Use & Care Guide

Guide d’utilisation et d’entretien

Heat Pump Dryer

Sécheuse avec pompe à chaleur

W10858718B

W10858720B - SP

Para obtener acceso

al Manual de uso y

cuidado en español, o para

obtener información adicional

acerca de su producto, visite:

www.whirlpool.com.

If you have any problems or questions, visit us at www.whirlpool.com

Pour tout problème ou toute question, consulter www.whirlpool.ca

Table of Contents

DRYER SAFETY ......................................................................2

OPERATING INSTRUCTIONS ............................................... 4

ACCESSORIES ................................................................. 4

HEAT PUMP TECHNOLOGY ............................................ 5

CONTROL PANEL AND FEATURES .................................6

PROGRAM/CYCLE GUIDE ............................................... 7

USING YOUR DRYER .......................................................9

DRYER CARE .................................................................12

INSTALLATION INSTRUCTIONS ......................................... 14

INSTALLATION REQUIREMENTS ...................................14

LOCATION REQUIREMENTS .........................................15

DRAIN SYSTEM .............................................................. 16

ELECTRICAL REQUIREMENTS – U.S.A. ONLY .............17

ELECTRIC DRYER POWER HOOKUP –

CANADA ONLY ............................................................... 18

ELECTRIC INSTALLATION – U.S.A. ONLY .................... 18

LEVEL DRYER ................................................................24

COMPLETE INSTALLATION CHECKLIST .......................24

DOOR REVERSAL (OPTIONAL) ...................................... 25

TROUBLESHOOTING ........................................................... 30

WARRANTY ...........................................................................35

ASSISTANCE OR SERVICE ..................................Back Cover

Table de matières

SÉCURITÉ DE LA SÉCHEUSE ............................................. 36

INSTRUCTIONS D’UTILISATION ........................................ 37

ACCESSOIRES ............................................................... 37

TECHNOLOGIE DE POMPE À CHALEUR ...................... 38

TABLEAU DE COMMANDE ET CARACTÉRISTIQUES ... 39

GUIDE DE PROGRAMMES ............................................40

UTILISATION DE LA SÉCHEUSE ....................................42

ENTRETIEN DE LA SÉCHEUSE......................................45

INSTRUCTIONS D’INSTALLATION ..................................... 47

EXIGENCES D’INSTALLATION .......................................47

EXIGENCES D’EMPLACEMENT ..................................... 48

SYSTÈME DE VIDANGE ................................................. 49

SPÉCIFICATIONS ÉLECTRIQUES –

ÉTATS-UNIS SEULEMENT .............................................50

RACCORDEMENT DE LA SÉCHEUSE ÉLECTRIQUE –

CANADA UNIQUEMENT .................................................51

INSTALLATION ÉLECTRIQUE –

ÉTATS-UNIS SEULEMENT ............................................51

RÉGLAGE DE L’APLOMB DE LA SÉCHEUSE ................57

LISTE DE VÉRIFICATION POUR

INSTALLATION TERMINÉE .............................................57

INVERSION DE LA PORTE (FACULTATIF) ......................58

DÉPANNAGE .........................................................................63

GARANTIE ............................................................................. 66

ASSISTANCE OU SERVICE ...................... Couverture arrière

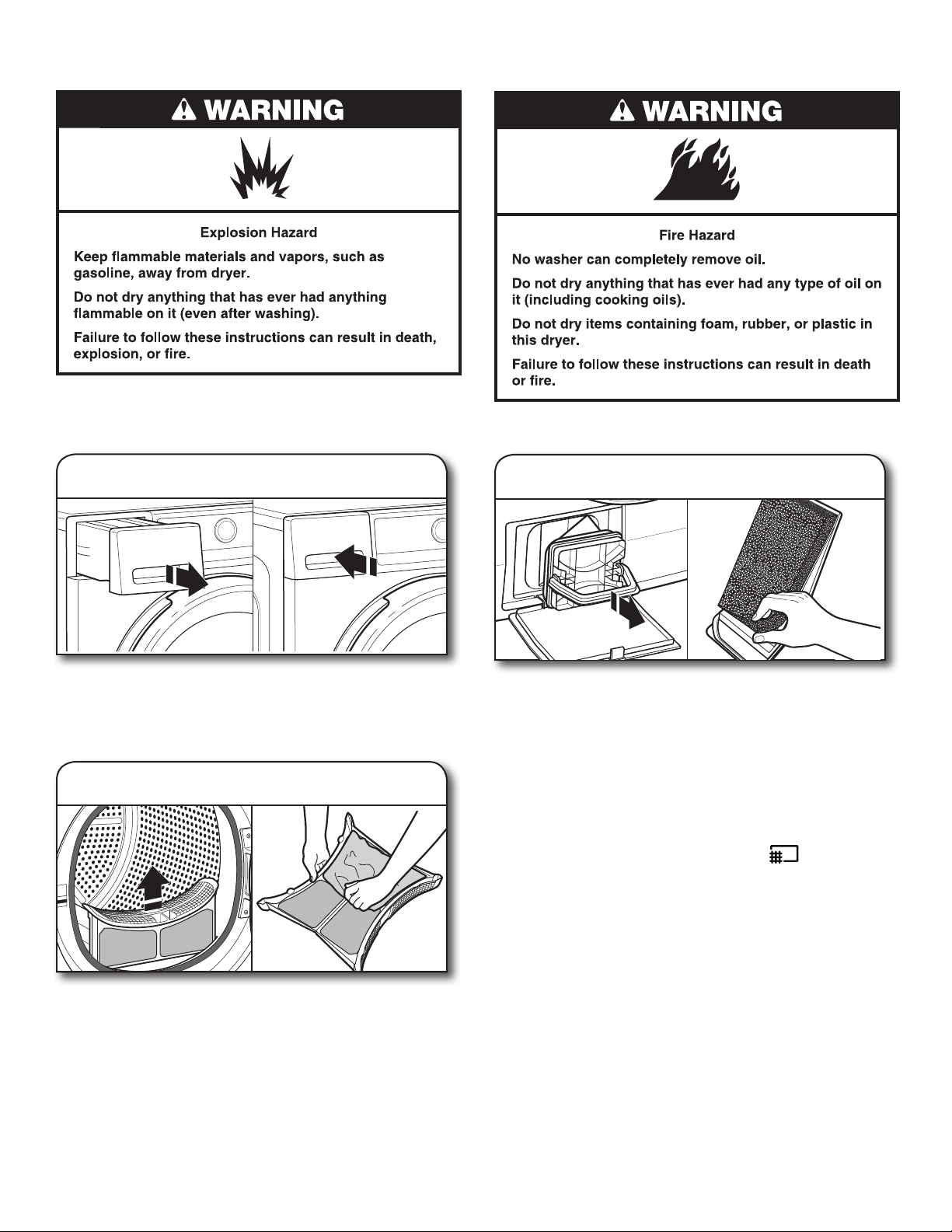

DRYER SAFETY

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of re, electric shock, or injury to persons when using the dryer, follow basic precautions,

including the following:

n Read all instructions before using the dryer.

n Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to a

chemical reaction that could cause a load to catch re. .

n Do not dry articles that have been previously cleaned

in, washed in, soaked in, or spotted with gasoline,

dry-cleaning solvents, or other ammable or explosive

substances as they give off vapors that could ignite or

explode.

n Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

n Before the dryer is removed from service or discarded,

remove the doors to the drying compartment.

n Do not reach into the dryer if the drum is moving.

n Do not install or store the dryer where it will be exposed

to the weather.

n Do not tamper with controls.

SAVE THESE INSTRUCTIONS

n Do not repair or replace any part of the dryer or attempt

any servicing unless specically recommended in

this Use and Care Guide or in published user-repair

instructions that you understand and have the skills

to carry out.

n Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

n Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

n Clean lint screen before or after each load.

n Keep the grille on the rear of the dryer free from the

accumulation of lint, dust, and dirt.

n The interior of the appliance should be cleaned

periodically by qualied service personnel.

n See “Electrical Requirements” in “Installation

Instructions” for grounding instructions.

3

OPERATING INSTRUCTIONS

Accessories

INSTALLATION & MAINTENANCE

ACCESSORIES

FACTORY CERTIFIED PARTS – these three

words represent quality parts and accessories

designed specically for your appliance.

Time tested engineering that meets

our strict quality specications.

FACTORY CERTIFIED PARTS

Accessories designed for your appliance:

Enhance your new washer and dryer with the following

genuine Whirlpool accessories. For more information

on options and ordering, call 1-866-698-2538, or visit us

at: www.whirlpool.com/accessories. In Canada, call

1-800-688-2002 or visit us at www.whirlpoolparts.ca.

Stack Kit

If space is at a premium, the stack kit

allows the dryer to be installed on top

of the washer.

12" Pedestal

Color-matched pedestals raise the

washer and dryer to a more comfortable

working height.

4

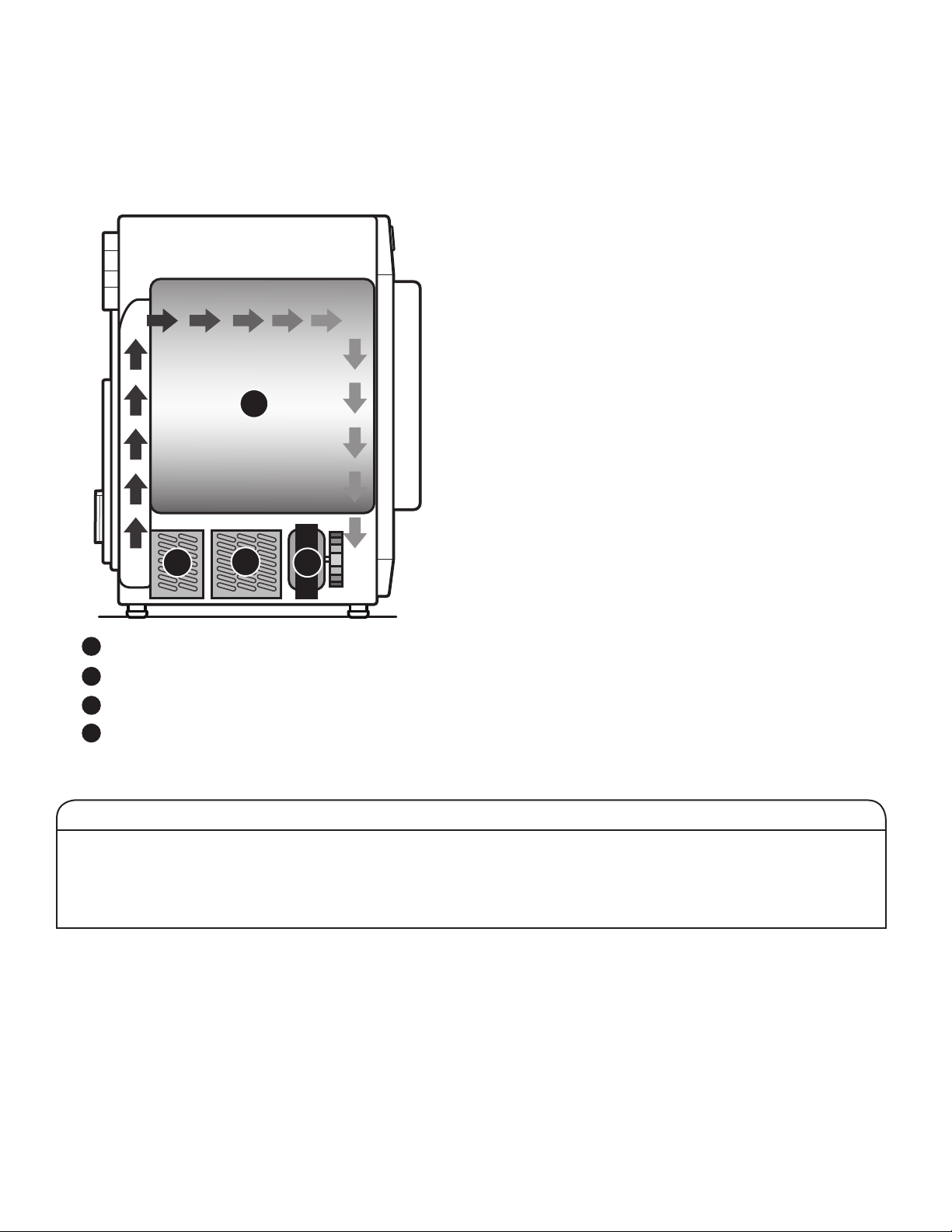

Heat Pump Technology

A typical dryer uses large amounts of energy; this dryer consumes a fraction of the energy by recycling and reclaiming heat.

This dryer is a ventless heat pump dryer that uses a refrigeration system to dry and recycle the same air. The laundry

is dried with low temperatures; therefore it may feel cooler than expected during and after the drying process.

The heat pump dryer’s heating phase is longer than in traditional dryers. If possible, do not open the dryer door during the process

as heat can escape from the drum and can make longer drying times.

Heat Pump Unit

2

1

4

Benets of a Heat Pump

• ENERGY: Regenerates energy to reduce overall energy

consumption.

• PERFORMANCE: Allows flexibility to manage drying

performance and energy savings.

• FABRIC CARE: Capability to use less heat than vented dryer.

• VENTLESS DESIGN: Allows installation in more locations

throughout the home.

New Sounds from a Heat Pump

• Dryer runs on a compressor like your refrigerator and you

may notice a hum from the compressor.

• The water from wet clothes is pumped out to your drain or

water tank. You may notice a gurgling sound occasionally.

3

1

Condenser is heating up the air

Drying

2

Air blower

3

4

Evaporator is drying air and discharging

condensation water

Use Automatic Cycles for better fabric care and energy savings

Use the Automatic Cycles to provide the most energy savings and enhanced fabric care from the dryer. During Automatic Cycles,

heat pump unit temperature and moisture level are sensed in the load. This sensing occurs throughout the drying cycle and the

dryer shuts off when the load reaches the selected dryness. Use the NORMAL dryness level to provide optimal energy savings.

With Timed Dry, the dryer runs the amount of time set and can result in shrinkage, wrinkling, and static due to over-drying.

Use Timed Dry for the occasional damp load that needs a little more drying time.

5

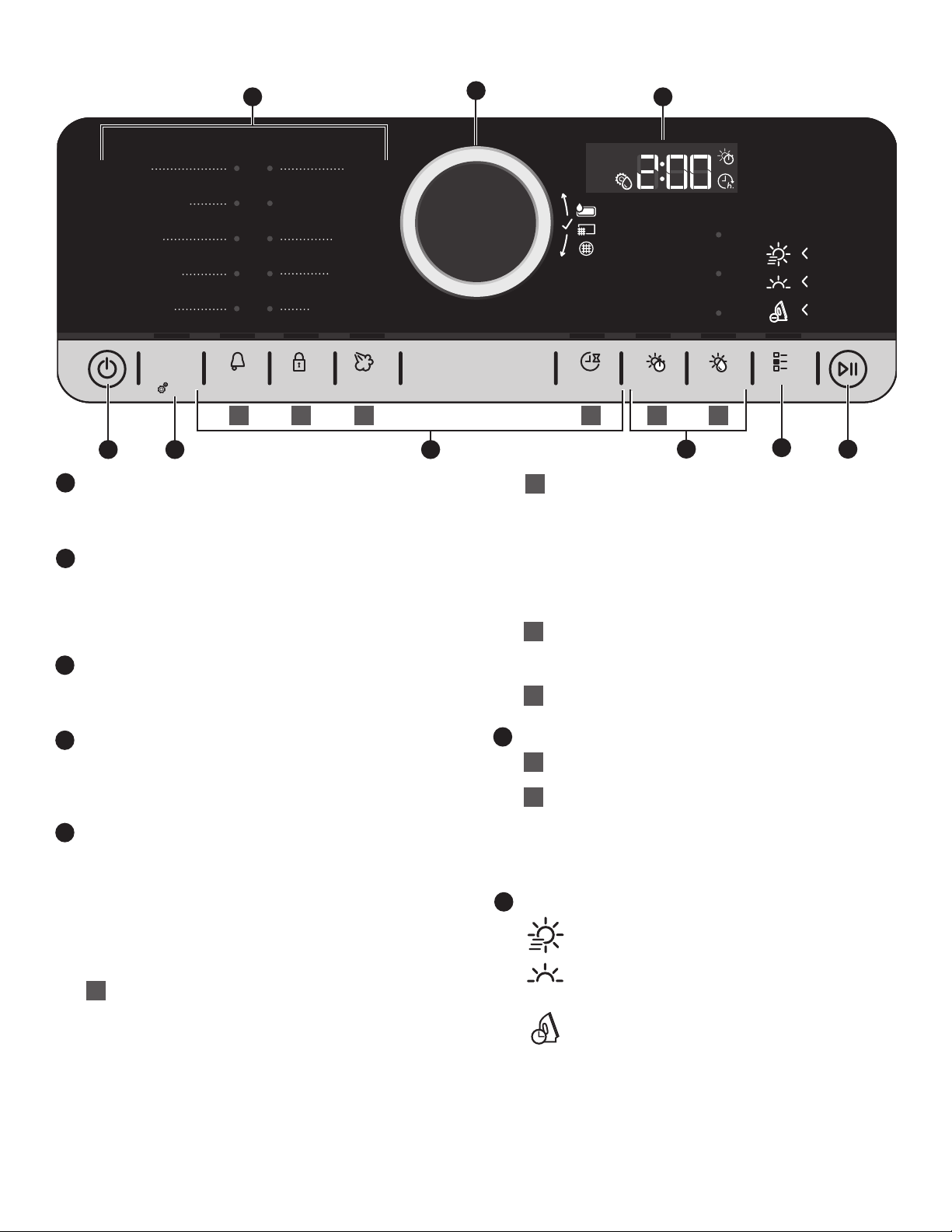

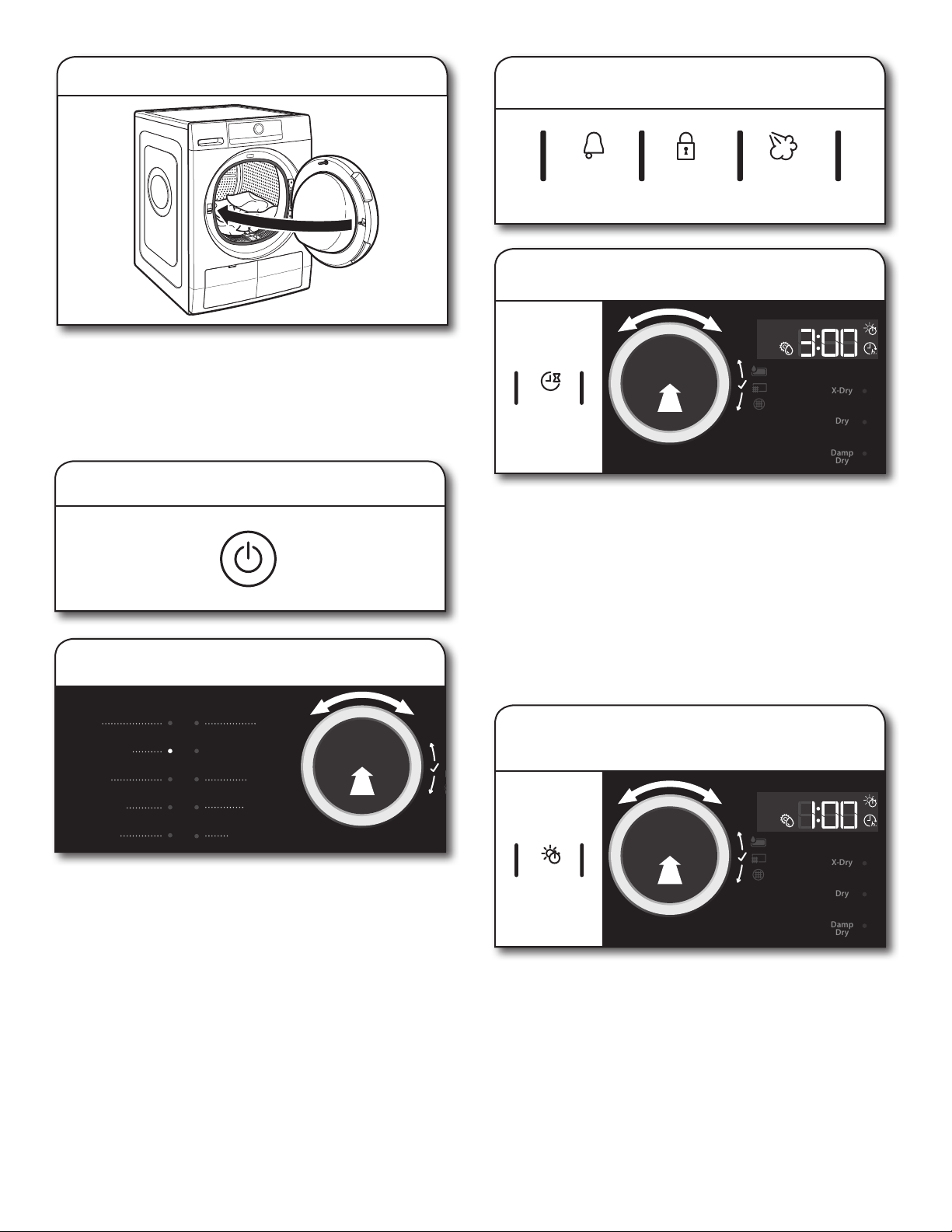

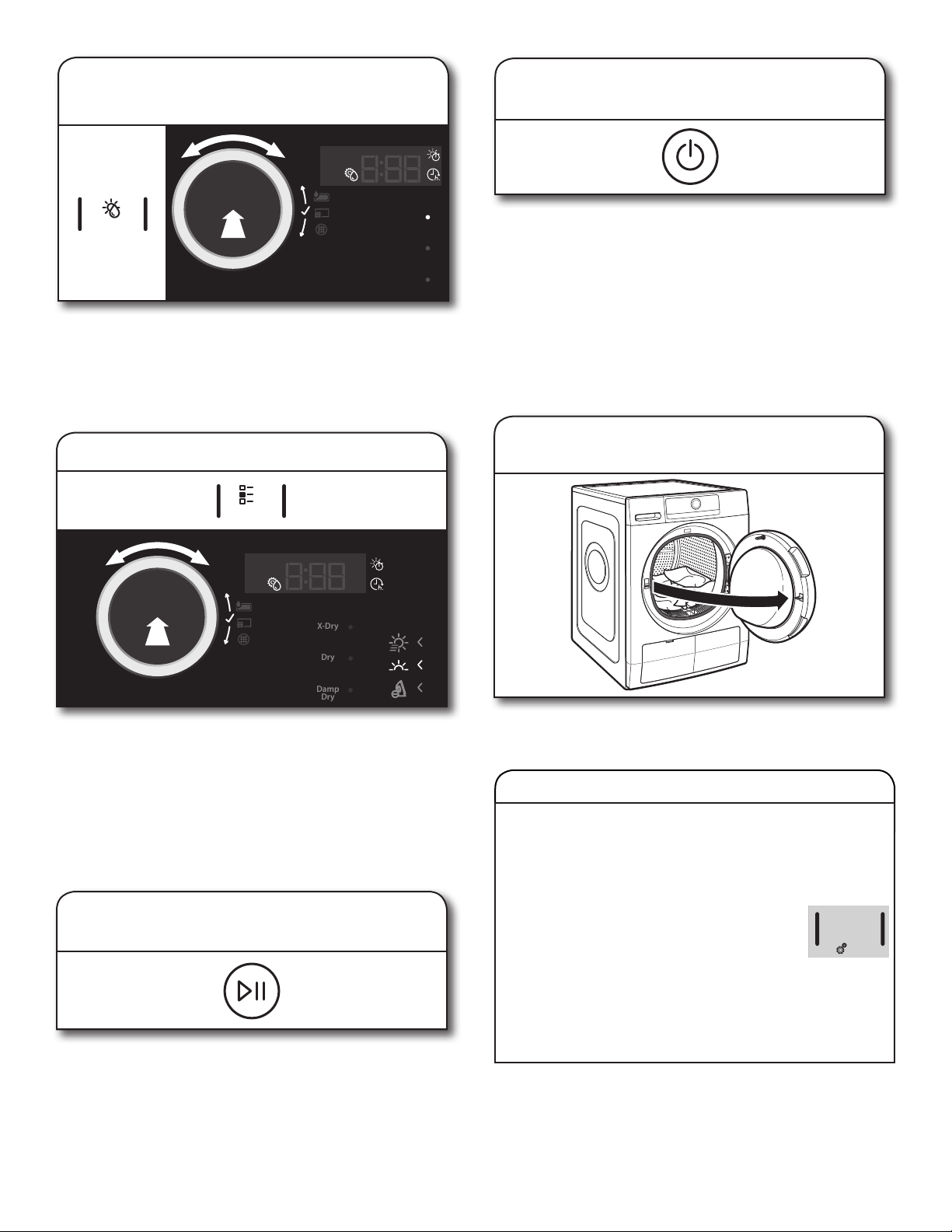

Control Panel and Features

3 9

4

Mixed

Heavy Duty

Normal

Synthetics

Delicates

P

Program

3 Sec

Bulky/Bedding

Cycle

Signal

A B C

Control

Lock

Hold 3 Sec

Wool

Air Dry

Refresh

Timed Dry

Steam

1 2 5

POWER BUTTON

1

Touch until the indicator above the Program button lights

up. Symbols appear on the control panel and sounds are

played.

PROGRAM (cycle)

2

When you turn on the dryer, the light above this button

will turn on. The program settings which you used last

will appear on the control panel. This button also lets you

set water conductivity (see “Adapting the dryer to water

conductivity” for more information).

PROGRAM/CYCLE AREA

3

An indicator next to each program/cycle lights up as you

use the knob to scroll through the list. Press the knob when

the indicator next to the desired program/cycle lights up.

4

CONTROL KNOB

Turn the knob to select a program/cycle for your laundry

load, change dryness level, set drying time or delay start

time, or select Other Options. Press the knob to confirm

your selection.

5

OPTIONS

Touch to activate additional dry options or additional

features on the dryer before touching the Start/Pause

button. Additional dry options or additional features

selected after touching the Start/Pause button may

not be activated.

To return to factory default cycle settings, unplug the dryer

for 30 seconds, then plug back in.

NOTE: Not all options are available with all cycles.

Cycle Signal

A

Use to turn on or off the signal indicating the end

of a drying cycle.

NOTE: Touch and hold the Cycle Signal button for

about one second to turn sounds on or off.

Control Lock

B

Use to lock the controls of the dryer and avoid

an accidental change in cycle options or preferences

during a drying cycle.

Touch and hold CONTROL LOCK to lock or unlock

the controls of the dryer.

NOTE: The Control Lock function may be enabled

when recovering from a power failure. To unlock

the control, touch and hold CONTROL LOCK.

Steam

C

Touch to activate the Steam option, which adds

humidity to the end of the Heavy Duty, Normal,

or Synthetics cycle to help smooth out wrinkles.

Delay Start

D

Touch to start your program/cycle at a later time.

6

SETTINGS

Timed Dry

A

Sets the length of a Timed Dry cycle.

Dryness Level

B

When using some Automatic Cycles, you may

select a Dryness Level based on the type of load

you are drying.

NOTE: Dryness Level is for use with Automatic

Cycles only.

7

OTHER OPTIONS

Save Time

This option provides quicker drying.

Gentle

This option dries laundry more gently by reducing

the drying temperature.

Wrinkle Shield™

This option helps to avoid creasing if you cannot

unload the laundry soon after the program/cycle

ends. The dryer starts to tumble the laundry

periodically a few minutes after the program/cycle

ends. This tumbling will last up to approximately

12 hours. Tumbling can be stopped any time by

touching the Power button to turn off the dryer.

Delay

Start

D A

Timed

Dry

X-Dry

Dry

Damp

Dry

6

Dryness

Level

B

Options

7

8

6

8

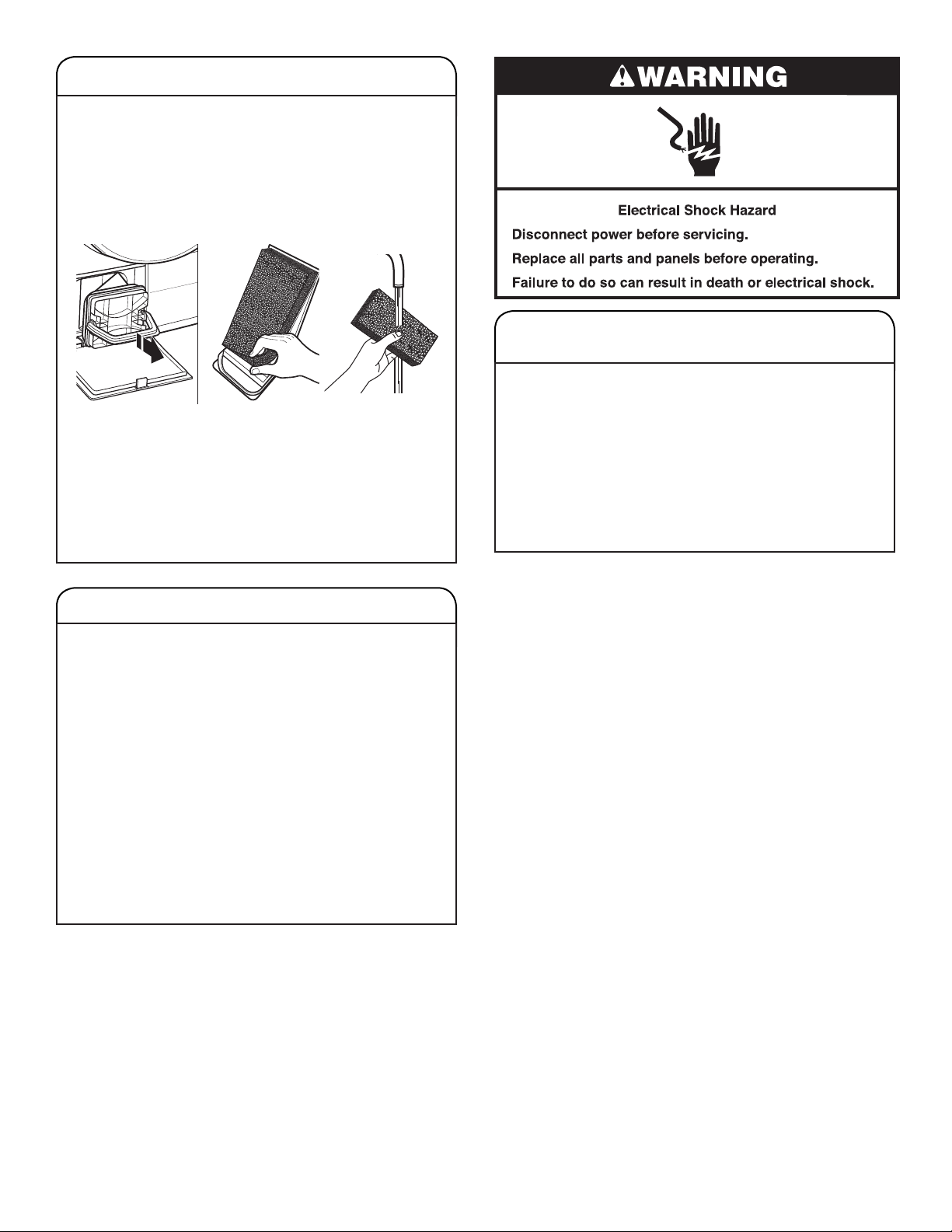

START/PAUSE BUTTON

Touch to start, or touch and hold to pause, a program/

cycle.

9

LED DISPLAY

When you select a program/cycle, its default settings

will light up and the Estimated Time Remaining will be

displayed. Factors such as load size and dryness level

may affect the time shown in the display.

Symbols

Drying time

Delay start

Conductivity adjustment

STATUS INDICATORS (next to control knob)

These indicators will light up to alert you when certain

conditions occur.

Symbols

Water tank full (see “Empty Water Tank” in “Using Your

Dryer”)

Clean bottom filter (see “Cleaning the Bottom Filter” in

“Dryer Care”)

Clean door filter (see “Cleaning the Lint Screen”

in “Dryer Care”)

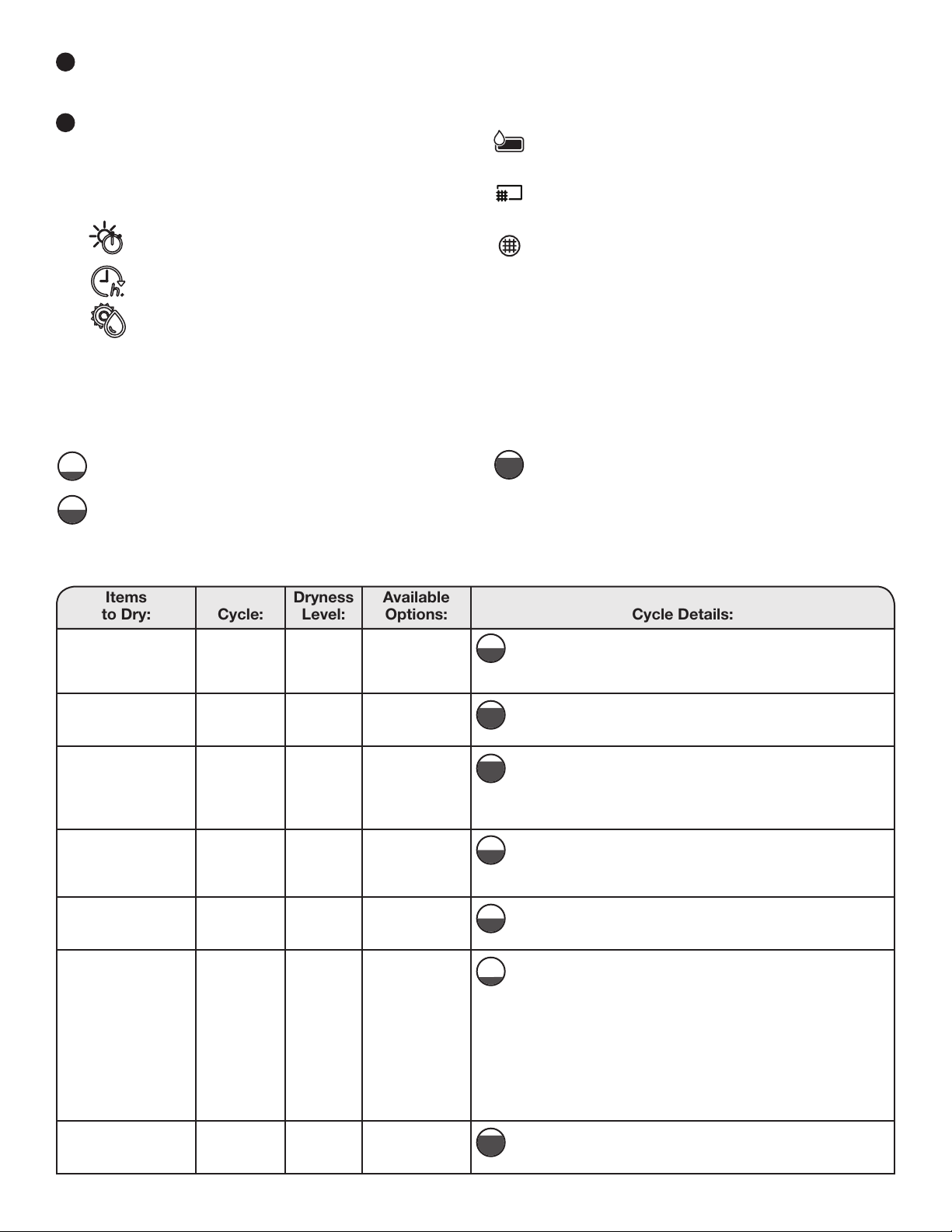

Program/Cycle Guide – Automatic Cycles

Settings and options shown in bold are default settings for that cycle. If settings are changed, the new settings will be remembered.

If there is a power failure, settings will return to the default. Not all settings and options are available on each cycle.

Load Size Recommendations

For best results, follow the wet load size recommendations noted for each cycle.

Small load: Fill the dryer drum with 3–4 items, not more

than ¼ full.

Medium load: Fill the dryer drum up to about ½ full.

Large load: Fill the dryer drum up to about ¾ full.

Do not pack tightly. Items need to tumble freely.

Use Automatic Cycles for better fabric care and energy savings

The dryer senses moisture in the load or air temperature and shuts off when the load reaches the selected dryness level.

Use the NORMAL dryness level to provide optimal energy savings.

Items

to Dry:

Mixed laundry

made of cotton,

linen, or synthetic

fibers and blends

Heavyweight items

or heavy work

clothes

Work clothes,

mixed cottons,

corduroys

Normally soiled

laundry made of

artificial fibers or

cotton blends

Undergarments,

blouses, lingerie,

performance wear

Wool items labelled

with the Woolmark

logo and identified

as machine

washable, as well

as textiles made of

silk (see care label

recommendations),

linen, wool, and

viscose marked as

hand-wash only

Comforters, pillows,

sheets

Cycle:

Mixed

Heavy Duty

Normal Extra Dry

Synthetics Extra Dry

Delicates

Wool

Bulky/

Bedding

Dryness

Level:

Dry

Dry

Dry

Damp Dry

Dry

Damp Dry

Dry

Dry

Dry

Available

Options:

Wrinkle Shield

Steam

Wrinkle Shield

Gentle

Steam

Dryness Level

Wrinkle Shield

Gentle

Save Time

Steam

Dryness Level

Wrinkle Shield

Gentle

Wrinkle Shield

N/A

Wrinkle Shield

Cycle Details:

™

™

™

™

™

™

Uses Medium heat to dry large loads of mixed fabrics and

items.

Offers stepped drying, starting with High heat followed by

Medium heat for enhanced fabric care and energy savings.

Uses Medium heat to dry large loads of cotton or mixed

fabrics and items. Tumbling reverses intermittently to

redistribute the load for thorough drying.

Uses lower heat than the Normal cycle. Tumbling reverses

intermittently to redistribute the load for thorough drying.

Uses Extra Low heat to gently dry delicate items.

Uses Low heat to provide a short, finishing touch to items

that have been air-dried.

Use for drying large, bulky items; do not overfill dryer drum.

Partway through the cycle, the signal will sound to indicate

when it is time to rearrange items for optimal drying.

7

Program/Cycle Guide – Adjustable Time Cycles

Settings and options shown in bold are default settings for that cycle. If settings are changed, the new settings will be

remembered. If there is a power failure, settings will return to the default. Not all settings and options are available on each cycle.

Load Size Recommendations

For best results, follow the wet load size recommendations noted for each cycle.

Small load: Fill the dryer drum with 3–4 items, not more

than ¼ full.

Medium load: Fill the dryer drum up to about ½ full.

Adjust drying time on Timed Dry Cycles

When you select the Timed Dry or Air Dry

cycle, the time appears in the display. Use

the knob to set the drying time from 10 to

180 minutes (3 hours).

Items

to Dry:

Any load

NOTE: Line dry

foam, rubber,

plastic, or heatsensitive fabrics.

Any load Timed

Cycle:

Air Dry Wrinkle Shield

Dry

Available

Options:

Wrinkle Shield

™

™

Large load: Fill the dryer drum up to about ¾ full.

Do not pack tightly. Items need to tumble freely.

Cycle Details:

For airing out, refreshing, and loosening up laundry without heating.

Use to dry items with low heat to a damp level for items that do not require

an entire drying cycle.

Program/Cycle Guide – Refresh Cycle

The Refresh cycle is designed for use with dry loads to loosen wrinkles, reduce odors, and refresh fabrics.

Items to

Refresh:

Shirts, blouses,

and slacks

Cycle:

Refresh

Available

Options:

Dry

Cycle Details:

Use to reduce odors and light wrinkles. Do not add dryer sheets. Before

loading laundry into the drum, spray it with a maximum of 6.8 oz (200 ml)

water.

8

Using Your Dryer

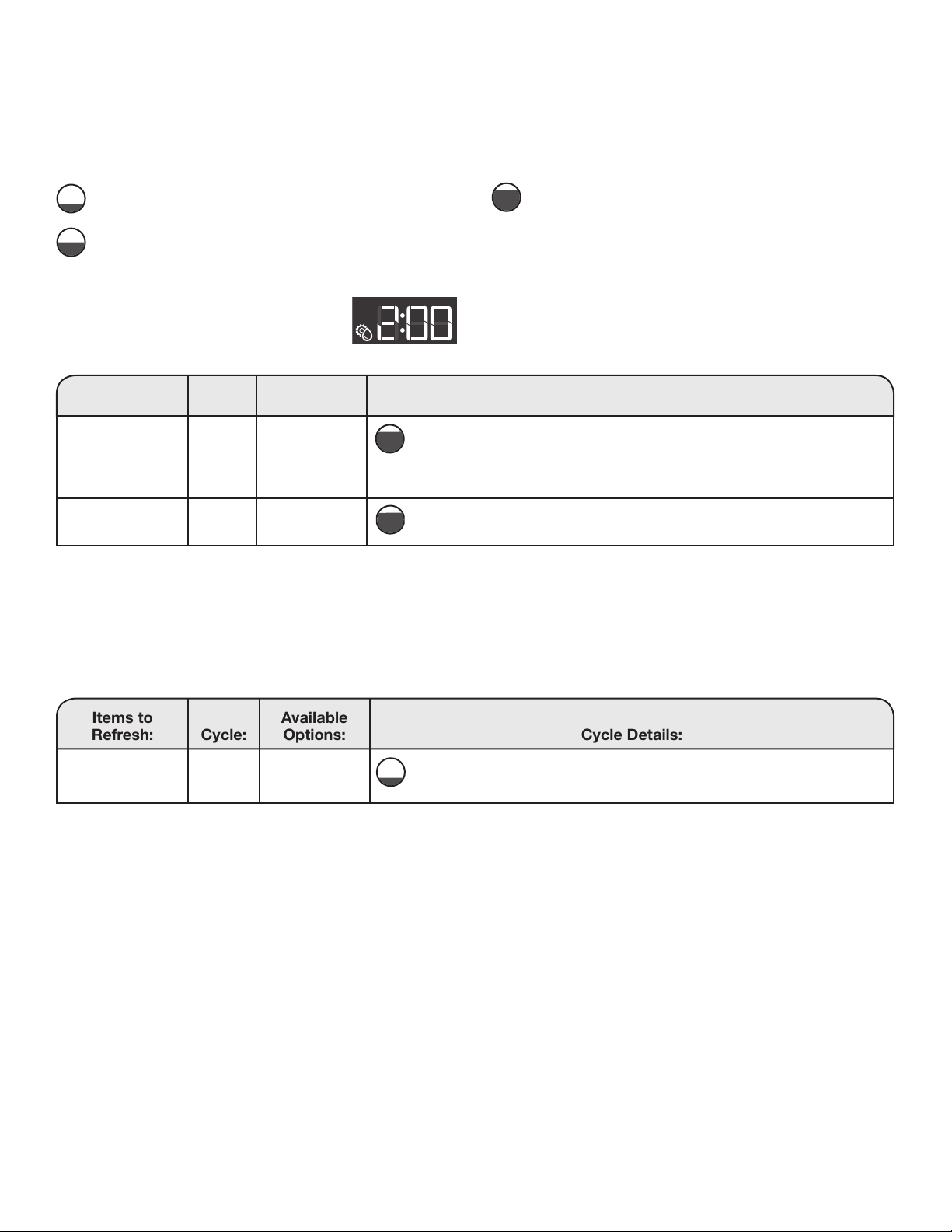

WARNING: To reduce the risk of fire, electric shock, or injury to

persons, read the IMPORTANT SAFETY INSTRUCTIONS before

operating this appliance.

1. Empty water tank

Hold the handle and carefully pull out the water tank.

Holding the full water tank with both hands, empty out the

water. Then push the container back into place. Make sure

that it is properly inserted.

2. Clean door lint screen

3. Clean bottom lter

Clean the bottom filter after every 5 cycles. Open the filter

door on the bottom of the dryer and grab the handle to pull

out filter. Remove the foam from the bottom filter. Clean the

filter foam and filter by hand or rinse with water – do not

wash the filter foam in a washer. Wring out the filter foam –

do not insert it in the bottom filter dripping wet. For additional

cleaning information, see “Dryer Care.”

Replace the filter foam on the bottom filter. Replace the

bottom filter in the filter chamber. Fold the filter handle down

and close the bottom door.

NOTE: To turn off the “Clean bottom filter” ( ) status

indicator, the filter must be removed and replaced with the

Power button touched ON and no cycle running.

Clean the lint screen before each load. Pull the lint screen

straight up and out. Press tab down and open lint screen.

Roll lint off the screen with your fingers. Push the lint screen

firmly back into place.

IMPORTANT: Clean lint screen before each dryer use

as a screen blocked with lint will increase drying time.

9

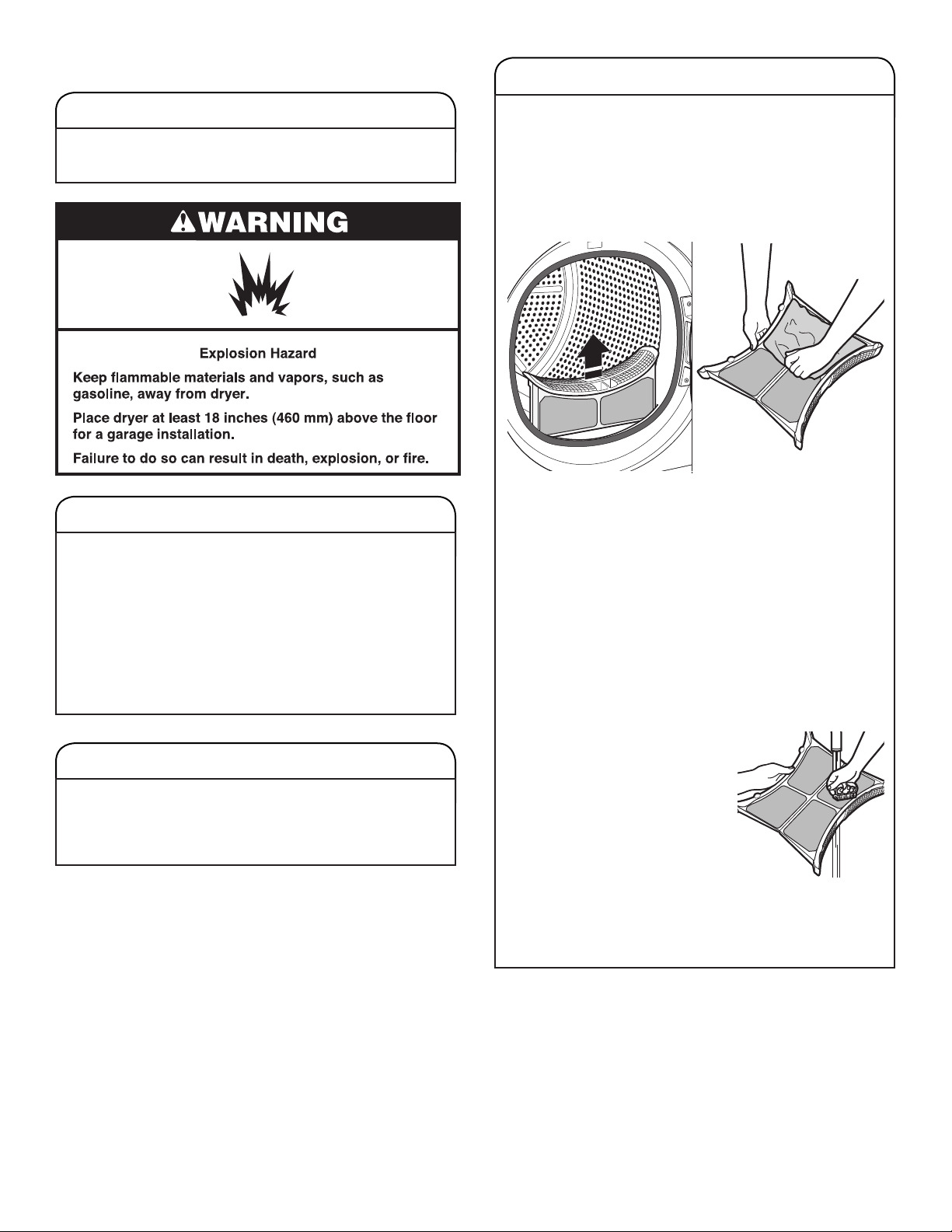

4. Load dryer

X-Dry

Dry

Damp

Dry

X-Dry

Dry

Damp

Dry

7. Select options, if desired

Open the door by pulling on the handle. Place laundry

in the dryer. Add a dryer sheet to wet load if desired.

Close the door.

IMPORTANT: Do not tightly pack the dryer. Items need

to tumble freely. Tightly packing can lead to poor drying

performance and may increase wrinkling and tangling.

5. Touch Power button to turn on dryer

6. Select program/cycle

Cycle

Signal

Control

Lock

Hold 3 Sec

Steam

8. Setting a delayed start, if desired

Delay

Start

If you do not want to begin a cycle immediately, you may

choose the Delay Start option. This will delay the start

of the drying cycle by up to 23 hours.

To set a Delayed Start:

1. Touch the Delay Start button to set the desired delay time.

2. Turn the knob to the number of hours you want to delay

the start of the drying cycle. The delay time will appear

on the display. Press the knob to confirm your selection.

After touching the Start/Pause button, the time will count

down until the delay time has been reached. The dryer will

start and the display will show the remaining time in the cycle.

Mixed

Heavy Duty

Normal

Synthetics

Delicates

Turn the knob to select a program/cycle for your laundry load.

As you turn the knob, an indicator light will light up next to

the program/cycle names to the left of the knob. Stop turning

when the indicator next to the desired program/cycle lights up.

Press the knob to confirm your selection.

See “Program/Cycle Guide” for details on program/cycle

features.

Bulky/Bedding

Wool

Air Dry

Refresh

Timed Dry

9. If Air Dry or Timed Dry was selected,

set drying time

Timed

Dry

When you select a timed cycle, the indicator light above

“Timed Dry” lights up. Turn the knob to select the desired

time, up to 180 minutes. Press the knob to confirm your

selection.

10

X-Dry

Dry

Damp

Dry

10. If an automatic cycle was selected,

Options

Delay

Start

Timed

Dry

Dryness

Level

P

Cycle

Signal

Control

Lock

Steam

X-Dry

Dry

Damp

Dry

Wool

Air Dry

Refresh

Timed Dry

Bulky/Bedding

set dryness level

13. Touch Power button to turn off

dryer after program/cycle ends

Dryness

Level

X-Dry

Dry

Damp

Dry

When you select an automatic cycle, the indicator light above

“Dryness Level” lights up. Turn the knob to select the desired

level. As you turn the knob, an indicator light will light up next

to the dryness levels to the right of the knob. Stop turning

when the indicator next to the desired level lights up. Press

the knob to confirm your selection.

11. Select any additional options

Options

*

When the display indicates that the cycle has finished, touch

the Power button to turn off the dryer. Open the door and take

out your laundry.

To save energy, the dryer turns off automatically about

a quarter hour after the program/cycle ends.

If not turned off right after the program/cycle ends, the

dryer will tumble the laundry for about 10 minutes to prevent

wrinkling. The display shows an animation.

NOTE: If the Power button is touched and held, a countdown

will be displayed. At the end of the countdown, any errors will

be erased and the program/cycle will restart.

14. Remove garments promptly

after cycle is nished

After setting drying time or dryness level, the indicator light

above “Options” lights up. Turn the knob to select the desired

option(s). As you turn the knob, the option symbols above the

Options button will light up one at a time as you turn the knob.

Stop turning when the symbol of the desired option lights up.

Press the knob to confirm your selection.

*

Not all options and settings are available with all program/

cycles. See “Program/Cycle Guide” for available options

and settings.

12. Touch Start/Pause button to begin

drying program/cycle

Touch the Start/Pause button to start the drying program/

cycle. To pause a program/cycle in progress, touch the Start/

Pause button once, then touch again to continue the program/

cycle. To cancel a program/cycle, touch the Power button.

Promptly remove garments after cycle has completed

to reduce wrinkling.

Adapting the dryer to water conductivity

The drying results are affected by the conductivity of the water

used during washing. If, by modifying the available dryness

levels (damp dry, dry, and extra dry), you are not satisfied with

the final drying results, you can adapt the water conductivity

level. The dryer comes with preset level 3. Choose between

level 1 (most damp results) and 5 (most dry results).

1. Touch and hold the Program button. The

display will count down until the Conductivity

Adjustment symbol on the display flashes

and the current setting is shown.

2. Turn the knob to adjust the level (1-2-3-4-5). Press the

knob to confirm your selection.

NOTE: This new setting will affect all future cycles. If the

desired drying results are attained, water conductivity will

not require further adjustment.

Program

3 Sec

11

Dryer Care

CLEANING THE LINT SCREEN

CLEANING THE DRYER LOCATION

Keep dryer area clear and free from items that would

block the airflow for proper dryer operation. This includes

clearing piles of laundry in front of the dryer.

CLEANING THE DRYER INTERIOR

To clean dryer drum:

1. Use a mild hand dish detergent mixed at a low

concentration with very warm water, and rub with

a soft cloth.

2. Rinse well with a wet sponge or towel.

3. Tumble a load of clean clothes or towels to dry drum

OR

Use a microfiber cloth and hot water in a spray bottle

to clean the drum and a second microfiber towel to dry.

REMOVING ACCUMULATED LINT

From Inside the Dryer Cabinet

Lint should be removed every 2 years, or more often,

depending on dryer usage. Cleaning should be done

by a qualified appliance servicer.

Clean lint screen after every load.

The lint screen is located in the door opening of the dryer.

A screen blocked by lint can increase drying time.

To clean:

1. Pull the lint screen straight up and out. Press tab down

and open lint screen. Roll lint off the screen with your

fingers.

2. Push the lint screen firmly back into place.

IMPORTANT:

n

Do not run the dryer with the lint screen loose,

damaged, blocked, or missing. Doing so can cause

overheating and damage to both the dryer and fabrics.

As-needed cleaning

Laundry detergent and fabric softener residue can build

up on the lint screen. This buildup can cause longer drying

times for your clothes, or cause the dryer to stop before

your load is completely dry.

Clean the lint screen with a nylon brush every 6 months,

or more frequently, if it becomes clogged due to a residue

buildup.

To wash lint screen:

1. Roll lint off the screen with

your fingers.

2. Wet both sides of lint screen

with hot water.

3. Wet a nylon brush with hot water

and liquid detergent. Scrub lint

screen with the brush to remove

residue buildup.

4. Rinse screen with hot water.

5. Thoroughly dry lint screen with

a clean towel. Reinstall screen

in dryer.

12

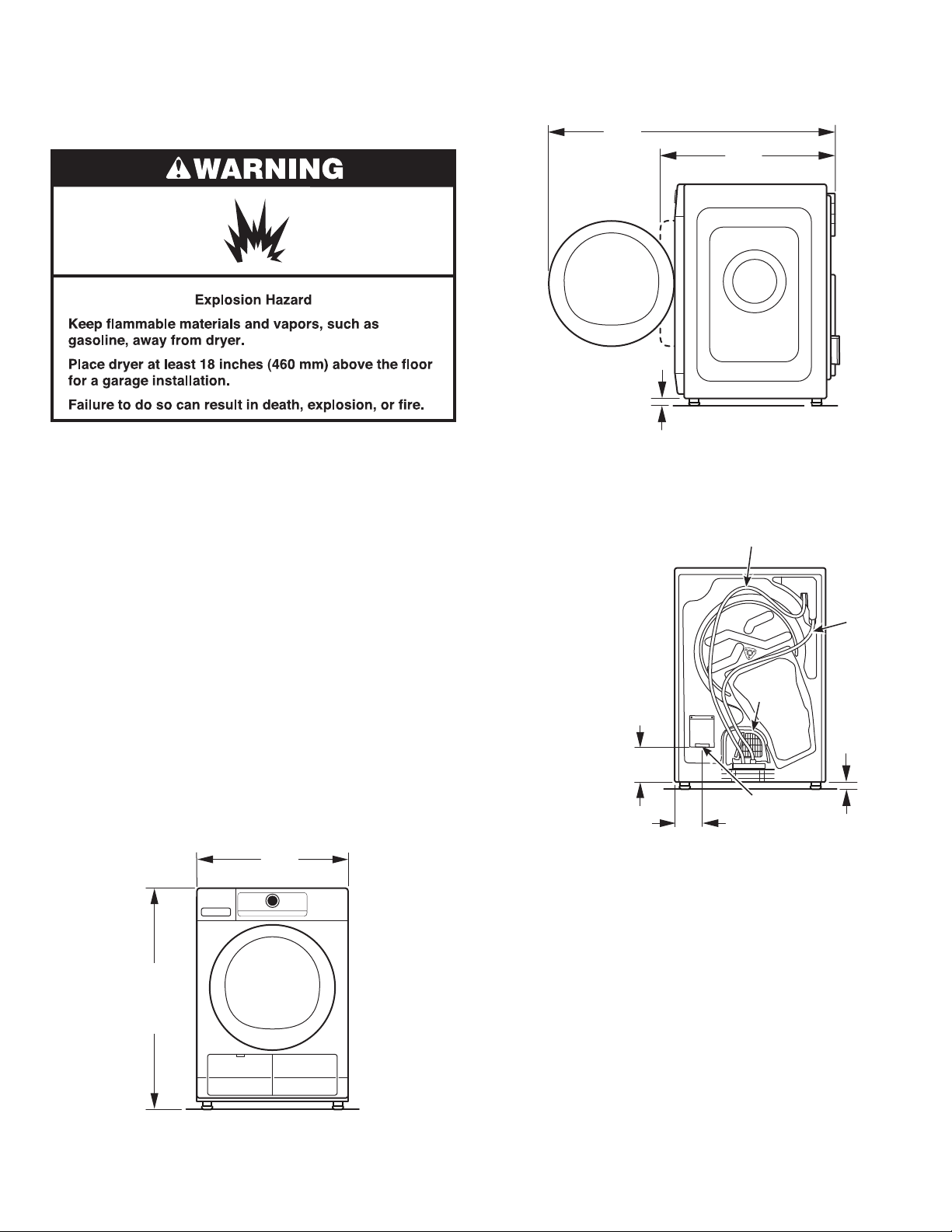

CLEANING THE BOTTOM FILTER

Clean bottom filter after every 5 loads.

The filter is located in bottom corner of dryer.

1. Open the filter door on the bottom of the dryer and grab

the handle to pull out the filter. Remove the foam from

the bottom filter. Clean the filter foam and the filter by

hand or rinse with water – do not wash the filter foam

in a washer. Wring out the filter foam – do not insert

it in the bottom filter dripping wet.

2. Replace the filter foam on the bottom filter. Replace the

bottom filter in the filter chamber. Fold the filter handle

down and close the bottom door.

IMPORTANT:

n

Do not run the dryer with the filter loose, damaged,

blocked, or missing. Doing so can cause overheating

and damage to both the dryer and fabrics.

NON-USE, STORAGE, AND

MOVING CARE (cont.)

For direct-wired dryers:

1. Empty water tank.

2. Disconnect power.

3. Disconnect wiring.

4. Make sure leveling legs are secure in dryer base.

5. Use tape to secure dryer door.

Reinstalling the Dryer

Follow the “Installation Instructions” section to locate, level,

and connect the dryer.

NON-USE, STORAGE, AND MOVING CARE

Non-Use or Storage Care

If you will be on vacation or not using your dryer for an

extended period of time, you should:

1. Empty water tank.

2. Unplug dryer or disconnect power.

3. Clean lint screen. See “Cleaning the Lint Screen.”

4. In colder climates, store your dryer where it will not

freeze. Because some water may stay in the hose,

freezing can damage your dryer.

Moving Care

For power supply cord-connected dryers:

1. Empty water tank.

2. Unplug the power supply cord.

3. Make sure leveling legs are secure in dryer base.

4. Use tape to secure dryer door.

13

INSTALLATION INSTRUCTIONS

Installation Requirements

TOOLS AND PARTS

Gather the required tools and parts before starting installation.

Tools needed:

Flat-blade screwdriver #2 Phillips screwdriver

Min. 8" long TORX® T20®†

screwdriver

1/4" and 5/16" nut driver

(recommended)

If using a power supply cord:

Use a UL-listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

n A UL-listed 30-amp power supply cord, rated 120-/240-volt

minimum. The cord should be type SRD or SRDT and

be at least 4 ft. (1.22 m) long. The wires that connect to

the dryer must end in ring terminals or spade terminals

with upturned ends.

Additional Accessories: (Not supplied with dryer)

Refer to “Operating Instructions” for information about

accessories available for your dryer.

Wire stripper (direct wire

installations)

Adjustable wrench that

opens to 1" (25 mm) or

hex-head socket wrench

Utility knife Tape measure

Channel locks

Pliers

Level

14

†® TORX and T20 are registered trademarks of Acument Intellectual Properties, LLC.

Location Requirements

Check code requirements. Some codes limit, or do not permit,

installing dryer in garages, closets, mobile homes, or sleeping

quarters. Contact your local building inspector.

You will need:

■ A separate 30-amp circuit.

■ If using power supply cord, a grounded electrical outlet

located within 2 ft. (610 mm) of either side of dryer.

See “Electrical Requirements.”

■ Floor must support dryer weight of 200 lbs. (90.7 kg).

Also consider weight of companion appliance.

■ Level floor with maximum slope of 1" (25 mm) under entire

dryer. If forward slope is greater than 1" (25 mm), water

could run out from front of filter. If not level, clothes may

not tumble properly and automatic sensor cycles may

not operate correctly.

■ For garage installation, place dryer at least 18" (460 mm)

above floor. If using a pedestal, you will need 18" (460 mm)

to bottom of dryer.

IMPORTANT: Do not operate, install, or store dryer where

it will be exposed to water, weather, or at temperatures below

40°F (4°C). Lower temperatures may cause dryer not to shut

off at end of automatic sensor cycles, resulting in longer

drying times.

DRYER DIMENSIONS

Front view:

24"

24"

(610 mm)

(610 mm)

1

331⁄2" Min.

33

/2" Min.

(851 mm)

(851 mm)

3

/4" Max.

33

341⁄2" Max.

(857 mm)

(876 mm)

Side view:

1

435⁄16"

41

/2"

(1100 mm)

Back view:

(1054 mm)

3

/4"

(18 mm)

26"

24"

(654 mm)

(610 mm)

White hose from pump

to water tank

NOTES:

■ Allow clearance

behind dryer for

proper drain hose

Grey

water

drain

routing and cooling

fan ventilation. Push

dryer back as far as

possible and make

Cooling

fan

sure drain hose

is not crushed

or kinked.

■ Water can be

drained into an

alternate location.

Remove the top

end of the white

hose from the water

1

7

/4 "

(184 mm)

4"

(102 mm)

Power cord/

cable

3

/4"

(18 mm)

tank and install,

for example, in

a floor standpipe

(see “Drain

System”).

IMPORTANT: Do not block cooling fan as your dryer may not

operate properly.

15

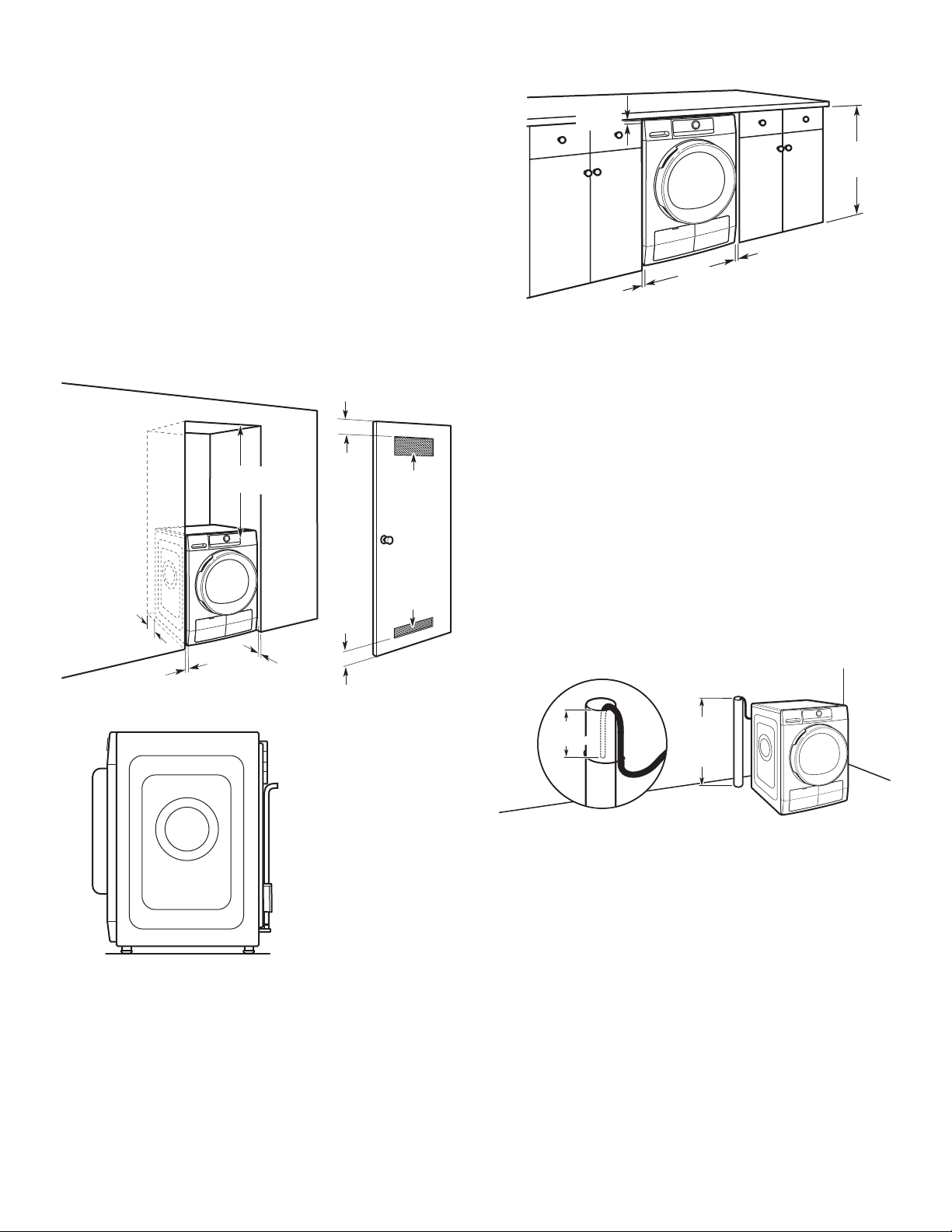

Installation spacing for recessed area

or closet installation

All dimensions show recommended and minimum spacing

allowed.

n Additional spacing should be considered for ease of

installation and servicing.

n Additional clearances might be required for wall, door,

floor, moldings, and drain system.

n Additional spacing should be considered on all sides

of the dryer to reduce noise transfer.

n For closet installation with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

n Companion appliance spacing should also be considered.

Custom under-counter installation:

0" Min.

(0 mm)

341⁄2" Min.

(876 mm)

1" Min.

(25 mm)

1" Min.

(25 mm)

Recommended installation clearances (dryer only):

3"

(76 mm)

(76 mm)

1"

3"

48 in.2 min.

(310 cm

24 in.2 min.

(155 cm2)

*NOTE: 0"–5"

(0 mm–127 mm)

spacing is allowed

behind dryer, providing

drain hose is not kinked

or pinched.

0" - 5"*

(0 mm - 127 mm)

18" min.

(457 mm)

1"

(25 mm)

(25 mm)

Mobile home – Additional installation requirements:

This dryer is suitable for mobile home installations.

The installation must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR,

Part 3280 (formerly the Federal Standard for Mobile

home construction and Safety, Title 24, HUD Part 280)

or Standard CAN/CSA-Z240 MH.

2

)

Drain System

Drain system can be installed by routing the white hose to

a floor drain, wall standpipe, floor standpipe, or laundry tub

instead of to the water tank. Select the method you need.

IMPORTANT: To avoid siphoning, only 4.5" (114 mm) of drain

hose should be inside standpipe; do not force excess hose

into standpipe. Always secure drain hose with a cable tie

(not supplied).

Floor standpipe drain system

max. 36"

4.5"

4.5"

(114 mm)

(114 mm)

Minimum diameter for a standpipe drain: 2" (51 mm). Top of

standpipe must be at least 30" (762 mm) high; install no higher

than 36" (910 mm) from bottom of dryer.

max. 48"

(910 mm)

(1219 mm)

min. 30"

min. 30"

(762 mm)

(762 mm)

16

Electrical Requirements –

U.S.A. Only

It is your responsibility:

n To contact a qualified electrical installer.

n To be sure that the electrical connection is adequate and

in conformance with the National Electrical Code, ANSI/

NFPA 70 – latest edition and all local codes and ordinances.

The National Electrical Code requires a 4-wire power supply

connection for homes built after 1996, dryer circuits involved

in remodeling after 1996, and all mobile home installations.

A copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch Park,

Quincy, MA 02269.

n To supply the required 3- or 4-wire, single-phase,

120-/240-volt, 60 Hz, AC-only electrical supply (or 3- or

4-wire, 120/208-volt electrical supply, if specified on the

serial/rating plate) on a separate 30-amp circuit, fused

on both sides of the line. Connect to an individual branch

circuit. Do not have a fuse in the neutral or grounding circuit.

n Do not use an extension cord.

n If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that

the ground path is adequate.

Electrical Connection

To properly install your dryer, you must determine the type

of electrical connection you will be using and follow the

instructions provided for it here.

n This dryer is manufactured ready to install with a 3-wire

electrical supply connection. A neutral ground conductor

(white wire) is provided between the power supply neutral

connection (center terminal) and the dryer external

grounding point (green screw). If the dryer is installed with

a 4-wire electrical supply connection, one end of the neutral

ground conductor must be removed from the external

ground connector (green screw), and secured under the

neutral terminal (center screw) of the terminal block. When

both ends of the neutral ground conductor are secured

under the neutral terminal (center or white wire) of the

terminal block, the dryer cabinet is isolated from the neutral

conductor. The green ground wire of the 4-wire power cord

must be secured to the dryer cabinet with the green ground

screw.

n If local codes do not permit the connection of a neutral

ground wire to the neutral wire, see “Optional External

Ground 3-wire connection”.

n A 4-wire power supply connection must be used when the

appliance is installed in a location where grounding through

the neutral conductor is prohibited. Grounding through the

neutral is prohibited for (1) new branch-circuit installations

after 1996, (2) mobile homes, (3) recreational vehicles, and

(4) areas where local codes prohibit grounding through the

neutral conductors.

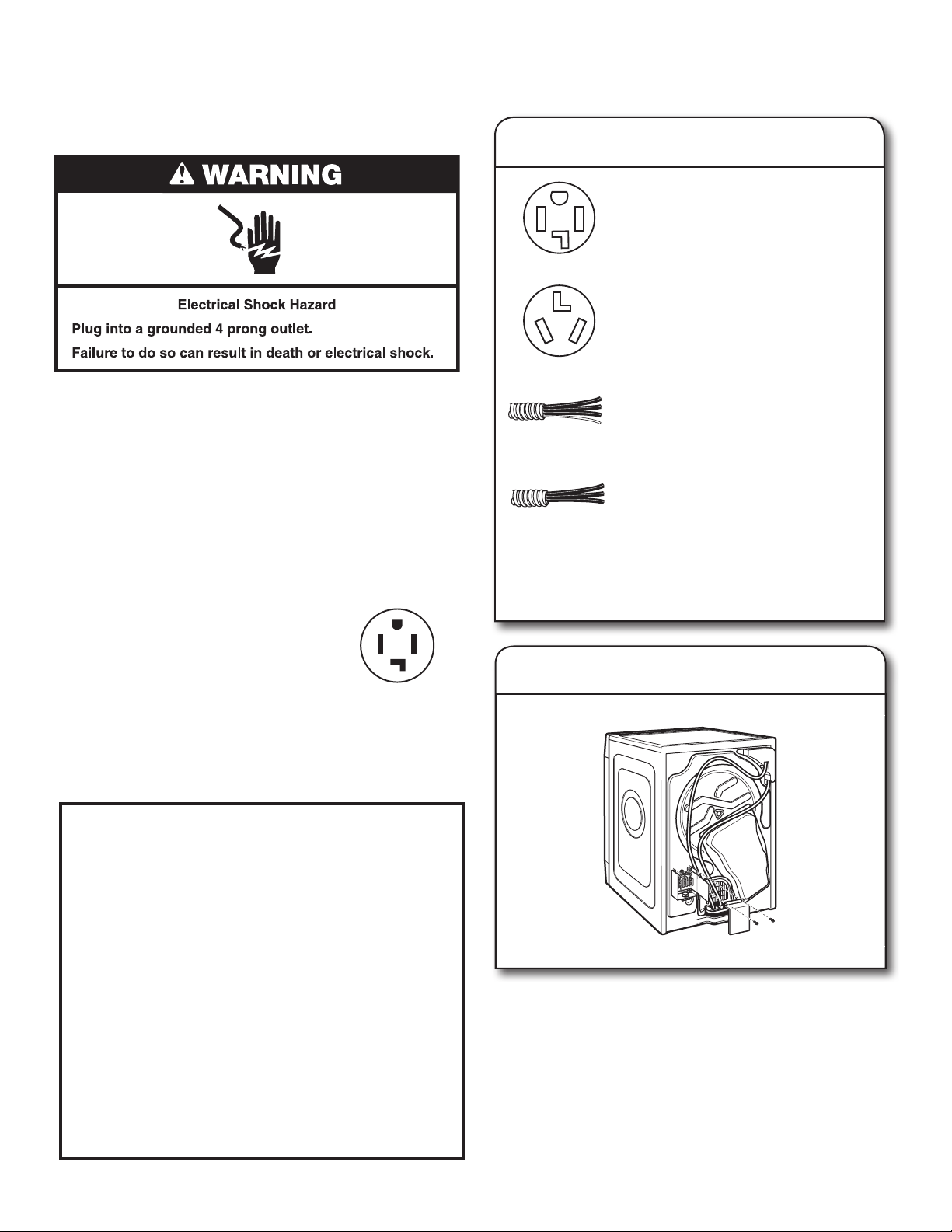

If your outlet looks like this:

Then choose a 4-wire power supply cord with

ring or spade terminals and UL-listed strain

relief. The 4-wire power supply cord, at least

4 ft. (1.22 m) long, must have four 10-gauge

copper wires and match a 4-wire receptacle

of NEMA-Type 14-30R. The ground wire

4-wire

receptacle

(14-30R)

3-wire

receptacle

(10-30R)

(ground conductor) may be either green

or bare. The neutral conductor must be

identified by a white cover.

Then choose a 3-wire power supply cord with

ring or spade terminals and UL-listed strain

relief. The 3-wire power supply cord, at least

4 ft. (1.22 m) long, must have three 10-gauge

copper wires and match a 3-wire receptacle

of NEMA-Type 10-30R.

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire)

and be:

n Flexible armored cable or nonmetallic sheathed copper

cable (with ground wire), covered with flexible metallic

conduit. All current-carrying wires must be insulated.

n 10-gauge solid copper wire (do not use aluminum) at least

5 ft. (1.52 m) long.

If using a power supply cord:

Use a UL-listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

n A UL-listed 30-amp power supply cord, rated 120/240-volt

minimum. The cord should be type SRD or SRDT and be

at least 4 ft. (1.22 m) long. The wires that connect to

the dryer must end in ring terminals or spade terminals

with upturned ends.

17

Electric Dryer Power Hookup –

Electric Installation – U.S.A. Only

Canada Only

Electrical Requirements

It is your responsibility:

n To contact a qualified electrical installer.

n To be sure that the electrical connection is adequate

and in conformance with the Canadian Electrical Code,

C22.1 – latest edition and all local codes. A copy of the

above codes standard may be obtained from: Canadian

Standards Association, 178 Rexdale Blvd., Toronto, ON

M9W 1R3 CANADA.

n To supply the required 4-wire, single-phase, 120/240-volt,

60 Hz., AC-only electrical supply on a separate 30-amp

circuit, fused on both sides of the line. A time-delay fuse

or circuit breaker is recommended. Connect to an individual

branch circuit.

n This dryer is equipped with a CSA

International Certified Power Cord intended

to be plugged into a standard 14-30R wall

receptacle. The cord is 5 ft. (1.52 m) in

length. Be sure wall receptacle is within

reach of dryer’s final location.

n Do not use an extension cord.

If using a replacement power supply cord, it is recommended

that you use Power Supply Cord Replacement Part Number

8579325. For further information, please reference the

“Assistance or Service” section.

4-wire receptacle

(14-30R)

Before you start: disconnect power.

1. Choose electrical connection type

Power supply cord 4-wire receptacle

(NEMA-Type 14-30R):

Go to “Power Supply Cord Connection.”

Power supply cord 3-wire receptacle

(NEMA Type 10-30R):

Go to “Power Supply Cord Connection.”

4-wire direct connection:

Go to “Direct Wire Connection.”

3-wire direct connection:

Go to “Direct Wire Connection.”

NOTE: If local codes do not permit connection of a

cabinet-ground conductor to neutral wire, go to “Optional

External Ground for 3-Wire Connection.” This connection

can be used with either a power supply cord or a direct

wire connection.

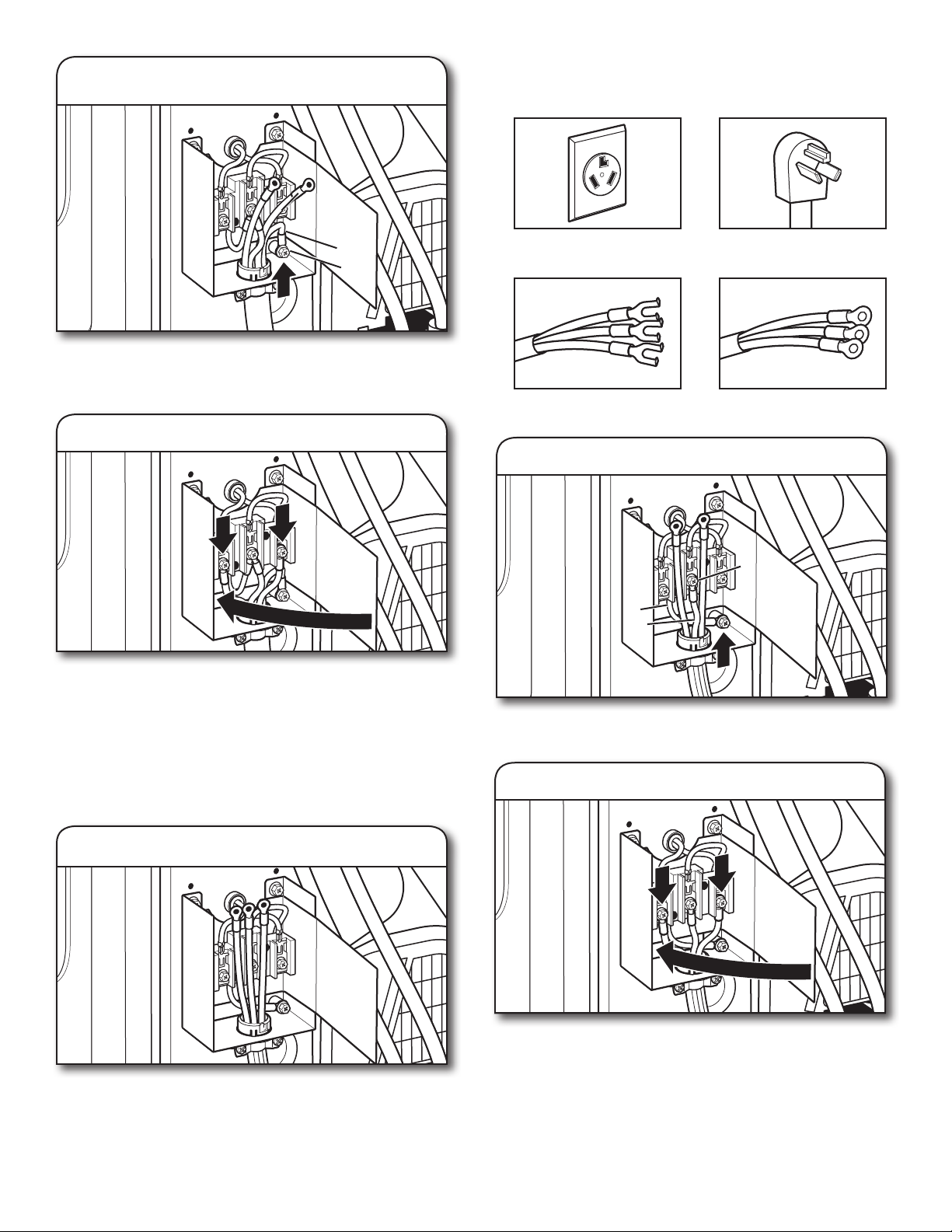

2. Remove terminal block cover

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualied electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not t the outlet, have a proper outlet

installed by a qualied electrician.

SAVE THESE INSTRUCTIONS

18

Remove hold-down screws and terminal block cover.

Power Supply Cord Connection

WARNING

4-Wire Power Supply Cord Connection

IMPORTANT: A 4-wire connection is required for mobile

homes and where local codes do not permit the use

of 3-wire connections.

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

4-Wire Power Supply Cord Strain Relief:

IMPORTANT: Use the strain relief supplied with the dryer.

Attach power supply cord to strain relief

4-wire receptacle

(NEMA-type 14-30R)

Spade terminals with

upturned ends

4 prong plug

Ring terminals

1. Prepare to connect neutral wire

D

B

Put power supply cord through the strain relief. Be sure that

the wire insulation on the power supply cord is inside the

strain relief. Do not further tighten strain relief screws at

this point.

If your outlet looks like this:

Power supply cord 4-wire receptacle

(NEMA-Type 14-30R):

Go to “4-Wire Power Supply Cord

Connection.”

Power supply cord 3-wire receptacle

(NEMA-Type 10-30R):

Go to “3-Wire Power Supply Cord

Connection.”

A

Remove center terminal block screw (B) and green external

ground conductor screw (A). Loop neutral bonding wire (white)

(D) to center terminal block.

2. Connect neutral wire

C

D

Connect neutral wire (white or center) (C) of power supply cord

under center terminal block screw (B). Make sure the end of

neutral bonding wire (white) (D) looped in Step 1 remains on

the center terminal when the power supply cord neutral wire is

attached. Tighten screw.

B

19

3. Connect ground wire

3-Wire Power Supply Cord Connection

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

F

F

A

Connect ground wire (F) (green or bare) of power supply

cord under green external ground conductor screw (A).

Tighten screw.

4. Connect remaining wires

Connect remaining wires under outer terminal block screws.

Tighten screws, tighten strain relief screws, and fold insulator

over terminal block. Finally, reinsert tab of terminal block cover

into slot at bottom edge of terminal block housing. Secure

cover with the 2 hold-down screws. Now, go to “Level Dryer.”

3-wire receptacle

(NEMA-type 10-30R)

Spade terminals with

upturned ends

3 prong plug

Ring terminals

1. Connect neutral (center) wire

B

D

C

Connect neutral (center) wire (C) of power supply cord

center terminal block screw (B)

. Tighten screw.

under

3-Wire Power Supply Cord Strain Relief:

IMPORTANT: Use the strain relief supplied with the dryer.

Attach power supply cord to strain relief

Put power supply cord through the strain relief. Be sure that

the wire insulation on the power supply cord is inside the

strain relief. Do not further tighten strain relief screws at

this point.

20

2. Connect remaining wires

Connect remaining wires under outer terminal block

screws. Tighten screws, tighten strain relief screws,

and fold insulator over terminal block. Finally, reinsert

tab of terminal block cover into slot at bottom edge

of terminal block housing. Secure cover with the

2 hold-down screws. Now, go to “Level Dryer.”

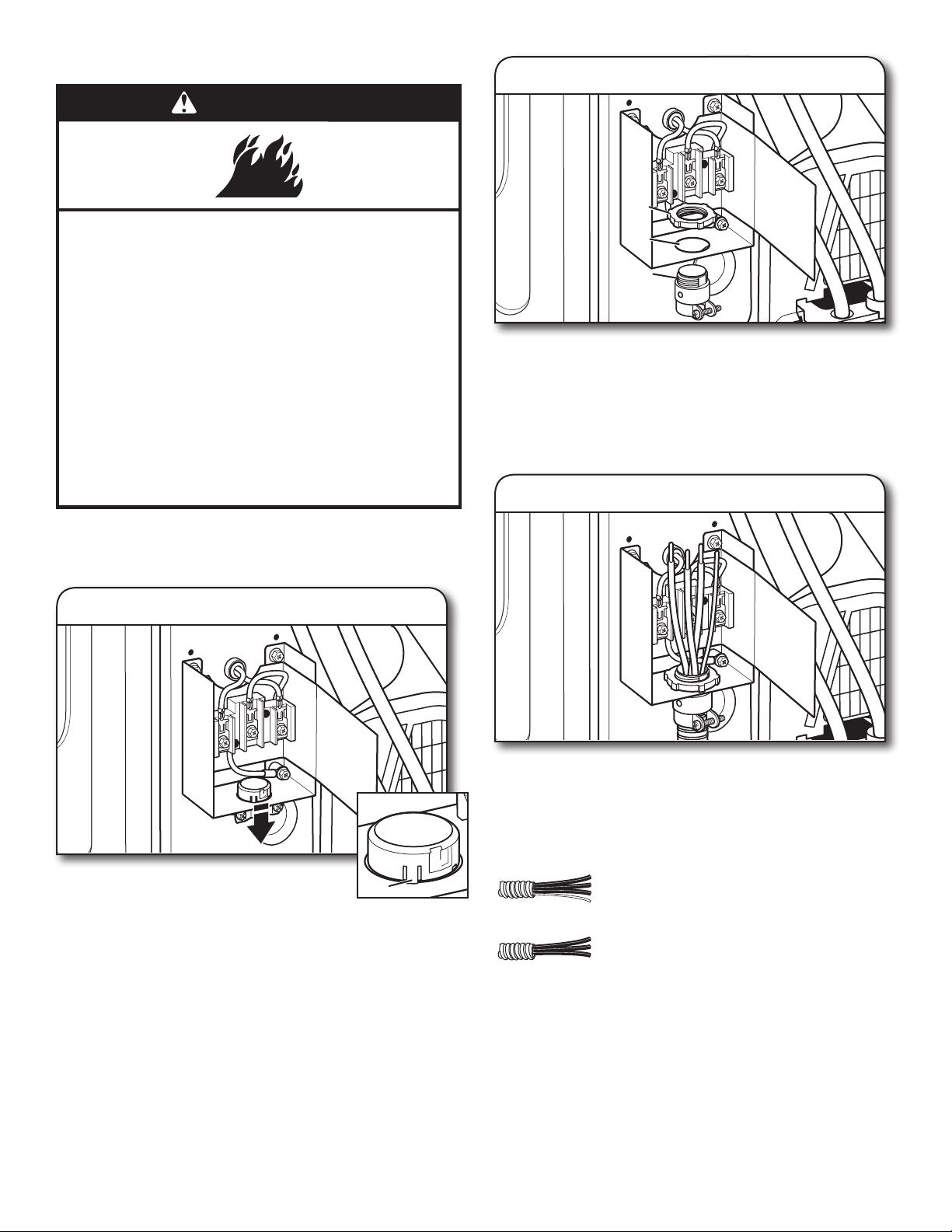

Direct Wire Connection

WARNING

Fire Hazard

Use 10 gauge copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal.

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

2. Attach direct wire strain relief

A

B

C

Unscrew the removable conduit connector (A) and any

screws from a 3/4" (19 mm) UL-listed strain relief (UL marking

on strain relief). Put the threaded section of the strain relief (C)

through the hole below the terminal block opening (B).

Reaching inside the terminal block opening, screw the

removable conduit connector (A) onto the strain relief

threads, and tighten securely.

3. Attach direct wire cable to strain relief

Direct Wire Strain Relief

IMPORTANT: Use a conduit strain relief (not supplied).

1. Remove existing strain relief

With a flat-blade screwdriver, flatten the three

tabs on the band at the top of the strain relief.

Pull out strain relief.

Tab

Put direct wire cable through the strain relief. The strain

relief should have a tight fit with the dryer cabinet and be

in a vertical position. Tighten strain relief screw against the

direct wire cable.

If your wiring looks like this:

4-wire direct connection:

Go to “4-Wire Direct Wire Connection.”

3-wire direct connection:

Go to “3-Wire Direct Wire Connection.”

21

Loading...

Loading...