Whirlpool WGG745S0FS Installation Instructions

INSTALLATION INSTRUCTIONS

30" (76.2 CM) DOUBLE OVEN GAS RANGES

INSTRUCTIONS D’INSTALLATION

DES CUISINIÈRES À GAZ À DOUBLE FOUR

DE 30" (76,2 CM)

INSTRUCCIONES DE INSTALACIÓN ESTUFAS

A GAS CON HORNO DOBLE DE 30" (76,2 CM)

Table of Contents Table des matières Índice

RANGE SAFETY ........................................2

INSTALLATION REQUIREMENTS ............4

Tools and Parts ........................................ 4

Location Requirements ...........................4

Electrical Requirements ..........................6

Gas Supply Requirements ......................6

INSTALLATION INSTRUCTIONS ..............7

Unpack Range.........................................7

Adjust Leveling Legs ...............................7

Install Anti-Tip Bracket ............................8

Make Gas Connection ............................8

Plastic Hose Installation ..........................9

Verify Anti-Tip Bracket Is Installed

and Engaged .........................................10

Level Range ...........................................11

Electronic Ignition System ....................11

Complete Installation ............................12

GAS CONVERSIONS ...............................13

Propane Gas Conversion ......................13

Natural Gas Conversion ........................16

SÉCURITÉ DE LA CUISINIÈRE ..............20

EXIGENCES D’INSTALLATION ..............22

Outils et pièces ......................................22

Exigences d’emplacement ....................22

Spécications électriques .....................24

Spécications de l’alimentation

en gaz ....................................................24

INSTRUCTIONS D’INSTALLATION ........25

Déballage de la cuisinière .....................25

Réglage des pieds de nivellement ........25

Installation de la bride

antibasculement ....................................26

Raccordement au gaz ...........................26

Vérier que la bride anti-basculement

est bien installée et engagée ................26

l’installation de tuyau en plastique ........27

Réglage de l’aplomb de la cuisinière ....29

Système d’allumage électronique.........29

Terminer l’installation ............................. 30

CONVERSIONS DE GAZ .........................31

Conversion pour l’alimentation

au propane ............................................31

Conversion pour l’alimentation

au gaz naturel ........................................34

SEGURIDAD DE LA ESTUFA..................38

REQUISITOS DE INSTALACIÓN ............ 40

Herramientas y piezas ...........................40

Requisitos de ubicación ........................40

Requisitos eléctricos .............................42

Requisitos del suministro de gas ..........42

INSTRUCCIONES DE INSTALACIÓN .... 43

Desembale la estufa ..............................43

Regule las patas niveladoras ................43

Instalación del soporte antivuelco ........44

Conexión del suministro de gas ...........44

Instalación de mangueras de plástico ..45

Verique que el soporte antivuelco

esté instalado y enganchado ................46

Nivelación de la estufa ..........................47

Sistema de encendido electrónico .......47

Complete la instalación .........................48

CONVERSIONES DE GAS ......................49

Conversión a gas propano ....................49

Conversión a gas natural ......................53

IMPORTANT:

Save for local electrical inspector’s use.

Installer: Leave installation instructions with the homeowner.

Homeowner: Keep installation instructions for future reference.

IMPORTANT :

Conserver ces instructions à l’usage de l’inspecteur des installations électriques local.

Installateur : Remettre les instructions d’installation au propriétaire.

Propriétaire : Conserver les instructions d’installation pour référence ultérieure.

IMPORTANTE:

Guarde para tener a disposición del inspector de electricidad local.

Instalador: Déjele las instrucciones de instalación al propietario.

Propietario: Guarde las instrucciones de instalación para futuras consultas.

W11256513A

RANGE SAFETY

WARNING: If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

– Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch.

•

Do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

•

instructions.

If you cannot reach your gas supplier, call the fire department.

•

– Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the “What to do if you smell gas” instructions.

IMPORTANT: Do not install a ventilation system that blows air downward toward this gas cooking appliance. This type of

ventilation system may cause ignition and combustion problems with this gas cooking appliance resulting in personal injury or

unintended operation.

2

In the State of Massachusetts, the following installation instructions apply:

Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

Acceptable Shut-off Devices: Gas Cocks and Ball Valves installed for use shall be listed.

A flexible gas connector, when used,must not exceed 4 feet (121.9 cm).

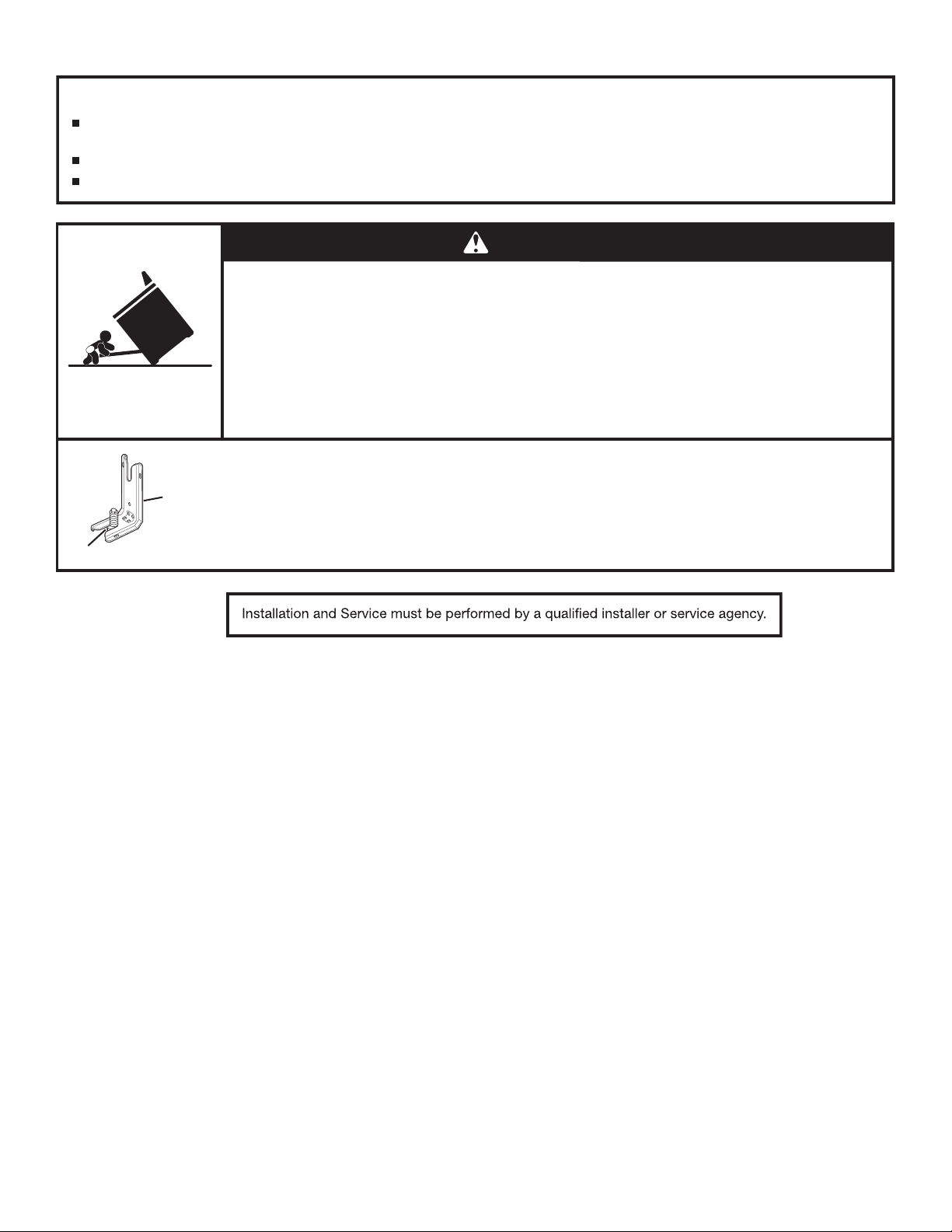

Range Foot

Anti-Tip

Bracket

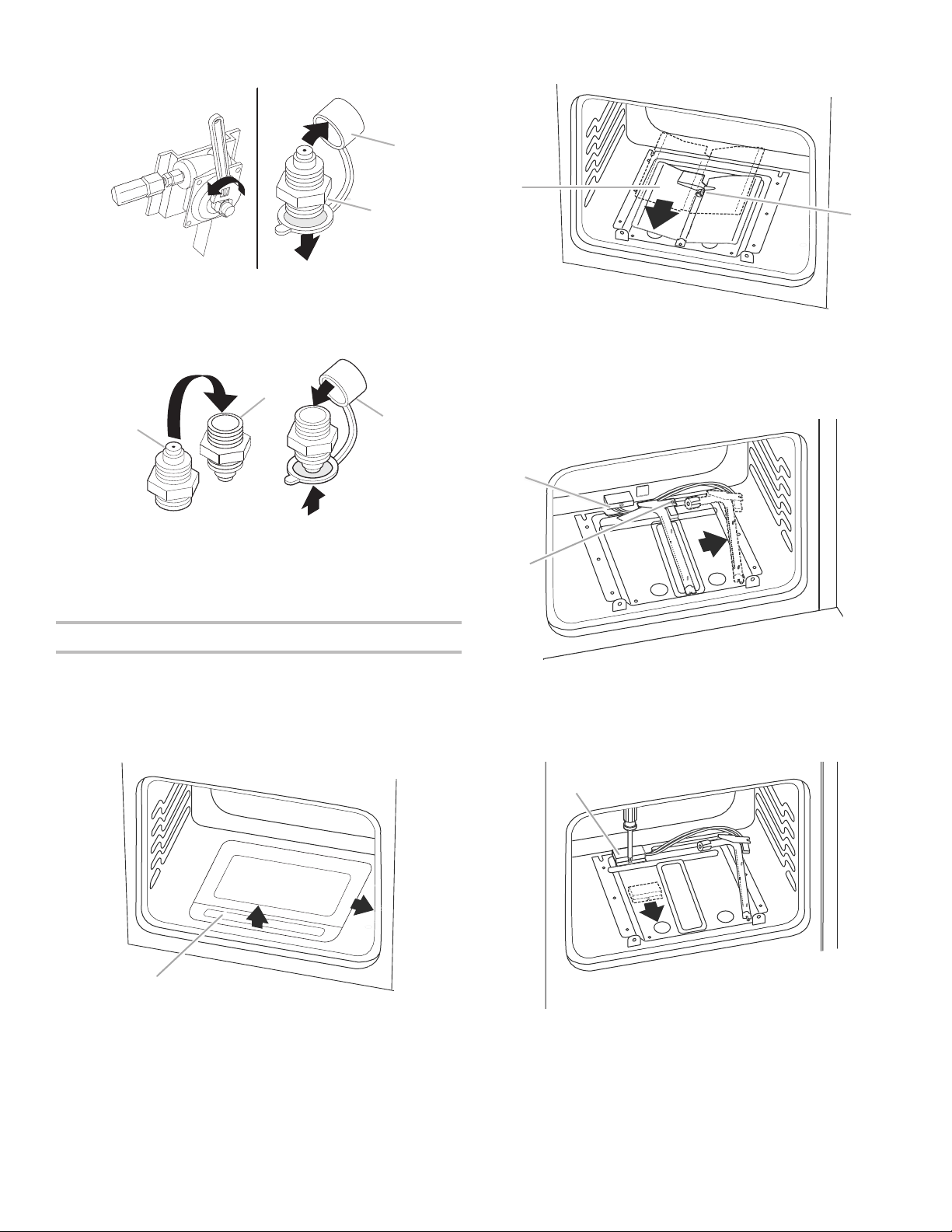

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

To verify the anti-tip bracket is installed and engaged:

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

• Slide range back so rear range foot is under anti-tip bracket.

• See installation instructions for details.

3

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

■ Tape measure

■ Phillips screwdriver

®†

■ Torx

■ Flat-blade screwdriver

■ 1/8" (3.2 mm) at-blade

T20®† screwdriver

screwdriver

■ Level

■ Hand or electric drill

■ Wrench or pliers

■ Pipe wrench

■ 15/16" (23.8 mm)

combination wrench

■ 1/8"(3.2 mm) drill bit

■ Marker or pencil

Parts supplied

Check that all parts are included.

■ Propane/Natural Gas Conversion Kit (located on back of

range near lower side)

■ Burner grates

■ Burner caps

■ Oven racks

■ 2 - #12 x 1

■ Anti-tip bracket (taped inside upper oven with package

5

⁄8" screws (for mounting anti-tip bracket)

containing literature)

Anti-tip bracket must be securely mounted to the back wall

or oor. Thickness of ooring may require longer screws to

anchor bracket to suboor. Longer screws are available from

your local hardware store.

Parts needed

Check local codes and consult gas supplier. Check existing gas

supply and electrical supply. See “Electrical Requirements” and

“Gas Supply Requirements” sections.

■ Pipe-joint compound

resistant to Propane gas

■ Noncorrosive leak-detection

solution

For Propane/Natural Gas

Conversions

■ 1/2" (12.7 mm) combination

wrench

■ 9/32" (7.0 mm) nut driver

■ Masking tape

For Plastic Hose Installation

■ Metal Clamps

Location Requirements

IMPORTANT: Observe all governing codes and ordinances. Do

not obstruct ow of combustion and ventilation air.

■ It is the installer’s responsibility to comply with installation

clearances specied on the rating number plate. The rating

number plate is located behind the control panel.

■ The range should be located for convenient use in the

kitchen.

■ Recessed installations must provide complete enclosure of

the sides and rear of the range.

■ To eliminate the risk of burns or re by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood

or microwave hood combination that projects horizontally a

minimum of 5" (12.7 cm) beyond the bottom of the cabinets.

■ All openings in the wall or oor where range is to be installed

must be sealed.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

■ The oor anti-tip bracket must be installed. To install the

anti-tip bracket shipped with the range, see “Install Anti-Tip

Bracket” section.

■ Grounded electrical supply is required. See “Electrical

Requirements” section.

■ Proper gas supply connection must be available. See “Gas

Supply Requirements” section.

■ Contact a qualied oor covering installer to check that the

oor covering can withstand at least 200°F (93°C).

■ Use an insulated pad or 1/4" (0.64 cm) plywood under range

if installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check with

your builder or cabinet supplier to make sure that the materials

used will not discolor, delaminate or sustain other damage. This

oven has been designed in accordance with the requirements

of UL and CSA International and complies with the maximum

allowable wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR,

Part 3280 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD Part 280). When such

standard is not applicable, use the Standard for Manufactured

Home Installations, ANSI A225.1/NFPA 501A or with local codes.

In Canada, the installation of this range must conform with the

current standards CAN/CSA-A240-latest edition, or with local

codes.

Mobile home installations require:

■ When this range is installed in a mobile home, it must be

secured to the oor during transit. Any method of securing

the range is adequate as long as it conforms to the

standards listed above.

†®TORX and T20 are trademarks of Acument Intellectual Properties, LLC.

4

Product Dimensions

B*

Range may be installed with zero clearance to combustible

construction at the rear and on the sides below the cooktop.

B

D

C

C**

A

D

F

A. 35³⁄4" ± 1/8" (90.8 ± 0.3 cm)

cooktop height (minimum)

with leveling legs screwed

all the way in

B. Model/serial/rating plates

(located behind the control

panel)*

C. 47¹⁄8" ± 1/8" (119.7 ± 0.3 cm)

overall height (minimum) with

leveling legs screwed all the

way in**

D. 28¹⁄2" ± 1/4" (72.4 ± 0.6 cm)

depth with handle

E. 26¹⁄8" to 27¼" ± 1/8" (66.4 to

69.2 cm ± 0.3 cm)***

F. 2915⁄16" ± 1/16" (76.0 ± 0.2 cm)

width

E***

*Model/serial/rating plates may be rotated up from behind the

control panel for viewing from the front of the range.

**Range can be raised approximately 1" (2.5 cm) by adjusting

the leveling legs.

***Excludes handle. Dimension given is from wall to front of

oven door and will vary based on electrical outlet receptacle

installation.

Cabinet Dimensions

A

E

F

J

I

K

L

G

H

8½"

(21.6 cm)

14"

(35.6 cm)

***

1½"

(3.8 cm)

A. 18" (45.7 cm) upper cabinet to countertop

B. 13" (33.0 cm) upper cabinet depth

C. 30" (76.2 cm) min. opening width

D. For minimum clearance to the top of the cooktop, see NOTE.

E. 30" (76.2 cm) min. opening width

F. 3" (7.6 cm) min. clearance from both sides of the range to the side

wall or other combustible material.

G. Cabinet door or hinges should not extend into the cutout.

H. 3" (7.6 cm) distance from wall

I. 1¹⁄2" (3.8 cm) min. from right side cabinet

J. 8" (20.3 cm) width

K. 7" (17.8 cm) min. from floor

L. 2" (5.1 cm) min. from floor

1¼"*

(3.2 cm)

8½" (21.6 cm)**

gas line location

2¼" (5.7 cm)

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth and

36" (91.4 cm) countertop height.

IMPORTANT: If installing a range hood or microwave hood

combination above the range, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

*Drill on centerline 1¼" (3.2 cm) from rear wall for gas supply

line.

**Gas lines must be installed within the shaded area to ensure

proper alignment of this oven with cabinets.

***Electrical plugs must be installed within the shaded area to

ensure proper alignment of this oven with cabinets.

NOTE: 24" (61.0 cm) minimum when bottom of wood or

metal cabinet is covered by not less than 1/4" (0.64 cm) ame

retardant millboard covered with not less than No. 28 MSG sheet

steel, 0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum

or 0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the

cooking platform and the bottom of an uncovered wood or metal

cabinet.

5

Electrical Requirements

IMPORTANT: The range must be electrically grounded in

accordance with local codes and ordinances, or in the absence

of local codes, with the National Electrical Code, ANSI/NFPA 70

or Canadian Electrical Code, CSA C22.1.

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrical installer determine that

the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

■ A 120 V, 60 Hz, AC only, 15 A fused, electrical circuit

is required. A time-delay fuse or circuit breaker is also

recommended. It is recommended that a separate circuit

serving only this range be provided.

■ Electronic ignition systems operate within wide voltage limits,

but proper grounding and polarity are necessary. Check that

the outlet provides 120 V power and is correctly grounded.

■ The wiring diagram is located on the back of the range in a

clear plastic bag.

Gas Supply Requirements

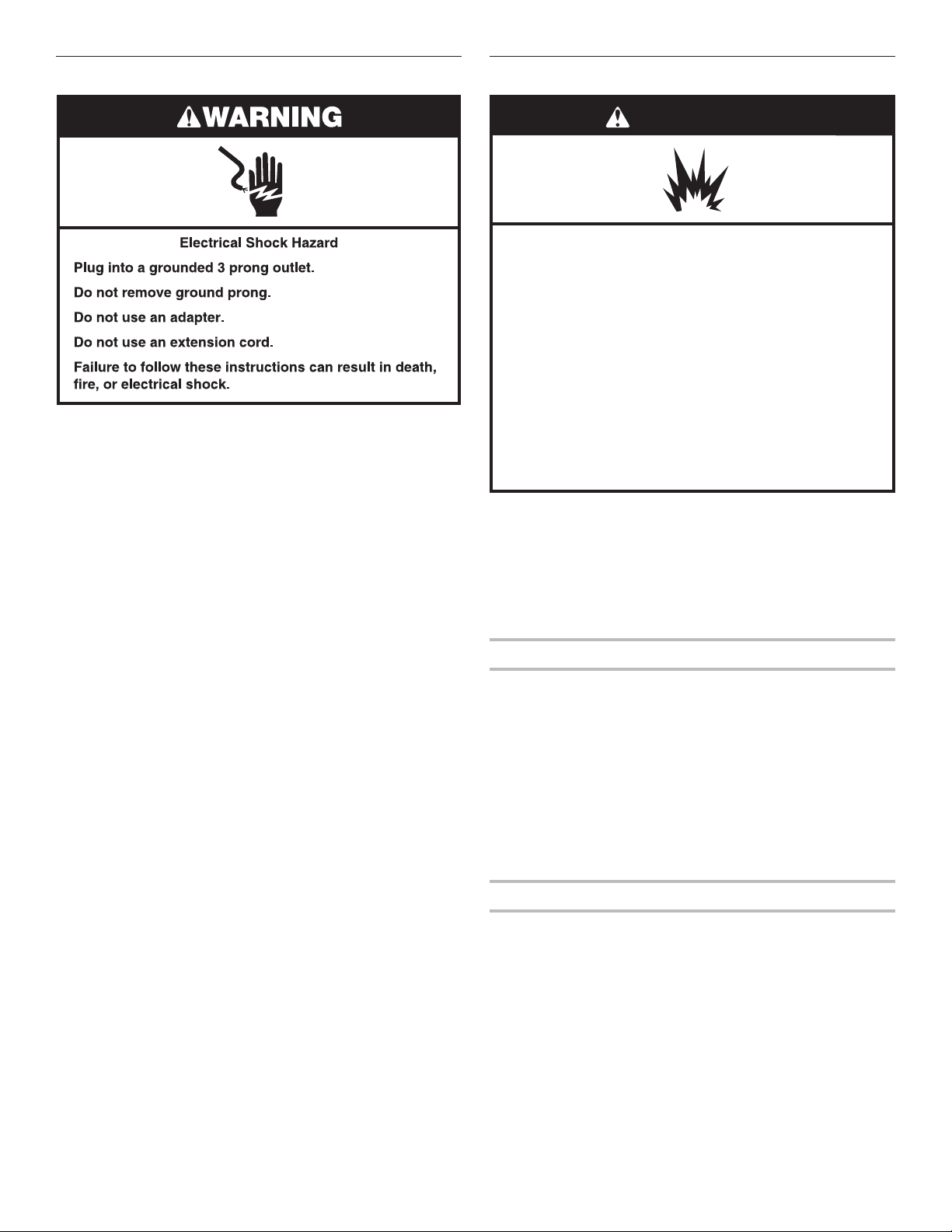

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local codes

and ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1 - latest edition or CAN/CGA B149 - latest

edition.

IMPORTANT: Leak testing of the range must be conducted

according to the manufacturers instructions.

Type of Gas

Natural gas:

■ This range is factory set for use with Natural gas. See “Gas

Conversions” section. The model/serial rating plate located

behind the control panel has information on the types of gas

that can be used. If the types of gas listed do not include the

type of gas available, check with the local gas supplier.

Propane gas conversion:

Conversion must be done by a qualied service technician.

No attempt shall be made to convert the appliance from the gas

specied on the model/serial rating plate for use with a different

gas without consulting the serving gas supplier. See “Gas

Conversions” section.

Gas Supply Line

■ Provide a gas supply line of 3/4" (1.9 cm) rigid pipe to the

range location. A smaller size pipe on longer runs may

result in insufcient gas supply. With propane gas, piping or

tubing size can be 1/2" (1.3 cm) minimum. Usually, propane

gas suppliers determine the size and materials used in the

system.

NOTE: Pipe-joint compounds that resist the action of

propane gas must be used. Do not use TEFLON®† tape.

†®TEFLON is a registered trademark of Chemours.

6

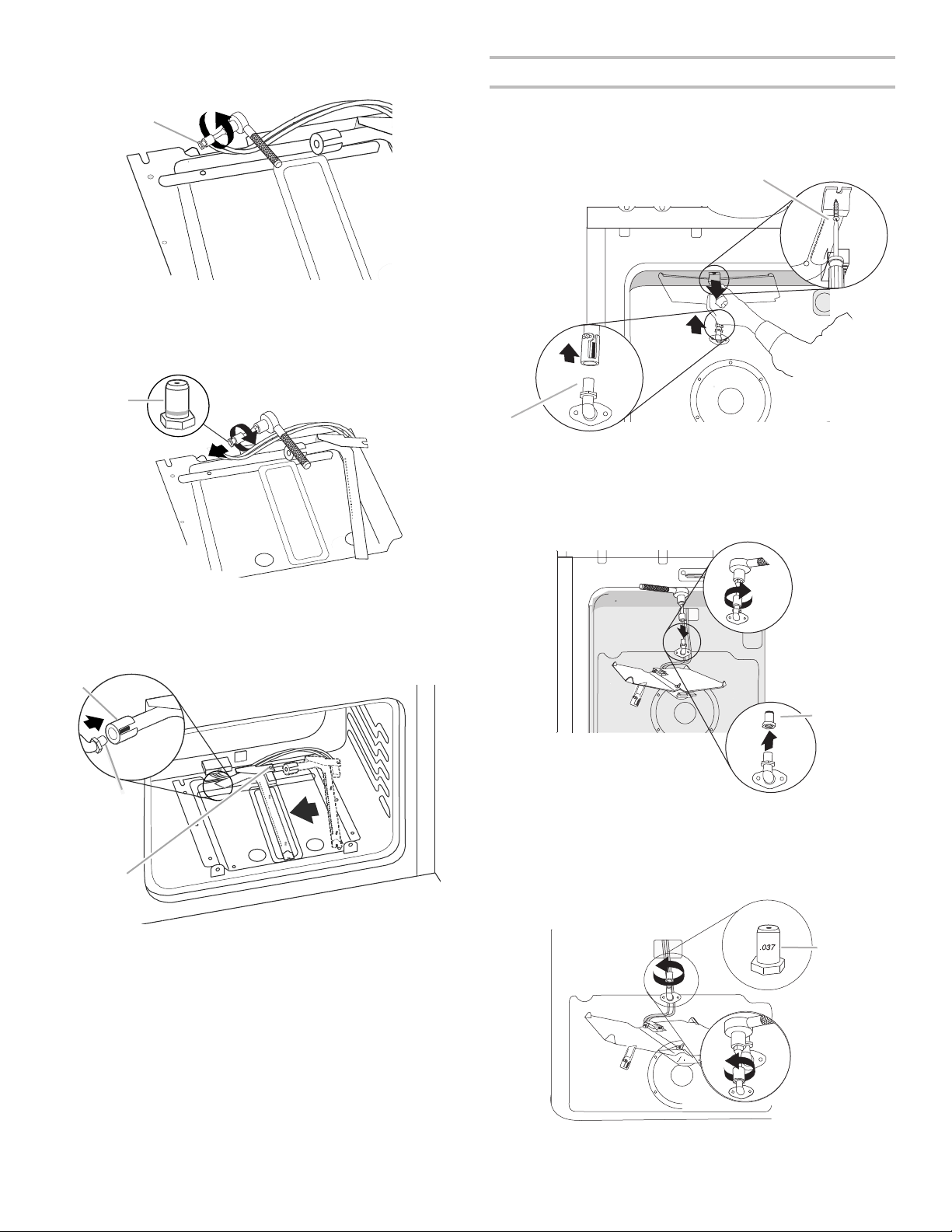

Flexible metal appliance connector:

A

C

■ If local codes permit, a new CSA design-certied,

4 to 5 ft (122 to 152.4 cm) long, 1/2" (1.3 cm) or

3/4" (1.9 cm) I.D., exible metal appliance connector may

be used for connecting range to the gas supply line.

■ A 1/2" (1.3 cm) male pipe thread is needed for

connection to the female pipe threads of the inlet to the

appliance pressure regulator.

■ Do not kink or damage the exible metal tubing when

moving the range.

■ Must include a shutoff valve:

Install a manual gas line shut-off valve in an easily accessible

location. Do not block access to shut-off valve. The valve is

for turning on or shutting off gas to the range.

B

A. Gas supply line

B. Shutoff valve “open” position

C. To range

Gas Pressure Regulator

The gas pressure regulator supplied with this range must be

used. The inlet pressure to the regulator should be as follows for

proper operation:

Natural gas:

Minimum pressure: 5" (12.7 cm) WCP

Maximum pressure: 14" (35.6 cm) WCP

Propane gas:

Minimum pressure: 11" (27.9 cm) WCP

Maximum pressure: 14" (35.6 cm) WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

Burner Input Requirements

Input ratings shown on the model/serial rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced at

a rate of 4% for each 1,000 ft (304.8 m) above sea level (not

applicable for Canada).

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least

1" (2.5 cm) water column pressure above the manifold pressure

shown on the model/serial rating plate.

Line pressure testing above 1/2 psi (3.5 kPa) gauge [14" (35.6

cm) WCP]

The range and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2 psi (3.5 kPa).

Line pressure testing at 1/2 psi (3.5 kPa) gauge [14" (35.6

cm) WCP] or lower

The range must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal

to or less than 1/2 psi (3.5 kPa).

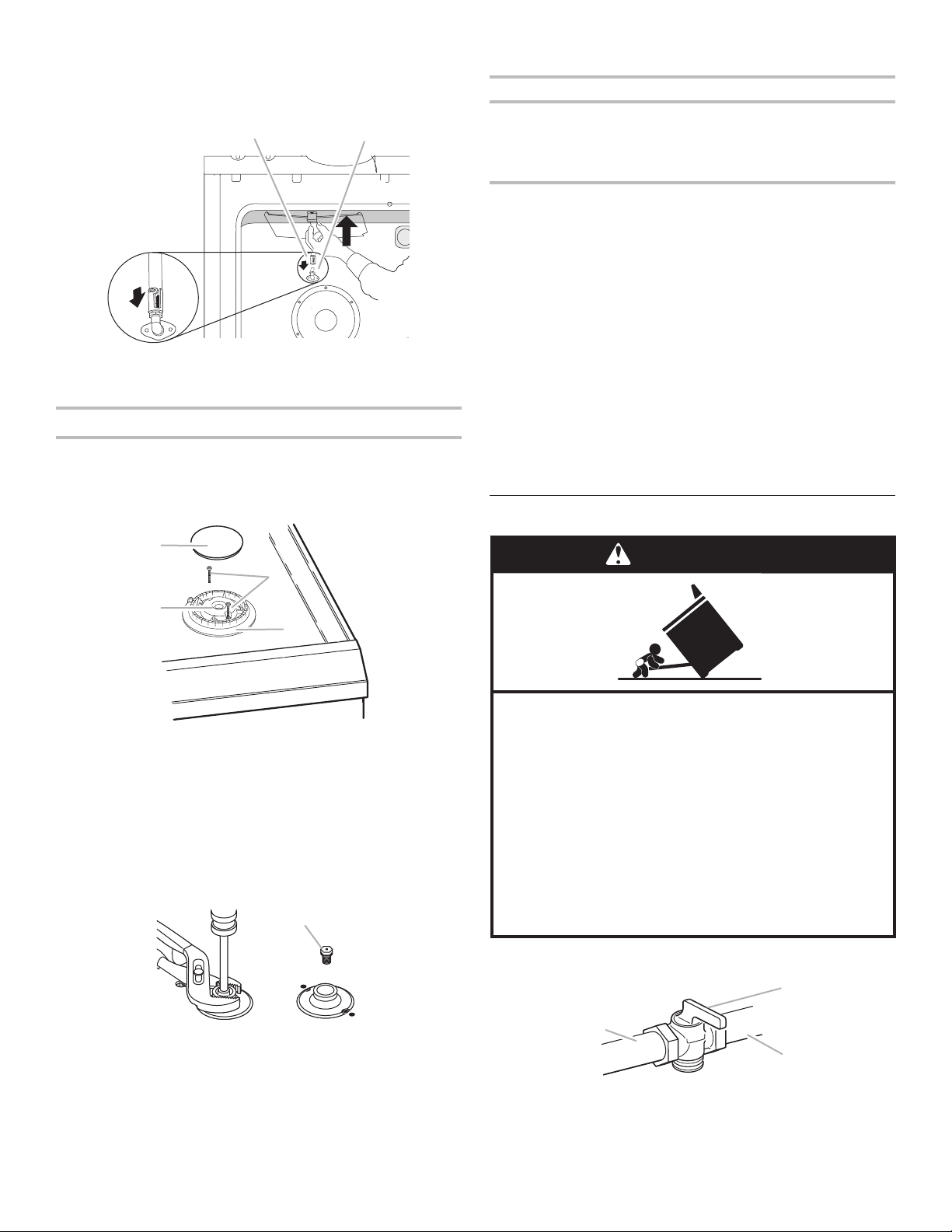

INSTALLATION INSTRUCTIONS

Unpack Range

1. If range height adjustment is necessary, use a wrench or

WARNING

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

1. Remove shipping materials, tape and lm from the range.

Keep cardboard bottom under range.

2. Remove oven racks and parts package from inside oven.

3. To place range on its back, take 4 cardboard corners from

the carton. Stack one cardboard corner on top of another.

Repeat with the other 2 corners. Place them lengthwise on

the oor behind the range to support the range when it is laid

on its back.

4. Using 2 or more people, rmly grasp the range and gently lay

it on its back on the cardboard corners.

5. Pull cardboard bottom rmly to remove.

6. Use an adjustable wrench to loosen the leveling legs.

7. Place cardboard or hardboard in front of range. Using 2

or more people, stand range back up onto cardboard or

hardboard.

pliers to loosen the 4 leveling legs.

This may be done with the range on its back or with the

range supported on 2 legs after the range has been placed

back to a standing position.

NOTE: To place range back up into a standing position, put

a sheet of cardboard or hardboard in front of range. Using 2

or more people, stand range back up onto the cardboard or

hardboard.

2. Adjust the leveling legs to the correct height. Leveling legs

can be loosened to add up to a maximum of 1" (2.5 cm). A

minimum of 3/16" (5.0 mm) is needed to engage the anti-tip

bracket.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, then tilt forward to

adjust the rear legs.

3. When the range is at the correct height, check that there is

adequate clearance under the range for the anti-tip bracket.

Before sliding range into its nal location, check that the

anti-tip bracket will slide under the range and onto the rear

leveling leg prior to anti-tip bracket installation.

Adjust Leveling Legs

7

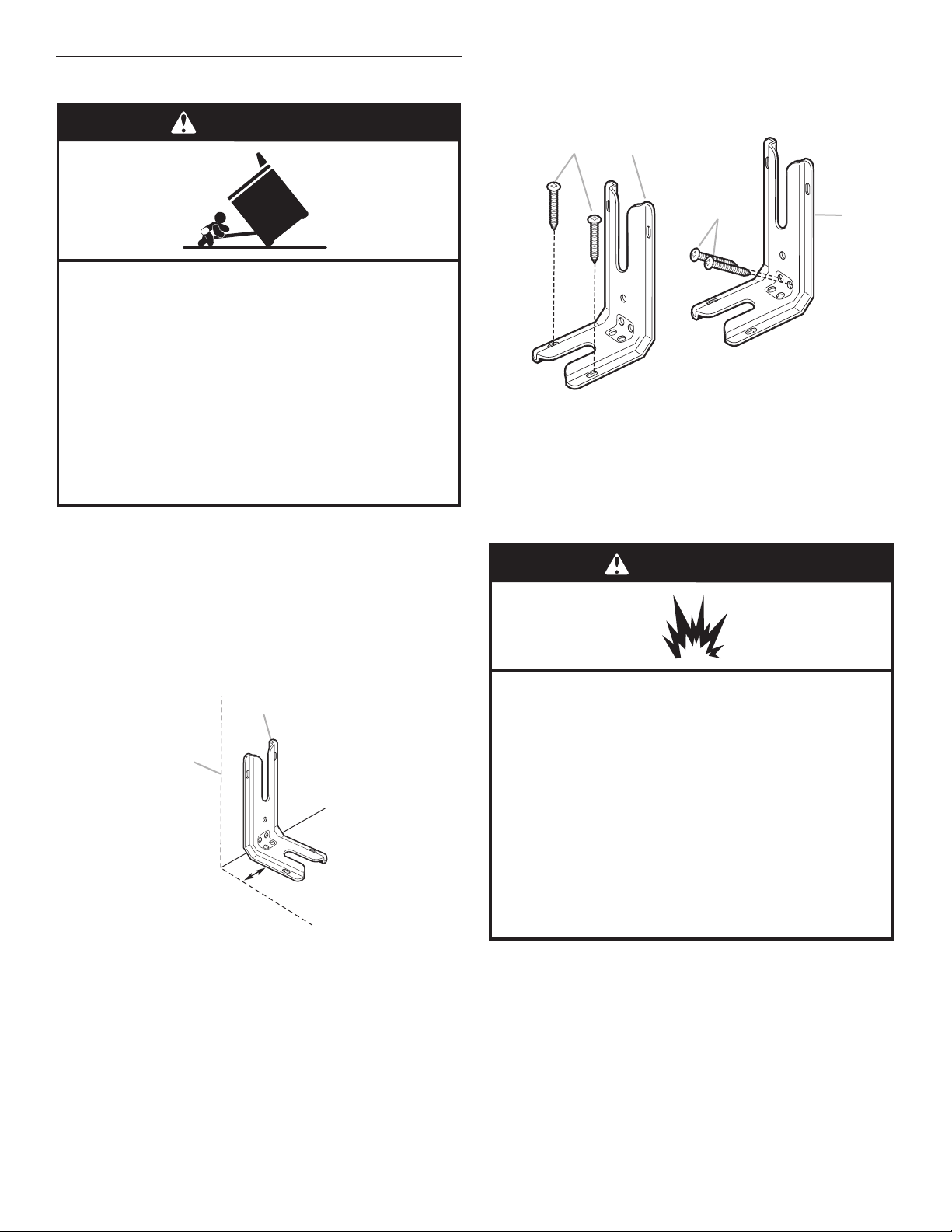

Install Anti-Tip Bracket

B

4. Drill two 1/8" (3.0 mm) holes that correspond to the bracket

holes of the determined mounting method. See the following

illustrations.

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Remove the anti-tip bracket that is taped inside the upper

oven with the package containing literature.

2. Determine which mounting method to use: oor or wall.

If you have a stone or masonry oor, you can use the wall

mounting method.

3. Determine and mark edge of range in the cutout space. The

mounting bracket can be installed on either the left side or

right side of the cutout. Position mounting bracket in cutout

so that right (or left) edge of the bracket is 15/16" (2.4 cm)

from the marked edge of the range, as shown.

A

B

C

A. Anti-tip bracket

B. Mark edge of range.

C. 15⁄16" (2.4 cm)

Floor Mounting Wall Mounting

A

A. #12 x 1

B. Anti-tip bracket

5. Using a Phillips screwdriver, mount anti-tip bracket to the

wall or oor with the two #12 x 15⁄8" screws provided.

⁵⁄₈

" screws

B

A

A. #12 x 1

B. Anti-tip bracket

⁵⁄₈

" screws

Make Gas Connection

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Typical flexible connection

1. Apply pipe-joint compound made for use with propane gas

to the smaller thread ends of the exible connector adapters

(see B and G in the following illustration).

2. Attach one adapter to the gas pressure regulator and the

other adapter to the gas shutoff valve. Tighten both

adapters, being certain not to move or turn the gas pressure

regulator.

8

3. Use a 15/16" (23.8 mm) combination wrench and an

A

adjustable wrench to attach the exible connector to the

adapters. Check that connector is not kinked.

IMPORTANT: All connections must be wrench-tightened. Do

not make connections to the gas pressure regulator too tight.

Making the connections too tight may crack the regulator

and cause a gas leak. Do not allow the regulator to turn

when tightening the ttings.

B

C

H

G

F

D

E

4. Use a flat blade screwdriver (or other tool that fits your metal

clamp) to tighten the metal clamp and fix the hose on the

gas connection.

5. Attach a metal clamp to the other edge of the hose and

connect this edge to the pressure regulator of your gas

cylinder. Tighten the metal clamp with the flat blade

screwdriver (or other tool that fits your metal clamp).

A. Gas pressure regulator

B. Use pipe-joint compound.

C. Adapter (must have 1/2"

(12.7 mm) male pipe thread)

D. Flexible connector

E. Manual gas shutoff valve

F. 1/2" or 3/4" (12.7 mm or 19.0

mm) gas pipe

G. Use pipe-joint compound.

H. Adapter

Plastic Hose Installation

IMPORTANT: If you are using a plastic hose, make sure it can

withstand temperatures above 120°C (248°F) and is approved

by local regulations. The hose must be resistant to abrasion and

chemicals. Check the hose expiration date before installation,

it must be replaced before it. The hose must not stay in contact

with the back part of the product and must not be exposed to

sunlight. The maximum length of the hose is 1.25 m (4.1 ft).

1. Apply pipe-joint compound made for use with propane

gas to the plastic hose adapter following its manufacturer

instructions.

2. Attach the adapter on the pressure regulator, tightening it

and being certain not to move or turn the gas pressure

regulator.

A

B

6. Make sure the gas valve is closed before connecting it to the

gas cylinder.

7. Make sure the hose is not folded or too close to heating

sources. Test all connections by brushing on an approved

noncorrosive leak-detection solution. Bubbles will show a

leak. Correct any leak found.

A. Pressure Regulator

B. Plastic hose adapter

3. Attach a metal clamp to one of the plastic hose edges and

attach this edge to the plastic hose adapter that is just

installed.

9

Complete connection

1. Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A

B

A. Closed valve

B. Open valve

2. Test all connections by brushing on an approved

noncorrosive leak-detection solution. If bubbles appear, a

leak is indicated. Correct any leak found.

3. Remove cooktop burner caps and grates from parts

package. Align recess in burner caps with pins in burner

base. Burner caps should be level when properly positioned.

If burner caps are not properly positioned, surface burners

will not light. Place burner grates over burners and caps.

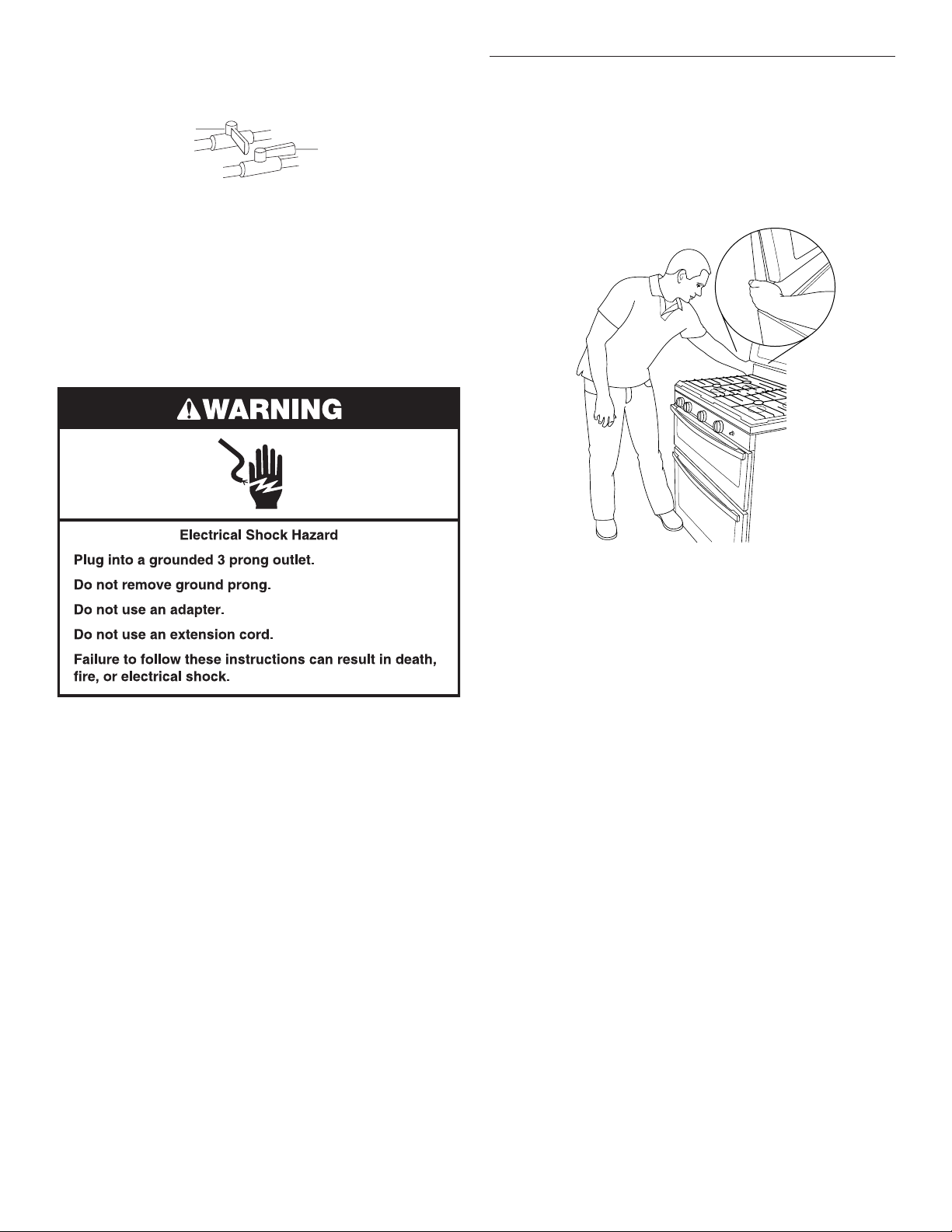

Verify Anti-Tip Bracket Is Installed and

Engaged

1. Place the outside of your foot against the bottom front of the

oven door to keep the unit from moving, and grasp the lower

right or left side of the control panel as shown.

NOTE: If your countertop is mounted with a backsplash, it

may be necessary to grasp the range higher than is shown in

the illustration.

4. Plug into a grounded 3 prong outlet.

2. Slowly attempt to tilt the range forward.

If you encounter immediate resistance, the range foot is

engaged in the anti-tip bracket.

3. If the rear of the range lifts more than 1/2" (1.3 cm) off the

oor without resistance, stop tilting the range and lower it

gently back to the oor. The range foot is not engaged in the

anti-tip bracket.

IMPORTANT: If there is a snapping or popping sound when

lifting the range, the range may not be fully engaged in the

bracket. Check to see if there are obstructions keeping the range

from sliding to the wall or keeping the range foot from sliding

into the bracket. Verify that the bracket is held securely in place

by the mounting screws.

4. Slide the range forward, and verify that the anti-tip bracket is

securely attached to the oor or wall.

5. Slide range back so the rear range foot is inserted into the

slot of the anti-tip bracket.

IMPORTANT: If the back of the range is more than 2" (5.1 cm)

from the mounting wall, the rear range foot may not engage

the bracket. Slide the range forward and determine if there

is an obstruction between the range and the mounting wall.

Changes to the gas supply must be performed by a qualied

service technician. If you need assistance or service, refer to

the “Assistance or Service” section of the Use and Care Guide,

or the cover or “Warranty” section of the User Instructions, for

contact information.

6. Repeat steps 1 and 2 to ensure that the range foot is

engaged in the anti-tip bracket.

If the rear of the range lifts more than 1/2" (1.3 cm) off the

oor without resistance, the anti-tip bracket may not be

installed correctly. Do not operate the range without antitip bracket installed and engaged. Please reference the

“Assistance or Service” section of the Use and Care Guide,

or the cover or “Warranty” section of the User Instructions,

to contact service.

10

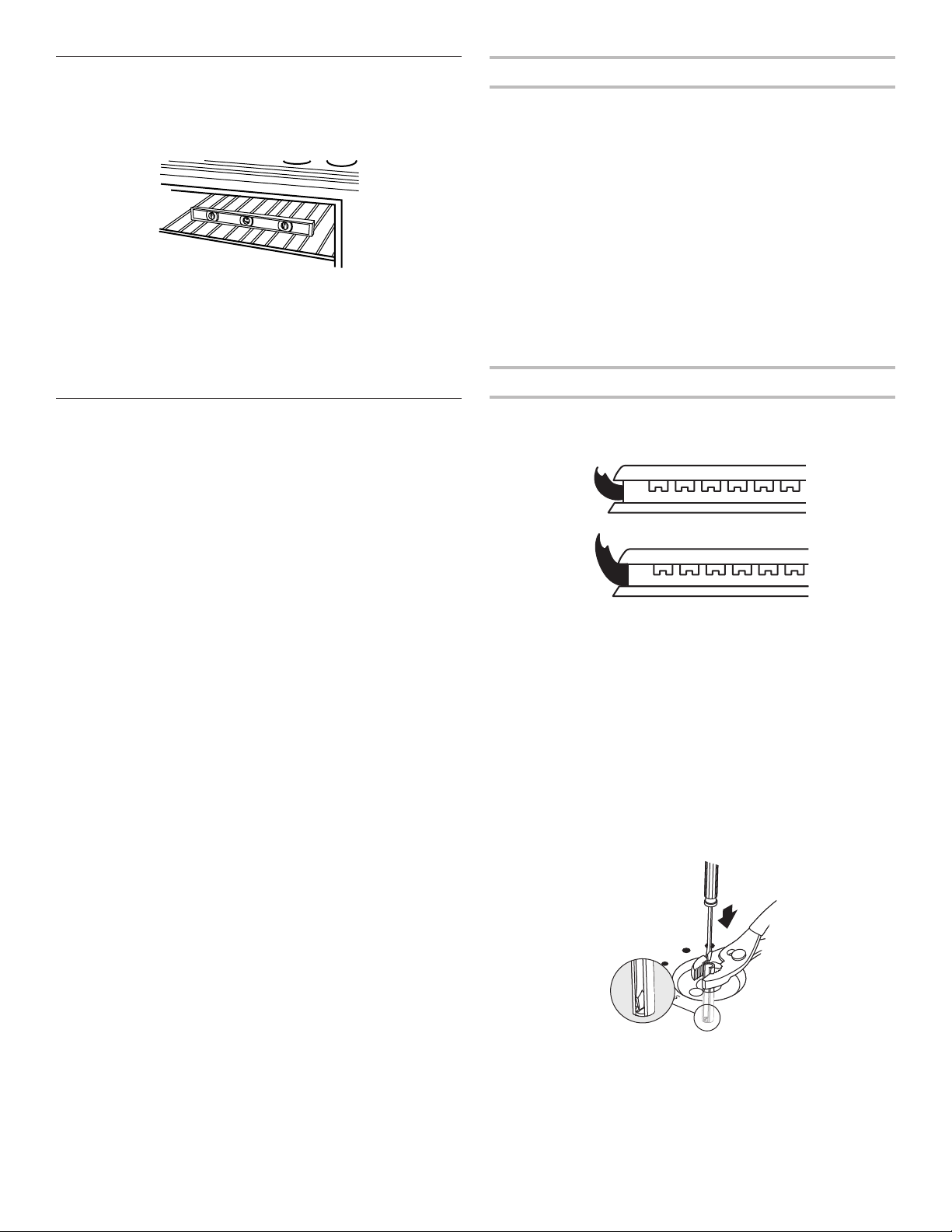

Level Range

1. Place rack in oven.

2. Place level on rack and check levelness of range, rst side to

side; then front to back.

3. If range is not level, pull range forward until rear leveling leg

is removed from the anti-tip bracket.

4. Use wrench to adjust leveling legs up or down until range is

level. Push range back into position.

5. Check that rear leveling leg is engaged in anti-tip bracket.

NOTE: Range must be level for satisfactory baking performance.

Check Operation of Cooktop Burners

Standard Surface Burners

Push in and turn each control knob to the “IGNITE” position.

The ame should light within 4 seconds. The rst time a burner

is lit, it may take longer than 4 seconds to light because of air in

the gas line.

If burners do not light properly:

■ Turn cooktop control knob to the “OFF” position.

■ Check that the range is plugged in and the circuit breaker

has not tripped or the household fuse has not blown.

■ Check that the gas shutoff valve is set to the “open” position.

■ Check that burner caps are properly positioned on burner

bases.

Repeat start-up. If a burner does not light at this point, turn the

control knobs to “OFF” and contact your dealer or authorized

service company for assistance.

Adjust Flame Height

Electronic Ignition System

Initial lighting and gas flame adjustments

Cooktop and oven burners use pilotless igniters in place of

standing pilots. When the cooktop control knob is turned to the

“IGNITE” position, the system creates a spark to light the burner.

This sparking continues, as long as the control knob is turned to

“IGNITE.”

When the oven control is turned to the desired setting, a glow

bar igniter heats and ignites the gas.

Adjust the height of top burner ames. The cooktop “Low”

burner ame should be a steady blue ame approximately

1/4" (0.64 cm) high.

A

B

A. Low flame

B. High flame

To adjust standard burners:

The ame can be adjusted using the adjustment screw in the

center of the valve stem. The valve stem is located directly

underneath the control knob.

If the “Low” flame needs to be adjusted:

1. Light 1 burner and turn to lowest setting.

2. Remove the control knob.

Hold the knob stem in the low position using a pair of pliers.

Use a 1/8" (3.0 mm) at-blade screwdriver to turn the screw

located in the center of the control knob stem until the ame

is the proper size.

3. Replace the control knob.

4. Test the ame by turning the control from “LOW” to “HIGH,”

checking the ame at each setting.

5. Repeat steps 1 - 4 for each burner.

11

Check Operation of Both Oven Bake Burners

1. Press BAKE for the desired oven.

“BAKE” scrolls down in the upper text display area or

scrolls up in the lower text display area, depending on oven

selection, and 350°F is displayed. After 3 seconds “Set

temp” scrolls in the selected oven text display area, followed

by “Push START.”

2. Press START for the desired oven. “Baking” scrolls in the

selected oven text display area. Then, after 3 seconds,

“Preheating” scrolls in the display.

The igniter used to light the bake burner will glow. Once

the igniter is hot, the oven bake burner should light. Under

certain conditions, it may take up to 60 seconds for it to

light.

If burners do not light properly:

■ Press CANCEL for the desired oven to turn off the oven

■ Check that the range is plugged in and circuit breaker has

not tripped or the household fuse has not blown.

■ Check that the gas shutoff valve is set to the “open” position.

Repeat start-up. If burner does not light, press CANCEL for the

desired oven to turn off the oven and contact your dealer or

authorized service company for assistance.

Check Operation of Oven Broil Burner

1. Press BROIL for the upper oven. “BROIL” scrolls down in

the upper text display area, and 550°F is displayed. After 3

seconds, “Set temp” scrolls in the upper oven text display

area, followed by “Push START.”

2. Press START for the upper oven. “Broiling” scrolls in the

upper oven text display area and remains there until the set

temperature is reached.

The igniter used to light the broil burner will glow. Once the

igniter is hot, the oven burner should light. Under certain

conditions, it may take up to 60 seconds for it to light.

If burners do not light properly:

■ Press CANCEL for the upper oven to turn off the oven.

■ Check that the range is plugged in and circuit breaker has

not tripped or the household fuse has not blown.

■ Check that the gas shutoff valve is set to the “open” position.

Repeat start-up. If burner does not light, press CANCEL for

the upper oven to turn off the oven and contact your dealer or

authorized service company for assistance.

Complete Installation

1. Check that all parts are now installed. If there is an extra

part, go back through the steps to see which step was

skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Check that the range is level. See the “Level Range” section.

5. Use a mild solution of liquid household cleaner and warm

water to remove waxy residue caused by shipping material.

Dry thoroughly with a soft cloth. For more information, see

the “Range Care” section of the Use and Care Guide or User

Instructions.

6. Read the Use and Care Guide or User Instructions.

7. Turn on surface burners and oven. See the Use and Care

Guide or User Instructions for specic instruction on range

operation.

If range does not operate, check the following:

■ Household fuse is intact and tight, or circuit breaker has not

tripped.

■ Range is plugged into a grounded 3 prong outlet.

■ Gas pressure regulator shutoff valve is in the “on” position.

■ Electrical supply is connected.

■ See “Troubleshooting” in the Use and Care Guide or User

Instructions.

8. When the range has been on for 5 minutes, check for heat.

If the range is cold, turn off the range and check that the gas

supply line shutoff valve is open.

■ If the gas supply line shutoff valve is closed, open it, then

repeat the 5-minute test as outlined above.

■ If the gas supply line shutoff valve is open, press the

CANCEL button on the oven control panel and contact a

qualied technician.

If you need Assistance or Service:

Please reference the “Assistance or Service” section of the Use

and Care Guide or the cover of the User Instructions, or contact

the dealer from whom you purchased your range.

12

A

GAS CONVERSIONS

Gas conversions from Natural gas to Propane gas or from

Propane gas to Natural gas must be done by a qualied installer.

Propane Gas Conversion

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to propane, have a qualified person make

sure gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn manual shutoff valve to the closed position.

B

A

C

A. To range

B. Shutoff valve (closed position)

C.Gas supply line

2. Unplug range or disconnect power.

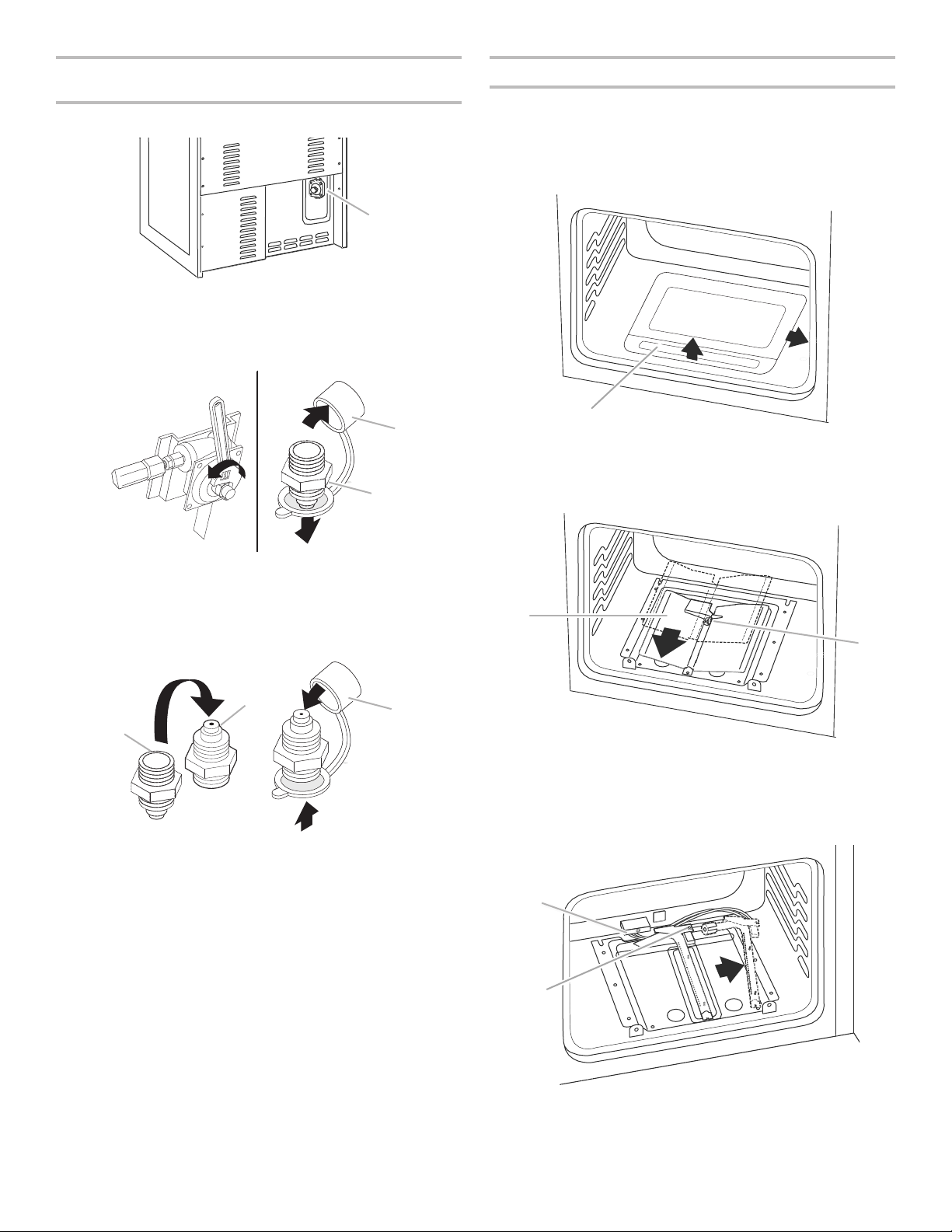

To Convert Gas Pressure Regulator (Nat. gas to

Propane)

1. Locate gas pressure regulator at the rear of the range.

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

13

2. Unscrew the regulator cap and remove the plastic cover.

A

A

B

A. Plastic cover

B. Regulator cap

5. Unscrew wing nut and remove oven bafe.

A

B

3. Flip the regulator cap over and replace the plastic cover.

B

A

A. Natural gas position

B. Propane gas position

C. Plastic cover

C

4. Screw the regulator cap securely back into place. Do not

overtighten.

To Convert Oven Bake Burners (Nat. gas to Propane)

To Convert Lower Oven Bake Burner:

1. Remove oven racks from inside the oven cavity.

2. Remove oven door. See “Oven Door” section in the Use and

Care Guide for oven door removal instructions.

3. Push the bake burner cover to the right.

A.Oven baffle

B. Wing nut

6. Remove the oven bake burner screw and set aside.

7. Gently set the bake burner to the side.

B

A. Igniter and wires

B. Bake burner screw

8. Unscrew and remove the cover over the orice.

A

A

A. Bake burner cover

4. Lift up and remove oven bake burner cover.

A. Orifice cover

14

9. Turn the Number 0.070 Natural gas orice hood

A

A

A

counterclockwise to remove.

A

A. Number 0.070 Natural gas orifice hood

10. Install the Number 0.044 Propane gas orice hood, turning it

clockwise 4 or 5 turns. Do not overtighten.

.044

To Convert Oven Broil Burner (Nat. gas to Propane)

1. Remove broil burner screw and set aside.

2. Remove the broil burner from the broil burner orice hood.

The broil burner will hang in the back of the oven while

changing the orice hood.

B

A. Broil burner screw

B. Broil burner orifice hood

3. Turn the Number 0.054 Natural gas broil burner orice hood

counterclockwise to remove.

A. Number 0.044 Propane gas orifice hood

11. Position the oven bake burner over the orice hood and

reinstall using screw.

B

A

A

A. Number 0.054 Natural gas broil burner orifice hood

4. Install the green Number 0.037 Propane gas broil burner

C

A. Bake burner orifice hood

B. Oven bake burner

C. Oven bake burner screw

orice hood, turning it clockwise 4 or 5 turns. Do not

overtighten.

To Convert Upper Oven Bake Burner

12. Repeat previous steps 1 through 8 for conversion of the

upper oven bake burner.

13. Remove the Number 0.055 Natural gas orice spud in the

upper oven and replace with a Number 0.037 propane gas

orice spud.

14. Reverse steps to reinstall the orice covers, oven bake

burners, oven bafes and oven bake covers in both ovens.

A. Number 0.037 Propane gas broil burner orifice hood

15

5. Place the broil burner on the broil burner orice hood. Insert

the broil burner locater pin in the hole in the oven back.

6. Position the broil burner against the roof of the oven cavity

and attach with screw.

A

A. Broil burner orifice hood

B. Broil burner

B

To Convert Surface Burners (Nat. gas to Propane)

1. If the burner grates are installed, remove them.

2. Remove the burner caps.

3. Using a Phillips or Torx® screwdriver, remove the burner

base.

A

C

Propane Gas Orifice Spud Chart

Burner Rating Color Number

4,000 BTU Blue 64L

7,000 BTU Black 81L

9,100 BTU Green 97L

14,000 BTU Red 114L

5. Replace the Natural gas orice spud with the correct Propane

gas orice spud. See the “Propane Gas Orice Spud Chart.”

6. Replace burner base and hand tighten the screws.

7. Replace burner cap.

8. Repeat steps 1 through 7 for the remaining burners.

9. Place Natural gas orice spuds in plastic parts bag for future

use and keep with package containing literature.

10. Replace burner grates.

11. Complete installation. See “Make Gas Connection” and

“Electronic Ignition System” sections.

Checking for proper cooktop burner ame is very important.

The small inner cone should have a very distinct blue ame

1/4" to 1/2" (6.3 mm to 12.7 mm) long. The outer cone is

not as distinct as the inner cone. Propane gas ames have a

slightly yellow tip.

IMPORTANT: You may have to adjust the “Low” setting

for each cooktop burner. See “Adjust Flame Height” in the

“Electronic Ignition System” section.

Natural Gas Conversion

WARNING

B

D

A. Burner cap

B.Gas tube opening

C. Burner base screws

D. Burner base

4. Apply masking tape to the end of a 9/32" (7.0 mm) nut driver

to help hold the Natural gas orice spud in the nut driver

while changing it. Press nut driver down onto the Natural gas

orice spud and remove by turning it counterclockwise and

lifting out. Set the Natural gas orice spud aside.

A

A. Natural gas orifice spud

Use the following chart for correct Propane gas orice spud for

each burner. Refer to the model/serial rating plate behind the

control panel for proper sizing of propane gas orice spuds for

each burner location.

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

1. Turn manual shutoff valve to the closed position.

B

A

C

A. To range

B. Shutoff valve (closed position)

C.Gas supply line

16

2. Unplug range or disconnect power.

To Convert Gas Pressure Regulator (Propane to

A

A

Nat. gas)

1. Locate gas pressure regulator at the rear of the range.

A. Gas pressure regulator

IMPORTANT: Do not remove the gas pressure regulator.

2. Unscrew the regulator cap and remove the plastic cover.

A

B

To Convert Oven Bake Burners (Propane to Nat. gas)

To Convert Lower Oven Bake Burner:

1. Remove oven racks from inside the oven cavity.

2. Remove oven door. See “Oven Door” section in the Use and

Care Guide for oven door removal instructions.

3. Push the bake burner cover to the right.

A

A. Bake burner cover

4. Lift up and remove oven bake burner cover.

5. Unscrew wing nut and remove oven bafe.

A. Plastic cover

B. Regulator cap

3. Flip the regulator cap over and replace the plastic cover.

B

C

A

A. Propane gas position

B. Natural gas position

C. Plastic cover

4. Screw the regulator cap securely back into place. Do not

overtighten.

A

B

A. Oven baffle

B.Wing nut

6. Remove the oven bake burner screw and set aside.

7. Gently set the bake burner to the side.

B

A. Igniter and wires

B. Bake burner screw

17

Loading...

Loading...