Whirlpool WGFBT, WGFBLT, WGFAT, WGFAR Installation Instructions

80% 2-STAGE VARIABLE SPEED GAS FURNACE

INSTALLATION INSTRUCTIONS

Table of Contents

GAS FURNACE SAFETY................................................................1

INSTALLATION REQUIREMENTS................................................3

Tools and Parts ............................................................................3

Location Requirements................................................................4

Installation Configurations ...........................................................5

Ductwork Requirements ..............................................................6

Electrical Requirements ...............................................................6

Gas Supply Requirements...........................................................6

Venting Requirements..................................................................6

INSTALLATION INSTRUCTIONS..................................................8

Inspect Shipment.........................................................................8

Plan Vent System.........................................................................8

Determine Vent Pipe Direction...................................................12

Connect Venting.........................................................................14

Install Ductwork..........................................................................15

Filter Specifications....................................................................15

Make Electrical Connections .....................................................16

GAS FURNACE SAFETY

Make Gas Connections..............................................................16

Check the Furnace Input Rate ...................................................17

Adjust the Furnace Input Rate ...................................................17

Complete Installation..................................................................18

Shut Down..................................................................................22

SEQUENCE OF OPERATION (VARIABLE SPEED MODELS)...23

Heating .......................................................................................23

Fan On........................................................................................23

Cooling .......................................................................................23

SEQUENCE OF OPERATION (MULTI-SPEED MODELS).........24

Heating .......................................................................................24

Fan On........................................................................................24

Cooling .......................................................................................24

CONTROLS ...................................................................................25

TROUBLESHOOTING ..................................................................26

ASSISTANCE OR SERVICE.........................................................31

Accessories ................................................................................31

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Whirlpool Gold® Models

WGFBT, WGFBLT, WGFAT, WGFAR

47724B008

Whirlpool® Home Cooling and Heating

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

14610 Breakers Drive

Jacksonville, FL 32258

follow

IMPORTANT SAFETY INSTRUCTIONS

Use only with type of gas approved for this furnace.

■

Refer to the furnace rating plate.

Install this furnace only in a location and position

■

as specified in the “Location Requirements” section

of these instructions.

Provide adequate combustion and ventilation air to

■

the furnace space as specified in the “Venting

Requirements” section of these instructions.

■

Combustion products must be discharged outdoors.

Connect this furnace to an approved vent system

only, as specified in the “Venting Requirements”

section of these instructions.

Never test for gas leaks with an open flame. Use a

■

commercially available soap solution made

specifically for the detection of leaks to check all

connections, as specified in the “Make Gas

Connections” section of these instructions.

Adequate clearance must be provided around the

■

vent-air intake terminals.

Always install furnace to operate within the furnace’s

■

intended temperature-rise range with a duct system

which has an external static pressure within the

allowable range, as specified in the “Complete

Installation” section of these instructions. See

furnace rating plate.

■

When a furnace is installed so that supply ducts

carry air circulated by the furnace to areas outside

the space containing the furnace, the return air

shall also be handled by duct(s) sealed to the

furnace casing and terminating outside the space

containing the furnace.

A gas-fired furnace for installation in a residential

■

garage must be installed as specified in the

“Location Requirements” section of these

instructions.

■

The furnace is not to be used for temporary heating

of buildings or structures under construction.

The furnace shall be installed so the electrical

■

components are protected from water.

■ Furnaces for indoor installation on combustible

flooring shall not be installed directly on carpeting,

tile or other combustible material other than wood

flooring.

SAVE THESE INSTRUCTIONS

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death or property

damage.

— Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the fire department.

— Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

2

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the “What to do if you smell gas” instructions.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of substances

known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires businesses to warn of

potential exposure to such substances.

WARNING: This product contains a chemical known to the State of California to cause cancer, birth defects, or other

reproductive harm.

This appliance can cause low-level exposure to some of the substances listed, including benzene, formaldehyde, carbon

monoxide, toluene, and soot.

ADDITIONAL SAFETY INFORMATION

In the State of Massachusetts, the following installation instructions apply:

■ Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

■ If using a ball valve, it shall be a T-handle type.

■ A flexible gas connector, when used, must not exceed 3 feet.

INSTALLATION REQUIREMENTS

These instructions are intended as a general guide only for use by

qualified persons and do not supersede any national or local

codes in any way. Compliance with all local, state, or national

codes pertaining to this type of equipment should be determined

prior to installation.

Read this entire instruction manual, as well as the instructions

supplied in separate equipment, before starting the installation.

The installation of the furnace, wiring, warm air ducts, venting,

etc. must conform to the requirements of the National Fire

Protection Association; the National Fuel Gas Code, ANSI

Z223.1/NFPA No. 54 (latest edition) and the National Electrical

Code, ANSI/NFPA No. 70 (latest edition) in the United States, and

any state laws, local ordinances (including plumbing or

wastewater codes), or local gas utility requirements.

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed

■ Pipe wrench

■ Screwdriver

■ Tape m eas u re

■ Thread sealant

■ Level

■ Noncorrosive leak check

solution

■ Tes t ga ug e wi th ¹⁄₈" (3.2 mm)

NPT connection (for measuring

gas supply pressure)

■ Allen wrench

Local authorities having jurisdiction should be consulted before

installation is made. Such applicable regulations or requirements

take precedence over the general instructions in this manual.

This furnace design is certified by CSA International as a

Category I furnace in compliance with the latest edition of

American National Standard Z21.47/CSA Standard 2.3 for GasFired Central Furnaces, for operation with Natural gas or

propane. Consult the rating plate on the furnace for gas type

before installing.

Parts needed

Check local codes and with gas supplier. Check existing gas

supply, electrical supply, and venting, and read “Ductwork

Requirements,” “Electrical Requirements,” “Gas Supply

Requirements” and “Venting Requirements” before purchasing

parts.

Parts Supplied

■ Inlet air restrictor plate

3

Location Requirements

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from furnace.

Place furnace so that burners are at least 18 inches

(46 cm) above the floor for a garage installation.

Failure to follow these instructions can result in death,

explosion, or fire.

WARNING

■ Furnaces may be installed as suspended units in the

horizontal position. These furnaces are not designed for

direct attachment of suspension rods to the furnace casing.

See “Installation Configurations.”

■ If the furnace is to be installed in an attic or other insulated

space, it must be kept free and clear of insulating materials.

■ WGFAT models may be installed as upflow or horizontal

furnaces. WGFAR models may be installed as counterflow

(downflow) or horizontal furnaces. When the furnace is

installed horizontally, secure the furnace door by installing a

sheet metal screw through the side and door on the upper

left-hand side of the furnace.

Installation Clearances

■ A 2" (5.1 cm) minimum clearance is required in front for air

openings into the combustion chamber.

■ All servicing and cleaning of the furnace can be performed

from the front. If the furnace is installed in a closet or utility

room, provide 24" (61 cm) clearance in front for service if the

door to the room is not in line with the front of the furnace.

Where servicing clearances are greater than clearances to

combustibles, servicing clearances take precedence.

Minimum Clearance to Combustibles Chart

All measurements in inches (centimeters)

Explosion Hazard

Do not install this furnace in a mobile home.

Doing so can result in death, explosion, fire, or

carbon monoxide poisoning.

IMPORTANT: Do not use the furnace as a heater in a building

under construction. The furnace can be severely damaged due to

the abnormal environment caused by construction. Chlorides

from sources such as paint, stain, or varnish; tile and counter

cements; adhesives; and foam insulation are abundant in a

structure under construction and can be highly corrosive. Low

return air temperature can cause condensation in the furnace and

other damage that can shorten the life of the furnace.

■ The furnace is suitable for installation in buildings

constructed on site. The furnace should be centralized in

respect to the heat distribution system as much as

practicable.

■ All models are suitable for closet or utility room installation.

Utility room installation requires:

A door opening large enough for the widest part of the

furnace.

A door opening large enough to remove/replace any other

appliance located in the utility room, such as a water heater.

Any other appliances arranged so that each appliance can be

removed/replaced without disturbing the furnace.

■ In a residential garage, a gas-fired furnace must be installed

so the burner(s) and the ignition source are located not less

than 18" above the floor. The furnace is to be located or

protected to avoid physical damage by vehicles.

Upflow Installations

Sides

Cabinet Width Front Back Top Vent Left Right

17¹⁄₂

(44.4)

21

(53.3)

24¹⁄₂

(62.3)

4

(10.2)

4

(10.2)

4

(10.2)

01

1

1

1

(2.5)6 (15.2)

01

(2.5)6 (15.2)

01

(2.5)6 (15.2)

2

2

(5.1)

00

2

00

2

0

3

Horizontal Installations

Minimum clearances on sides and back are 0".

Airflow

R to L L to R

Cabinet Width Front Vent Top Bottom Top Bottom

17¹⁄₂

(44.4)

21

(53.3)

24¹⁄₂

(62.3)

1

May be 2" (5.1 cm) when Type B-1 vent pipe is used.

2

May be 1" (2.5 cm) when Type B-1 vent pipe is used.

3

Where values greater than 0 are shown, may be 0" when Type

B-1 vent pipe is used.

18 6

18 6

18 6

(15.2)

(15.2)

(15.2)

1

2

(2.5)3 (7.6)

1

2

(2.5)2 (5.1)

1

2

(2.5)

3

(7.6)

2

(5.1)

0

2

0

3

2

3

000

4

High Altitude Installations

B

■ This furnace is approved for operation at altitudes from 0 to

4,500 ft (0 to 1,371.6 m) above sea level without any required

modifications.

■ From 4,500 to 7,500 ft (1,371.6 m to 2,286 m), the gas

manifold pressure needs to be adjusted according to the

information shown in the Manifold Pressure vs. Altitude

Chart.

Installation Configurations

Upflow Installations

Furnaces can be installed with either a side or bottom air return.

For bottom air return the bottom air return knockout plate must

be removed. For furnaces that do not include a side or bottom

return filter rack, kit no. AFILT524-1 (side return) or kit no.

AFILT529-1 (bottom return) can be used.

To provide sufficient filter area for installations requiring more

than 1,600 CFM nominal air delivery, return air will have to be

brought through both sides of the furnace, or through one side

and the bottom.

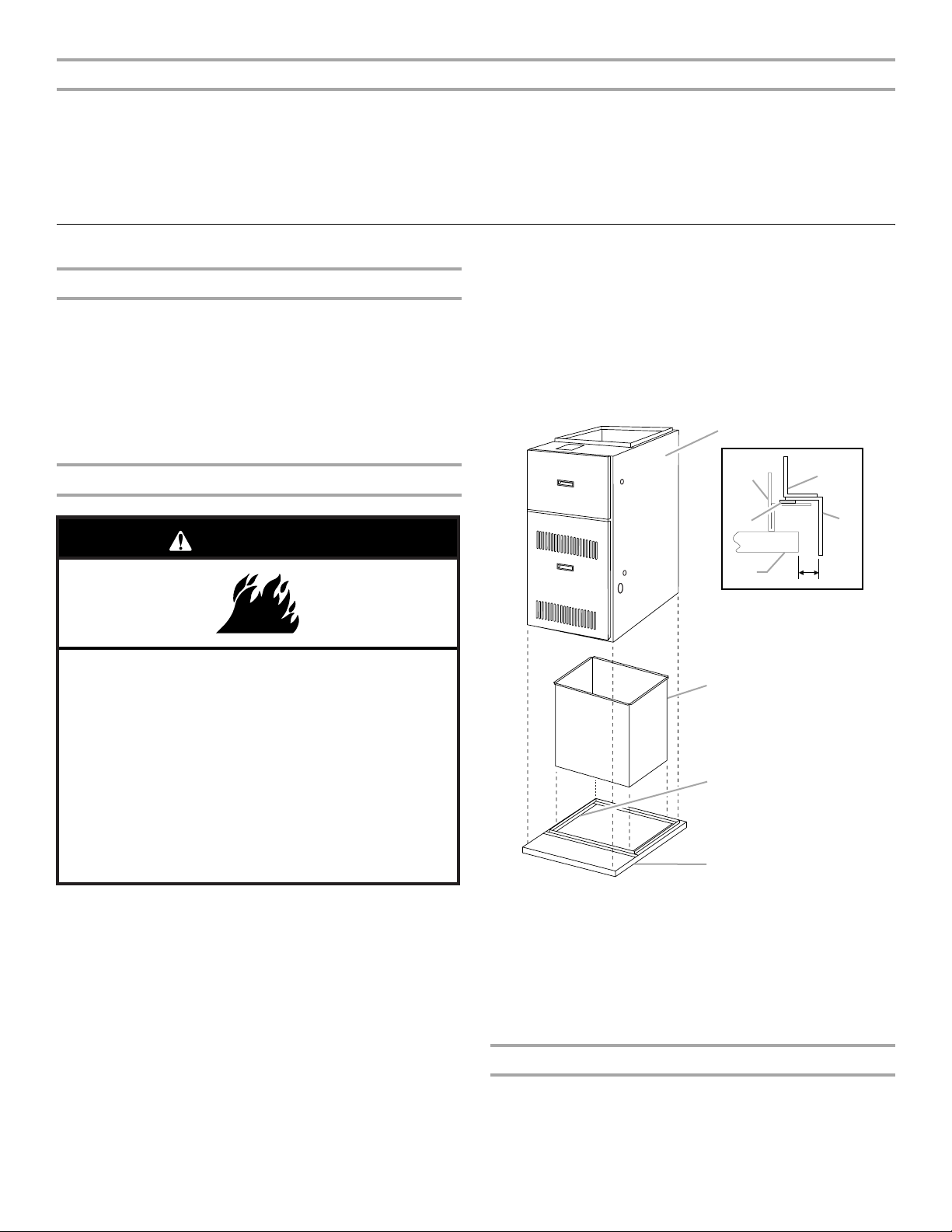

Counterflow (Downflow) Installations

WARNING

IMPORTANT:

For installations above 7,500 ft (2,286 m), the furnace input rate is

to be reduced per the requirements of the National Fuel Gas

Code (ANSI Z223.1/NFPA 54, latest edition), at the rate of

4 percent for each 1,000 ft (304.8 m) above sea level.

The furnace is not recommended for installation above 10,000 ft

(3,048 m).

2. Construct duct connections with 1" to 1³⁄₄" (2.5 cm to 4.4 cm)

right-angle flanges, and long enough to extend below the

floor joists.

3. Drop the duct connections through the top of the base

assembly with the right-angle flanges secure against the

woven glass tape on the top of the base assembly.

4. Position the furnace over the right-angle duct flanges.

Combustible Floor Installation (Counterflow Models Only)

A

E

D

B

C

1"

Fire Hazard

Before installing counterflow (downflow) furnace on

combustible surface, such as wood, install one of the

following kits:

WABASE 511 (14.5" cabinets)

WABASE 512 (17.5" cabinets)

WABASE 568 (21" cabinets)

WABASE 569 (24.5" cabinets)

Contact your local dealer.

Failure to do so can result in death or fire.

IMPORTANT:

■ WGFAT and horizontally installed WGFAR models may be

installed on wood flooring, but should not be installed directly

on carpeting, tile or other combustible material.

■ WGFAR models installed as counterflow (downflow) models

may be installed on combustible flooring provided a special

combustible floor base is used.

■ For installations on combustible flooring, a special base must

be ordered and used. See the furnace rating plate for the

appropriate base model number.

■ WGFAR furnaces may be installed directly on the supply

plenum or coil cabinet if the furnace is installed on a

noncombustible floor.

1. Cut a hole in the floor, sized to provide 1" (2.5 cm) clearance

between all 4 sides of the duct and the edge of the flooring.

The 4 angles on the base assembly should recess into the

floor joists and the base should rest on all 4 outside flanges.

C

E

A

A. Base assembly

B. Furnace

C. Outlet duct (drops into

base assembly)

D. Combustible floor

E. Woven glass tape (between

flanges of outlet duct and

base assembly)

Filters

If a filter other than the one supplied by the furnace manufacturer

is used, see Minimum Filter Requirements in “Filter

Specifications.”

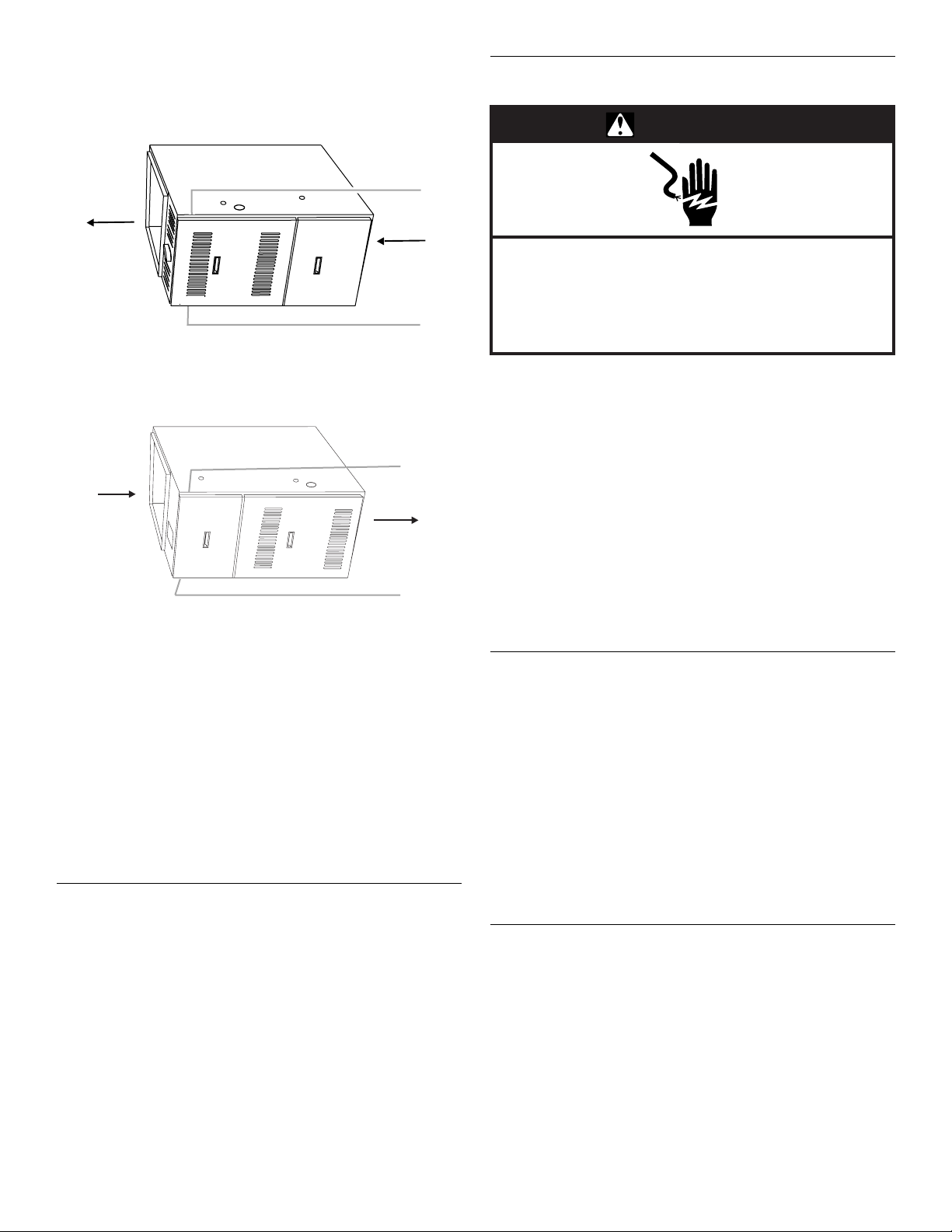

Horizontal Installations

Furnaces can be horizontally installed for airflow right to left or

left to right. To ensure access to parts for servicing, install upflow

and counterflow furnaces so that the burner and blower access

panels are readily accessible.

5

NOTE: When installed horizontally, the installer must install a

C

sheet metal screw to retain the upper door as shown following, in

either Position B or D, depending on installation configuration.

Electrical Requirements

Horizontal Installation—WGFAT Models

A

A. Outlet airflow

B. Screw placement for

Right to Left airflow

C. Inlet airflow

D. Screw placement for

Left to Right airflow

Horizontal Installation—WGFAR Models

A

A. Inlet airflow

B. Screw placement for

Left to Right airflow

C. Outlet airflow

D. Screw placement for

Right to Left airflow

WARNING

B

Electrical Shock Hazard

Electrically ground furnace.

Connect ground wire to green ground screw.

D

B

C

D

Failure to do so can result in death or electrical shock.

■ The furnace must be grounded and wired in accordance with

local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition).

■ In all instances, other than wiring for the thermostat, the

wiring to be done and any replacement of wire shall conform

with the temperature limitation for Type T wire (63°F [17ºC]

rise).

■ The line voltage supply should be routed through a readily

accessible disconnect located within sight of the furnace. A

junction box on the furnace side panel is provided for line

voltage connections. See the Wiring Connection Diagram in

the “Troubleshooting” section for specific connection

information.

■ Proper polarity of the supply connections (“HOT” and

“NEUTRAL”) must be observed to be sure that the control

system provides the protection intended.

Horizontal Installation—Suspended

Furnaces may be installed as suspended furnaces in the

horizontal position. These furnaces are not designed for direct

attachment of suspension rods to the furnace casing.

■ The suspending means must be field fabricated, and should

consist of 2 “cradles” made by attaching 2 rods to a length of

angle iron or suitable gauge steel.

■ Locate the cradles so that they are as close as possible to the

ends of the furnace (this will provide access for removal of

major components such as the blower assembly).

■ Provide enough clearance between the suspension rods and

the furnace to allow removal of access panels.

Ductwork Requirements

■ Install all conditioned air plenums, ducts and air filters (if not

provided on the furnace) in accordance with NFPA 90B

Standard for the Installation of Warm Air Heating and AirConditioning Systems (latest edition).

■ The furnace is provided with flanges for the connection of the

plenum and ducts.

■ All air filters must be listed as Class 2 furnace air filters.

■ All ductwork must be made of materials and insulated to

meet local, state and national codes. Ductwork installed

outdoors must be sealed, weatherproofed and protected

against physical damage. Caulking, flashing or other means

of adequately providing a permanent weather seal should be

used where duct penetrates a building or structure opening.

Gas Supply Requirements

This furnace is equipped for use with Natural gas. A conversion

kit is required for use with propane. To order the correct

conversion kit, see “Accessories.”

■ Gas supply piping should be installed in accordance with

local, state and national codes and the regulations of the

utility. Piping must be of adequate size to avoid undue

pressure drop. Consult the local utility or gas supplier for

complete details on special requirements for sizing gas

piping.

■ If local codes allow the use of a flexible gas appliance

connector, use a CSA design-certified outdoor flexible

stainless steel appliance connector or rigid gas supply line as

needed. Do not use a connector which has previously

serviced another gas appliance.

Venting Requirements

Adequate provisions for combustion air and ventilation of

furnace must be made. Refer to Section 5.3, “Air for

Combustion and Ventilation,” of the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 (latest edition), or applicable provisions

of the local building codes. For Category 1 furnaces, vent

installations shall be in accordance with parts 7 and 11 of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, the local building

codes, and the furnace and vent manufacturer’s instructions.

6

Existing Venting Systems

Venting Options

When an existing furnace is removed or replaced, the original

venting system may no longer be sized to properly vent the

attached appliances. An improperly sized venting system can

result in spillage of flue products into the living space, the

formation of condensate, leakage, etc. See the “Carbon

Monoxide Poisoning Hazard” for proper test procedure.

WARNING:

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being

placed into operation could result in carbon monoxide

poisoning or death.

The following steps shall be followed for each appliance

connected to the venting system being placed into operation,

while all other appliances connected to the venting system are

not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 or the CSA B149.1, Natural Gas and

Propane Installation Codes and these instructions.

Determine that there is no blockage or restriction, leakage,

corrosion and other deficiencies which could cause an

unsafe condition.

3. As far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they are operating

at maximum speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so

appliance is operating continuously.

7. Test for spillage from draft hood equipped appliances at the

draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle.

8. If improper venting is observed during any of the above

tests, the venting system must be corrected in accordance

with the National Fuel Gas Code, ANSI Z223.1/NFPA 54

and/or CSA B149.1, Natural Gas and Propane Installation

Codes.

9. After it has been determined that each appliance connected

to the venting system properly vents when tested as

outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas-fired burning

appliances to their previous conditions of use.

The furnace can be installed as either direct vent or nondirect

vent furnace.

For either type of installation, special venting considerations

must be followed. See “Determine Vent Pipe Direction” for the

type of furnace and venting being installed.

Direct Vent

A direct vent (two pipe) installation requires that all the air

necessary for combustion be supplied from outside the dwelling

through an air intake pipe.

■ All vents passing through floors, ceilings, and walls must be

installed in accordance with National Fuel Gas Code, ANSI

Z223.1/NFPA 54 (latest edition). In all applications in which

the flue pipe is run through an unconditioned space, ¹⁄₂"

insulation must be used over the pipe. In extremely cold

climates, ³⁄₄" (1.9 cm) insulation is recommended.

Nondirect Vent

A nondirect vent (one pipe) installation uses air from inside the

dwelling for combustion.

■ The furnace is shipped with the air inlet pipe terminated to the

top panel for either inside or outside combustion air. An inlet

air restrictor plate is supplied with this furnace and can be

found in the plastic bag containing these Installation

Instructions and the User’s Information Manual.

■ For installations using inside air for combustion (nondirect

vent), attach a 90° elbow (not supplied) to the inlet coupler

and install the restrictor plate inside the elbow. See “Plan

Vent System.”

Inlet Air Restrictor Plate

NOTE: The inlet air restrictor plate must be installed in all

installations that are nondirect vent.

Unconfined Space

An unconfined space is defined as “a space whose volume is

more than 50 cu. ft (1.4 m3) per 1,000 Btu/h of the combined input

rating of all appliances installed in that space.”

When a furnace is installed in an unconfined space in a building,

it can be assumed that the infiltration will be sufficient to supply

the required air.

If the furnace is installed in a ventilated attic or crawl space, it is

assumed that the air infiltration is sufficient to supply the required

combustion air. However, in a building of unusually tight

construction, additional outdoor air should be provided.

Confined Space

A confined space is defined as “a space whose volume is less

than 50 cu. ft (1.4 m

rating of all appliances installed in that space.”

NOTE: Choose a combustion air supply option. See “Plan Vent

System.”

3

) per 1,000 Btu/h of the combined input

7

Contaminated Combustion Air

Excessive exposure to contaminated combustion air will result in

performance-related problems. The recommended source of

combustion air is outdoor air.

Outdoor air as the source of combustion air

If the furnace is installed in a confined space, it is recommended

that the necessary combustion air come from the outdoors by

way of an attic, crawl space, air duct, or direct opening.

Outdoor air is required as the source of combustion air when the

indoor air is contaminated with chemical substances and in the

following types of installations:

■ Furnaces installed in commercial buildings

■ Furnaces installed in buildings with indoor pools

■ Furnaces installed in hobby or craft rooms

■ Furnaces installed near chemical storage areas

■ Furnaces installed in laundry rooms

■ Furnaces installed in hair salons

Indoor air as the source of combustion air

Indoor air as the source of combustion air is acceptable in most

applications if the following guidelines are met:

■ All provisions for indoor combustion air must meet the

requirements for combustion air indicated in the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 (latest edition), and/or any

applicable local codes.

■ If indoor combustion air is used, the air supply to the furnace

should not be exposed to the following substances:

Permanent wave solutions

Chlorinated waxes and cleaners

Chlorine-based swimming pool chemicals

Water softening chemicals

Deicing salts or chemicals

Carbon tetrachloride

Halogen-type refrigerants

Cleaning solvents (such as perchloroethylene)

Printing inks, paint removers, varnishes, etc.

Cements and glues

Antistatic fabric softeners for clothes dryers

Masonry acid washing materials

Chlorinated laundry products

Hydrochloric acid

INSTALLATION INSTRUCTIONS

WARNING

Explosion Hazard

Furnace must be installed and serviced by a

qualified person.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel.

Read and follow all instructions provided for

installation, adjustment, service, alteration, or

maintenance.

Failure to follow these instructions can result in death,

explosion, fire, or carbon monoxide poisoning.

Inspect Shipment

WARNING

Excessive Weight Hazard

Use two or more people to move and install furnace.

Failure to do so can result in back or other injury.

1. Check the furnace rating plate to confirm specifications are

as ordered.

2. Upon receipt of the furnace, inspect it for possible shipping

damage. Examine the furnace inside the carton if the carton

is damaged.

If damage is found, it should be noted on the carrier’s freight bill.

Damage claims should be filed with the carrier immediately.

Claims of shortages should be filed with the seller within 5 days.

NOTE: If any damages are discovered and reported to the carrier,

do not install the furnace, because your claim may be denied.

Plan Vent System

IMPORTANT: The venting system must be supported with

mounting straps to avoid any weight load from being applied to

the vent blower. Horizontal vent pipe must be supported every

5 ft (1.5 m) and vertical pipe should be supported every 10 ft

(3 m) to avoid sagging and provide rigid support.

Materials—Air Intake Pipe Only

■ All pipe, fittings, primer, and solvent cement must conform

with American National Standard Institute and the American

Society for Testing and Materials (ANSI/ASTM) standards.

The solvent shall be free flowing and contain no lumps,

undissolved particles, or any foreign matter that adversely

affects the joint strength or chemical resistance of the

cement. The cement shall show no gelatinization,

stratification, or separation that cannot be removed by

stirring. See Piping and Fitting Specifications for approved

piping and fitting materials.

This furnace is shipped in one package, completely assembled

and wired. The indoor thermostat and accessories are shipped in

a separate carton when ordered.

8

Piping and Fitting Specifications

E

D

Piping and Fitting Material ASTM Specification

Schedule 40 PVC (Pipe) D1785

Schedule 40 PVC (Cellular Core Pipe) F891

Schedule 40 PVC (Fittings) D2466

SDR-26 (Pipe) D2241

Schedule 40 ABS (Pipe) D1527

Schedule 40 ABS (Fittings) D2468

Schedule 40 & 80 CPVC (Pipe) F441

ABS-DWV Drain Waste & Vent

(Pipe & Fittings)

PVC-DWV Drain Waste & Vent

(Pipe & Fittings)

■ The primers and solvents used must also meet ASTM

specifications. PVC primer is specified in ASTM F656. Use

PVC solvent as specified in ASTM D2564 and ABS solvent

cement as specified ASTM D2235. Low temperature solvent

cement is recommended. Metal or plastic strapping may be

used for vent pipe hangers.

■ When making ABS joints, pieces can be prepared with a

cleaner. When joining ABS to PVC materials, use PVC solvent

cement as specified in ASTM D3138.

■ Preferred fittings are DWV style or long sweep. Seal all joints

gas tight with appropriate cement. In areas where vent and air

intake pipes are exposed to abnormal stress or are subject to

damage, schedule 80 pipe should be used.

■ Use high temperature RTV silicone sealant to attach the air

intake pipe into the connector on the burner box so the air

intake pipe can be removed if service is required.

NOTE: Do not use cement.

D2661

D2665

Typical Installation—Vertical Vent with Outdoor Fresh Air

B

A

C

E

F

A. Approved vent system

B. 65 ft (19.8 m) maximum

C. 6" (15.2 cm) minimum

D. Inlet located away from obstructions

and maximum snow level

E. 12" (30.5 cm) maximum

F. PVC inlet pipe

(see Inlet Pipe

Specifications chart)

Inlet Pipe Specifications

Inlet Pipe

Input—KBtu/h Inlet Pipe Size

50 2" (5.1 cm) 65 ft (19.8 m)

75 & 100 2" (5.1 cm) 30 ft (9.1 m)

75, 100, 125 & 150 3" (7.6 cm) 65 ft (19.8 m)

*The inlet air lengths listed are maximum “equivalent pipe

lengths.”

NOTE: One 90º elbow or two 45º elbows are the equivalent of 5 ft

(1.5 m) of pipe.

Total Length*

Confined Space Installation—Direct Venting

■ If the furnace is installed in a confined space and all the air

necessary for combustion is supplied to the furnace through

an air intake pipe vented directly outside, the pipe size and

materials used must conform to the specification listed in

“Materials—Air Intake Pipe Only.”

Confined Space Installation—Direct Venting

B

A

H

A. Chimney or gas vent

B. Approved vent

C. 65 ft (19.8 m) maximum

D. 6" (15.2 cm) minimum

E. Inlet located away from obstructions

and maximum snow level

F. 12" (30.5 cm) maximum

G. Air intake pipe

H. Furnace

C

D

F

G

Optional Attic Inlet Air

NOTE: Attic must be well ventilated.

A

F

E

D

A. Gable vent

B. 12" (30.5 cm) maximum

C. Gas furnace

B

C

D. Gas water heater

E. Joist and insulation

F. Soffit vent

9

Optional Outside Air

C

C

D

C

B

D

E

F

E

D

A

B

Outside

If air from outside is brought in for combustion, the confined

space shall be provided with 2 permanent openings. One

opening shall be within 12" (30.5 cm) of the ceiling and 1 opening

within 12" (30.5 cm) of the floor. Several methods can be used to

bring the outside air in through these openings. The openings

must open directly or by ducts to the outdoors, through spaces

(crawl space or attic) that freely open to the outdoors, or

indirectly through vertical ducts.

NOTE: If any of these methods are used, the inlet and outlet air

openings must each have a free area of 1 sq. in. (6.4 cm

4,000 Btu/h of the total input rating of all equipment within the

enclosure.

2

) per

Equipment in Confined Space—All Air from Outside

Confined Space Installation—Nondirect Venting Air from

C

(Inlet air from crawl space and outlet air to ventilated attic)

A. Gable vent

B. 16" to 24" (40.6 cm to 61 cm)

C. Gas furnace

D. Gas water heater

E. Joist and insulation

F. So f fit v en t

NOTE: The actual height of the roof termination should be 12"

(30.5 cm) above the average snow accumulation.

Confined Space Installation—Nondirect Venting Air from

Inside

If the furnace is installed in a confined space within the building

and combustion air is taken from a heated space, the

combustion air and ventilating air must enter and leave the space

through 2 permanent openings of equal area. One opening shall

be located within 12" (30.5 cm) of the ceiling and the other within

12" (30.5 cm) of the floor.

NOTE: Each opening must have a free area of at least 1 sq. in.

2

(6.4 cm

the enclosure, and not less than 100 sq. in. (645 cm

) per 1,000 Btu/h of total input rating of all equipment in

2

) each.

Equipment in Confined Space—All Air from Inside

B

A

A

G

F

A. Chimney or gas vent

B. Ventilation louvers (each end of attic)

C. Outlet air

D. Water heater

E. Inlet air

F. Ventilation louvers

(for unheated crawl space)

G. Furnace

Equipment in Confined Space—All Air from Outside

(All air through ventilated attic)

A

B

E

10

F

D

A. Chimney or gas vent

B. Water heater

C. Openings

D. Furnace

A. Chimney or gas vent

B. Ventilation louvers

(each end of attic)

C. Outlet air

D. Inlet air (ends 12" (30.5 cm) above

bottom)

E. Water heater

F. Furnace

Loading...

Loading...