Whirlpool MGDE900VJ2, MGDE900VW1, MGDE900VW2, MGDE900VJ1, MGDE500WR0 Installation Guide

...

DRYER INSTALLATION INSTRUCTIONS

GAS (U.S_. AND CANADA)

ELECTRIC (CANADA ONLY)

INSTRUCTIONS D'INSTALLATION DE LA SI_CHEUSE

.&.GAZ (l_.-U. ET CANADA)

I_LECTRIQUE (CANADA UNIQUEMEN'r)

Para una version de estas intrucciones en EspaSol, visite www.Whirlpool.com

TABLE OF CONTENTS

DRYER SAFETY .............................................................................. 2

INSTALLATION REQUIREMENTS ................................................ 4

Tools and Parts ............................................................................ 4

Optional Equipment ..................................................................... 4

Location Requirements ................................................................ 5

ELECTRIC DRYER POWER HOOKUP- CANADA ONLY .......... 8

Electrical Requirements ............................................................... 8

GAS DRYER POWER HOOKUP .................................................... 9

Gas Supply Requirements ........................................................... 9

Make Gas Connection ............................................................... 10

Electrical Requirements ............................................................. 10

VENTING ....................................................................................... 11

Venting Requirements ................................................................ 11

Plan Vent System ....................................................................... 12

Install Vent System ..................................................................... 13

INSTALL LEVELING LEGS........................................................... 13

CONNECT VENT ........................................................................... 13

CONNECT INLET HOSE

(STEAM MODELS) ........................................................................ 13

LEVEL DRYER .............................................................................. 14

COMPLETE INSTALLATION ....................................................... 14

TROUBLESHOOTING .................................................................. 15

TABLE DES MATII_RES

SECURITE DE LA SECHEUSE .................................................... 17

EXIGENCES D'INSTALLATION ................................................... 19

Outillage et pieces ...................................................................... 19

I_quipement facultatif ................................................................. 19

Exigences d'emplacement ......................................................... 19

RACCORDEMENT DE L'ALIMENTATION .ALA

SECHEUSE ELECTRIQUE ........................................................... 23

Specifications electriques .......................................................... 23

RACCORDEMENT DE L'ALIMENTATION

.ALA SI_CHEUSE .AGAZ .............................................................. 24

Alimentation en gaz .................................................................... 24

Raccordement au gaz ................................................................ 25

Specifications electriques .......................................................... 25

E'VACUATION ................................................................................ 26

Exigences concernant I'evacuation ........................................... 26

Planification du systeme d'evacuation ...................................... 27

Installation du systeme d'evacuation ......................................... 28

INSTALLATION DES PIEDS DE NIVELLEMENT ........................ 29

RACCORDEMENT DU CONDUIT D'IeVACUATION .................. 29

RACCORDEMENT DES TUYAUX D'ALIMENTATION

(MODF:LES .&VAPEUR) ................................................................ 29

REGLAGE DE L'APLOMB DE LA SECHEUSE ........................... 30

ACHEVER L'INSTALLATION ....................................................... 30

DI:!:PANNAG E................................................................................. 31

W10255469B

W10259188B - SP

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

WARNING - "RiskofFire"

- Clothes dryer installation must be performed by a qualified installer,

- install the clothes dryer according to the manufacturer's instructions and local codes.

- Do not install a clothes dryer with flexible plastic venting materials, if flexible metal

(foil type) duct is installed, it must be of a specific type identified by the appliance

manufacturer as suitable for use with clothes dryers. Flexible venting materials are

known to collapse, be easily crushed, and trap lint. These conditions will obstruct

clothes dryer airflow and increase the risk of fire.

- To reduce the risk of severe injury or death, follow all installation instructions.

- Save these instructions.

2

iMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the riskof fire, electric shock, or injury to personswhen using the dryer, follow basic precautions,

including the following:

[] Read all instructions before using the dryer.

[] Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

[] Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, dry-

cleaning solvents, or other flammable or explosive

substances as they give off vapors that could ignite or

explode.

[] Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

[] Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

[] Do not reach into the dryer if the drum is moving.

[] Do not install or store the dryer where it will be exposed

to the weather.

[] Do not tamper with controls.

SAVE THESE INSTRUCTIONS

[] Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user-repair

instructions that you understand and have the skills to

carry out.

[] Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

[] Do not use heat to dry articles containing foam rubber or

similarly textured rubber=like materials.

[] Clean lint screen before or after each load.

[] Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

[] The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

[] See installation instructions for grounding requirements.

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSi Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1.

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

= Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

IntheStateofMassachusetts,thefollowinginstallationinstructionsapply:

mInstallationsandrepairsmustbeperformedbyaqualifiedorlicensedcontractor,plumber,orgasfitterqualifiedorlicensedby

theStateofMassachusetts.

mIfusingaballvalve,itshallbeaT-handletype.

mAflexiblegasconnector,whenused,mustnotexceed3feet.

StateofCaliforniaProposition65Warnings:

WARNING:ThisproductcontainsachemicalknowntotheStateofCaliforniatocausecancer.

WARNING:ThisproductcontainsachemicalknowntotheStateofCaliforniatocausebirthdefectsorotherreproductiveharm.

INSTALLATION REQUIREMENTS

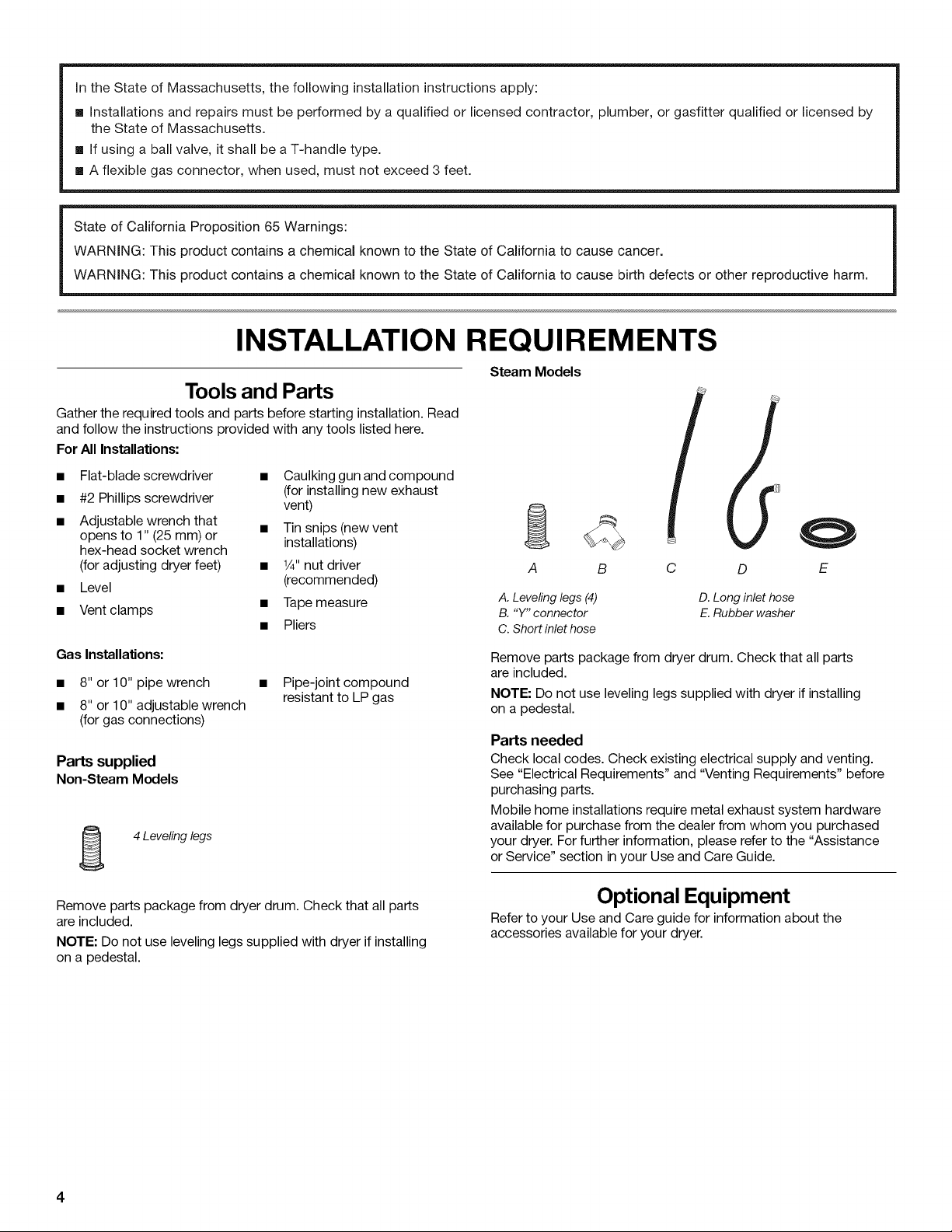

Steam Models

Tools and Parts

Gather the required tools and parts before starting installation. Read

and follow the instructions provided with any tools listed here.

For All Installations:

Flat-blade screwdriver

#2 Phillips screwdriver

Adjustable wrench that

opens to 1" (25 ram) or

hex-head socket wrench

(for adjusting dryer feet)

• Level

• Vent clamps

Gas Installations:

• 8" or 10" pipe wrench • Pipe-joint compound

• 8" or 10" adjustable wrench

(for gas connections)

Parts supplied

Non-SteamModels

4 Leveling legs

• Caulking gun and compound

(for installing new exhaust

vent)

• Tin snips (newvent

installations)

• 1_" nut driver

(recommended)

• Tape measure

• Pliers

resistant to LP gas

A B

A.Levelinglegs (4)

g. "Y"connector

C.Short inlet hose

Remove parts package from dryer drum. Check that all parts

are included.

NOTE: Do not use leveling legs supplied with dryer if installing

on a pedestal.

Parts needed

Check local codes. Check existing electrical supply and venting.

See "Electrical Requirements" and "Venting Requirements" before

purchasing parts.

Mobile home installations require metal exhaust system hardware

available for purchase from the dealer from whom you purchased

your dryer. Forfurther information, please refer to the "Assistance

or Service" section in your Use and Care Guide.

C D

D. Long inlet hose

E.Rubber washer

E

Remove parts package from dryer drum. Check that all parts

are included.

NOTE: Do not use leveling legs supplied with dryer if installing

on a pedestal.

4

Optional Equipment

Refer to your Use and Care guide for information about the

accessories available for your dryer.

Location Requirements

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (460 ram) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

You will need

• A location that allows for proper exhaust installation.

See "Venting Requirements."

A separate 15 or 20-amp circuit needed for gas dryers and

30-amp circuit needed for electric dryers.

If you are using a power supply cord, a grounded electrical

outlet located within 2 ft (610 mm) of either side of the dryer.

See "Electrical Requirements."

A sturdy floor to support the total dryer weight of 200 Ibs

(90.7 kg). The combined weight of a companion appliance

should also be considered.

A level floor with a maximum slope of 1" (25 mm) under entire

dryer. If slope is greater than 1" (25 mm), install Extended Dryer

Feet Kit, Part Number 279810. Clothes may not tumble properly

and automatic sensor cycles may not operate correctly if dryer is

not level.

• For a garage installation,you will need to place the dryer at least

18" (460 mm) above the floor. If using a pedestal, you will need

18" (460 mm) to the bottom of the dryer.

• Steam models only: Cold water faucets located within

4 ft (1.2 m) of the dryer, and water pressure of 20-100 psi

(137.9-689.6 kPa). You may use the cold water supply from

your washer using the "Y" connector provided.

Do not operate your dryer at temperatures below 45°F (7°C). At

lower temperatures, the dryer might not shut off at the end of an

automatic sensor cycle. This can result in longer drying times.

The dryer must not be installed or stored in an area where it will be

exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

NOTE: No other fuel-burning appliance can be installed in the same

closet as a dryer.

Installation clearances

The location must be large enough to allow the dryer door to

open fully.

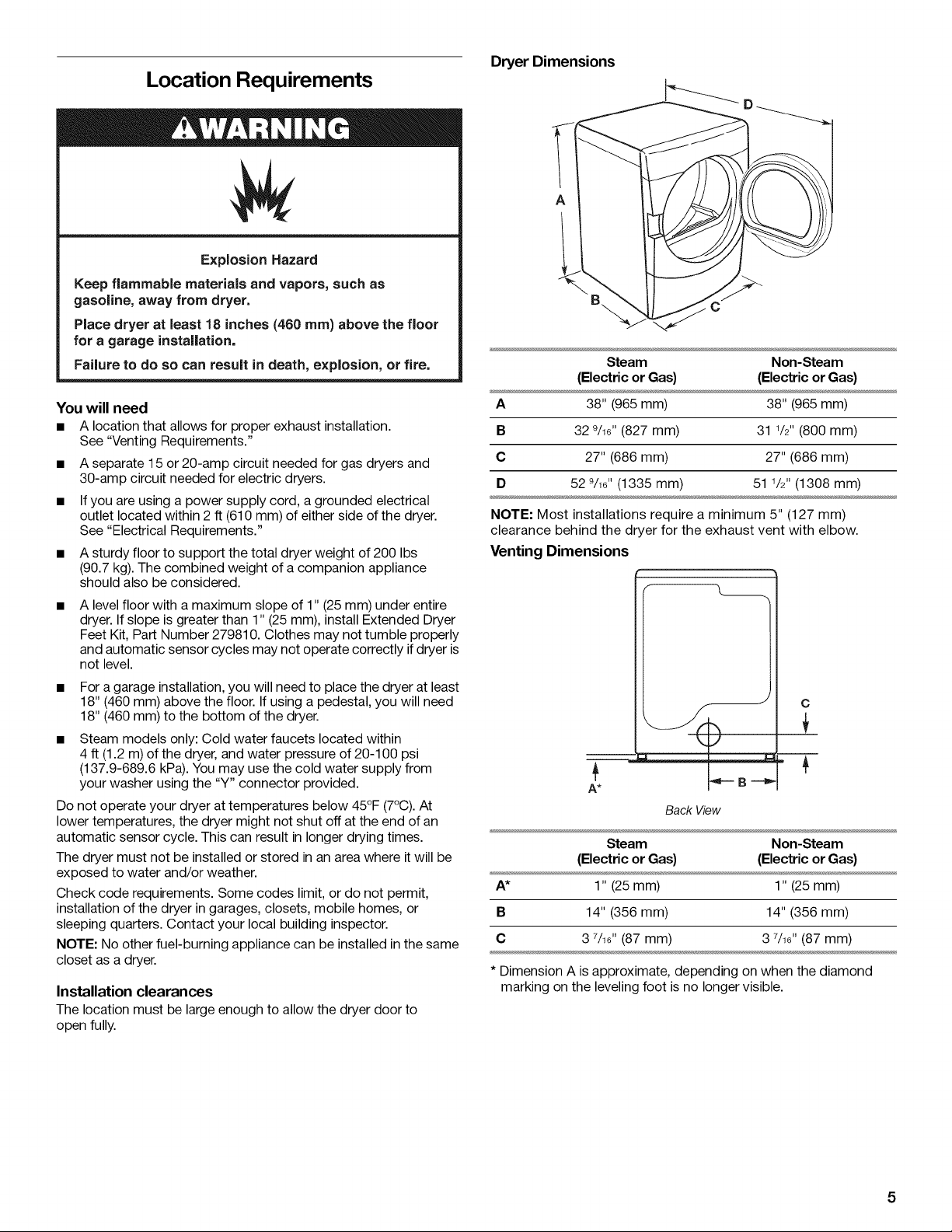

Dryer Dimensions

A

Steam Non-Steam

(Electric or Gas) (Electric or Gas)

A 38" (965 mm) 38" (965 mm)

B 32 9/16"(827 mm) 31 lh" (800 mm)

C 27" (686 mm) 27" (686 mm)

D 52 9/16"(1335 mm) 51 1/2"(1308 mm)

NOTE: Most installations require a minimum 5" (127 mm)

clearance behind the dryer for the exhaust vent with elbow.

Venting Dimensions

c

m

A*

Back View

Steam Non-Steam

(Electric or Gas) (Electric or Gas)

A* 1" (25 mm) 1" (25 mm)

B 14" (356 mm) 14" (356 mm)

C 3 7/16"(87 mm) 3 7/16"(87 mm)

* Dimension A is approximate, depending on when the diamond

marking on the leveling foot is no longer visible.

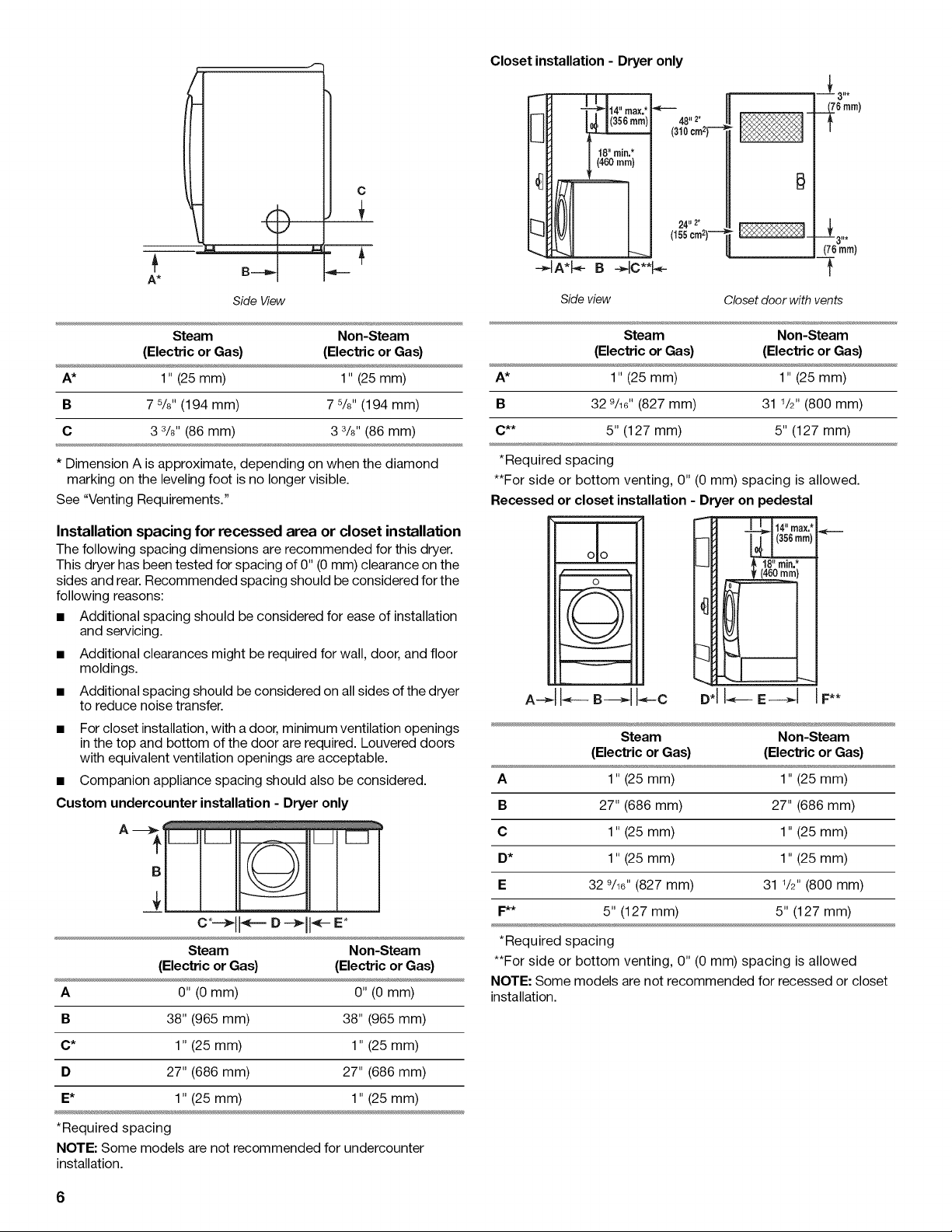

Closet installation - Dryer only

__1 48Jr 2*

+

A*

Side View

Steam Non-Steam

(Electric or Gas) (Electric or Gas)

A* 1" (25 mm) 1" (25 mm)

B 7 5/8"(194 mm) 7 5/8"(194 mm)

C 3 3/8" (86 mm) 3 3/s" (86 mm)

* Dimension A is approximate, depending on when the diamond

marking on the leveling foot is no longer visible.

See "Venting Requirements."

Installation spacing for recessed area or closet installation

The following spacing dimensions are recommended for this dryer.

This dryer has been tested for spacing of 0" (0 mm) clearance on the

sides and rear.Recommended spacing should be considered for the

following reasons:

• Additional spacing should be considered for ease of installation

and servicing.

• Additional clearances might be required for wall, door, and floor

moldings.

• Additional spacing should be considered on all sides of the dryer

to reduce noise transfer.

For closet installation, with a door, minimum ventilation openings

in the top and bottom of the door are required. Louvered doors

with equivalent ventilation openings are acceptable.

• Companion appliance spacing should also be considered.

Custom undercounter installation - Dryer only

10crn2)--_

5;;cm2)---4

(76 rnm)

-,4A*_ B -qC**_

Side view Closet door with vents

Steam Non-Steam

(Electric or Gas) (Electric or Gas)

A* 1" (25 mm) 1" (25 mm)

B 32 9/16"(827 mm) 31 lh" (800 mm)

C** 5" (127 mm) 5" (127 mm)

*Required spacing

**For side or bottom venting, 0" (0 mm) spacing is allowed.

Recessed or closet installation - Dryer on pedestal

$ 18"rain,*

B--q D*I E-- I F**

Steam Non-steam

(Electric or Gas) (Electric or Gas)

A 1" (25 mm) 1" (25 mm)

B 27" (686 mm) 27" (686 mm)

C 1" (25 mm) 1" (25 mm)

D* 1" (25 mm) 1" (25 mm)

E 32 9/16"(827 mm) 31 lh" (800 mm)

F** 5" (127 mm) 5" (127 mm)

g

Steam Non-steam

(Electric or Gas) (Electric or Gas)

A 0" (0 mm) 0" (0 mm)

B 38" (965 mm) 38" (965 mm)

C* 1" (25 mm) 1" (25 mm)

D 27" (686 mm) 27" (686 mm)

E* 1" (25 mm) 1" (25 mm)

*Required spacing

NOTE: Some models are not recommended for undercounter

installation.

6

*Required spacing

**For side or bottom venting, 0" (0 mm) spacing is allowed

NOTE: Some models are not recommended for recessed or closet

installation.

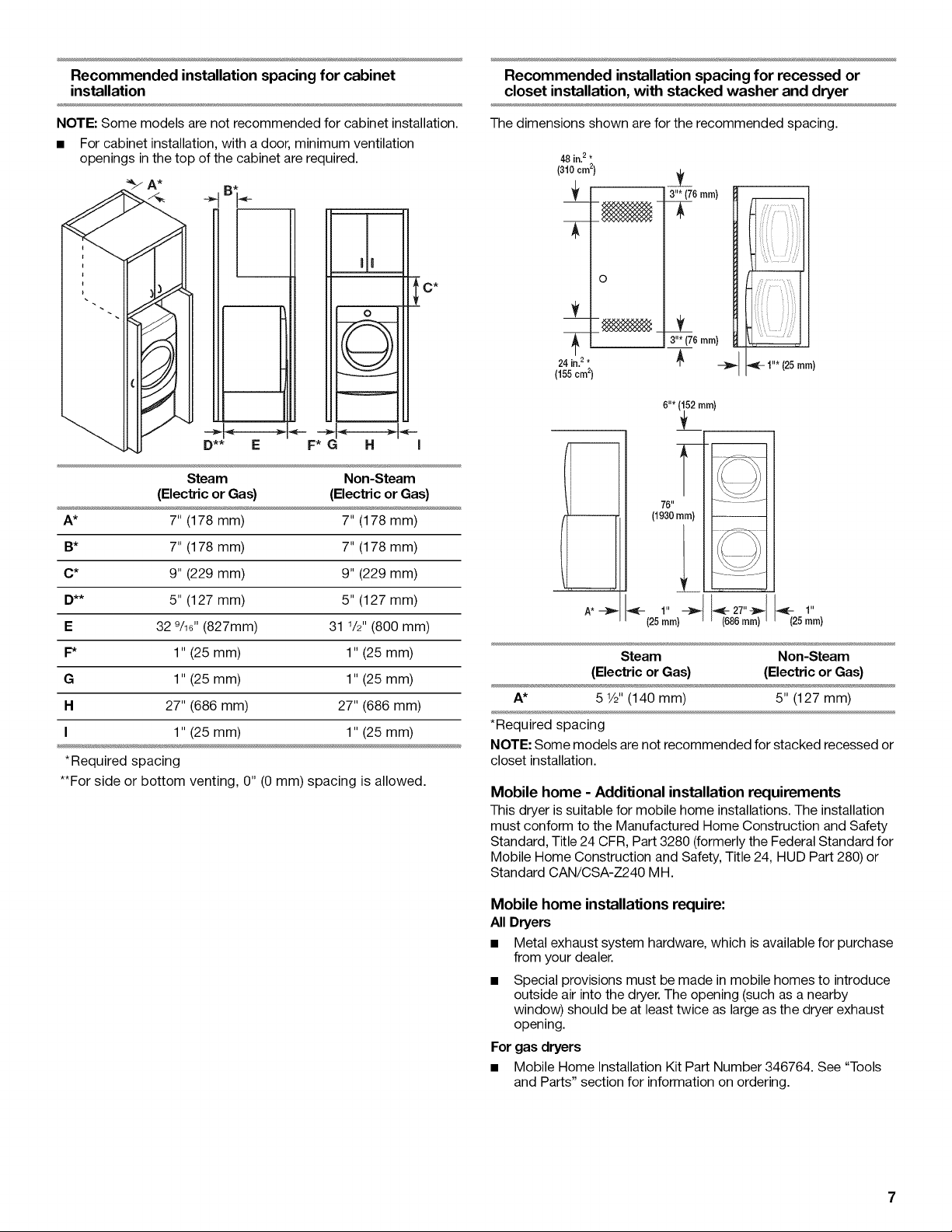

Recommended installation spacing for cabinet

installation

Recommended installation spacing for recessed or

closet installation, with stacked washer and dryer

NOTE: Some models are not recommended for cabinet installation.

• For cabinet installation, with a door, minimum ventilation

openings in the top of the cabinet are required.

B _

BB

o

©

I I

D** E

Steam Non-Steam

(Electric or Gas) (Electric or Gas)

A* 7" (178 mm) 7" (178 mm)

B* 7" (178 mm) 7" (178 mm)

C* 9" (229 mm) 9" (229 mm)

D** 5" (127 mm) 5" (127 mm)

E 32 9/16"(827mm) 31 1/2" (800 mm)

F* 1" (25 mm) 1" (25 mm)

G 1" (25 mm) 1" (25 mm)

H 27" (686 mm) 27" (686 mm)

I 1" (25 mm) 1" (25 mm)

*Required spacing

**For side or bottom venting, 0" (0 mm) spacing is allowed.

F* G H I

Thedimensionsshown arefor therecommendedspacing.

48 in,2 *

(310cm2)

+

o

24 in,2 * +

(155cm2)

Steam Non-steam

(Electric or Gas) (Electric or Gas)

A* 5 1/2"(140 mm) 5" (127 mm)

*Required spacing

NOTE: Some models are not recommended for stacked recessed or

closet installation.

Mobile home - Additional installation requirements

This dryer is suitable for mobile home installations. The installation

must conform to the Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280 (formerly the Federal Standard for

Mobile Home Construction and Safety, Title 24, HUD Part 280) or

Standard CAN/CSA-Z240 MH.

t_

3"* (76 mm)

3"* (76mm)

6"* (_52 mm)

1" _ ,_- 27"-_

(25 mm) (686mm)

1'1

(25mm)

Mobile home installations require:

All Dryers

• Metal exhaust system hardware, which is available for purchase

from your dealer.

Special provisions must be made in mobile homes to introduce

outside air into the dryer. The opening (such as a nearby

window) should be at least twice as large as the dryer exhaust

opening.

For gas dryers

• Mobile Home Installation Kit Part Number 346764. See "Tools

and Parts" section for information on ordering.

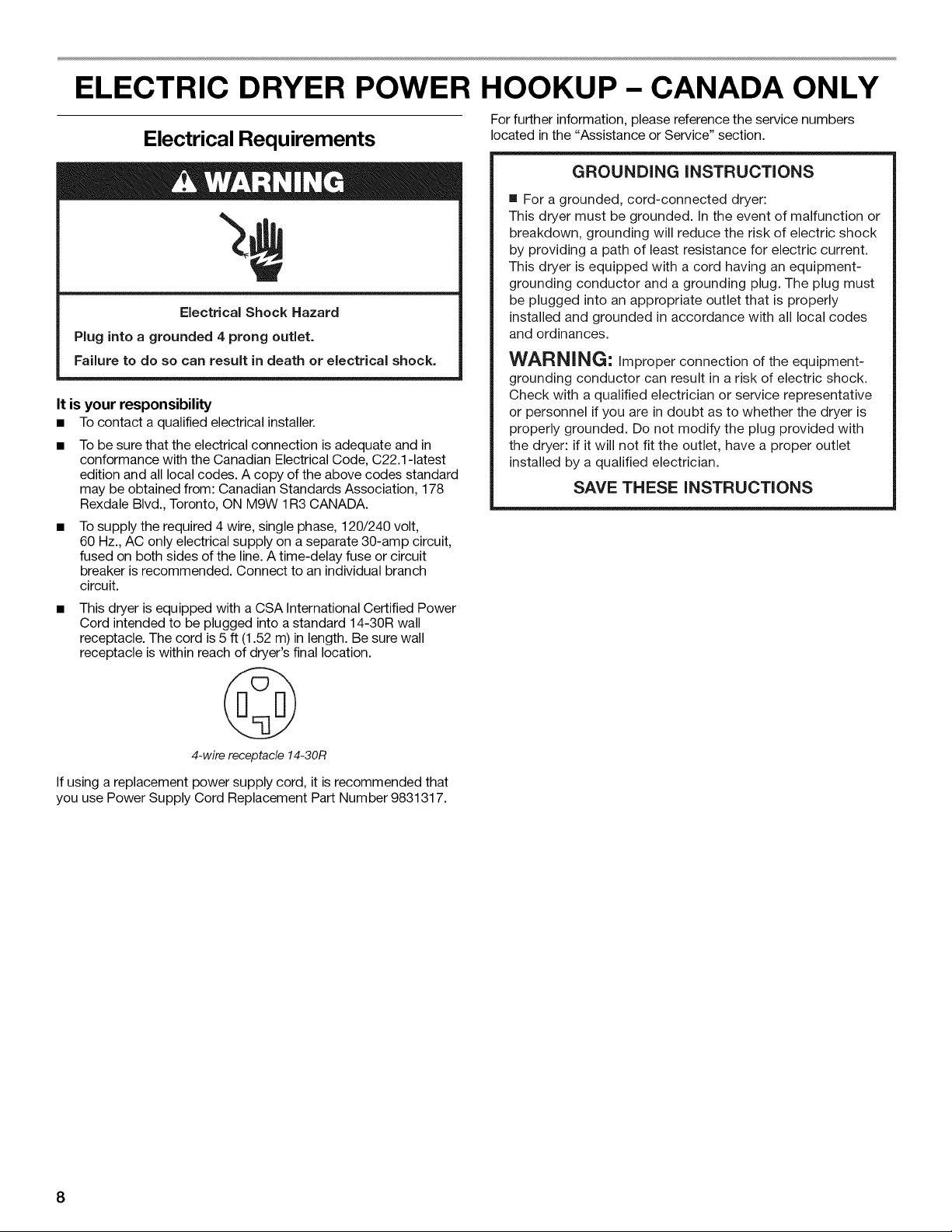

ELECTRIC DRYER POWER HOOKUP- CANADA ONLY

For further information, please reference the service numbers

Electrical Requirements

Electrical Shock Hazard

Plug into a grounded 4 prong outlet.

Failure to do so can result in death or electrical shock.

It is your responsibility

• Tocontact a qualifiedelectrical installer.

To be sure that the electrical connection is adequate and in

conformance with the Canadian Electrical Code, C22.1-1atest

edition and all local codes. A copy of the above codes standard

may be obtained from: Canadian Standards Association, 178

Rexdale Blvd., Toronto, ON M9W 1R3 CANADA.

Tosupply the required 4 wire, single phase, 120/240 volt,

60 Hz., AC only electrical supply on aseparate 30-amp circuit,

fused on both sides of the line. A time-delay fuse or circuit

breaker is recommended. Connect to an individual branch

circuit.

This dryer is equipped with a CSA International Certified Power

Cord intended to be plugged into a standard 14-30R wall

receptacle. The cord is5 ft (1.52 m) in length. Be sure wall

receptacle is within reach of dryer's final location.

located in the "Assistance or Service" section.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded, in the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

4-wire receptacle 14-30R

If using a replacement power supply cord, it is recommended that

you use Power Supply Cord Replacement Part Number 9831317.

8

GAS DRYER POWER HOOKUP

Gas Supply Requirements

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut=off valve,

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (330 ram) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Ifyour dryer has been converted to use LP gas, 3/8"LP

compatible copper tubing can be used. Ifthe total length of the

supply line is more than 20 ft (6.1 m), use larger pipe.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLONe)t tape.

• Must include a shutoff valve:

In the U.S.A.:

An individualmanual shutoff valve must be installedwithin six (6)

feet (1.8 m) of the dryer in accordance with the National Fuel

Gas Code, ANSI Z223.1.

In Canada:

An individualmanual shutoff valve must be installedwithin six (6)

feet (1.8 m) of the dryer in accordance with the B149.1, Natural

Gas and Propane Installation Code.

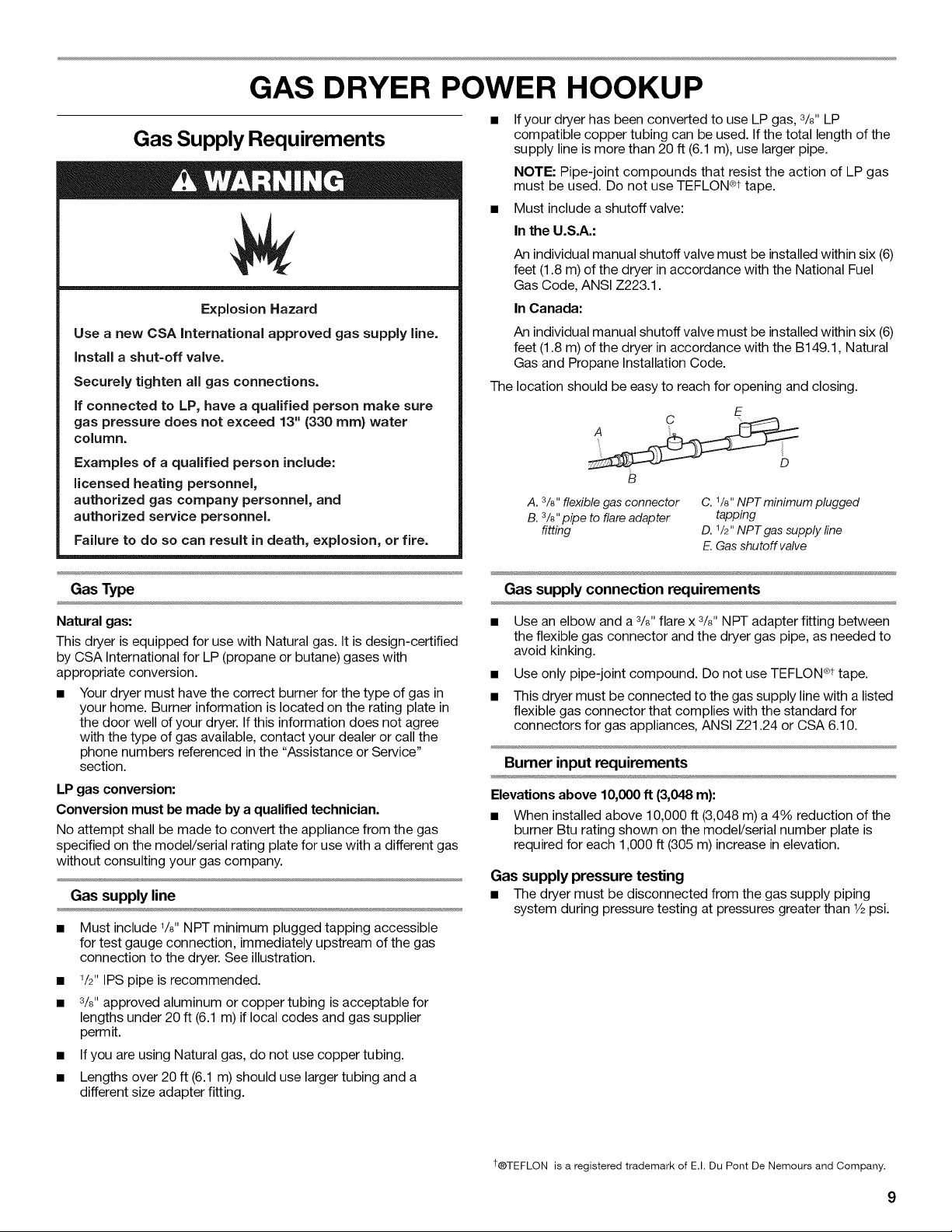

The

location should be easy to reach for opening and closing.

E

B

A. 3/8" flexible gas connector

B. 3/8"pipe to flare adapter

fitting

C. 1/8"NPT minimum plugged

tapping

D. 1/2"NPTgas supply line

E. Gas shutoff valve

Gas Type

Natural gas:

This dryer is equipped for use with Natural gas. It is design-certified

by CSA International for LP (propane or butane) gases with

appropriate conversion.

• Your dryer must have the correct burner for the type of gas in

your home. Burner information is located on the rating plate in

the door well of your dryer. Ifthis information does not agree

with the type of gas available, contact your dealer or call the

phone numbers referenced in the "Assistance or Service"

section.

LP gas conversion:

Conversion must be made by a qualified technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different gas

without consulting your gas company.

Gas supply line

• Must include 1/8"NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

connection to the dryer. See illustration.

• 1/2"IPS pipe is recommended.

• 3/8"approved aluminum or copper tubing is acceptable for

lengths under 20 ft (6.1 m) if local codes and gas supplier

permit.

• If you are using Natural gas, do not use copper tubing.

• Lengths over 20 ft (6.1 m) should use larger tubing and a

different size adapter fitting.

Gas supply connection requirements

Use an elbow and a 3/8"flare x 3/8"NPT adapter fitting between

the flexible gas connector and the dryer gas pipe, as needed to

avoid kinking.

Use only pipe-joint compound. Do not use TEFLON Qt tape.

This dryer must be connected to the gas supply line with a listed

flexible gas connector that complies with the standard for

connectors for gas appliances, ANSI Z21.24 or CSA 6.10.

Burner input requirements

Elevations above 10,000 ft (3,048 m):

• When installed above 10,000 ft (3,048 m) a 4% reduction of the

burner Btu rating shown on the model/serial number plate is

required for each 1,000 ft (305 m) increase in elevation.

Gas supply pressure testing

• The dryer must be disconnected from the gas supply piping

system during pressure testing at pressures greater than 1/2psi.

t®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

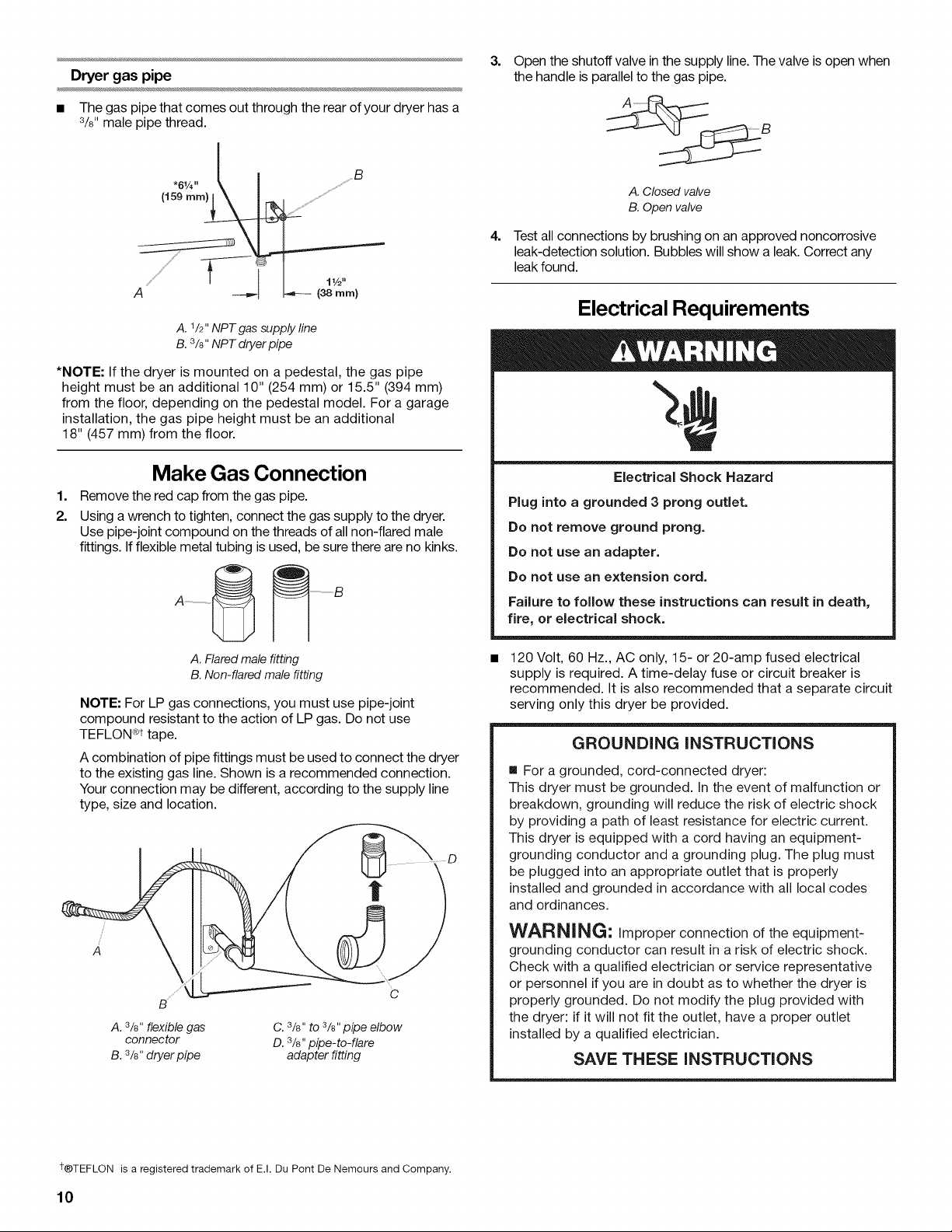

Dryer gas pipe

• The gas pipe that comes out through the rearof your dryer has a

3/8"male pipe thread.

3,

Open the shutoff valve in the supply line. The valve is open when

the handle is parallel to the gas pipe.

.61/4,,

(159 ram)

A (38ram)

A. 1/2" NPT gas supply line

B. 3/8" NPT dryer pipe

sB

1½"

*NOTE: If the dryer is mounted on a pedestal, the gas pipe

height must be an additional 10" (254 mm) or 15.5" (394 mm)

from the floor, depending on the pedestal model. For a garage

installation, the gas pipe height must be an additional

18" (457 mm) from the floor.

Make Gas Connection

1,

Remove the red cap from the gas pipe.

2.

Using a wrench to tighten, connect the gas supply to the dryer.

Use pipe-joint compound on the threads of all non-flared male

fittings. If flexible metal tubing is used, besure there are no kinks.

A. Closed valve

B. Open valve

4.

Test all connections by brushing on an approved noncorrosive

leak-detection solution. Bubbles will show a leak. Correct any

leak found.

Electrical Requirements

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

A. Flared male fitting

B. Non-flared male fitting

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to the action of LP gas. Do not use

TEFLON°t tape.

A combination of pipe fittings must be used to connect the dryer

to the existing gas line. Shown is a recommended connection.

Your connection may be different, according to the supply line

type, size and location.

/

F

A

S ¸

A.3/8"flexiblegas C.3/8"to 3/8"pipeelbow

connector D.3/8"pipe-to-flare

B.3/8"dryerpipe adapter fitting

120 Volt, 60 Hz., AC only, 15- or 20-amp fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is also recommended that a separate circuit

serving only this dryer be provided.

GROUNDING iNSTRUCTiONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

1®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

10

Loading...

Loading...