Whirlpool WSR413YW0 User Manual

Water Filtration

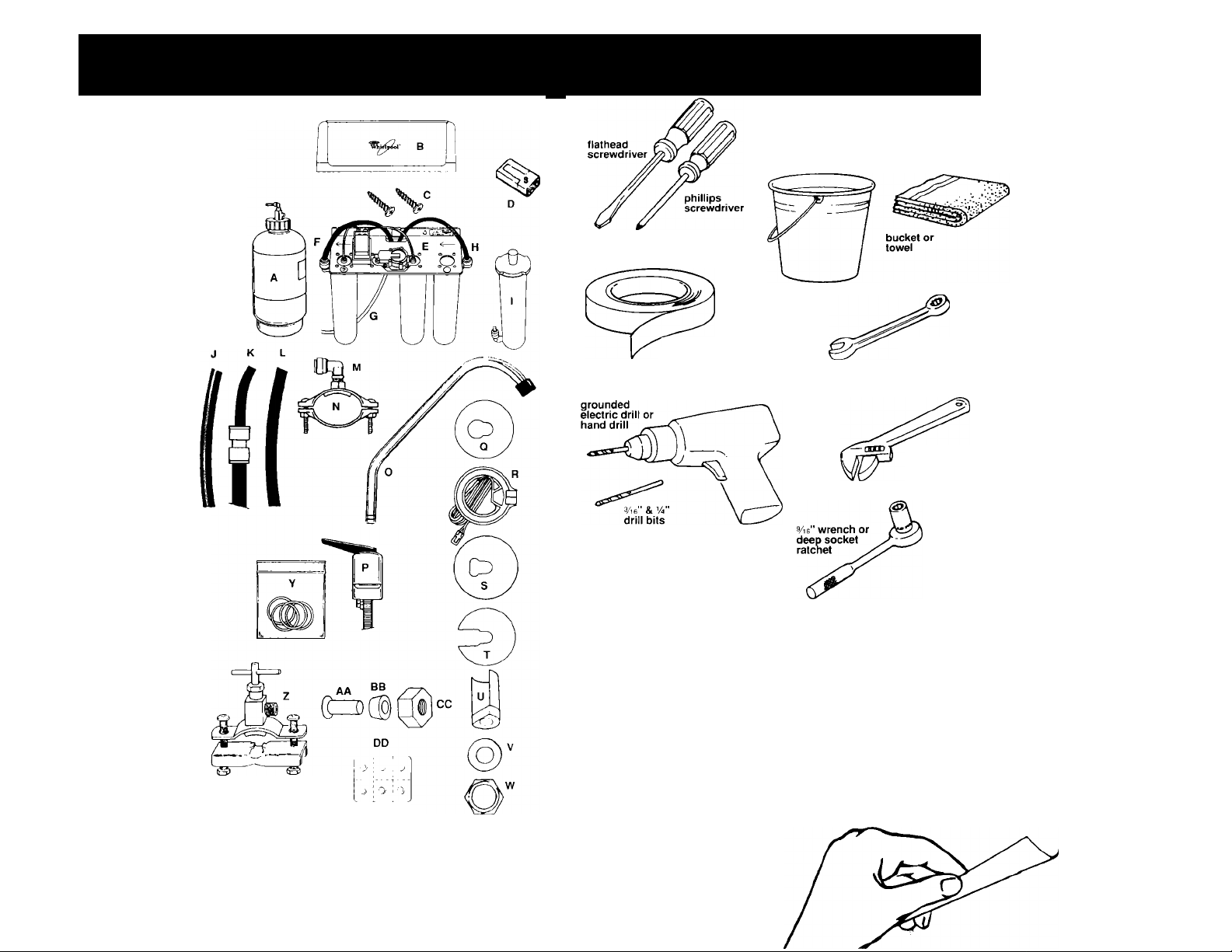

System Parts

Remove parts from packages.

Check that you have all the parts.

storage tank with base (A)

filtration assembly cover (B)

two mounting screws (C)

9-volt battery (D)

filtration assembly (E)

%" blue tubing (F)

Va" yellow tubing (G)

Va" orange tubing (H)

RO membrane cartridge (I)

3/e" black tubing (J)

'/i" red tubing with push-in

connector attached (K)

Va" green tubing (L)

drain saddle elbow (M)

drain saddle valve

assembly (N)

air-gap faucet assembly:

faucet spout (O)

faucet base (P)

chrome base plate (Q)

LED indicator disk (R)

rubber washer (S)

slotted washer (T)

spacer(U)

flat washer (V)

Va" hex nut (W)

%" grey connector

with push-in end (X)

packet of extra o-rings (Y)

saddle valve assembly (Z)

insert (AA)

plastic sleeve (BB)

brass compression nut (CC)

nitrate test kit (DD)

literature package

1

masking tape

Materials Needed for Basement

Installation

• step ladder

• shelf or bracket capable of

supporting 16 pounds

• Va" drill bit

• safety glasses

• Basement Installation Kit,

Part No. 4373517 available

from your Whirlpool dealer.

Tools Needed

for Installation

V2” wrench

ii"wrench

adjustable

wrench

NOTE:

Some state and local plumbing

codes prohibit the use of saddletype valves. The use of saddle-type valves is

prohibited in: Alaska, Delaware, Idaho, Kentucky,

Massachusetts, Michigan, Minnesota, New Hampshire, North

Dakota, Ohio, Oregon and South Dakota. Check your local plumbing

codes for details.

Massachusetts CMR 248 strictly prohibits the use of saddle-type

valves. The feed-water connection must conform to applicable

plumbing codes.

Open This Flap For Installation Overview

B

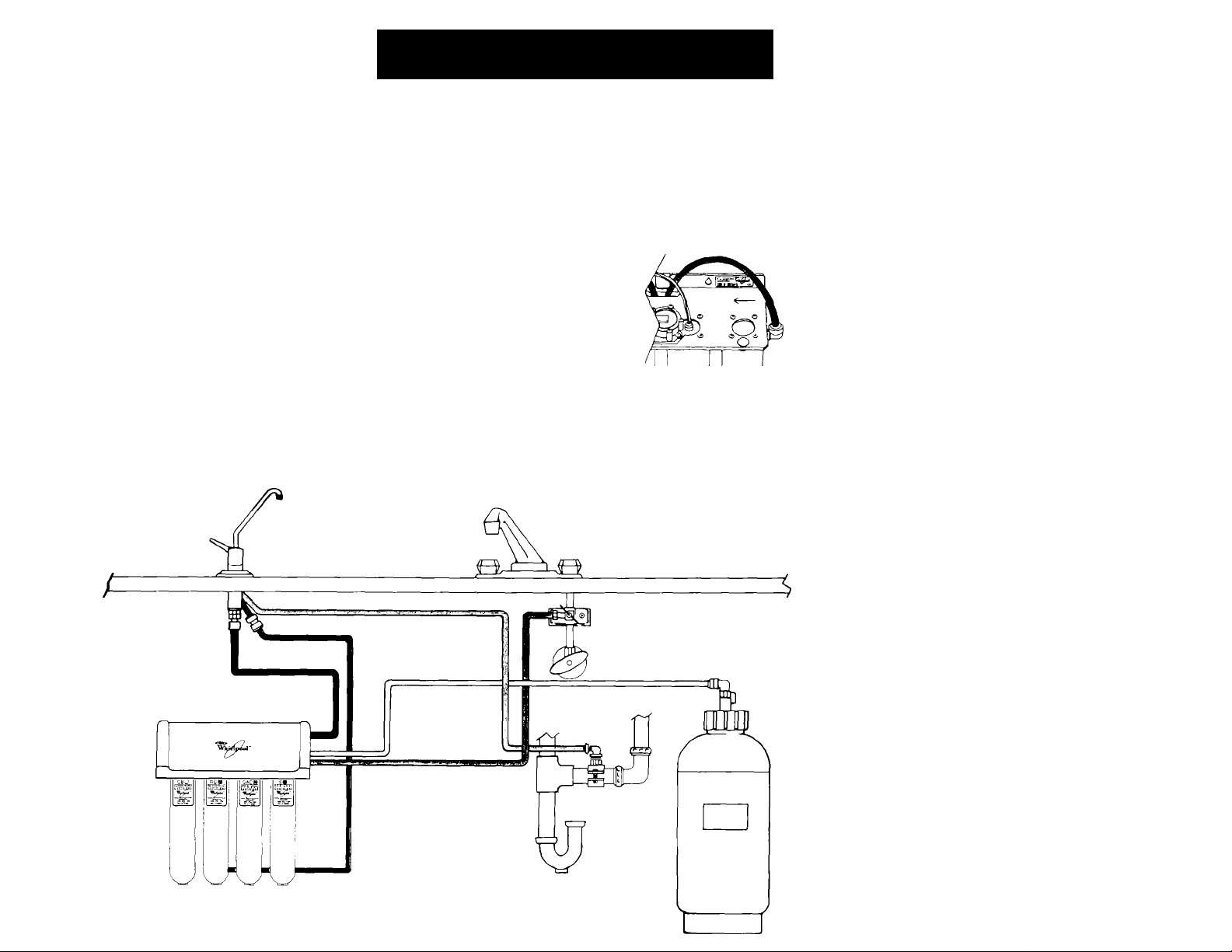

Installation Overview

Before You Start...

IMPORTANT: Read and save these instructions.

It is recommended that this system be installed by a licensed

plumber. It is the responsibility of the installer to comply

with the installation specifications provided and with

state and local plumbing codes.

If you decided to install the system yourself, see

“General Information” on page 13 before continuing.

Water Filtration System IV can be installed in the basement if

there is not adequate room for under-sink installation, howev

er. no more than 14 additional feet of tubing should be used.

Order Basement Installation Kit, Part No. 4373517 from your

Whirlpool dealer and follow the kit instructions. DO NOT use

filtration system if water is microbiologically unsafe or water

quality is unknown. Pretreat water that exceeds limits for

hardness, iron, manganese, and hydrogen sulfide.

If you need assistance ...

Refer to the Use & Care information at the end of this

booklet. If you need more help, the Whirlpool Consumer

Assistance Center will answer any questions you may

have about operating or maintaining your RO water

filtration system. The Whirlpool Consumer Assistance

Center is open 24 hours a day. 7 days a week. Just dial

1-800-253-1301—the call is

free. When you call, you will

need the RO water filtration

system model number and

serial number. Both num

bers can be found labeled

on the top right side of filtra

tion assembly.

Reverse Osmosis

Water Filtration System

HOOK UP WATER

• Turn off cold water supply.

• Turn on faucet to drain water

from line.

• Connect saddle valve to cold

water supply.

• Turn saddle valve handle clockwise until

piercing lance enters pipe and stops.

0

CONNECT FAUCET

• Connect faucet spout, chrorne

base plate, indicator light disk

and rubber washer to faucet base.^

• Connect green tubing and black tubing

to faucet. '

• Place faucet in sink opening. Secure

faucet to sink with slotted washer,

spacer, flat washer, hex nut and grey

connector. Connect blue tubing to

bottom of faucet assembly.

• Connect faucet indicator wire to wire

harness on filtration assembly.

Insert battery.

CONNECT TUBING

• Install RO cartridge into filtration

assembly. Connect one end of

red tubing to bottom of RO

cartridge. Connect other end to green

tubing from faucet.

• Connect orange tubing to saddle valve.

• Use orange tubing from filtration

assembly to fill storage tank with water.

• Connect yellow tubing to storage tank.

CONNECT DRAIN

• Decide where'drain saddlewill

be mounted. The best place Is

on a horizontal drain tailpiece

above (before) the trap. ■ v

• Connect drain saddle to drain pipe.

• Drill hole in drain using opening in drain

saddle as a guide.'. :

• Thread elbow into drain saddle.

Connect black tubing to elbow.

FLUSH SYSTEM

• Slide filtration assembly onto

mounting screws.

• Turn on faucet and drain tank to

flush disinfectant from tank.

• Turn on cold water supply and

saddle valve.

• Allow tank to fill • approximately 4 hours.

Lift faucet handle to drain tank, Fill and

drain tank again - another 4 hours. Wait

for tank to fill again. When faucet is

turned on, green indicator light will

indicate water is ready for use.

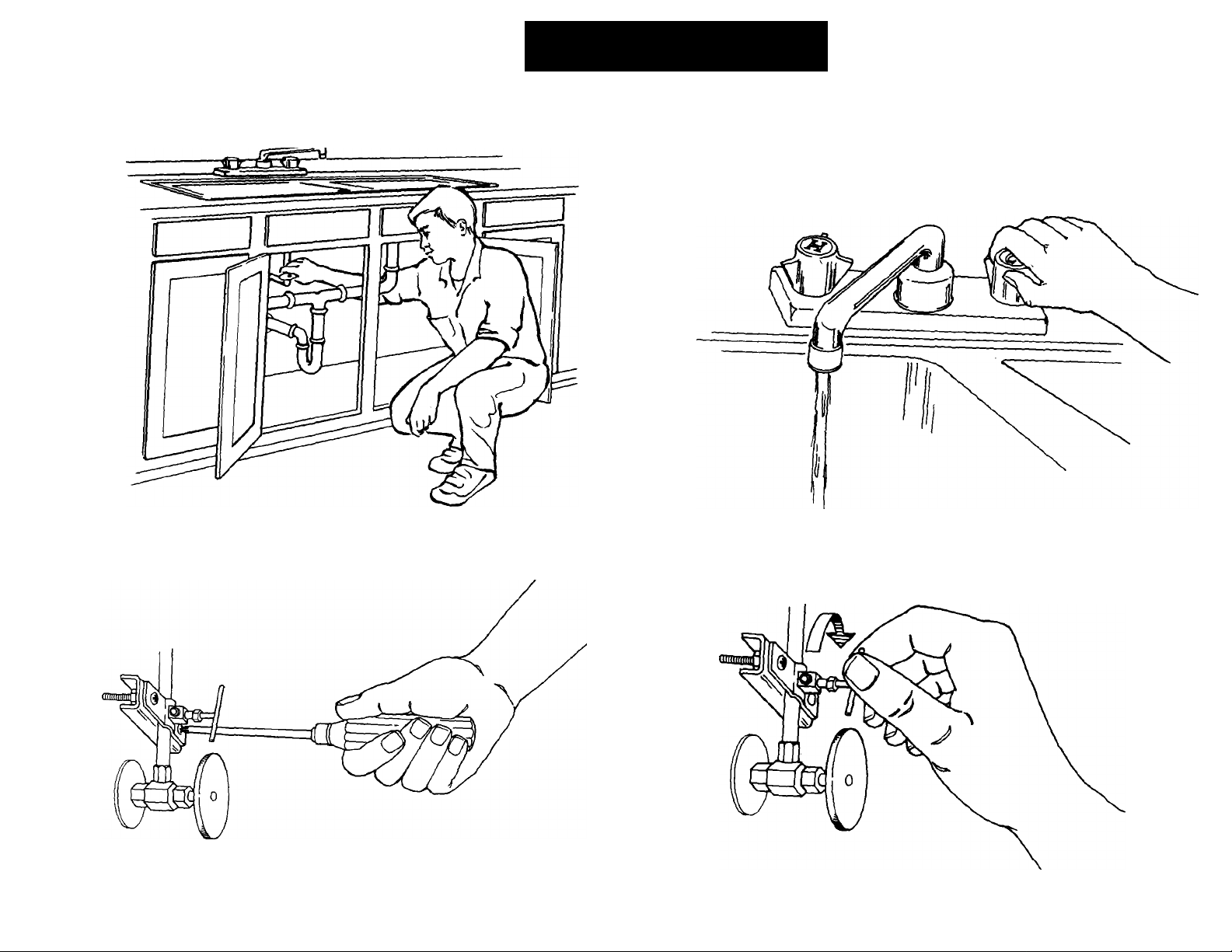

Hook Up Water

Instructions At A Glance • For detailed instructions see following page.

□

1

.

Turn off cold water supply. (Steps 1a-1b)

3. Connect saddle valve to cold water supply.

(Steps 1 c-1 e or 1 h-1 j)

2. Turn on faucet to drain water from line. (Step 1b)

handle clockwise until piercina

lance enters pipe and stops. (Steps If-lg or 1k-1l)

Hook Up Water

! CAUTION

Product Damage

DO NOT connect to a hot water supply line.

Failure to follow this instruction could result in

product damage.

10 water requirements listed

IQ ■ under the Use & Care section of this booklet.

The filtration system’s feed line (orange tubing)

connects to your cold water supply line using the

saddle valve.

Do not use saddle valve if it is prohibited by your

state or local plumbing codes.

The saddle valve is for use with %" to '/2" outer

diameter (O.D.), soft copper pipe (plain or chrome

plated) or rigid metal or plastic pipe. Important: DO

NOT use the saddle valve on flexible ribbed

tubing. The wall thickness of flexible ribbed tubing is

thin and will not support the saddle valve supplied.

If your cold water supply is connected to the cold

water faucet with flexible ribbed tubing, contact your

local plumbing supply distributor to obtain special

connecting hardware.

Important: If local codes do not permit the use

of saddle valves, special feed valves can be

obtained from your local plumbing supply distrib

utor. Use only %" polyethylene tubing for water

line connection. DO NOT USE COPPER TUBING.

! CAUTION

Property/Product Damage

• DO NOT install tubing in an area where

temperatures drop below 32°F.

• DO NOT overtighten saddle valve to copper

pipe. This will crush pipe.

• Keep a bucket or towel under area where

saddle valve connection is made.

Failure to follow these instructions may result in

water damage to property or product damage.

H1« Turn off cold water supply. Turn on cold water

IW ■ faucet and allow all water to drain from line.

Turn off faucet. Determine it your cold water supply

line is soft copper pipe or rigid metal or plastic pipe.

If your cold water supply line is soft copper pipe

proceed to step 1c. If your cold water supply line is

rigid metal or plastic pipe, skip ahead to step 1 h.

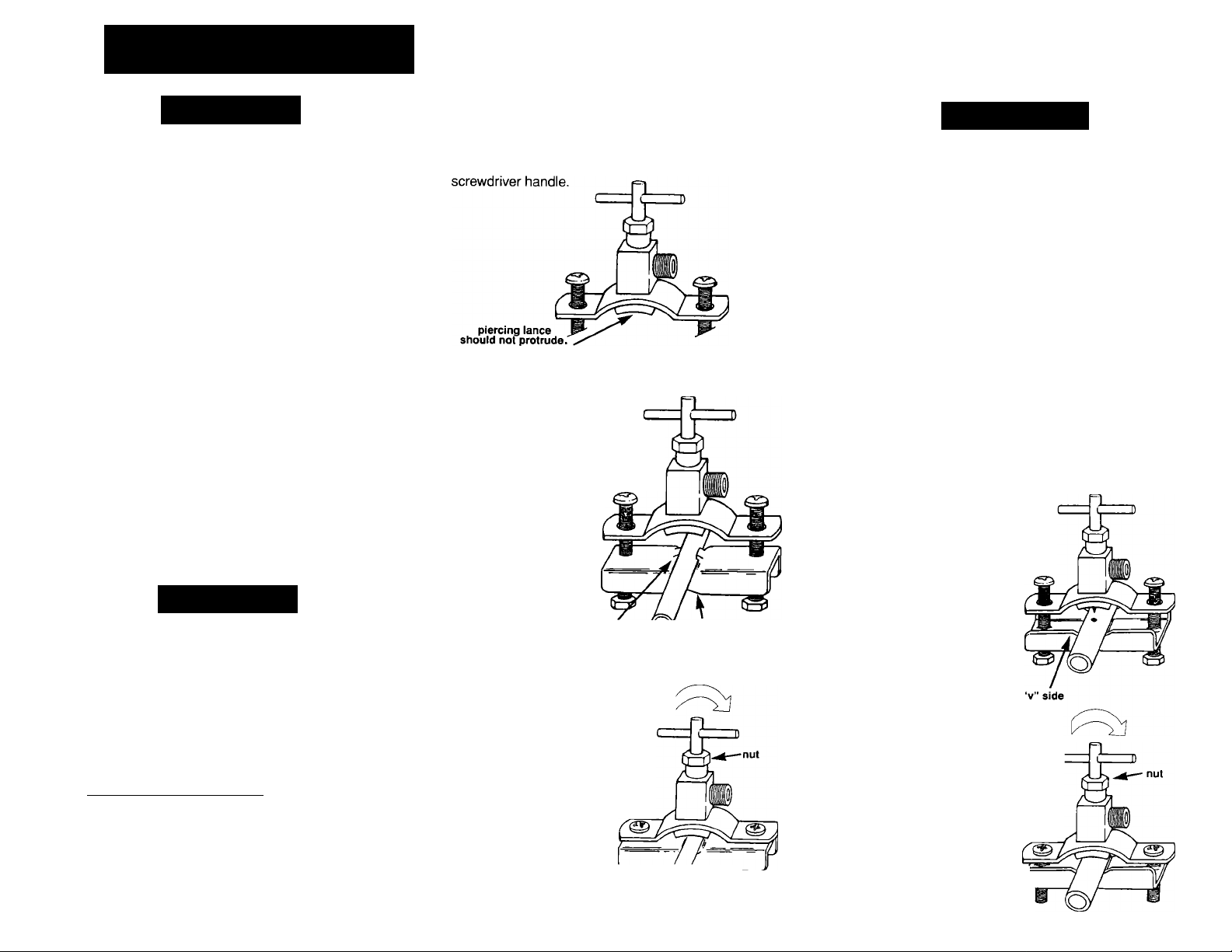

Connect saddle valve to cold water supply

1c.

soft copper pipe. Check that saddle valve

piercing lance does not protrude beyond rubber gas

ket. If it is protruding, carefully push it in flush with the

rubber gasket, using a hard object like the end of a

Assemble both halves of saddle valve to

I vl ■ cold water pipe. Saddle valve must be on top

side of horizontal pipe or side of

vertical pipe to keep sedi

ment from collecting in its valve.

If you are connecting the saddle

valve to %" O.D. copper pipe,

assemble bracket with

projections against tubing

to prevent distortion

of tubing. If you are

connecting the saddle

valve to 7/16" or Vz O.D.

pipe, assemble bracket

with “v” side against

pipe.

projections “v” side

Tighten screws evenly and firmly, keeping

IC ■ both halves parallel. DO NOT overtighten;

copper pipe could be crushed.

Have a towel ready in case of

lie leakage. Turn saddle valve

handle clockwise until the lance

pierces soft copper pipe and then

stops. Do not continue to turn the

saddle valve handle after it has

stopped because you may pierce

through the opposite side of

pipe. The saddle valve is

now in the closed position.

Turn on cold water 1 Ox ^ H”

1^ ■ supply to check for leaks. In case of leaks, use

an adjustable wrench to tighten nut below valve's han

dle. Turn cold water back off and proceed to step 2.

c;

! WARNING

Electrical Shock Hazard

Special care must be taken when drilling into

water pipes. Some water may remain in water

supply pipe.

• If an electric driil is used, it must be properly

grounded to prevent severe or lethal shock if

water should enter drill.

• Use only an electric drill that is double

insulated or properly grounded.

• Check with qualified electrician if you are in

doubt as to whether your electric drill is

properly grounded.

• Only drill at top or side of horizontai water

supply pipe. DO NOT drill at bottom of

horizontal pipe where water may remain.

Faiiure to follow these instructions couid resuit in

personal injury or death.

^ ^ Connect saddle valve to cold water supply

Ilia rigid metal or plastic pipe. Use a grounded

electric drill or hand drill to drill yie" hole in top side of

horizontal pipe or side of vertical pipe. This will keep

sediment from collecting in valve.

•41 Turn saddle valve handle

III clockwise to expose

piercing lance a maximum of

beyond the rubber gasket.

^ : Align piercing lance

II ■ over hole you drilled in

pipe. Then assemble both

halves of saddle valve on

pipe with “v” side of bracket

against pipe. Tighten

screws evenly and firmly,

keeping both halves parallel.

Turn saddle valve handle

llVa clockwise until piercing lance

enters hole in pipe and then stops.

The saddle valve is now in the c

closed position.

I Have a towel ready in case

11 ■ of leaks. Turn on cold water

supply to check for leaks. In case

of leaks, use an adjustable

wrench to tighten nut below

valve. Turn cold water back [

off and proceed to step 2.

►

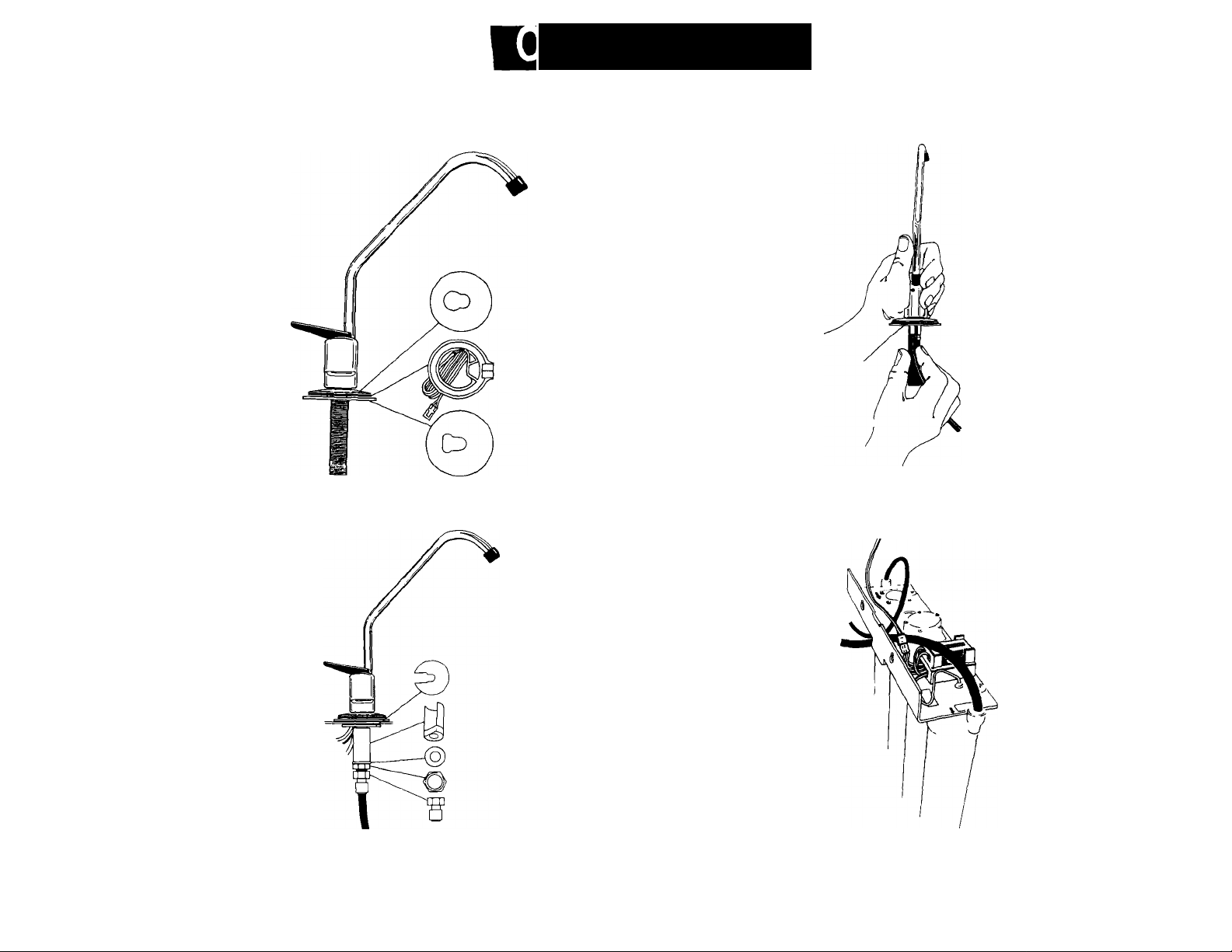

onnect Faucet

Instructions At A Glance • For detailed instructions see following page.

1. Connect faucet spout, chrome base plate, indicator light

disk and rubber washer to faucet base. (Steps 2a-2b)

3. Place faucet in sink opening. Secure faucet to sink

with slotted washer, spacer, flat washer, hex nut

and grey connector. Connect blue tubing to

bottom of faucet assembly. (Steps 2e-2j)

2. Connect green tubing and black tubing

to faucet. (Steps 2c-2d)

4. Connect faucet indicator wire to wire harness

on filtration assembly. Insert battery. (Step 2k)

Loading...

Loading...