Whirlpool WWA-780, WWA-880 Service Manual

SERVICE MANUAL

Automatic Washer WWA-780

(Philippines)

SPECIFICATION

Power source

Overall dimension(Net dimension)

Net weight

Power consumption

Motor output

Marked capacity of washing/spinning

Washing method

Water capacity

Water consumption

Pulsator speed

Spinner tub speed

AC 220V, 60Hz

540mmX562mmX940mm

33kg

380W

180W

7.8kg

Automatic reverse turn

52Liters

127 Liters (Regular wash cycle

Water level: High)

170 rpm(DELICATE 60 rpm)

850 rpm

Specification: Subject to change without notice.

WWA-780

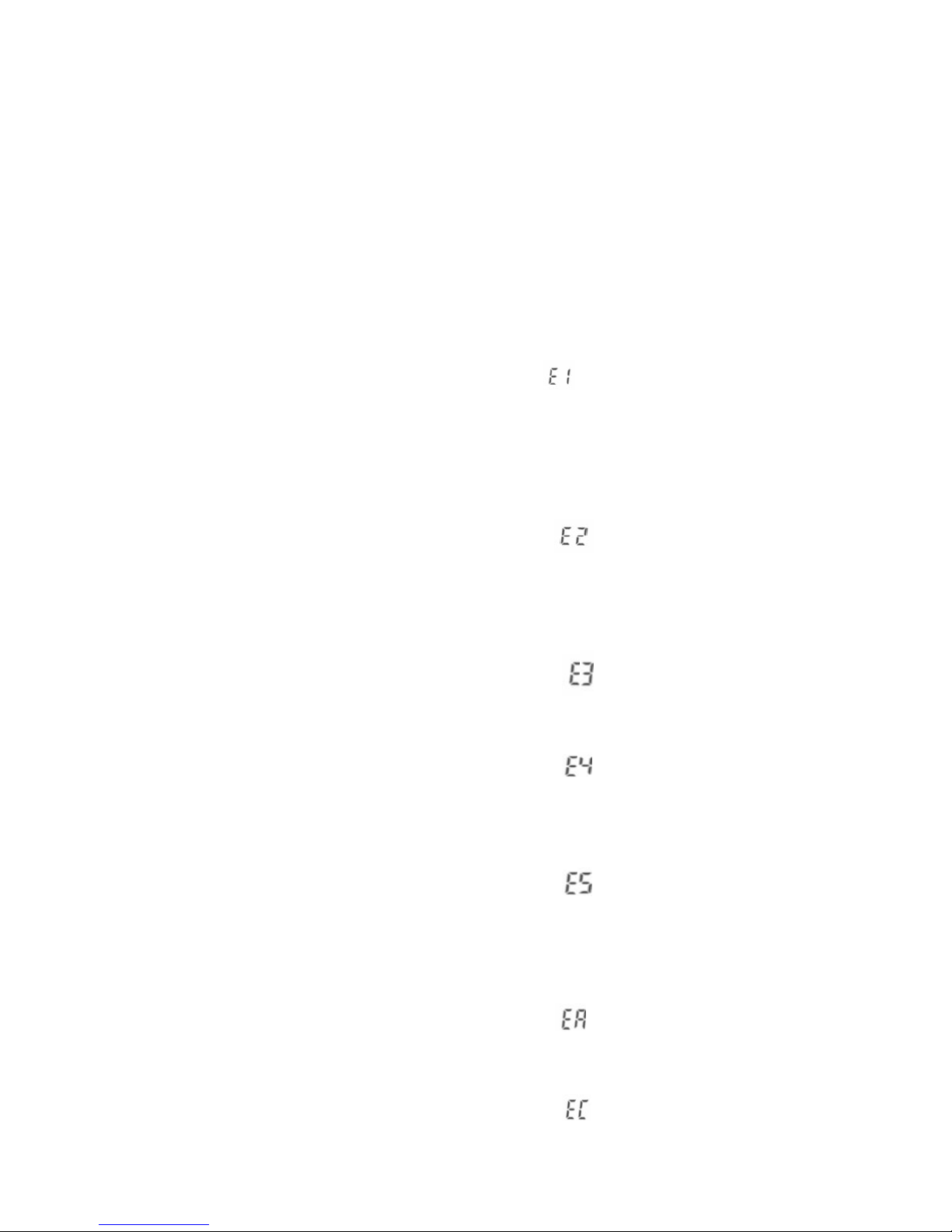

ABNORMAL CONDITION

When the washer is abnormal, the washer stops as the every actions turns off, beep tone

sounds ON-0.1 second and OFF-0.1 second for 6 seconds and number window LED display

abnormal code and blink on and off. The washer judges the following six conditions as abnormal

condition.

1) Abnormal condition of water supply

In supplying with water, the water level does not reach 1 level within 10 minutes or does not

reach your chosen water level within 20 minutes.

The number window LED display abnormal code: and begin blinking on and off at the

same time and the electric buzzer sounds to indicate a problem.

2) Abnormal condition of drain

In draining, the water level does not go down below the reset level of the water level sensor

within 8 minutes.

The number window LED display abnormal code: and the electric buzzer sounds to

indicate a problem at the same time.

3) Abnormal condition of spin-dry

• The safety switch works 3 times continuously during the program of rinse-spin or works 1

time in the single program of spin-dry.

The number window LED display abnormal code: and the electric buzzer sounds to

indicate a problem at the same time.

• The washer lid is opened.

The number window LED display abnormal code: and the electric buzzer sounds to

indicate a problem at the same time.

4) Abnormal condition of wash(child lock).

Running in setting child lock, the washer lid is opened beyond 4 seconds.

The number window LED display abnormal code: and the electric buzzer sounds to

indicate a problem at the same time.

5) Abnormal condition of water level sensor.

The water level sensor malfunctions or the water level is overrunning the alert level when the

water does not stop.

The number window LED display abnormal code: and the electric buzzer sounds to

indicate a problem at the same time.

6) Abnormal condition of load sensor.

The number window LED display abnormal code: and the electric buzzer sounds to

indicate a problem at the same time.

WWA-780

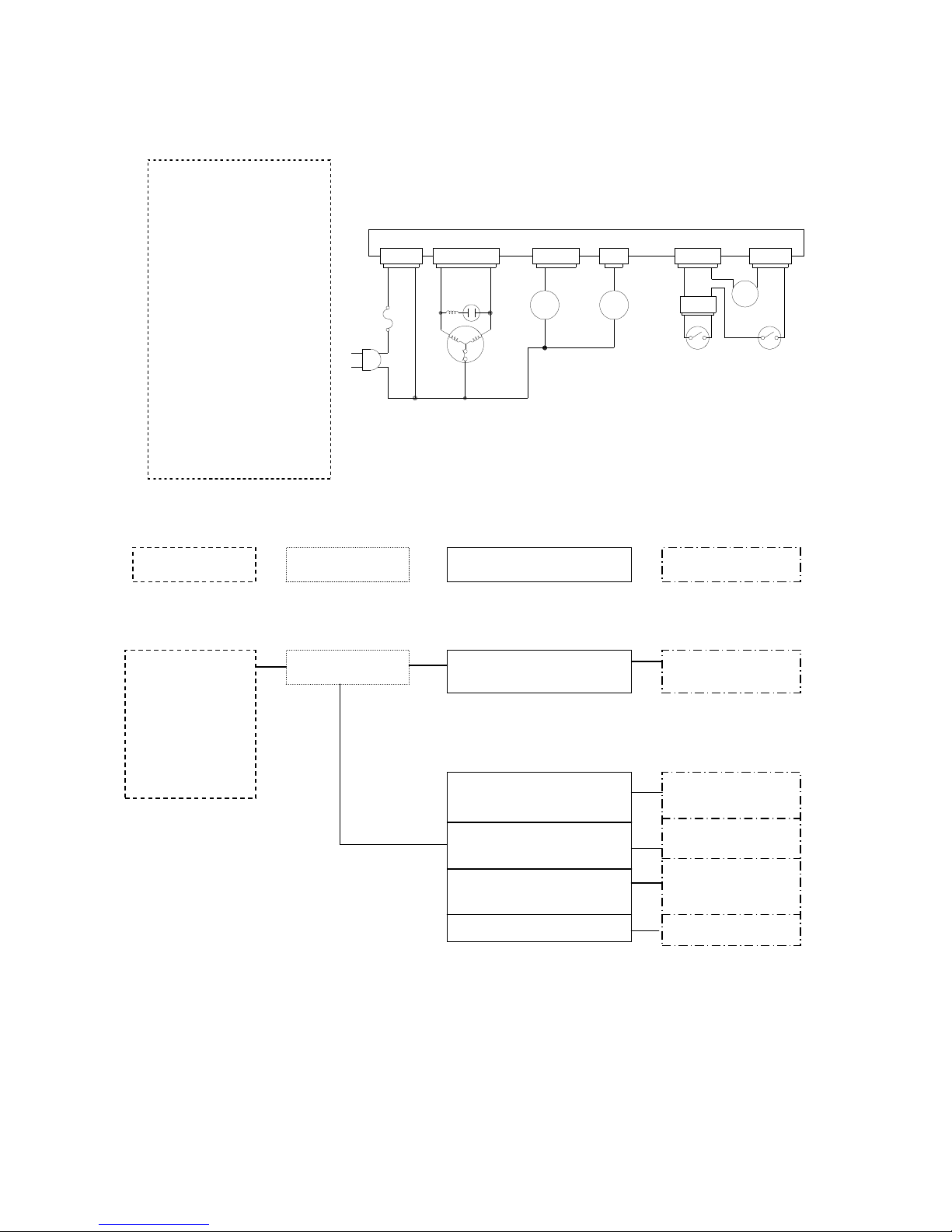

CIRCUIT DIAGRAM

Br Y

RLB

V Bl

W Gr

B

P. S

FUSE

5 A

LB

Br

MOTOR

LB

SWI TCH

PRESSURE

TUB

SWI TCH

PRI NTED CI RCUI T BOARD

CAPACI TOR

P

Y

R

2P W2P Bl2P O

1P P

2P Br

2P R

SWI TCH

LI D

2P B

B B

B

W. V

LB

WATER

VALVE

T. M

MOTOR

TORQUE

LB

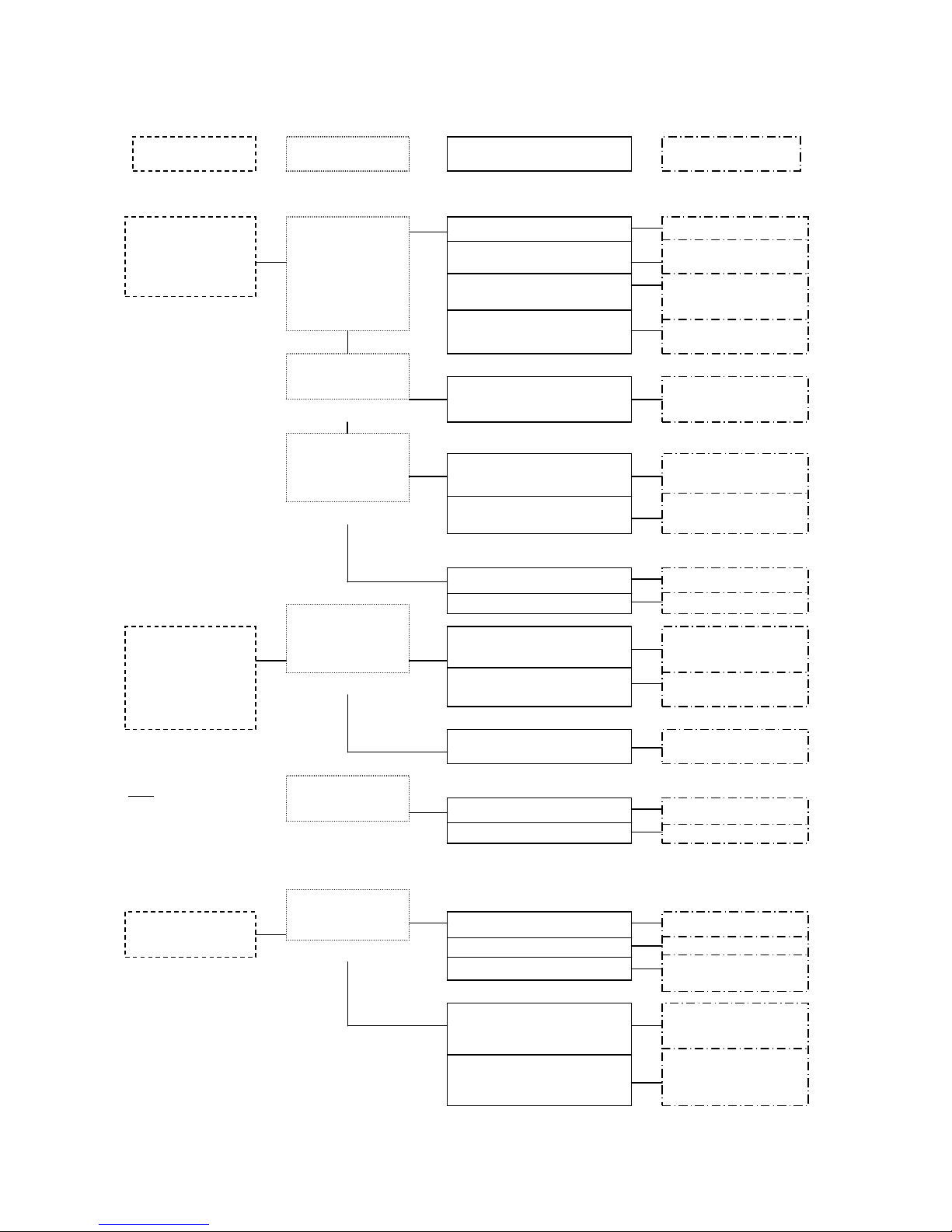

TROUBLE SHOOTING

a. Power Source

Yes

No

COLOR SYMBOL

Gr

Bl

G

B

LB

Br

O

P

R

W

Y

V

GRAY

BLUE

GREEN

BLACK

LIGHT BLUE

BROWN

ORANGE

PINK

RED

WHITE

YELLOW

VIOLET

TROUBLE INSPECTION CAUSES REMEDY

Any indications

and beep do not

work when

power switch is

on and the start

button is pressed

INSPECTION

Is fuse blown? Deterioration of fuse.

Replace.

Poor connect of

connectors

Control circuit board is

defective

Motor is defective.

Capacitor is defective.

Repair or replace.

Replace.

Replace.

Replace.

Feed hose assembly

Cushion

Does water stop

when the plug

is removed or

power switch is

OFF

Filter

WWA-780

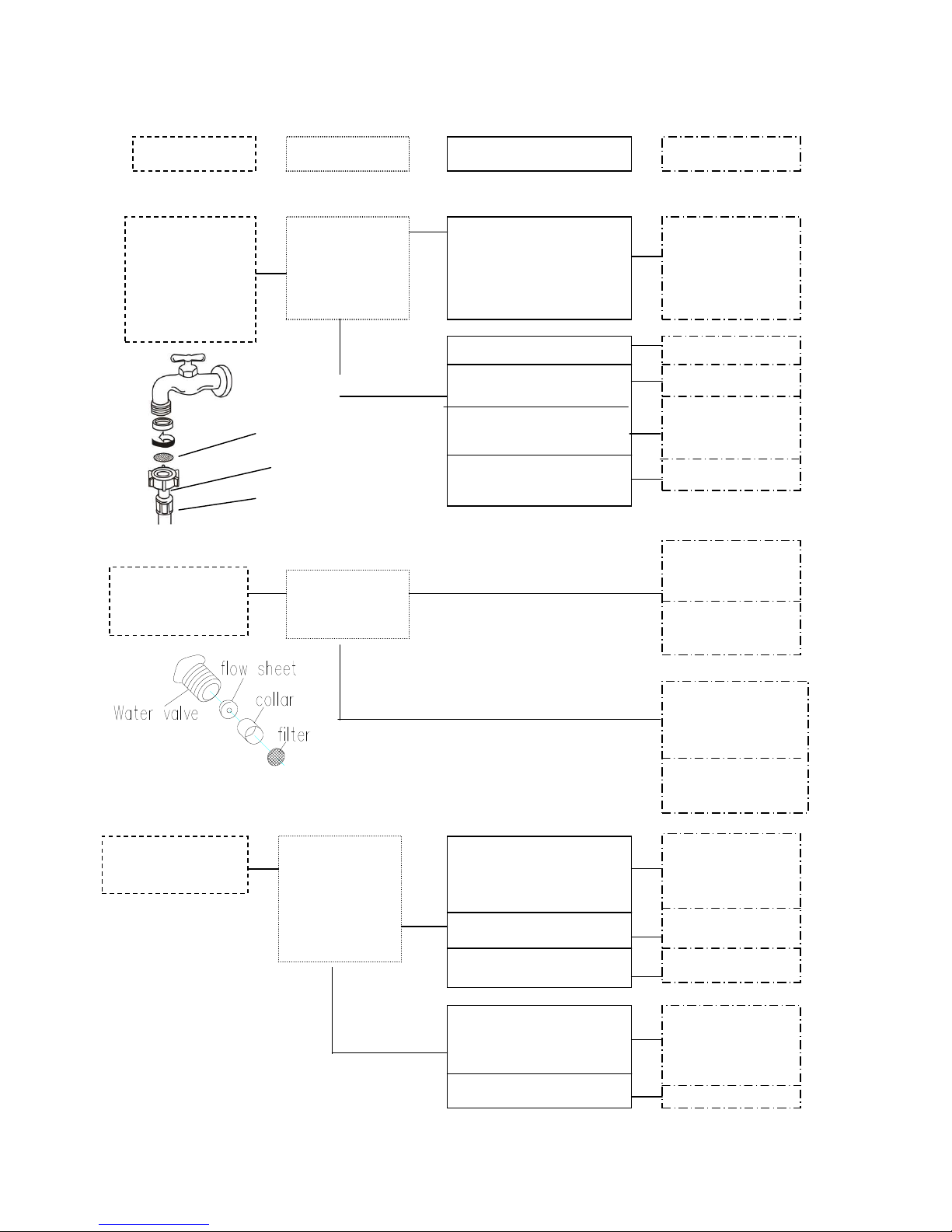

b. Water Supply

Yes

No

Low

High

Note: When removing the flow sheet, reinstate the filter in place correctly.

Yes

No

TROUBLE INSPECTION CAUSES REMEDY

Water does not

flow when the

power switch is

on and start

button is pressed.

INSPECTION

Does humming

noise come on

from water

Valve

Something on the filter of

the water valve or

feed hose assembly.

Clean the filter.

Water valve is defective.

Water level sensor is

defective.

Control circuit board is

defective.

Poor connect of

connectors

Replace.

Replace.

Replace.

Repair or replace.

Water is not

supplied normally.

Check water

pressure.

Remove the flow

sheet of the water

valve.

Replace the water

valve.

Clean the filter on

the water valve or

feed hose assembly.

Replace the water

valve.

Water

does not stop

Something in the air trap

hose or air leaks from a

part related water level

sensor system.

Water level sensor is

defective.

Control circuit board is

defective

.

Something on the

diaphragm on the water

valve.

Diaphragm is deformed

Clean or replace.

Replace .

Replace.

Replace or

disassemble the

valve and clean

the diaphragm

Replace

Bearing ass'y is defective.

Replace.

Motor wires are

dis-connected.

Capacitor wires are

dis-connected

.

Capacitor is defective.

Motor coil shorten.

Brake lining on bearing ass’y

is

worn out.

Brake lever ass’y is defective.

Brake lining

is

worn out.

Brake lever ass

’

y is defective.

Torque motor is broken.

Foreign matter in valve.

Valve spring is deformed.

Valve bellows is

deformed.

Torque motor lead wire is

disconnected.

Control circuit board is

defective.

WWA-780

c. Wash/Rinse

No

Yes

No

Yes

No

Yes

Yes

No

No

d. Drain

Yes

No

TROUBLE INSPECTION CAUSES REMEDY

Washing cycle does

not start even if

water keeps the

selected water level.

INSPECTION

Does the spin tub

rotated normally

when the

WASH OPTIONS

button is set t

o

SPIN?

Bearing ass’y is defective.

Poor connect of

connectors

Thermostat on motor is

opened.

Control circuit board is

defective.

Replace.

Replace.

Repair or replace

after cooling down.

Replace.

Does the pulsator

rotate by hand?

Does humming

noise come on

from motor?

Replace or repair.

Replace or repair.

Replace.

Replace.

The spin tub rotates

together with the

pulsator during

washing or rinsing

cycle.

Replace bearing ass’y.

Replace bearing ass’y.

Note:

Break-work is

normal when spin

tub stops within 10

sec. under no-load.

Does brake-work

normally?

Replace bearing ass’y.

Replace

bearing

ass’y.

Is the torque motor

working normally?

Replace.

Water does not

drain out.

Clean valve inside.

Replace spring.

Replace bellows or

replace valve.

Repair or replace.

Replace.

Is the torque motor

working normally?

WWA-780

e. Spin Drying

Yes

No

TROUBLE INSPECTION CAUSES REMEDY INSPECTION

Note: In draining, the water lever sensor can

not reset in 8minutes.

The number window LED display

abnormal code: and begin blinking

on and off at the same time and the

electric buzzer sounds to indicate a

problem.

Note: In draining, the water level sensor can

not reset in 10 minutes.

The number window LED display

abnormal code: and begin blinking

on and off at the same time and the

electric buzzer sounds to indicate a

problem.

Spin drying cycle

does not work.

INSPECTION

Does safety

device work?

Machine inclines. Replace with level.

The V-belt is slipping.

The V-belt is snapped.

Small pulley mounting

screw is loosed.

Motor is disconnected or

burnt.

Capacitor is broken or

disconnected.

Bearing ass’y is defective.

Torque motor is defective.

Brake lever is defective.

Thermostat on motor is

opened.

Poor contact of

connectors

Control circuit board is

defective.

Adjust the motor

position.

Replace.

Tighten up.

Replace.

Replace.

Replace.

Replace.

Repair or replace.

Repair or replace

after cooling down.

Repair or replace.

Replace.

Note:

1. The safety switch works 3 times

continuously or works 1 time in the

single program of spin-dry. The

number window LED display abnormal

code: and begin blinking on and off

at the same time and the electric buzzer

sounds to indicate a problem.

2. Do not disconnect the wire from the

capacitor, because this wire acts as

de-pressing noise from outside to the

micro-computer.

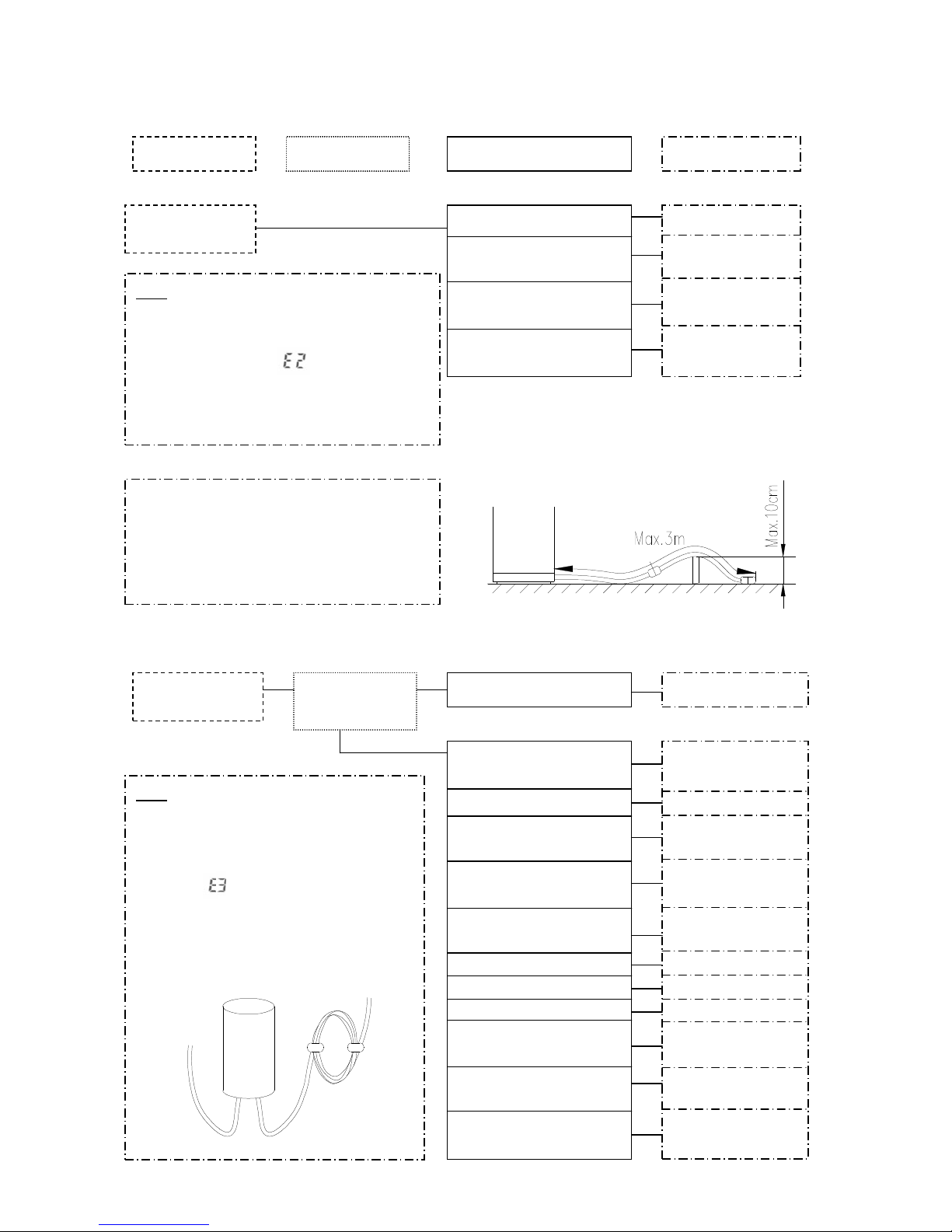

Drain takes time too

long.

Valve bellows is deformed.

Drain hose ass’y is

deformed.

Hose is connected in the

wrong way.

Hose is too long or position of

hose is too high.

Replace.

Repair or replace.

Repair.

Repair.

• If the Drain Hose is too long or high, it may

make draining impossible.

• The extend Drain Hose to a maximum long of

3 meters and maximum high of 10

centimeters.

Loading...

Loading...