Page 1

Twin Tub Washing Machine

PARTS &

SERVICE Manual

NARSO MODELS

Doc No. WOI/washer/2001/009 Page No 1

Modified on date 03/08/2001 Subject to modification

Page 2

MODEL NUMBERS

SAP_MODEL_NO DESCRIPTION OLD_MODEL_NUMBER

1099 WASHING MACHINE -ROPER - APWH WWBDQ59E0

1100 WASHING MACHINE -SUPER PLUS - APWH WWBDS50E8

1104 WASHING MACHINE -SUPER PLUS -APWH WWBCP59E6

1108 WASHING MACHINE-SUPER+APWH-S.MARTIN-220V WWBDI58E3

1109 WASHING MACHINE -SUPER+ APWH -SURINAME WWBDJ58E4

1113 WASHING MACHINE -WWBCM58-E0A-APP.WHITE WWBCM58E0

1294 WASHING MACHINE-SUPER+APWH-S.MARTIN-110V WWBDH58E0

2254 WASHING M/C - 110 V AC, 60Hz APWH-PANAMA WWBDR58-E0A

2255 WASHING M/C-115 V AC,60Hz APWH-TRINIDAD WWBDT58-E6A

MODEL DETAILS

WWBCM58E0A WWBDM58E5A WWBDN58E0A

With pump With pump With pump

110v 110v 110v

WWBDH58E0A WWBDL58E0A WWBDI58E3A

No pump No pump No pump

110v 110v 220v

Doc No. WOI/washer/2001/009 Page No 2

Modified on date 03/08/2001 Subject to modification

Page 3

TWIN TUB WASHING MACHINE

CONTENTS

NARSO MODELS

S.NO DESCRIPTION PAGE NO

1. SPECIFICATIONS 6

2. SPECIAL FEATURES OF SUPER PLUS NEW & SUPER NEW 7

3. CONTROL & FUNCTIONS 8

4. EXPLODED VIEW AND PARTS LIST 10

5. WIRING DIAGRAM 16

6. FAULT FINDING GUIDE 17

7. COMPONENT CHECK GUIDE 18

Doc No. WOI/washer/2001/009 Page No 3

Modified on date 03/08/2001 Subject to modification

Page 4

Doc No. WOI/washer/2001/009 Page No 4

Modified on date 03/08/2001 Subject to modification

Page 5

SPECIFICATIONS

Doc No. WOI/washer/2001/009 Page No 5

Modified on date 03/08/2001 Subject to modification

Page 6

MODEL: SUPER PLUS NEW & SUPER NEW

NARSO MODELS

1. POWER SOURCE : 110V /60 Hz (Except model BDI58E3A)

2. CAPACITY WASH : 5 KG DRY WEIGHT

SPIN : 5 KG WET WEIGHT

3. OVERALL DIMENSIONS : W 750MM/D 490 MM/H-812MM

4. MACHINE WEIGHT PACKED : 37 KGS

UNPACKED : 30 KGS

5. MOTOR SPEED WASH : 1400 RPM+ 25 RPM

SPIN : 1400 RPM+ 25 RPM

6. MOTOR POWER WASH : 330 W

(INPUT) SPIN : 150 W

7. WASH SYSTEM : AGITATOR TYPE

8. SPIN SYSTEM : CENTRIFUGAL

9. WATER LEVEL SELECTION : 3

10. WATER CAPACITY HIGH : 50 L

MEDIUM : 43 L

LOW : 36 L

11. AGITATOR SPEED : 13 STROKES PER MINUTE

12. INDICATOR : BUZZER AT THE END OF

SUPER PLUS NEW – WASH/RINSE

SUPER NEW – WASH/RINSE & SPIN

13. DRIVE SYSTEM WASH : BELT & PLANETARY GEAR

SPN : DIRECT

14. WASH TIMER SETTINGS : 1 TO 15 MINUTES

15. SPIN TIMER SETTINGS : 1 TO 5 MINUTES (Super Plus New only)

16. TIMER WASH : ELCTRO MECHANICAL

SPIN : MECHANICAL (Super Plus New only)

Doc No. WOI/washer/2001/009 Page No 6

Modified on date 03/08/2001 Subject to modification

Page 7

FEATURES OF – SUPER PLUS NEW & SUPER NEW TWIN TUB

MACHINES

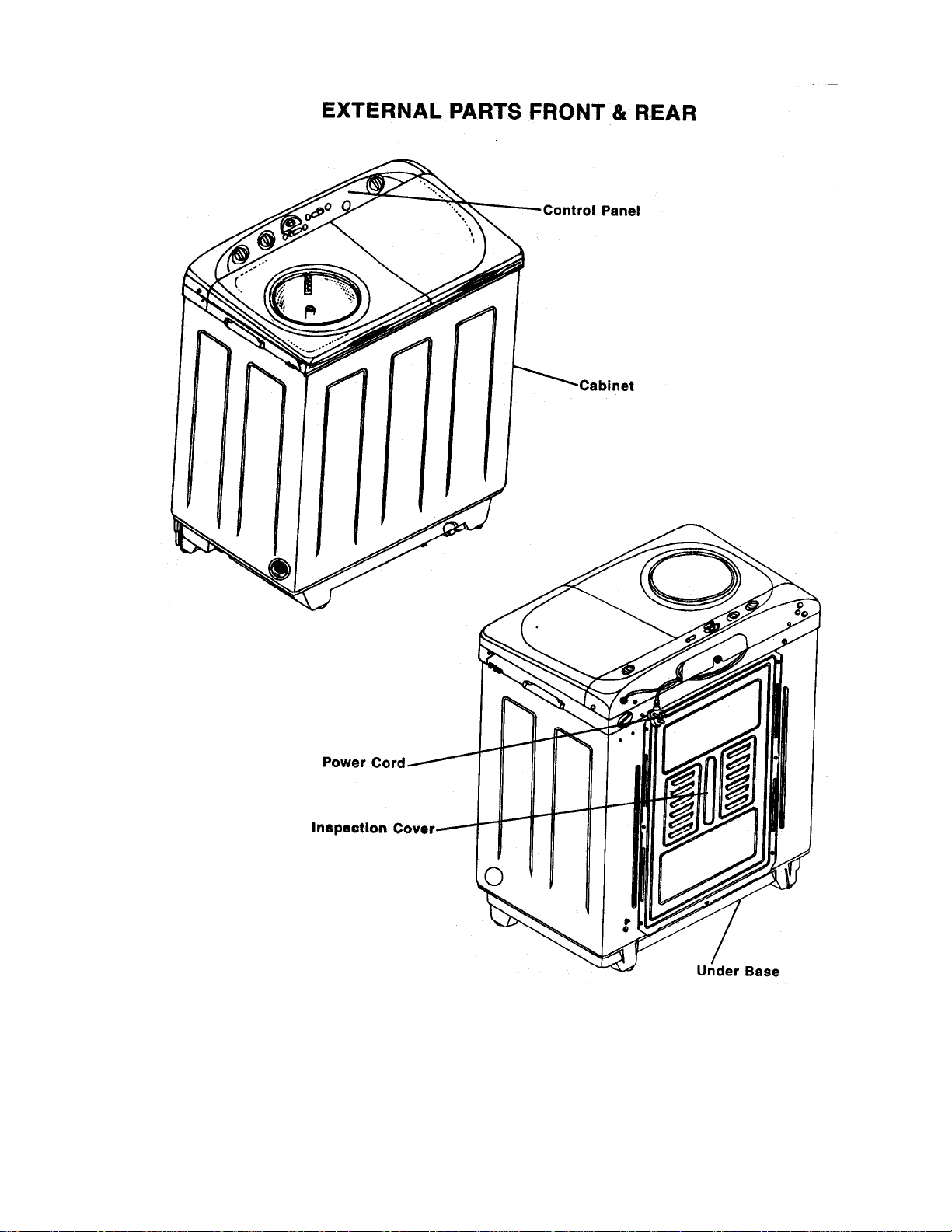

The following are of the main features available in – Super plus New and Super New semi

automatic washing machine:

⇒ Stainless steel spin basket with liquid balancing ring.

(Only for SUPER PLUS NEW MODEL)

⇒ Prepainted galvanized sheet for cabinet.

⇒ Unique agitator washing system

⇒ Towel hanger ( Only for SUPER PLUS NEW model)

⇒ True 5-kg wash & matched spin capacity.

⇒ Rat mesh

⇒ Transparent wash lid

⇒ Improved Spin shower option

⇒ Wheels for mobility

⇒ Buzzer indication

⇒ Electro mechanical wash timer

⇒ Drain hose routing on all four sides

⇒ Power card winding facility

⇒ Drain Pump in models BCM58 E0A, BDM58 E5A AND BDN58 E0A

⇒ Hinged wash lid and also easily accessible & can be hinged on the side

⇒ Fuse 3A – Enclosed in Polyphone cover

Doc No. WOI/washer/2001/009 Page No 7

Modified on date 03/08/2001 Subject to modification

Page 8

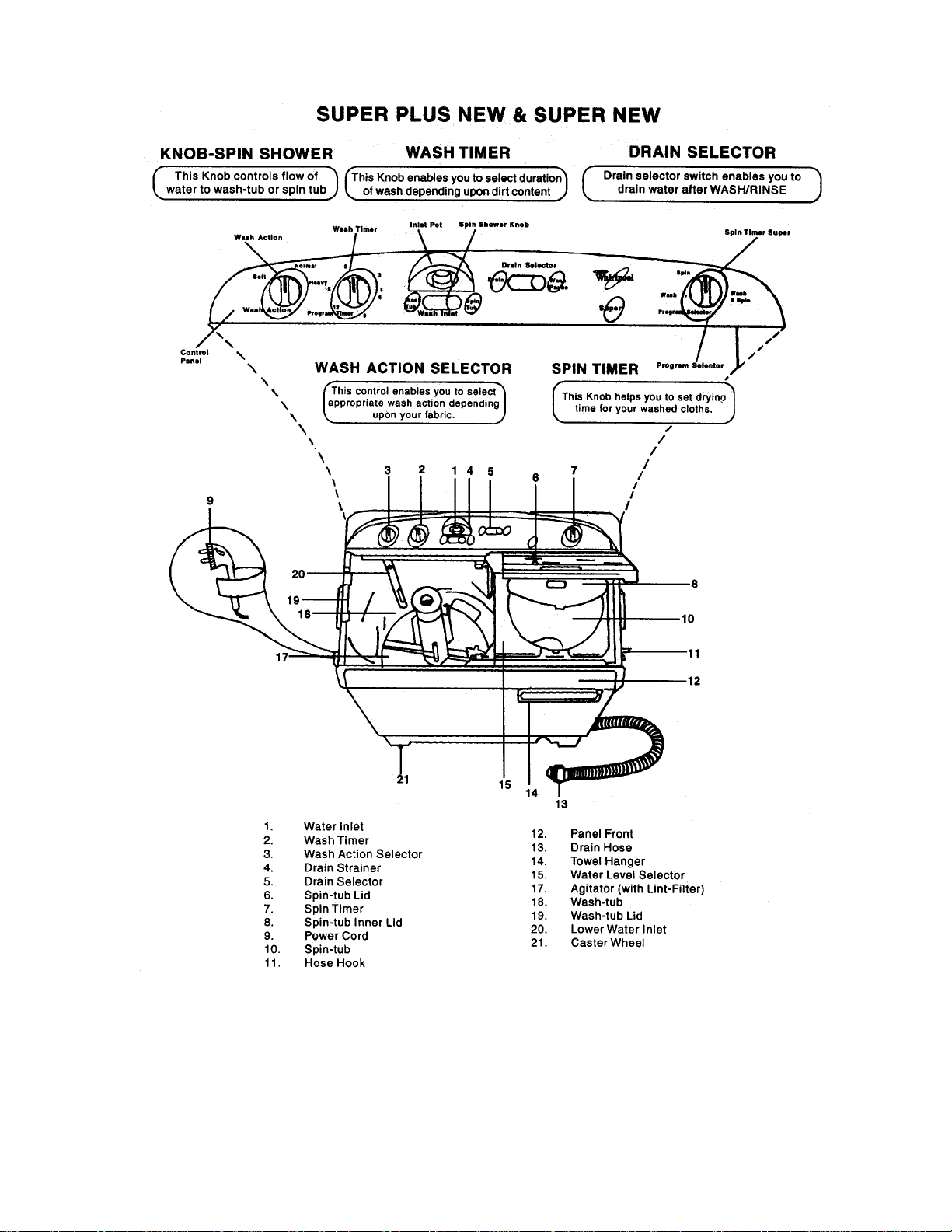

1.WASH TIMER

This Electro mechanical timer is meant for selecting the WASH / RINSE duration ranging

from 1 minute to 15 minutes. Indications for 3,6,9,12 & 15 minutes are given in the dial. For

setting the required duration, the knob has to be rotated in clockwise direction and set at

corresponding mark in the dial. Once the knob is set at the required position, the machine is

switched on and the timer automatically rewinds in anticlockwise direction while performing

WASH / RINSE. Once the timer knob reaches the 'OFF' position, the buzzer indicates the

completion of the cycle and the machine gets automatically switched off.

2 . WASH ACTION

Wash action switch is basically a three position switch viz., HEAVY, NORMAL, & SOFT.

This knob controls the ON and OFF duration of the motor during agitation thereby varying

the washing action. The following are the wash timing corresponding to various settings:

3. DRAIN SELECTOR

This is a mechanical, slide type knob with two positions WASH/RINSE and DRAIN. When

set at WASH/RINSE position, the drain valve attached to the wash tub is closed thereby

allowing the water to get retained in the tub to perform wash/rinse , If the knob Is pushed to

DRAIN mode , the drain and the water in the wash tub is drained out.

4. SPIN TIMER (only in SUPER PLUS NEW Model)

This is a mechanical, spring wound timer meant for setting the spin duration ranging form 1

to 5 minutes. For setting the required duration, the knob has to be rotated clockwise and set at

the required mark. Never attempt to rotate the timer in anticlockwise direction. Once the

knob is set at the required position, the spin motor starts rotating thereby completing the

drying process. Once the cycle is completed, the knob reaches OFF position and thereby the

supply to the spin motor is automatically cut off.

Since the spin timer is a spring wound type, in case of any power cut, the same will not be

sensed by the timer and it continues to rewind till it reaches the OF POSITION.

Doc No. WOI/washer/2001/009 Page No 8

Modified on date 03/08/2001 Subject to modification

Page 9

5. SPIN SHOWER

This is again a tow position knob viz. WASH TUB and SPIN SHOWER. When set at WASH

TUB position, it allows the water to be filled in the wash tub. When set at SPIN SHOWER

position, the water gets filled in the spin tub.

Spin shower option is generally used to aid the soap removal form the clothes. During this

process, the clothes are loaded in the spin tub and the knob is set at SPIN SHOWER mode.

Water is then filled into the machine. This water gets sprayed over the clothes in spintub.

After 2 minutes of spraying, the water supply needs to be cut off and then spin timer is set

ON for few minutes of spinning. This removes the suds from the clothes effectively.

6. PROGRAM SELECTTOR (applicable only for SUPER NEW model)

In super new models, the spin timer is replacing this three way switch. The three positions

available are WASH, SPIN and WASH & SPIN. This switch will work in conjunction with

the wash timer (Known as PROGRAM TIMER in SUPER NEW model) as detailed below:

AT WASH POSITION : The wash motor will be ON for the duration set at

PROGRAM TIMER

AT SPIN POSITON : The spin motor will be ON for the duration set at

PROGRAM TIMER

AT WASH & SPIN : BOTH THE WASH AND SPIN MOTORS will be ON for

the duration set at PROGRAM TIMER

Doc No. WOI/washer/2001/009 Page No 9

Modified on date 03/08/2001 Subject to modification

Page 10

POS_NO material PART_CODE DESCRIPTION

1 P013200160D P0132001516-0 LID WASH - APP. WHITE 1111 1

2 P013200040B P0132001504-0 WINDOW - LID WASH 111111

3 P013200170F P0132001517-0 LID SPIN - APP. WHITE 111111

4 P013200080C P0132001508-0 BRACKET - LID WASH - OFF WHITE 1 1 1

4 P013200280C P0132001528-0 BRACKET - LID WASH - APWH 1 1 1

5 P013200180D P0132001518-0 PANEL FRONT - APP. WHITE 111111

6 P010600020C P0106001502-0 INNER COVER-SPIN 111111

7 P014200010B P0142001501-0 SPIN CAP - PL/SS 111111

8 P010612290B P0106121529-0 FILTER CAP - APWH 111111

9 P010612350A P0106121535-0 COUPLING LINT FILTER - APWH 111111

10 P010612380A P0106120005-0 FILTER NET ASSY 111111

11 S011280120B S011280T 012-0 AGIT AT OR SCREW 111111

12 P010612320G P0106121532-0 AGITATOR - APWH 111111

13 P0132120300 P0132120003-0 BELLOW SPIN ASSY - TT 111111

14 P0106180200 P0106180006-0 DRUM COUPLING ASSY 111111

15 P010618250A P0106180901-0 BRAKE FIX PLATE 111111

16 P010618010H P0106181501-0 UNDER BASE 111111

17 P0132400200 P0132401502-0 DIVERTOR 111111

18 P013200310B P0132005702-0 SPRING LID 111111

19 P014213020B P0142131502-0 COVER - SPIN BASKET - PLASTIC 111111

20 P010613030E P0106130003-0 BALANCE RING ASSEMBLY (TT) 111111

21 P013513020D P0135131501-0 SPIN BASKET - PLASTIC 111111

22 P010613020R P0106130002-0 SHAFT FIX PLATE ASSY 111111

23 P010618040I P0106180004-0 BRAKE WIRE ASSY 111111

24 P013218040B P0132180901-0 PULLEY FAN - BOTTOM (BIG) 111111

24 P013218050B P0132180902-0 PULLEY FAN - TOP (SMALL) 111111

25 P010618240F P0106182503-0 MOTOR - WASH (30MM STACK) 1

25 P013818010F P0138182501-0 MOTOR - WASH - 110 ~ 127V, 60HZ 11111

26 P0106181601-0 P0106181601-0 GROMMET 333333

27 P0106181800 P0106181503-0 GROMMET SUPPORT PLATE 111111

28 P0106181502-0 P0106181502-0 WHEEL CASTOR 444444

28 P0106182800 P0106181502-0 W HEEL CASTOR 444444

29 P0136181200 P0136180701-0 WHEEL - SHAFT (LONG) 444444

30 P013240250D P0132401525-0 KNOB SLIDE SELECTOR - APP. WHITE 111111

31 P0132401300 P0132401513-0 RETAINER - SPIN SHOWER 111111

32 P0136700100 P0136700001-0 FILL HOSE ASSY - EXPORT 1 1111

33 P0106123700 P0106121602-0 O RING - TT 111111

With pump

With pump

With pump

110v

110v

110v

BCM58E0A

BDM58E5A

BDN58E0A

No pump

No pump

No pump

110v

110v

220v

BDH58E0A

BDL58E0A

BDI58E3A

Doc No. WOI/washer/2001/009 Page No 10

Modified on date 03/08/2001 Subject to modification

Page 11

POS_NO material PART_CODE DESCRIPTION

34 P010612010C P0106121601-0 RUBBER RING 111111

35 P0132170000 P0132170000-0 DRIVE ASSY 111111

36 P013212070C P0132121502-0 PULLEY - DRIVEN 111111

37 S011590010A S011590T 001-0 NUT (NYLOC) 111111

38 P010612330C P0106121533-0 LOWER WATER INLET - APWH 111111

41 P010618050A P0106181505-0 BAND-BRAKE 111111

42 P0132180300 P0132180003-0 CUSH MOTOR ASSY - TT 333333

43 P010618190C P0106182801-0 DUAL CAPACITOR - (1O+5 MFD) 1

43 P0138180700 P0138182801-0 DUAL CAPACITOR - (40+15 MFD) 1

43 P0138180800 P0138182802-0 DUAL CAPACITOR - (40+20MFD) 1 1 1 1

44 P013240120F P0132401512-0 BRACKET - TIMER STRIGHT 111111

46 P013240270F P0132401527-0 KNOB SLIDE DRAIN - APP. WHITE 111111

47 P013240140B P0132401514-0 HOUSING - CONTROL LEVER (EXPORT) 1 1 1

48 P013240240G P0132401524-0 KNOB ROTARY - A - APP. WHITE 222222

49 P013240280G P0132401528-0 CONTROL PANEL - SUPER + - APP. WHITE 1 1 1 1

49 P013840060G P0138401506-0 CONTROL PANEL - APWH-MEXICO-WHIRLPOOL 1 1

50 P013240050A P0132400005-0 SPIN TIMER ASSY- S(3A)-TANGO 111111

51 P013200060D P0132001506-0 COVER - SPLASH - NATURAL 1 1 1

51 P013200260D P0132001526-0 COVER - SPLASH - APWH 1 1 1

52 P013240550B P0132402702-0 ROTARY SWITCH - WASH (SUPER PLUS) 1

52 P013840010A P0138402701-0 ROTARY SWITCH - WASH - 127V, 60HZ 11111

53 P010600060C P0106001506-0 RETAINER-BRAKE WIRE 111111

54 P0106125300 P0106121606-0 COUNTER FLOW PROTECTOR 111111

55 P010612260I P0106121526-0 TUB - APWH 111111

56 P010600530B P0106001601-0 V-BELT(T WIN TUB) 111111

57 S017100000A S017100T000-0 PIG TAIL CONNECTOR-3 DIA 888888

58 S0171000100 S017100T001-0 PIG TAIL CONNECTOR-3.8 DIA 2 2 2

58 S0171000100 S0171000001-0 PIG TAIL CONNECTOR-3.8 DIA 2 2 2

59 P013240100A P0132400010-0 MICRO SWITCH ASSY - TT 111111

60 P011050030A P0110502703-0 SWITCH - KICKOUT (3 TERMINAL + LEVER) 1 1 1

61 P0106125100 P0106120002-0 DRAIN ASSY 111111

62 P010612500D P0106121507-0 VALVE CAP 111111

63 P010612460C P0106125701-0 VALVE SPRING 111111

64 P0106122000 P0106121520-0 VALVE ROD-ADJUSTABLE 111111

65 P010612050A P0106121605- 0 BELLOW S-VALVE 111111

66 P010612450D P0106125101-0 HOSE-TUB TO DRAIN (D:36, L:275) 111111

67 P010612040G P0106121504-0 INLET JOINT 111111

With pump

With pump

With pump

110v

110v

110v

BCM58E0A

BDM58E5A

BDN58E0A

No pump

No pump

No pump

110v

110v

220v

BDH58E0A

BDL58E0A

BDI58E3A

Doc No. WOI/washer/2001/009 Page No 11

Modified on date 03/08/2001 Subject to modification

Page 12

POS_NO material PART_CODE DESCRIPTION

68 P010612520E P0106121505-0 VALVE HOUSING 111111

69 P013200250C P0132001525-0 BASE WATER PASSAGE - APWH 111111

70 P013200010I P0132000901- 0 BRACKET-BRAKE WIRE 111111

71 P010612280D P0106121528-0 COVER SLIDER - APWH 111111

72 P014212020D P0142121502-0 SLIDER - ADJ. OVERFLOW - APWH 111111

73 P010612470F P0106125102-0 HOSE-ADJUSTABLE OVERFLOW 111111

74 P010612300A P0106121530-0 STRAINER - APWH 111111

75 P010612310B P0106121531-0 STRAINER BRACKET - APWH 111111

76 P0142000700 P0142001507-0 INSPECTION COVER - HIPS - APWH 111111

77 P010612070D P0106120007-0 INNER EARTH ASSY 1 1 1

77 P0136180500 P0136182605-0 INNER EARTH - WMOTOR JT / SM JT. - 300L 111111

78 P013240570B P0132400006-0 FUSE ASSY (3A) - TT 1

78 P013840080A P0138400008-0 FUSE ASSY - 6.3A/240V - SCREW TYPE 11111

79 P0136400500 P0136402802-0 POWER CORD - 2FLAT PIN-ONE ROUND PIN 111111

80 P0136180100 P0106125104-0 DRAIN HOSE 1 1 1

80 P0136180100 P0136185101-0 DRAIN HOSE - EXPORT 1 1 1

81 P013621050G P0136211001-0 CABINET - APP. WHITE - EXPORTS 1111 1

82 P010612340D P0106121534-0 OVERFLOW FILTER - APWH 111111

83 P0106182600 P0106185701-0 STRING-BRAKE 111111

84 P013200270C P0132001527-0 TOP PLATE - APWH 111111

85 P010618220D P0106182504-0 MOTOR SPIN -20MM 1

85 P013818020D P0138182502-0 MOTOR - SPIN - 110 ~ 127V, 60HZ 11111

86 P013240260K P0132401526-0 KNOB ROTARY - C - APP. WHITE 111111

P010640030B P0106401803-0 DRAIN CABLE - STEEL 1 1 1

P010690150A P0106900015-0 LINT FILTER ASSY - APWH 111111

P011050030A P0110502703-0 SWITCH - KICKOUT (3 TERMINAL + LEVER) 1 1 1

P0115900100 P0115906501-0 CUSHION-UNDER 111111

P011590080A P0115901501-0 DRAIN BEND - EXPORT 1 1 1

P012112010B P0121125101-0 HOSE-VALVE HOUSING TO PUMP (D-36, L275) 1 1 1

P0121180100 P0121180901-0 BRACKET - PUMP 1 1 1

P012140010B P0121400901-0 SPRING PLATE - DRAIN SWITCH 1 1 1

P0132120600 P0132121002-0 HOOK - VALVE ROD 1 1 1

P0132120600 P0142121001-0 HOOK - VALVE ROD 1 1 1

P013240040D P0132401504-0 HOUSING - LEVER CONTROL 1 1 1

P0132400700 P0132400007-0 DRAIN CONTROL ASSY 111111

P013240490B P0132401506-0 BRACKET - ROTARY SWITCH 111111

With pump

With pump

With pump

110v

110v

110v

BCM58E0A

BDM58E5A

BDN58E0A

No pump

No pump

No pump

110v

110v

220v

BDH58E0A

BDL58E0A

BDI58E3A

Doc No. WOI/washer/2001/009 Page No 12

Modified on date 03/08/2001 Subject to modification

Page 13

POS_NO material PART_CODE DESCRIPTION

P013290010E P0132906501-0 CUSHION - TOP 111111

P0132900300 P0132906503-0 TOP COVER - EDGE 222222

P0132900400 P0132906504-0 TOP COVER - MIDDLE 111111

P013290050B P0132906505-0 CUSHION - MIDDLE 111111

P0138220100 P0138220001-0 PUMP ASSEMBLY - 127V - 60HZ 1 1 1

P013890080B P0138906502-0 BOX PACKING - SRILANKA 111111

P0142400900 P0142401509-0 BRACKET - MICRO SWITCH 111111

With pump

With pump

With pump

110v

110v

110v

BCM58E0A

BDM58E5A

BDN58E0A

No pump

No pump

No pump

110v

110v

220v

BDH58E0A

BDL58E0A

BDI58E3A

Doc No. WOI/washer/2001/009 Page No 13

Modified on date 03/08/2001 Subject to modification

Page 14

Doc No. WOI/washer/2001/009 Page No 14

Modified on date 03/08/2001 Subject to modification

Page 15

Doc No. WOI/washer/2001/009 Page No 15

Modified on date 03/08/2001 Subject to modification

Page 16

Doc No. WOI/washer/2001/009 Page No 16

Modified on date 03/08/2001 Subject to modification

Page 17

Trouble shooting chart

S.NO PROBLEM POSSIBLE CAUSE REMEDY

1 Shock/Current Leak Earth Not Proper Connect Proper

Earthing

2 Machine Not Functioning No Supply At The Power Point Check Electrical

Supply At Socket

Plug Switch Is Not On Switch On The Plug

Blown Up Fuse Replace Fuse

Defective Power Cord Refer CCG *

Defective Wash Timer Refer CCG

Defective Capacitor Refer CCG

Defective Drive Assy Refer CCG

Defective Drive Belt Replace

3 No Drain Drain Hose Hooked On Place The Drain Hose

Machine At Ground Level

Kinked / Clogged Drain Hose Remove / Clean

Drain Valve Control Wire Reconnect Drain

Dislodged Wire

Control Cable Cut Replace Cable

Clogged Drain Valve Clean Drain Valve

4 No Agitation Wash Timer Defective Refer CCG

Wash Motor Defective Refer CCG

Drive Belt Cut Replace Drive Belt

Defective Drive Assy Refer CCG

Defective Capacitor Refer CCG

Wire Discontinuity Rectify

5 One Side Agitation Defective Wash Timer Refer CCG

Defective Wash Motor Refer CCG

Defective Drive Assy Refer CCG

6 Noisy Agitation Loose Drive Belt Adjust

Defective Drive Assy Refer CCG

Loose Agitator Fix The Agitator

Proper ly

Defective Wash Motor Refer CCG

7 Leak During Drain Defective Drain Valve Refer CCG

Punctured Drain Hose Replace

8 No Spin Lid Open Close Lid

Defective Lid Switch Replace

Defective Capacitor Refer CCG

Defective Spin Motor Refer CCG

Improper Brake Adjust

Defective Brake Cable Replace

9 Noisy Spin Defective Spin Basket Replace

Loose Coupling Bolt Tighten

Loose Basket Shaft Tighten

Defective Spin Motor Refer CCG

* CCG is the Component Check Guide table in the next page

Doc No. WOI/washer/2001/009 Page No 17

Modified on date 03/08/2001 Subject to modification

Page 18

COMPONENT CHECK GUIDE

S.NO COMPONENT NATURE OF TESTING PROCEDURE REMEDY

PROBLEM

1 Machine Gives Check for proper earthing to Inform customer

shock which the machine is connected to correct for

using multimeter. proper earthing

Check voltage between

Phase & Neutral

Phase & Earth

both should be equal.

Check continuity between

Neutral & Earth

If found to be short Earthing is

defective

2 Fuse Blown Using multimeter check continuity

between both the ends.

Replace the fuse

3 Power cord Discontinuity Check for proper continuity

between plug side and machine

side also check for short circuit

between wires

4 capacitor Not functioning

WARNING

DISCHARGE

BEFORE

HANDLING

5 Wash Motor Does not run Check the winding resistance

6 Spin Motor Does not run Check the winding resistance

Check the capacitor with the

multimeter in continuity mode.

The meter should first read ohms

and gradually the needle should

swing back to infinity Ohms. It

indicates a good capacitor and

any thing other than this is

defective.

using a multimeter between wires

BLACK & BLUE 37.6 Ohms

approx. BLACK & YELLOW 42.6

Ohms. If the resistances are not

as per the given value it could be

short or open

using a multimeter between wires

BLACK & BROWN 69 Ohms

approx. BLACK & WHITE 77.5

Ohms. If the resistances are not

as per the given value it could be

short or open

Replace power

cord

Replace the

capacitor

Replace the wash

motor

Replace the Spin

motor

Doc No. WOI/washer/2001/009 Page No 18

Modified on date 03/08/2001 Subject to modification

Page 19

COMPONENT CHECK GUIDE

7 Wash / Spin

motor

Electric current

8 Timer No spin Check continuity between the

1. In OFF position the meter should read infinit

2. In ON position the meter should read zero Ohms.

Noisy Operation

Wash / Spin

leakage

Visually check the damages on

pulley and refer, also check for

free rotation of the rotor. If any

damages noticed or the rotor not

rotating freely indicates defective

motor (Wash & Spin).

Check the motors for short

between body and terminals

using a multimeter. If meter

shows continuity, it indicates

motor is defective.

terminals of the spin timer using a

multimeter.

resistance.

Cont’d

Replace the

Wash / Spin

motor.

Replace the

motor.

Replace the spin

timer

If the meter not showing as per above statements it

indicates defective spin timer

Not advancing Set the Timer to one position and

check the knob whether coming

back to OFF position. If not

coming indicates defective spin

timer.

9 Wash Timer Not advancing /

No Wash

11 Circuit breaker No spin Adjust / Replace the circuit

12 Drive assy Noisy agitation Visually check for excessive play

Set the timer to one position and

check the knob whether coming

back to OFF position after

switching On the machine. If not

coming indicates defective wash

timer

breaker and check for the

continuity using a multimeter. If

no continuity indicates circuit

breaker defective.

in the shaft. If anything as above

noticed indicates defective drive

assy.

Replace the spin

timer.

Replace the wash

timer.

Make contact

between the two

leads to the

circuit breaker

assy.

Replace the drive

assy

Doc No. WOI/washer/2001/009 Page No 19

Modified on date 03/08/2001 Subject to modification

Loading...

Loading...