Whirlpool WTW6300WW0 Parts Diagram

NECÈIP1EGAPW10240480A.ONTRAP

o

W10240480A

FOR SERVICE TECHNICIAN ONLY – D O NOT REMOVE OR DESTROY POURLETECHNICIEN SEULEMENT – NE PAS ENLEVERNIDÉTRUIRE

■

Check all connections before replacing

components. Look for broken or loose wires, failed

terminals, or wires not pressed into connectors far

enough.

■

A potential cause of a control not functioning

is corrosion or contamination on connections.

Observe connections and check for continuity

with an ohmmeter.

■

Connectors: Look at top of connector. Check for

broken or loose wires. Check for wires not pressed

into connector far enough to engage metal barbs.

■

Resistance checks must be made with washer

unplugged or power disconnected.

DIAGNOSTIC TESTS

There are three diagnostic test modes available:

Automatic, Manual, and Console and Indicators. These

tests allow the factory or service personnel to test and

verify all inputs to the machine/motor control. You may

want to allow the automatic test cycle to complete prior

to going into specific troubleshooting tests, to verify the

functionality of all of the washer subsystems.

ACTIVATION OF AUTOMATIC

DIAGNOSTIC TEST MODE

1. Be sure the washer is in standby mode (plugged

in with all indicators off; or with only the Clothes

Clean or Done indicator on).

2. Select any one button (except POWER, STAR T,

STOP, and PAUSE/CANCEL) and follow the steps

below, using the same button:

a. Press/hold 3 seconds.

b. Release for 3 seconds.

c. Press/hold 3 seconds.

d. Release for 3 seconds.

e. Press/hold 3 seconds.

➔

If this test mode has been entered successfully,

all indicators on the console are illuminated for

5 seconds with

88 showing in the Estimated

Time Remaining two-digit display.

➔

If indicators do not display as described above,

the press/hold/release procedure above may

not have been performed within the time frame

necessary for successful entry. Repeat step 2

to ensure this was not the cause. If still

unsuccessful, see Diagnostic: Unsuccessful

Entry, at right.

3. The test sequence continues by checking for saved

fault codes:

➔

If there are saved fault codes, see Diagnostic:

Saved Fault Codes, page 2.

➔

If there are no saved fault codes, all indicators

on the console will momentarily turn off, then

turn back on with

88 displayed. After

5 seconds, the Automatic test, below, begins.

DIAGNOSTIC: Automatic

Per forms a five-minute automatic test with water

functions to check major washer functions (lid can be

open). Press the same button used in step 2 above to

advance through automatic test steps.

NOTE: Basket must be floating in order to agitate.

Step C1 must be allowed to complete before

advancing to step C5.

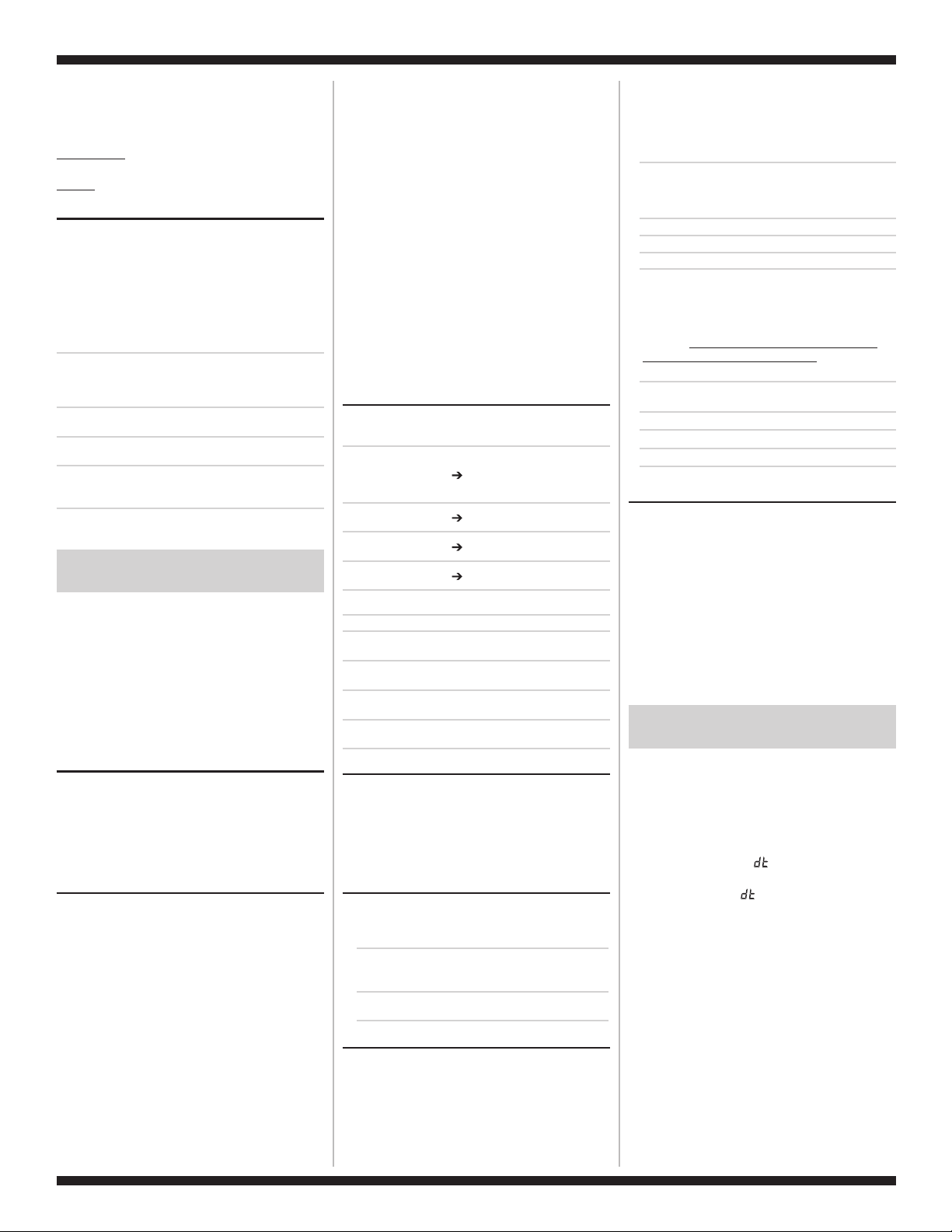

Two-Digit

Indicator

Washer

Function

Recommended

Procedure

C0

Slow spin to

23 rpm.

If no spin, go to

Manual: Motor, Spin

test, page 2.

Two-Digit

Indicator

Washer

Function

Recommended

Procedure

C1

Warm water fills

through Fresh

and Detergent

valves, then

Fresh valve until

basket floats

(disengages);

then washer

continues filling

through Fresh

and Detergent

valves to

minimum water

level.

If no water, or fill

temperature is wrong, go

to Manual: Water Valves

test, page 2.

If basket does not float

or disengage, determine

cause of friction.

C2

Cold water fills

through Bleach

valve for

10 seconds.

If no water in bleach cup,

go to Manual: Water

Valves test, page 2.

C3

Hot water fills

through Fabric

Softener* valve

for 10 seconds.

If no water in fabric

softener cup, go to

Manual: Water Valves

test, page 2.

C4

Warm water fills

through

Detergent valve

for 10 seconds.

If no water in detergent

cup, go to Manual: Water

Valves test, page 2.

C5

Heater turns on

for 5 seconds.

Test the heater element

as described in

TEST #9, page 6.

C6

Agitate for

15 seconds.

If no wash action, go to

Manual: Motor, Agitate

test; page 2.

C7

Recirculate for

10 seconds.

If water is not being

recirculated, go to Manual:

Pumps test, page2.

C8

Drain to basket

engaged plus

timed drain for

10 seconds.

If water is not draining,

go to Manual: Pumps

test, page 2.

If basket does not

engage determine cause

of friction.

C9

Drain & Slow

spin 23 rpm for

5 seconds, then

coast to 0 rpm.

If drain pump is not on,

go to Manual: Pumps

test, page 2.

If basket is not turning,

go to Manual: Motor test,

page 2.

If basket does not stop

spinning within

10 seconds, press STOP

or PAUSE/CANCELand

restarttest.

(none)

(Test

ends)

End of Cycle

beep.

If no end of cycle beep,

make sure cycle signal is

on. From Setting Mode,

pressing buttons should

sound valid key press

beep.

*

C3 will be displayed but no water will be dispensed

in models that have a centrifugal fabric softener

dispenser.

C5 will be displayed but no action will be taken on

non-heater models.

DIAGNOSTIC: Unsuccessful Entry

If entry into diagnostic mode is unsuccessful (see steps

1and2ofActivationofAutomatic DiagnosticTestMode,

at left), refer to the following indications and actions:

Indication 1: None of the indicators or display

turns on.

Action:

Press POWER button to enter setting mode.

➔

If indicators come on, try to change the function

for the button used to activate the diagnostic test

mode. If that button fails to change the function,

IMPORTANT

Electrostatic Discharge (ESD) Sensitive

Electronics

ESD problems are present everywhere. ESD may

damage or weaken the electronic control assembly.

The new control assembly may appear to work well

after repair is finished, but failure may occur at a later

date due to ESD stress.

■

Use an anti-static wrist strap. Connect wrist strap

to green ground connection point or unpainted

metal in the appliance -OR- Touch your finger

repeatedly to a green ground connection point or

unpainted metal in the appliance.

■

Before removing the part from its package, touch

the anti-static bag to a green ground connection

point or unpainted metal in the appliance.

■ Avoid touching electronic parts or terminal

contacts; handle electronic control assembly

by edges only.

■ When repackaging failed electronic control

assembly in anti-static bag, observe above

instructions.

WARNING

Electrical Shock Hazard

D

isconnect power before

servicing.

R

eplace all parts and

panels before operating.

Failure to do so can result

in death or electrical shock.

4,693,095

4,697,293

4,700,554

4,709,951

4,715,401

4,719,769

4,754,622

4,759,202

4,774,822

4,779,431

4,782,544

4,784,666

4,785,643

4,793,820

4,807,452

4,809,524

4,835,991

4,854,559

4,856,303

4,870,988

4,888,965

4,890,465

4,891,959

4,910,979

4,945,735

4,947,516

4,969,341

4,972,134

4,977,394

4,986,093

4,987,627

5,000,016

5,031,427

5,033,277

5,074,003

5,075,613

5,113,542

5,130,624

5,150,588

5,154,071

5,166,568

5,167,722

5,172,573

5,177,659

5,191,667

5,191,668

5,191,669

5,193,361

5,199,127

5,199,281

5,200,684

5,205,141

5,219,370

5,233,718

5,249,441

5,255,844

5,257,901

5,259,217

5,269,160

5,271,251

5,297,403

5,305,485

5,312,138

5,314,044

5,345,637

5,345,792

5,345,793

5,359,744

5,373,715

5,460,018

5,493,745

5,504,955

5,507,053

5,515,565

5,582,039

5,582,199

5,651,278

5,671,494

5,765,404

5,784,902

5,791,167

5,836,180

5,852,942

5,875,655

5,878,602

5,883,490

5,946,946

6,065,171

6,070,282

6,105,403

6,115,863

6,125,490

6,185,774

6,212,722

6,227,013

6,227,014

6,269,666

6,347,645

6,363,563

6,393,872

6,430,971

6,505,370

6,550,292

6,564,413

6,584,811

6,591,439

6,591,638

6,637,062

6,640,372

6,647,575

6,658,902

6,715,175

6,766,670

6,786,058

6,820,447

6,845,536

6,860,032

6,906,270

6,927,351

6,961,642

6,966,204

D375,390

D381,140

D423,740

D426,686

D456,572

D459,844

D463,631

D465,308

D474,566

D502,577

D511,955

SOFTWARE COPYRIGHTED. MANUFACTURED UNDER ONE OR MORE OF

THE FOLLOWING U.S. PATENTS:

DIAGNOSTIC GUIDE

Before servicing, check the following:

■

Make sure there is power at the wall outlet.

■

Has a household fuse blown or circuit breaker tripped?

Was a regular fuse used? Use a time-delay fuse.

■

Are both hot and cold water faucets open and water

supply hoses unobstructed?

■

Alltests/checks shouldbemadewithaVOM(volt-ohmmilliammeter) or DVM(digital-voltmeter) havinga

sensitivity of 20,000 Ω per voltDCorgreater.

NOTE: Avoid using large diameter probes when

checking harness connectors as the probes may

damage the connectors upon insertion.

♦

♦

NECÈIP2EGAPW10240480A.ONTRAP

o

W10240480A

FOR SERVICE TECHNICIAN ONLY – D O NOT REMOVE OR DESTROY POURLETECHNICIEN SEULEMENT – NE PAS ENLEVERNIDÉTRUIRE

something is faulty with the button, and it is not

possible to enter the diagnostic mode.

➔

If no indicators come on after pressing POWER

button, go to TEST #1, page 4.

Indication 2: Fault code flashes from the

display.

Action:

Review the Display Fault/Error Codes table,

page 3, for the recommended procedure.

DIAGNOSTIC: Saved Fault Codes

ACTIVATION OF MANUAL DIAGNOSTIC

TEST MODE

1. Read and perform steps 1 and 2 under

Activation of Automatic Diagnostic Test Mode,

page 1, and press the same button once during the

5 second display time of the

88.

NOTE: If the button is not pressed within 5 seconds,

the Automatic test will start (after saved fault codes).

2. If done successfully, a single beep occurs and the

two-digit display shows the User Interface ID# (

08,

09, etc.) for

3 seconds, then displays

00 and the

Add A Garment indicator LED flashes. See

Diagnostic: Manual, below.

DIAGNOSTIC: Manual

Enter Manual Diagnostic test mode, above. Two-digit

display shows

00, and Add A Garment indicator LED

is flashing.

NOTE: If there is no activity (button press, cycle select)

within 5 minutes, the control automatically exits

Diagnostic mode and enters standby mode.

Manual: Water Valves (See Manual Activation,

above)

To check FRESH valve selectorpressthefollowing:

WHITEST WHITES ➔ START (turns on Fresh valve,

cycle indicator flashes) ➔ WASH TEMP/RINSE TEMP

(enables fill of Hot, Warm, Cold, or no water according

to WASH TEMP/RINSE TEMP selection and indicator)

➔ START (turns off Fresh valve, cycle indicator is

steady on).

To check DETERGENT valve select or press the

following:

HEAVY DUTY ➔ START (turns on Detergent valve,

cycle indicator flashes) ➔ WASH TEMP/RINSE TEMP

(enables fill of Hot, Warm, Cold, or no water according

to WASH TEMP/RINSE TEMP selection and indicator)

➔ START (turns off Detergent valve, cycle indicator

is steady on).

T

o check FABRIC SOFTENER valve

select or press

the following:

NORMAL ➔ START (turns on Fabric Softener valve,

cycle indicator flashes) ➔ WASH TEMP/RINSE TEMP

(enables fill of Hot, Warm, Cold, or no water according

to WASH TEMP/RINSE TEMP selection and indicator)

➔ START (turns off Fabric Softener valve, cycle

indicator is steady on).

To check BLEACH valve selectorpressthefollowing:

CASUAL (if present; otherwise, SHEETS) ➔ START

(turns on Bleach valve, cycle indicator flashes) ➔

WASH TEMP/RINSE TEMP (enables fill of Hot,

Warm, Cold, or no water according to WASH TEMP/

NOTE: Models with Bleach valve located in alternate

➔

If any valve fails to turn on go to TEST #2, page 4.

Manual: Pumps (See Manual Activation, at left)

Models with Push-button cycles:

Press and release:

CLEAN WASHER

(Impeller) or DRAIN &

SPIN (Agitator)

Turns on recirculation pump,

button indicator is steady on.

Repeat

Turns off recirculation pump,

button indicator turns off.

Repeat

Turns on drain pump, button

indicator flashes.

Repeat

Turns off drain pump, button

indicator turns off.

Models using Cycle Selector:

Select CLEAN WASHER or DRAIN & SPIN.

Press and release:

START

➔

Turns on recirculation pump,

cycle indicator is steady on.

Repeat ➔

Turns off recirculation pump,

cycle indicator is off.

Repeat ➔

Turns on drain pump, cycle

indicator flashes.

Repeat ➔

Turns off drain pump, cycle

indicator is off.

➔ If pumpsfail to turn on, go to TEST #7, page 6.

Manual: Lid Switch (See Manual Activation,

at left)

Opening the lid should cause the Clothes Clean or Done

status indicator to turn off. Closing the lid should cause

the indicator to turn on.

➔

If Clothes Clean or Done indicator does not turn

off or on, go to TEST #8, page 6.

Manual: Lid Lock (See Manual Activation, at left)

NOTE: Lid must be closed. If lid is not closed, an invalid

button press beep will occur when performing next step.

Press and release:

2nd RINSE or

EXTRA RINSE

➔

Lid locks, Lid Lock indicator

turns on.

Repeat ➔

Lid unlocks, Lid Lock

indicator turns off.

➔

If lid does not lock or unlock,go to TEST #8, page 6.

Manual: Motor (See Manual Activation, at left)

Rotor Position Sensor (RPS): Uses Wash, Rinse,

and Spin indicators to detect the three hall sensors.

Console may have up to two of these indicators on

at one time when the basket is not moving. Open lid

and rotate basket by hand. The Wash, Rinse, and Spin

status indicators should toggle on and off according

to direction the basket is being turned.

Spin: To activate Spin, lid must be closed with lid lock

enabled. See Manual: Lid Lock test, at left.

NOTE: If lid is not closed, an invalid button press

beep will occur when performing next step.

Press and release:

SPIN SPEED,

WATER LEVEL

or LOAD SIZE

➔

Motor/basket spins at 23 rpm.

Repeat ➔

Motor/basket spins at 530 rpm.

Repeat ➔

Motor/basket spinsat ≥ 950 rpm.

Repeat ➔

Motor turns off.

NOTE: Indicators above button scroll from top to bottom.

➔

If motor fails to spin, go to TEST #3, page 4.

Agitate: Water must cover the wash plate (or agitator

vanes) to ensure the basket is floating prior to

agitation. Enabling agitation without enough water

may cause a fault condition to occur. See Manual:

Water Valves test, at left.

Press and release:

SOIL LEVEL

➔

Gentle wash action.

Repeat

➔

Normal wash action.

Repeat

➔

Heavy wash action.

Repeat

➔

Motor turns off.

NOTE: Indicatorsabove button scroll from top to bottom.

➔

If motor fails to agitate, go to TEST #3, page 4.

Manual: Heater (If supplied) (See Manual

Activation, at left)

Water must cover the wash plate to ensure the heater

is completely submerged. Heater will not be enabled

if there is less than 75 mm of water in the washer tub,

and if the Cold valve is not ON.

➔ Press WASH TEMP/RINSE TEMP until selecting

Cold/Cold or Cool/Cold.

ACTIVATION OF CONSOLE AND

INDICATORS DIAGNOSTIC TEST MODE

This test checks the cycle selector knob, indicators,

buttons, two-digit display, and beeper.

1. Plug in washer or reconnect power.

2. From Standby (Off) Mode press and release

(key-dance) the following buttons within 4 seconds:

SOIL

LEVEL

➔

WASH/RINSE

TEMP

➔

SOIL

LEVEL

➔

WASH/RINSE

TEMP

If successful, two-digit will display and you will

have 5 seconds to complete next step.

3. Within 5 seconds of showing in display, press

START (all indicators in display are illuminated and

88 is displayed.

➔

Press START a second time. This turns off the

two-digit display and status indicators except

for the Delay indicator (if present). All other

➔

Press START a third time. This turns on the twodigit display and status indicators except for the

Delay indicator (if present). All other indicators

4. Rotate WASH CYCLE selector back and forth.

Indicators will toggle on (or off).

5. Press buttonstoverify function.Indicatorswilltoggleon

(or off) and beep tonewill soundwhen buttonsarepressed.

The washer will save up to 4 of the most recent

fault codes. Fault codes will not be saved or displayed

in any order. If there are saved fault codes (as indicated

in step 3 of Activation of Automatic Diagnostic Test

M

ode, page 1), a saved fault code will be displayed and

alternately show “F” and “XX” where XX is the fault code,

and all the cycle selector indicators flash.

Press and release

the same button

used to activate

Diagnostics

➔

The next saved fault code

is displayed.

Repeat ➔

The next saved fault code

is displayed.

Repeat ➔

The final saved fault code

is displayed.

Repeat ➔

All indicators momentarily turn

off, then stay on. After 5 seconds,

Automatic test cycle begins.

NOTE: Fault codes are retained, after displaying them

and/or interrupting power.

RINSE TEMP selection and indicator) ➔ START

(turns off Bleach valve, cycle indicator is steady on).

position, as shown in Figure 4, can only fill cold through

bleach valve;for thesemodels, it is only necessary to Select

CASUAL andpress START for water tostart flowing through

thebleach dispenser.

➔

Ifnoneofthese indicatorsare on,goto TEST#3,page 4.

indicators remain illuminated.

remain illuminated.

➔

Press DELAY START (DELAY WASH). This turns

➔

Press DELAY START (DELAY WASH) a second

off the Delay indicator.

time. This turns on the Delay indicator.

To turn the Cold Valve ON:

➔ Select RINSE & SPIN cycle.

To turn the Heater ON:

➔ Press START/PAUSE or RINSE/DRAIN & SPIN.

➔ To verify Heater element, go to Test #9, page 6.

NECÈIP3EGAPW10240480A.ONTRAP

o

W10240480A

FOR SERVICE TECHNICIAN ONLY – D O NOT REMOVE OR DESTROY POURLETECHNICIEN SEULEMENT – NE PAS ENLEVERNIDÉTRUIRE

NOTE: Pressing SOIL LEVEL, SPIN SPEED,WATER

LEVELorLOAD SIZE, andWASH/RINSETEMPwillcause

allindicatorsabove thesebuttonstotoggleon(oroff)at

one time.

If either of the following occurs during preceding steps,

see TEST #4, page 5:

✔

No beep sound is heard

✔

Some buttons do not light indicators

DEACTIVATION OF DIAGNOSTIC

TEST MODE

Press the STOP, PAUSE/CANCEL, or POWER button

at any time to exit Automatic, Manual, or Console &

Indicators diagnostic test modes.

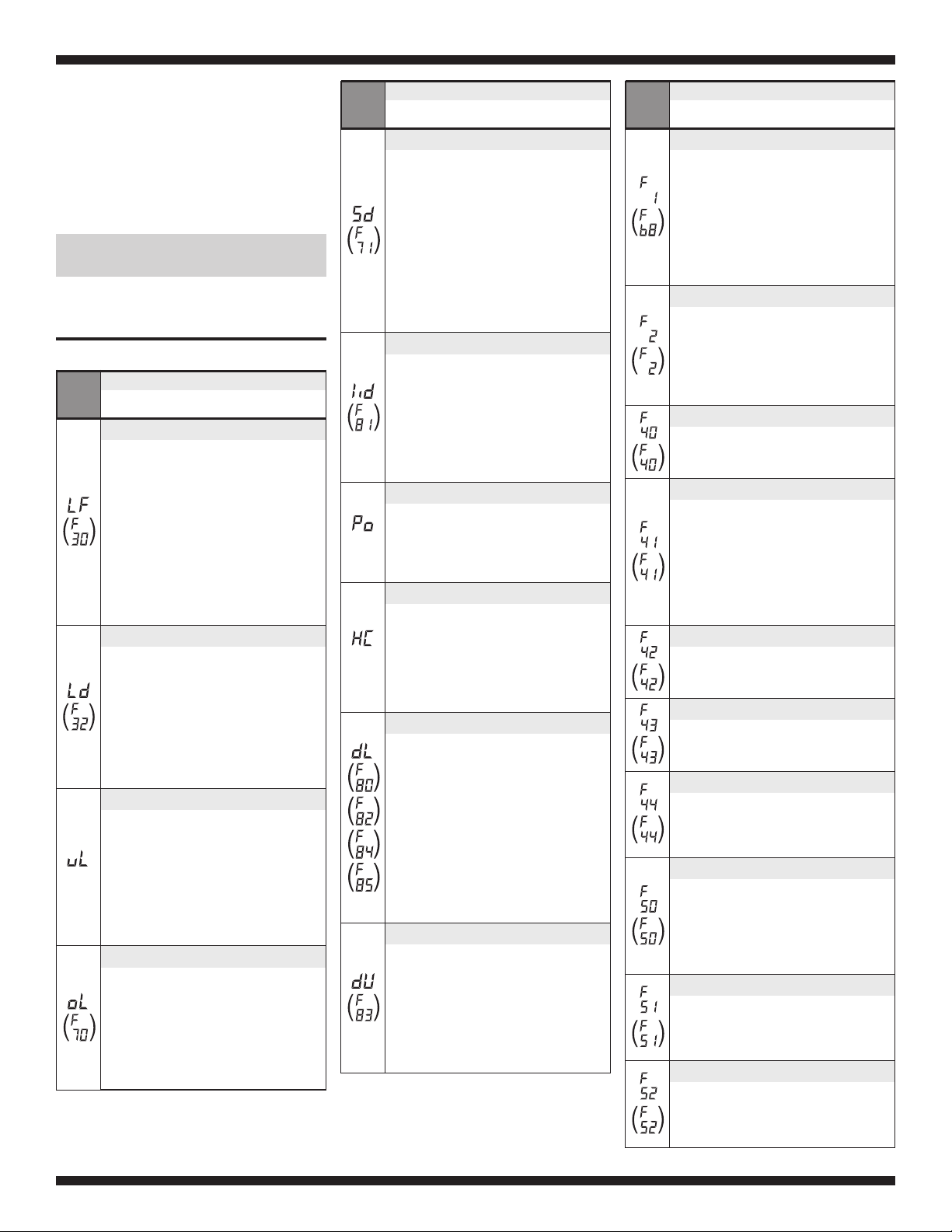

DISPLAY FAULT/ERROR CODES

Display

(Saved

Code)

EXPLANATION AND

RECOMMENDED PROCEDURE

Long Fill

LF flashes whenthewaterleveldoesnot

change foraperiodoftimeORwateris

present butcontrol does not detect thewater

levelchanging.

➔

Is water supply connectedandturnedon?

➔

Arehosescreensplugged?

➔

Is water siphoning out of the drain hose?

Check for proper drainhoseinstallation.

➔

Is thepressure hoseconnection from the tub

to the machine/motor control pinched,

kinked, plugged, or leaking air?

➔ SeeTEST#2,page4.

Long Drain

Ld flashes whenthewaterleveldoesnot

change after the drain pump is on.

➔

Is thedrain hoseorthedrain pump clogged?

➔

Is the drainhoseheight greater than 96"?

➔

Is thepressure hoseconnection from the tub

to the machine/motor control pinched,

kinked, plugged, or leaking air?

➔

Is thepumprunning? If not, see TEST #7,

page6.

(none)

Unbalanced Load

uL is displayedwhenthemachine/motor

control detectsanoff-balanceload,andis

steady on whilethewasherrunsamini-cycle

to rebalancetheload.

➔

Display clearsifmini-cyclesuccessfully

rebalancedtheload.

➔

If themini-cycleisunsuccessful,uL will

flash until the lid is opened,allowing the

customer to view and redistribute theload.

Overloaded

oL flashes when the machine/motor control

detects a load size that exceeds the

washer’s capacity OR basket cannot

disengage. This may signify:

➔

Load size exceeds washer capacity.Remove

excess laundry,thenrestart cycle.

➔

Mechanicalfriction on drive mechanism,

not allowing the basket to disengage.

Display

(Saved

Code)

EXPLANATION AND

RECOMMENDED PROCEDURE

Suds Detection

Sd is displayedwhenthemachine/motor

control, by analyzing drag on the basket,

detectsasuds-lockcondition, and is steady on

while thecontrol then runs a mini-clean out

cycle.Iftheclean outcycleisunabletocorrect

theover-sudsing problem, the cycle ends and

Sd flashes in the display. This may signify:

➔

Loadisbunchedortwistedaround agitator.

➔

Excessive detergentusage.

➔

Basket cannot engage during drain step.

➔

Mechanicalfriction on drive mechanism,

not allowing basket to engage.

Open/Close Lid

lid flasheswhen thefollowing conditions

occur:

➔

Userpresses START with lid open.

➔

UserpressesSTARTafter2consecutive

washer cycles without opening lid.

➔

The machine/motor control cannot detect the

lid switch opening and closing properly.

➔

SeeTEST#8,page6.

(none)

Pump Out(lid opened)

Po flasheswhen drain pump begins pumping

out water fromtubuponactivation by the

lid having been left open for more than 10

minutes.

➔ Close lid to stop drainpump.

(none)

Hot, Cold Reversed

HC flasheswhen the hot and cold inlethoses

arereversed.

➔ Make sureinlet hoses are connected

correctly.

➔ If hosesareinstalledproperly, Automatic

Temperature Control maybestuck in low

resistance range. SeeTest #5, page 5.

LidLockFailure

dL flashesifthefollowing conditions occur:

➔

Lidisnotclosed completely due to

interference.

➔

Check for lock interference with lid or lock

bezel.

➔

Washmedia buildup is preventing thelock

bolt from extending.

➔

Machine/motorcontrol detectsopenlid

switch whenattempting to lock.

➔

Machine/motor control cannot determine

if lidlock is in a locked state.

➔

SeeTEST#8,page6.

LidUnlockFailure

dU flashesifthefollowing conditions occur:

➔

Excessive forceonlidispreventing lock bolt

from retracting.

➔

Washmediabuildupispreventing lock bolt

from retracting.

➔

Machine/motor control cannot determine

if lid lock is in an unlocked state.

➔

SeeTEST#8,page6.

Display

(Saved

Code)

EXPLANATION AND

RECOMMENDED PROCEDURE

Pressure Signal Out-of-Range

F then 1 flasheswhen thecontrol detectsan

outofrange pressure signal.

➔

Check pressure hose connection from tub

to machine/motorcontrol.Ishosepinched,

kinked,plugged, or leaking air?

➔

If F then 1 repeats numerous times after

POWER is pressed and the pressure hose

connection is not pinched or kinked,

replace the machine/motor control.

Keypad/User Interface Failure

F then 2 flashes whenin:

➔

Diagnostic Test modeifastuck key

is detected.

➔

Standbymodeifthere is a user interface

mismatch.

➔

SeeTEST#4,page5.

ATCThermistorOpen/Short

F then 40 flasheswhen the ATC Thermistor

is detected to be open or shorted.

➔

See TEST #5, page 5.

Motor RPS Thermistor Open/Short

F then 41 flasheswhen the motor rotor

position sensor (RPS) thermistorisdetected

to be open or shorted.

➔

See TEST #3, page 4.

NOTE: This errorcodeisonly displayed when

viewing savedfault codes.

➔ See Diagnostic Test, page 1, for accessing

saved fault codes.

Heater in unknown state

F then 42 flasheswhen thecontrol cannot

detectiftheheaterisONorOFF.

➔

See TEST #9, page 6.

Heater is continuously ON

F then 43 flashes when the heater is ON

when it should be OFF.

➔

See TEST #9, page 6.

Heater cannot be turned ON

F then 44 flashes when the heater has been

turned ON by the control, but the control

cannot detect that the heater is ON.

➔

See TEST #9, page 6.

Motor Stalled

F then 50 flasheswhen the motor rotor

position sensor (RPS) sensesnorotation.

➔

Does basket turn freely? If not, make sure

bottomshipping packhasbeenremoved.

Determine cause of friction.

➔

If basket turnsfreely, seeTEST#3,page4.

Motor RPS Failure

F then 51 flasheswhen thereisamotor rotor

positionsensor (RPS)failure or lower harness

problem.

➔

See TEST #3, page 4.

Motor Stop Failure

F then 52 flasheswhen the motor rotor position

sensor (RPS) senses rotation afterStop

command.

➔

See TEST #3, page 4.

If none of the indicators light up, see TEST #1, page 4.

NECÈIP4EGAPW10240480A.ONTRAP

o

W10240480A

FOR SERVICE TECHNICIAN ONLY – D O NOT REMOVE OR DESTROY POURLETECHNICIEN SEULEMENT – NE PAS ENLEVERNIDÉTRUIRE

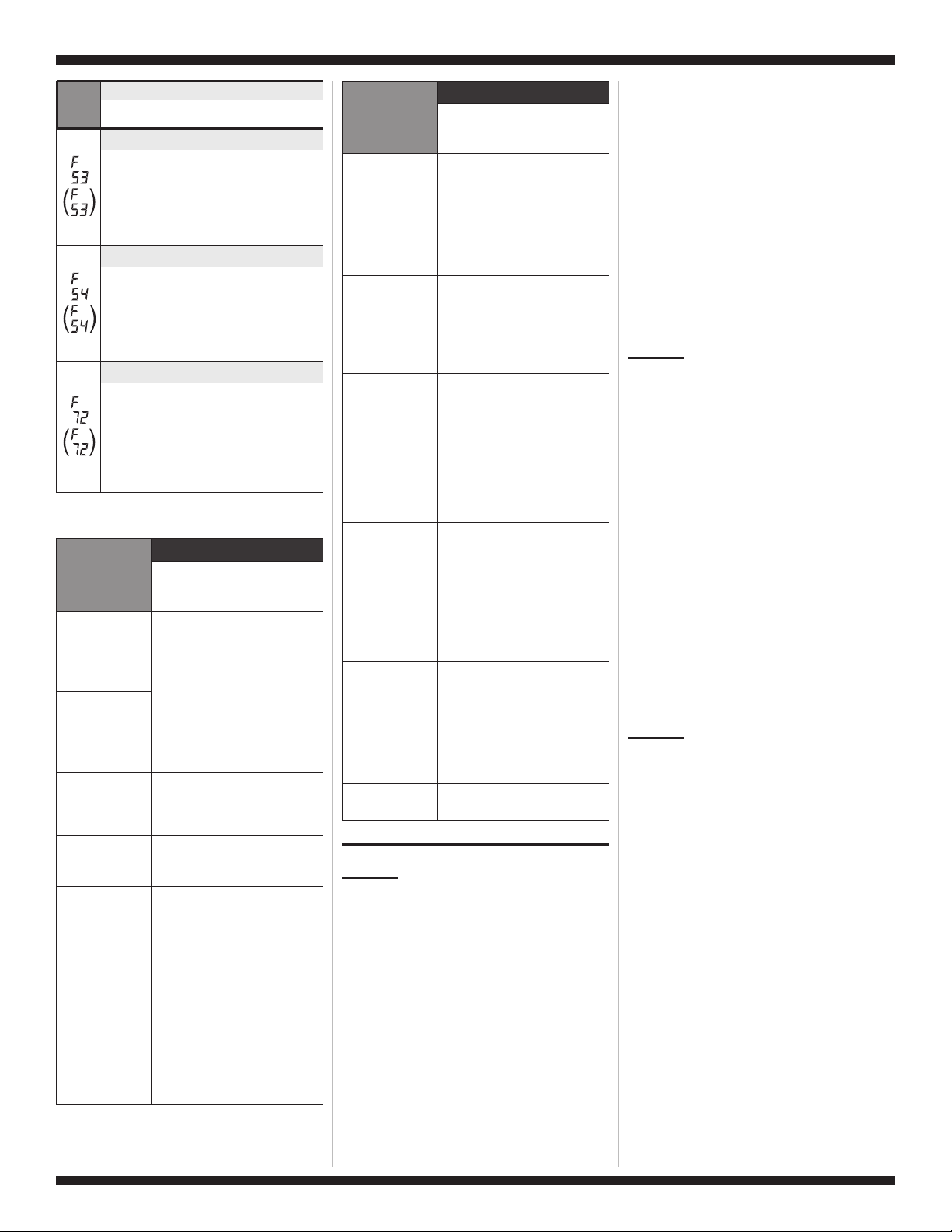

Display

(Saved

Code)

EXPLANATION AND

RECOMMENDED PROCEDURE

Motor ControlOvertemp

F then 53 flasheswhen themachine/motor

control detects high temperatureforthe motor

module.

➔

Does basket turn freely?Ifnot, determine

causeoffriction.

➔

If basket turnsfreely, seeTEST #3, at right.

MotorControl Overcurrent

F then 54 flasheswhen themachine/motor

control detects high currentforthe motor

module.

➔

Does basket turn freely?Ifnot, determine

causeoffriction.

➔

If basket turnsfreely, seeTEST #3, at right.

Basket Re-engagement Failure

F then 72 flashes when the basket check

routine fails to determine if the basket is

re-engaged after being disengaged.

➔

Is the basket floating? if yes, pump out

water. See Long Drain (Ld) procedure.

➔

Does basket turn freely? If not, determine

cause of friction.

TROUBLESHOOTING GUIDE

PROBLEM

POSSIBLE CAUSE/TEST

NOTE: Possible Cause/Test must

be performed in the sequence

shown for each problem.

WON’T POWER

UP

(No response

when buttons are

pressed.)

1. Supply connections. See

TEST #1, at right.

2. Unplug washer or disconnect

power.

3. Check harness connections.

4. User interface assembly. See

TEST #4, page 5.

WON’T START

CYCLE

(No response

when Start button

is pressed.)

WON’T SHUT

OFF WHEN

EXPECTED

1. User interface assembly. See

TEST #4, page 5.

2. Lid switch. See TEST #8,

page 6.

CONTROL

WON’T ACCEPT

SELECTIONS

User interface assembly. See

TEST #4, page 5.

WON’T

DISPENSE

1. Check water connections to

washer.

2. Check for plugged screen in

water source.

3. Log valve. See TEST #2, at

right.

WON’T FILL

1. Check water connections to

washer.

2. Check for plugged screen in

water source.

3. Log valve. See TEST #2,atright.

4. Unplug washer or disconnect

power.

5. Check harness connections.

PROBLEM

POSSIBLE CAUSE/TEST

NOTE: Possible Cause/Test must

be performed in the sequence

shown for each problem.

OVER FILLS

1. Unplug washer or disconnect

power.

2. Checkpressure hose connections.

3. Check to see if the pressure

hose has a hole, is pinched or

plugged.

4. Water level and calibration.

See TEST #6, page 5.

WON’T AGITATE

1. Make sure basket is floating.

2. Unplug washer or disconnect

power.

3. Check harness connections.

4. Lid switch. See TEST #8, page 6.

5. Motor. See TEST #3, at right.

WON’T SPIN

1. Lid switch. See TEST #8,

page 6.

2. Unplug washer or disconnect

power.

3. Check harness connections.

4. Motor. See TEST #3, at right.

WON’T DRAIN

1. Check drain hose installation.

2. Check for plugged drain hose.

3. Drain pump. See TEST #7, page6.

INCORRECT

WATER

TEMPERATURE

1. Check for swapped water

connections to washer.

2. ATC (Automatic Temperature

Control). See TEST #5,

page 5.

ALL HOT FILLS

1. ATC thermistor stuck in high

resistance range.

2. ATC (Automatic Temperature

Control). See TEST #5, page 5.

WON’T

RECIRCULATE

WATER

1. Unplug washer or disconnect

power.

2. Check for plugged recirculation

hose.

3. Check for leaks in recirculation

system.

4. Recirculation pump. See

TEST #7, page 6.

DISPLAY IS

FLASHING

See Display Fault/Error Codes,

page 3.

TROUBLESHOOTING TESTS

TEST #1 Supply connections

This test assumes that proper voltage is present at the

outlet.

1. Unplug washer or disconnect power.

2. Access the machine/motor control assembly. See

Accessing & Removing the Electronic Assemblies,

page 6.

3. With an ohmmeter, checkforcontinuity between the

neutral (N) terminal of theplugandP13-1 on the

machine/motorcontrol.Seefigures 4 and 5, page 15.

➔

If there is continuity, go to step 4.

➔

If there is no continuity, replace the power cord.

4. In a similar way, check the continuity between the L1

terminal of the plug and P13-3 on the machine/motor

control. See figures 4 and 5, page 15.

➔

If there is continuity, go to step 5.

➔

If there is no continuity, replace the power cord.

5. Visually check that the P13 connector is inserted

all the way into the machine/motor control.

6. Visually check that the user interface assembly

(P11 Connector) is properly inserted into the machine/

motor control.

7. If both visual checks pass, unplug the washer power

cord and then unplug the P11 connector (User Interface

board). Wait 1 min. 30 sec. Plug in the power cord

with only the P11 connector unplugged. Did the washer

lid lock and unlock just after plugging in? Did the

washer dispense water through any of the valves?

If not, replace the machine/motor control. If yes,

replace the user interface assembly. See Reinstalling

the Electronic Assemblies, page 6.

8. Plug in washer or reconnect power.

9. Follow procedure under Activation of Console and

Indicators Diagnostic Test mode, page 2, to verify

repair.

TEST #2 Log Valve

This test checks the electrical connections to the valves,

and the valves themselves.

1. Check the relays and electrical connections to the

valves by performing the steps under Diagnostic:

Manual, then Manual: Water Valves, page 2. Each

step in the test activates a group of valves. The

following steps assumes one (or more) valve(s)

failed to turn on.

2. For the valve(s) in question check the individual

solenoid valves:

➔

Unplug washer or disconnect power.

➔ Disconnect connector P1 and P2 from the

machine/motor control. See figure 5, page 15.

➔

Check harness connection to solenoid valves.

3. Check resistance of valve coils at contacts P1 and P2

shown in the wiring diagram on page 16. Resistance

should be between 790–840 Ω.

➔ If resistance readings are tens of ohms outside of

range, replace the entire log valve assembly.

➔ If resistance readings are within range, replace the

machine/motor control assembly.

4. Reconnect connectors P1 and P2 to the machine/

motor control.

TEST #3 Motor Circuit

This test checks the wiring to the motor and rotor

position sensor; and the motor and rotor position

sensor themselves.

NOTE: Drain water from tub.

1. See Activation of Manual Diagnostic Test Mode,

page 2 and check the motor and electrical

connections by performing the Spin test under

Manual: Motor, page 2. The following steps assumes

that this step failed.

2. Unplug washer or disconnect power.

3. Check to see if basket will turn freely.

➔

If basket turns freely, go to step 4.

➔

If basket does not turn freely, determine what is

causing the mechanical friction or lock up.

4. Remove the console to access the machine/motor

control assembly. See Accessing & Removing the

Electronic Assemblies, page 6.

5. Visually check that the P5 and P10 connectors are

inserted all the way into the machine/motor control.

➔

If visual checks pass, go to step 6.

➔

If visual checks fail, reconnect P5 and P10 and

repeat step 1.

NECÈIP5EGAPW10240480A.ONTRAP

o

W10240480A

FOR SERVICE TECHNICIAN ONLY – D O NOT REMOVE OR DESTROY POURLETECHNICIEN SEULEMENT – NE PAS ENLEVERNIDÉTRUIRE

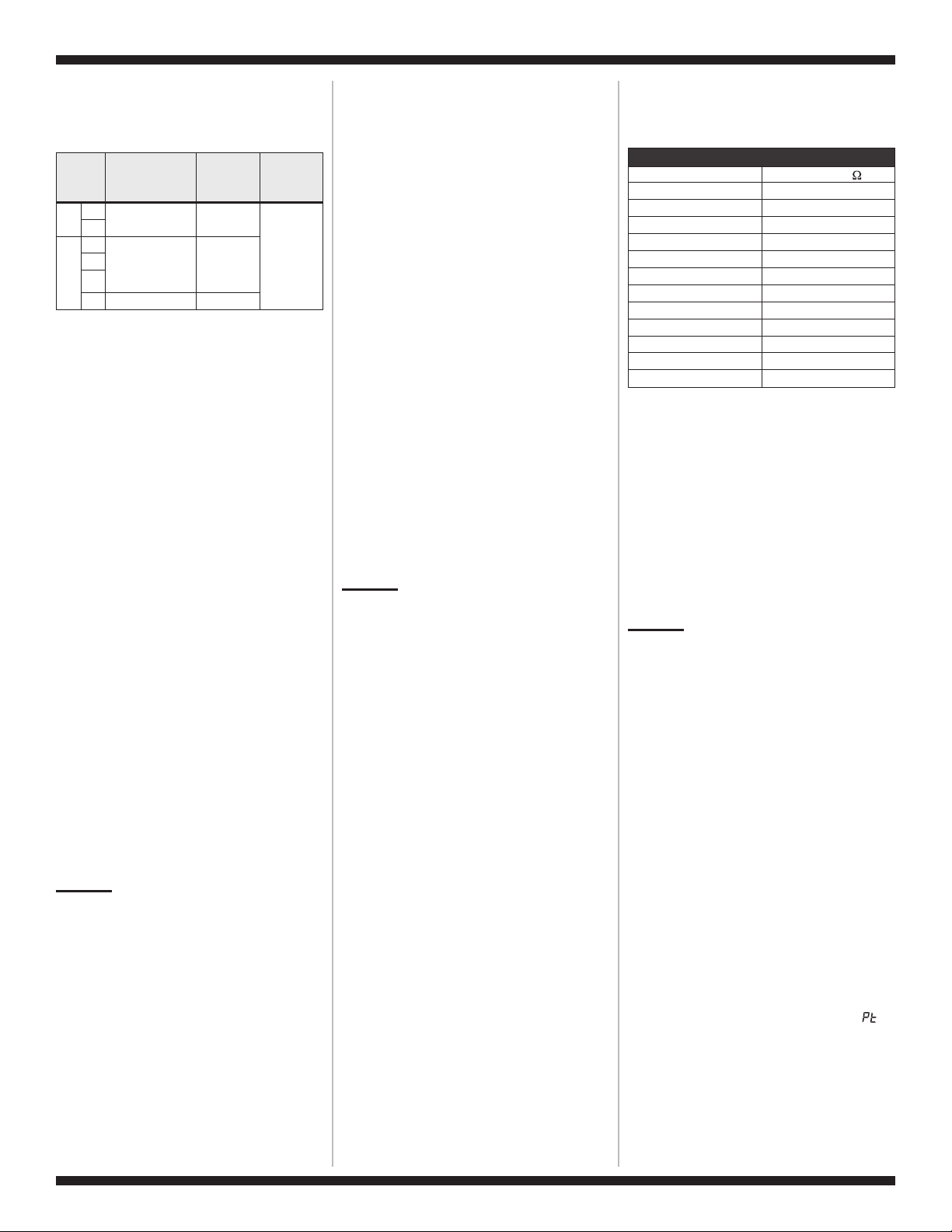

6. Visually check that the P5 and P10 connectors are

inserted all the way into the machine/motor control.

➔

With an ohmmeter, verify resistance values as

shown below:

C

heck

b

etween

c

onnector

pins

R

esistance

values

should be:

G

o to

step7if

values are:

G

o to

s

tep12if:

P5

1-2

31 Ω ± 5 Ω

Much higher

than 31 Ω

Resistances

at all

connectors

are correct

1-3

P10

6-5

1.5 kΩ ± 100 Ω

Much higher

or much

lower than

1.5 kΩ

6-4

6-3

1-7 600 Ω to 21.2 kΩ Out of range

7. Tilt washer forward to access the bottom of the

washer and the drive motor area. See figure 1,

page 14. Remove the motor bolt, then the motor

cover to access the motor connections. See figure 2,

page 14.

8. Visually check the mounting bracket and electrical

connections to the motor and rotor position sensor

board.

➔

If visual check passes, go to step 9.

➔

If visual check fails, reconnect the electrical

connections, reassemble stator and motor cover

and repeat step 1.

9. With an ohmmeter, check for continuity between all

pins on the P10 machine motor control connector

and the motor rotor position sensor (RPS) connector.

See figures 2 and 5, pages 14 and 15.

➔

If there is continuity, check the motor windings.

If the motor windings are open, replace the drive

motor.

➔ If there is no continuity, replace the lower machine

harness.

10. With an ohmmeter, check for continuity between

all pins on the P5 machine/motor control connector

and the drive motor connector.

➔

If there is continuity, replace the drive motor.

➔

If there is no continuity, replace the lower

machine harness.

11. The drive motor and lower harness are good.

Replace the motor RPS board and perform the

Diagnostics test in step 1 to verify repair.

12. If the Diagnostics motor test in step 1 failed, then

the machine/motor control has failed:

➔

Unplug the washer or disconnect power.

➔

Replace the machine/motor control assembly.

➔

Per form the Motor Diagnostics in step 1 to verify

repair.

TEST #4 Console and Indicators

This test is performed when either of the following

situations occurs during the Console and Indicators

Diagnostic Test, page 2:

✔

No beep sound is heard

✔

Some buttons do not light indicators

None of the indicators light up:

Execute TEST #1, page 4.

No beep sound is heard:

1. Per form steps in Accessing & Removing the

Electronic Assemblies, page 6 and visually check

that the P11 connector is inserted all the way into

the machine/motor control.

➔

If visual check passes, replace the user interface

assembly.

2. Plug in washer or reconnect power.

3. Follow procedure under Activation of Console and

Indicators Diagnostic Test mode, page 2 to verify

repair.

4. If replacing the user interface assembly failed:

➔

Unplug washer or disconnect power.

➔

Replace the machine/motor control assembly.

➔

Plug in washer or reconnect power.

➔

Activate the Console and Indicators Diagnostic

Test mode, page 2 to verify repair.

Some buttons do not light indicators:

1. Per form steps in Accessing & Removing the

Electronic Assemblies, page 6 and visually check

that the console electronics and housing assembly

is properly inserted into the front console.

➔ If visual check passes, replace the user interface

assembly.

2. Plug in washer or reconnect power.

3. Follow procedure under Activation of Console and

Indicators Diagnostic Test mode, page 2 to verify

repair.

TEST #5 Automatic Temperature Control

This test checks the water inlet valves, the temperature

sensor, and the machine/motor control.

1. Check the valves by performing Test #2, page 4

before continuing to the next step.

2. Ensure proper hose connections and that

household’s hot water is present.

3. Plug in washer or reconnect power.

4. Remove all clothes from the washer.

5. Select POWER ➔ wash cycle NORMAL➔

Wash/Rinse Temp. WARM/COLD ➔ START.

6. After the tub fills and star ts to wash, stop the

washer.

7. Measure the water temperature, and verify it is

85°±10°F (29°±6°C).

➔

If the water temperature is correct,ATCis

functional.

➔

If the water temperature is incorrect, then go

to step 8.

8. Unplug washer or disconnect power.

9. Access the machine/motor control assembly. See

Accessing & Removing the Electronic Assemblies,

page 6.

10. Remove the P9 connector, and using an ohmmeter,

measure the resistance between pins P9-1 and

P9-3. Verify that the resistance is within range as

shown in the following table:

THERMISTOR RESISTANCE

Temperature Resistance(

)

32°F (0°C) 32.6–34.2 kΩ

40°F (4.4°C) 26–27.5 kΩ

50°F (10°C) 19–20.5 kΩ

60°F (16°C) 15–15.7 kΩ

70°F (21°C) 11.7–12.2 kΩ

80°F (27°C) 9.1–9.5 kΩ

90°F (32°C) 7.2–7.6 kΩ

100°F (38°C) 5.6–5.9 kΩ

110°F (44°C) 4.6–4.9 kΩ

120°F (49°C) 3.6–3.8 kΩ

130°F (55°C) 2.9–3.1 kΩ

140°F (60°C) 2.4–2.6 kΩ

➔

If the resistance is within the range shown in the

table, go to step 12.

➔

If the resistance is infinite or close to zero, go to

step 11.

11. Using an ohmmeter, measure continuity between

all pins on the P9 connector and the thermistor

contacts.

➔

If there is continuity, replace the log valve

assembly.

➔ If there is no continuity, replace the upper

harness.

12. The log valve and upper harness are good.

Replace the machine/motor control assembly. See

Reinstalling the Electronic Assemblies, page 6.

TEST #6Water Level and Pressure

Transducer Calibration

This test checks the water level sensing components,

and calibrates the pressure sensor.

1. Unplug washer or disconnect power.

2. Access the machine/motor control assembly. See

Accessing & Removing the Electronic Assemblies,

page 6.

3. Check hose connection between the pressure

transducer on the machine/motor control and the

pressure dome attached to the tub. Check to ensure

hose is routed correctly in the lower cabinet and not

pinched or crimped by the back panel.

4. Plug in washer or reconnect power.

5. Drain the tub until all water has been removed

from tub.

6. Remove all clothes from the washer.

7. Calibrate the pressure transducer:

➔

See Activation of Manual Diagnostic Test Mode,

page 2, and perform steps 1 and 2 until the

display shows

00 and the Add A Garment

indicator LED is flashing.

➔

Press and hold the Cycle Signal button until a

single beep sounds, and the display shows

to indicate zero calibration has completed.

➔

Exit Diagnostic: Manual by pressing either STOP,

PAUSE/CANCEL, or POWER.

8. Select POWER ➔ wash cycle NORMAL ➔ START.

9. Verify that the tub fills to the top of the impeller plate

(impeller models) or to a level above the agitator

vanes (agitator models), but much lower than the

SUPER Load Size or KING PLUS water level.

NOTE: On some models, the EOC button and the EOC

Off button (if present) do not have an LED indicator.

Loading...

Loading...