Whirlpool Parts and Accessories. For more

information, seethe "Assistance or Service" section of your

"Washer/Dryer User Instructions."

• The dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, or a concealed space of a building.

• Do not use an exhaust hood with a magnetic latch.

• Do not install flexible metal vent in enclosed walls, ceilings or

floors.

• Use clamps to seal all joints. Exhaust vent must not be

connected or secured with screws or other fastening devices

which extend into the interior of the duct. Do not use duct

tape.

IMPORTANT: Observe all governing codes and ordinances.

Excessive Weight Hazard

Use two or more people to move and install

washer/dryer.

Failure to do so can result in back or other injury.

To protect the floor, use a large flat piece of cardboard from the

shipping carton. Gently place the washer/dryer on its side, on the

cardboard.

Install the rear leveling legs

1. Push legs into holes in rear corners until they snap into place.

2. Check adjustability of rear legs by pushing in one leg. The

other leg should come out. Check both legs. If they do not

move freely, repeat step 1.

Install the front leveling legs

1. Examine the front leveling legs. Find the diamond marking.

2. Screw front legs by hand, into the holes in the triangular

braces in the front corners. Use wrench to finish turning the

legs until the diamond marking is no longer visible.

Improper venting can cause moisture and lint to collect

indoors, which may resumt in:

[] Moisture damage to woodwork, furniture, paint, wall-

paper, carpets, etc.

[] Housecleaning probJems and heaJth problems.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended to prevent crushing and kinking.

Flexible metal vent must be fully extended and supported when

the washer/dryer is in its final position. Remove excess flexible

metal vent to avoid sagging and kinking that may result in reduced

airflow and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home.

Exhaust hood must be at least 12 in. (30.5 cm) from the ground or

any object that may be in the path of the exhaust (such as flowers,

rocks or bushes, etc.).

If using an existing vent system, clean lint from the entire length of

the system and make sure exhaust hood is not plugged with lint.

Replace any plastic or metal foil vent with rigid metal or flexible

metal vent.

3. Carefully stand the washer/dryer upright.

1. Open the washer lid. The latch under the dryer will keep the lid

open.

2. Pull the foam packing ring out of the washer.

NOTE: Keep the foam ring and use it when transporting your

washer/dryer. This packing material is used to keep the washer

tub stable during transport.

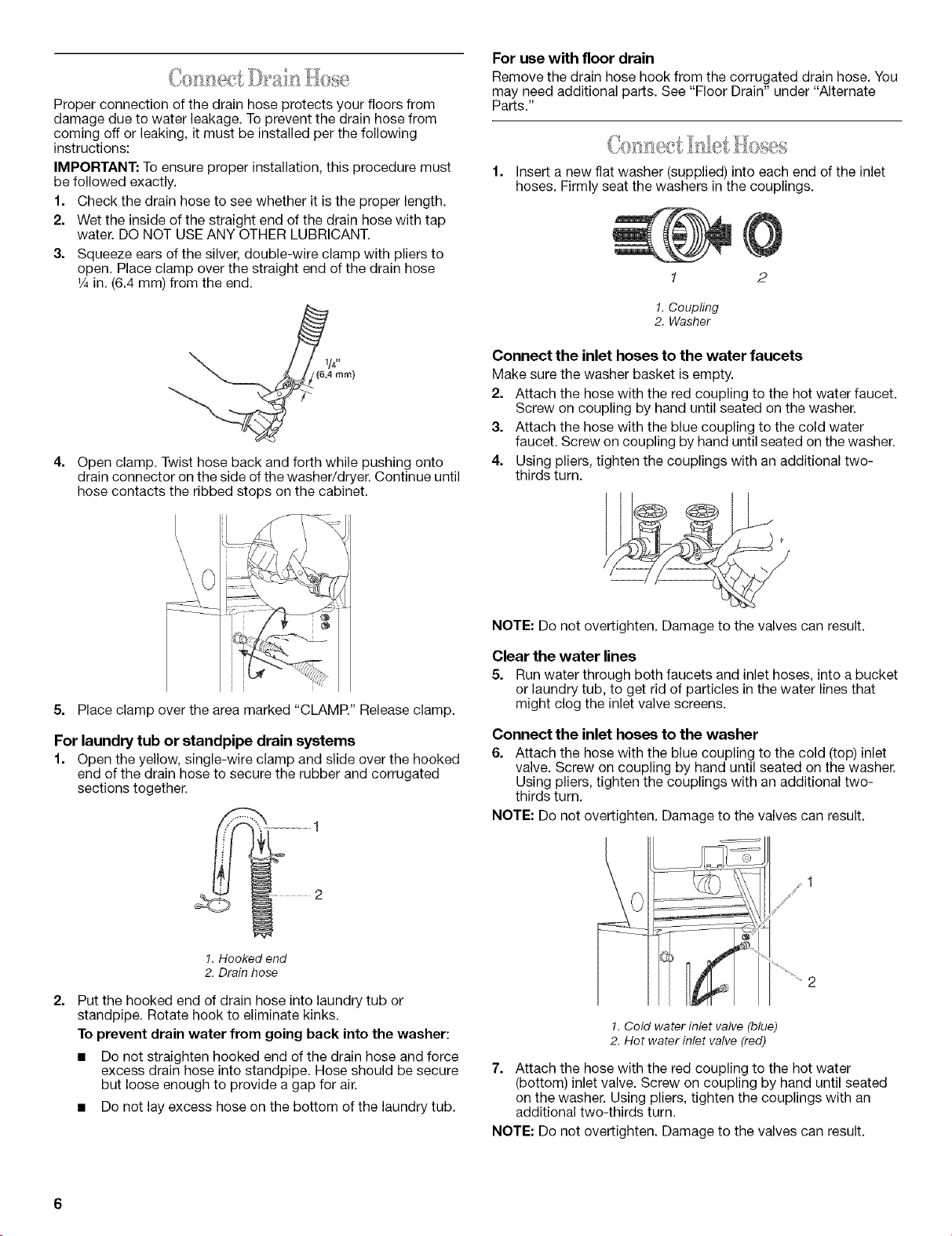

Properconnectionofthedrainhoseprotectsyourfloorsfrom

damageduetowaterleakage.Topreventthedrainhosefrom

comingofforleaking,itmustbeinstalledperthefollowing

instructions:

IMPORTANT:Toensureproperinstallation,thisproceduremust

befollowedexactly.

1. Checkthedrainhosetoseewhetheritistheproperlength.

2. Wettheinsideofthestraightendofthedrainhosewithtap

water.DONOTUSEANYOTHERLUBRICANT.

3. Squeezeearsofthesilver,double-wireclampwithpliersto

open,Placeclampoverthestraightendofthedrainhose

1Ain.(6.4mm)fromtheend.

ram)

4. Open clamp. Twist hose back and forth while pushing onto

drain connector on the side of the washer/dryer. Continue until

hose contacts the ribbed stops on the cabinet.

For use with floor drain

Remove the drain hose hook from the corrugated drain hose. You

may need additional parts. See "Floor Drain" under "Alternate

Parts."

1. Insert a new flat washer (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

1 2

1. Coupling

2. Washer

Connect the inlet hoses to the water faucets

Make sure the washer basket is empty.

2. Attach the hose with the red coupling to the hot water faucet.

Screw on coupling by hand until seated on the washer.

3. Attach the hose with the blue coupling to the cold water

faucet. Screw on coupling by hand until seated on the washer.

4. Using pliers, tighten the couplings with an additional two-

thirds turn.

\

\

\

\

\

5. Place clamp over the area marked "CLAMR" Release clamp.

For laundry tub or standpipe drain systems

1. Open the yellow, single-wire clamp and slide over the hooked

end of the drain hose to secure the rubber and corrugated

sections together.

2

!. Hooked end

2. Drain hose

2.

Put the hooked end of drain hose into laundry tub or

standpipe. Rotate hook to eliminate kinks.

To prevent drain water from going back into the washer:

• Do not straighten hooked end of the drain hose and force

excess drain hose into standpipe. Hose should be secure

but loose enough to provide a gap for air.

• Do not lay excess hose on the bottom of the laundry tub.

NOTE: Do not overtighten. Damage to the valves can result.

Clear the water lines

5. Run water through both faucets and inlet hoses, into a bucket

or laundry tub, to get rid of particles in the water lines that

might clog the inlet valve screens.

Connect the inlet hoses to the washer

6. Attach the hose with the blue coupling to the cold (top) inlet

valve. Screw on coupling by hand until seated on the washer.

Using pliers, tighten the couplings with an additional two-

thirds turn.

NOTE: Do not overtighten. Damage to the valves can result.

1. Cold water inlet valve (blue)

2. Hot water inlet valve (red)

7. Attach the hose with the red coupling to the hot water

(bottom) inlet valve. Screw on coupling by hand until seated

on the washer. Using pliers, tighten the couplings with an

additional two-thirds turn.

NOTE: Do not overtighten. Damage to the valves can result.

Loading...

Loading...