Page 1

Model

WHCF-DUF

Filter Replacement:

The contaminants or other substances removed or reduced by

this water filter are not necessarily in all users’ water.

Filter life varies depending on local water conditions and the volume of water used.We recommend that you change your filter

every 6 months.However, it can be replaced earlier if there is a

drop in pressure at the faucet.

To reduce Chlorine Taste and Odor,

use Replacement Filter: WHCF-GAC

Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

Systems certified for Cyst reduction may be used on disinfected water

that may contain filterable cysts.EPA Establishment #070595-CT-001

Filter Cartridge Replacement Instructions:

NOTE: Before changing cartridge, turn off incoming water

supply. Place a bucket under filter to catch the small amount

of water that will run out after housing removal.

1. Shut off water.

2. Relieve pressure in housing by pushing red vent button.

3. Unscrew housing and remove old cartridge.Wash housing

thoroughly with mild soap and water.

4. Insert new cartridge and re-install housing. Be sure cartridge is

seated in the housing before tightening onto head.

5. Use filter wrench to fully seat the cartridge.Tighten to make a

water tight seal.

6. Turn on water. If any leaks appear, tighten housing as needed.

7. Flush system for five (5) minutes.

Troubleshooting Guide

Water Leaks at Threaded Fittings:

Tighten slightly more until leak stops.

Water leaks at Push-in Connections

Push tubing in as far as it will go.If leaking continues, shut off

water at the original valve and remove water line by pushing in on

the connector collar while pulling the tubing away. (See Push-in

Fittings Section) Inspect tubing for cracks and scratches.If tubing

is cracked or scratched, simply cut that portion away and reinsert

tubing into fitting.

Make sure tubing is cut straight.If not, recut.

Help Line 1-866-245-9474

Monday Through Friday

8:00 a.m. to 9:00 p.m. EST

or write us at

Whirlpool Water Products

PO Box 765

Meriden, CT 06450

INSTR7016 1203 04/04

8562175 Whirlpool Water Products

Meriden, CT 06450

UNDER SINK MAIN FAUCET

FILTRATION

Standard System

Installation, Use & Care Guide

8562175/INSTR7016 1203

® Registered trademark/TM Trademark of Whirlpool, USA,

used under license.

© 2004 Whirlpool Corporation. All rights reserved.

TEFLON is a registered trademark of E.I. Dupont

® Marca registrada/TM Marca de comercio de Whirlpool, USA,

usado bajo licencia.

Todos los derechos reservados.

TEFLON es una marca registrada de E.I. Dupont

1 Y ear Limited Warranty

CUNO Incorporated warrants the original purchaser-consumer of its Product

that is free of defects in materials and workmanship.Any defect, malfunction, or

other failure of the Product to conform to this warranty will be remedied by

Warrantor in the manner provided below.

This Warranty, together with any warranties implied by law, shall be limited to a

duration of one (1) year from the original date of purchase by the consumer.

This Warranty does not apply to defects that result from abuse, misuse, alteration or damage not caused by CUNO Incorporated.

THIS WARRANTY DOES NOT COVER, AND IS INTENDED TO EXCLUDE ANY

LIABILITY ON THE PART OF WARRANTOR, WHETHER UNDER THIS WARRANTY OR UNDER ANY WARRANTY IMPLIED BY LAW, FOR ANY INDIRECT

OR CONSEQUENTIAL DAMAGES FOR BREACH HEREOF OR THEREOF.

Note: Some states prohibit limitations on the duration of implied warranties and

on the exclusion of indirect or consequential damages; and so the limitation on

implied warranties and on incidental and consequential damages may not be

applicable to you.

RESPONSIBILITY OF WARRANTOR

CUNO Incorporated’s responsibility under this warranty shall be to repair at its

expense, at no charge to the original purchaser-consumer any product that is

actually defective, malfunctioning or otherwise in violation of this warranty. If

CUNO Incorporated for any reason cannot repair a Product covered hereby

within two (2) weeks after receipt of the original purchaser-consumer’s notification of a Warranty claim and the Product, then CUNOIncorporated’s responsibility shall be, at its option, either to replace the defective Product with a comparable new unit at no charge to the consumer or to refund the full purchase price.

CUNO Incorporated’s obligations of repair, replacement, or refund are conditioned upon the return of the defective product to CUNO Incorporated.

If any Product hereby is actually defective within the terms of this Warranty, then

CUNO Incorporated will bear all the reasonable and proper shipping and mailing charges actually incurred in the consumer’s return of the Product set forth

herein. If the Product proves not to be defective within the terms of this

Warranty, then all costs and expenses in connection with the processing of the

consumer’s claim hereunder shall be borne by the consumer.

RESPONSIBILITY OF THE CONSUMER

The original purchaser-consumer’s sole responsibility in the instance of a warranty claim shall be to notify CUNO Incorporated of the defect, malfunction or

other manner in which the terms of this Warranty are violated.You may secure

performance or obligations hereunder by (in writing):

1. Identifying the Product involved (by model or serial number or other sufficient

description that will allow Warrantor to determine which product is defective).

2. Specifying where, when and from whom the Product was purchased.

3. Describing the nature of the defect, malfunction or other violation of this

Warranty.

4. Return the Product, with the above information to:

CUNO Incorporated, 400 Research Parkway, Meriden, CT 06450, U.S.A.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY

ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE.

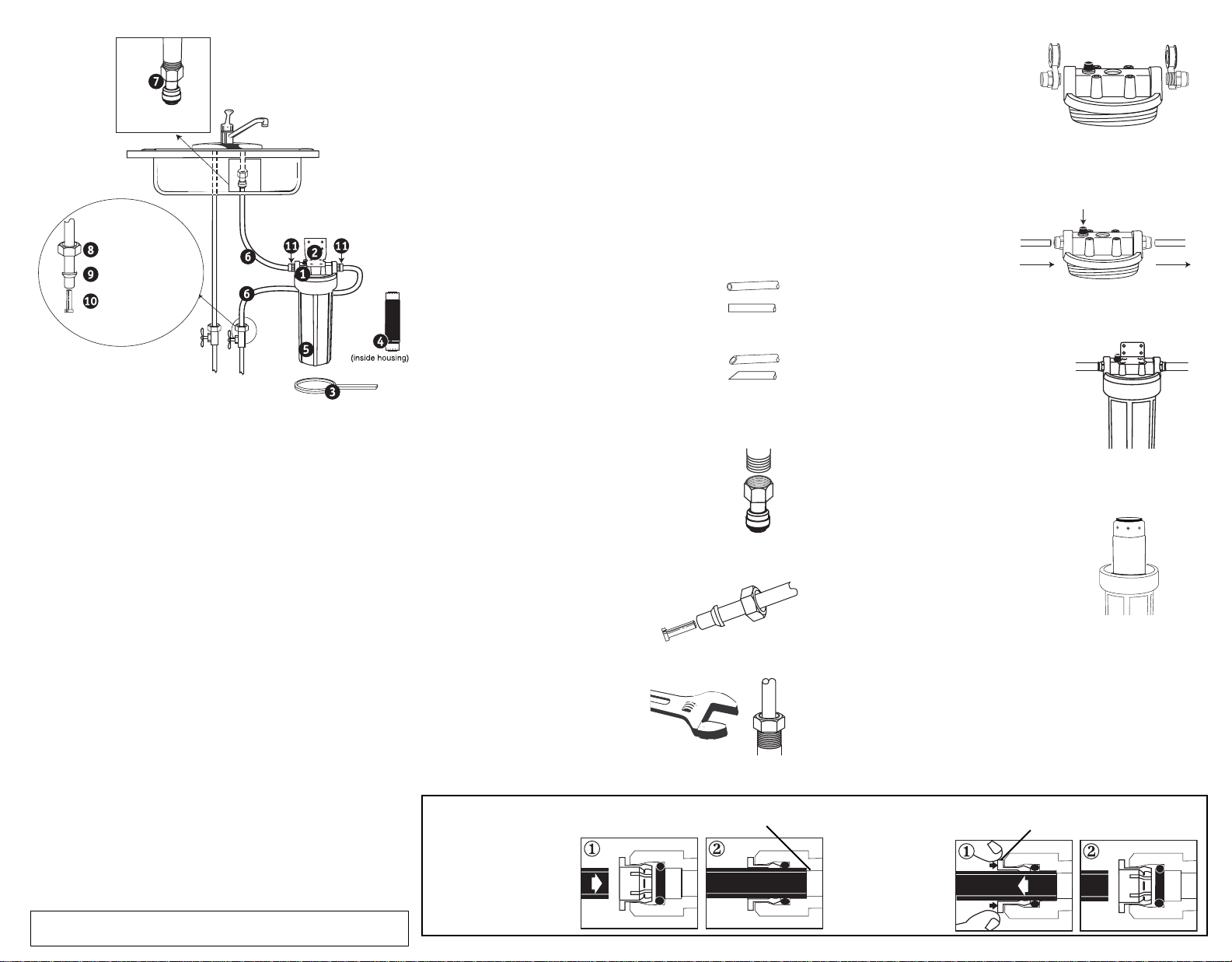

Page 2

3/8" x 1/2"

Faucet Adapter

3/8" Compression

Hex Nut

3/8" Ferrule

3/8" Tube Insert

Parts and Material Included:

1. Filter Head

2. Filter Head Bracket

and eight Phillips

head screws

3. Housing Wrench

4. Filter Cartridge

5. Opaque Housing

6. 5’ of 3/8”Tubing

Kit contains components necessary to connect 3/8” outlet tube to 1/2”

faucet fitting and 3/8” water supply. If you have any other size faucet

connection, you may need other parts for installation as required.

7. 3/8” Fitting x 1/2”

Faucet Adapter

8. 3/8” Compression

Hex Nut

9. 3/8” Ferrule

10. 3/8” Tube Insert

11. Two 3/8”x 3/8”

Push-In Fittings

Tools and Parts Needed:

Gather the required tools before starting installation. Read and follow the instructions provided with any tools listed here.

• Phillips Head Screwdriver

• Adjustable Wrench

• Teflon

®

Tape

• Utility Knife or Tube Cutter for

copper piping

Installation Instructions

For Use With Cold Water Only

NOTE: Remove items from under the sink. Place a catch basin

there to collect small amounts of water that may run out when disconnecting water supply lines.

1.Turn off cold water supply valve and remove existing fitting and/or

tubing from cold water side of faucet.

2. Loosely assemble sump to filter head and attach filter bracket.

Use this assembly to mark a location under the sink that is not in

the way but allows for easy access to change filter. Allow room to

operate housing wrench and a minimum of 2 1/2” clear space below

the unit to facilitate changing cartridge. Once this is done disassemble components for installation.

3. Determine length of tubing required from filter

head/bracket to faucet and from water supply line

to filter head/bracket by holding tubing in place

ensuring it is of appropriate length. Do not kink

tubing as this will impede water flow. If necessary,

loop tubing around to avoid it being kinked.

Cut tubing straight with a utility knife or tube cutter (for copper piping). (See Figure 1.)

4. Install faucet adapter fitting to faucet (see

Figure 2). Do not overtighten to prevent damage to fitting. Referring to section “Using

Push-In Fittings”, insert a section of plastic

tubing into fitting, making sure end of tubing is

firmly seated to backstop.

5. Onto one end of the remaining section of tubing, slide the compression

hex nut and ferrule onto the tubing and

put in the tube insert (see Figure 3).

Fasten this assembly onto 3/8”water

supply outlet. Do not overtighten (see

Figure 4). Overtightening will cause

tubing to separate from fitting.

Correct

Incorrect

Figure 1

Figure 2

Figure 3

6. Wrap Teflon®tape (2 1/2

wraps) around the 3/8” fitting in a clockwise direction

and fasten to filter head

(see Figure 5). Do not use

pipe sealant (dope), as solvents in some types of pipe

dope may cause damage to

Figure 5

plastic fittings.

7. Insert water supply line to

port marked "IN" (see

Figure 6, A) and insert

faucet line to port marked

"OUT" (see Figure 6, B).

Referring to section “Using

Red Air

Release Button

AB

Inlet Outlet

Push-in Fittings,” insert

plastic tubing into fittings,

Figure 6

making sure end of tubing

is firmly seated to backstop.

8. Fasten bracket to filter head with

four Phillips head screws provided.

(See Figure 7.) Fasten bracket to wall

with four Phillips head screws provided. If pre-drilling holes, bracket may

be used as a template for making

screw hole locations.

9. Lubricate housing o-ring with water.

Figure 7

10. Place filter into housing.

(See Figure 8.)

Align housing to filter head and screw

onto filter head.Tighten with wrench to

seal.

Figure 8

11. Slowly turn water supply on while depressing red air

release button on filter head and check for leaks.Then run

water for 5 minutes with an open faucet to flush out air.

Installation Requirements:

• Proper ly tighten all fittings to ensure a leak-free assembly.

• Install in a location that is not susceptible to freezing temperatures

as damage to the housing could occur.

• Install away from direct sunlight as prolonged exposure to light

can weaken plastic components.

• Some local codes may require the use of a licensed plumber or

certified installer when disrupting a potable water line. Determine

and follow any and all local codes and requirements.

• Allow room to operate housing wrench and a minimum of 2 1/2”

clear space below the unit to facilitate changing of the filter.

This filter can be used at any sink where water is used for drinking.

To Attach Tubing

Push tubing in as far as

it will go.Tubing must be

inserted past o-ring and

hit backstop.Pull tube

to ensure it is secured.

Figure 4

“Using Push-In Fittings”

Backstop

To Release Tubing

Push in grey

collet to release

tubing.With collet

held, pull tubing

straight out.

Collet

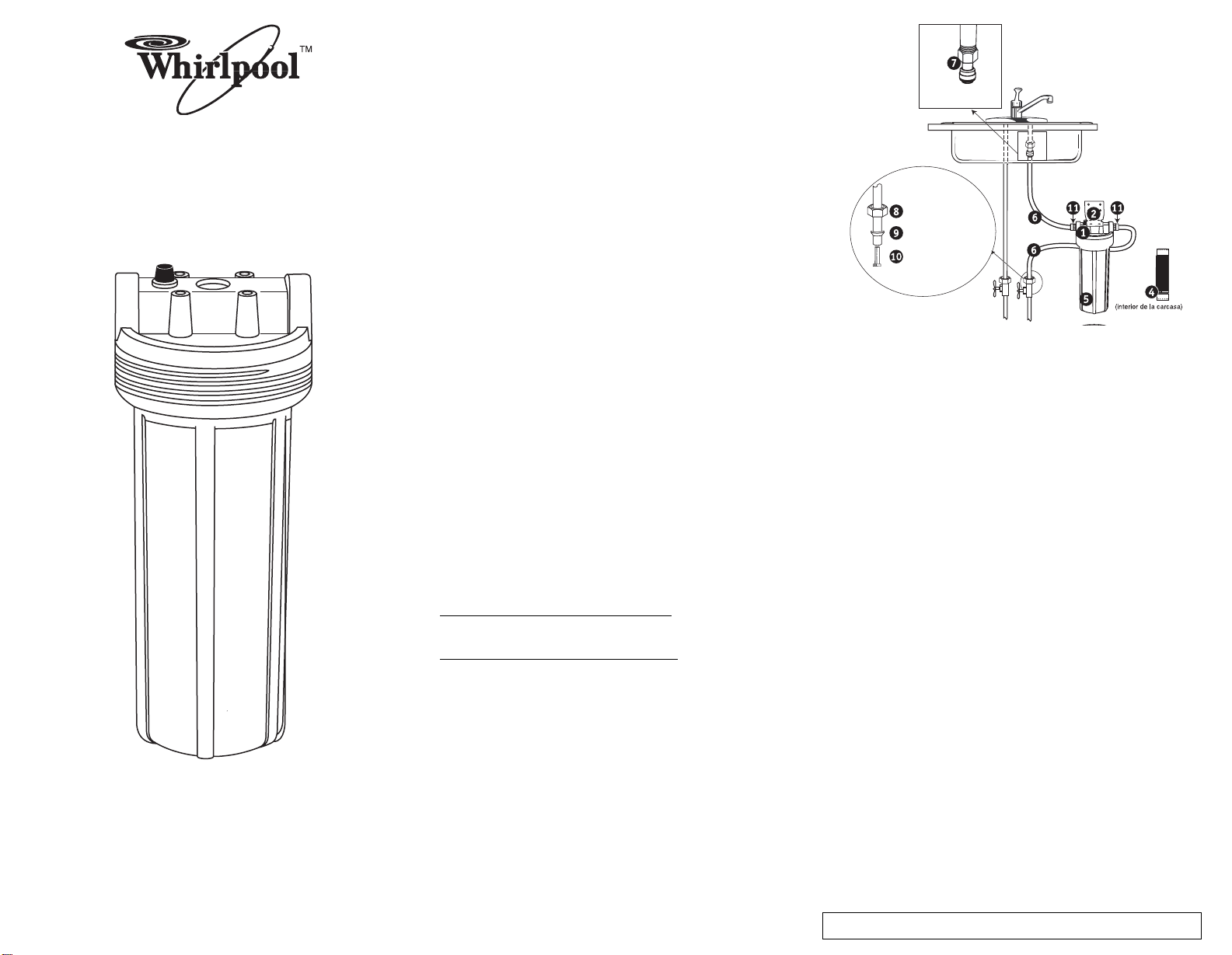

Page 3

FILTRACIÓN BAJO LA LLAVE DE

AGUA PRINCIPAL DE LA PILA

Sistema estándar

Guía de instalación, uso y cuidado

Modelo

WHCF-DUF

8562175/INSTR7016 1203

Reemplazo del filtro:

Los contaminantes u otras substancias que elimina o reduce

este filtro de agua no se encuentran necesariamente en el agua

de todos los usuarios.

La vida útil del filtro varía dependiendo de las condiciones del agua

local y del volumen de agua utilizado.Le recomendamos que cambie su filtro cada 6 meses.Sin embargo, puede ser reemplazado

antes si se reduce la presión de agua en la llave de agua.

Para reducir el nivel de sabor y olor a cloro, use el filtro de reemplazo WHCF-GAC

No lo utilice con agua que contenga microbios o con agua de

calidad dudosa sin una adecuada desinfección antes o después

del sistema. Los sistemas certificados para la reducción de

quistes pueden ser utilizados con agua desinfectada que podría

contener quistes filtrables. Establecimiento EPA Nº 070595-CT -001

Instrucciones de reemplazo del cartucho del filtro:

NOTA: Antes de cambiar el cartucho, cierre el suministro de

agua que entra. Coloque una cubeta bajo el filtro para recoger la

pequeña cantidad de agua que saldrá cuando retire la carcasa.

1. Cierre el suministro de agua.

2. Disminuya la presión en la carcasa oprimiendo el botón de

ventilación rojo.

3. Desenrosque la carcasa y retire el cartucho usado. Enjuague

bien la carcasa con jabón suave y agua.

4. Inserte el nuevo cartucho y reinstale la carcasa. Cerciórese de

que el cartucho asiente en la carcasa antes de fijarlo a la

cabeza.

5. Utilice una llave de ajuste del filtro para asentar bien el cartucho.Apriete para crear impermeabilidad al agua.

6. Abra el suministro de agua. Si hay fugas, apriete la carcasa

según sea necesario.

7. Enjuague el sistema durante cinco (5) minutos.

Guía de solución de problemas

Fugas de agua en los accesorios de rosca:

Apriete un poco más hasta que desaparezca la fuga.

Fugas de agua en los accesor

Empuje la tubería hacia dentro todo lo que pueda. Si la fuga continúa, cierre el agua en la válvula original y retire la tubería de

agua oprimiendo sobre el collar del conector mientras jala hacia

fuera la tubería. (ver la sección "Accesorios de presión"). Vea si

la tubería tiene rajaduras o rayaduras. Si la tubería está rajada o

rayada, retire esa porción y reinserte la tubería en el accesorio.

Cerciórese de que la tubería esté cortada recta. De lo contrario,

vuelva a cortarla.

Número de Ayuda 1-866-245-9474

De lunes a viernes

de 8:00 a.m. a 9:00 p.m. hora oficial del Este

Whirlpool Water Products

Meriden, CT 06450

ios de presión

o escríbanos a

PO Box 765

Adaptador para llave

de agua de 3/8" x 1/2"

Tuerca hexagonal

de compresión de 3/8"

Férula de 3/8"

Inserción para

tubo de 3/8"

Partes y materiales incluidos:

1. Cabeza del filtro

2. Soporte de la cabeza del

filtro y ocho tornillos de

cabeza Phillips

3. Llave de ajuste de la

carcasa

4. Cartucho del filtro

5. Carcasa opaca

6. 5 pies de tuber ía de 3/8"

El juego contiene los componentes necesarios para conectar el tubo

de salida de 3/8" a un accesorio de llave de agua de 1/2" y a un

suministro de agua de 3/8". Si tiene una conexión de llave de agua

de otra medida, podría necesitar otras partes para hacer la instalación como se requiere..

7. Accesor io de 3/8" x

adaptador para llave

de agua de 1/2"

8. Tuerca hexagonal de compresión de 3/8"

9. Férula de 3/8"

10. Inserción para tubo

de 3/8"

11. Dos conexiones de

presión de 3/8" x 3/8"

Herramientas y partes necesarias:

Reúna las herramientas necesarias antes de comenzar la instalación.

Lea y siga las instrucciones incluidas con todas las herramientas

enumeradas aquí.

• Destornillador de cabeza Phillips

• Llave ajustable

• Cinta de Teflon

®

• Cuchillo de uso general o cortadora de tubo para tubería de

cobre

Requisitos de instalación:

• Apriete todos los accesorios adecuadamente para asegurar un

ensamblaje libre de fugas.

• Haga la instalación en un lugar en que la temperatura no baje al

grado de congelación para evitar daños en la carcasa.

• Instale el filtro lejos de la luz solar, pues su exposición prolongada

podría debilitar los componentes plásticos.

• Algunas reglamentaciones locales podrían obligar a contratar los servicios de un plomero autorizado o de un instalador certificado cuando se corta una tubería de agua potable. Verifique lo anterior y

observe todos los reglamentos y códigos locales.

• Deje espacio para utilizar la llave de la carcasa y un mínimo de

6.4cm de espacio libre bajo la unidad para facilitar el acceso al filtro

que será cambiado.

Este filtro puede ser usado en cualquier pila de agua para beber.

Page 4

® Marca registrada/TM Marca de comercio de Whirlpool, USA, usada

bajo licencia.

© 2004 Whirlpool Corporation.Todos los derechos reservados.

TEFLON es una marca registrada de E.I. Dupont

Garantía Limitada de Un Año

CUNO Incorporated garantiza al comprador-consumidor original de su Producto

que éste se encuentra libre de defectos de material y de fabricación. El

Garante reparará cualquier defecto, malfuncionamiento u otra avería del

Producto amparado por esta garantía de acuerdo a lo estipulado a continuación.

Esta Garantía, juntamente con otras garantías implícitas por ley, se limitarán a

la duración de un (1) año a partir de la fecha de compra original del consumidor.

Esta Garantía no cubre defectos que resulten del abuso, mal uso, alteración o

daños no ocasionados por CUNO Incorporated.

ESTA GARANTÍA NO AMPARA, Y DE HECHO TIENE EL PROPÓSITO DE

EXCLUIR CUALQUIER RESPONSABILIDAD DE PARTE DEL GARANTE, SEA

EN VIRTUD DE ESTA GARANTÍA O DE LA GARANTÍA IMPLÍCITA DE LEY,

POR DAÑOS INDIRECTOS O CONSECUENCIALES POR LA VIOLACIÓN DE

LA MISMA.

Nota: Algunos estados prohíben limitaciones en la duración de garantías

implícitas y en la exclusión de daños indirectos o consecuenciales, de modo

que la limitación de garantías implícitas y de daños indirectos y consecuenciales quizás no le corresponda a usted.

RESPONSABILIDAD DEL GARANTE

La responsabilidad de CUNO Incorporated en virtud de esta garantía será de

reparar por cuenta propia, sin costo para el comprador-consumidor original

cualquier producto que esté realmente defectuoso, funcione mal o que de alguna otra manera esté en violación de esta garantía. Si por algún motivo, CUNO

Incorporated no pudiera reparar un Producto amparado por la presente garantía dentro de dos (2) semanas después de haber recibido la notificación original

del comprador-consumidor de un reclamo de Garantía, entonces la responsabilidad de CUNO Incorporated será, a elección propia, ya sea de sustituir el

Producto defectuoso con una unidad nueva equiparable sin costo alguno para

el consumidor o reembolsar el precio total de la compra. Las obligaciones de

CUNO Incorporated en cuanto a reparación, sustitución o reembolso son condicionales a la devolución del producto defectuoso a CUNO Incorporated.

Si cualquier Producto amparado por la presente garantía es en realidad defectuoso según las condiciones estipuladas en esta Garantía, entonces CUNO

Incorporated correrá con todos los gastos razonables y apropiados de envío

incurridos en la devolución del Producto por el consumidor tal como se estipula

en la presente Garantía. Si se compr ueba que el Producto no tiene defectos

de conformidad con las condiciones de esta Garantía, entonces todos los gastos relacionados con el procesamiento del reclamo serán por cuenta del consumidor

RESPONSABILIDAD DEL CONSUMIDOR

La única responsabilidad del comprador-consumidor original en el caso de

reclamo de la garantía será de notificar a CUNO Incorporated del defecto, malfuncionamiento o cualquier otra forma que viole las condiciones de esta

Garantía. Usted podrá garantizar el rendimiento u obligaciones, enumeradas a

continuación, al (por escrito):

1. Identificar el Producto en cuestión (por número de modelo o de serie u otra

descripción suficiente que permita al Garante determinar cuál producto es

defectuoso.)

2. Especificar dónde, cuándo y de quién se adquirió el Producto.

3. Describir la índole del defecto, malfuncionamiento u otra violación de esta

Garantía.

4. Devolver el Producto, con la información especificada arriba, a:

CUNO Incorporated, 400 Research Parkway, Meriden, CT 06450, U.S.A.

ESTA GARANTÍA LE OTORGA DERECHOS LEGALES ESPECÍFICOS Y

PUEDE QUE USTED TENGA TAMBIÉN OTROS DERECHOS, LOS

CUALES VARÍAN DE UN ESTADO A OTRO.

Para liberar la tubería

Empuje hacia dentro

la pinza de sujeción

gris para liberar la

tubería. Sosteniendo

la pinza de sujeción,

jale la tubería en línea

recta.

Para sujetar la tubería

Empuje la tubería hacia

dentro todo lo que pueda.

La tubería debe insertarse

detrás del anillo en o y llegar

hasta el tope trasero. Jale el

tubo para cerciorarse de que

esté bien sujeto

Pinza de sujeción

Tope trasero

"Utilización de los Accesorios de Presión"

6. Envuelva con cinta de

Teflon

®

(2 1/2 vueltas) alrededor del accesorio de 3/8" en el

sentido de las manecillas del

reloj y asegúrela contra la

cabeza del filtro (ver Figura 5).

No utilice sellador para tubos

(acetato), puesto que los solventes de algunos tipos de

acetatos para tubos podrían hacer que se dañen los

accesorios plásticos.

7. Inserte la tuber ía de

suministro de agua al

puerto marcado con "IN"

(ver Figura 6, A) e inserte

la tubería de la llave de

agua en el puerto marcado con "OUT" (ver Figura

6, B). Remítase a la sección "Utilización de los accesorios

de presión," inserte la tubería plástica en los accesorios,

cerciorándose de que el extremo de la

tubería quede firmemente asentado

contra el tope trasero

8. Asegure el soporte a la cabeza del

filtro con los cuatro tornillos de cabeza

Phillips incluidos. (ver Figura 7).

Asegure el soporte a la pared con los

cuatro tornillos de cabeza Phillips incluidos. Si es necesario taladrar los hoyos,

el soporte puede ser usado como plantilla para marcar el

lugar donde van los hoyos para los tornillos.

9. Lubrique con agua el anillo en o de la carcasa.

10. Coloque el filtro en la carcasa.

(Ver Figura 8.)

Alinee la carcasa con la cabeza del filtro

y enrósquela en la cabeza del filtro.

Apriete con la llave de ajuste para sellar.

11. Abra lentamente el suministro de agua mientras presiona el botón rojo de escape de aire que se encuentra en

la cabeza del filtro y verifique la presencia de fugas. Luego

deje correr el agua durante 5 minutos con la llave de agua

abierta para drenar el aire.

Instrucciones de instalación

Para usar sólo con agua fría

NOTA: Retire los objetos que se encuentren bajo la pila.Coloque un

colector de agua para recoger las pequeñas cantidades de agua

que pudieran salir cuando desconecte las tuberías de suministro de

agua.

1. Cierre la válvula de suministro de agua fría y retire el accesorio

y/o tubería existente del lado del agua fría de la llave.

2. Ensamble suavemente el depósito con la cabeza del filtro y sujete

el soporte del filtro. Use este conjunto para marcar un lugar bajo la

pila que no estorbe, sino que permita un fácil acceso para cambiar

el filtro. Deje espacio para manipular la llave de ajuste de la carcasa y un mínimo de espacio libre de 6.4cm bajo la unidad para

facilitar el cambio del cartucho. Una vez que haya hecho esto

desarme los componentes para proceder a la instalación.

3. Determine la longitud de la tubería necesar ia desde

la cabeza del filtro/soporte hasta la llave de agua y

desde la tubería de suministro de agua a la cabeza del

filtro/soporte sosteniendo la tubería en su lugar, cerciorándose de que sea la longitud apropiada. No

doble la tubería, pues esto impedirá que el agua fluya.

Si es necesario, enrolle la tubería para evitar que se

doble.

Corte la tubería recta con cuchillo de uso general o cortadora de tubo (para tuberías de cobre) (ver Figura 1).

4. Instale el accesorio adaptador de la llave de agua a

la llave de agua (ver Figura 2).No apriete demasiado

para evitar que se dañe el accesorio.Remítase a la

sección "Utilización de los accesorios de presión",

inserte una sección de tubería plástica en el accesorio,

cerciorándose de que el extremo de la

tubería quede firmemente asentado

contra el tope trasero.

5. Sobre una de las secciones

restantes de la tubería, introduzca la

tuerca hexagonal de compresión y la

férula en la tubería y coloque la inserción del tubo (ver Figura 3).Asegure

este conjunto contra la boquilla de salida del suministro de agua de 3/8". No

apriete en exceso (Ver Figura 4).

Apretar en exceso hará que la tubería

se separe del accesorio.

a

Figura 1

Figura 3

Figura 4

Figura 5

Figura 6

Figura 7

Figura 8

Figura 2

Correcto

Incorrecto

Botón rojo de

escape de aire

AB

Orificio

de entrada

Boquilla

de salid

Loading...

Loading...